Fluxing agent for smelting steel as well as preparation and use methods thereof

A flux and pre-melting technology, applied in the field of steelmaking, can solve the problems of large molten steel temperature drop, poor slag removal effect, high slag removal effect, etc., so as to improve the quality of steel, have sufficient raw material sources, and shorten the time of steelmaking. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further describe the present invention, below in conjunction with embodiment, by comparative production test, the present invention is described in more detail.

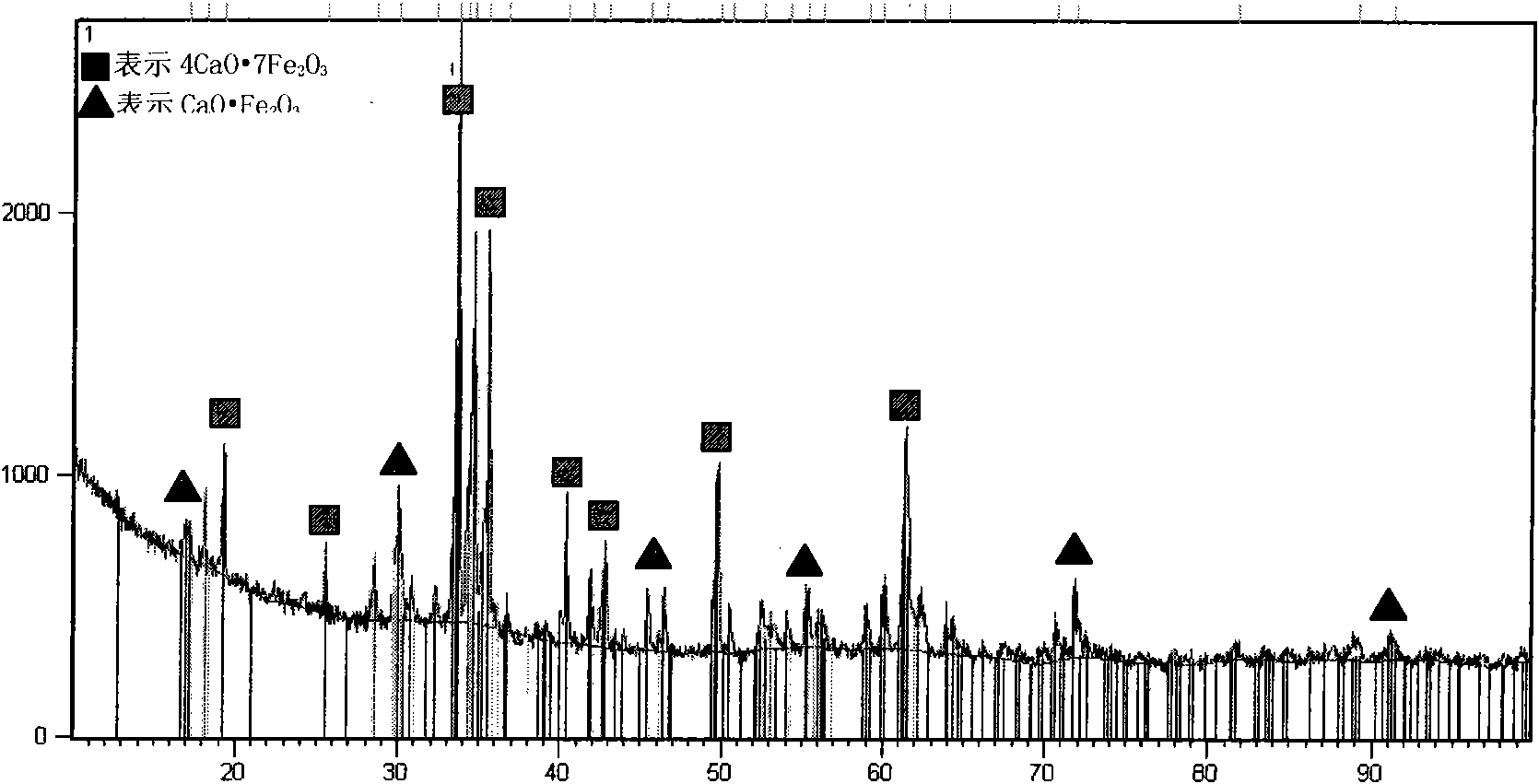

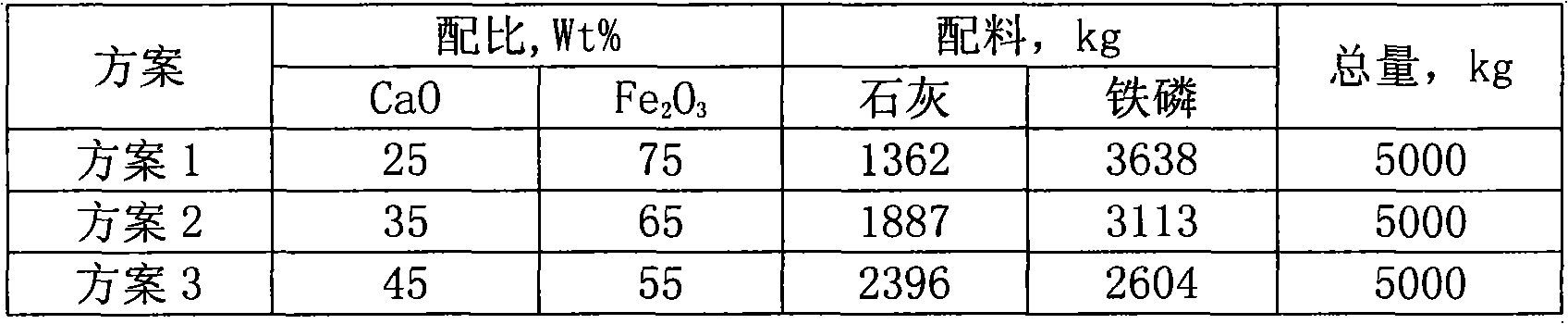

[0030] Select quicklime undersieve and iron-phosphorus powder with a particle size of 0-10mm, prepare 5000kg according to the composition standard mass ratio Table 1, mix the preparation materials evenly, and press 5000kg of the mixture into a spherical shape with a diameter of about Φ50mm, and then The molded product is melted in an iron furnace, the temperature of the melting zone is controlled at 1200-1300°C, and the molten product is discharged every 10 minutes, and the resulting product is about 4000kg. After cooling, the resultant is broken into blocks below 40mm, and used as a flux and dephosphorization agent for steelmaking. The composition and the melting point of the flux of the present invention are shown in Table 2 and Table 3 respectively.

[0031] Table 1: Example mass ratio table

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com