Oxygen lance spray nozzle for converter

An oxygen lance nozzle and converter technology, applied in the field of oxygen lances, can solve the problems of production efficiency restriction, occupation time, etc., and achieve the effects of reducing labor intensity, improving steelmaking efficiency, and having broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A multifunctional oxygen lance nozzle for converter designed in the present invention is based on the converter steelmaking principle and process status quo described in the background technology, and three processes of oxygen blowing, cooling steel and slag splashing protection are carried out through an oxygen lance. Finish.

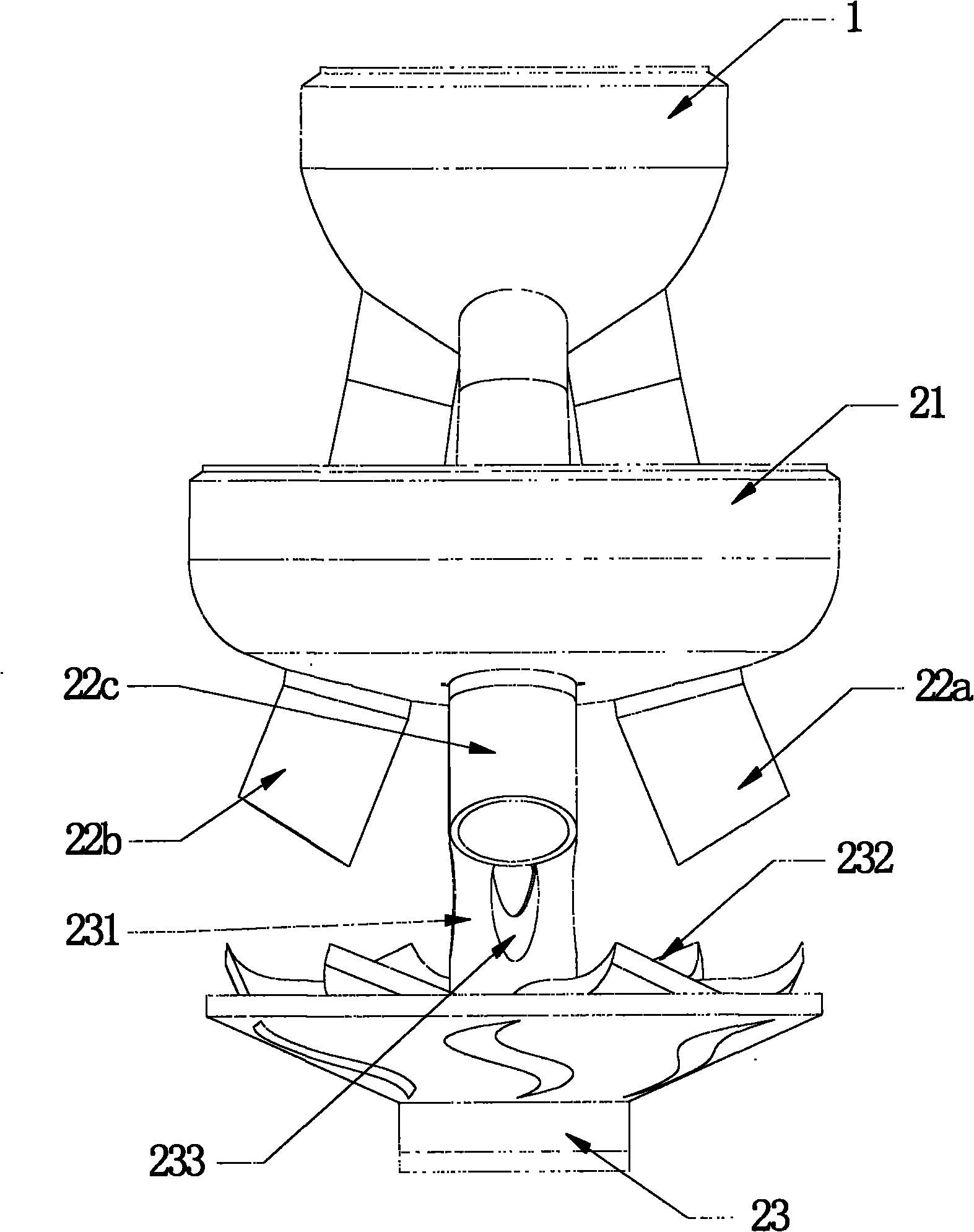

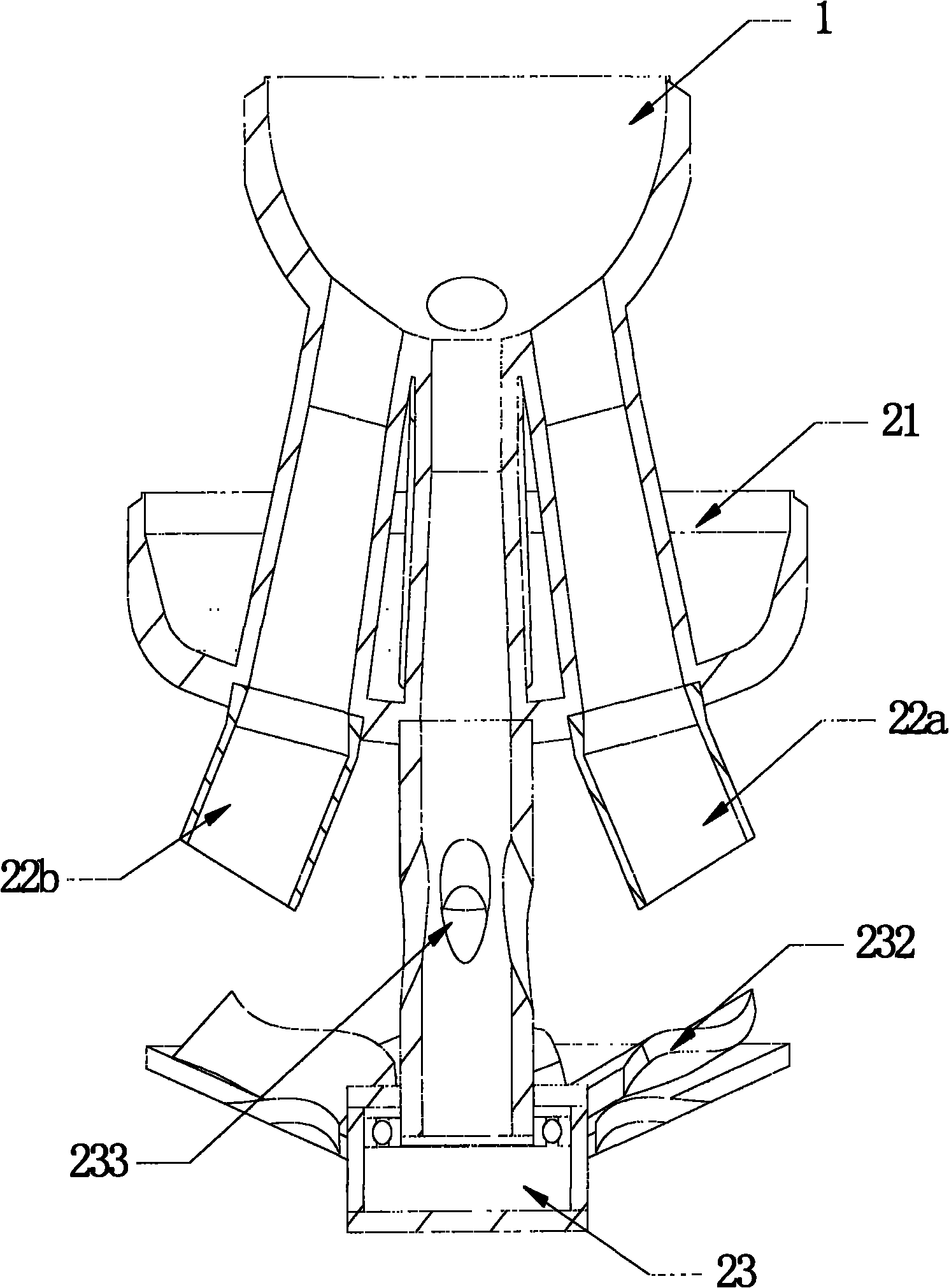

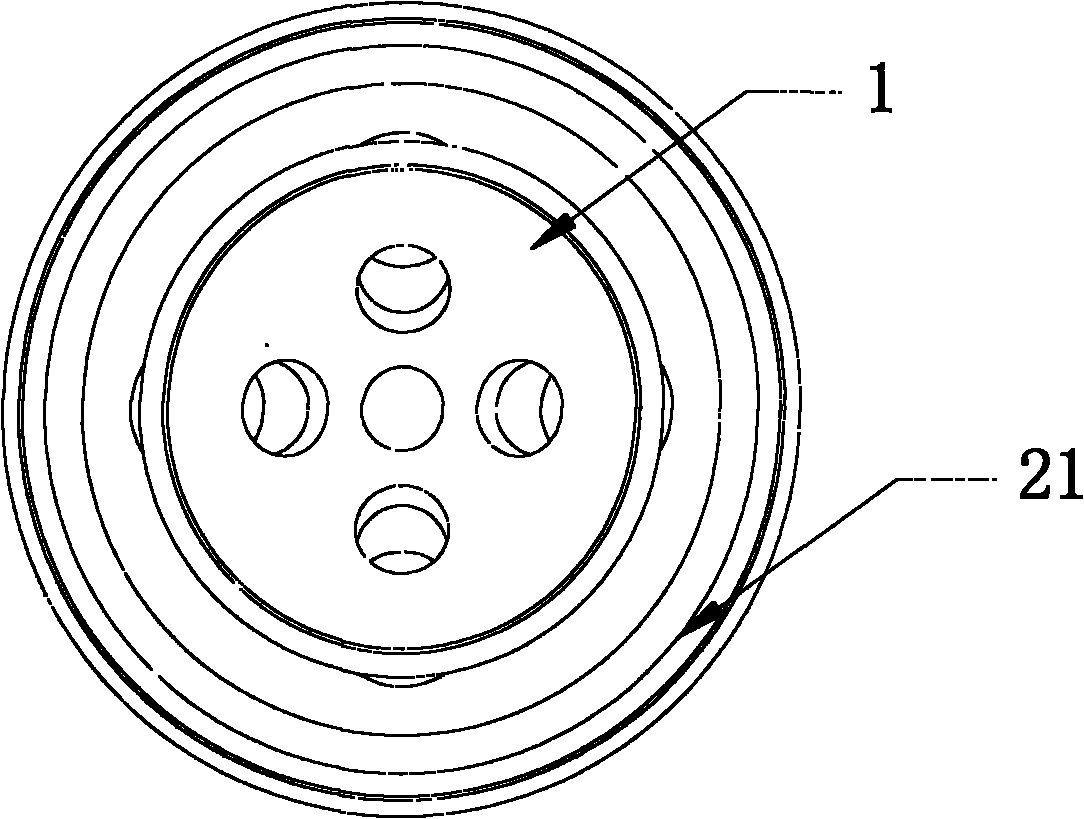

[0018] Such as figure 1 with figure 2 The oxygen lance nozzle for the converter shown is a schematic structural diagram and a schematic cross-sectional diagram of a complete assembly with the oxygen lance. It can be seen that the oxygen lance nozzle is attached to the gas injection port 1 at the end of the oxygen lance, and mainly includes the nozzle body connected through the gas injection port 1 21. A plurality of nitrogen nozzles 22a-22c and the rotary vane device 23 detachably connected to the nozzle body 21, wherein the nozzle body 21 can be permanently assembled on the gas injection port 1 for oxygen supply; and the nitrogen nozzle The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com