Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Improve dimensional accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

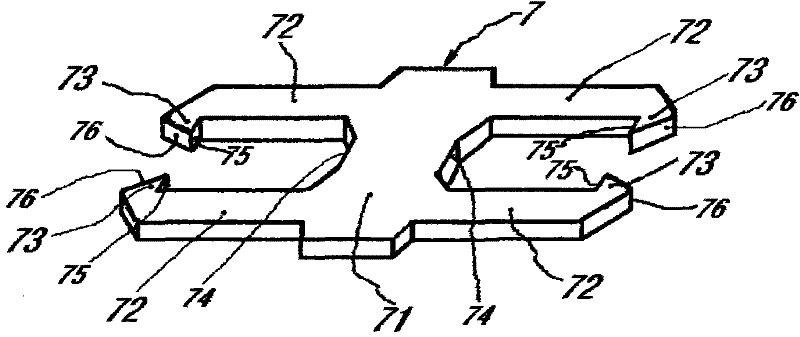

Method for manufacturing acceleration sensing unit

InactiveUS20080229566A1Improve dimensional accuracySmall accelerationAcceleration measurement using interia forcesSemiconductor/solid-state device testing/measurementStress sensingEngineering

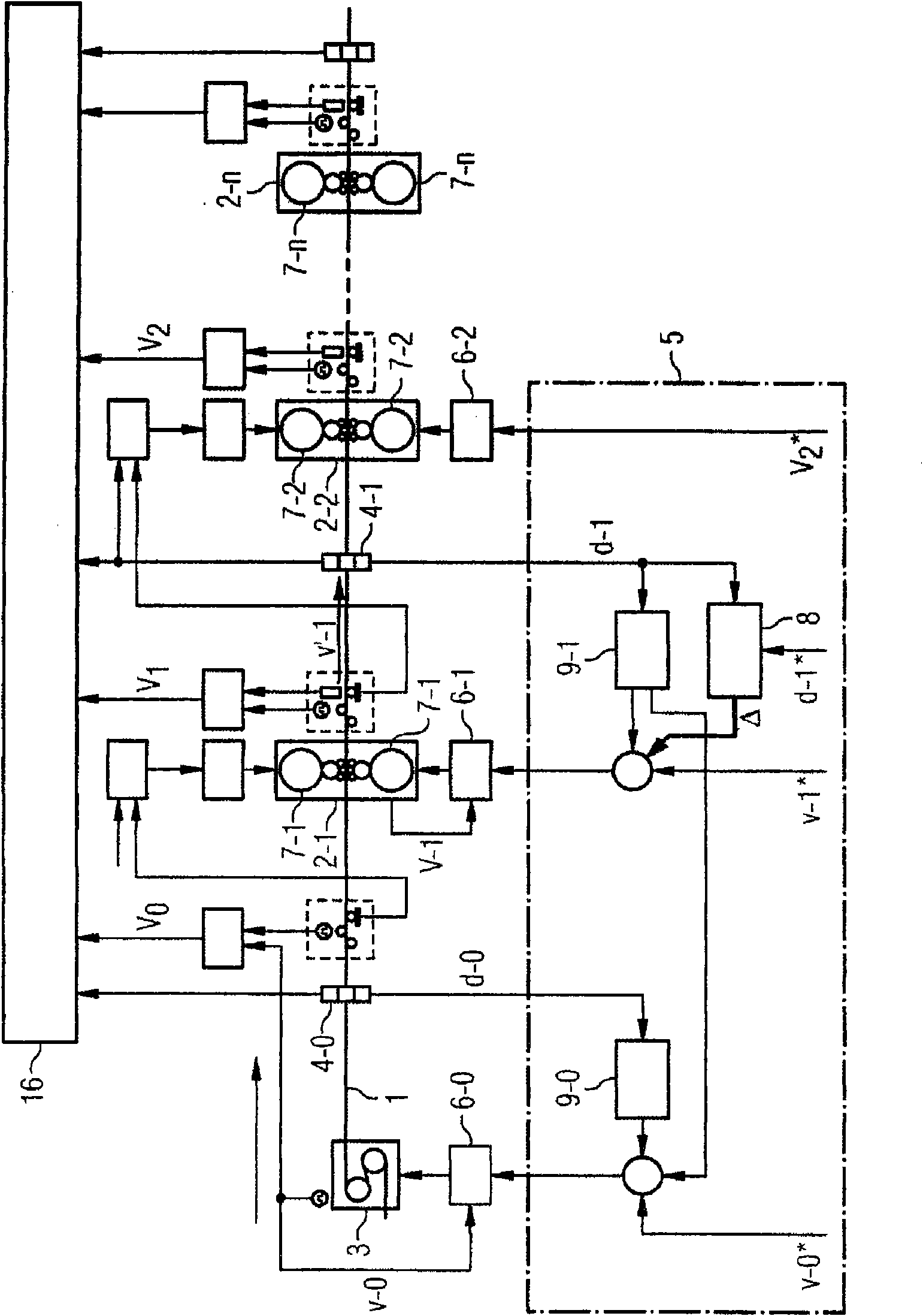

A method for manufacturing an acceleration sensing unit includes: providing an element support substrate in which a plurality of element supporting members is arranged so as to form a plane, each of the element supporting members being coupled to the other element supporting member through a supporting part and having a fixed part and a movable part that is supported by the fixed part through a beam, the beam having a flexibility with which the movable part is displaced along an acceleration detection axis direction when an acceleration is applied to the movable part; providing an stress sensing element substrate in which a plurality of stress sensing elements is arranged so as to form a plane, each of the stress sensing elements being coupled to the other stress sensing element through an element supporting part and having a stress sensing part and fixed ends that are formed so as to have a single body with the stress sensing part at both ends of the stress sensing part; disposing the stress sensing element substrate on the element support substrate such that the fixed ends of each stress sensing element are situated on the fixed part and the movable part; fixing the fixed ends onto the fixed part and the movable part, and dividing the element supporting part and the supporting part.

Owner:SEIKO EPSON CORP

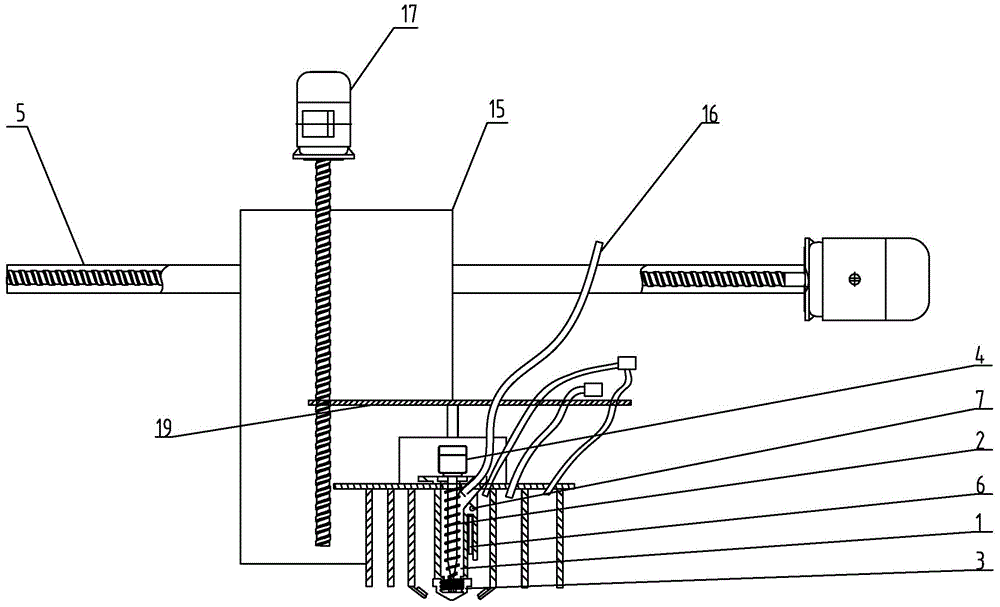

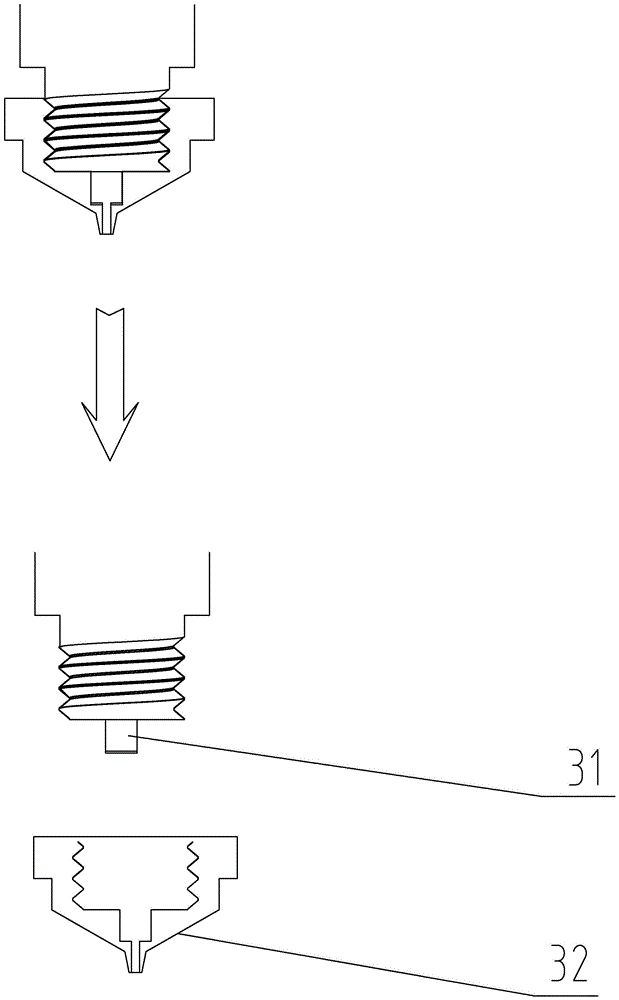

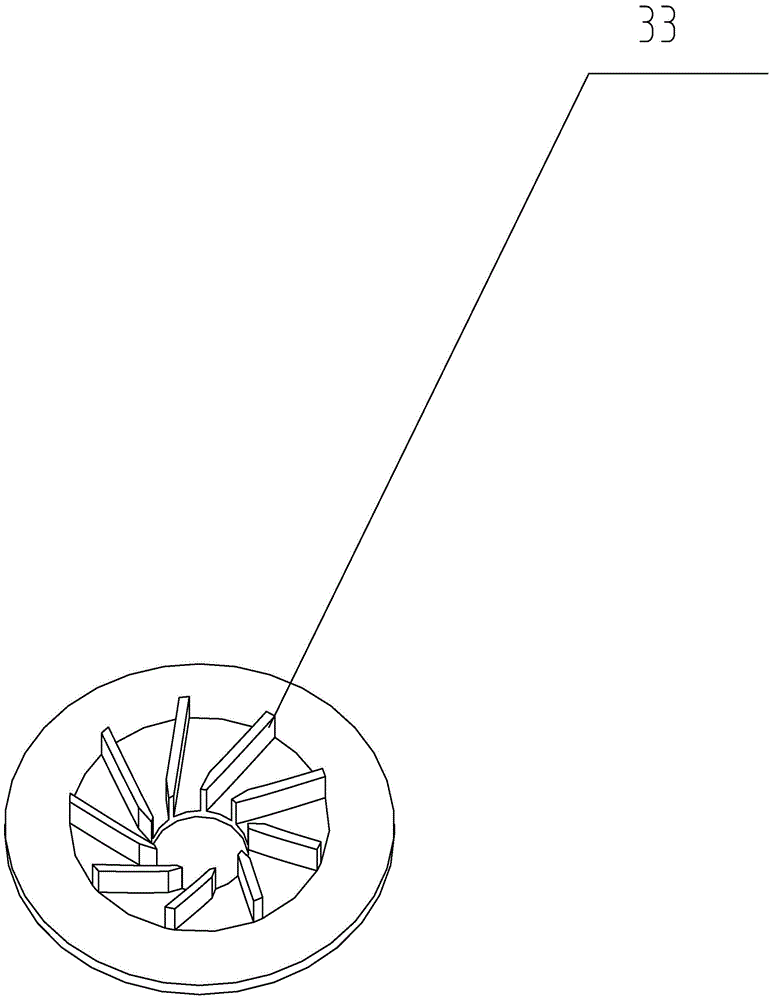

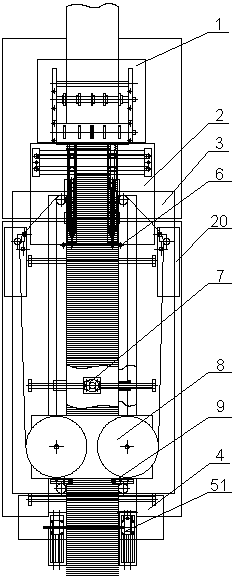

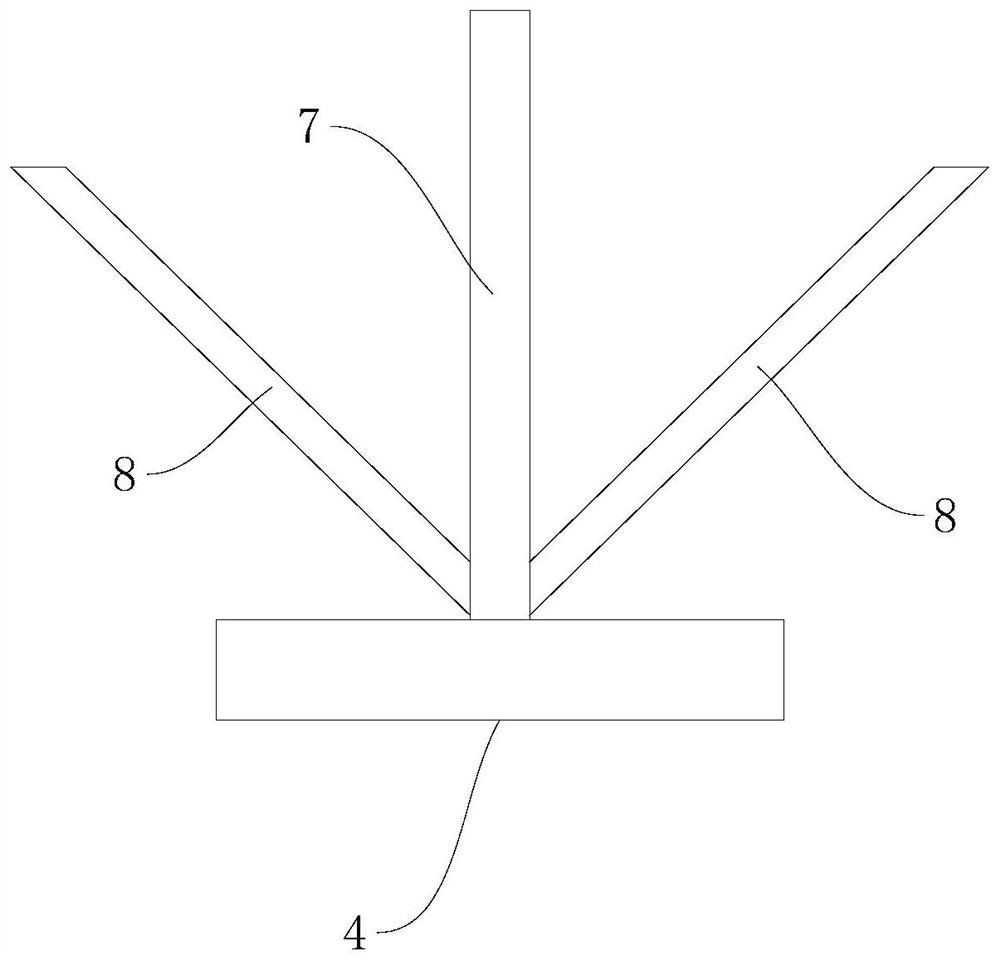

Multifunctional 3D printing head

The invention discloses a multifunctional 3D printing head, which is suitable for 3D printers in any hot melting additive stacking forms. The 3D printing head includes a hot melting chamber, an extrusion pump, a double sleeve spray nozzle, a hot air polishing and cold air shaping apparatus. During 3D printing by means of the multifunctional 3D printing head, a plurality of sub spray nozzles in different pore diameters can be selected conveniently. A raw material is hot-melted in the hot melting chamber, and then the hot-melted material is outputted by means of an extruding pump in an extruded manner. The double sleeve spray nozzle extrudes a paste-like melted wire which is then subjected to re-treatment through the hot air polishing and cold air shaping apparatus, wherein the extruded material is polished and extruded through spiral hot air, and meanwhile, the hot air is pumped back, and then the stacked material is cooled and shaped by means of cold air generated through semi-conductor refrigeration. Through the hot air for polishing and flatting and the cold air for cooling the material, printing precision is greatly increased, and the material after additive printing is flat and smooth and is free of deformation. A shaped product is more firm.

Owner:CHANGZHOU DONGKE ELECTRONICS TECH CO LTD

Multilayer Electronic Component, Electronic Device, and Method for Manufacturing Multilayer Electronic Component

ActiveUS20070267218A1Uniform thicknessImprove dimensional accuracyWave amplification devicesFinal product manufactureExtremity PartEngineering

A multilayer electronic component having a ceramic substrate and a resin layer mounted on a mounting substrate. Recess portions are formed at an outside-facing major surface side of the resin layer. In the resin layer, columnar conductors are disposed so that axis line directions thereof are aligned in a thickness direction of the resin layer. End portions of the columnar conductors are located inside the recess portions further from opening faces thereof and have end surfaces exposed in the recess portions. When a multilayer electronic component is mounted on a mounting substrate, solder is provided on the end surfaces of the columnar conductors in the recess portions. The thickness of solder used in the above mounting does not interfere with a reduction in size and height of an electronic device that includes the above multilayer electronic component.

Owner:MURATA MFG CO LTD

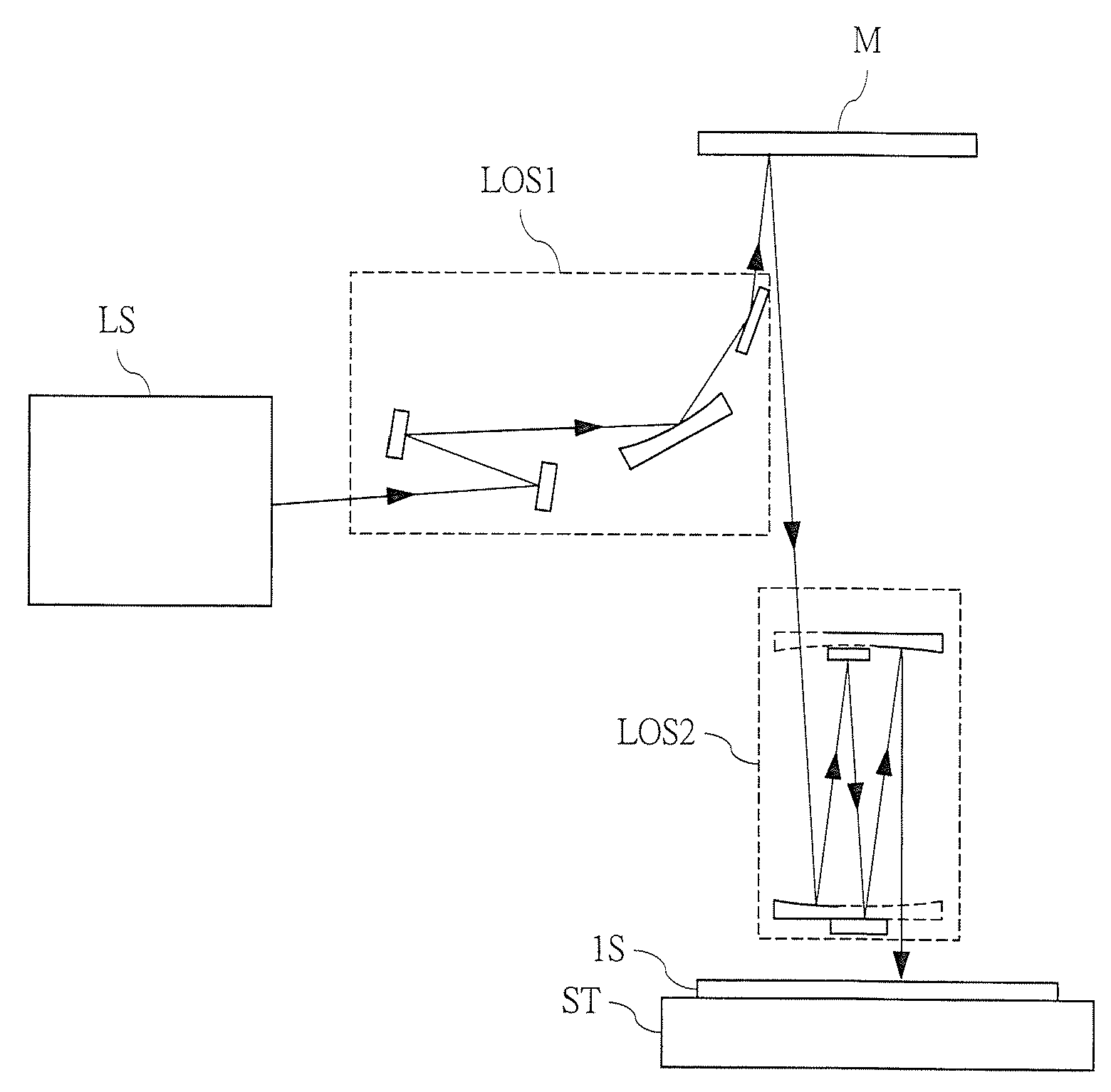

Manufacturing method of semiconductor device and manufacturing method of mask

ActiveUS20100080647A1Improve dimensional accuracyReduce transferFluid pressure sealed jointsPhoto-taking processesPhysicsResist

Provided is a technique capable of improving the dimensional accuracy of a transfer pattern in a lithography technique in which EUV light is used and the EUV light is incident obliquely on a mask and an image of the EUV light reflected from the mask is formed on a semiconductor substrate (resist film), thereby transferring the pattern formed on the mask onto the semiconductor substrate. The present invention is based on a lithography technique in which EUV light is used and an exposure optical system in which the EUV light is obliquely incident on a mask is used. In this lithography technique, an absorber and a difference in level are formed on the mask, and a projective component projected on a mask surface out of a direction cosine component of the incident light is set to be almost orthogonal to an extending direction of the difference in level.

Owner:RENESAS ELECTRONICS CORP +1

Metal plate stamping method and stamping apparatus

ActiveUS20150266078A1Improve dimensional accuracyHigh precision machiningMetal-working apparatusCollectors/separatorsEngineeringMechanical engineering

A metal plate stamping method is provided for cutting a metal plate, on which a bulging portion is formed through stamping, at a cutting area that is defined in a portion other than the bulging portion. The method includes forming a bead on the opposite side of the cutting area from the bulging portion and crushing the bead prior to the cutting of the metal plate.

Owner:TOYOTA BOSHOKU KK

Steel structure detailed drawing labeling method based on BIM (building information modeling) system

ActiveCN104573211AImprove dimensional accuracyGuarantee the construction qualitySpecial data processing applicationsSensing by electromagnetic radiationEngineeringStandardization

The invention provides a steel structure detailed drawing labeling method based on a BIM (building information modeling) system. The steel structure detailed drawing labeling method is a 'two-dimensional code or three-dimensional code' labeling method which is based on the position of a welding auxiliary positioning plate and comprises lots of information. By labeling the position of the welding auxiliary positioning plate, a follow-up connecting plate and component production process is standard and automatic, and the size accuracy of connecting plates and the size accuracy of the components are improved greatly, so that the follow-up construction quality is guaranteed; and 'two-dimensional codes or three-dimensional codes' are inserted in a detailed drawing, the information of the connecting plates, the information of the components, the information of adjacent components and the information of parts in a whole BIM system can be taken in, and standardization and automation of the follow-up connecting plate and component production process are facilitated greatly.

Owner:HENAN AUSPIC TECH

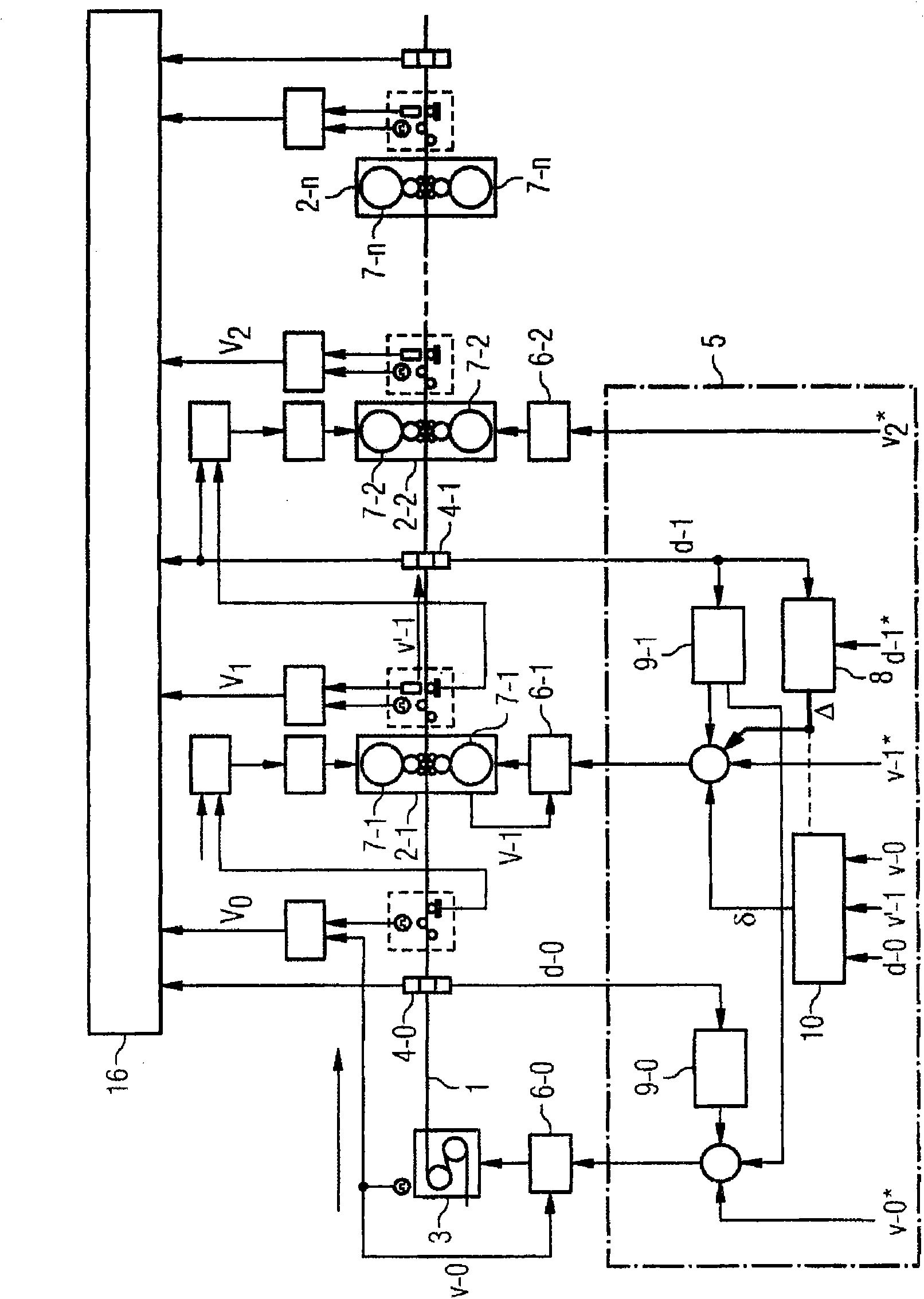

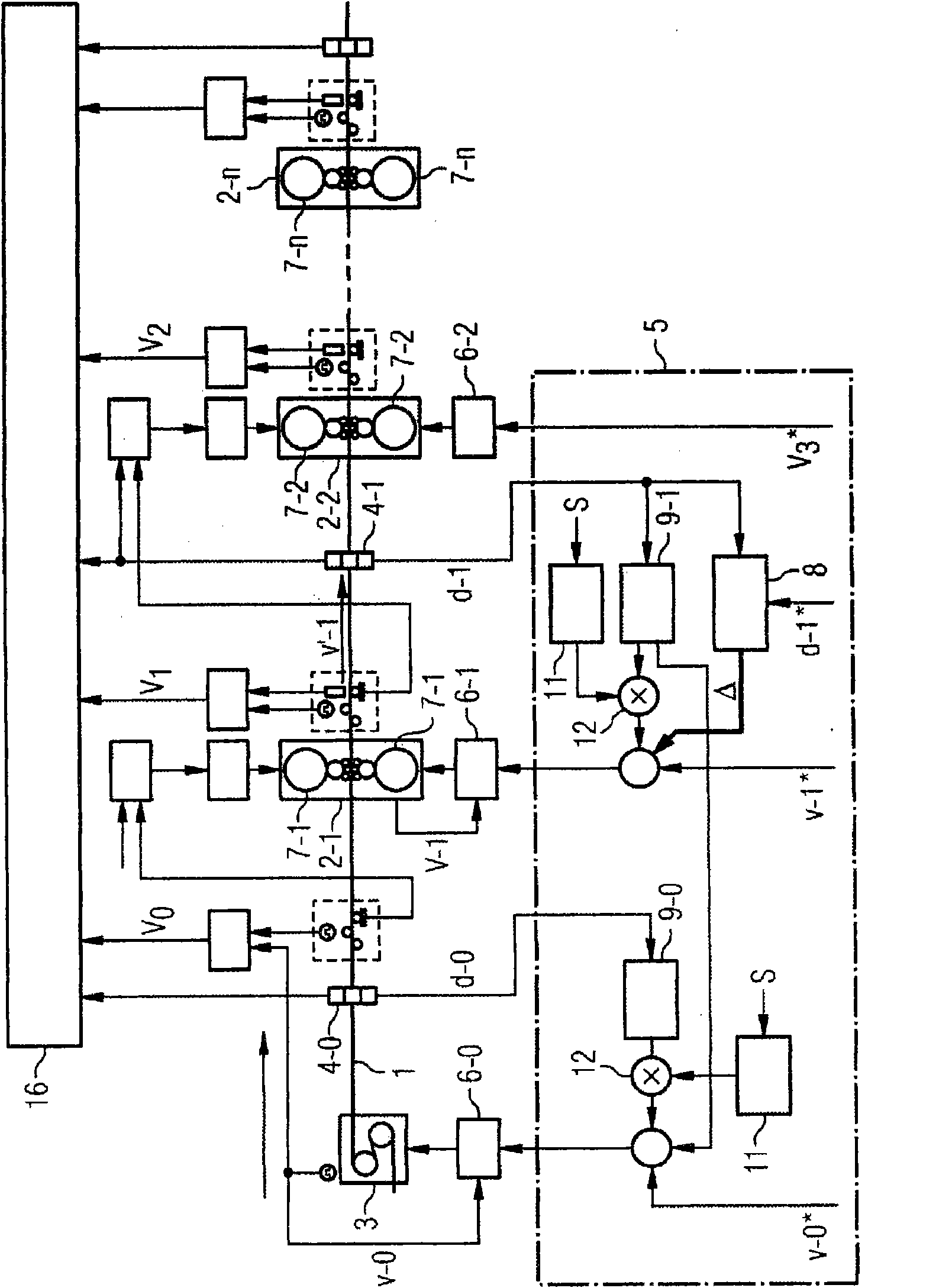

Regulation method for a cold-rolling train with complete mass flow regulation

ActiveCN101932391AImprove dimensional accuracyMeasuring devicesRolling mill drivesRegulatorControl engineering

A cold-rolling train comprises a plurality of rolling stands (2) through which a cold strip (1) passes in succession and a strip feeding device (3) located prior to the first passed-through rolling stand (2-1). A nulled setpoint speed (v-0*) is sent to the strip feeding device (3) so that the strip feeding device (3) feeds the cold strip (1) to the first passed-through rolling stand (2-1) at a nulled actual speed (v-0) corresponding to the nulled setpoint speed (v-0*). A first setpoint speed (v-1*) is sent to the first passed-through rolling stand (2-1) so that rolls (7-1) of the first passed-through rolling stand (2-1) rotate at a first actual speed (v-1) corresponding to the first setpoint speed (v-1*). Between the first passed-through rolling stand (2-1) and the rolling stand (2-2) passed through next is a first thickness detection device (4-1), by means of which a first actual thickness (d-1) of the cold strip (1) is detected. A base output signal (delta) is determined using the first actual thickness (d-1) and a first setpoint thickness (d-1*), said base output signal being used to adjust the first setpoint speed (v-1*), but not the nulled setpoint speed (v-0*), so that the first actual thickness (d-1) is conformed to the first setpoint thickness (d-1*). Between the strip feeding device (3) and the first passed-through rolling stand (2-1) is a nulled thickness detection device (4-0), by means of which a nulled actual thickness (d-0) of the cold strip (1) is detected. The nulled setpoint speed (v-0*) is adjusted by way of a nulled feed-forward controller (9-0) in such a way that the product is adjusted to a setpoint mass flow by the nulled setpoint speed (v-0*) and the nulled actual thickness (d-0).

Owner:PRIMETALS TECH GERMANY

Sliding contact surface-forming material, and multi-layered sliding contact component having the same

ActiveUS20120178327A1Improve dimensional accuracyGood affinityWaterborne vesselsShaftsPolyesterWoven fabric

A sliding contact surface-forming material includes a reinforcing base impregnated with a resol-type phenolic resin having polytetrafluoroethylene resin dispersed therein. The reinforcing base being composed of a woven fabric formed by using, respectively as the warp and the weft, a ply yarn which is formed by paralleling at least two strands of a single twist yarn spun from fluorine-containing resin fiber and a single twist yarn spun from polyester fiber, and by twisting them in the direction opposite to the direction in which the single twist yarns were spun Additionally, a multi-layered sliding contact component having the overall shape of a flat plate or a circular cylinder includes the above-described sliding contact surface-forming material so as to configure at least the sliding-contact surface thereof.

Owner:OILES CORP

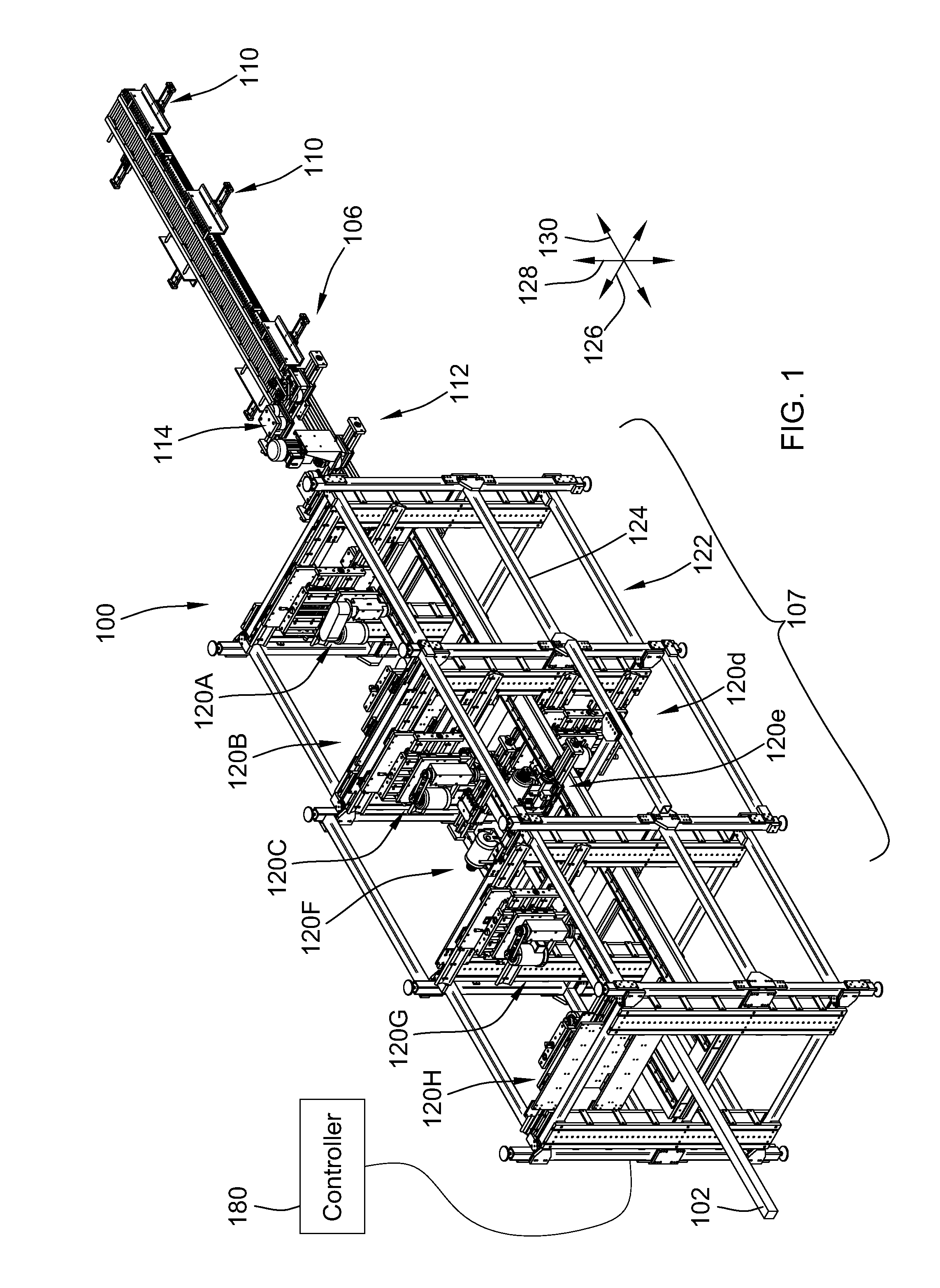

Simultaneous Integral Milling Operation Machine

InactiveUS20110308066A1Reduce machining timeImprove dimensional accuracyAutomatic control devicesLinear bearingsEngineeringSingle pass

A machining apparatus and method of machining a work piece are provided. The method generally includes machining a plurality of independent surfaces of the work piece as the work piece travels along a work path and through a plurality of machining stations in a single pass. The machining apparatus includes a frame and first and second machining stations mounted to the frame. Each machining station is configured to form an independent surface in a work piece passed through the machining apparatus. The machining apparatus also includes a feed arrangement for feeding the work piece through the apparatus along a feed path and relative to the first and second machining stations and the frame while machining is performed on the work piece.

Owner:PACIFIC BEARING

Method for rolling metal wire bars under magnetostatic field auxiliary effect

ActiveCN105032926AReduce deformation resistanceImprove plastic deformation abilityMetal rolling arrangementsUltimate tensile strengthMaterial Deformation

The invention mainly relates to the technical field of extrusion rolling and drawing of metal wire bars, in particular to a method for rolling metal wire bars under a magnetostatic field auxiliary effect. The method is characterized by comprising the following steps: a magnetostatic field is installed in the advancing direction of metal wire bar blanks; before the metal wire bar blanks are rolled, extruded and drawn, the metal wire bar blanks are suffered from a magnetic field effect in the process of passing through the magnetostatic field area; the longitudinal center line of the metal wire bar blanks is consistent with the advancing direction thereof; and the blanks are rolled, extruded and drawn by rollers after the treatment of the magnetostatic field auxiliary effect. For multiple times of rolling, extrusion and drawing, the magnetostatic field treatment is performed before each time of rolling. The method has the following advantages: the material deformation resistance is prominently reduced; the rolling defects are reduced; the finished product size precision is high; the material mechanical performance, in particular the strength and the toughness are improved; and the synchronous reinforcement of the material toughness is realized.

Owner:JIANGSU UNIV

Manufacturing method of non-uniform crankle box girder rotary ladder

ActiveCN109531062AImprove manufacturing precisionGood molding effectNumerical controlSpatial structure

The invention discloses a manufacturing method of a non-uniform crankle box girder rotary ladder. According to the construction scheme, the manufacturing method includes the steps that 1, flange plates and webs are lofted through a computer and then subjected to numerical control programming, and the flange plates and the webs are cut with plasma and discharged according to programming; 2, the flange plates and the webs are curled on a roller bed; 3, the projection contour of the rotary ladder is drawn on a bed mould, and the projection contour is divided into N equal parts corresponding to all levels of stairs; 4, the altitude differences of bisectrices relative to the stepping initial side are calculated, and a bed jig is welded to each bisectrix through profile steel according to the altitude differences; 5, bottom plates are spot-welded and assembled on the bed jigs; 6, the webs and the flange plates are spot-welded and assembled on the bottom plates; 7, top plates are spot-weldedand assembled on the flange plates and the webs, and step scribing of the levels of stairs is carried out; 8, the levels of stairs are spot-welded and assembled after discharging is completed throughnumerical control programming according to an expanded view of steps of the levels of stairs; 9, omni-bearing welding is carried out; and 10, inspection and coating are carried out. Assembly is carried out by simulating the actual mounting space structure size of the rotary profile steel ladder, the manufacturing precision is greatly improved, and the forming effect is good.

Owner:FANGCHENGGANG ZHONGYI HEAVY IND

Automatic edge sticking device for filter element

InactiveCN109367134AImprove productivityImprove dimensional accuracyPaper/cardboard articlesPulp and paper industryPaper sheet

The invention discloses an automatic edge sticking device for a filter element. The automatic edge sticking device comprises a paper feeding device, a paper folding device, an edge sticking device body and a cutting device, wherein the paper feeding device conveys folded paper to the paperfolding device, the paper folding device is used for sequentially conveying the folded paper to the edge sticking device body and the cutting device, when the paper folding device is used for conveying the folded paper, the paper folding device is used for folding the current folded paper to form a pluralityof paper folding units, moreover, the edge sticking device body is used for sticking edge strips on the two sides of the current folded paper, and the cutting device is used for cutting the folded paper and the edge strips. According to the automatic edge sticking device for the filter element, the folded paper can be stably and uniformly folded, the automatic edge sticking operation can be carried out stably and uniformly, and meanwhile, the sizes of the paper folding units of each folded paper can be accurately controlled, so that the qualified rate of produced products is guaranteed, the production efficiency is improved, and the internal quality and the appearance attractiveness of the products are greatly improved.

Owner:张洪彬

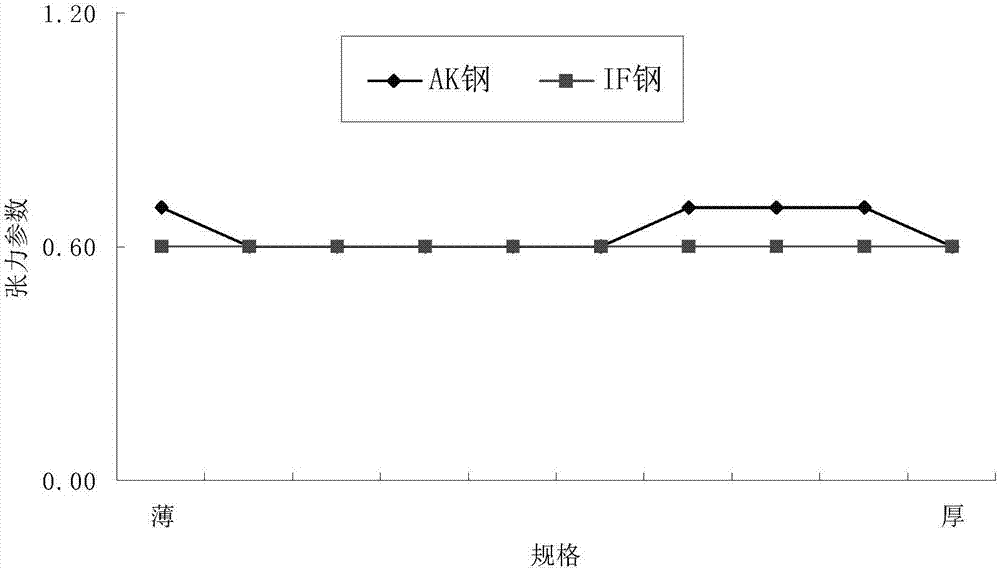

Control method for cold-rolled product size precision

ActiveCN107442576AImprove dimensional accuracyReduce requisition widthMetal rolling stand detailsRoll mill control devicesRegression analysisMaterials science

The invention relates to the field of cold rolling, in particular to a control method for the cold-rolled product size precision. The control method comprises the steps that regression analysis is conducted on relevant parameters of the raw material texture, an acid pickling and cold rolling technology of an acid pickling and cold rolling unit and a continuous annealing technology of a continuous annealing unit by adopting a five-stand six-roll UCM rolling mill, and a final reasonable regression equation and main influence factors are determined through multiple times of analysis and selection. According to the control method, the improving direction is provided for size precision control of various cold-rolled varieties, main points of new variety size precision control and size precision control of all unit products obtained after technology optimization are adjusted, and the good guiding significance is achieved. In addition, reference is provided for galvanized product size precision control according to analysis on the factors influencing the product size precision.

Owner:BENGANG STEEL PLATES

Processing method for surface coating

InactiveCN101745500AAvoid stickingExtended service lifeShaping toolsPretreated surfacesWear resistantWear resistance

The invention relates to a processing method for surface coating, comprising the following steps: carrying out pretreatment step for base material; pre-heating the base material under a certain temperature to lead the pores on the surface of the base material to expand; applying treating agent on the surface of the base material to lead the treating agent to penetrate into the inner layer of the base material through the pores on the surface of the base material and further to form a coating layer from the inner layer to the outer layer of the base material; and carrying out curing process on the coating layer, therefore, the wear resistance and dimensional stability of the base material can be increased, the friction between the base material and other wear-resistant base material is reduced, the service life of the base material is prolonged and the efficiency of production is improved.

Owner:秦璇朋

Floor plate connector and floor plate connection structure

InactiveCN102127956AEasy to assembleLess prone to displacementCovering/liningsFlooringEngineeringMechanical engineering

The invention relates to a floor plate connector and a floor plate connection structure, belonging to the technical field of building decoration materials. The floor plate connector comprises a plurality of splicing arms and a master body connected with the plurality of splicing arms; at least one side of the master body is provided with a plurality of splicing arms, which are parallel to each other and extend to the outside of the master body; a clamping body protruding outwards is arranged on the free end part of each splicing arm; and at least one pair of clamping bodies arranged on the splicing arms on the same side of the master body are arranged opposite to each other. For the design of the floor plate connection structure, two adjacent transverse sides of every two adjacent floor plates are connected through the floor plate connector, the lower surfaces of transverse side ports of the floor plates are respectively provided with a connection groove adaptive to the structure of the floor plate connector, each connection groove comprises a pair of parallel and symmetrical splicing grooves as well as a master body groove and a clamping body groove which are communicated with the two splicing grooves, and the splicing grooves and the clamping body grooves are used for accommodating the splicing arms on the floor plate connector, wherein the clamping bodies on the splicing arms are hooked and clamped inside the clamping body grooves, and the master body grooves are used for accommodating the master body on the floor plate connector.

Owner:李增清

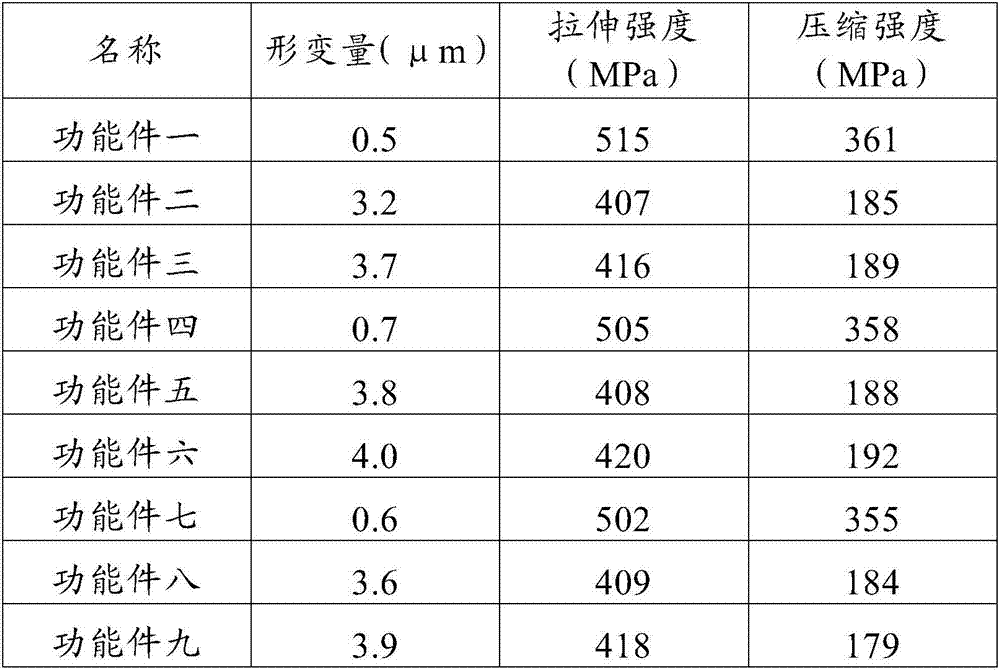

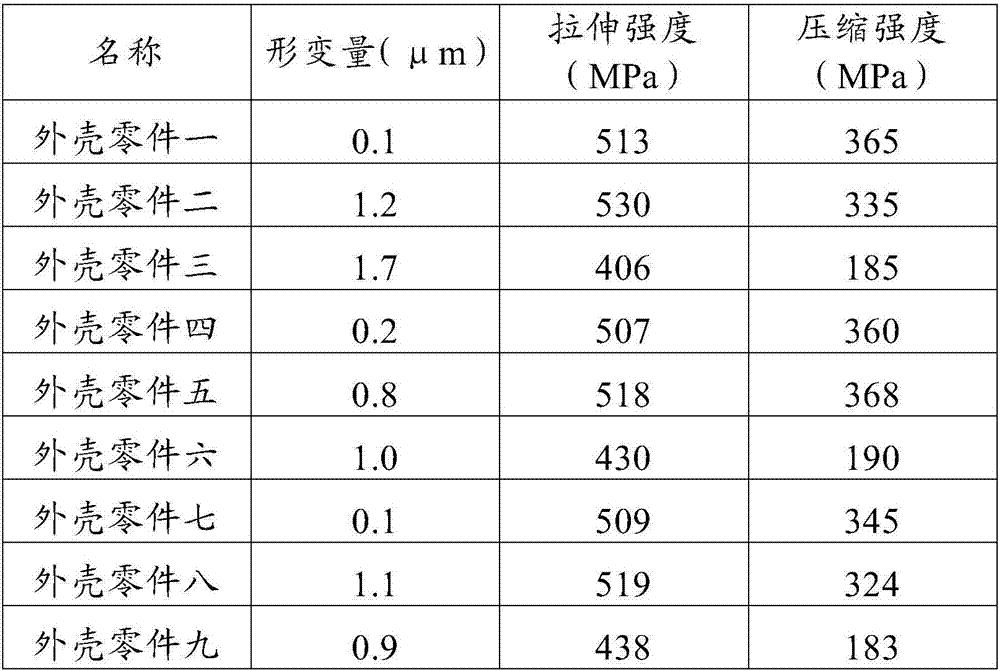

Composite functional prepreg material and preparation method thereof

The invention provides a composite functional prepreg material and a preparation method thereof. The preparation method comprises the following steps: carbon fibers and another kind of fibers are mixed and woven, so that mixed and woven fibers are obtained; resin is used to coat the mixed and woven fibers, thus a mixed and woven prepreg material is obtained; lay-up molding is performed on the mixed and woven prepreg material; and curing molding is performed on the mixed and woven prepreg material. The mixed and woven fiber prepreg material is used, so that the deformation quantity brought by shrinkage deformation caused by direct lamination of two kinds of single fibers is reduced, and the outline dimension accuracy of parts is improved.

Owner:LUOYANG INST OF CUTTING EDGE TECH +1

Method for restraining contraction in sintering ceramics under low temperature and prevent coating

InactiveCN1446775AAvoid pollutionImprove dimensional accuracyCeramic layered productsCeramic sinteringSintering shrinkage

A method for suppressing the low-temp sinter shrinkage of ceramic features that a suppressing layer is applied to the raw ceramic blank with heterogous material, said suppressing layer is perforated at the positions correspondent to said heterogous material, and the size of hole and the gap between holes, must meet a certain condition.

Owner:YAGEO CORP

Method for manufacturing automobile tyre mould

The invention relates to an auto-tyre mould making method, firstly completing the die space by mould steels, then installing the die space on the inequal-divided electro-spark tyre molder to make the figures part and then making electro-spark molding on the figured part by the finished alloy copper electrodes. It has largely improved and heightened strength, rigidity, corrosion resistance and wearability as well as figure surface fineness and size precision, and prolongs the using life.

Owner:潘伟润

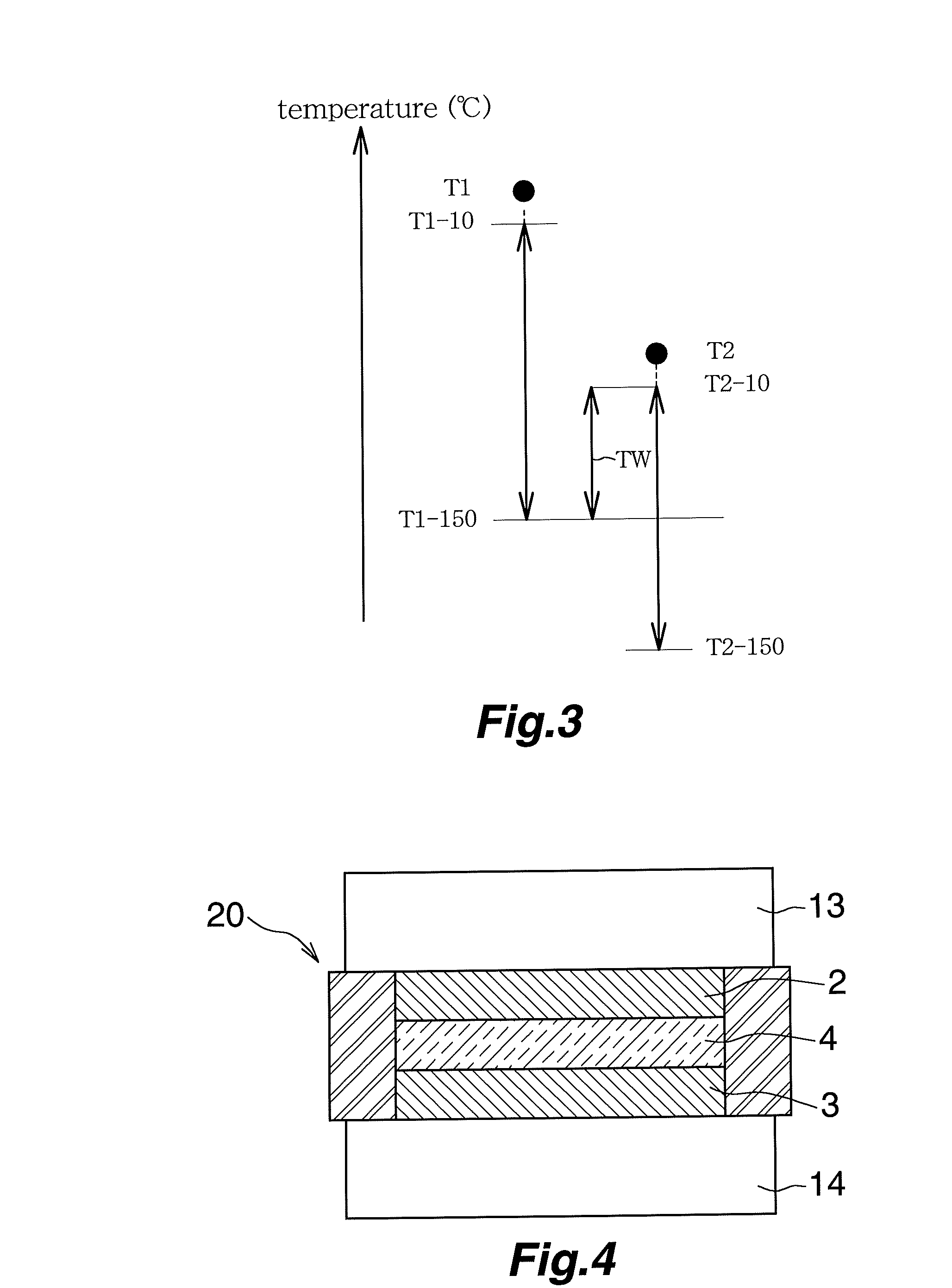

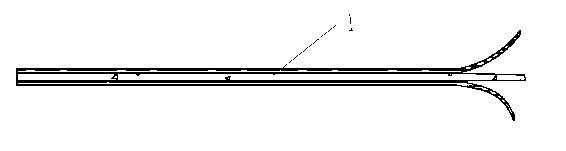

Laminate and manufacturing method for same

ActiveUS20130004791A1Improve dimensional accuracyExcellent productivityLamination ancillary operationsSemiconductor/solid-state device detailsPulse currentMelting temperature

A layered material 1 includes two metal sheets 2,3 and one ceramic sheet 4, wherein the metal sheets 2,3 and the ceramic sheet 4 are stacked so that the ceramic sheet 4 is disposed between the two metal sheets 2,3, and then bonded together through spark plasma sintering. The difference in melting temperature between the metal sheets 2 and 3 is 140° C. or less. The layered material 1 is produced by stacking two metallic sheets 2,3 that have a difference in melting temperature of 140° C. or less and the ceramic sheet 4 so that the ceramic sheet 4 is placed between the both metal sheets 2,3, then disposing the stacked structure of the metal sheet 2,3 and the ceramic sheet 4 between a pair of electrodes in a spark plasma sintering device, and bonding the metal sheets 2,3 and the ceramic sheet 4 by applying a pulse current between the electrodes while maintaining the conduction between the electrodes.

Owner:SHOWA DENKO KK

A kind of forging process of left axle shaft of automobile differential gear

ActiveCN107282849BReduce the blanking weightImprove shift outputEngine componentsLeft halfIndustrial engineering

The invention provides a forging process of a left half shaft of an automobile differential mechanism and relates to the technical field of forging. The forging process includes the procedures of feeding, heating, forming, edge cutting, hardening and tempering and shot blasting. A free forging drawing-out mold cavity is designed, it is guaranteed that the drawing-out mold cavity is matched with a finish forging mold cavity, a positioning device is designed and arranged on a drawing-out mold, it is guaranteed that the drawing-out mold cavity is matched with the finish forging mold cavity, and the situation that the size of a forging stock obtained after finish forging does not meet drawing requirements due to the fact that the blank making diameter is large or small is avoided. The positioning device is designed on the drawing-out mold, the axial and radial sizes of the forging stock are controlled, the product accuracy is greatly improved, multiple forging defects caused by the fact that the blank making length is large or small are overcome, effective controllability is brought to the production process, and the output per shift is increased.

Owner:安徽众鑫科技股份有限公司

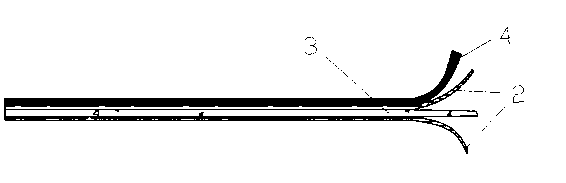

Production process of interior decorative ceiling of anatomical car

InactiveCN103192773AImprove dimensional accuracyImprove appearance qualityLamination ancillary operationsLaminationManufacturing technologyAnatomical part

The invention relates to a production process of an interior decorative ceiling of an anatomical car. The process includes: heating base materials (3), and allowing the base materials (3) to be bonded with face materials (2) on a pressing machine through a die so as to form an initial shape (1) of a ceiling; cutting the initial shape (1) of the ceiling with a cutting robot to form the ceiling; cutting the complete ceiling into the interior decorative ceiling of specific size; and using a forming die to adhere knitted fabric (4) to the interior decorative ceiling, cutting off knitted fabric (4) at the edge, and remaining the knitted fabric (4), which is 50mm longer than the edge of the interior decorative ceiling, on a middle anatomical part to form the finished interior decorative ceiling. By the production process, size accuracy in production of the interior decorative ceiling of the anatomical car is improved effectively, and appearance quality of the interior decorative ceiling is improved. Due to the fact that the anatomical car is most applicable to special occasions such as exhibitions, class of the whole car is improved by the improvement of appearance quality.

Owner:芜湖正海汽车内饰件有限公司

Forging process of left half shaft of automobile differential mechanism

ActiveCN107282849AReduce the blanking weightImprove shift outputEngine componentsLeft halfControllability

The invention provides a forging process of a left half shaft of an automobile differential mechanism and relates to the technical field of forging. The forging process includes the procedures of feeding, heating, forming, edge cutting, hardening and tempering and shot blasting. A free forging drawing-out mold cavity is designed, it is guaranteed that the drawing-out mold cavity is matched with a finish forging mold cavity, a positioning device is designed and arranged on a drawing-out mold, it is guaranteed that the drawing-out mold cavity is matched with the finish forging mold cavity, and the situation that the size of a forging stock obtained after finish forging does not meet drawing requirements due to the fact that the blank making diameter is large or small is avoided. The positioning device is designed on the drawing-out mold, the axial and radial sizes of the forging stock are controlled, the product accuracy is greatly improved, multiple forging defects caused by the fact that the blank making length is large or small are overcome, effective controllability is brought to the production process, and the output per shift is increased.

Owner:安徽众鑫科技股份有限公司

High-precision process of high-speed transmission shaft

The invention relates to a machining process of a hollow transmission shaft. The machining process comprises the steps of material preparation, rough turning, heat treatment, finish turning, aging, clamping, D-D section key slot line lineation, milling, outer circular grinding, thread milling, spline rolling, two tip positioning, spline rolling and turning as shown in picture, inner circular grinding, turning, end tooth grinding, clamping, turning, magnetic detection and dynamic balance of modules. In general, the machining process has the advantages of improving the working efficiency, the machining performances and the workpiece size precision.

Owner:HENAN XINZHOU TRANSMISSION MACHINERY CO LTD

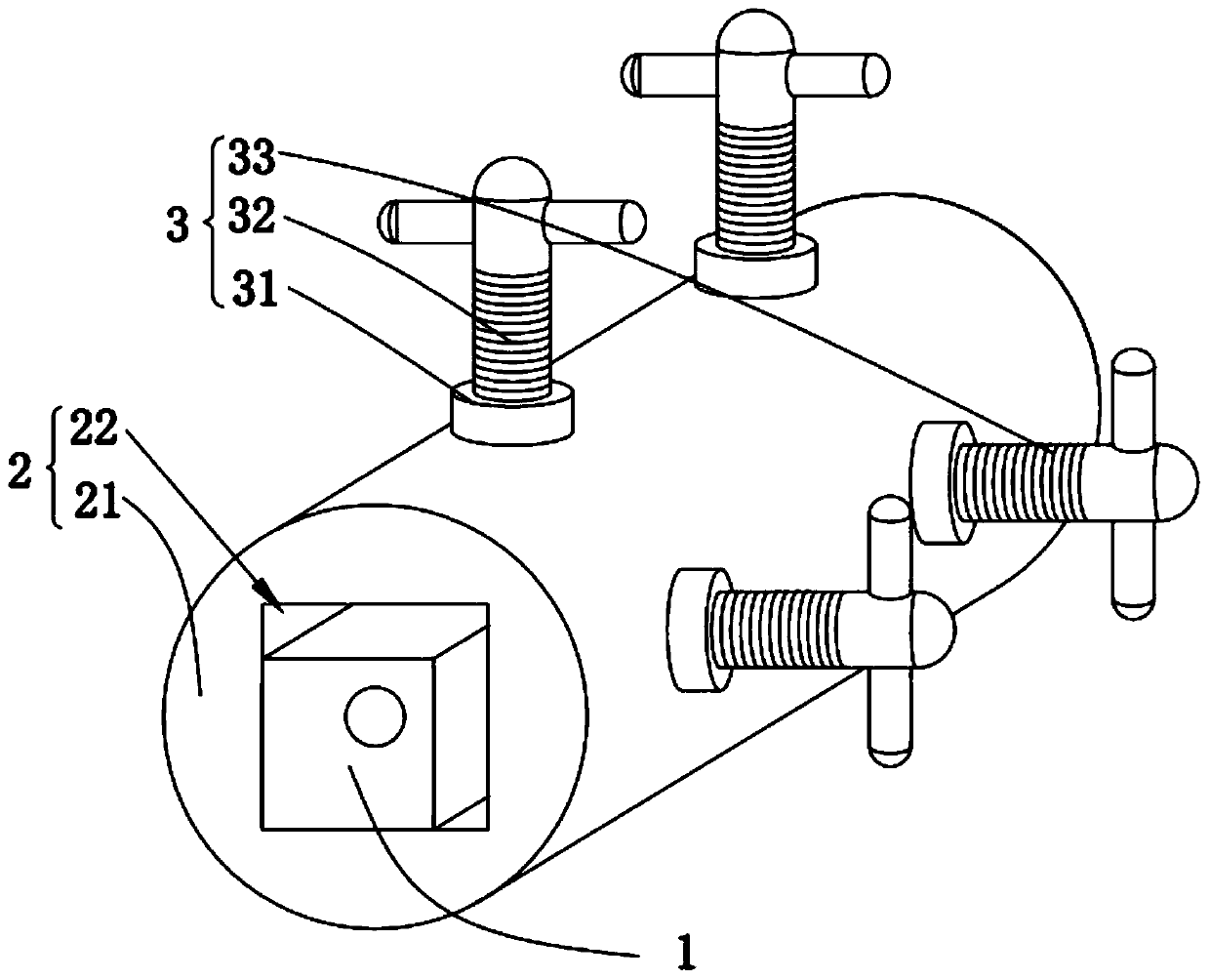

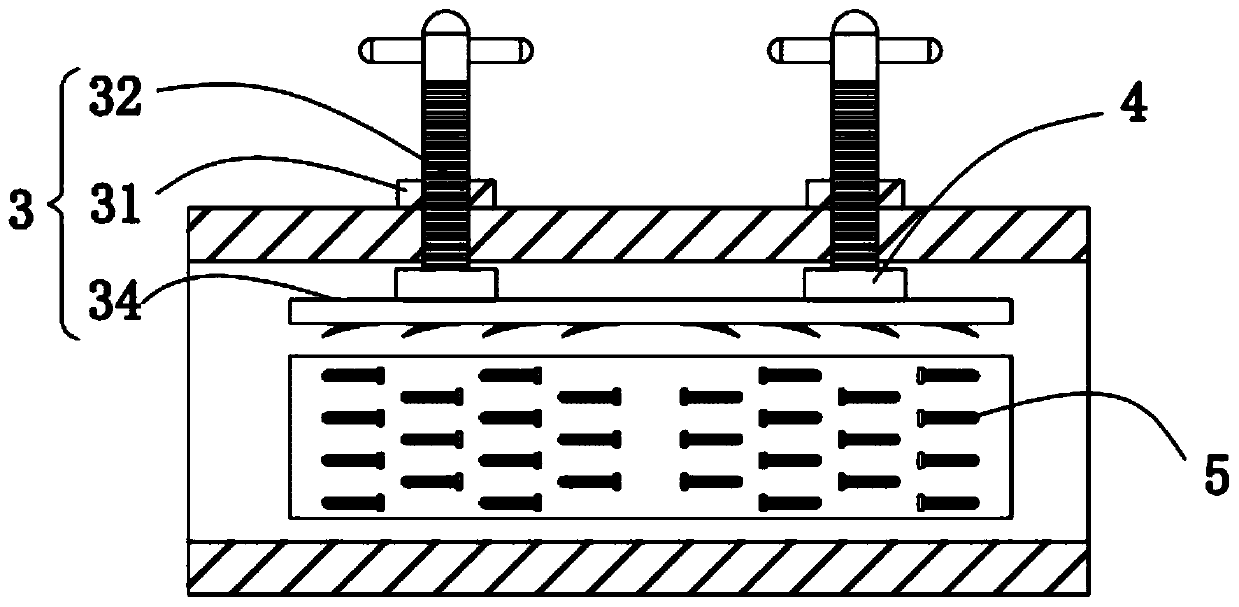

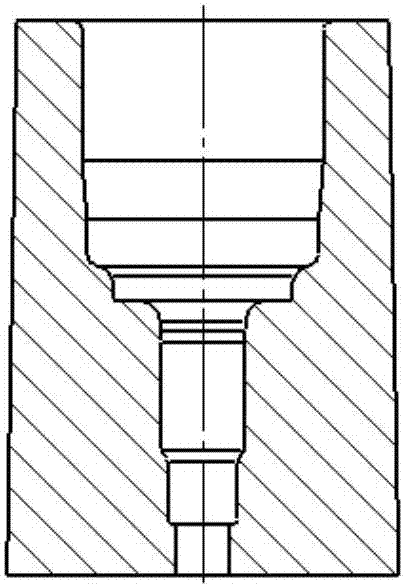

A Lathe Positioning Device for Eccentric Cylindrical Workpieces

ActiveCN109702517BImprove dimensional accuracyEasy to passPositioning apparatusMetal-working holdersEngineeringScrew thread

The invention provides a lathe positioning device of an eccentric cylindrical machining workpiece. The lathe positioning device of the eccentric cylindrical machining workpiece comprises the workpiece, a fixing mechanism, a limiting mechanism, connecting mechanisms, a blocking mechanism and a mounting mechanism, wherein the fixing mechanism comprises a fixing cylinder and a fixing groove; the limiting mechanism comprises connecting sleeves, a first screw rod, a second screw rod and a fixing plate, the top end and the side wall of the fixing cylinder are symmetrically provided with the connecting sleeves correspondingly, the interiors of the connecting sleeves and the interior of the fixing cylinder are in threaded connection with the first screw rod and the second screw rod correspondingly, and the first screw rod and the second screw rod are mutually perpendicular to each other; one end of the first screw rod and one end of the second screw rod are rotationally connected with the fixing plate, and the fixing plate is in sliding connection with the interior of the fixing groove; and the interiors of the plurality of the connecting mechanisms are rotationally connected with the first screw rod and the second screw rod correspondingly. The lathe positioning device of the eccentric cylindrical machining workpiece can conveniently determine the eccentric position of the workpiece.

Owner:娄底市佳鸿机械有限责任公司

Method for improving machining precision of reverse extrusion female die of outer joint

InactiveCN107414435AImprove dimensional accuracySimple processing methodExtrusion profiling toolsQuenchingEngineering

The invention discloses a method for improving machining precision of a reverse extrusion female die of an outer joint. The method is characterized by comprising the steps of sawing-rough turning-quenching-finish turning-rough milling-pressing fit-finish milling. The pressing fit step is additionally arranged before the finish milling step is executed to improve the final state and size progress of the die; the die is finely milled after pressing fit, and can be directly put into use after finish milling, that is, once molding is achieved during finish milling, so that the inner cavity size precision of the finished die is higher; the inner cavity size and the punch guide part are machined at the same time during finish milling; and the two parts are once molded to guarantee coaxiality of the two parts on machining.

Owner:JIANGSU SUNWAY PRECISION FORGING

Extrusion forming method of aluminum alloy door and window profile

InactiveCN110523799AImprove dimensional accuracyImprove surface qualityExtrusion control devicesElement analysisIngot

The invention discloses an extrusion forming method of an aluminum alloy door and window profile. The extrusion forming method comprises the following steps of preparing a cast ingot; cleaning an extrusion cylinder and a forming mold of an extruder; carrying out the step-by-step preheating and heat preservation treatment on the extrusion cylinder and the forming mold of the extruder; preheating anextrusion tool; utilizing the finite element analysis of a DEFORM-3D software to carry out simulated extrusion forming; correcting the forming mold; and extrusion forming, stretching and straightening. Before extrusion forming, the corresponding preheating, heat preservation and cleaning treatment is carried out on the extrusion cylinder, the forming mold and the extrusion tool of the extruder, so that the surface quality of the formed aluminum alloy door and window profile can be effectively improved. The forming mold is subjected to the related analysis through the finite element analysis of the DEFORM-3D software before the formal extrusion forming, so that the influence of the parameter problem of the forming mold on the forming quality can be effectively avoided, and the size accuracy of the extrusion forming can be improved.

Owner:金鹏智能家居有限公司

Automatic edge attaching device for filter element

PendingCN110001138AImprove productivityImprove dimensional accuracyPaper/cardboard articlesEngineeringMechanical engineering

The invention discloses an automatic edge attaching edging device for a filter element of a filter. The device consists of a paper feeding device, a paper collecting device, an edge attaching device body and a cutting device, wherein a paper folding induction device is arranged at a part, close to the cutting device, of the rear section of the edge attaching device body; an adjustable end head ofan interval adjustable part of the paper collecting device is clamped by a mechanical arm, and the position of the mechanical arm is controlled by a screw rod; a glue outlet of a gluing device is a strip-shaped notch with an included angle of greater than 15 degrees but less than 165 degrees with a horizontal plane; the cutting device is arranged on a frame of the edge attaching device body and consists of a horizontal sliding mechanism, a vertical sliding mechanism and a disc knife driving mechanism; meanwhile, the paper feeding device is provided with a vertical adjusting device; the paper collecting device is provided with an up and down and front and back adjusting device; and the edge attaching device body is provided with a left and right adjusting device connecting with a left and right moving mechanism of the paper collecting device and a left and right moving mechanism of the cutting device. By means of the device, size accuracy of each product can be well controlled, the qualified rate of products is guaranteed, and the production efficiency is improved.

Owner:张洪彬

Casting deformation preventing device

ActiveCN113560536AAvoid deformationGuaranteed size requirementsProcess efficiency improvementEngineeringStructural engineering

The invention relates to a casting deformation preventing device which comprises a cast-in pipe and control assemblies. An expansion space is formed in the side wall, close to the insert casting pipe, of a sand mold, each end, close to the cast-in pipe, of the sand mold is at least provided with a group of containing cavities and a molten metal channel, and the corresponding containing cavities are communicated with a mold cavity through corresponding molten metal channels. The control assemblies are arranged on the cast-in pipe, and the control assemblies are located in the containing cavities. One part of each control assembly is rigidly connected with the cast-in pipe, and the other part of the control assembly elastically abuts against the inner wall of one side of the corresponding containing cavity. The casting deformation preventing device device can automatically, directionally and quantitatively control the expansion movement of the cast-in pipe in the cast-in casting, is easy to operate, and ensures that the cast-in pipe is not prone to deformation in the cast-in process of the casting, so that the deformation of the casting is avoided; and the size accuracy is high, and the size and use requirements of casting are guaranteed.

Owner:KOCEL EQUIP

Precision control method for laser directional energy deposition shape

ActiveCN114714628AImprove dimensional accuracyAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringHeight difference

The invention provides a laser orientation energy deposition shape precision control method. The method comprises the following steps that an actual height value and an actual edge thickness value of a workpiece are acquired and converted through a first distance measuring sensor and a second distance measuring sensor; calculating a height difference value and an edge thickness difference value; and the workpiece is compensated in the lower layer deposition. According to the laser orientation energy deposition shape precision control method provided by the invention, the actual height value of the workpiece is acquired and converted through the first distance measuring sensor, and the actual edge thickness value of the workpiece is acquired and converted through the second distance measuring sensor; the actual height value and the actual edge thickness value are compared with a preset height value and a preset edge thickness value which are obtained through simulation calculation respectively, the difference value is calculated, the height difference value and the edge thickness difference value are obtained, compensation is conducted by adjusting machining parameters in lower layer deposition, and accurate control over the forming process is achieved; the shape precision of the workpiece is close to a preset value, and the size precision of workpiece machining is improved.

Owner:中国人民解放军32181部队

PVC (Polyvinyl Chloride) decorative plate, production process and mold therefor

InactiveCN107245204AImprove dimensional accuracyReduce stitching gapSynthetic resin layered productsFlat articlesWeather resistanceCorrosion

The invention relates to the technical field of sheet material production and particularly relates to a PVC (Polyvinyl Chloride) decorative plate. The PVC decorative plate is characterized in that foamed PVC serves as an inner core body of a plate body, and the outside surface of the foamed PVC is coated with a hard PVC external surface layer. A production process for the PVC decorative plate comprises the following steps: 1) mixing, 2) cooling, 3) impurity removal, 4) heating, 5) pressurizing, 6) coating, 7) cooling, 8) side edge optimizing, 9) surface beautification, 10) unit cutting, and 11) packaging. The PVC decorative plate and the production process thereof have the beneficial effects that the PVC decorative plate is resistant to corrosion and is high in impact strength, stable in size, good in weather resistance, light in weight, low in cost and good in economic benefit; and the product quality is improved.

Owner:THE SEA EMBELLISH OF HEZE NEW ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com