Core limb shearing length-cutting line guiding device

A technology of guiding device and cross-cutting line, which is applied in the direction of shearing device, accessory device of shearing machine, inductance/transformer/magnet manufacturing, etc., can solve problems such as electrical steel damage, reduce damage, facilitate guiding and conveying, reduce The effect of edge burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

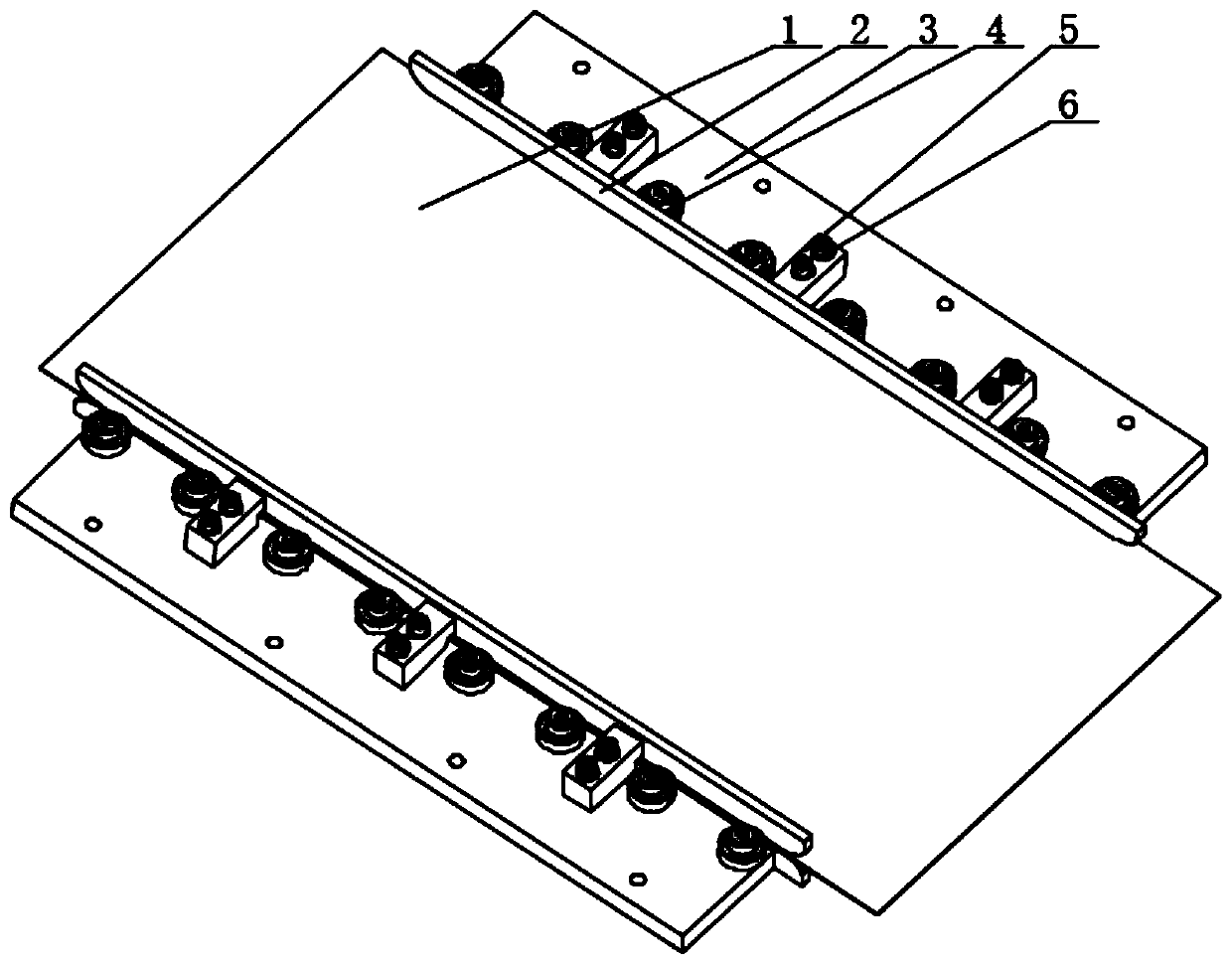

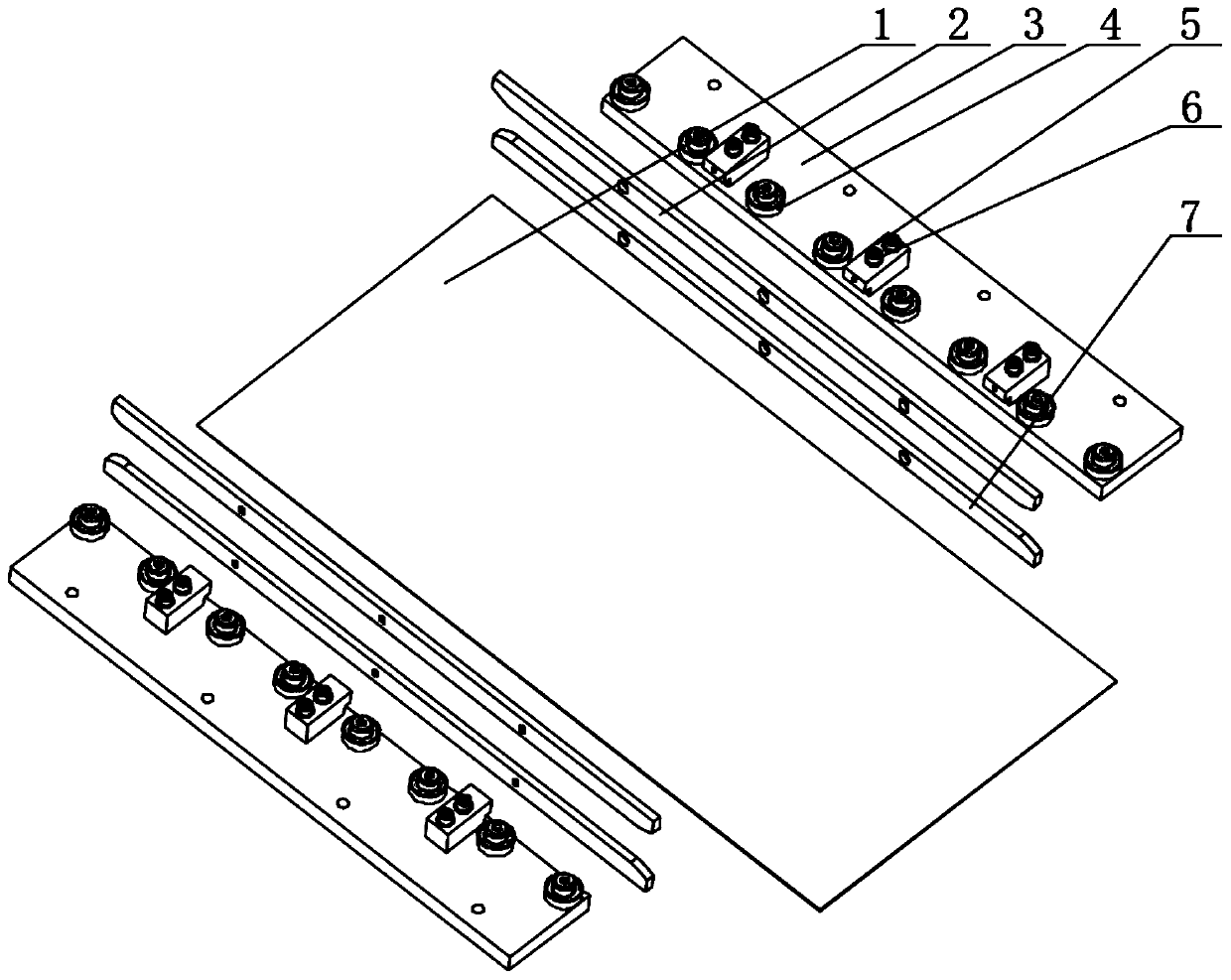

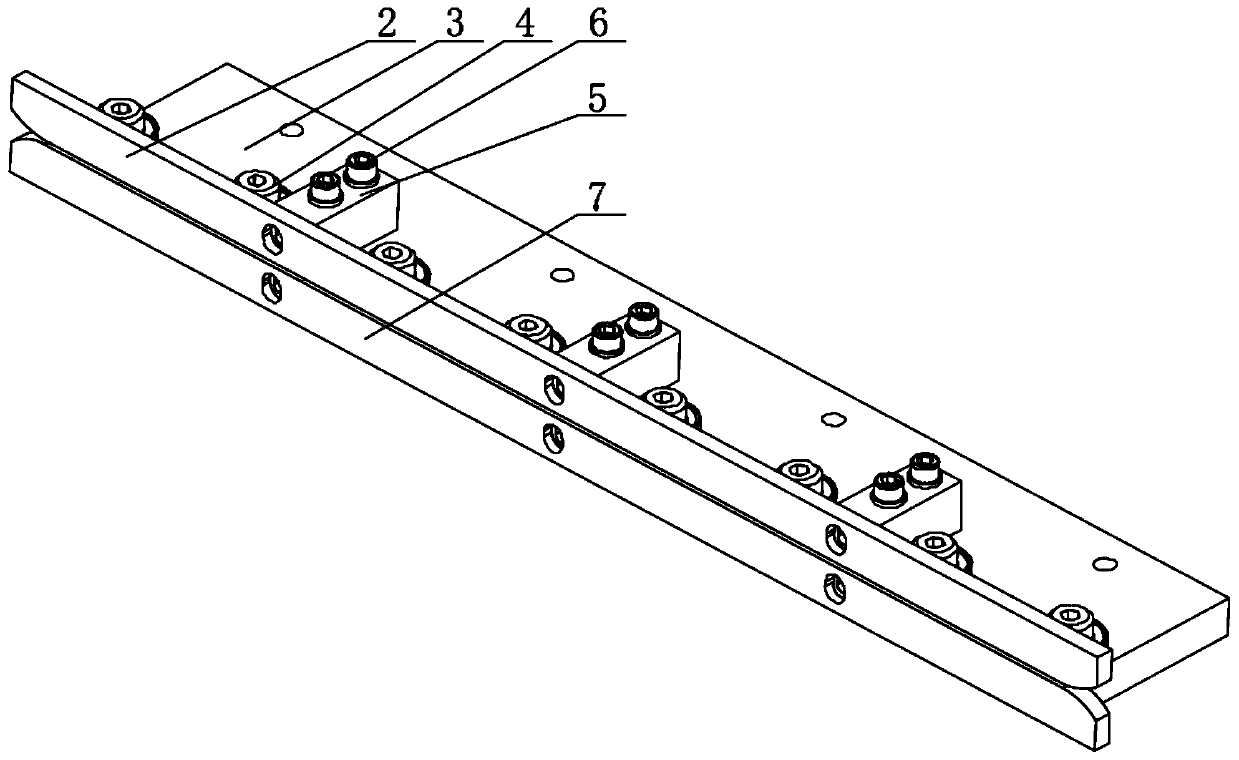

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a guide device for electrical steel cross-cutting lines in this embodiment includes two worktables 3 arranged at intervals. The lower track 7 is installed, and the upper surface of a single work surface 3 is equipped with a plurality of fixed blocks 5 at intervals through locking bolts 6. The end surface of the fixed block 5 is equipped with an upper track 2 through a fastener, and the upper track 2 and the lower track 7 are arranged oppositely. , and correspondingly, there is a gap between the upper track 2 and the lower track 7, and the gap runs through from front to back, and a plurality of guide wheel assemblies 4 are installed at intervals on the upper surface of the work table 3 at the same linear position, and the electrical steel sheet 1 wears P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com