High temperature resistant material for tea machinery

A high-temperature-resistant coating and high-temperature-resistant technology, which is applied in fire-resistant coatings, coatings, textiles, and papermaking, can solve the problems of short shelf life, easy precipitation, poor film-forming performance and suspension performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A high-temperature-resistant material for tea machinery is composed of high-temperature-resistant steel and high-temperature-resistant paint;

[0049] The high-temperature-resistant steel includes the following raw materials in parts by weight: 38 parts of carbon, 28 parts of iron, 20 parts of high-purity silicon carbide, 5 parts of titanium, 5 parts of chromium, 5 parts of molybdenum, 6 parts of vanadium, 1 part of niobium, and 1 part of boron;

[0050] The high temperature resistant coating comprises the following raw materials in parts by weight: 80 parts of inorganic silicone resin, 5 parts of titanium dioxide, 10 parts of modified mica powder, 3 parts of tungsten powder, 1 part of dispersant, 5 parts of primary antioxidant, 5 parts of auxiliary antioxidant parts, 10 parts of defoamer, 30 parts of deionized water;

[0051] The high-temperature-resistant paint prepared according to the above formula is coated on the surface of high-temperature-resistant steel in stag...

Embodiment 2

[0053] A high-temperature-resistant material for tea machinery is composed of high-temperature-resistant steel and high-temperature-resistant paint;

[0054] The high-temperature-resistant steel includes the following raw materials in parts by weight: 40 parts of carbon, 34 parts of iron, 30 parts of high-purity silicon carbide, 7.5 parts of titanium, 6.5 parts of chromium, 66.5 parts of molybdenum, 7 parts of vanadium, 1.5 parts of niobium, and 1.5 parts of boron;

[0055] The high temperature resistant coating comprises the following raw materials in parts by weight: 90 parts of inorganic silicone resin, 7.5 parts of titanium dioxide, 12.5 parts of modified mica powder, 6.5 parts of tungsten powder, 2 parts of dispersant, 6.5 parts of main antioxidant, 5.5 parts of auxiliary antioxidant parts, 15 parts of defoamer, 40 parts of deionized water;

[0056] The high-temperature-resistant paint prepared according to the above formula is coated on the surface of high-temperature-re...

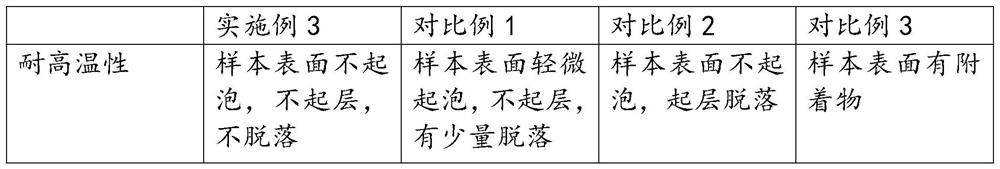

Embodiment 3

[0058] A high-temperature-resistant material for tea machinery is composed of high-temperature-resistant steel and high-temperature-resistant paint;

[0059] The high temperature resistant steel includes the following raw materials in parts by weight: 42 parts of carbon, 40 parts of iron, 40 parts of high-purity silicon carbide, 10 parts of titanium, 8 parts of chromium, 8 parts of molybdenum, 8 parts of vanadium, 2 parts of niobium, and 2 parts of boron;

[0060] The high temperature resistant coating comprises the following raw materials in parts by weight: 100 parts of inorganic silicone resin, 10 parts of titanium dioxide, 15 parts of modified mica powder, 10 parts of tungsten powder, 3 parts of dispersant, 8 parts of primary antioxidant, 6 parts of auxiliary antioxidant part, 20 parts of defoamer, 50 parts of deionized water;

[0061] The high-temperature-resistant paint prepared according to the above formula is coated on the surface of high-temperature-resistant steel i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com