Production process of interior decorative ceiling of anatomical car

A production process and dissecting car technology, which is applied in the production process of dissecting the ceiling of the car interior, can solve the problems of affecting the appearance of the finished product, low cutting size accuracy, and leakage of the edge of the substrate, so as to improve the size accuracy and appearance quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

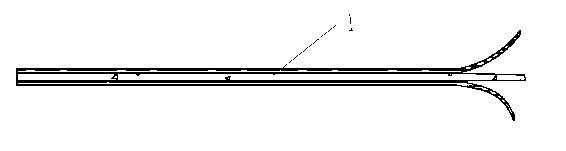

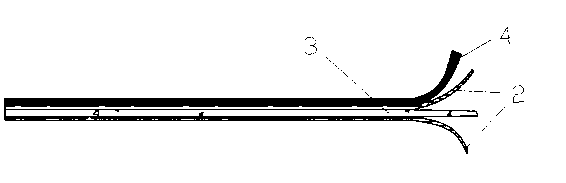

[0012] see figure 1 , figure 2 , the specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] Firstly, after the base material 3 is heated, the base material 3 and the fabric 2 are bonded together on a press through a mold to form a ceiling prototype 1 . The fabric 2 used in this embodiment is a non-woven fabric, and the upper and lower sides of the substrate 3 are adhered to the non-woven fabric.

[0014] Cut the initial model 1 of the ceiling on the cutting robot to form a complete ceiling, and then compile the cutting program according to the specified data to cut the complete ceiling into the required size of the anatomical car roof. At this time, the anatomical car roof is covered with non-woven fabric 2, Then spray glue on the surface of the anatomical car roof, the glue is selected from the polyurethane liquid glue used in wet roof production, use the forming mold to adhere the anatomical ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com