Control method for cold-rolled product size precision

A technology of dimensional accuracy and control method, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve problems such as affecting users' use, large cost losses, etc., achieve large economic and social benefits, and reduce the width of requests , the effect of improving the width accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In the specific implementation process, the quality of the raw material is the same as that of the steel product, and there is a certain degree of fluctuation in quality. This situation brings difficulties to the control and analysis of the dimensional accuracy of the product in the cold rolling process, so it is necessary to regard this raw material quality fluctuation as an existence The error is integrated into the control and improvement of the dimensional accuracy of cold-rolled finished products. The process equipment of pickling cold rolling and continuous annealing unit is extremely complex, and every production link will affect the dimensional accuracy of the product, and the production process and quality control of various varieties are still being optimized and adjusted. Dynamic management, so the impact trend of process factors and related dynamic changes on thickness and width accuracy.

[0061] (1) Continuous annealing unit

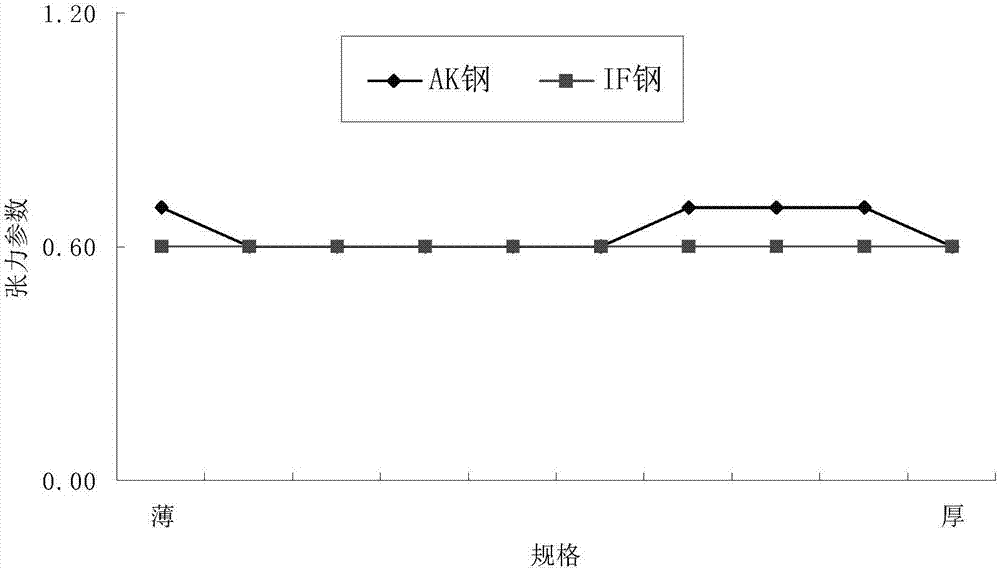

[0062] Such as figure 1 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com