Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Improve core performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

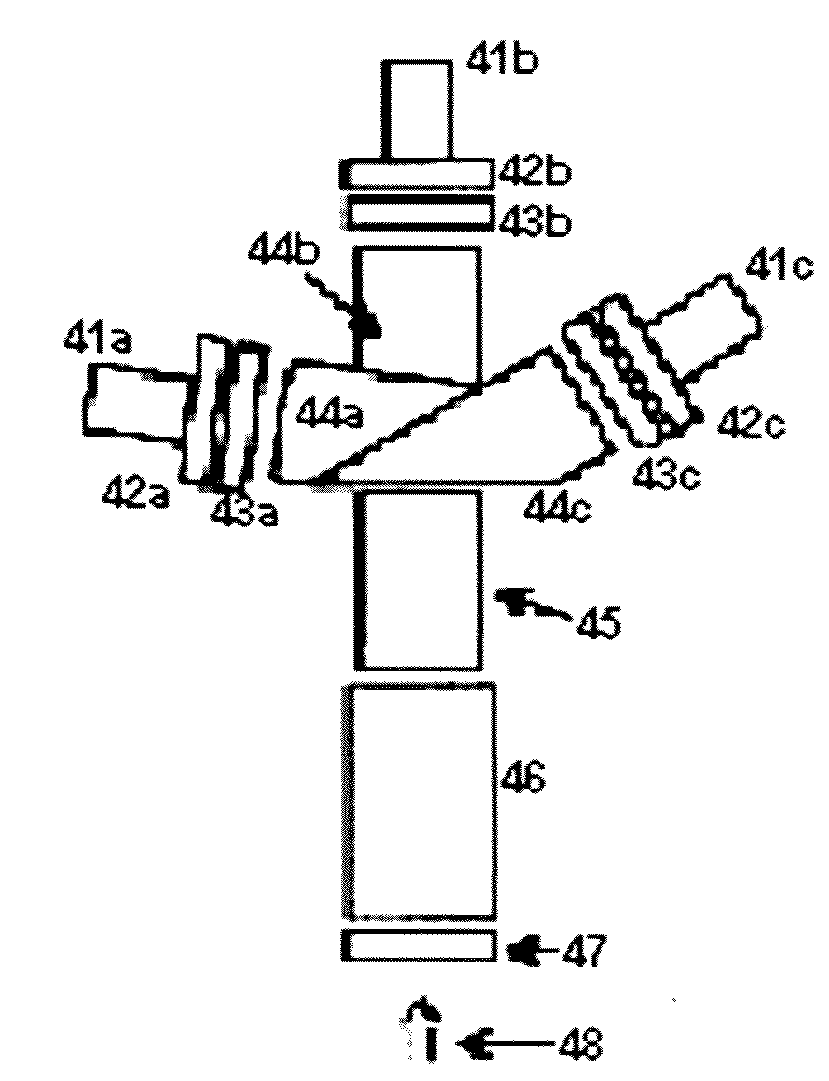

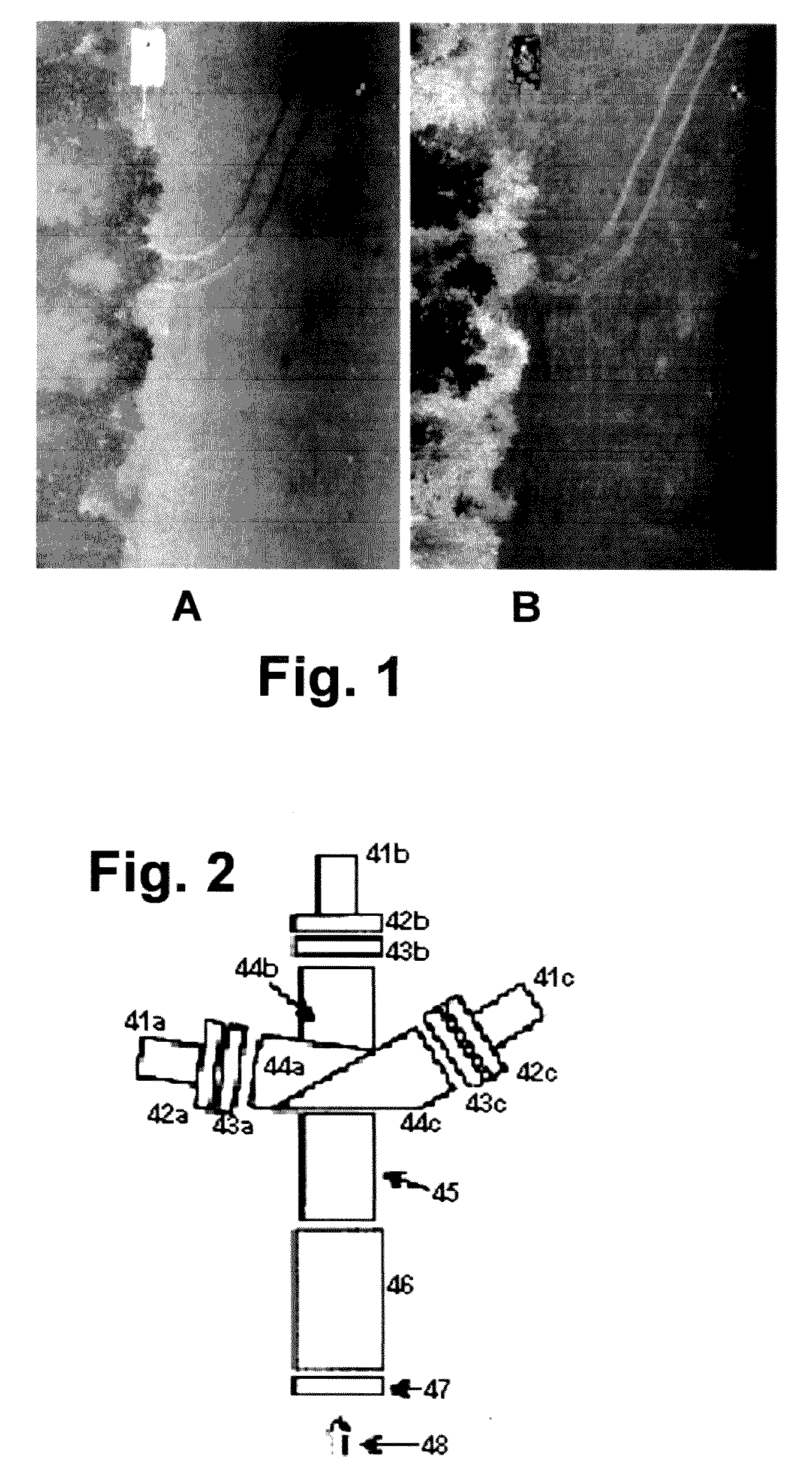

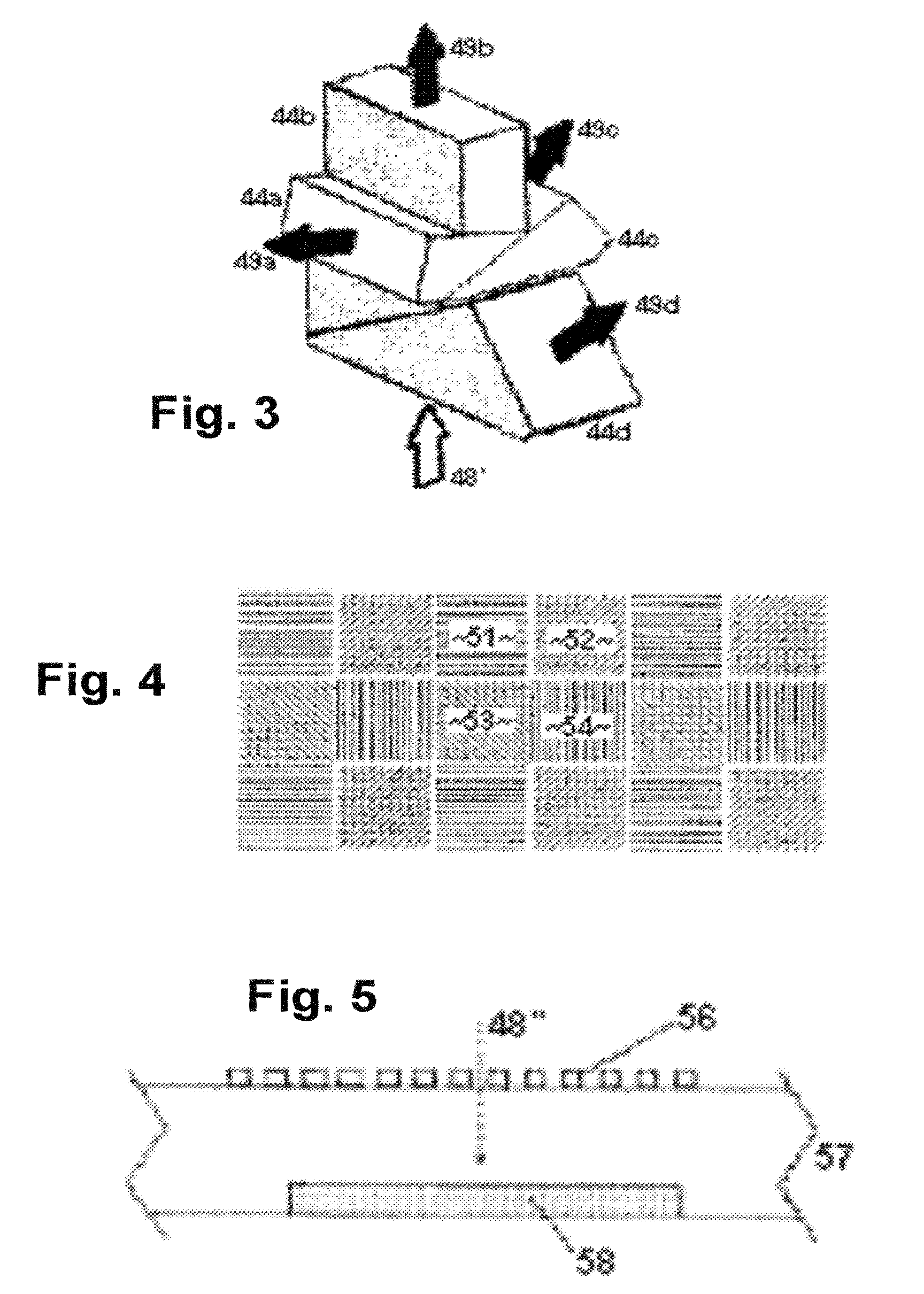

Miniature integrated multispectral/multipolarization digital camera

InactiveUS20090021598A1Increase in numberDecrease in numberTelevision system detailsPolarisation spectroscopyWave bandFrame rate

Several aspects of the invention respectively record one or more multispectral (MS) images using at least one sensor array, each array getting one respective image and simultaneously polarization state at the array points; and get and displays a MS, multipolarization (MP) movie, at MS / MP frame rates that suit a scene or the acquisition; and get an MS image, and a polarization-state image, so that the two are inherently in register; and provide a digital camera for plural-waveband imaging, including polarization data, using a chip with an optically sensitive layer continuously spanning a field of view—for each of at least two substantially distinct bands, and with stacked layers, some radiation penetrating plural layers to a corresponding sensitive layer, and with a polarization mosaic over the stack to define a superpixel array that differentiates polarization states, and with an electronic shutter actuating the layers. Another aspect makes a time sequence of registered MS / MP images; and yet another gets data for one or more MS images, including polarization state at most image points, via a single, common aperture.

Owner:ARETE ASSOCIATES INC

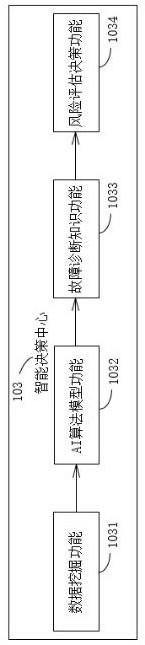

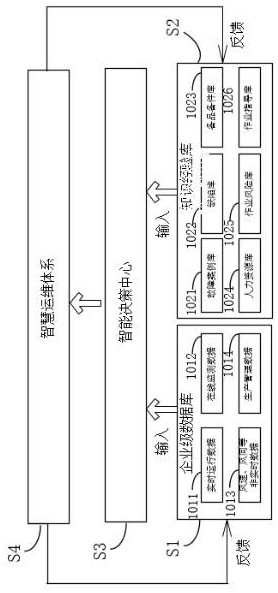

Production operation management system and method for wind power plant

PendingCN113450065AReduce operating costsImprove risk management and control capabilitiesDigital data information retrievalCircuit arrangementsDistributed structureBusiness process

The invention discloses a production operation management system and method for a wind power plant, the production operation management system for the wind power plant comprises a five-layer four-network distributed structure, and the five-layer four-network distributed structure comprises a group layer, a region layer, a power station layer, a spacing layer and a process layer which are connected by adopting a cross-domain cooperation and cloud side sharing architecture mode; the group layer comprises an enterprise-level database, a knowledge experience library, an intelligent decision-making center and an intelligent operation and maintenance system; the regional layer comprises a remote centralized control center and a secondary application cloud platform; through an intelligent decision-making center which takes wind power intelligent early warning, fault diagnosis and intelligent operation and maintenance which are uniformly deployed in a group layer as a core and a hierarchical application mode of a region layer, health assessment is carried out on the operation state of field equipment, so that service processes such as maintenance, overhaul, spare parts, personnel arrangement and misoperation-preventive locking are effectively triggered, and intelligent linkage and quick-response intelligent operation and maintenance between related equipment of each power station on site and between the equipment and operation and maintenance personnel are realized.

Owner:POWERCHINA XIBEI ENG

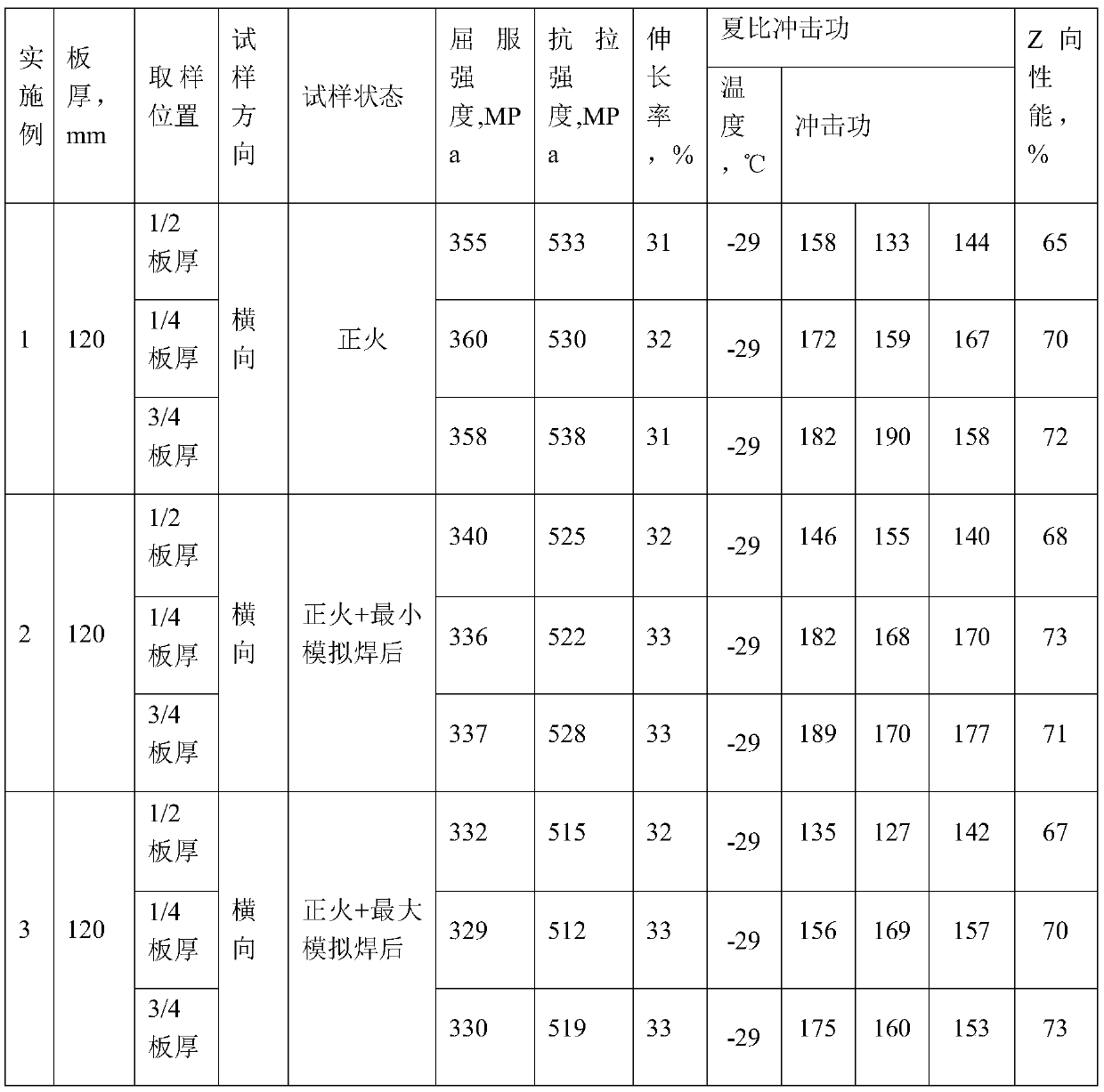

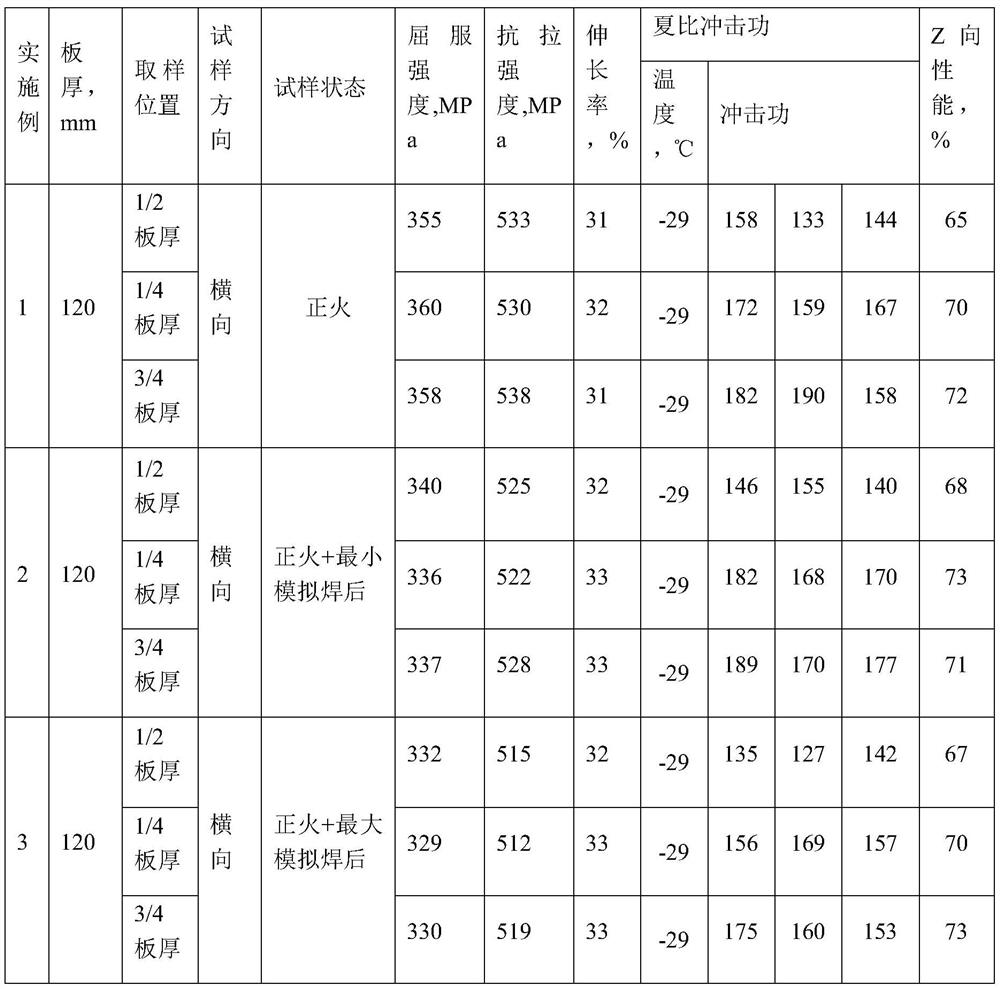

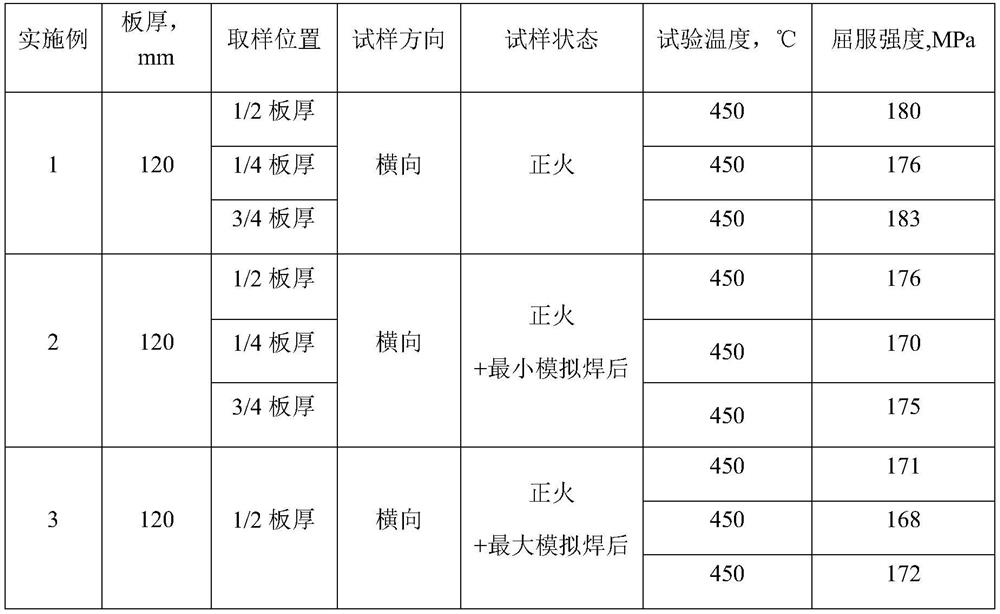

Low-compression-ratio high-performance Q345R super-wide extremely thick container steel and manufacturing method thereof

The invention relates to low-compression-ratio high-performance Q345R super-wide extremely thick container steel. In cooperation with a continuous casting process, the production process route comprises hot metal pretreatment, converter steelmaking, external refining, vacuum degassing, slab continuous casting, blank pile slow cooling, heating, rolling, steel plate pile slow cooling, ultrasonic flaw detection, normalization, ultrasonic flaw detection, air cooling and finishing. The thickness of a steel plate can reach 101 mm to 120 mm, and the width of the steel plate can reach 3500 mm to 4050mm. The core performance is excellent, wherein the low-temperature impact value at -29 DEG C is 100 J or above and exceeds the requirement of the ballistic work larger than or equal to 41 J at the temperature of -20 DEG C specified by the standard GB / T713-2014, and the high-temperature tensile performance at 450 DEG C meets the requirement of a table 3 in GB / T713-2014; and the Z-direction performance is excellent and exceeds the highest requirement of the standard for the Z-direction performance 35% of the steel plate. The steel plate is uniform in overall mechanical property, and it is indicated that the steel plate is very high in compactness and meets the strict requirement for the mechanical property and structural uniformity of the core and whole plate of large-thickness steel; and after the steel plate is subjected to simulated post-welding heat treatment, the structure is still kept uniform, and the core tensile performance and core impact performance do not obviously fluctuate.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

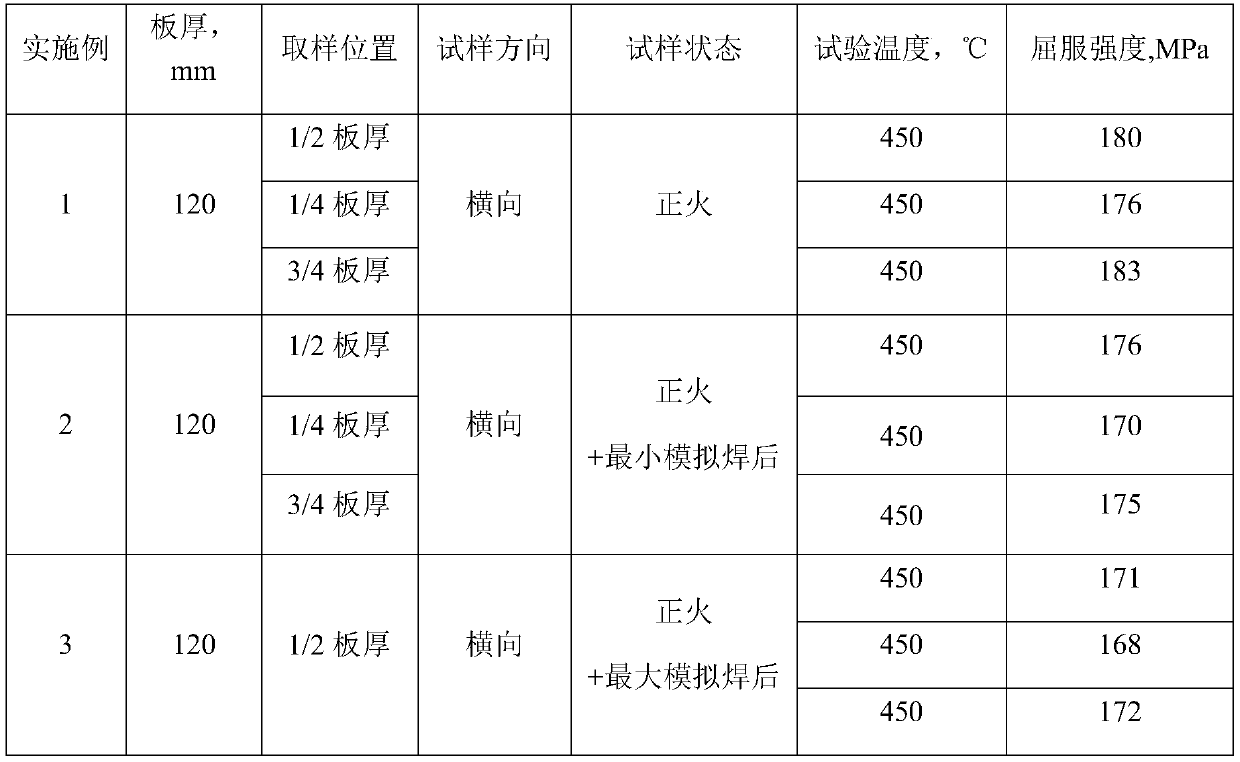

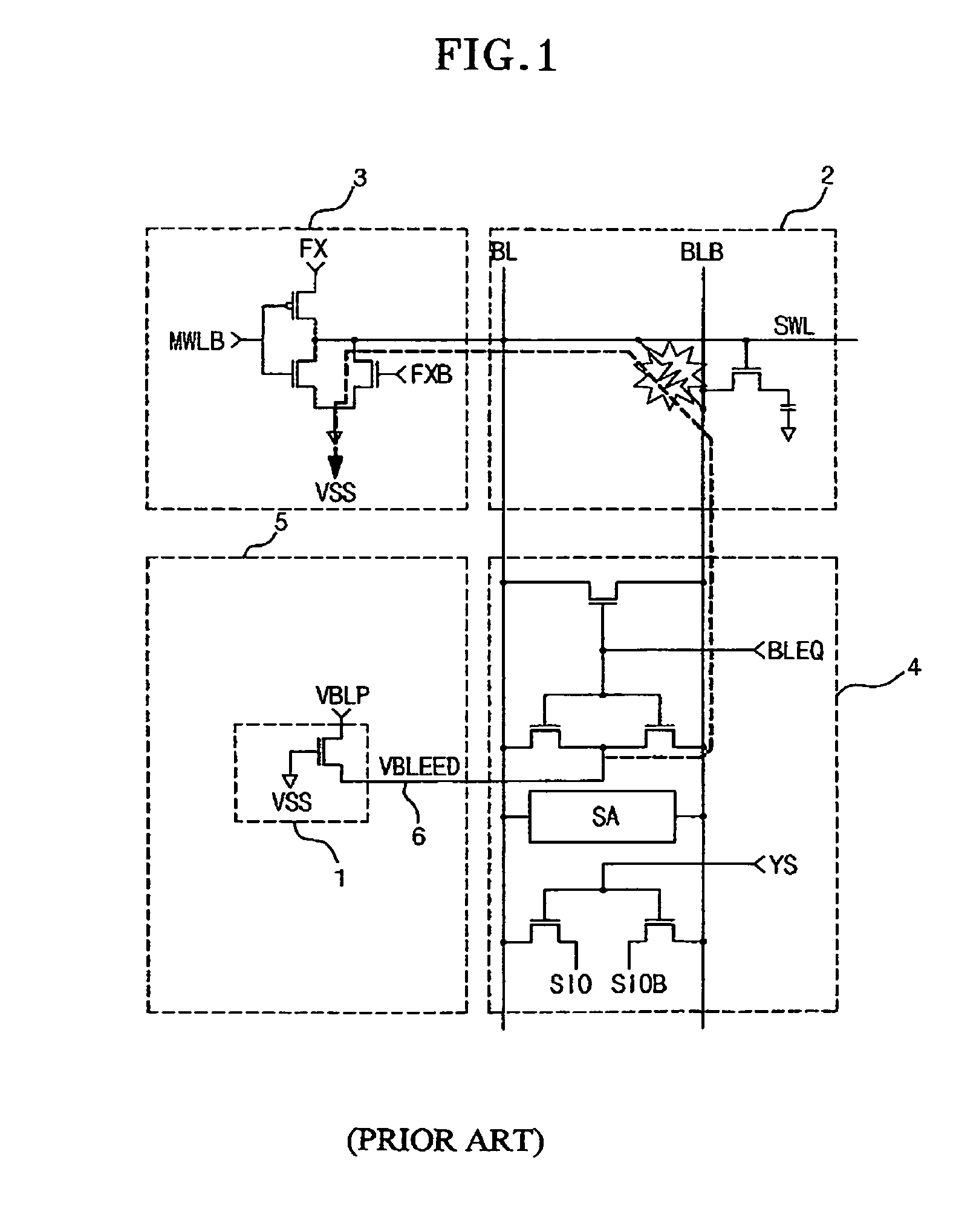

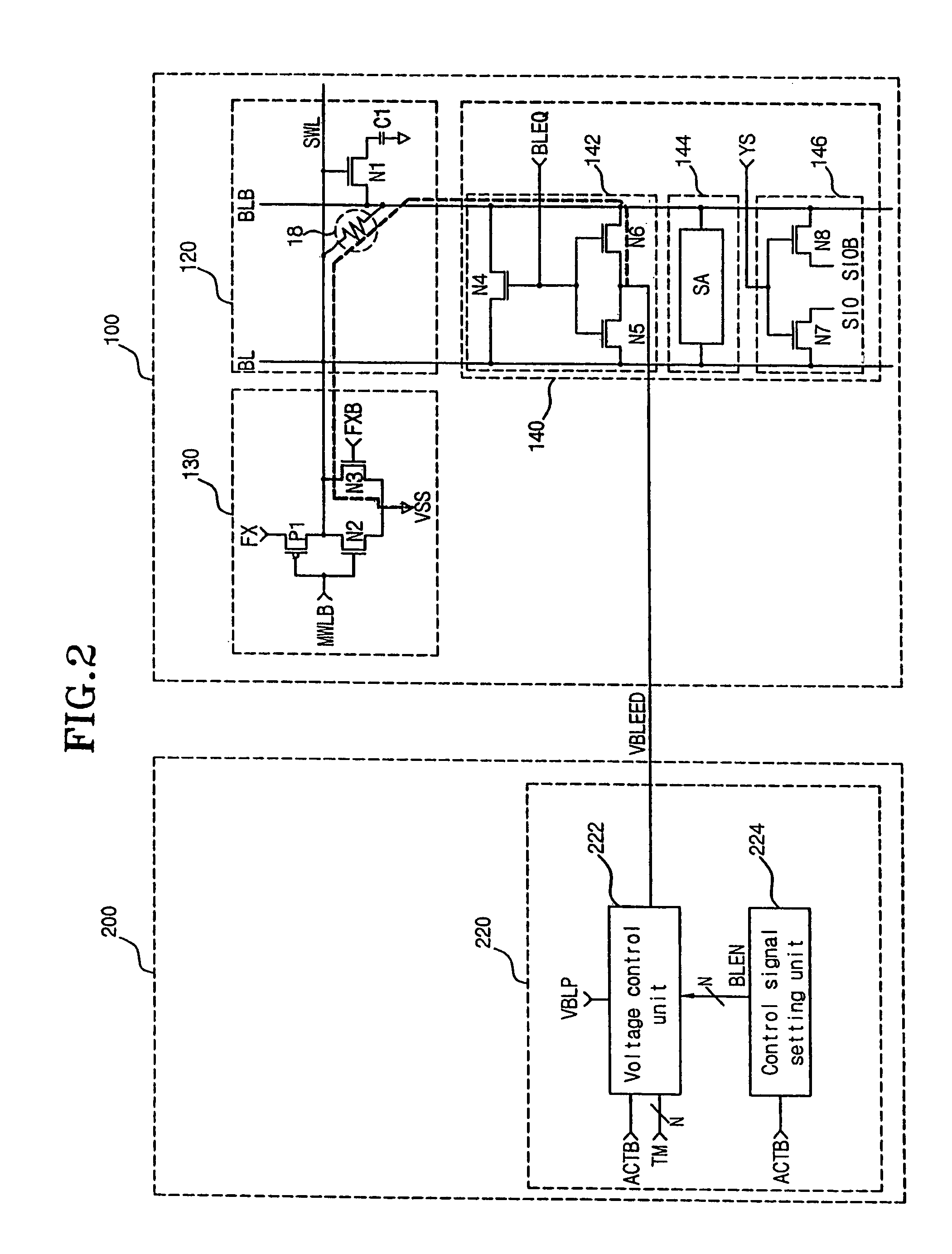

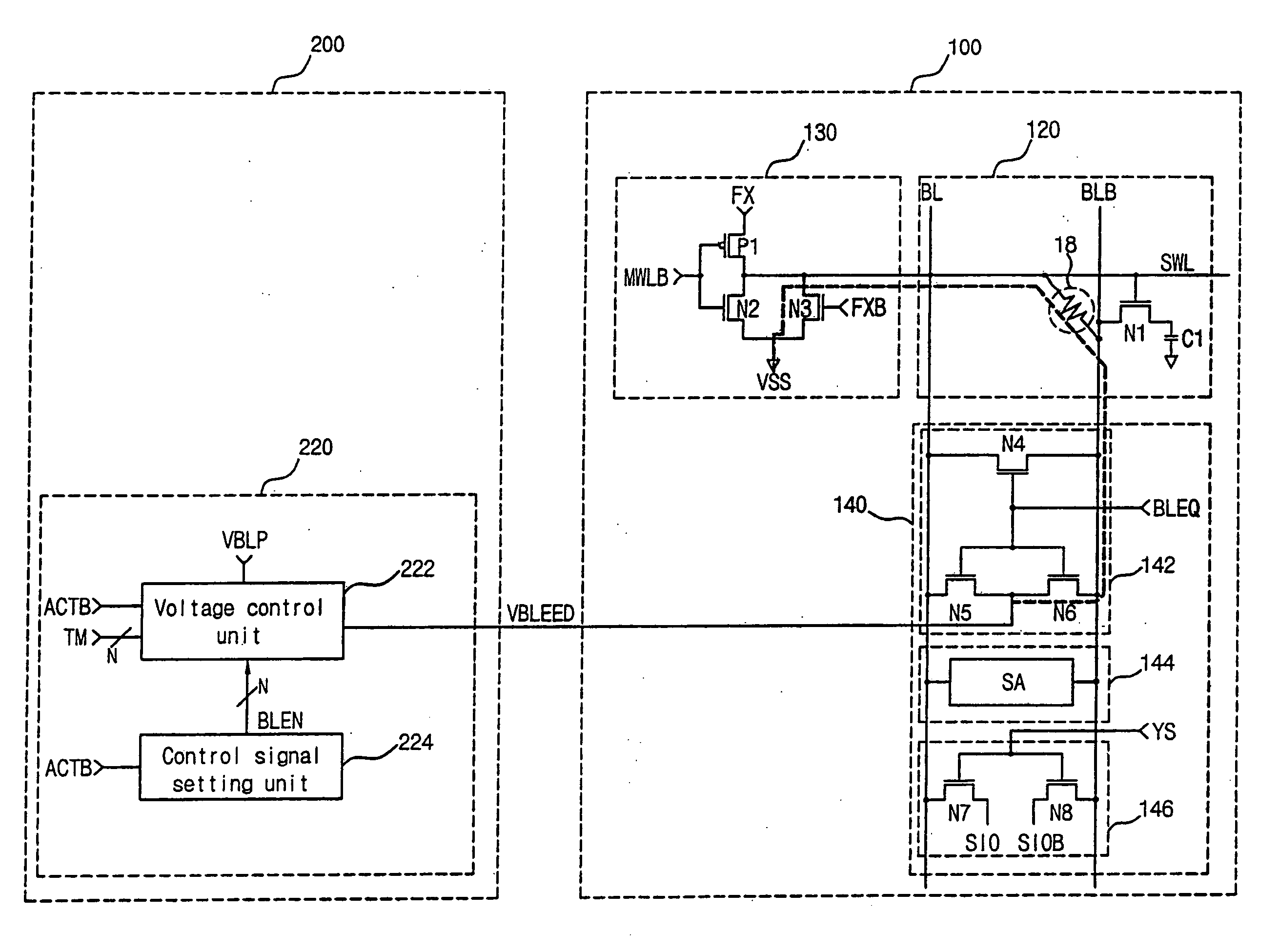

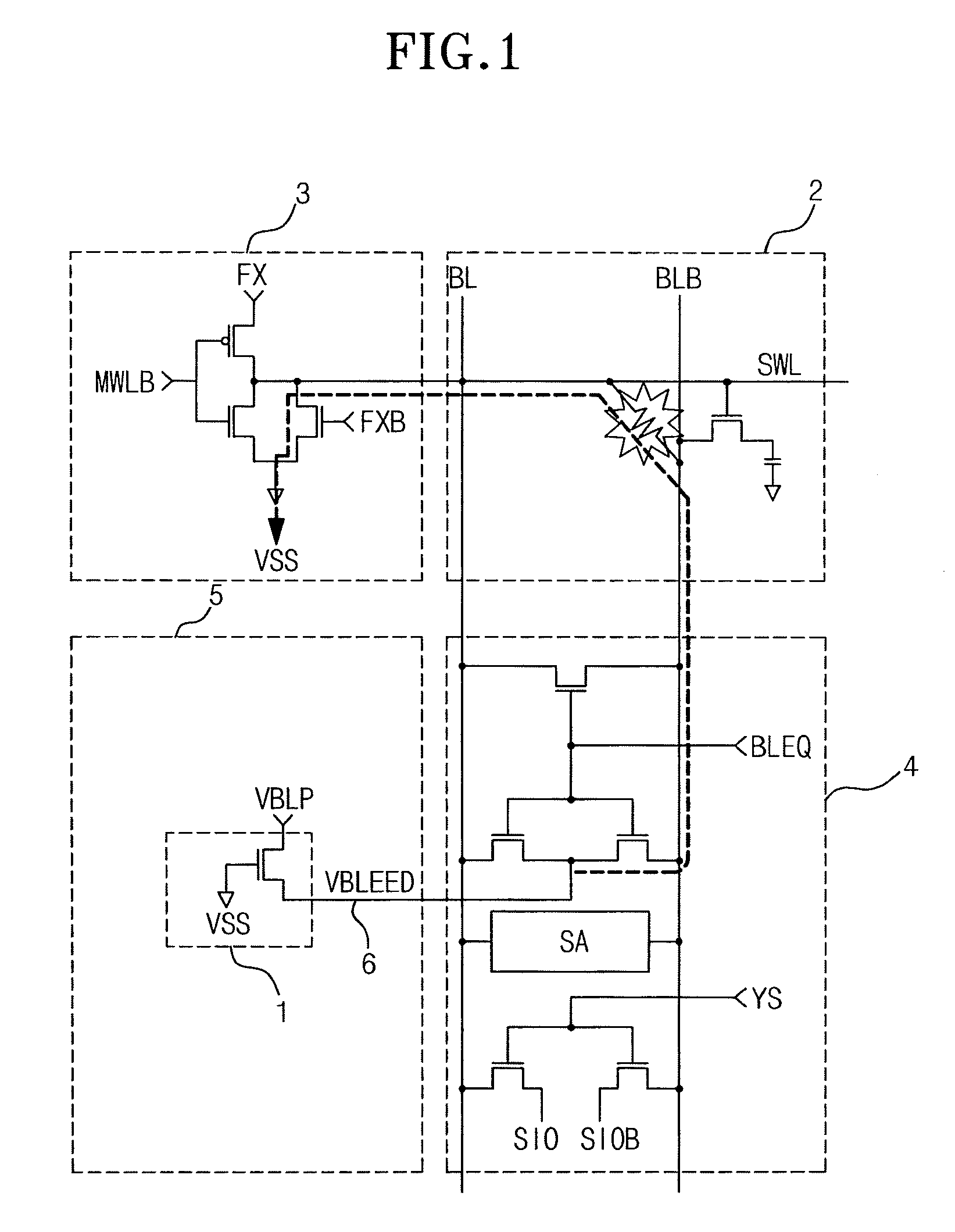

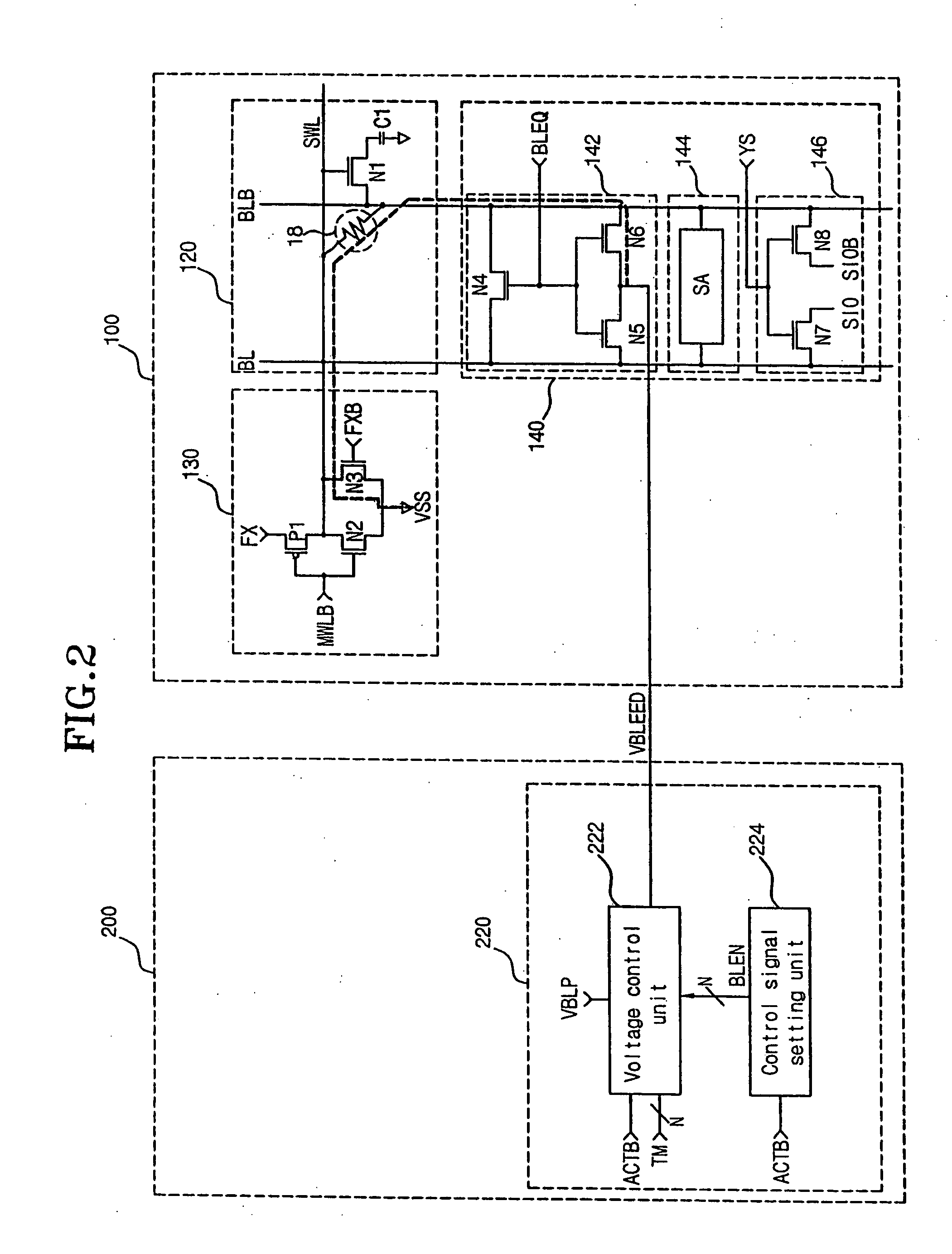

Voltage control circuit, a voltage control method and a semiconductor memory device having the voltage control circuit

ActiveUS7729190B2Improve area efficiencyImprove core performanceRead-only memoriesDigital storageHemt circuitsEngineering

A semiconductor memory device includes a voltage control circuit providing different voltages as a precharge voltage in accordance with an active state and a standby stage. The semiconductor memory device is arranged in a peripheral region, whereby the different voltages can be provided as a precharge voltage in accordance with the active state and the standby state and thus leakage current is reduced and area efficiency is enhanced.

Owner:SK HYNIX INC

Voltage control circuit, a voltage control method and a semiconductor memory device having the voltage control circuit

ActiveUS20080144420A1Improve area efficiencyImprove core performanceRead-only memoriesDigital storageCharge voltageEngineering

The present invention relates to a semiconductor memory device and more particularly there is disclosed a voltage control circuit, a voltage control method and a semiconductor memory device having the voltage control circuit which can reduce leakage currents and improve precharge performance. The present invention includes a voltage control circuit providing different voltages as a precharge voltage in accordance with an active state and a standby stage by arranging the semiconductor memory device in a peripheral region, whereby the different voltages can be provided as a precharge voltage in accordance with the active state and the standby state and thus leakage current is reduced and area efficiency is enhanced.

Owner:SK HYNIX INC

Biological enzyme fracturing outlet liquid recovery oil displacement and plugging relief technology

InactiveCN101608542AEnhanced overall recoveryImprove protectionWaste water treatment from quariesFluid removalOil waterSuspended matter

The invention relates to a biological enzyme fracturing outlet liquid recovery oil displacement and a plugging relief technology comprising the following steps: (1) after biological enzyme fracturing outlet liquid is subjected to gel breaking, a flocculating agent or an adhesive mud removing agent or a bactericide is added into the biological enzyme fracturing outlet liquid to accumulate suspended matters and sterilize the fracturing outlet liquid; (2) the sterilized biological enzyme fracturing outlet liquid is initially filtered and recovered by a well cleanout truck with a filtering function or a precise filter; (3) the recovered biological enzyme fracturing outlet liquid is finely filtered again from 2 microns to 150 microns by the precise filter according to requirements; and (4) after the recovered biological enzyme fracturing outlet liquid is finely filtered, a chemical agent is added into or compositely prepared with the biological enzyme fracturing outlet liquid. The recovery rate of the biological enzyme fracturing outlet liquid processed by the technology can reach more than 70 percent, the invention thoroughly solves the problem of the environment pollution of the biological enzyme fracturing outlet liquid, enhances the recovery ratio of crude oil by more than 6-18 percent, prevents incrustations being accumulated again and reduces the oil-water interfacial tension.

Owner:SUNCOO PETROLEUM TECH

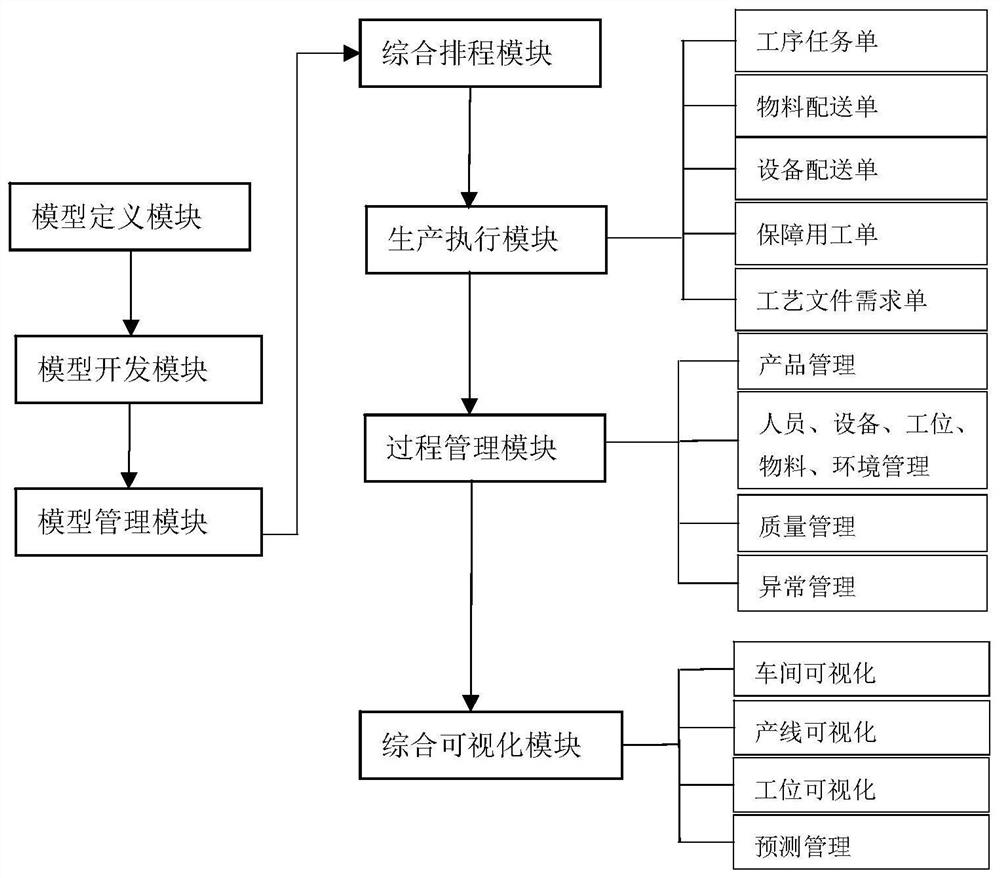

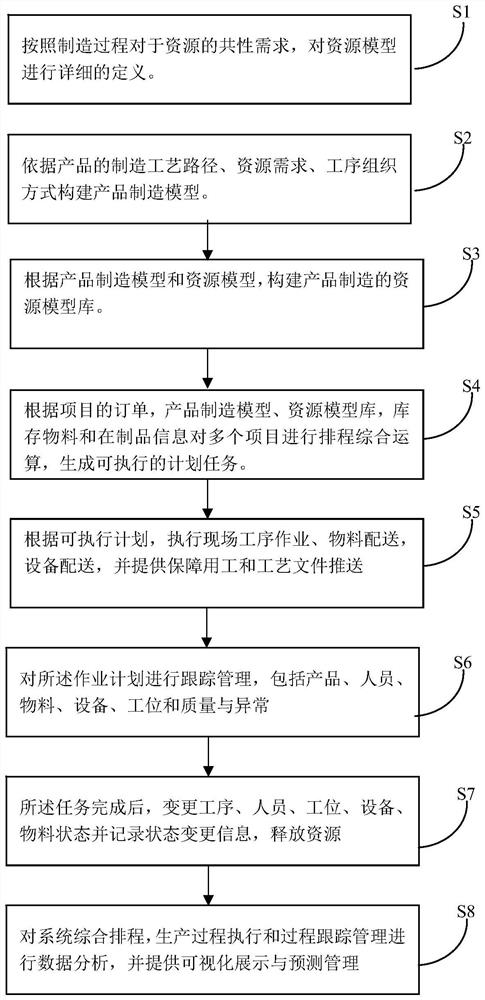

Model-based manufacturing execution management system and method

InactiveCN112288220AIncrease profitHigh frequencyResourcesManufacturing computing systemsProcess optimizationBusiness enterprise

The invention relates to the field of enterprise management, and discloses a model-based manufacturing execution management system and method, and the method comprises the steps: carrying out precisedefinition and description of a manufacturing execution process, constructing a product manufacturing model and a manufacturing process demand resource model, and constructing a manufacturing model library and a resource model library of a product through the model; carrying out comprehensive scheduling on manufactured product information through a manufacturing model library, a resource model library, orders and materials to generate planned task lists, carrying out material distribution and equipment distribution on site according to the planned task lists, providing electronic pushing of guarantee labor and operation process files, and carrying out on-site process on the basis of resources. A management method is provided in the operation process, the states and abnormal states of products, people, equipment, materials and stations are monitored, information change and recording are carried out after process operation is completed, and resources are released. Based on all data in the manufacturing process, a multi-level and multi-dimensional visualization situation is constructed and used for assisting in manufacturing process optimization.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

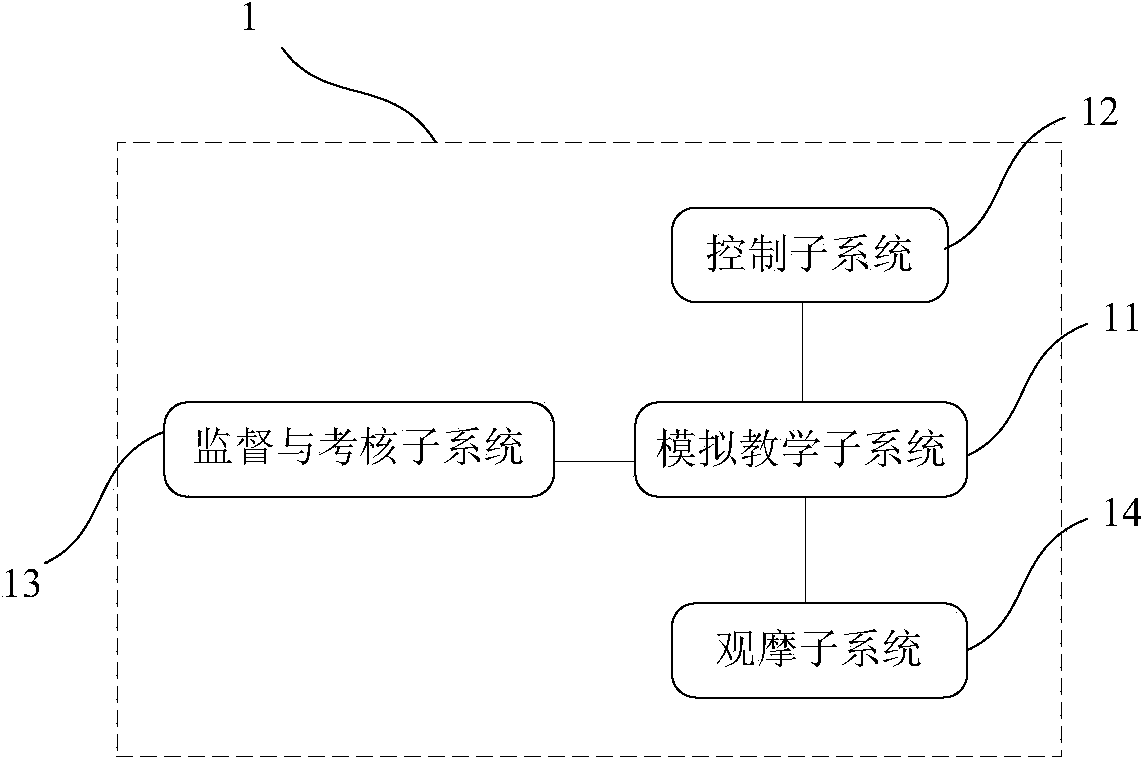

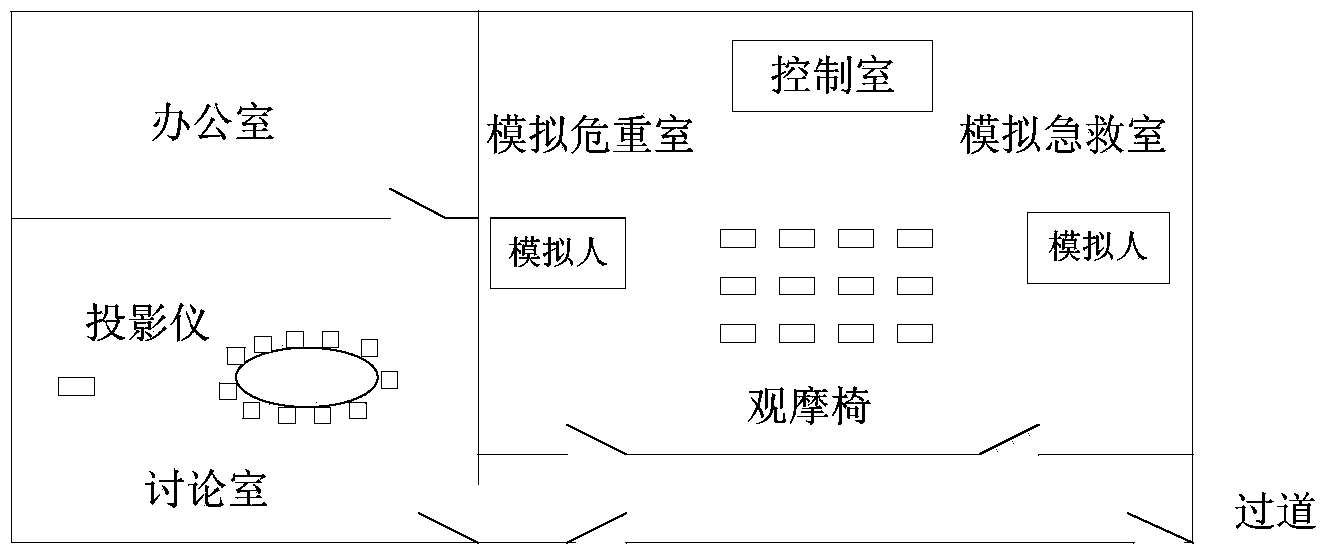

Learning practical training system based on simulation

InactiveCN103531069AImprove core performanceImprove training effectEducational modelsNursing theoryRemote control

The invention provides a learning practical training system based on simulation. The learning practical training system comprises a simulation teaching sub system, a control sub system, a supervision and checking sub system and an observation and learning sub system, wherein the simulation teaching sub system is provided with a plurality of simulation devices used for simulating people and devices in the actual nursing scene and multimedia teaching devices used for nursing teaching, the control sub system is used for setting pathological and physiological state to be simulated required by the simulating devices for simulating people, the supervision and checking sub system is provided with a display device used for practical training of nurses in the simulation teaching sub system and a remote control question answering device used for evaluating the practical training effect of the nurses in site, the observation and learning sub system is provided with a plurality of observation and learning chairs used for realizing observation and learning on the practical training of the nurses in the simulation teaching sub system and an observation and learning passage provided with one-way visual glass, the control sub system is provided with a PBL (problem-based learning) example practical training module used for controlling the practical training contents and flow processes, and the supervision and checking sub system is also provided with an OSCE (objective structured clinical examination) checking module. The learning practical training system can effectively solve the problem of the traditional single nursing theory and skill training mode.

Owner:SHANGHAI TENTH PEOPLES HOSPITAL

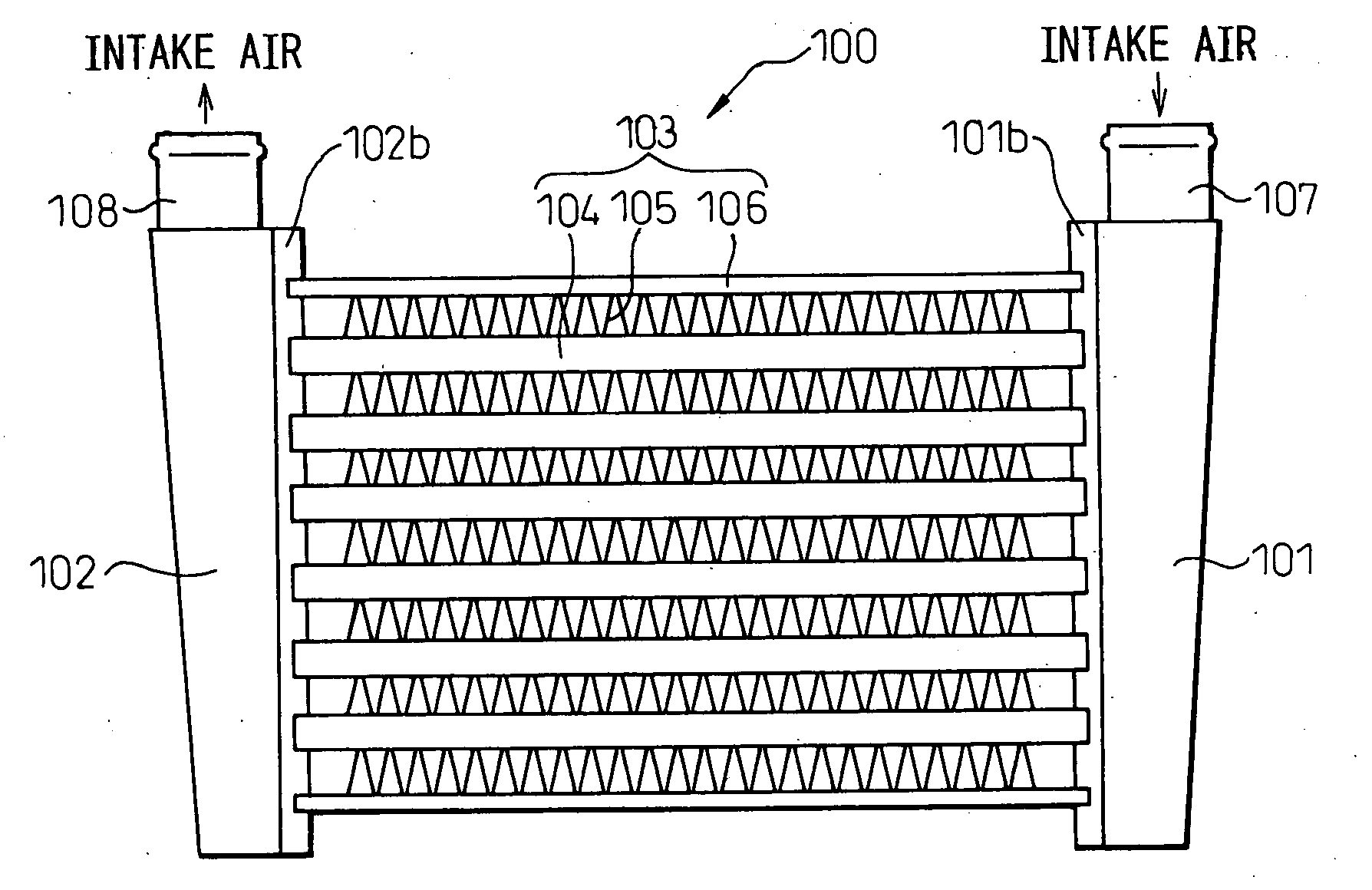

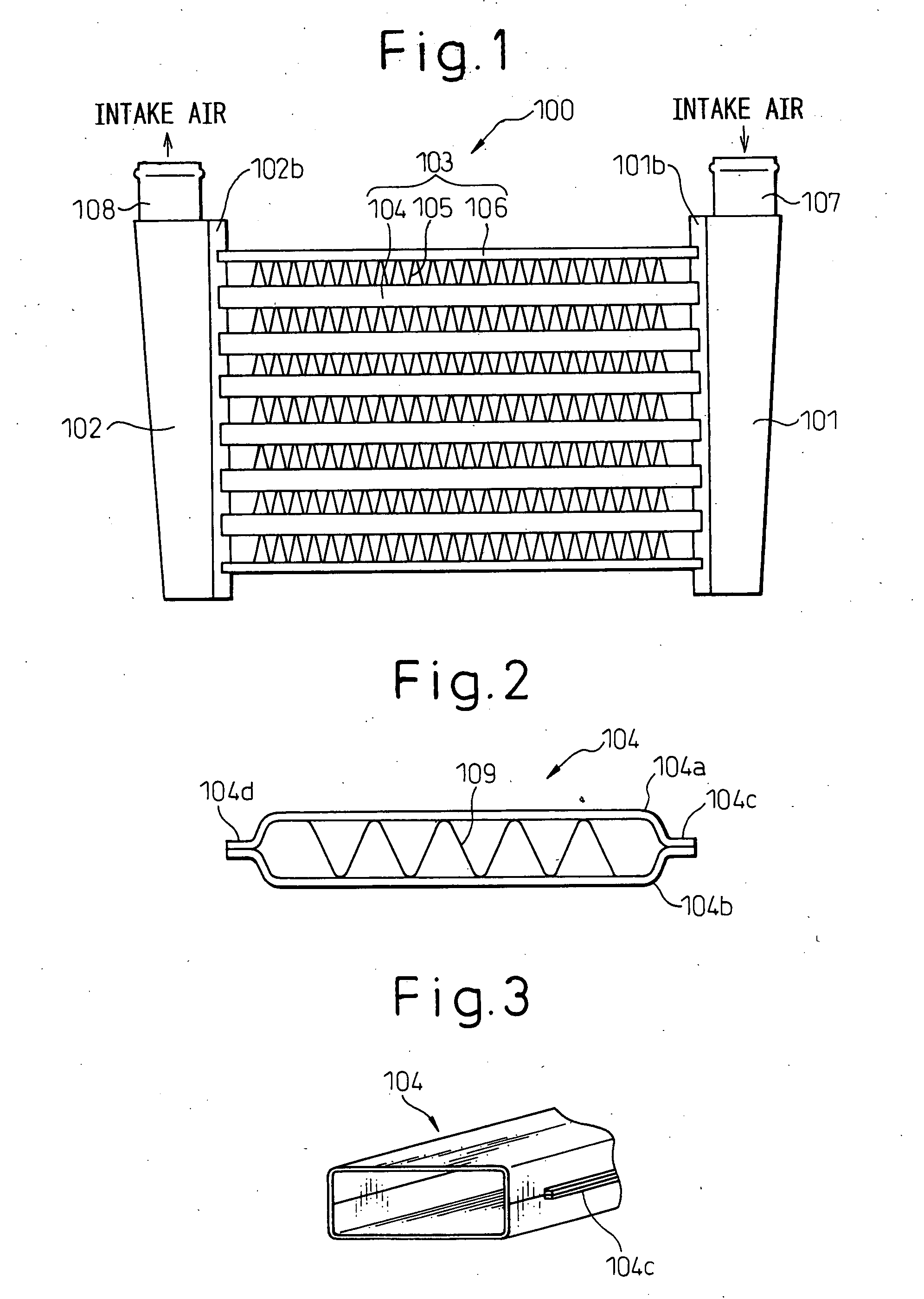

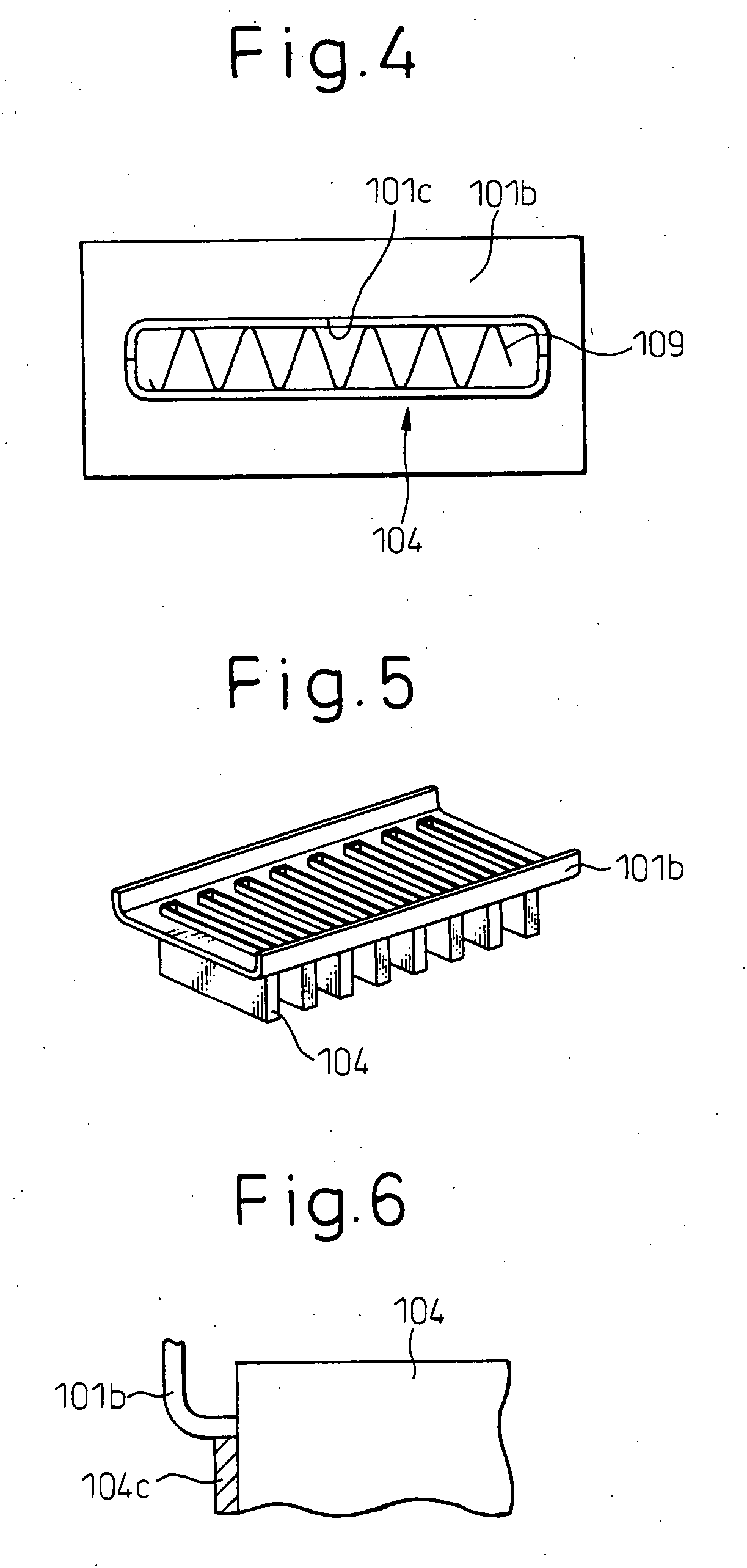

Heat exchanger

InactiveUS20070187081A1Excellent brazeabilityManufactured smallInternal combustion piston enginesStationary conduit assembliesMechanical engineeringHeat exchanger

A heat exchanger comprising: a plurality of tubes inside of which a fluid passes; fins which are joined to the outer surfaces of the tubes and promote heat exchange between a fluid passing around the tubes and the fluid passing through inside the tube; and tank sections comprising core plates having insertion holes formed for the tubes to be inserted therein and tank bodies having the core plates joined thereto for distributing or collecting the fluid to be passed through the tubes; the tube comprises a first and a second tube plates joined in opposition to each other and inner fins disposed between the first and second tube plates, and that the portion of the tube to be inserted into the insertion hole of the core plate has generally the same outer shape as the periphery of the insertion hole, and that the portions of the first and second tube plates not to be inserted into the insertion hole of the core plate have overlapping sections which overlap each other in laminating direction of the tubes.

Owner:DENSO CORP

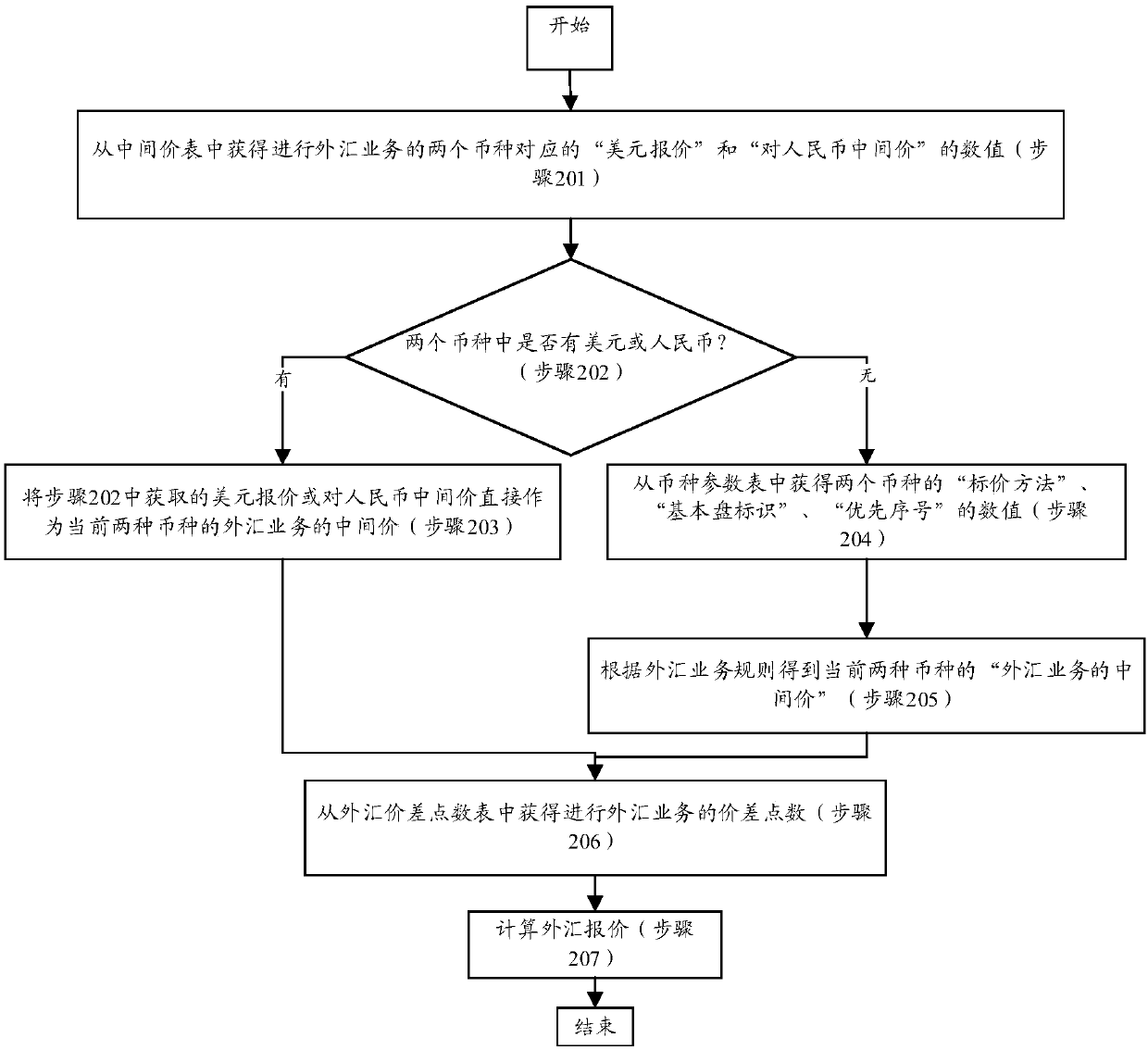

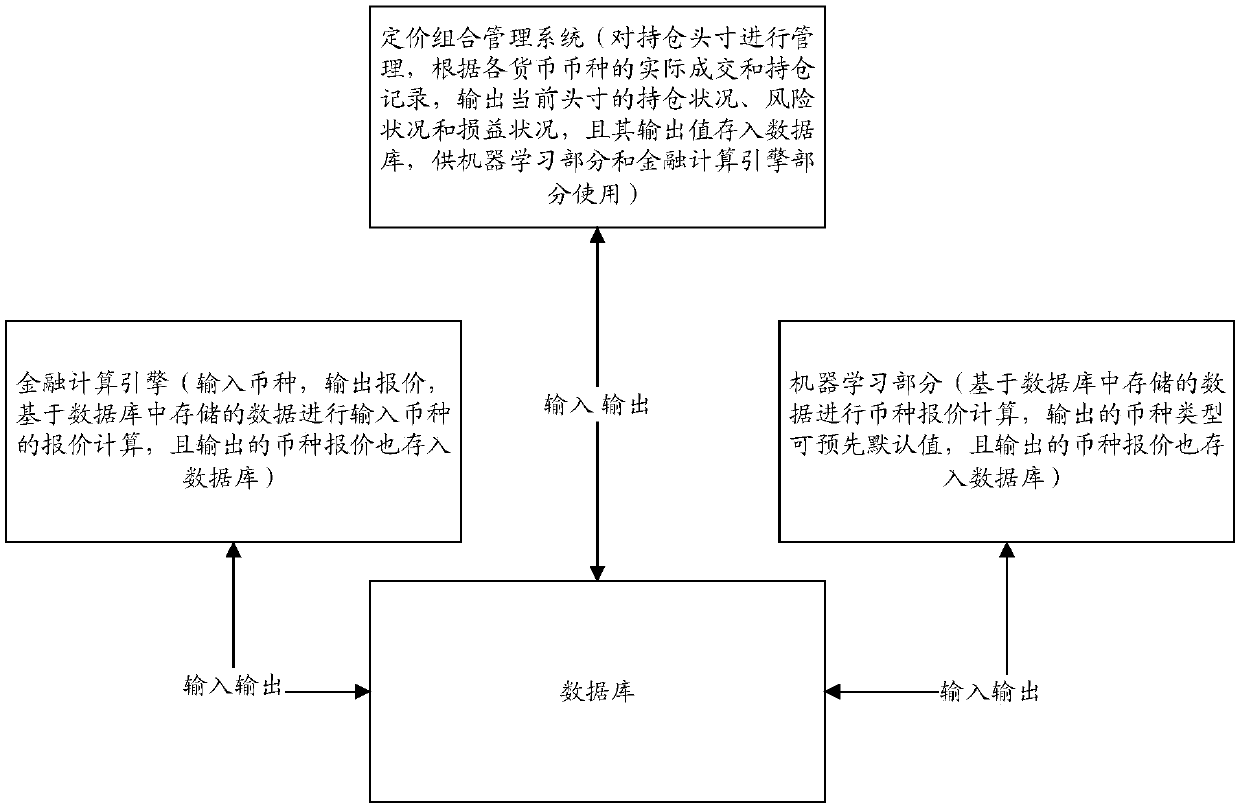

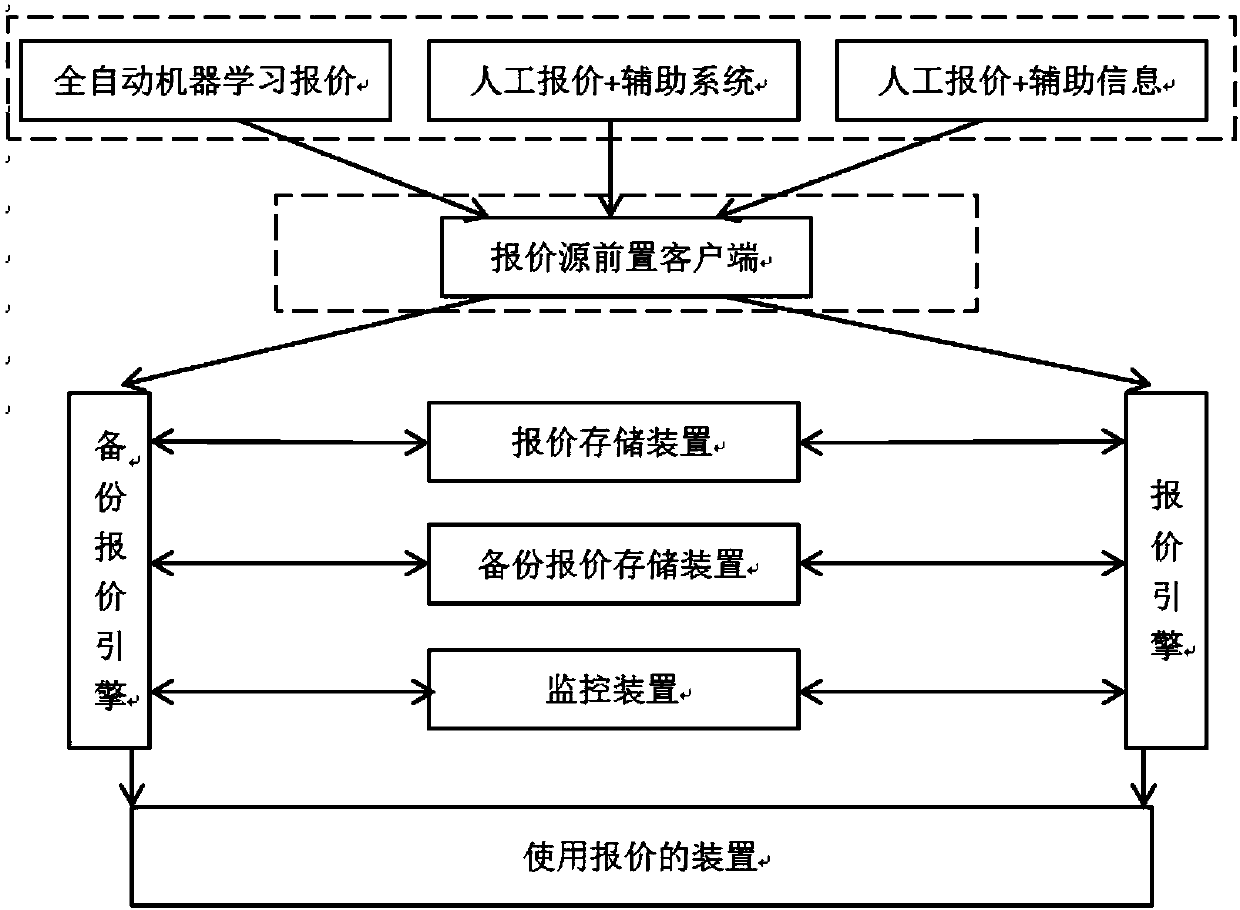

Quote-driven-market system for international foreign exchange market

The invention relates to a quote-driven-market system for an international foreign exchange market. The system comprises a financial calculation engine, a database and a quote combined management system, wherein the database and quote combined management system are built based on the financial calculation engine. The quote-driven-market system is beneficial in that continuous output can be realized; a machine learning part sufficiently considers interest liquidity and monetary liquidity, an interest rate futures derivative characteristic and a non-standard term characteristic; and furthermorebecause a high-speed modular design is utilized, the quote-driven-system realizes better price than Bloomberg foreign exchange quote; the system realizes higher speed than Murex quote; quote price andquote speed are remarkably improved; and furthermore model designing of the financial calculation engine is based on a no-risk hedging principle, and drainage can be performed on quote-driven-marketbehaviors which comprises standard-time quote-driven-market behaviors and non-standard-time quote-driven-market behaviors. Furthermore because the quote-driven-market system provided by the inventionhas no similar project or product or service in China, the quote-driven-market system has uniqueness, monopolistic property and high threshold.

Owner:来噻信息技术(上海)有限公司

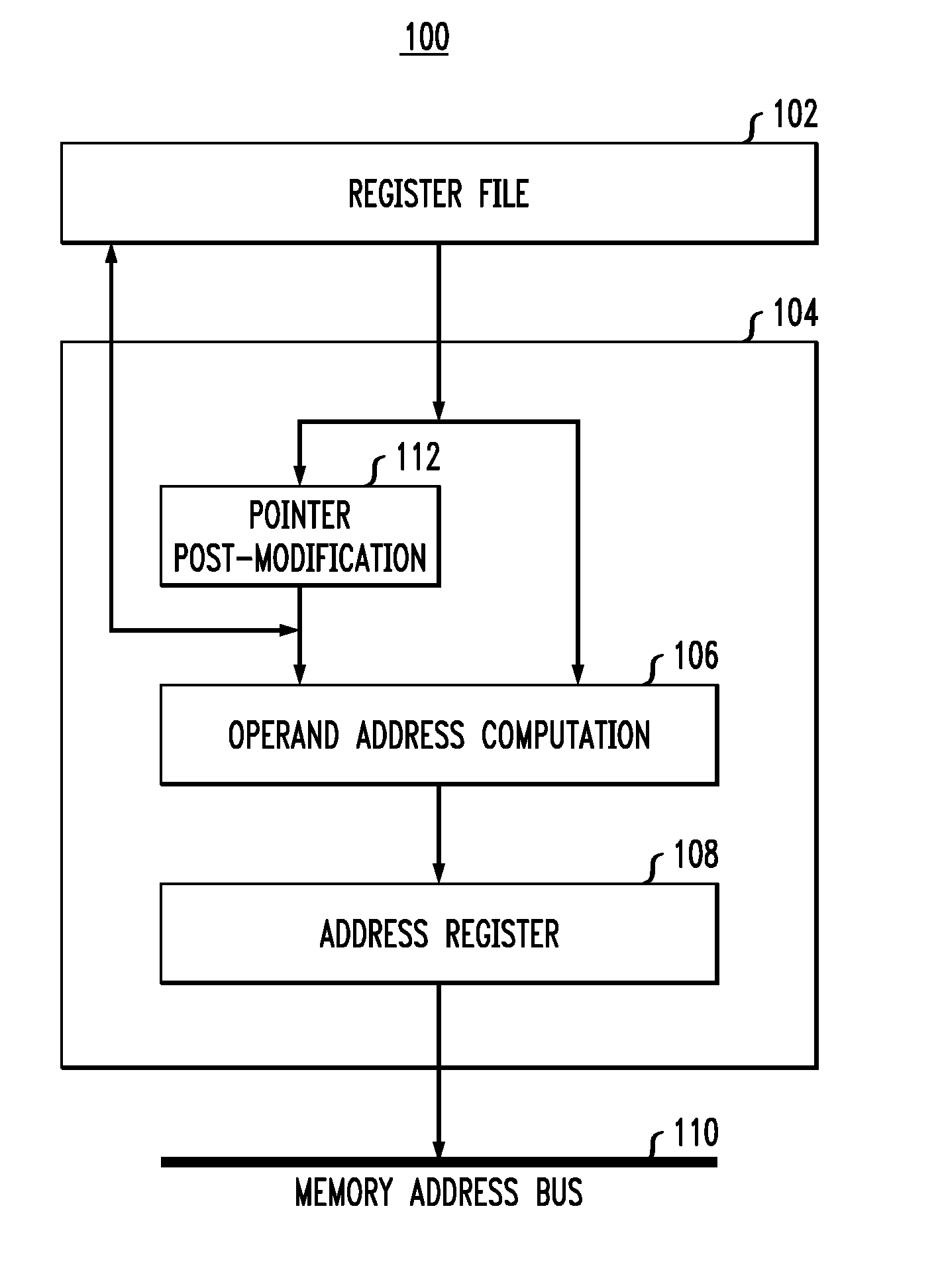

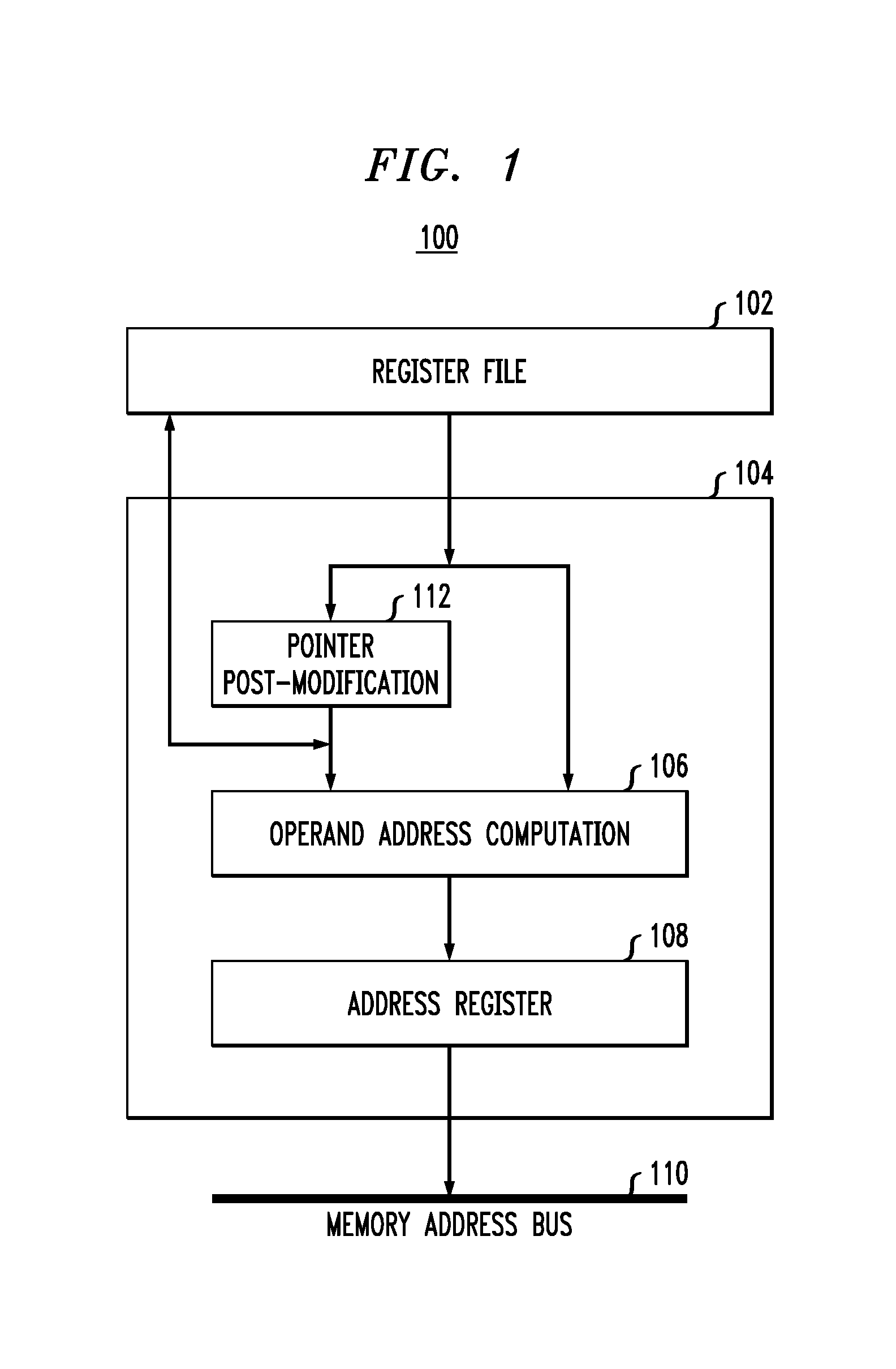

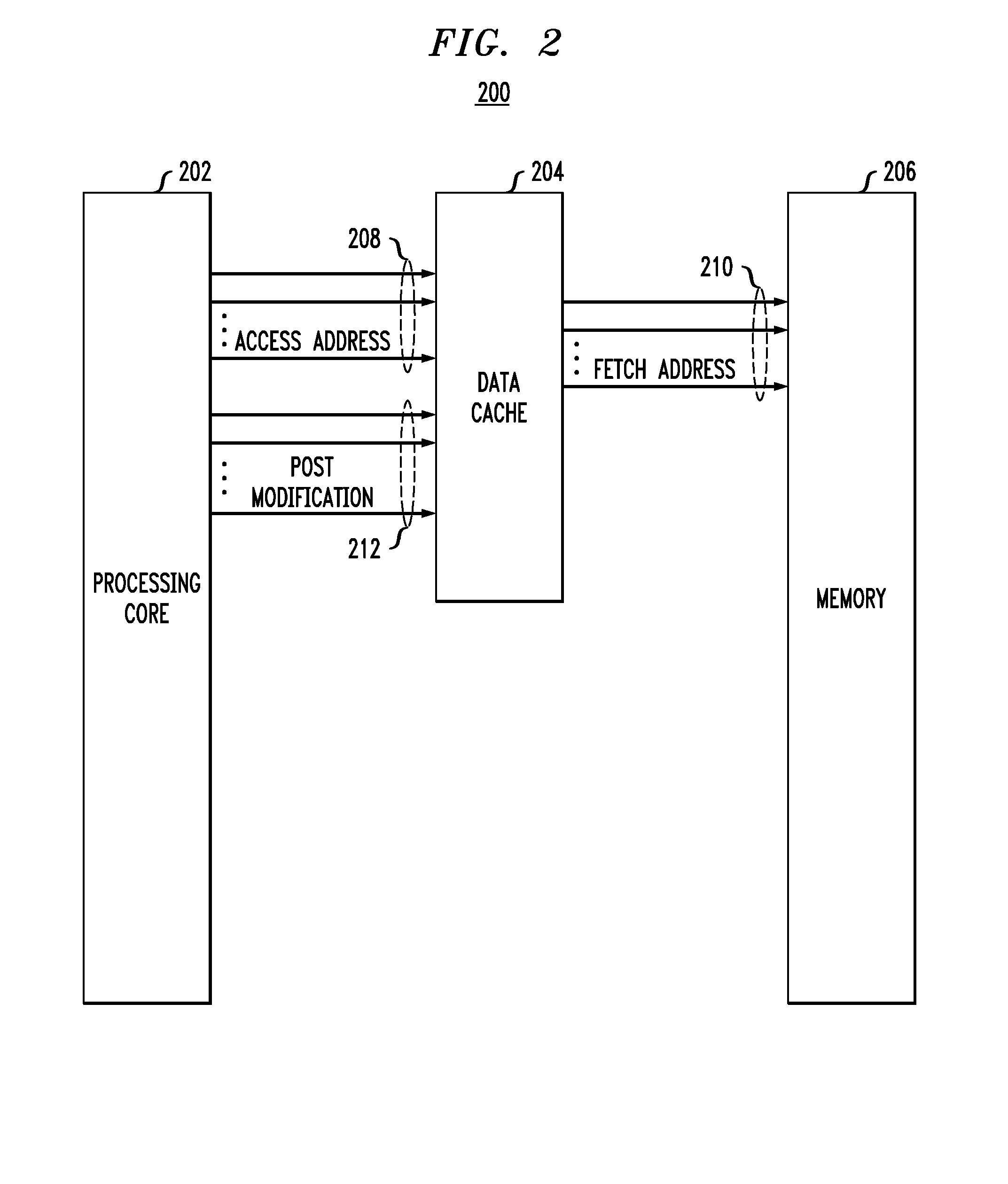

Cache Line Fetching and Fetch Ahead Control Using Post Modification Information

InactiveUS20120151150A1Facilitate data cache line fetching and cache fetch ahead controlReduce power consumptionEnergy efficient ICTMemory adressing/allocation/relocationMemory addressParallel computing

A method is provided for performing cache line fetching and / or cache fetch ahead in a processing system including at least one processor core and at least one data cache operatively coupled with the processor. The method includes the steps of: retrieving post modification information from the processor core and a memory address corresponding thereto; and the processing system performing, as a function of the post modification information and the memory address retrieved from the processor core, cache line fetching and / or cache fetch ahead control in the processing system.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

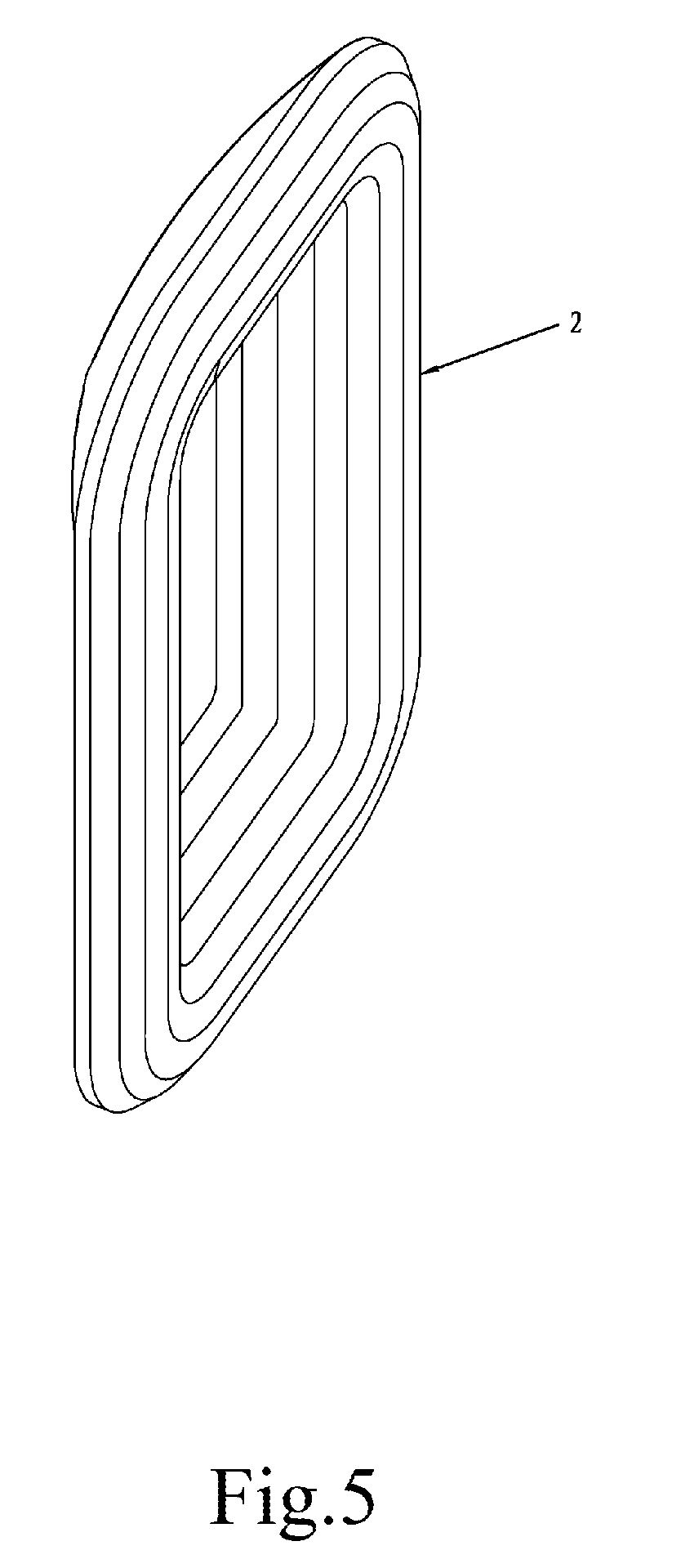

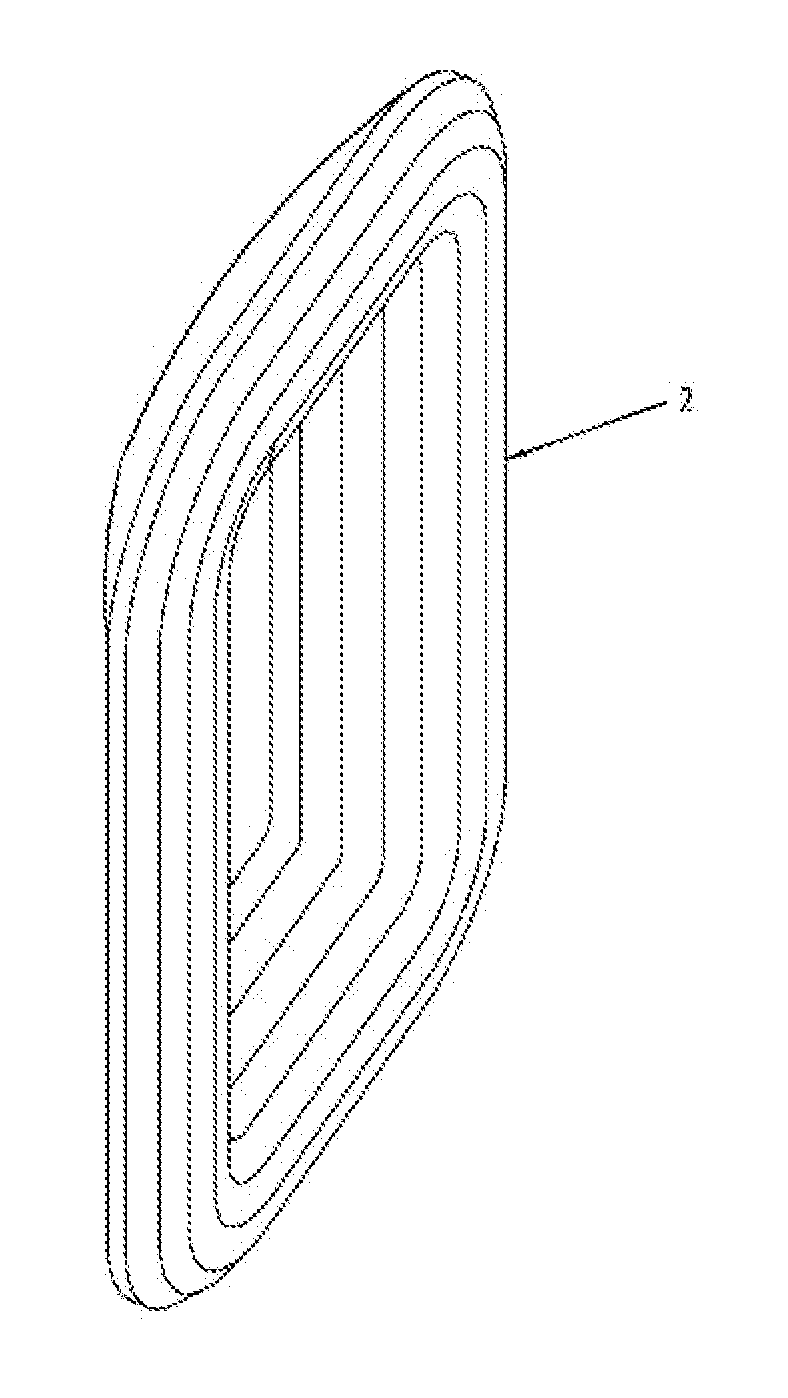

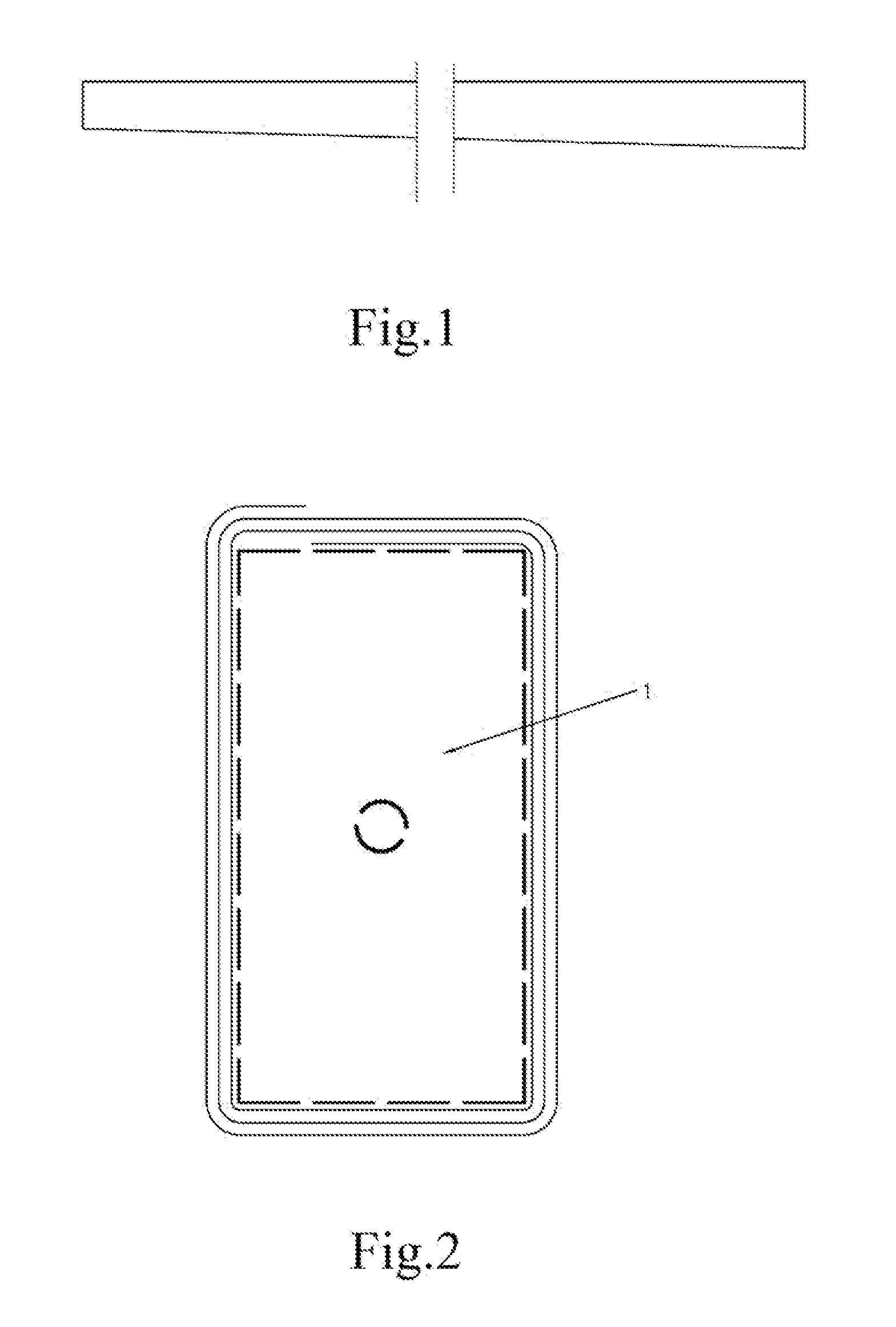

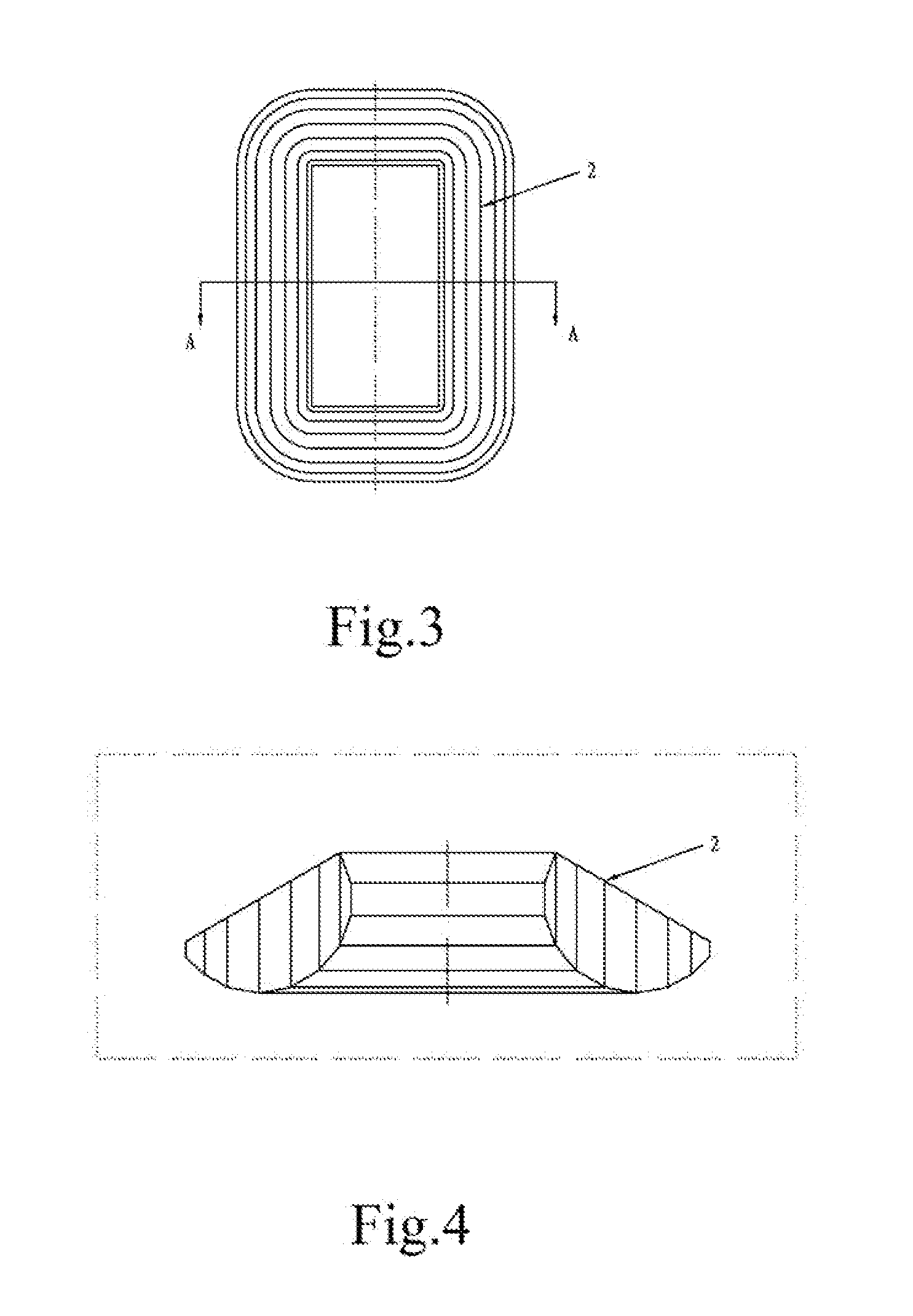

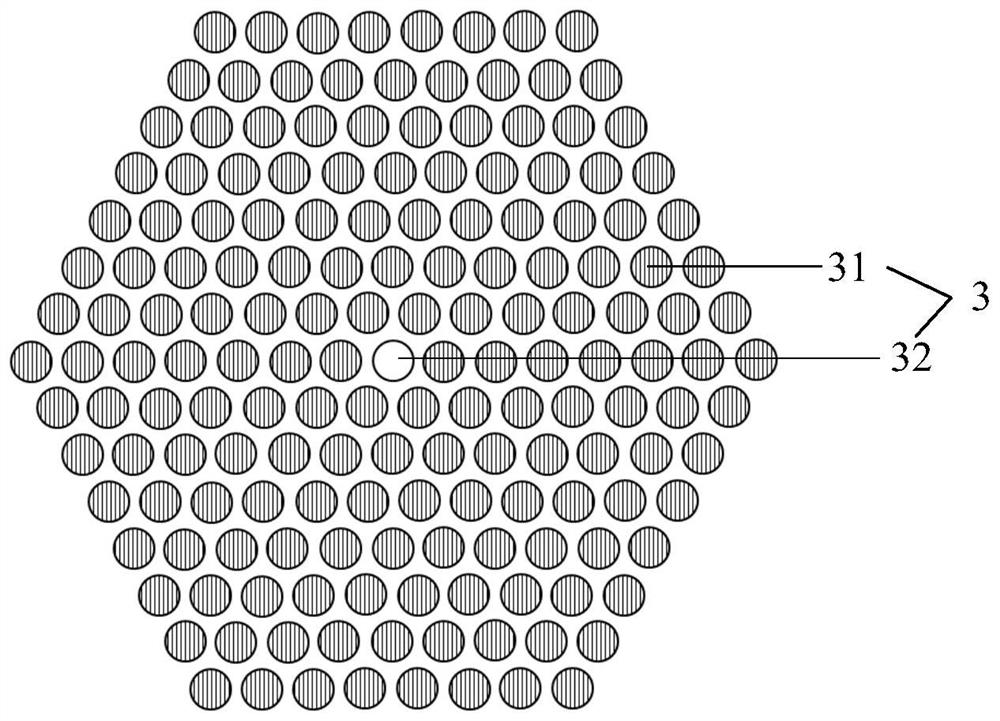

Amorphous alloy transformer iron core of three-dimensional triangle structure

ActiveUS20190131041A1Low costImprove performanceTransformers/inductances magnetic coresInductances/transformers/magnets manufactureElectrical devicesThree-phase

An amorphous alloy transformer iron core of a three-dimensional triangle structure belongs to the technical field of electrical devices. The amorphous alloy transformer iron core of the three-dimensional triangle structure is formed by piecing three identical rectangular single frames whose sections are approximately semicircular. A manufacturing method thereof comprises steps of cutting, winding, assembling, annealing and molding. The amorphous alloy transformer iron core of the three-dimensional triangle structure has the advantages of saving materials, reducing loss and noise, balancing three phases, enabling coils not to be sleeved, and being stable in performance and strong in anti-short circuit capacity.

Owner:HAIHONG ELECTRIC CO LTD

Bio-enzyme fracturing outlet liquid recovering, oil-displacing and de-plugging process

InactiveCN101638981AEnhanced overall recoveryImprove protectionFluid removalMultistage water/sewage treatmentFungicideFiltration

The invention relates to a bio-enzyme fracturing outlet liquid recovering, oil-displacing and de-plugging process. The process comprises the following steps: 1) after performing gel breakage on fracturing outlet liquid by adding SUN-Y100 bio-enzyme gel breaker, adding 10-100 ppm of flocculant, 10-100 ppm of slime stripping agent and 0-20 ppm of fungicide for suspended matter precipitation and sterilization; 2) primarily filtering and recovering by a well cleanout track with a filtration function, wherein the content of the treated suspended matter is equal to or less than 10 mg / l and oil content is equal to or less than 15 mg / l; 3) precisely 2-150-micron-filtering by a precise filter again; and 4) after the fine filtration, adding 0.1-0.3 percent by mass of bio-enzyme preparation, 0-1.1percent by mass of other additives and 0-50 percent by mass of water., The fracturing outlet liquid can not be discharged back after being filled into an oil water well, thereby thoroughly solving theproblem of environment pollution, increasing the crude oil extraction rate by over 6-18 percent, preventing the dirt re-precipitation and reducing the tensile force of an oil water interface.

Owner:DONGYING SHENGSHI PETROLEUM TECH CO LTD

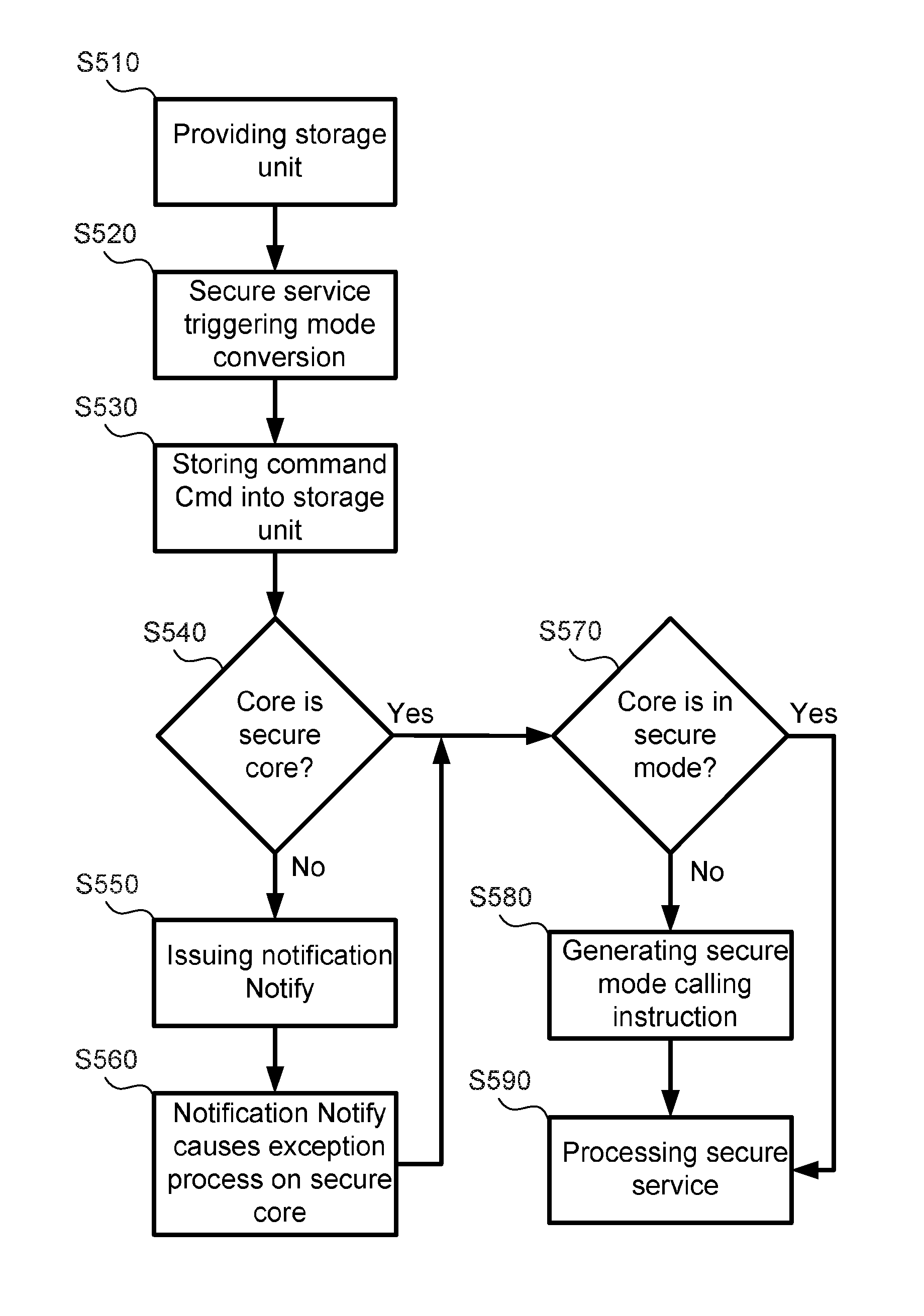

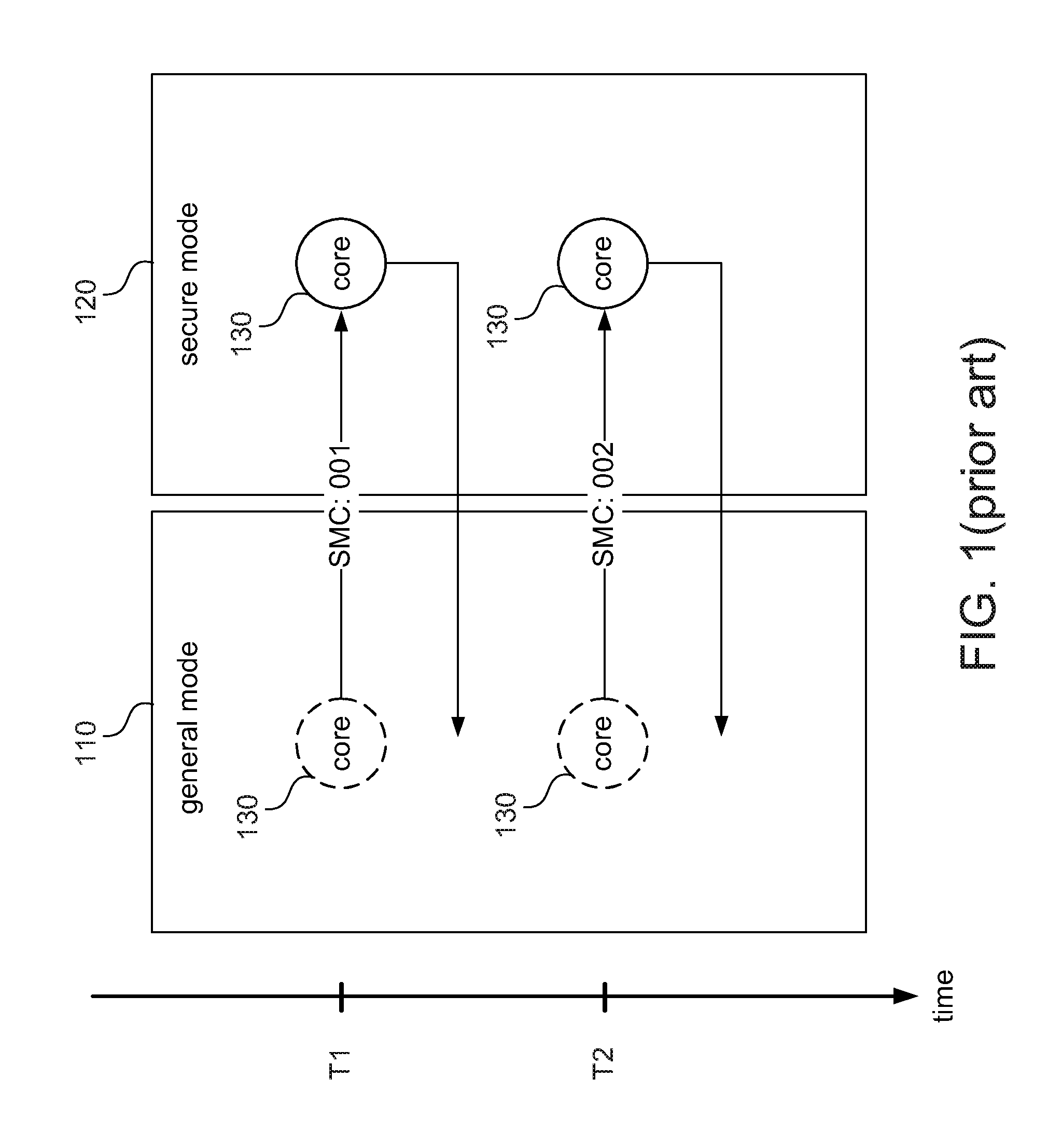

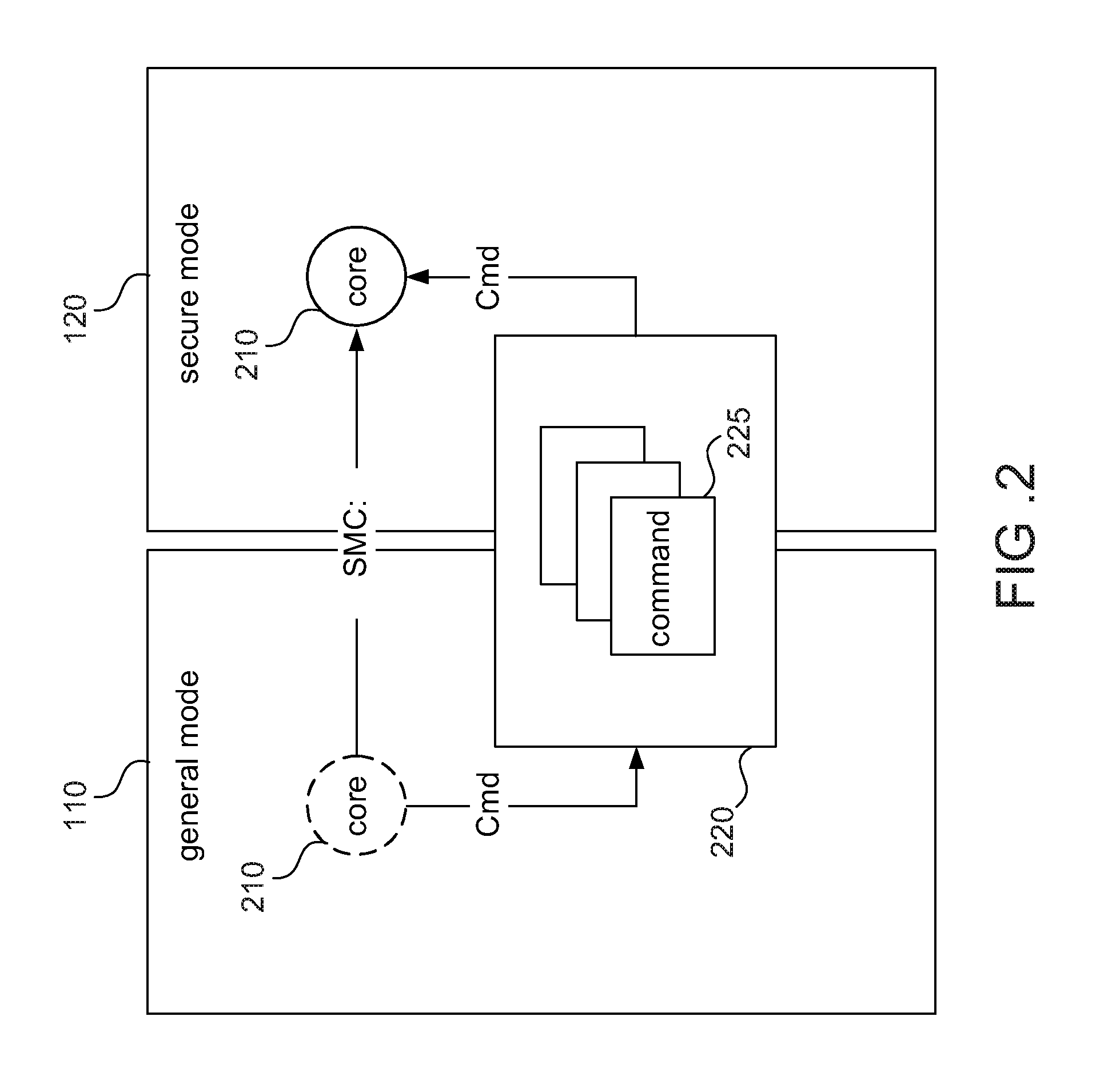

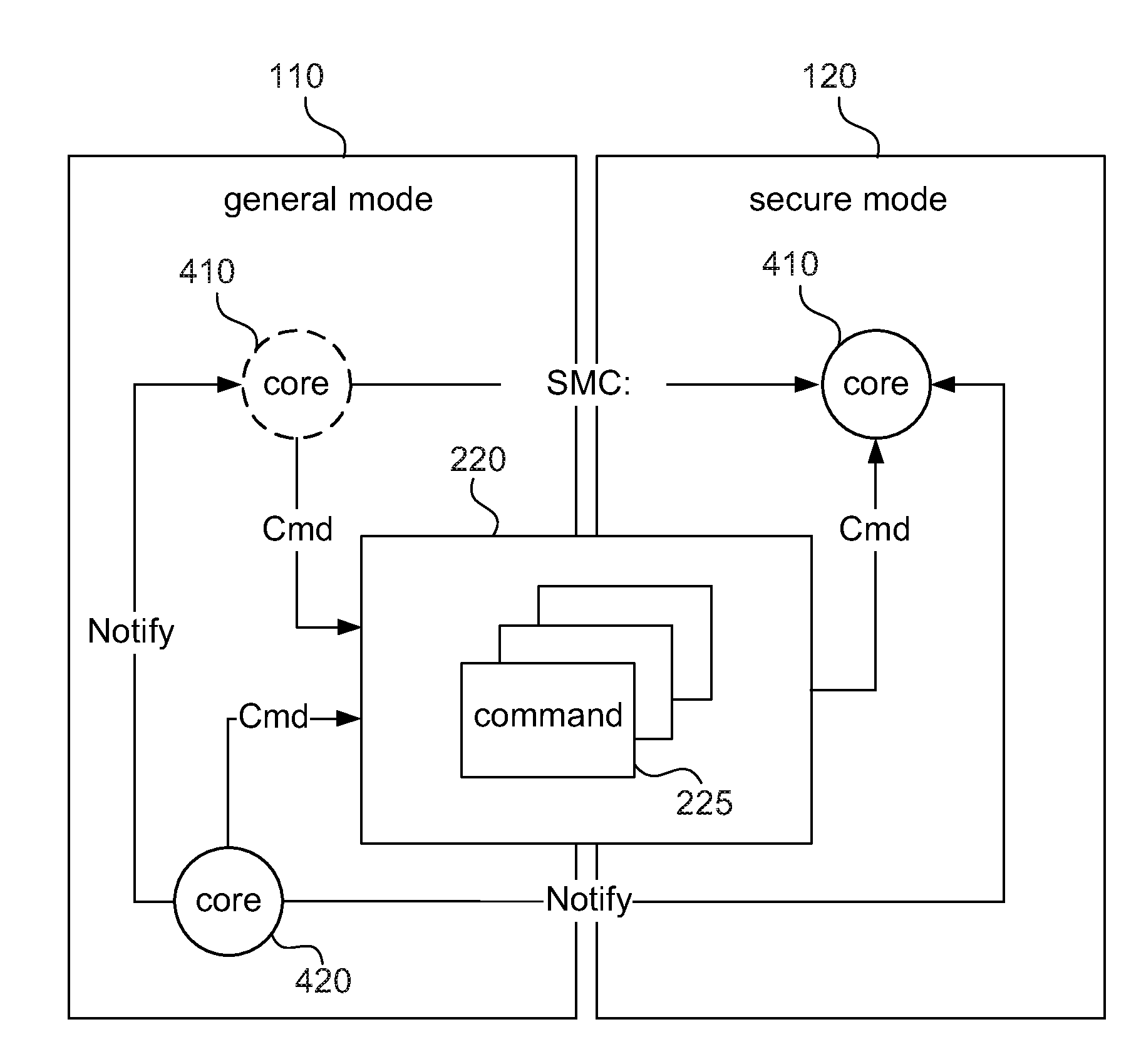

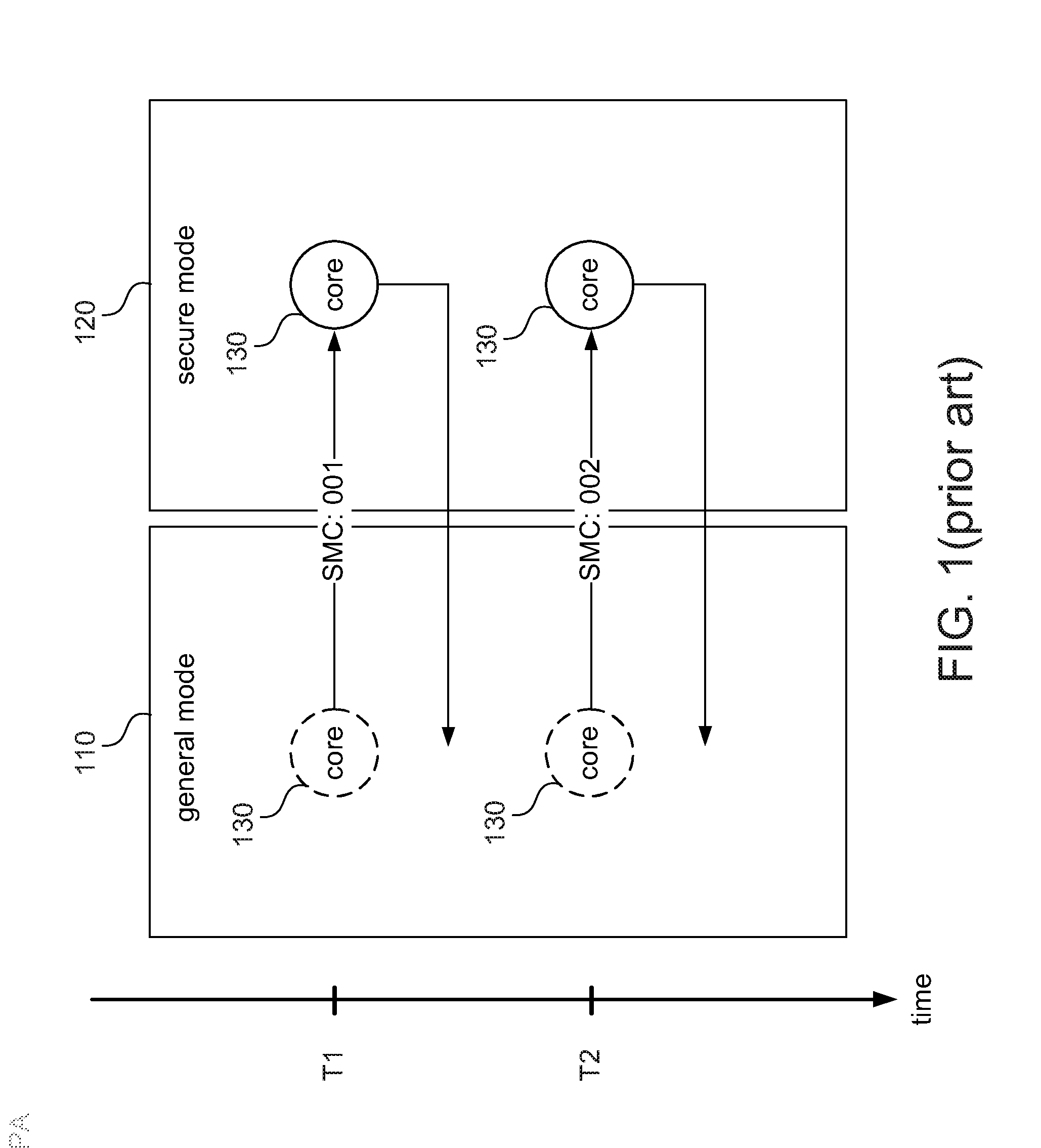

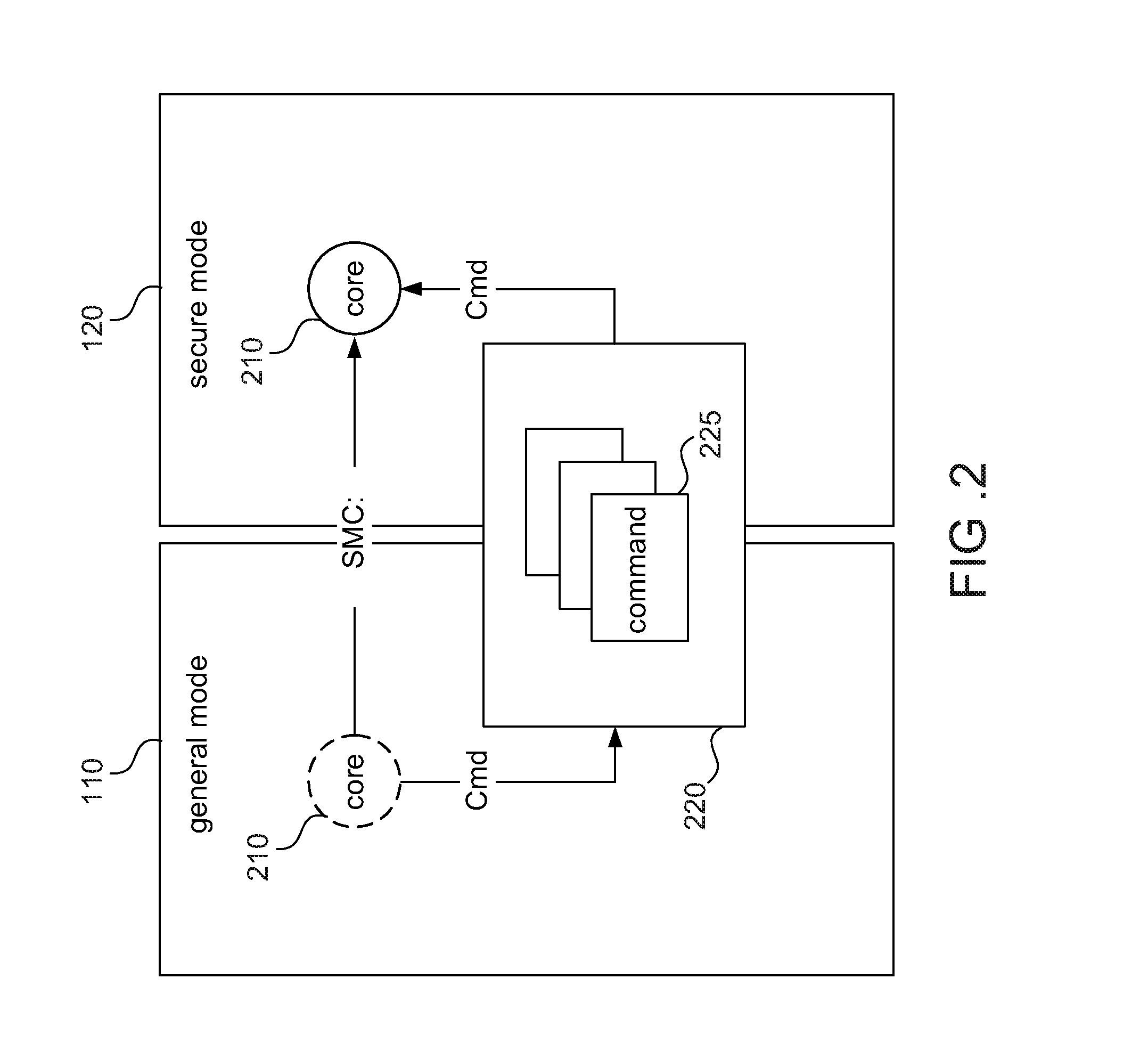

Computing device and method of processing secure services for computing device

ActiveUS9443109B2Improve performanceImprove core performanceInternal/peripheral component protectionService informationComputer science

A method of processing secure services is provided. The method is applied to a processing unit of a computing device to control the processing unit to process multiple secure services. The computing device includes a storage unit. The method includes: controlling a core of the processing unit to perform following steps in a secure mode: accessing the storage unit to obtain a first command that includes first secure service information, processing a first secure service associated with the first secure service information according to the first command, and accessing the storage unit to obtain a second command that includes second secure service information. During a period from a time point that the core accesses the storage unit to obtain the first to a time point that the core accesses the second command, the core is controlled to stay in the secure mode.

Owner:MEDIATEK INC

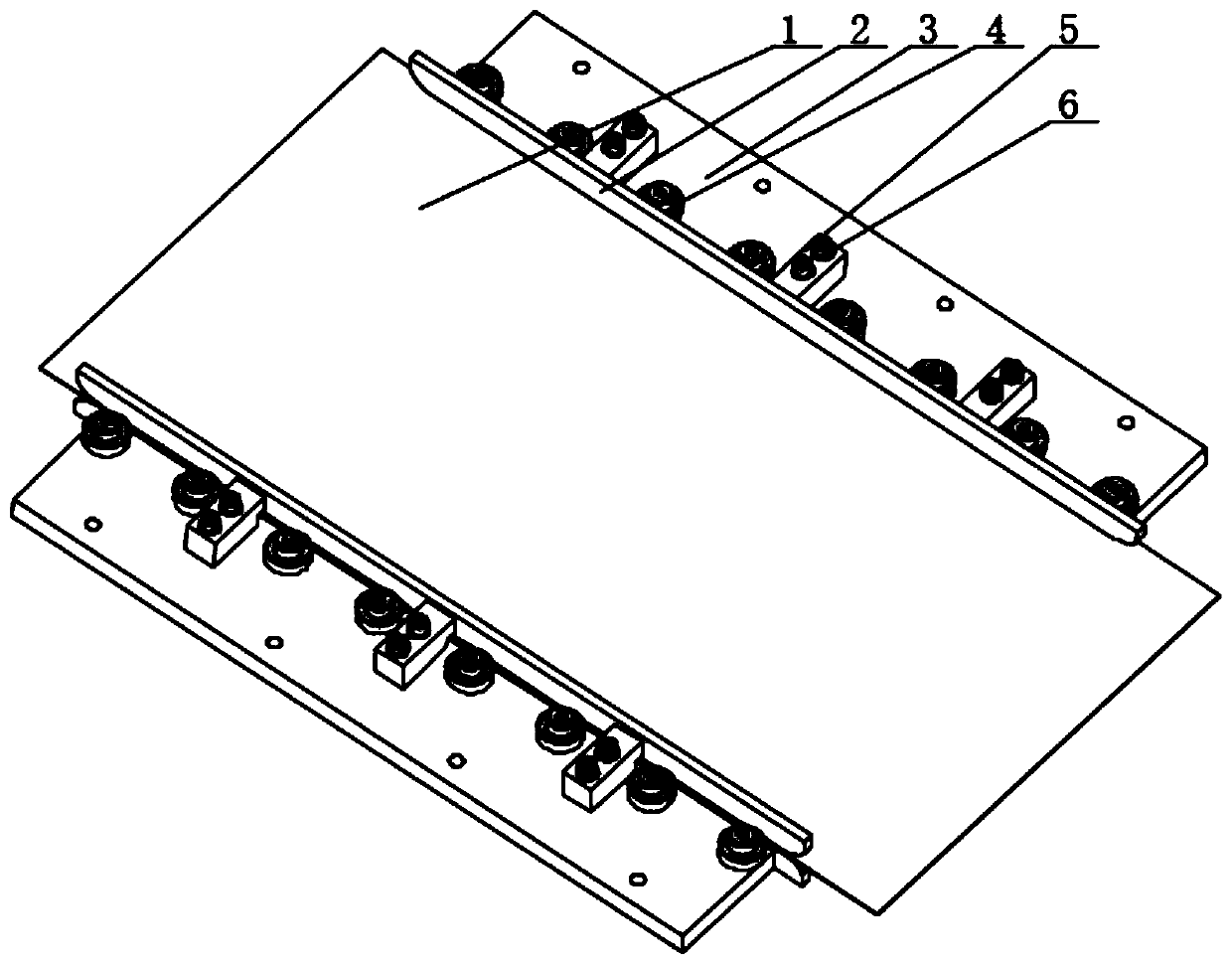

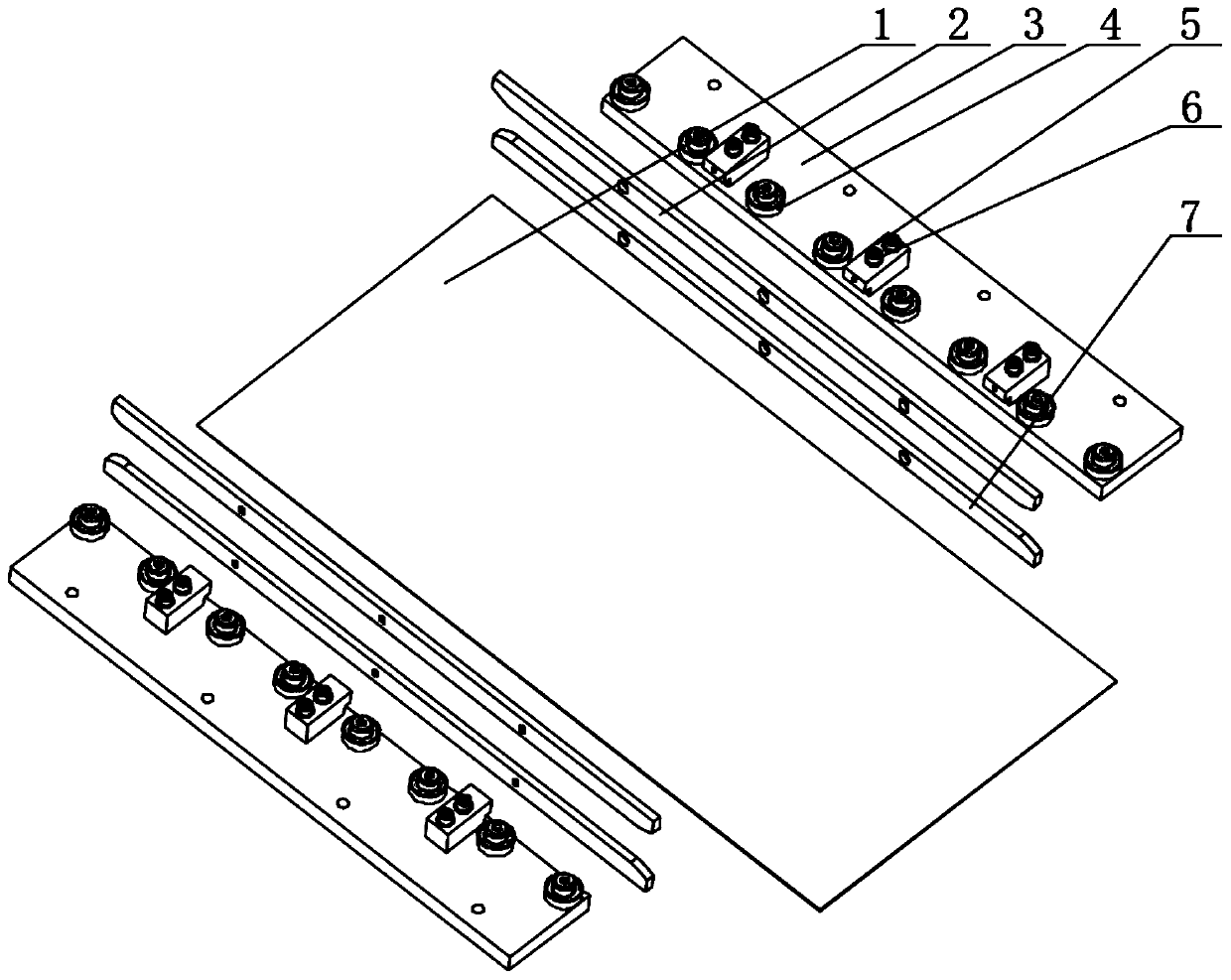

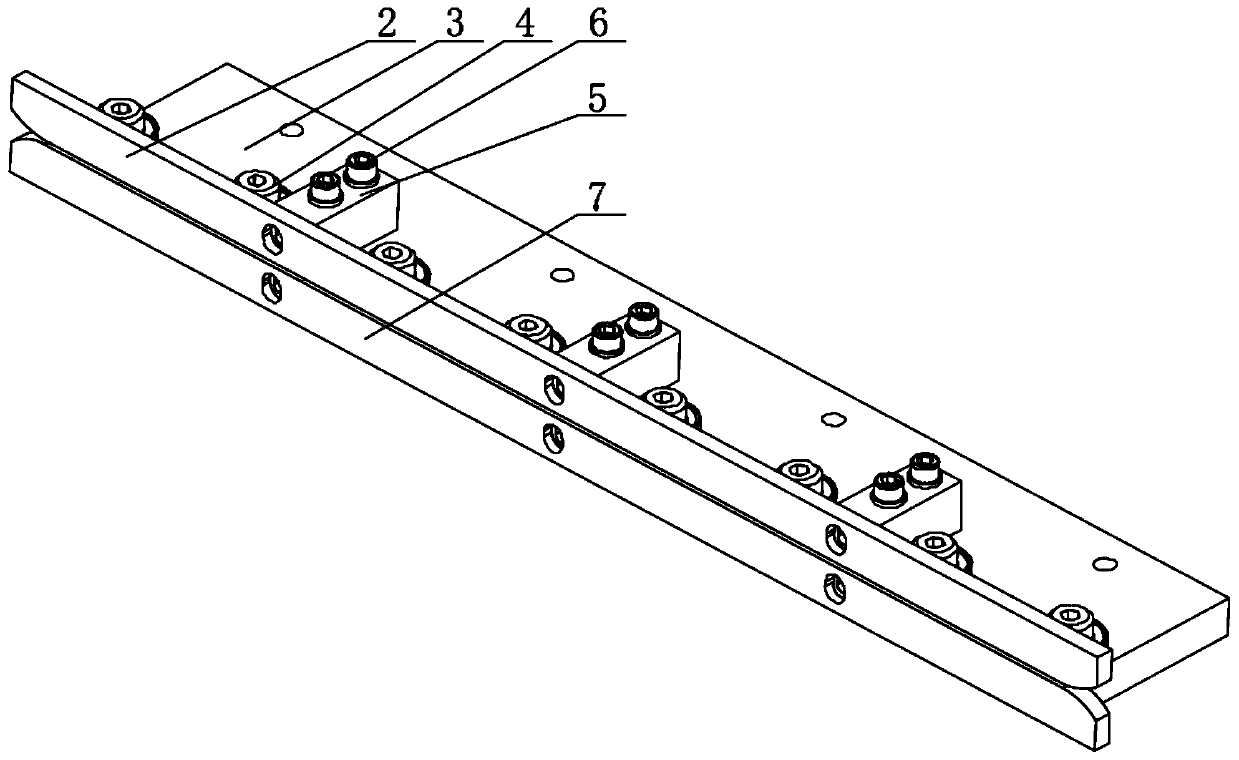

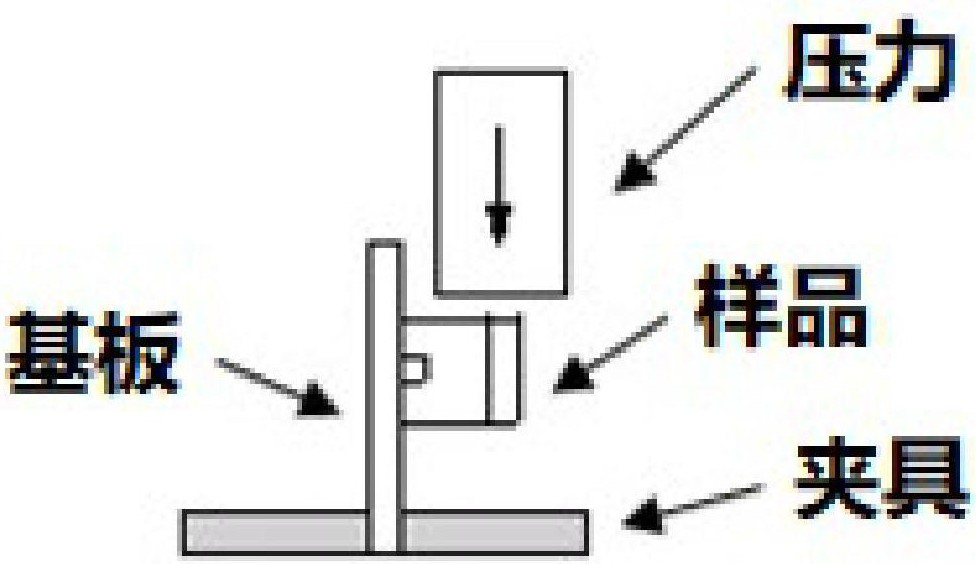

Core limb shearing length-cutting line guiding device

PendingCN110802270AEasy to navigateEasy to transportInductances/transformers/magnets manufactureMetal working apparatusElectrical steelFastener

The invention provides a core limb shearing length-cutting line guiding device. The core limb shearing length-cutting line guiding device comprises two working tabletops arranged in a spaced manner. The two working tabletops are located at the position of the same plane, lower rails are mounted on the inner side faces of the two working tabletops through fasteners, multiple spaced fixing blocks are mounted on the upper surface of each working tabletop through locking bolts, upper rails are mounted on the end faces of the fixing blocks through fasteners, the upper rails and the lower rails areoppositely arranged and correspond to gaps reserved between the upper rails and the lower rails, the gaps are through from front to back, multiple guiding wheel assemblies are further mounted on the portions, at same straight line position, of the upper surfaces of the working tabletops in a spaced manner, an electrical steel sheet penetrates through the portion between the two working tabletops,the two sides of the electrical steel sheet simultaneously stretch into the portions between the upper rails and the lower rails on the inner side faces of the two working tabletops, and meanwhile theedges of the two sides of the electrical steel sheet make contact with the guiding wheel assemblies. Guiding can be observed at any time, and the working reliability is greatly improved.

Owner:WUXI PUTIAN IRON CORE CO LTD

Preparation method and application of novel adsorptive iron salt compound flocculant

InactiveCN107117696AImprove adsorption capacityFast adsorption rateWater treatment parameter controlWater/sewage treatment by flocculation/precipitationActivated carbonIron salts

The invention provides a preparation method and an application of a novel adsorptive iron salt compound flocculant. The method comprises the following steps: (1) mixing activated carbon powder and poly-ferric sulfate powder at a mass ratio of (1-0.3):1; (2) adding into a stirrer, grinding, and mixing to obtain mixed powder; and (3) compounding the mixed powder and polyacrylamide at a mass ratio of 99:1, grinding, and mixing to obtain the novel adsorptive iron salt compound flocculant. The novel flocculant of the invention is prepared from poly-ferric sulfate flocculant, activated carbon and polyacrylamide as the raw materials, in which the poly-ferric sulfate flocculant can remove the dispersed impurities and macromolecular organic matters in water (which cannot be well adsorbed by powdered activated carbon), and the powdered activated carbon can remove micromolecular organic matters that are hardly removed by coagulation, so that the treatment capacities for removing organic matters of the poly-ferric sulfate flocculant and the powdered activated carbon are both further improved.

Owner:太原市淼洁环保技术有限公司

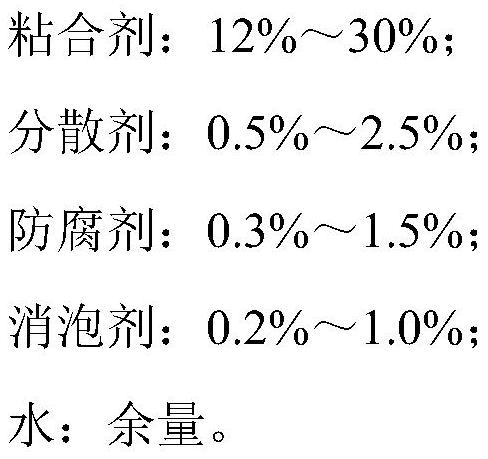

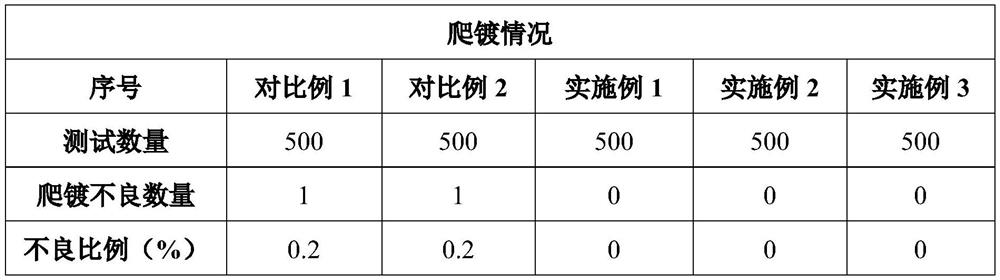

Water plating metallization method of manganese zinc ferrite magnetic core

ActiveCN113372141AImprove performanceOvercome the problem of water-plating metallizationMagnetic core manufactureTinningSlurry

The invention discloses a water plating metallization method of a manganese zinc ferrite magnetic core. The water plating metallization method comprises the following steps: 1) adding water into ZnO-B2O3-BaO system glass powder, and grinding to prepare glass slurry; 2) coating the surface of the manganese zinc ferrite magnetic core with the glass paste, drying, and sintering in a protective atmosphere to obtain a magnetic core containing a glass coating; 3) coating an electrode part of the magnetic core containing the glass coating with the copper paste, drying, and sintering in a protective atmosphere to obtain a copper-coated magnetic core; and 4) placing the copper-coated magnetic core in a nickel plating solution and a tin plating solution, and carrying out nickel plating and tin plating. According to the method, ZnO-B2O3-BaO system glass powder is firstly adopted to form the glass coating on the surface of the manganese zinc ferrite magnetic core, then water plating metallization is carried out, the problems of overplating and poor spot welding of the magnetic core, poor adhesion strength of a terminal electrode and the like are avoided, and the performance of the common mode inductor can be remarkably improved by applying the metallized magnetic core to the common mode inductor.

Owner:广东泛瑞新材料有限公司

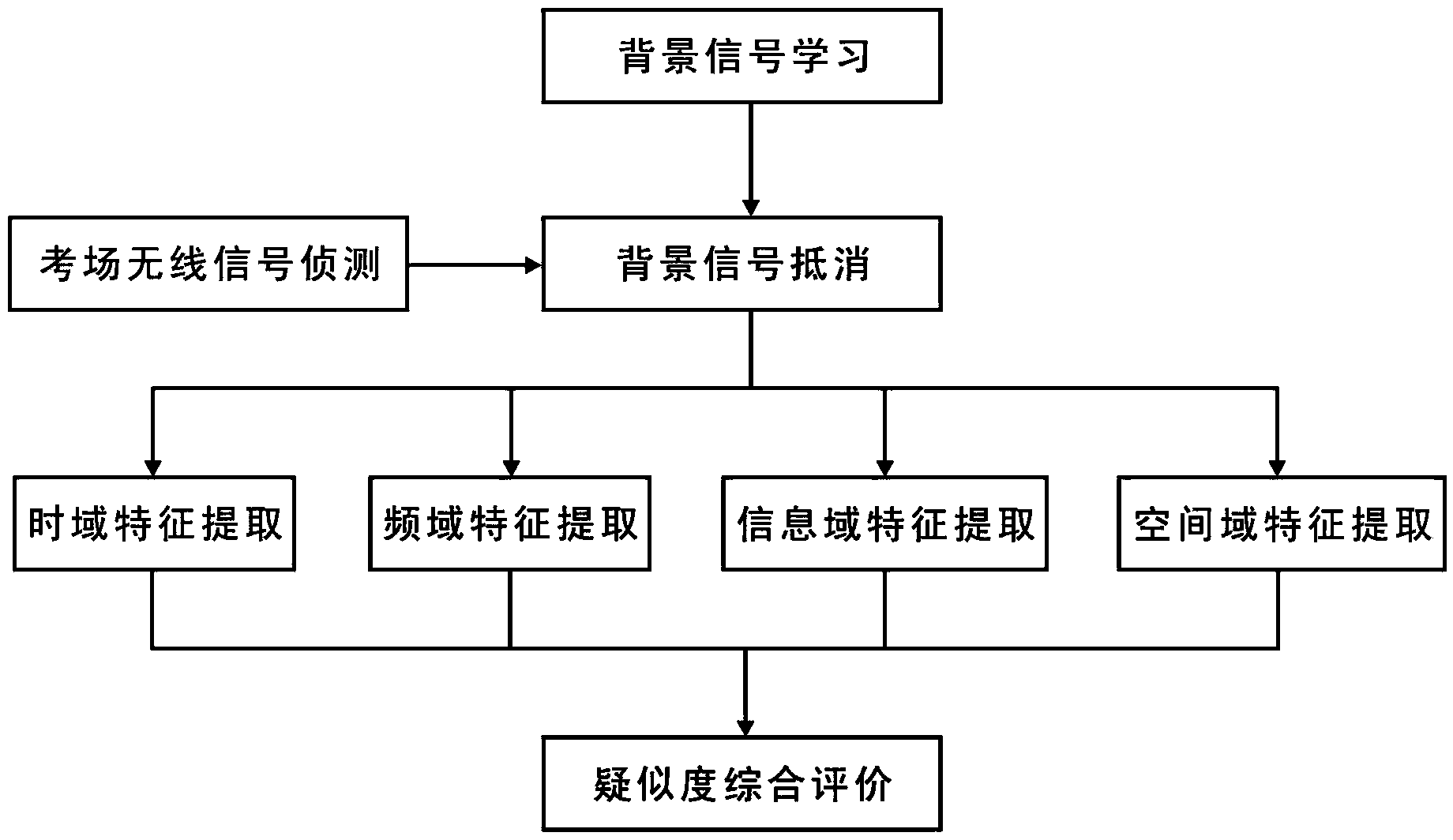

Method for comprehensively evaluating examination room cheating signal suspected degree

ActiveCN103986537AImprove core performanceStrong targetingTransmission monitoringSpecial data processing applicationsTime domainFeature extraction

The invention discloses a method for comprehensively evaluating the examination room cheating signal suspected degree. The method comprises the steps of learning background signals, counteracting the background signals, extracting time domain features, frequency domain features, information domain features and space domain features from the filtered signals at the same time or different time, comprehensively evaluating the suspected degree, grading the features based on a blacklist and a whitelist to obtain quantization values, carrying out weighted average calculation on the four kinds of quantization values to obtain the comprehensive quantization value and carrying out comprehensive evaluation. Cheating signals are comprehensively evaluated in the aspects of a time domain, a frequency domain, an information domain and a space domain, the features of the cheating signals in the aspects of the four domains are fully utilized, the method has higher pertinence and accuracy, the problem that according to a traditional method, it is difficult to accurately extract the cheating signals from the complex background environment is effectively solved, and the core competence for detecting the guidance blocking mechanism of a cheating preventing and controlling system is greatly improved.

Owner:成都佳发安泰教育科技股份有限公司

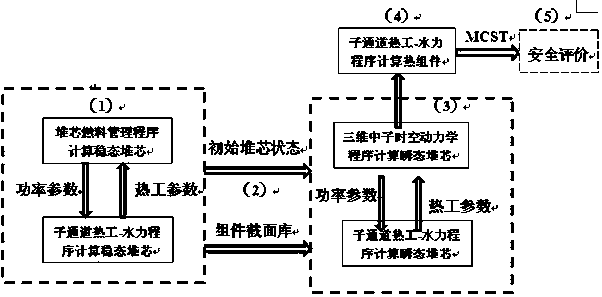

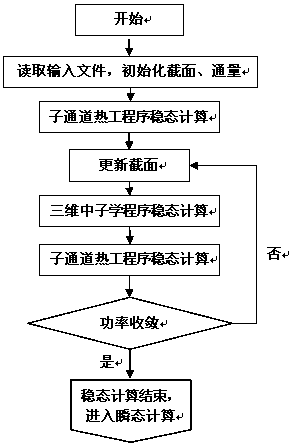

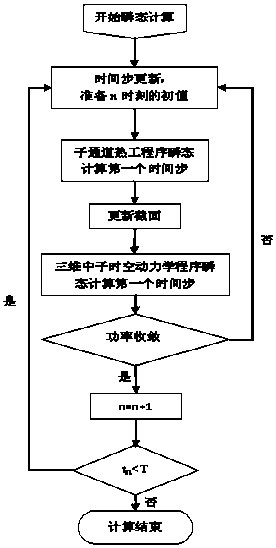

A 3D Transient Performance Analysis Method for Supercritical Water Reactor Core

ActiveCN105653869BDescribe the feedback accuratelyReal or exact simulationInformaticsSpecial data processing applicationsThermal engineeringCoupling

The invention discloses a three-dimensional transient performance analysis method of a supercritical water reactor core, which includes: step 1: performing core steady-state calculation, providing power parameters and thermal parameters, performing iterative coupling calculation until the core steady-state power parameters and Convergence of thermal parameters; Step 2: Provide core initial state and component section library; Step 3: Perform transient calculation, provide power parameters and thermal parameters, perform iterative coupling calculation until core transient power parameters and thermal parameters converge ; Step 4: Get the fine power distribution of the cell scale of the thermal component, analyze the sub-channels of the thermal component, and finally give the key parameters of the safety evaluation; Step 5: Determine whether the key parameters of the safety evaluation exceed the corresponding transient or accident safety limits value, which can accurately describe the feedback between physics and thermal-hydraulic, provide a more accurate three-dimensional power distribution of the core, and truly simulate the technical effects of the transient process and accident process of supercritical water reactors.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Amorphous alloy transformer iron core of three-dimensional triangle structure

InactiveUS20160086706A1Reduce consumptionShort processing timeTransformers/inductances magnetic coresInductances/transformers/magnets manufactureElectrical devicesAlloy

An amorphous alloy transformer iron core of a three-dimensional triangle structure belongs to the technical field of electrical devices. The amorphous alloy transformer iron core of the three-dimensional triangle structure is formed by piecing three identical rectangular single frames whose sections are approximately semicircular. A manufacturing method thereof comprises steps of cutting, winding, assembling, annealing and molding. The amorphous alloy transformer iron core of the three-dimensional triangle structure has the advantages of saving materials, reducing loss and noise, balancing three phases, enabling coils not to be sleeved, and being stable in performance and strong in anti-short circuit capacity.

Owner:HAIHONG ELECTRIC CO LTD

A supercritical water-cooled reactor based on stacked fuel assemblies

ActiveCN110853771BAvoid safety issues such as axial bendingImprove structural stabilityOptical rangefindersNuclear energy generationHoneycomb likeMechanics

The invention discloses a supercritical water-cooled reactor based on a stacked fuel assembly, which includes a fuel assembly channel and a control rod assembly channel, both of which are in the shape of a regular hexagon or a square; the outer side of each control rod assembly channel Fuel assembly passages are arranged continuously along the circumference to form a unit assembly, and several unit assemblies are arranged in a staggered array to form a honeycomb core structure; fuel assemblies with different enrichment standards are arranged in the fuel assembly passages, and along the fuel assembly passages The enrichment of the fuel assembly gradually increases from bottom to top in the axial direction; the control rod assembly channel is used to install the control rod bundle. The present invention effectively solves the problems faced by supercritical water-cooled reactors, such as excessive changes in axial temperature and coolant density, and unbalanced distribution of neutron moderating capacity in the core, without introducing moderating water rods and multi-flow flow schemes. It significantly simplifies the fuel assembly and core layout scheme, and improves the engineering feasibility.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

A kind of water plating metallization method of manganese zinc ferrite magnetic core

ActiveCN113372141BImprove performanceOvercome the problem of water-plating metallizationMagnetic core manufactureTin platingManganese

The invention discloses a water-plating metallization method for a manganese-zinc ferrite core, which comprises the following steps: 1) adding ZnO-B 2 o 3 ‑BaO system glass powder is added with water to make glass paste; 2) glass paste is coated on the surface of manganese zinc ferrite core, dried, and then sintered in a protective atmosphere to obtain a magnetic core with glass coating; 3) Copper paste is coated on the electrode part of the magnetic core containing glass coating, dried, and then sintered in a protective atmosphere to obtain a copper-coated magnetic core; 4) Place the copper-coated magnetic core in a nickel plating solution and a tin plating solution , nickel-plated and tin-plated. The present invention first adopts ZnO-B 2 o 3 ‑BaO system glass powder forms a glass coating on the surface of the manganese-zinc ferrite core, and then conducts water-plating metallization, which avoids the problems of core plating, poor spot welding, and poor adhesion strength of terminal electrodes, and completes the metallization process. The use of magnetic cores in common mode inductors can significantly improve the performance of common mode inductors.

Owner:广东泛瑞新材料有限公司

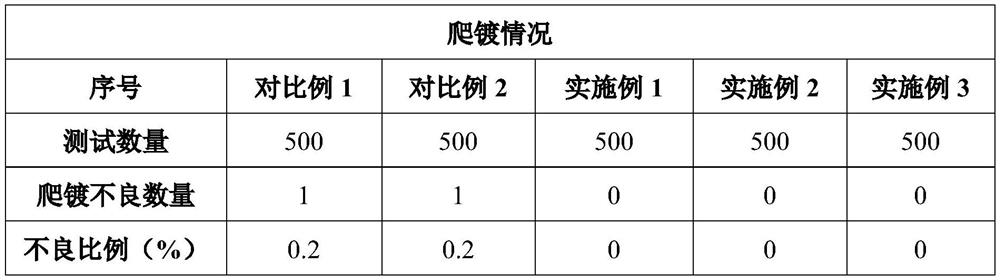

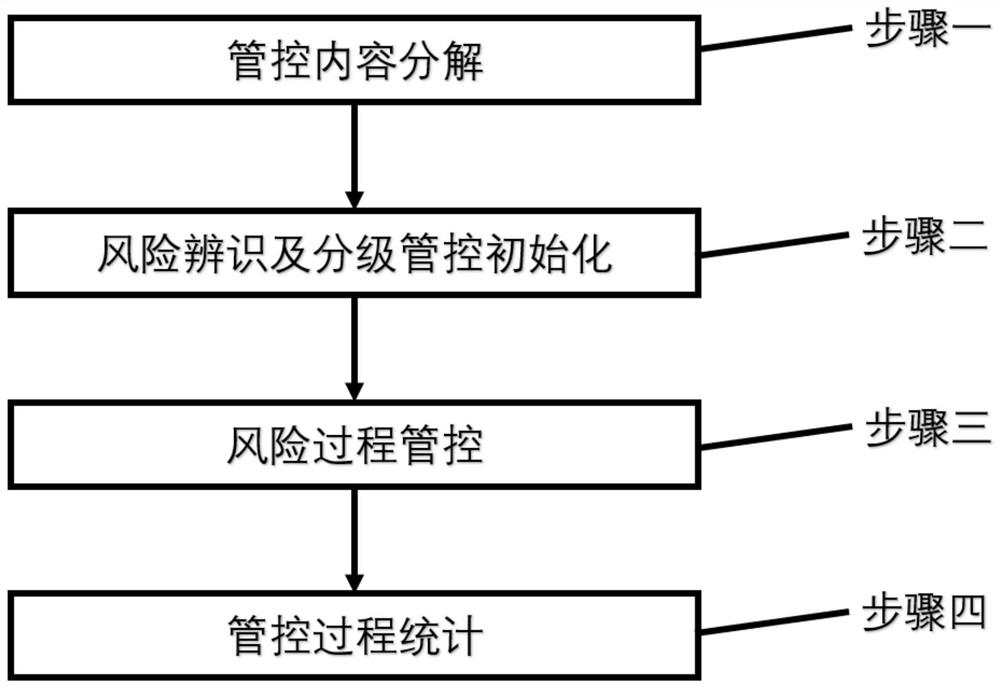

Risk hierarchical management and control method based on personnel behavior management

PendingCN113807656AImprove management and control efficiencyReduce security risksResourcesSensing by electromagnetic radiationSystems engineeringBusiness enterprise

The invention provides a risk hierarchical management and control method based on personnel behavior management. The risk hierarchical management and control method comprises four aspects of management and control content decomposition, risk identification and hierarchical management and control initialization, management and control process, management and control process statistics and performance statistics. According to the method, the contents needing to be managed and controlled in each level are managed and controlled in a hierarchical manner through risk decomposition, each management and control content is given, employment management is carried out on personnel through an informatization means, and the formed visual data can visually understand the current situation of safety management work, guide safety production and help to improve the safety production management level of enterprises.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Computing device and method of processing secure services for computing device

ActiveUS20150302224A1Improve performanceImprove core performanceDigital data processing detailsUnauthorized memory use protectionService informationStorage cell

A method of processing secure services is provided. The method is applied to a processing unit of a computing device to control the processing unit to process multiple secure services. The computing device includes a storage unit. The method includes: controlling a core of the processing unit to perform following steps in a secure mode: accessing the storage unit to obtain a first command that includes first secure service information, processing a first secure service associated with the first secure service information according to the first command, and accessing the storage unit to obtain a second command that includes second secure service information. During a period from a time point that the core accesses the storage unit to obtain the first to a time point that the core accesses the second command, the core is controlled to stay in the secure mode.

Owner:MEDIATEK INC

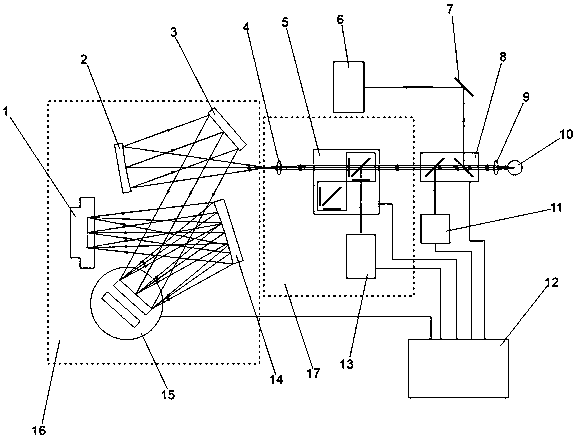

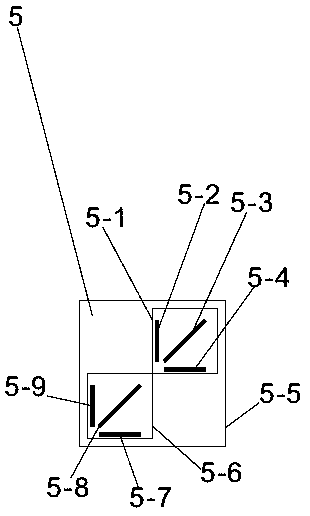

Dual-wavelength laser Raman spectrometer

InactiveCN111504457ARealize automatic switching measurementCost controlRadiation pyrometrySpectrometry/spectrophotometry/monochromatorsOptical spectrometerLight filter

The invention provides a dual-wavelength laser Raman spectrometer. The dual-wavelength laser Raman spectrometer comprises a dual-grating spectrometer, a laser emitting and collecting device and a controller. The double-grating spectrometer comprises a double-grating table, a first optical element and a detector. The laser emitting and collecting device comprises a dual-wavelength laser module anda dual-optical filter group. The dual-wavelength laser module is used for emitting first-wavelength laser or second-wavelength laser. The double-grating table comprises two gratings which are in one-to-one correspondence with the first wavelength laser and the second wavelength laser respectively. The double-optical-filter group comprises two optical filter groups which are in one-to-one correspondence with the first wavelength laser and the second wavelength laser respectively. The controller is respectively connected with the dual-grating table, the dual-wavelength laser module and the optical filter group. According to the invention, dual-wavelength automatic switching measurement can be effectively realized, the detection efficiency, the coupling efficiency, the core performance and the application range are improved, the hardware cost is controlled, and the economic benefit of the application field is improved.

Owner:ZOLIX INSTR

Method of manufacturing a golf ball

InactiveUS7935285B2Effectively prevents slugs from sticking and clumping togetherImprove workabilityLamination ancillary operationsMouldsElastomerCarboxylic acid

The invention provides a method of manufacturing a golf ball composed at least in part of a spherical elastomeric body. The method includes the steps of extruding a bar of an unvulcanized rubber compound for obtaining the elastomeric body, cutting the extruded bar into slugs of a given length, and coating the slug with a saturated or unsaturated carboxylic acid metal salt in powder form having a melting point at or below a vulcanizing temperature. This method prevents the slugs from clumping together and improves mold releasability.

Owner:BRIDGESTONE SPORTS

A low compression ratio, high-performance q 345R ultra-wide and extra-thick container steel and its manufacturing method

The invention relates to a low-compression-ratio, high-performance Q345R ultra-wide and extra-thick container steel, which is combined with a continuous casting process. The production process route is: molten iron pretreatment→converter steelmaking→external refining→vacuum degassing→slab continuous casting→billet Stack slow cooling→heating→rolling→steel stack slow cooling→ultrasonic flaw detection→normalizing→ultrasonic flaw detection→air cooling→finishing. The thickness of the steel plate can reach 101-120mm, and the width can reach 3500-4050mm. The core performance is excellent: the low-temperature impact value at ‑29°C is over 100J, which exceeds the requirement of "-20°C impact energy ≥ 41J" stipulated in the GB / T 713‑2014 standard, 450 The high-temperature tensile properties meet the requirements of Table 3 in GB / T713-2014, and the Z-direction performance is excellent: exceeding the standard's highest requirement of 35% for the Z-direction performance of steel plates. The uniform mechanical properties of the steel plate indicate that the steel is very compact and meets the stringent requirements for the mechanical properties and uniform structure of the large-thickness steel core and the entire plate; after the simulated post-weld heat treatment of the steel plate, the structure remains uniform and the core There is no obvious fluctuation in the tensile and core impact properties.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Multiple calibration index gas composition distinguishing and recognition method

InactiveCN101236178BImprove job stabilityExtend your lifeMaterial analysis by electric/magnetic meansElectrical field strengthIon current

The invention relates to a discrimination and recognition method of a gas composition with a plurality of standardized indicators, which belongs to the detection technological field. The invention takes ion current produced by local self-maintained discharge as a detection object, forms a discharge zone and a detection zone through a three-stage structure of 'discharge electrode anode-discharge electrode cathode-detection electrode', measures the ion current of a certain gas composition formed at different electric field strengths in the detection zone through changing the loaded voltage of the detection electrode, and takes the 'measured loaded voltage-detection electrode current' relationship as the indicators designating the gas composition. When recognizing the gas composition, a measured valve of the detection electrode current under the same loaded voltage is compared with a designated value. The discrimination and recognition method can significantly improve selectivity and sensibility of a field ionized gas sensor; relative to a clearance breakdown electric feature detection method, the discrimination and recognition method can greatly improve the stability, service life, reliability and identification accuracy of the device.

Owner:SHANGHAI JIAOTONG UNIV

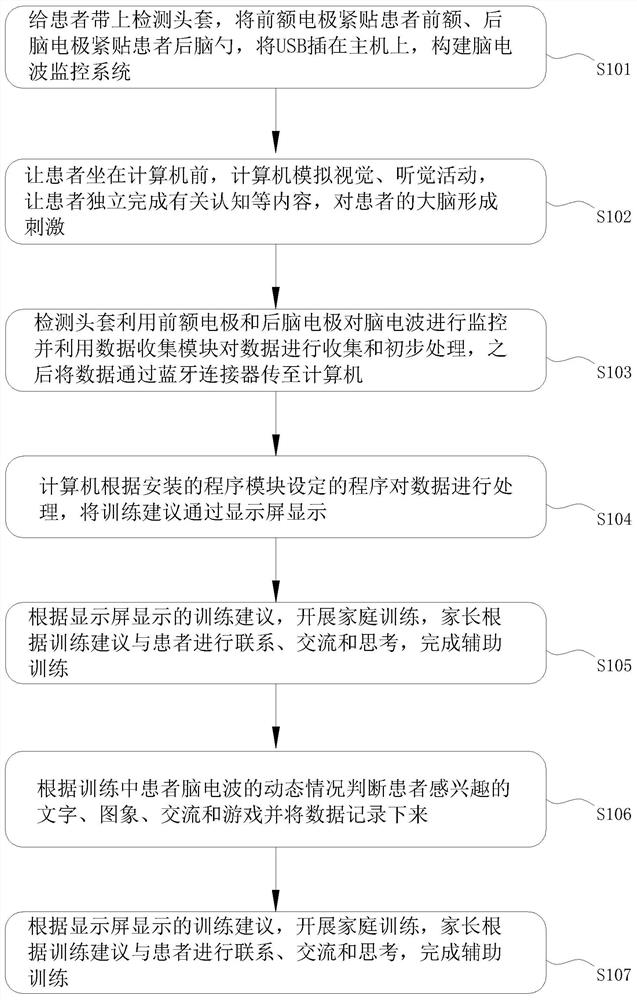

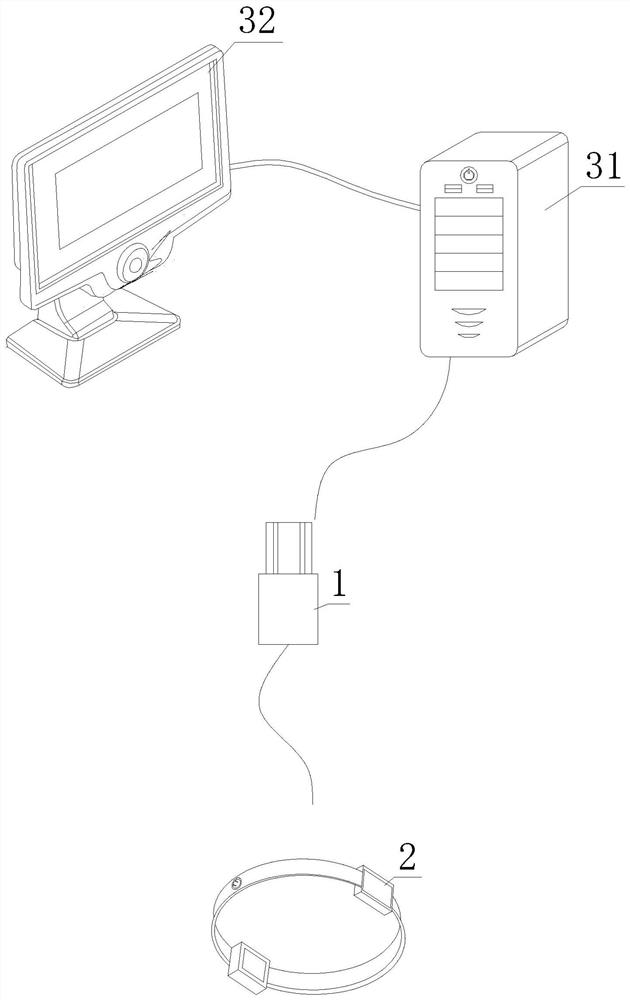

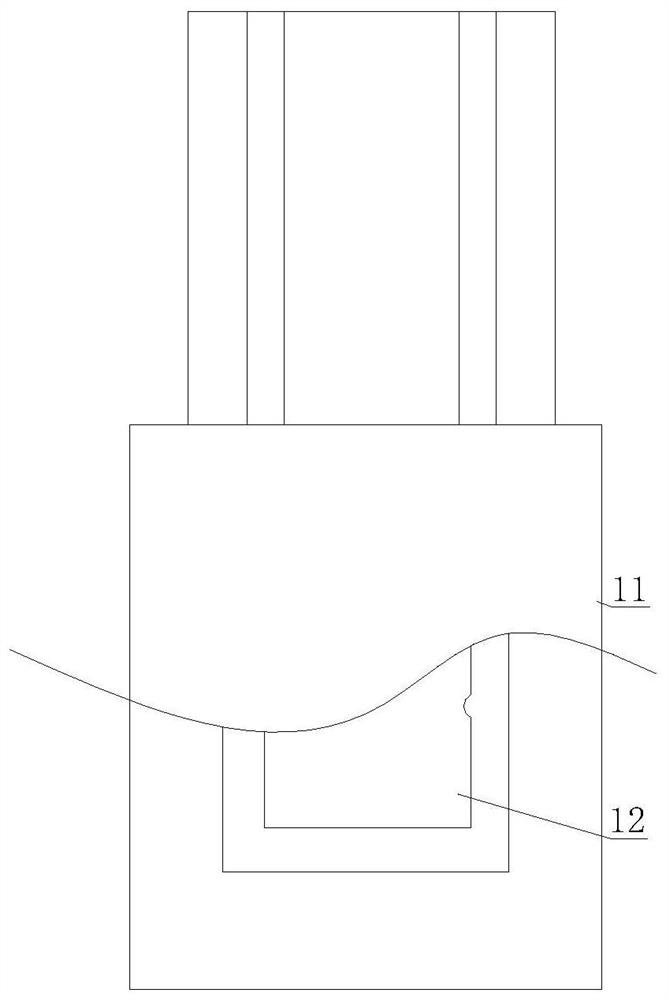

Autism brain wave auxiliary training tracking method

InactiveCN112037890AImprove core performanceCore competency trainingInput/output for user-computer interactionMental therapiesPhysical medicine and rehabilitationMonitoring system

The invention discloses an autism brain wave auxiliary training tracking method which comprises the following steps: S101, putting a detection hood on a patient, and constructing a brain wave monitoring system; S102, simulating visual and auditory activities by a computer, and enabling the patient to independently complete related cognition and other contents; S103, adopting the detection hood tomonitor brain waves through a forehead electrode and an afterbrain electrode, subjecting data to collecting and primary processing through a data collection module, and then transmitting the data to acomputer; S104, processing the data by a computer according to a program set by a program module, and displaying training suggestions through a display screen; S105, enabling the parents to communicate and think with the patient according to the training suggestions, and completing auxiliary training; S106, judging interested characters, images, communication and games of the patient according todynamic conditions of brain waves of the patient in training, and recording data; and S107, upgrading the database by the program module according to the collected data.

Owner:陈翰林

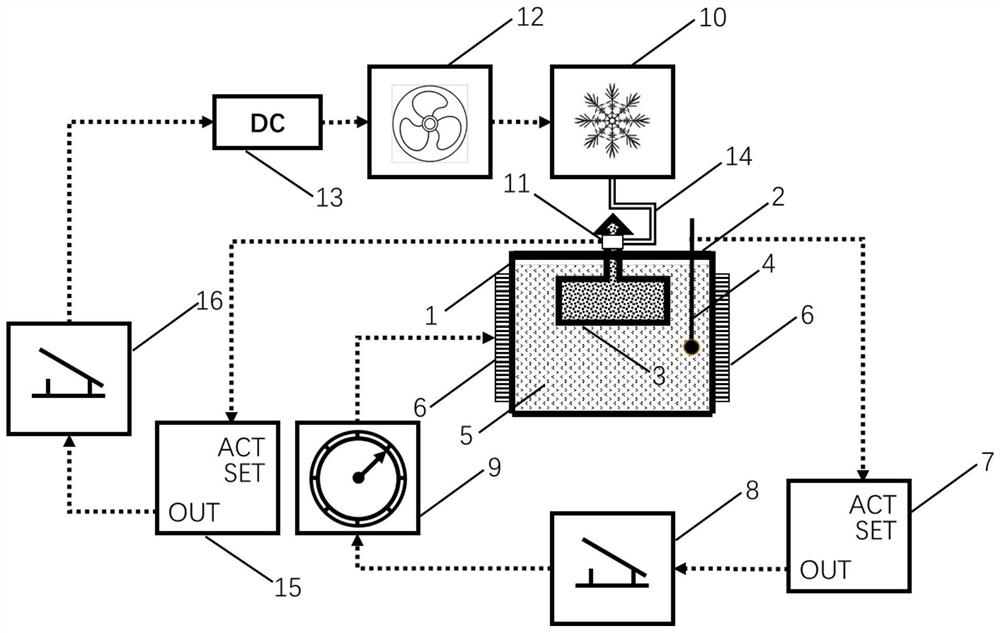

A coating alkali metal atom air cell curing system and its application method for prolonging the lifetime of atomic spin relaxation

ActiveCN110274472BEvenly heatedAvoid direct contactFurnace typesFurnace coolingPolypropyleneMaterials science

The invention discloses a coating alkali metal atom gas chamber curing system for prolonging the atom spin relaxation life. The coating alkali metal atom gas chamber curing system comprises a curing furnace module, a heating module, a refrigeration module and a temperature control module. According to the system, a curing furnace structure of a nested polypropylene inner furnace of a graphite outer furnace is mainly adopted, and direct contact between the polypropylene inner furnace and a high-temperature-resistant heating tape is avoided. The invention further discloses a using method of the coating alkali metal atom gas chamber curing system. According to the system, the coating material (such as paraffin, deuterium polyethylene, olefin and the like) of the inner wall of the alkali metal atom gas chamber can be uniformly distributed, a proper amount of alkali metal atom density of a gas chamber body is guaranteed, so that the alkali metal atom gas chamber is in the optimal working state and can be used for recovering the performance of the damaged alkali metal atom gas chamber under long-time high-temperature work, so that the service life of the atom gas chamber can be prolonged, and meanwhile, the system is suitable for various alkali metal atoms.

Owner:PEKING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com