Water plating metallization method of manganese zinc ferrite magnetic core

A manganese-zinc ferrite and metallization technology, which is used in magnetic core manufacturing, inductor/transformer/magnet manufacturing, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

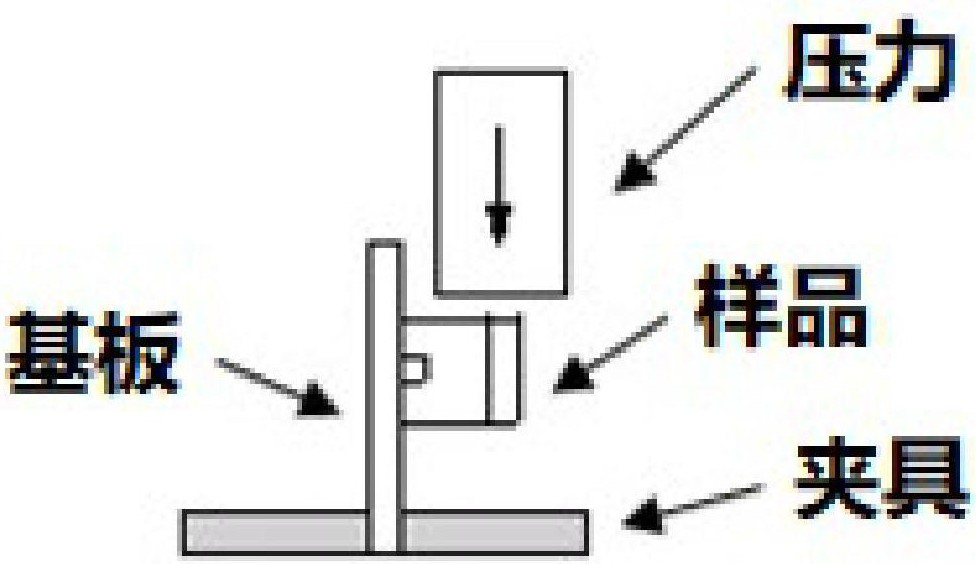

Method used

Image

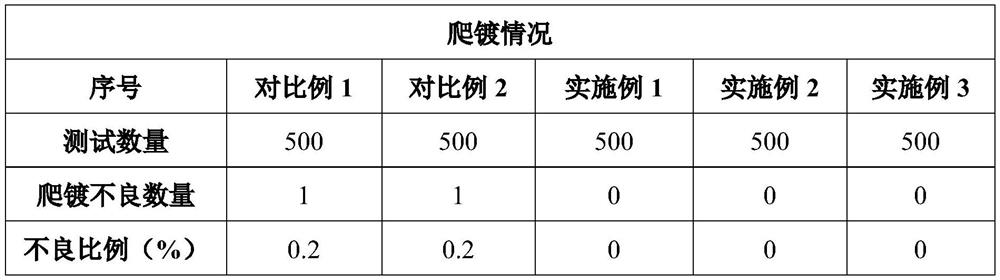

Examples

Embodiment 1

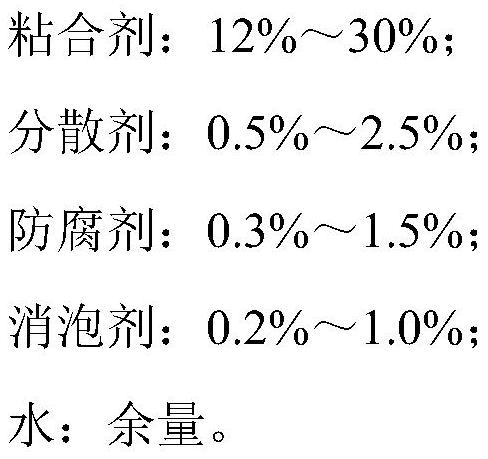

[0063] A water-plated metallization method for a manganese-zinc ferrite core, comprising the following steps:

[0064] 1) 10 parts by mass of ZnO-B 2 o 3 -BaO system glass powder, 25 parts by mass of water-based acrylic emulsion with a solid content of 40%, 1 part by mass of fatty alcohol polyoxyethylene ether, 0.5 parts by mass of parabens, and 0.5 parts by mass of polyether-modified silicone , 63 parts by mass of water and zirconium balls were added to a corundum ball mill jar, ball milled for 2 hours, and passed through a 350-mesh sieve to obtain glass slurry;

[0065] 2) Spray the glass slurry evenly on the surface of the MnZn ferrite core with a spray gun, dry at 140°C for 20 minutes, and then sinter at 850°C for 20 minutes in a nitrogen atmosphere to obtain a magnetic core with a glass coating (thickness 3 μm);

[0066] 3) Spray the copper paste evenly on the electrode part of the glass-coated magnetic core with a spray gun, dry at 140°C for 20 minutes, and then sinter...

Embodiment 2

[0069] A water-plated metallization method for a manganese-zinc ferrite core, comprising the following steps:

[0070] 1) 20 parts by mass of ZnO-B 2 o 3 -BaO system glass powder, 25 parts by mass of 8% hydroxypropyl methylcellulose solution, 1.2 parts by mass of fatty alcohol polyoxyethylene ether, 0.5 parts by mass of benzimidazole, 0.5 parts by mass of polydimethyl Siloxane, 52.8 parts by mass of water and zirconium balls were added to a corundum ball mill jar, ball milled for 2 hours, and passed through a 350-mesh sieve to obtain glass slurry;

[0071] 2) Spray the glass slurry evenly on the surface of the MnZn ferrite core with a spray gun, dry at 140°C for 20 minutes, and then sinter at 850°C for 20 minutes in a nitrogen atmosphere to obtain a magnetic core with a glass coating (thickness 9 μm);

[0072] 3) Spray the copper paste evenly on the electrode part of the glass-coated magnetic core with a spray gun, dry at 140°C for 20 minutes, and then sinter at 700°C for 15...

Embodiment 3

[0075] A water-plated metallization method for a manganese-zinc ferrite core, comprising the following steps:

[0076] 1) 30 parts by mass of ZnO-B 2 o 3 -BaO system glass powder, 30 parts by mass of polyvinyl alcohol solution with a mass fraction of 10%, 2.5 parts by mass of fatty alcohol polyoxyethylene ether, 0.5 parts by mass of benzimidazole, 0.5 parts by mass of polydimethylsiloxane, Add 36.5 parts by mass of water and zirconium balls into a corundum ball mill jar, mill for 2 hours, and pass through a 350-mesh sieve to obtain glass slurry;

[0077] 2) Spray the glass slurry evenly on the surface of the MnZn ferrite core with a spray gun, dry at 140°C for 20 minutes, and then sinter at 850°C for 20 minutes in a nitrogen atmosphere to obtain a magnetic core with a glass coating (thickness 15 μm);

[0078] 3) Spray the copper paste evenly on the electrode part of the glass-coated magnetic core with a spray gun, dry at 140°C for 20 minutes, and then sinter at 700°C for 15 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com