Composite functional prepreg material and preparation method thereof

A composite function and prepreg technology, applied in the field of prepreg, can solve problems such as enhancing tensile or compressive strength, dimensional deformation, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

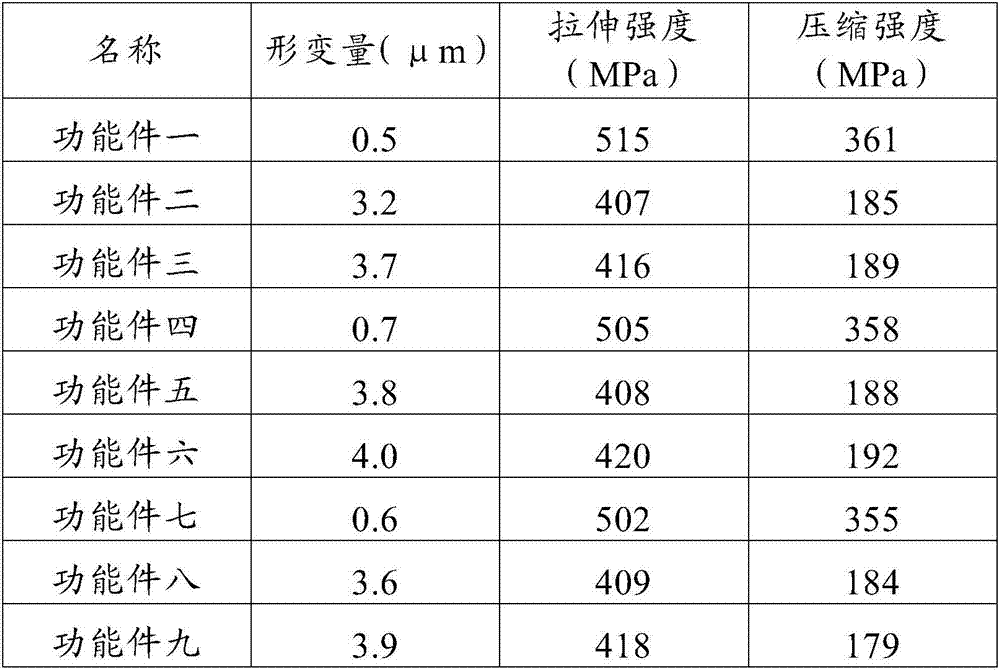

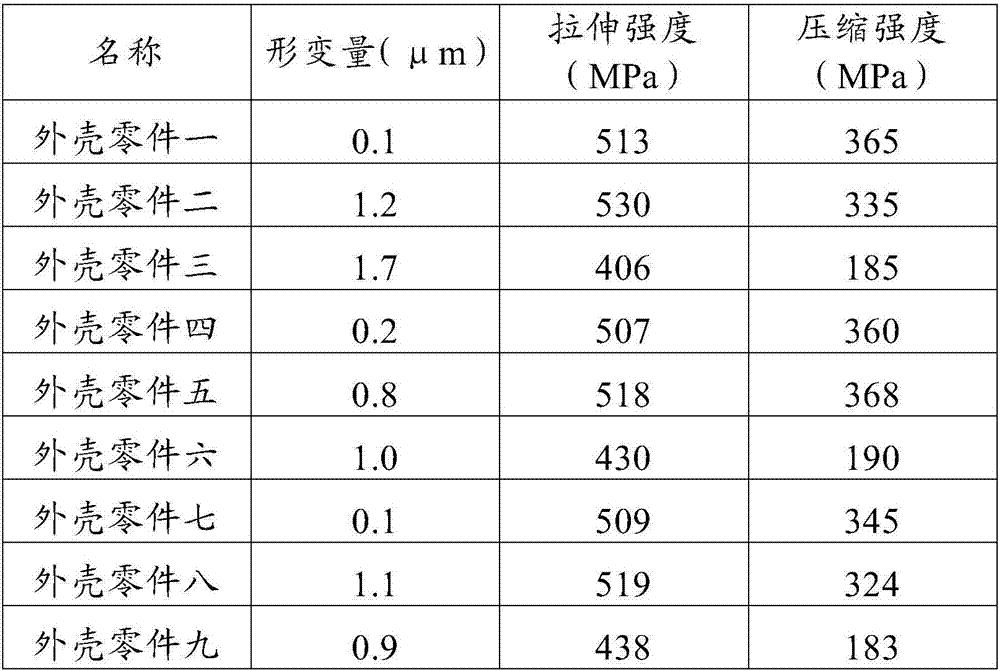

[0026] After mixing carbon fiber and quartz fiber, epoxy resin is used to make a mixed weaving prepreg of carbon fiber and quartz fiber. Among them, the volume content of carbon fiber in the mixed prepreg accounts for 30% of the total proportion, and the volume content of quartz fiber accounts for 30% of the total. The proportion is 30%, the volume content of epoxy resin is 40% of the overall proportion, and the epoxy resin is double-sided coated. The carbon fiber prepreg and the quartz fiber prepreg were prepared respectively by the same method, with the same epoxy resin content, and only the fiber was replaced by a single fiber. Then, layering is carried out, the carbon fiber prepreg is used as the bottom layer, the mixed braided prepreg is used as the middle layer, and the quartz fiber prepreg is used as the top layer, and the functional part 1 is obtained by vacuum bag pressure curing. The carbon fiber prepreg is used as the bottom layer, another carbon fiber prepreg is us...

Embodiment 2

[0028] After mixing carbon fiber and glass fiber, cyanate resin is used to make a mixed weaving prepreg of carbon fiber and glass fiber. Among them, the volume content of carbon fiber in the mixed prepreg accounts for 50% of the overall proportion, and the volume content of glass fiber accounts for 50%. The overall proportion is 20%, the volume content of the cyanate resin accounts for 30% of the overall proportion, and the cyanate resin is double-sided coated. Carbon fiber prepregs and glass fiber prepregs were prepared by the same method, with the same content of cyanate resin, and only the fiber was replaced by a single fiber. Then, lay up layers, using carbon fiber prepreg as the bottom layer, mixed braided prepreg as the middle layer, and glass fiber prepreg as the top layer, and the functional part 4 is obtained by vacuum bag pressure curing. The carbon fiber prepreg is used as the bottom layer, another carbon fiber prepreg is used as the middle layer, and the glass fibe...

Embodiment 3

[0030] After mixing carbon fiber and aramid fiber, bismaleic anhydride resin is used to make a mixed weaving prepreg of carbon fiber and aramid fiber. Among them, the volume content of carbon fiber in the mixed prepreg accounts for 70% of the total proportion, and aramid fiber The volume content of bismaleic anhydride resin accounts for 10% of the overall proportion, the volume content of bismaleic anhydride resin accounts for 20% of the overall proportion, and the bismaleic anhydride resin is double-sided coated. The carbon fiber prepreg and the aramid fiber prepreg were prepared respectively by the same method, with the same bismaleic anhydride resin content, and only the fiber was replaced by a single fiber. Then, layering is carried out, the carbon fiber prepreg is used as the bottom layer, the mixed braided prepreg is used as the middle layer, and the aramid fiber prepreg is used as the top layer, and the functional part 7 is obtained by curing in a vacuum bag. The carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com