Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Improve composite fastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

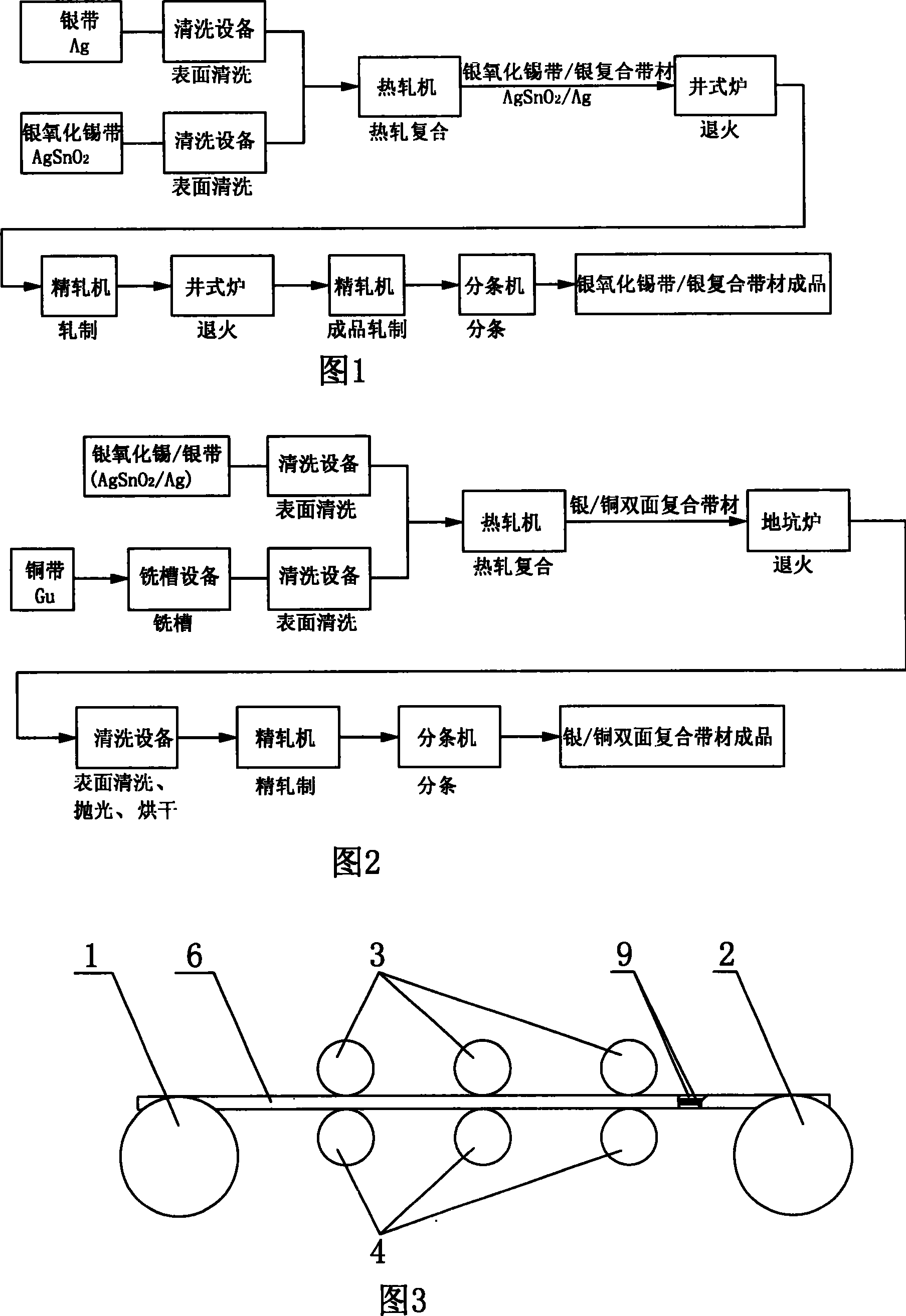

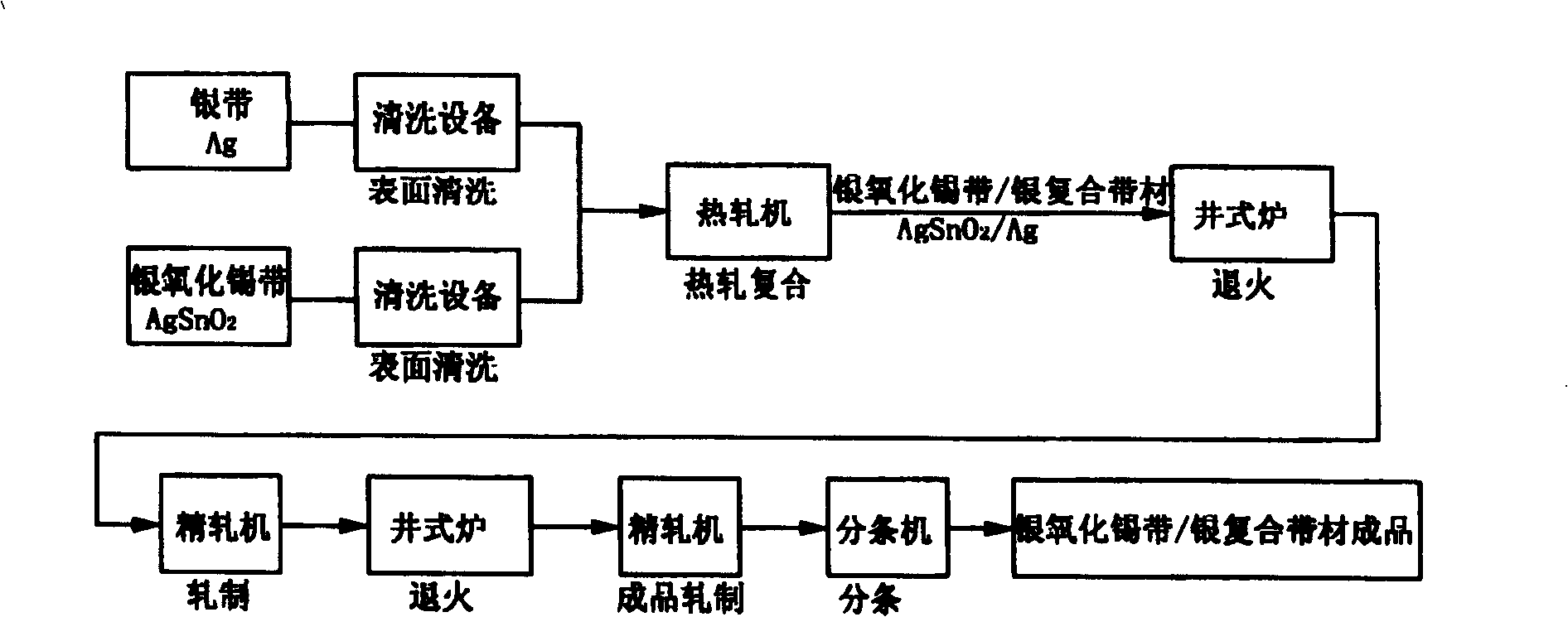

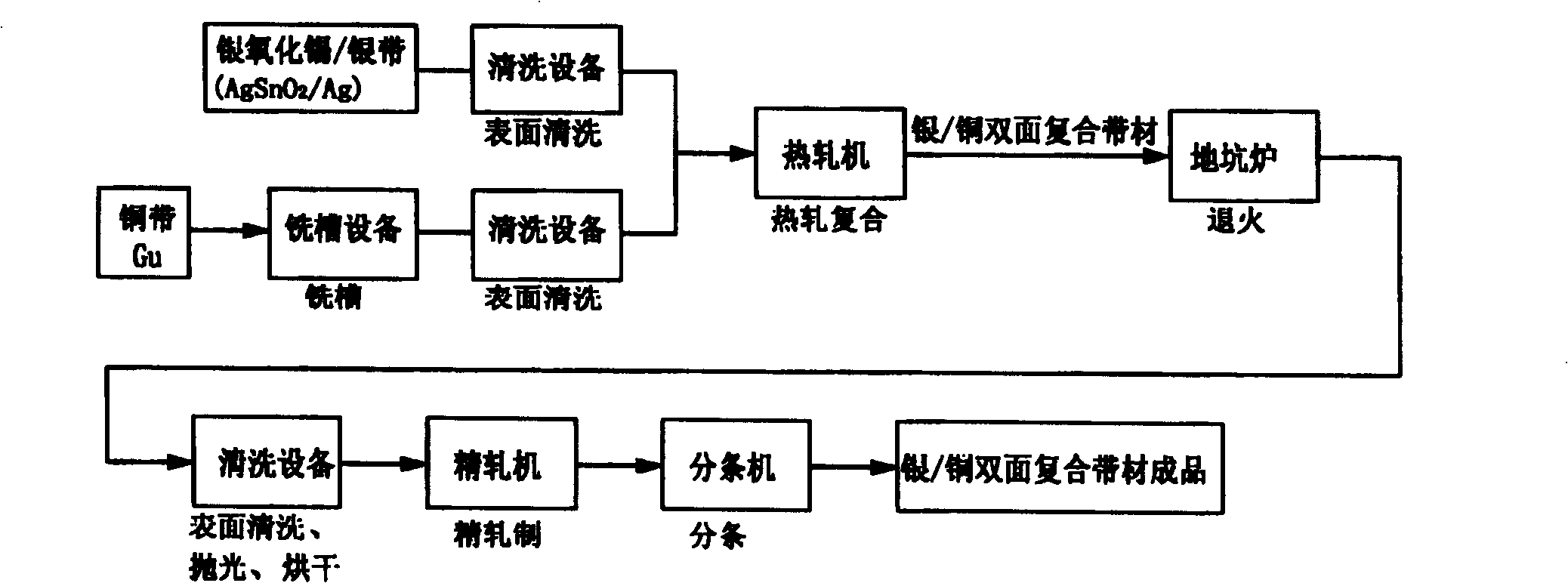

Machining technique of silver/copper double composite strip material

This invention relates to electricity materials technique field and to one silve to copper double compound band process method, which comprises the following steps: firstly grinding the silver metal oxidation with one thin siver band to form silver metal oxidation or silver compound materials; grinding silver metal oxidation and silver compound band through its top silver band layer and copper band heat grinding through heat compound band for annealing.

Owner:东莞市中一合金科技有限公司

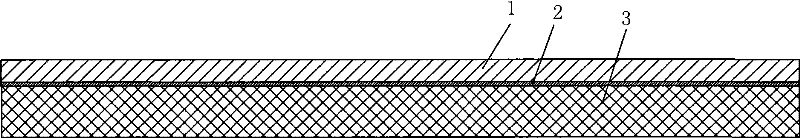

Thinned high-barrier liquid packaging film and manufacturing method thereof

InactiveCN101274690AImprove rigidityIncreasing the thicknessFlexible coversWrappersHigh densityMedium density

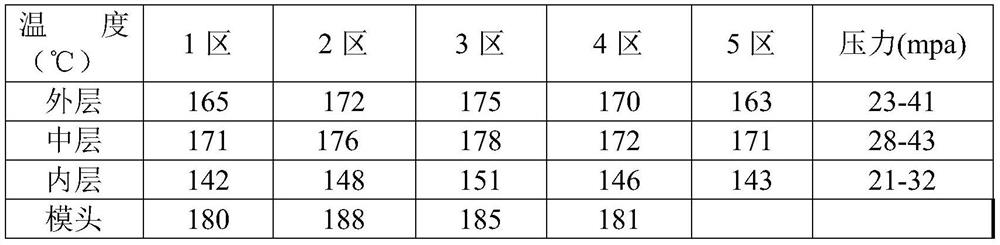

The invention relates to a thin-reducing and high impermeable liquid packaging membrane and a manufacturing method thereof. The product comprises a polyvinyl basilar membrane, a high impermeable polyvinyl alcohol layer, a composite adhesive layer and a protective polythene membrane layer, wherein, the polyvinyl basilar membrane comprises an outer layer, a middle layer and an inner layer and the outer layer and the middle layer comprise at least one of the two materials which are medium-density polythene or high-density polythene. The manufacturing method of the product comprises the steps of the preparation of the polyvinyl basilar membrane, the preparation of polyvinyl alcohol coating liquid and the preparation of the protective polythene membrane layer, coating and compounding, wherein, the polyvinyl alcohol coating liquid is diluted and the diluted polyvinyl alcohol coating liquid is coated on the outer layer of the polyvinyl basilar membrane to form the high impermeable polyvinyl alcohol layer and then the protective polythene member layer and the polyvinyl alcohol coating layer are compounded, cured and cut. The product of the invention has low thickness, good rigidness, high impermeable property, environmental protection, convenient use, low cost and simple technique.

Owner:马龙升

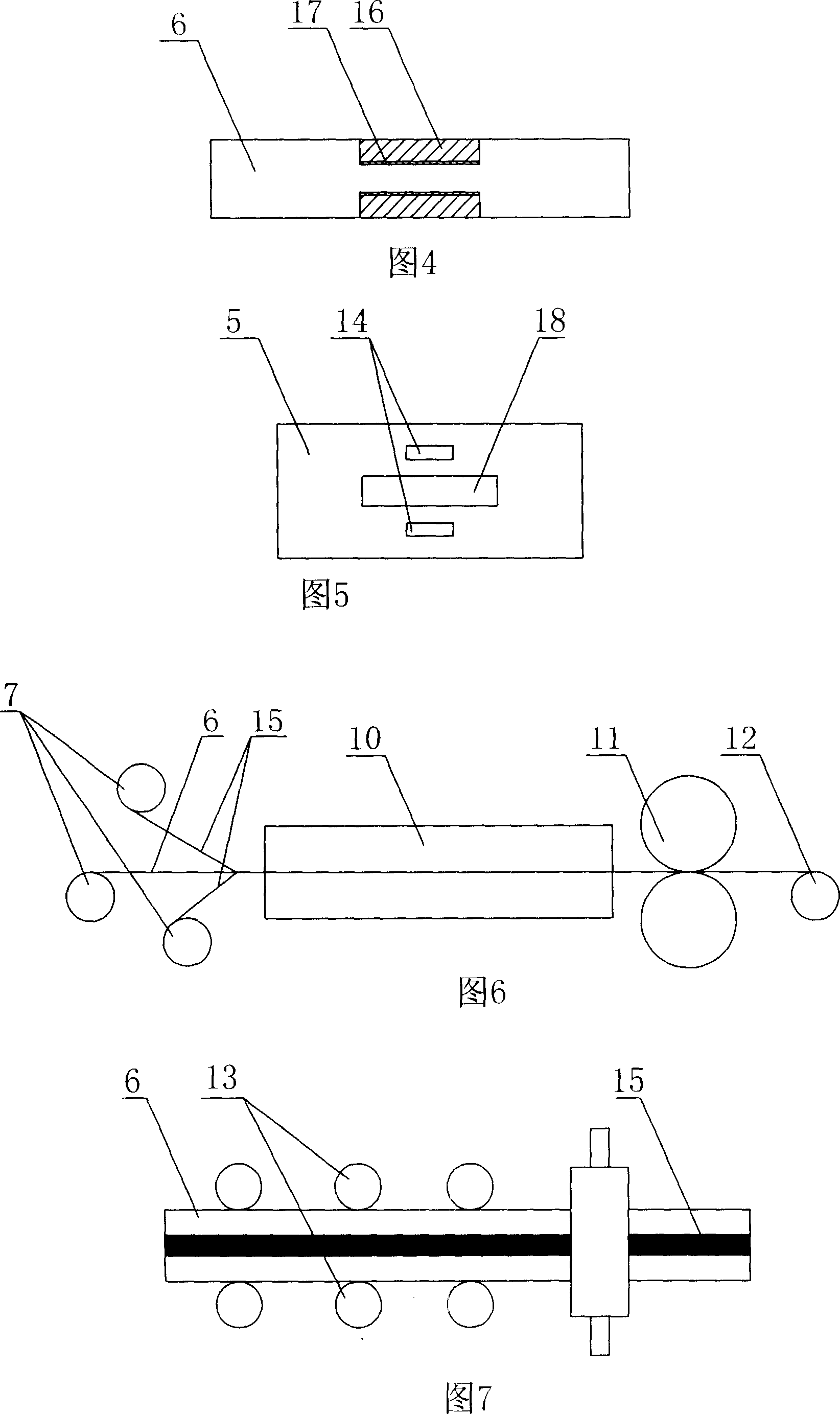

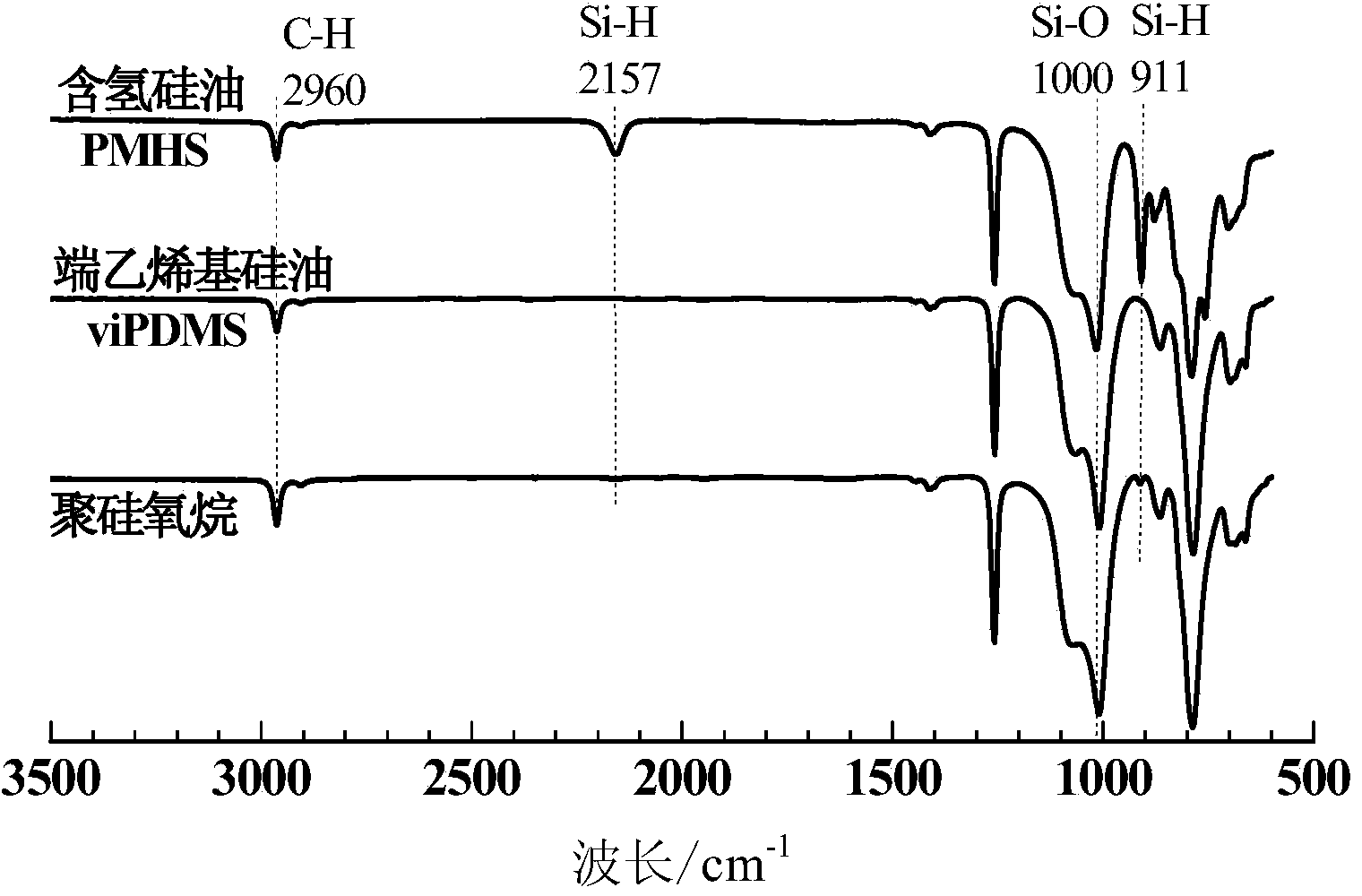

Preparation method of titanium dioxide/polysiloxane photocatalytic composite film

ActiveCN103483607AUniform and stable dispersionHigh mechanical strengthOrganic-compounds/hydrides/coordination-complexes catalystsComposite filmSolvent

The invention discloses a preparation method of a titanium dioxide / polysiloxane photocatalytic composite film, which comprises the following steps: adding vinyl-terminated silicone oil, hydrogen-containing silicone oil and titanium sol into a film-forming solvent, uniformly mixing, adding a reinforcing agent silicon dioxide, uniformly mixing, adding a platinum catalyst to initiate silicon hydrogen addition reaction, pouring into a mold, and gradually forming the film along with the solvent volatilization and silicon hydrogen addition reaction, thereby obtaining the titanium dioxide / polysiloxane photocatalytic composite film. The method is simple in technique and easy to implement; the crosslinking level of the stereoscopic network structure of the composite film is controllable, and silicon dioxide granules can be uniformly and stably dispersed in the composite film in the form of primary particles and can be easily enriched and embedded in the surface layer of the composite film; and the composite film has the advantages of favorable mechanical strength and obvious ultraviolet shielding effect, has excellent photocatalytic functions of resisting bacteria, degrading organic substances and the like, and can be used in the fields of textiles, paints, buildings, cosmetics, sanitation, medicine and the like.

Owner:ZHEJIANG SCI-TECH UNIV

Amorphous polyethylene terephthalate composite sheet and production method thereof

InactiveCN101885254AImprove composite fastnessLiquid surface applicatorsSynthetic resin layered productsPolyethylene terephthalate glycolPolyethylene terephthalate

The invention discloses an amorphous polyethylene terephthalate composite sheet and a production method thereof, relating to the production technical field of composite sheets. The amorphous polyethylene terephthalate composite sheet treated by corona improves adhesion properties. The production method comprises the following steps of: successively coating a polyurethane solution with a solvent and a polyvinylidene chloride solution on the amorphous polyethylene terephthalate composite sheet, successively baking two times, removing the solvent, cooling, rolling, curing and cutting into sheets in a designed size. The production method has simple and reasonable steps and easy production control. The product integrates the performance advantages of the APET and the PVDC, not only has high transparency, high luster, excellent physical and mechanical performances and plasticity heat sealability, but also has excellent capability of obstructing vapor, oxygen, odor and fragrance.

Owner:HONGDA XINGYE CO LTD

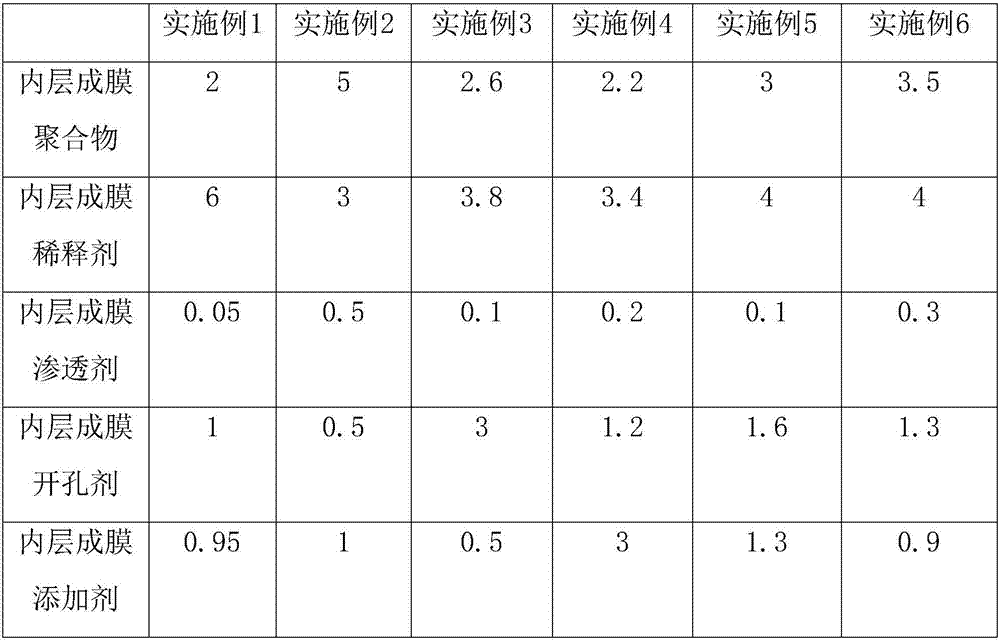

Manufacturing method of inner pressure pipe type multilayer composite film

InactiveCN107308825AImprove efficiencyExtended service lifeSemi-permeable membranesInternal pressureComposite film

The invention discloses a manufacturing method of an inner pressure pipe type multilayer composite film. The manufacturing method comprises: a, uniformly mixing a film forming polymer, a film forming diluent, a film forming penetrant, a film forming pore forming agent and a film forming additive according to a certain mass percentage ratio, heating to a temperature of 130-390 DEG C with an extrusion molding machine through a thermally induced phase separation method, melting, uniformly mixing, extruding with a pipe type film inner film mold, and cooling to obtain the inner layer film of a pipe type film; b, weaving a warp and weft mesh pipe outside the inner layer film by using a warp and weft weaving machine, wherein it is ensured that the warp and weft mesh pipe is tightly attached to the surface of the inner layer film; c, coating the inner layer film outer layer attached to the warp and weft mesh pipe with a layer of an outer layer film; and d, extracting the prepared inner pressure pipe type multilayer composite film semi-finished product by using ethanol or isopropanol to obtain the inner pressure pipe type multilayer composite film finished product. According to the present invention, the inner pressure pipe type multilayer composite film has advantages of good separation performance, good compounding fastness and good mechanical property, the area of the effective filtration membrane can be increased, and the breaking of the film pipe and the damage caused by the separating and the layering between the filtration membrane layer and the support layer can be effectively avoided, such that the use efficiency and the service life of the film can be improved.

Owner:李月玲

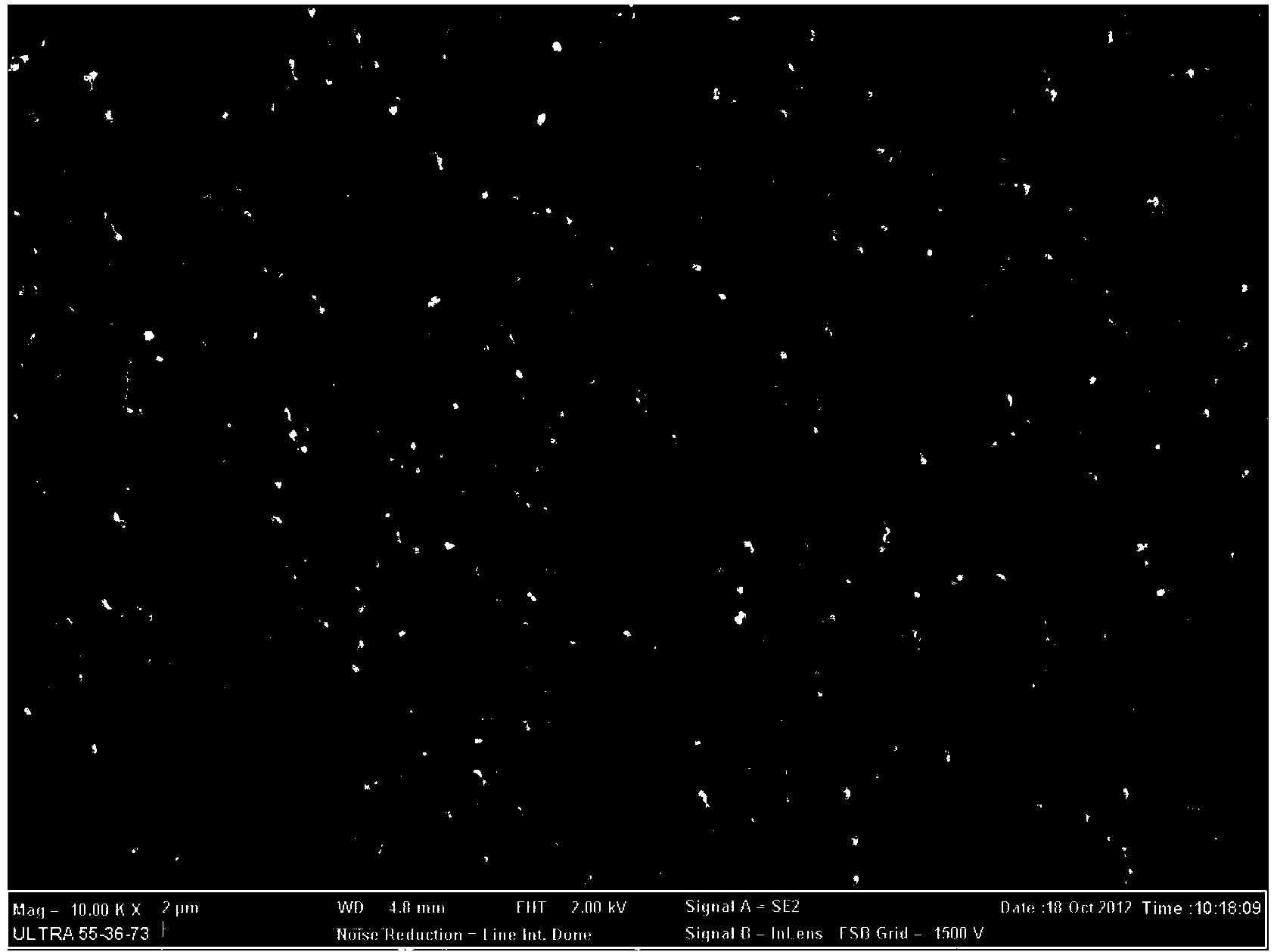

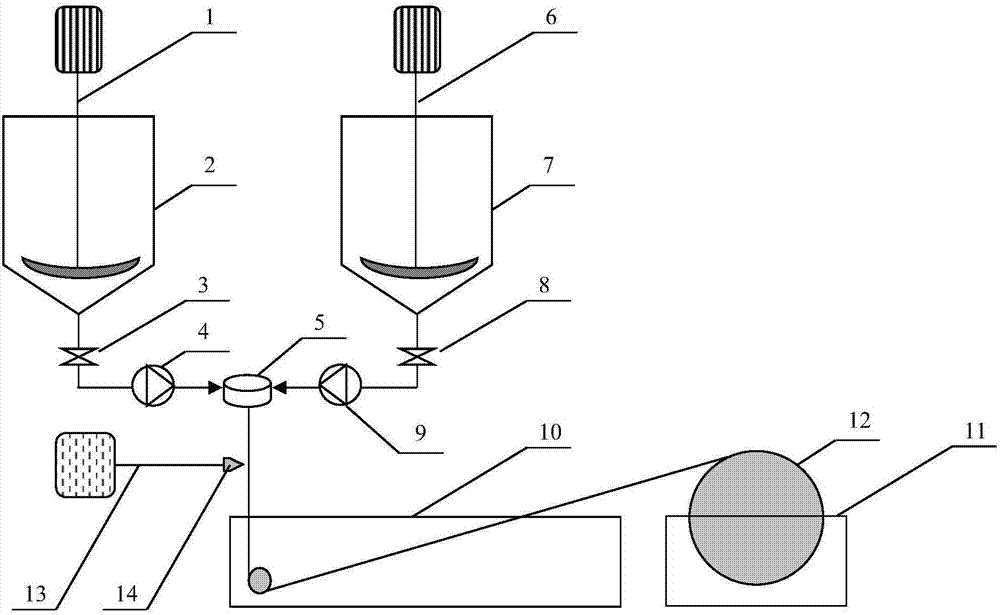

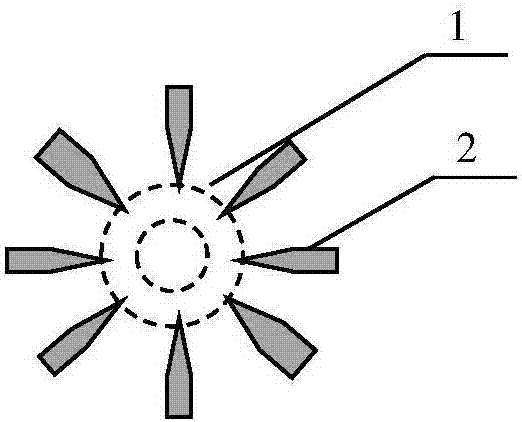

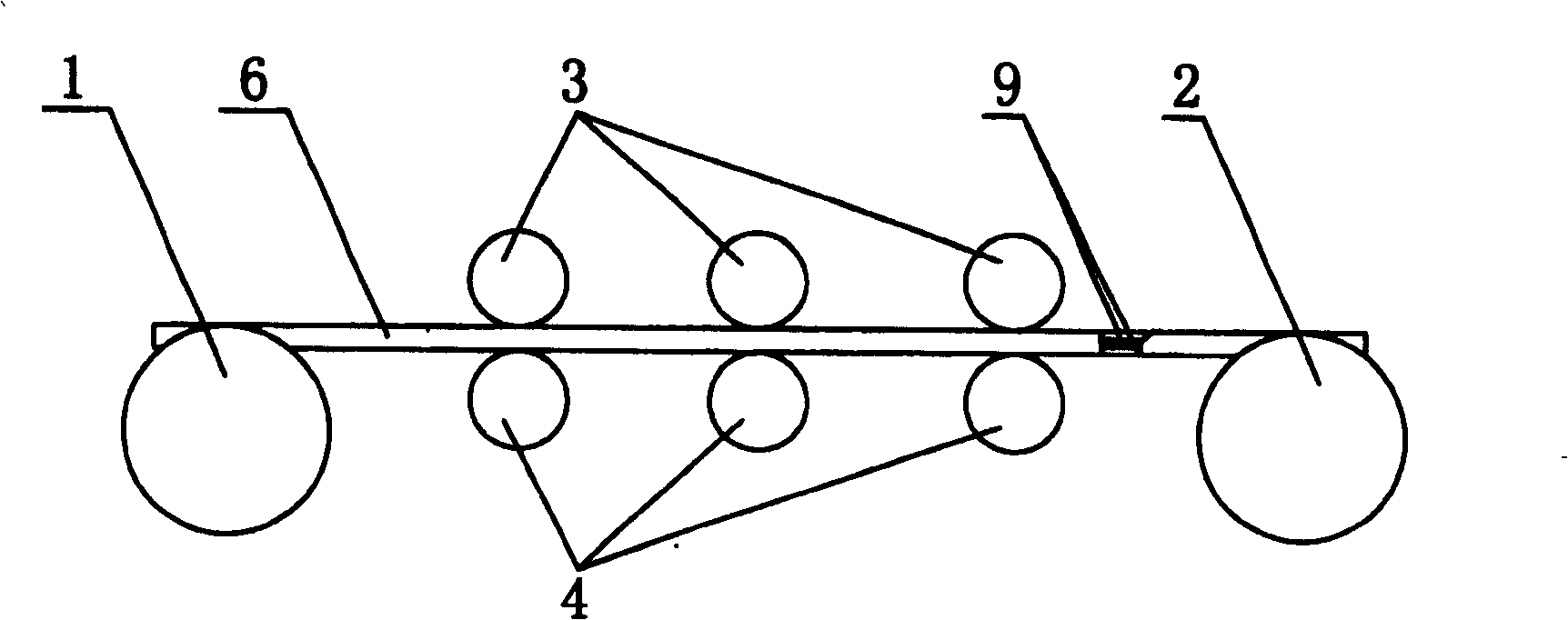

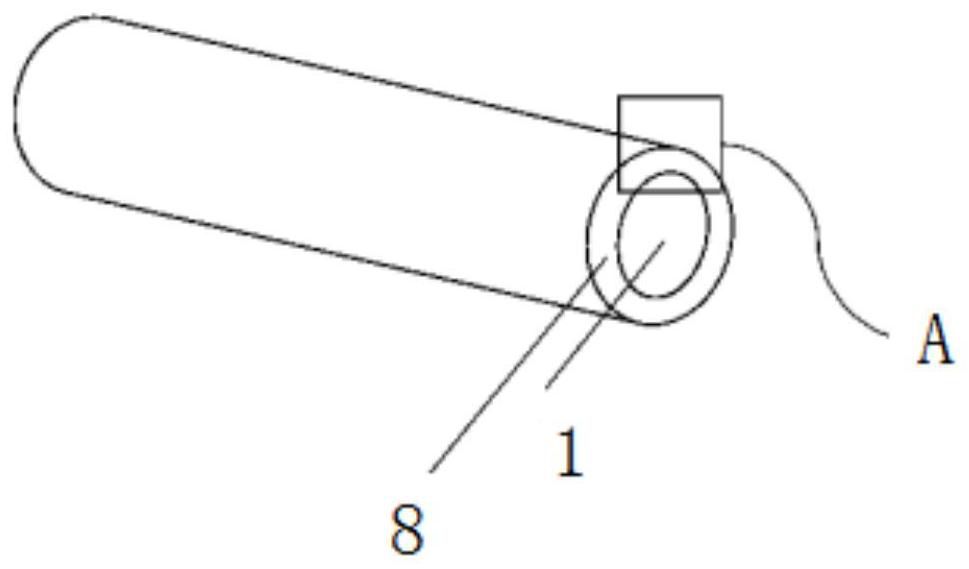

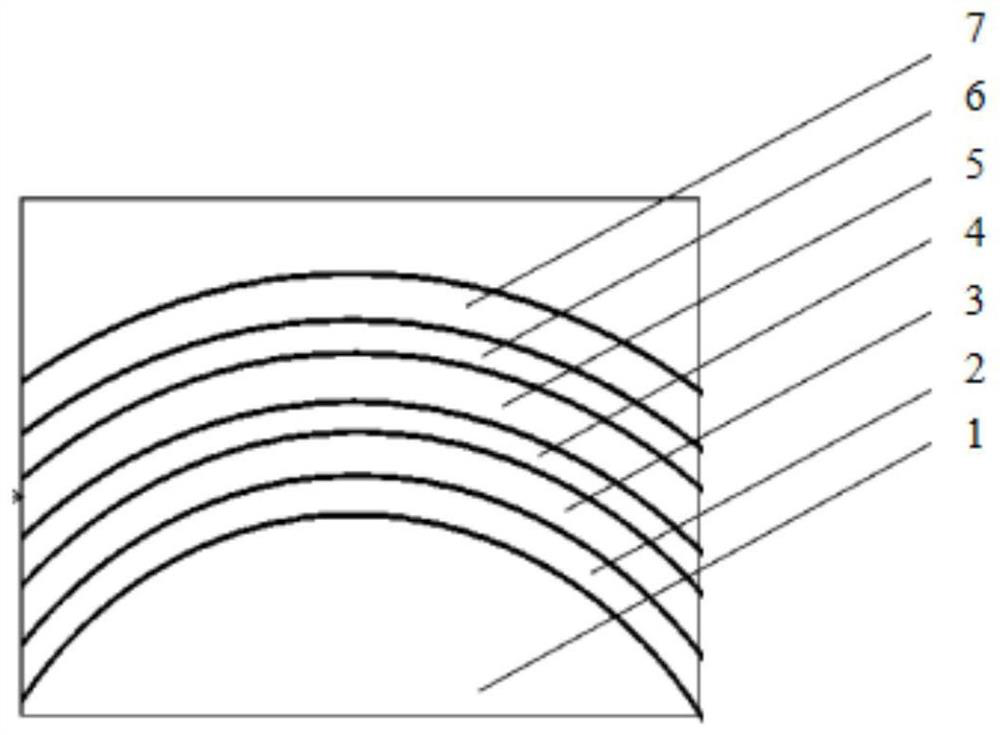

Preparation method of hollow fiber nanofiltration membrane

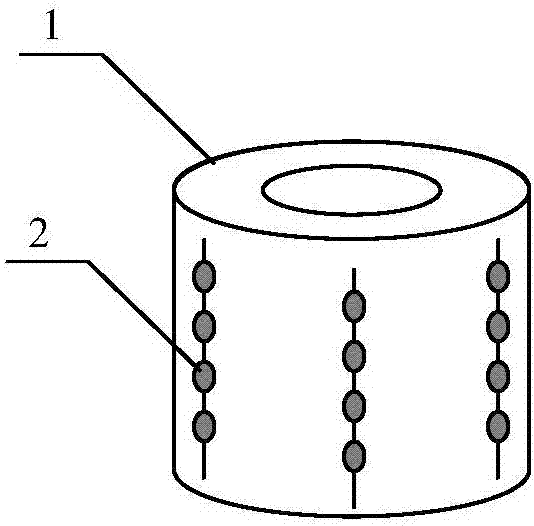

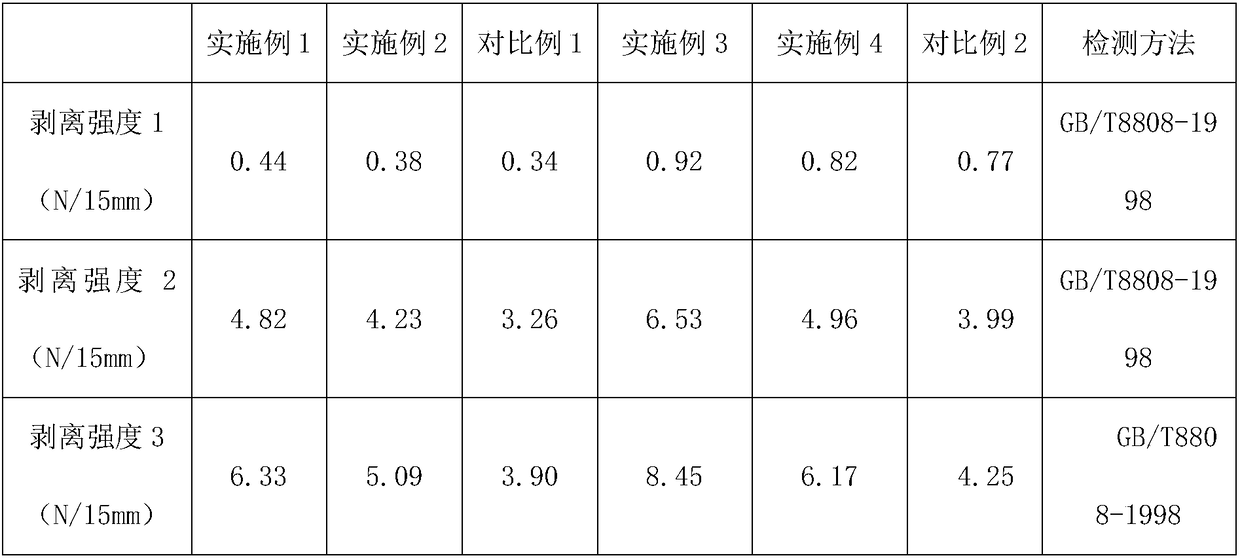

The invention relates to a preparation method of an anti-pollution and high-strength hollow fiber nanofiltration membrane. The technical solution of the present invention is to design a new spinning process (see Figure 1 and Figure 2), which uses polyethersulfone (PES), sulfonated polyethersulfone (SPES) or a blend of the two As the body material, the electrospinning technology is combined with the traditional non-solvent phase inversion spinning process. When the hollow fiber casting solution is extruded from the spinneret, the solution ejected from the electrospinning needle just enters the hollow fiber membrane wall. The two fall into the coagulation bath together to undergo phase inversion, and after rinsing, winding and other processes, a hollow fiber nanofiltration membrane with functionalized beaded fibers or superfine fiber bundles as reinforcements is obtained. Multiple beaded fibers or superfine fiber bundles form reinforcing ribs firmly embedded in the hollow fiber nanofiltration membrane (see Figure 3, Figure 4), which is difficult to peel off. The reinforcing rib is a high-strength resin mixed with inorganic particles, which endows the hollow fiber nanofiltration membrane with Higher strength and stain resistance. The process of the invention is simple and advanced, and is suitable for large-scale production of hollow fiber membrane plants.

Owner:上海健水源新材料科技有限公司

Digital pre-coating film and preparation method thereof

InactiveCN109337598AImprove liquidityImprove adhesionFilm/foil adhesive primer layersMacromolecular adhesive additivesPolyesterPolypropylene

The invention discloses a digital pre-coating film which comprises a hot melt adhesive layer, a primer coating layer and a substrate film layer which are arranged in sequence, wherein the hot melt adhesive layer is a mixture of an ethylene-vinyl acetate polymer and a tackifier; the content of vinyl acetate is 28wt%; the primer coating layer is polyethyleneimine; the substrate film layer is a biaxially oriented polypropylene film or a biaxially oriented polyester film. The digital pre-coating film has the benefits that the flowability of the ethylene-vinyl acetate polymer is improved by regulating the content of the vinyl acetate in the ethylene-vinyl acetate polymer, meanwhile, the softening point of the ethylene-vinyl acetate polymer is reduced, and the adhesion property of the ethylene-vinyl acetate polymer is improved; the tackifier is added into the hot melt adhesive layer, so that the wetting capability and the adhesion property of a hot melt adhesive to a substrate can be improved through the tackifier, and furthermore, the bonding strength of the pre-coating film can be improved.

Owner:ANHUI GUOFENG PLASTIC

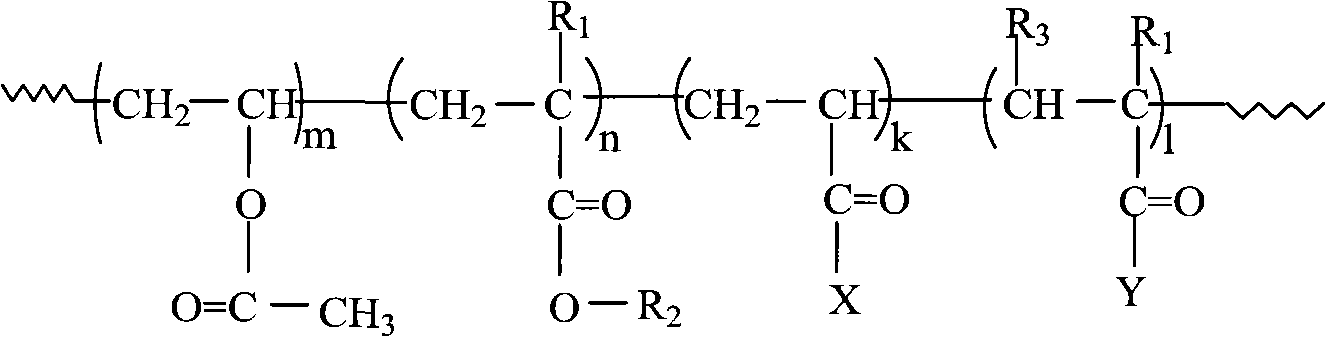

Preparation method of static loaded multi-coating yarn or fabric material

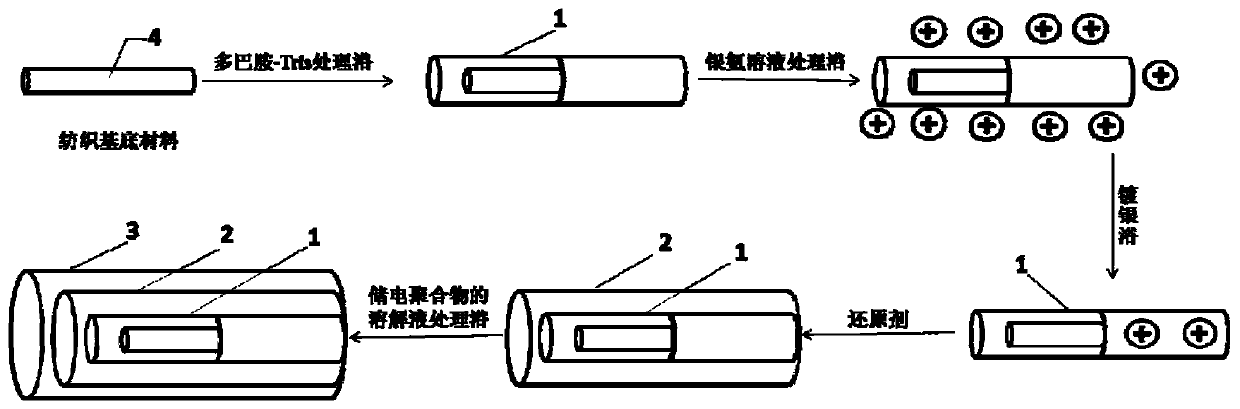

The invention discloses a preparation method of a static loaded multi-coating yarn or fabric material. The preparation method is characterized by including the following steps that 1), a yarn or fabric substrate material is put in a dopamine treatment bath to be treated, the material is washed and dried after being treated, and the yarn or fabric substrate material with a poly-dopamine binding layer is obtained; 2), the yarn or fabric substrate material with the poly-dopamine binding layer is put in a silver ammonia solution, a reducing agent solution is dropwise added into the silver ammoniasolution to be treated, the material is washed and dried after being treated, and the yarn or fabric substrate material with the binding layer and an electric conductance layer is obtained; 3), the yarn or fabric substrate material with the binding layer and the electric conductance layer is treated in a power storage polymer solution, then the redundant solution is removed through a roller, the material is dried, and the yarn or fabric substrate material with the binding layer, the electric conductance layer and a power storage layer is obtained. On the basis of the basic decorating and beautifying functions of textiles, the additional functions of the textiles are further improved, and functionalization development of the textiles can be promoted.

Owner:DONGHUA UNIV

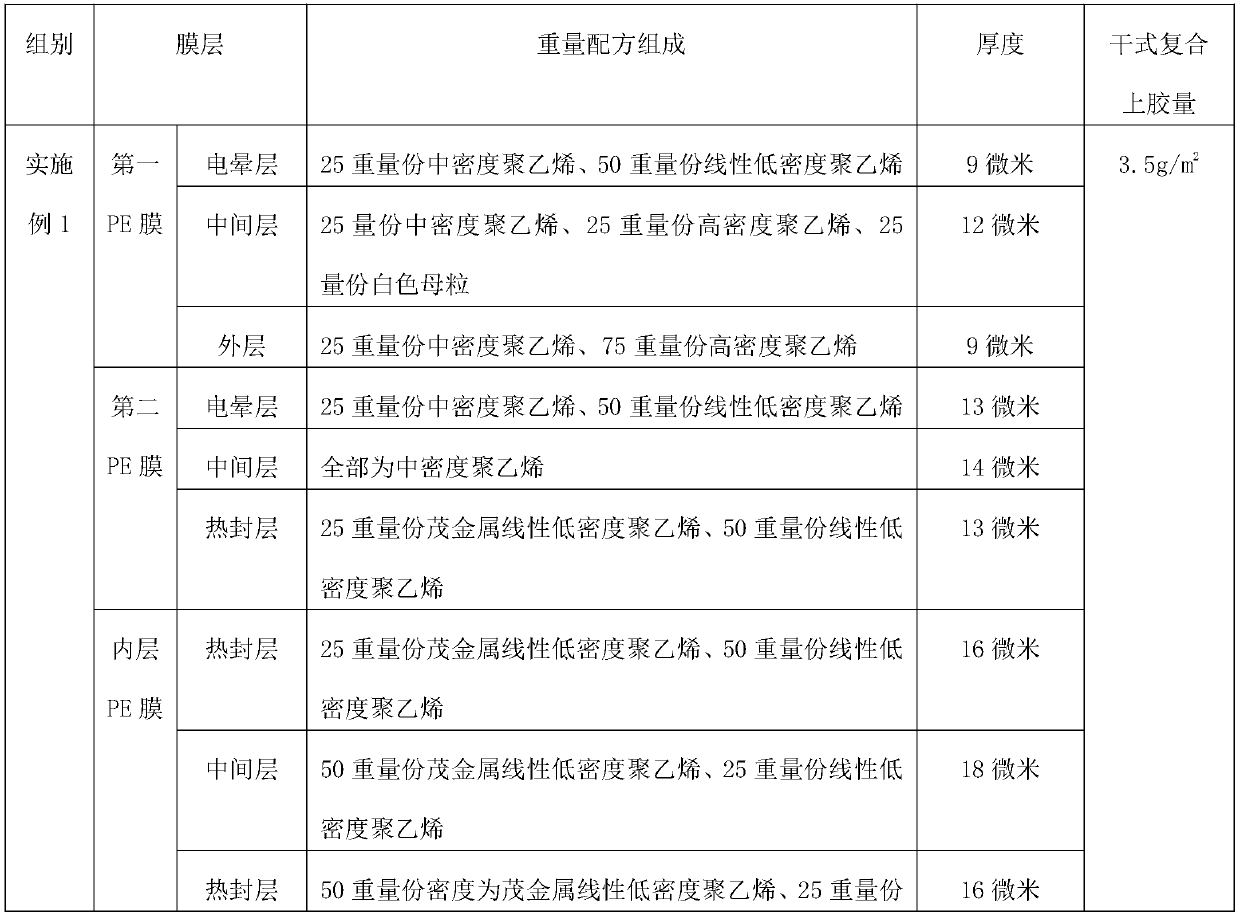

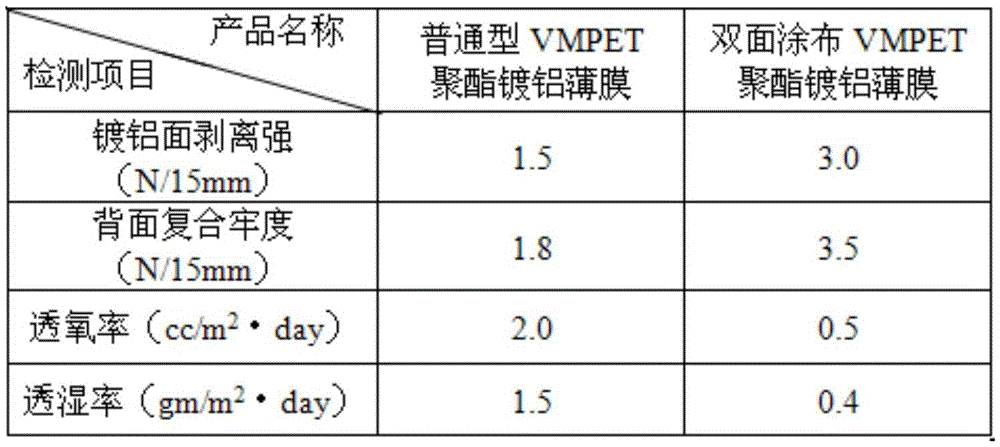

Milk machine aseptic packaging bag and production process thereof

ActiveCN110979956AGood flexibilityReduce heat sealing temperatureBagsSacksBiotechnologyAdhesive glue

The invention relates to a milk machine aseptic packaging bag. The packaging bag is composed of an outer layer composite film and an inner layer PE film, wherein the outer layer composite film and theinner layer PE film are superposed, then the periphery of the outer layer composite film and the inner layer PE film are heat-sealed, and an air interlayer is formed between the outer layer compositefilm and the inner layer PE film. The formula of a first PE film, a second PE film and the inner layer PE film is optimally designed, the glue with good toughness is selected and used, after the produced outer composite film and the inner layer PE film are used for bagging, the heat sealing strength can reach 50N / 15mm, after the bag is used for packaging 10 liters of liquid milk, the bag can resist positive pressure of 65kg and cannot break after dropping from a 1meter high place, and the defective rate is reduced from 0.1% to 0.05%.

Owner:HUANGSHAN NOVEL

Thinned high-barrier liquid packaging film and manufacturing method thereof

InactiveCN100532219CImprove rigidityIncreasing the thicknessFlexible coversWrappersPolymer scienceHigh density

The invention relates to a thinned high-barrier liquid packaging film and its manufacturing method. The product comprises a polyethylene-based film, a polyvinyl alcohol high-barrier layer, a composite adhesive layer and a polyethylene film protective layer from bottom to top, wherein the The polyethylene-based film includes an outer layer, a middle layer and an inner layer, wherein the outer layer and the middle layer contain at least one of medium-density polyethylene or high-density polyethylene; its manufacturing method includes: preparation of the polyethylene-based film; polyvinyl alcohol coating Preparation of cloth liquid; preparation of polyethylene film protective layer; coating and compounding, which include diluting polyvinyl alcohol coating liquid, coating the diluted polyvinyl alcohol coating liquid on the outer layer of polyethylene base film to form polyvinyl alcohol coating liquid Vinyl alcohol high barrier layer, composite polyethylene film protective layer and polyvinyl alcohol coating layer; aging, cutting. The product of the invention has the advantages of thin thickness, good rigidity, high barrier property, environmental protection, convenient use, low cost and simple process.

Owner:马龙升

Fine processing method of fish oil

ActiveCN105907456AKeep active ingredientsReduce enzyme activityFatty-oils/fats refiningFatty-oils/fats productionFish oilOil water

The invention relates to the field of the processing of fish products and discloses a fine processing method of fish oil. The fine processing method of fish oil comprises the following steps: a, washing fish guts, removing giblets, pounding the fish guts to prepare a blank material; b, adding the blank material into an enzymolysis solution containing an immobilized magnetic composite enzyme for carrying out enzymolysis, and recycling the immobilized magnetic composite enzyme by using a magnet after carrying out enzymolysis; c, filtering the enzymolysis solution to remove residues, then standing and layering, and separating to obtain upper fish oil and lower oil-water mixed solution; d, transferring the oil-water mixed solution to a foam separating column, aerating the bottom of the foam separating column, generating a foam layer on the upper layer of the oil-water mixed solution, and separating the foam layer from the liquid in time; e, carrying out centrifugal separation on the oil-water mixed solution to obtain upper fish oil; f, mixing the upper fish oil obtained in step c with the upper fish oil obtained in step e to prepare the fish oil. The processing method of the fish oil is simple in the process and high in the extraction efficiency and the extraction rate; the processed fish oil is high in purity, free of fishy smell and pure in color.

Owner:广州长生康生物科技有限公司

Preparation method of flexographic plate water-based ink

The invention discloses a preparation method of flexographic plate water-based ink. The flexographic plate water-based ink is prepared from the following raw materials of, in parts by weight, 30-35% of waterborne epoxy resin acrylate emulsion, 20-25% of organic pigments, 10-15% of ethyl alcohol, 22-25% of deionized water and 3-5% of relevant assistant, wherein waterborne epoxy resin acrylate emulsion is prepared by adopting an emulsion polymerization method, that is, 5-6% of epoxy resin and acrylate emulsion are organically combined; and the relevant assistant is prepared from the following components of, in parts by weight, 0.5-1% of antifoaming agent, 1.5-2% of waterborne film-forming agent, 0.5-1% of dispersing agent, 0.4% of cross-linking agent and 0.6-0.8% of pH stabilizer. The flexographic plate water-based ink is safe and environmentally friendly, epoxy resin is utilized to modify acrylate emulsion, the emulsion polymerization method is adopted to organically comine 5-6% of epoxy resin and acrylate emulsion to prepare waterborne epoxy resin acrylate emulsion, and the compound fastness and water resistance of the flexographic plate water-based ink can be improved.

Owner:JIANGSU LECAI PRINTING MATERIAL

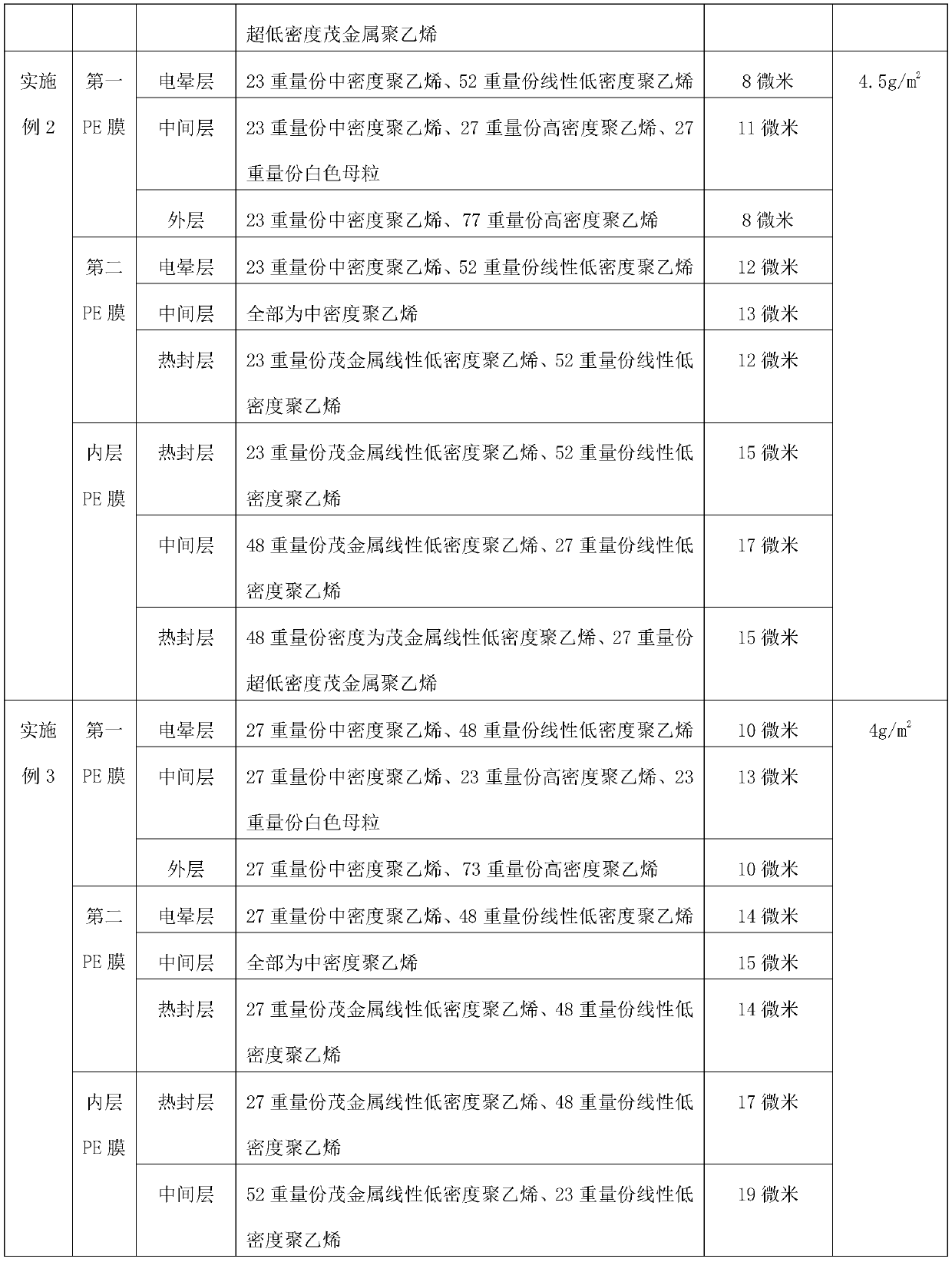

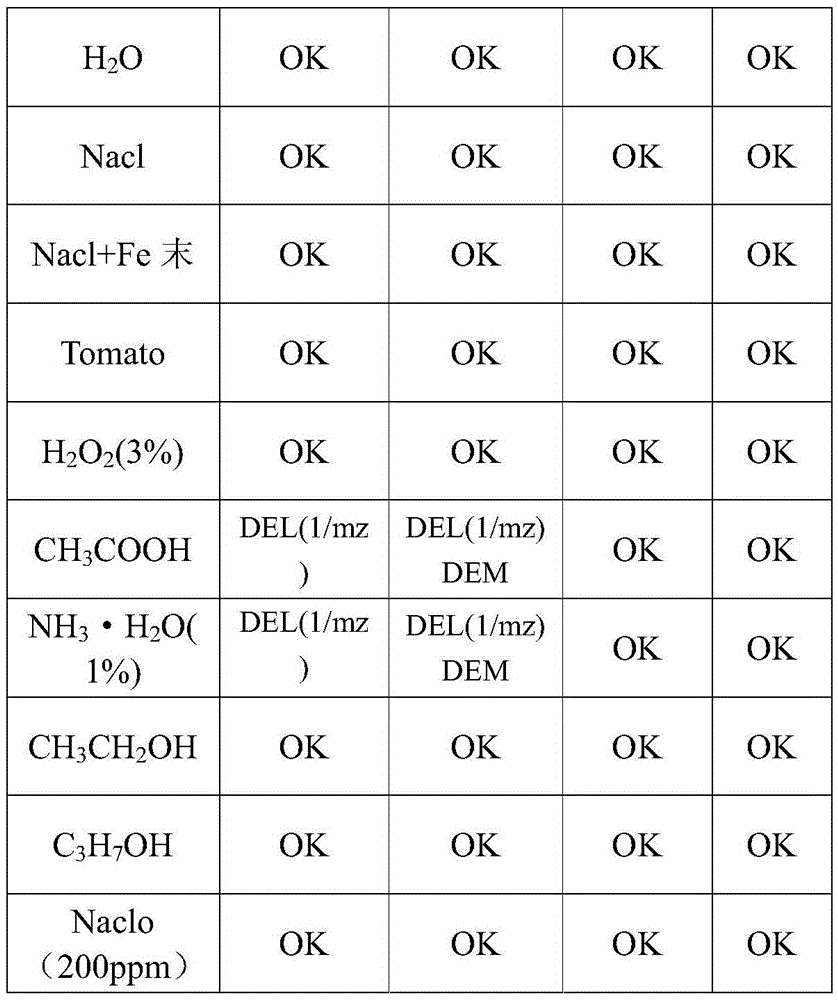

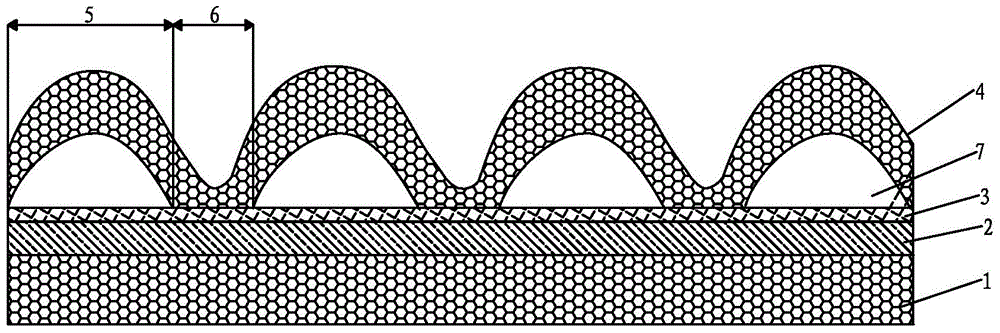

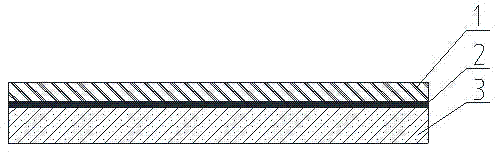

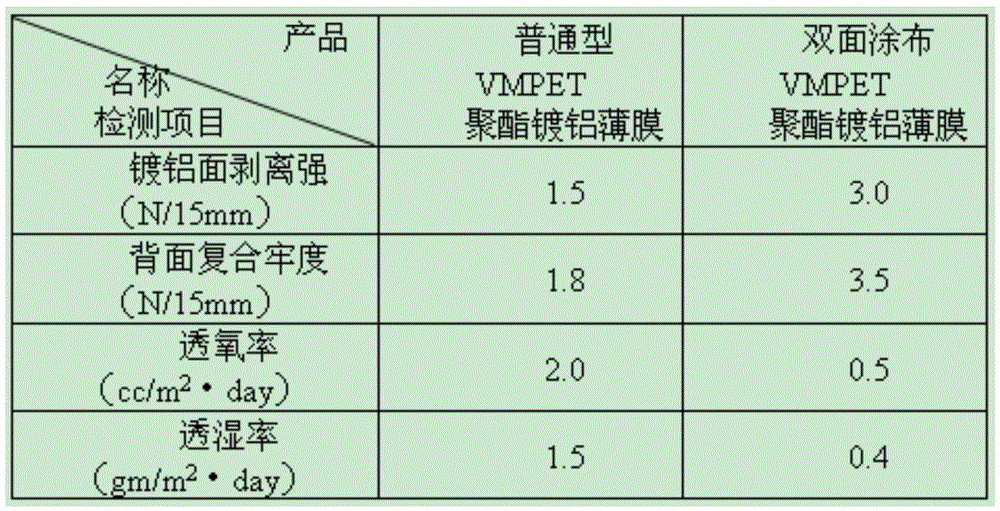

High temperature-resistant and anti-aging two-side coated polyester aluminized film and production method thereof

The invention discloses a high temperature-resistant and anti-aging two-side coated polyester aluminized film, which is prepared by double-side coating of a polyester substrate. Specifically, one side is coated with a PMMA composite coating, and the other side is coated with a polyurethane composite coating, wherein the polyurethane composite coating is prepared from the following raw materials by weight part: 40-50 of a waterborne polyurethane emulsion, 3-5 of a polytetrafluoroethylene emulsion, 2-4 of rosin, 2-4 of acrylic acid, 2-4 of dimethyl silicone oil, 0.1-0.2 of turkey red oil, 2-4 of nano alumina, 1-2 of nano titanium dioxide, 0.2-0.4 of propyl gallate, and 40-50 of water. The aluminized film provided by the invention not only can effectively prevent adhesion phenomenon, has good barrier properties, high peel strength, good acid and alkali resistance, increases the compounding fastness on the back of the aluminized film, and has good use performance, but also has good high temperature resistance, anti-aging properties, long service life and high practical value.

Owner:安徽省通达新材料有限公司

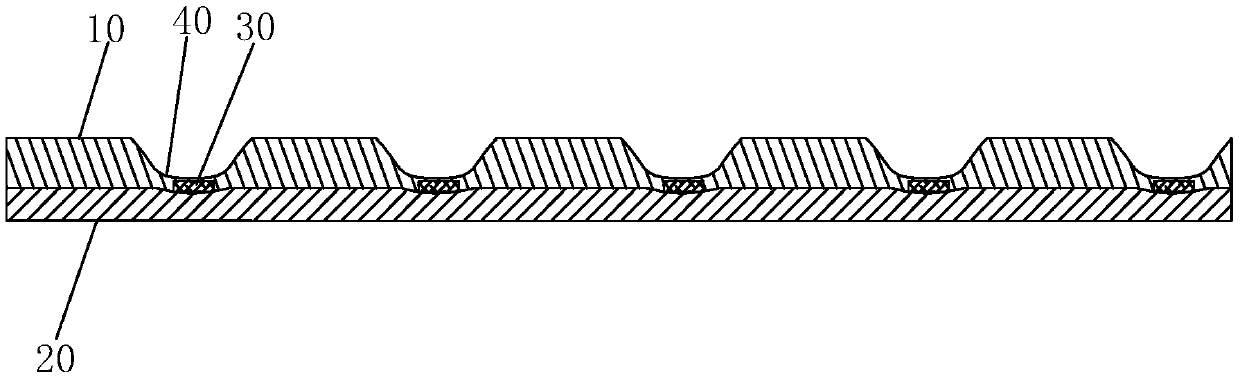

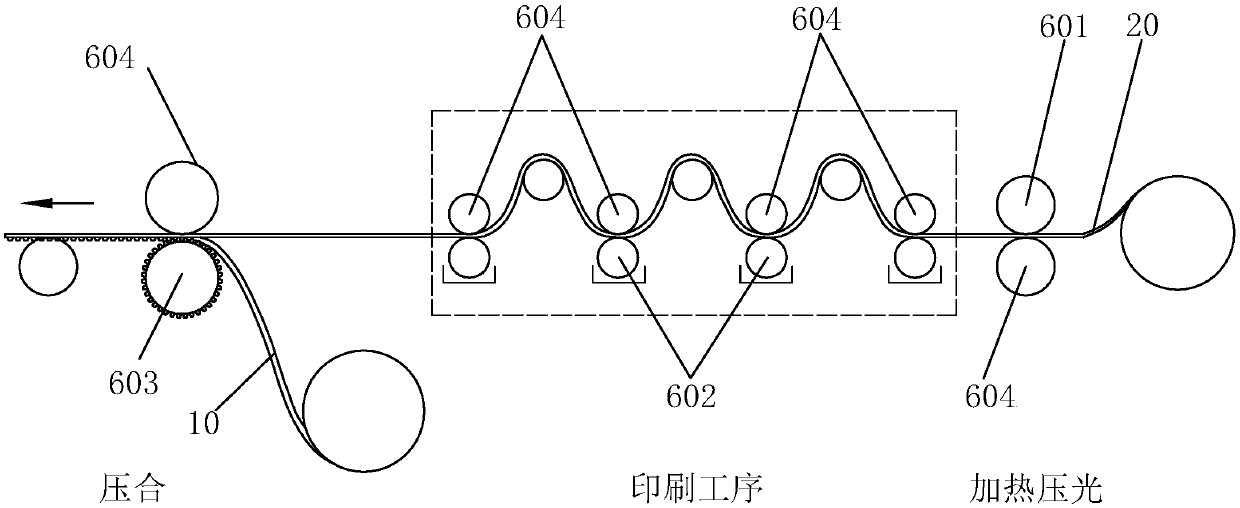

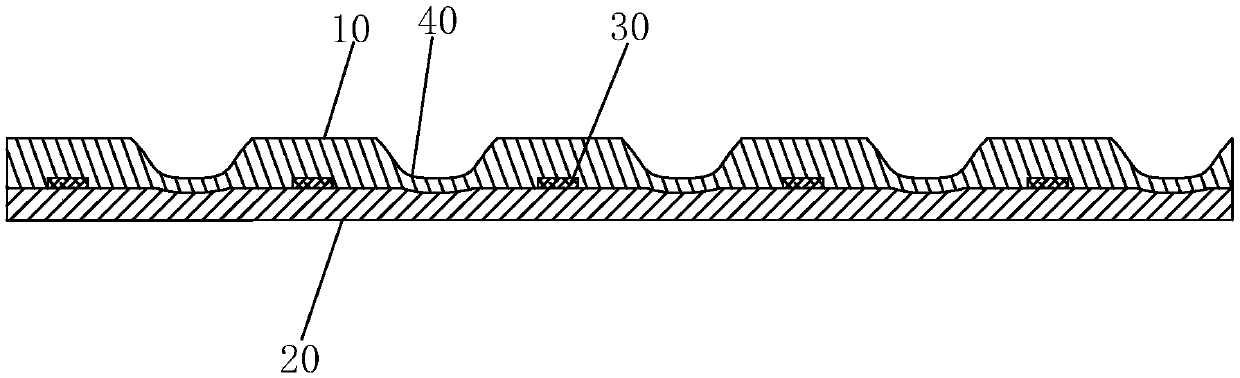

Magic tape and manufacturing method thereof

PendingCN106263305AImprove composite fastnessSolve the problem of air leakageHaberdasheryMagic teeWoven fabric

The invention discloses a magic tape and a manufacturing method thereof. The magic tape comprises an inner non-woven fabric layer, a surface non-woven fabric layer and a thin film interlayer, wherein an oil ink layer is printed on the thin film interlayer; the surface non-woven fabric layer and the inner non-woven fabric layer are hot-pressed and laminated on two surfaces of the thin film interlayer; a plurality of air cushion areas and fixed areas are formed between the surface non-woven fabric layer and the thin film interlayer; and each fixed area is located between every two adjacent air cushion areas. According to the magic tape disclosed by the invention, the three layers of materials are molded and combined through hot-pressing, so that the magic tape is lower in using temperature, higher in speed, softer and higher in combining fastness; oil ink can be printed on the thin film layer by virtue of normal equipment, so that a printing effect is fuller and clearer and the utilization rate of the oil ink is reduced, and subsequently, overall manufacturing cost is reduced; and meanwhile, properties are improved and efficiency is improved.

Owner:科思达(厦门)卫生制品有限公司

Polyester composite film applied to extrusion coating type packaging bags and preparation method of polyester composite film

InactiveCN104290422AImprove composite fastnessLess raw material consumptionSynthetic resin layered productsHigh-density polyethyleneAqueous solution

The invention discloses a polyester composite film applied to extrusion coating type packaging bags. The polyester composite film comprises a base material layer, a cross-linking agent layer and a hot melt glue layer, wherein the base material layer is integrally laminated with the hot melt glue layer by virtue of the cross-linking agent layer; the base material layer is made of a biaxially oriented polyester film; the cross-linking agent layer is made of an aqueous prime coating and curing cross-linking agent; the hot melt glue layer is made of high-density polyethylene; the aqueous prime coating and curing cross-linking agent is an aqueous solution with the pH value being 8-11; the effective component of the aqueous prime coating and curing cross-linking agent is polyethyleneimine with the molecular weight being 7500-10000; the content of polyethyleneimine in the mass of the aqueous prime coating and curing cross-linking agent is 1-5%. Hot melt layers formed by the biaxially oriented polyester film and the high-density polyethylene are laminated as a whole body by virtue of the cross-linking agent layer, so that the compounding fastness of the hot melt layers cannot be stripped and can be greater than or equal to 4.0N per 15mm; the polyester composite film is low in raw material consumption and low in production cost.

Owner:ANHUI GUOFENG PLASTIC

Primer-free double-faced adhesive tape layer polypropylene pre-coated film and preparation method thereof

InactiveCN111690330AAvoid harmHarm reductionNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePlasticizer

The invention discloses a primer-free double-faced adhesive tape layer polypropylene pre-coated film and a preparation method thereof. The pre-coated film comprises a first hot melt adhesive layer, abase material film layer and a second hot melt adhesive layer which are arranged in sequence. Raw materials of the first hot melt adhesive layer and the second hot melt adhesive layer comprise an ethylene-vinyl acetate polymer, an antioxidant, a plasticizer and a tackifier, and the base material film layer is a biaxially oriented polypropylene film. The primer-free pre-coated film prepared by theinvention can be used for well bonding two materials with different properties, and has the advantages of high bonding composite fastness, stable product performance after bonding, no cracking and nodemolding.

Owner:ANHUI GUOFENG PLASTIC

Low temperature resistance dual-surface coating polyester aluminum plating film and production method thereof

InactiveCN105462422AHigh peel strengthHigh utility valuePolyurea/polyurethane coatingsEpoxyPolyester

The invention discloses a low temperature resistance dual-surface coating polyester aluminum laminated film, which is made from polyester base materials by coating on two surfaces, wherein one surface is coated with a polymethyl methacrylate (PMMA) composite coating, the other surface is coated with a polyurethane composite coating, the polyurethane composite coating is made from raw materials with parts by weight: aqueous polyurethane emulsion 30-40, water-epoxy resin emulsion 10-15, glycerol 2-4, rosins 2-4, acyclic acids 2-4, epoxidized soybean oil 1-2, turkey red oil 0.3-0.5, nano talcum powder 2-4, nanometer titania 1-2 and water 40-50. The low temperature resistance dual-surface coating polyester aluminum plating film can effectively an adhesion phenomenon, is excellent in barrier property and high in peel strength, has excellent acid and alkali resistance, improves compound fastness of the back surface of aluminum laminated films, is excellent in use performance, has excellent low temperature resistance simultaneously, is suitable to be used in low temperature cold environment, and is wide in appliance range and high in practical value.

Owner:ANHUI TIANLI CENT ALUMINUM CO LTD

Adhesive for cable shielding film and preparation method thereof

InactiveCN102153983BWith continuous stretch aluminumNo crackingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses an adhesive for a cable shielding film and a preparation method thereof and belongs to the field of adhesive manufacture. The adhesive is synthesized by using polyester polyol, toluene diisocynate, an organic solvent and gamma-epoxy propoxy propyl triethoxysilane as the raw materials through performing a synthetic reaction on the raw materials and has solid content of 65 percent to 75 percent, viscosity of 2,000mPas to 3,500mPas and hydroxyl value of 10 to 20mgKOH / g, wherein the polyester polyol is prepared by using adipic acid, diethylene glycol, isophthalic acid, propanediol and trimethylolpropane as the raw materials through primary esterification, secondary esterification and condensation polymerization. The adhesive product has excellent flexibility and extensibility. Trimethylolpropane tri-functionality micromolecule alcohol is induced into the adhesive product. Due to the curing process, a polyurethane chain segment has higher crosslinking degree. The adhesive has the characteristics that the composite fastness is high, and no aluminium breaking and cracking phenomena is generated when the adhesive is stretched. The shielding effect of the cable shielding film is ensured.

Owner:NANTONG GAOMENG NEW MATERIAL

Woodenware polishing paint and preparation method thereof

Owner:CHANGSHU GUOHE NEW MATERIALS CO LTD

Machining technique of silver/copper double composite strip material

Owner:东莞市中一合金科技有限公司

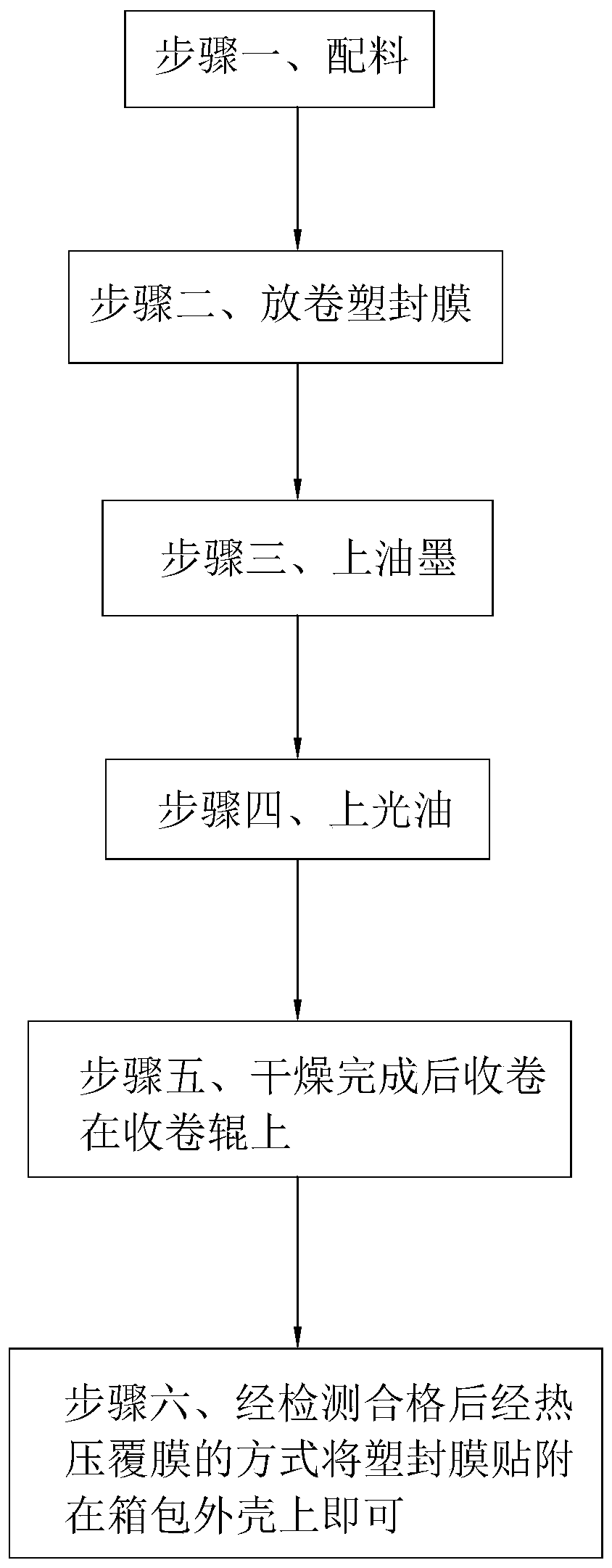

Bag printing technology adopting environment-friendly water-based ink

ActiveCN111251742AImprove wetting and levelingEasy to cleanDuplicating/marking methodsInksPrinting pressMechanical engineering

The invention discloses a bag printing technology adopting environment-friendly water-based ink and belongs to the technical field of printing. The technology is characterized by comprising the following operation steps that a laminating film is unreeled, and one side of the laminating film is coated with at least one environment-friendly water-based ink layer through a printer; a fan is adopted for initial acceleration drying for 5-30 minutes; the side, away from the laminating film, of the environment-friendly water-based ink layer continues to be coated with a gloss oil layer, the fan is adopted for secondary acceleration drying for 5-30 minutes, after drying is performed, the laminating film rolls a wind-up roll, and after the laminating film is qualified via detection, a hot press film covering mode is adopted for attaching the laminating film to a shell of a bag. According to the bag printing technology adopting environment-friendly water-based ink, the arrangement positions of the environment-friendly water-based ink and the laminating film in the technology are improved, so that the laminating film is coated with the environment-friendly water-based ink first and then adheres to the shell of the bag through the hot press film covering mode, the situation that the laminating film is separated from the shell of the bag is reduced, the connection strength between the laminating film and the shell of the bag is improved, and thus the bag has good hardness and wear and scratch resistance.

Owner:上海聿琪包装材料有限公司

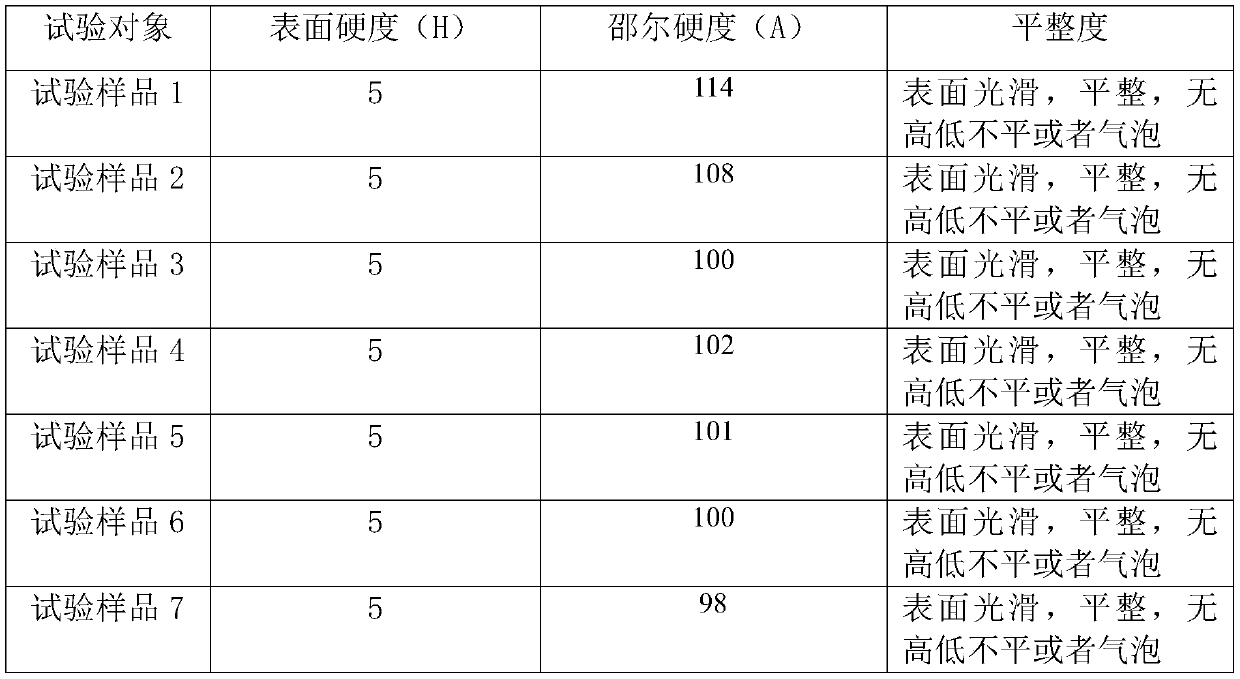

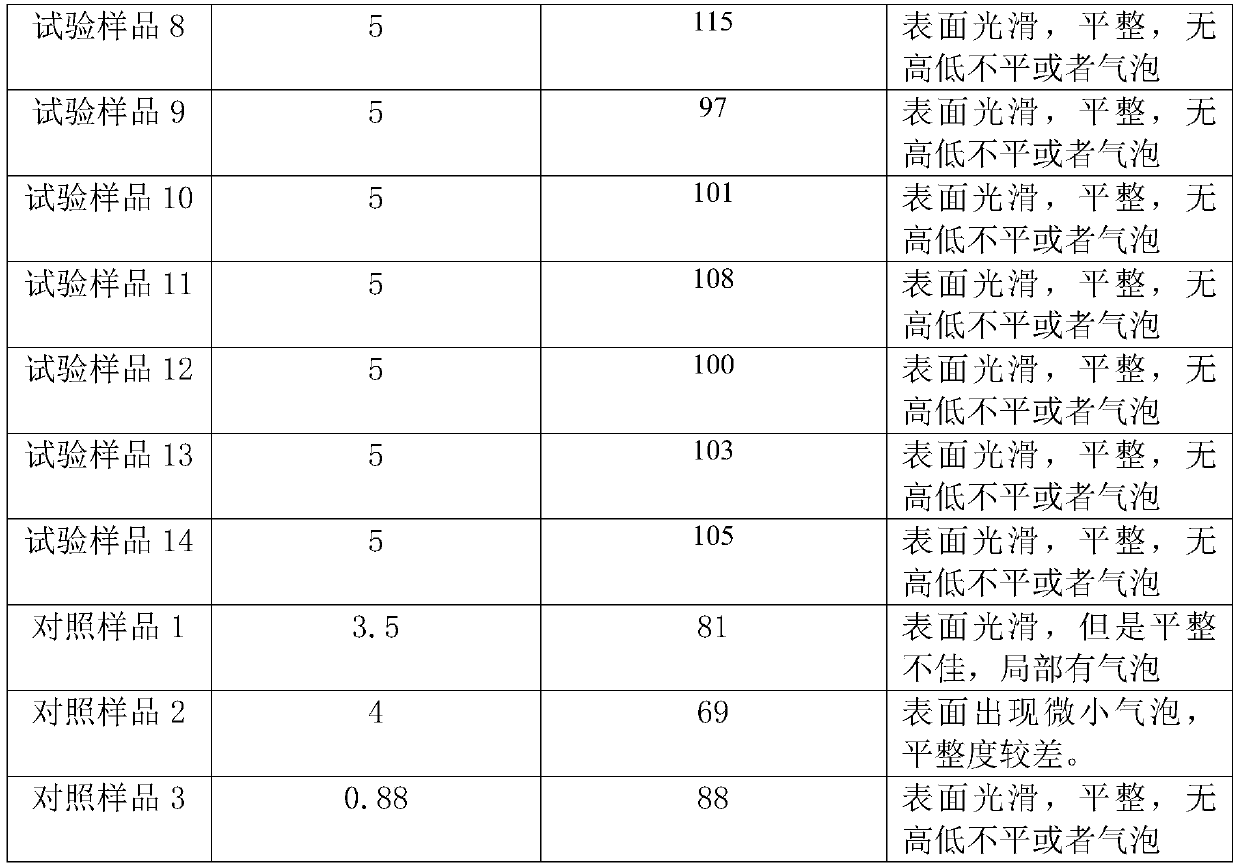

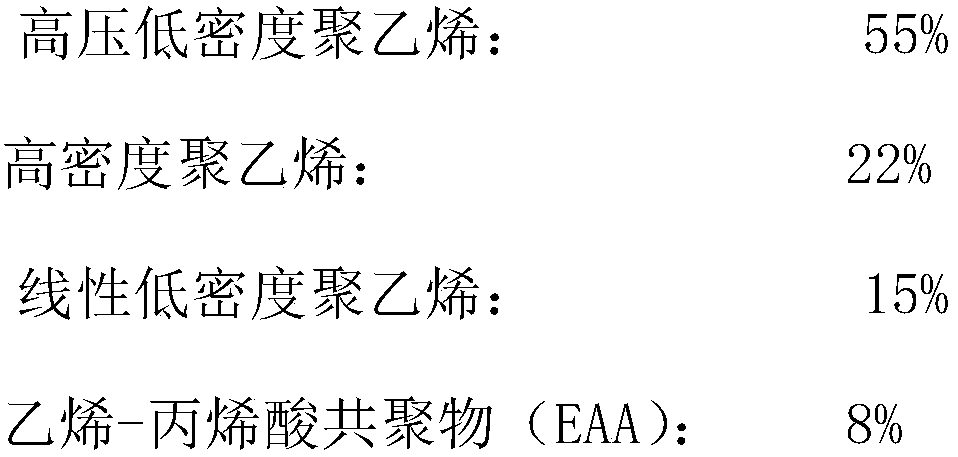

Two-way easy-to-tear film

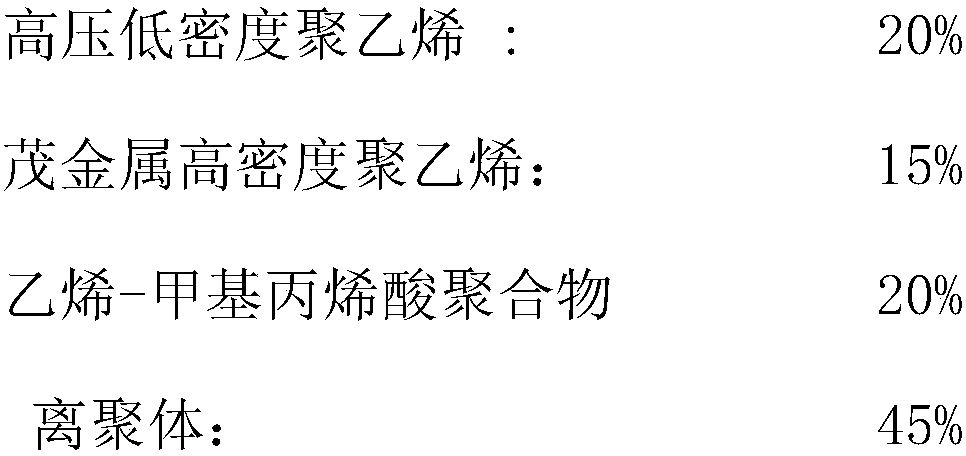

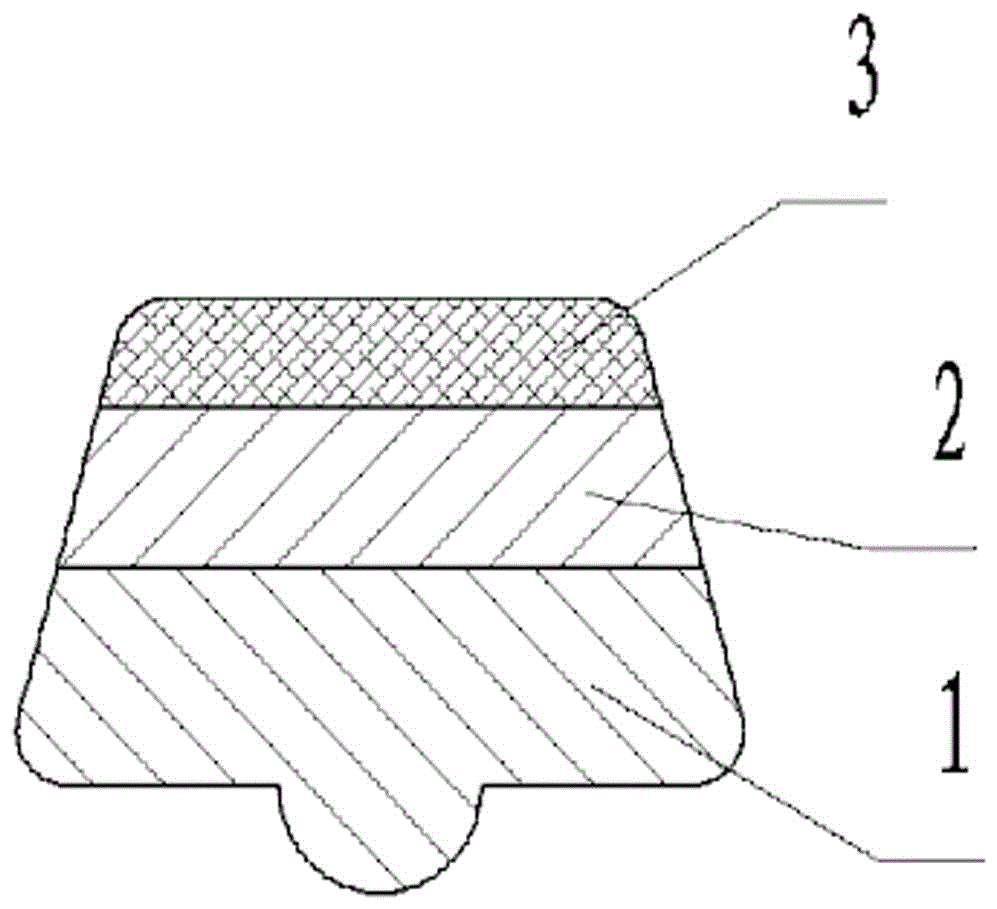

ActiveCN109648968AImprove experienceImprove composite fastnessSynthetic resin layered productsIonomerOctene

The invention discloses a two-way easy-to-tear film. The two-way easy-to-tear film is three layers, including an outer layer, a middle layer and an inner layer. The outer layer comprises high-pressurelow-density polyethylene, low-pressure high-density polyethylene, linear low-density polyethylene and an ethylene-acrylic copolymer; the middle layer includes low-density polyethylene, metallocene medium-density polyethylene, an ethylene-methacrylic acid copolymer, and an ionomer or ethylene-norborneol dilute copolymer; and the inner layer comprises high pressure low density polyethylene, metallocene low density polyethylene, linear low density polyethylene, an ethylene-octene copolymer and functional master batch. The two-way easy-to-tear film has characteristics of good compound fastness, good customer experience and low cost, and is easy to tear in straight line in two directions.

Owner:江门市华龙膜材股份有限公司

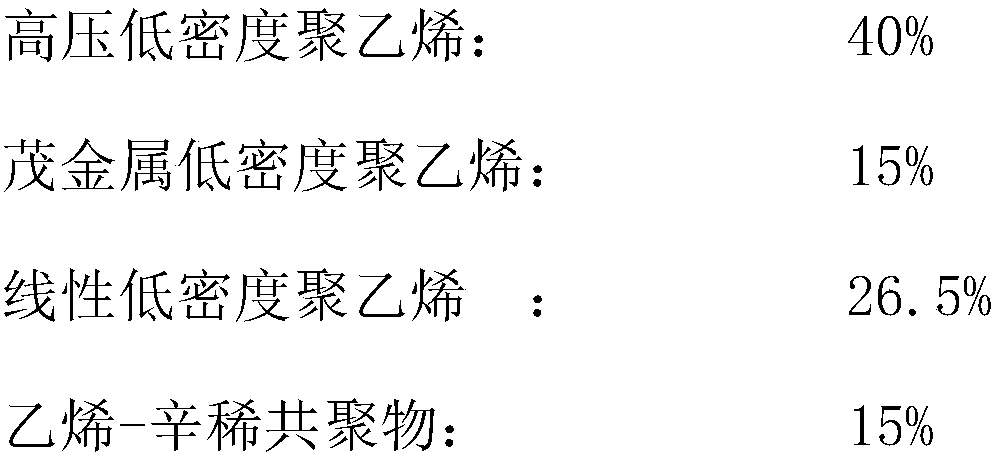

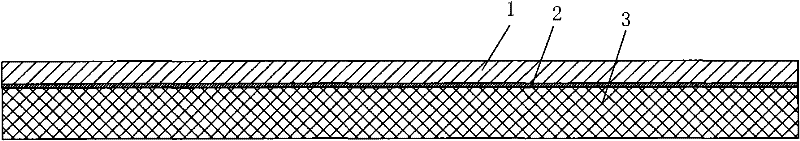

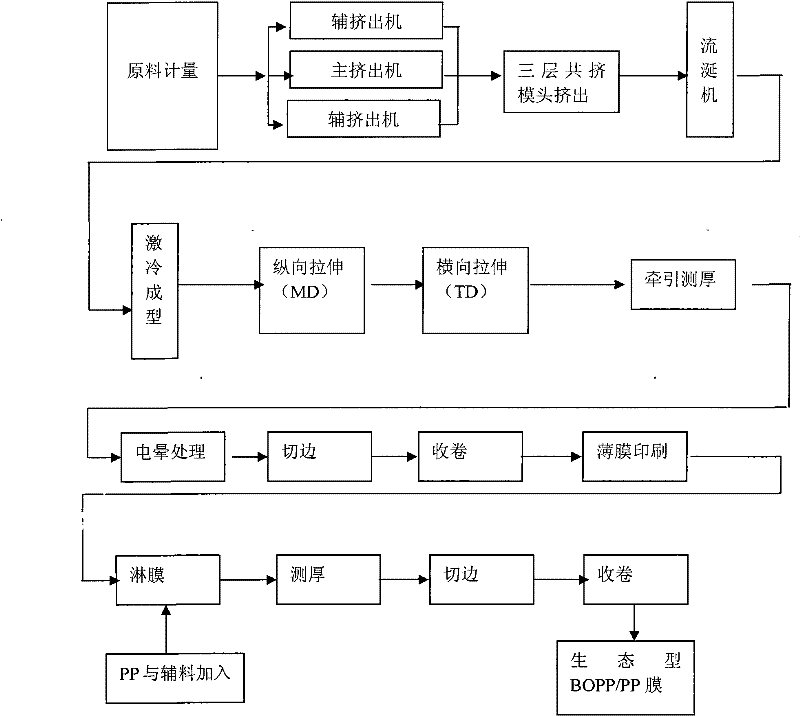

Ecological type BOPP/PP color printing food packaging film and preparation method thereof

InactiveCN101708788BEliminate hidden dangersImprove securityFlexible coversWrappersInter layerColor printing

Owner:ZHEJIANG GREAT SOUTHEAST PACKAGING

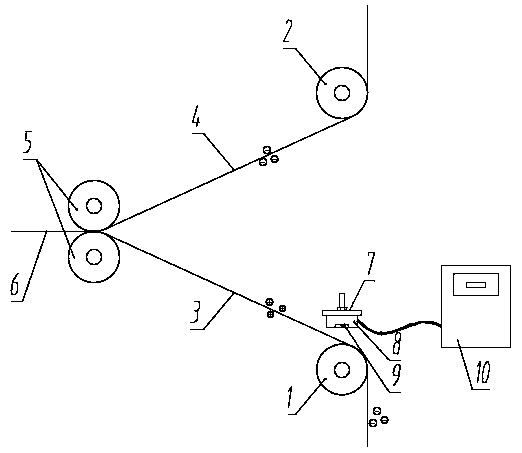

PVDC film electrostatic compounding device and compounding method

InactiveCN110901200AImprove product qualityImprove composite fastnessLamination ancillary operationsLaminationComposite filmThin membrane

The invention provides a PVDC film electrostatic compounding device and a compounding method, and solves the problems that bubbles easily appear in the existing compounding process and can affect thecompounding fastness. The compounding device comprises a frame, a discharge plate is arranged on the frame, a tip is arranged on the discharge plate, the tip faces a film A, and the discharge plate iselectrically connected to an electrostatic generator. According to the compounding method, the tip of the discharge plate faces the film A, the electrostatic generator provides high voltage for the discharge plate, the discharge plate enables the film A to generate positive charge, the positive charge on the film A and the negative charge on a film B attract each other during compounding, thus enhancing the compounding effect. The device and the method have the advantages that: the sparkless positive charge electrostatic generator is additionally arranged on one layer of film to endow the layer of film with positive charge, so that the compounded two layers of films can be firmly laminated under the attraction of positive and negative charges, thus improving the compounding fastness and the increasing the product quality of the composite film; the device is simple in structure and convenient to install, can be additionally installed on various compound machines, and the field application effect is good.

Owner:河南双汇投资发展股份有限公司

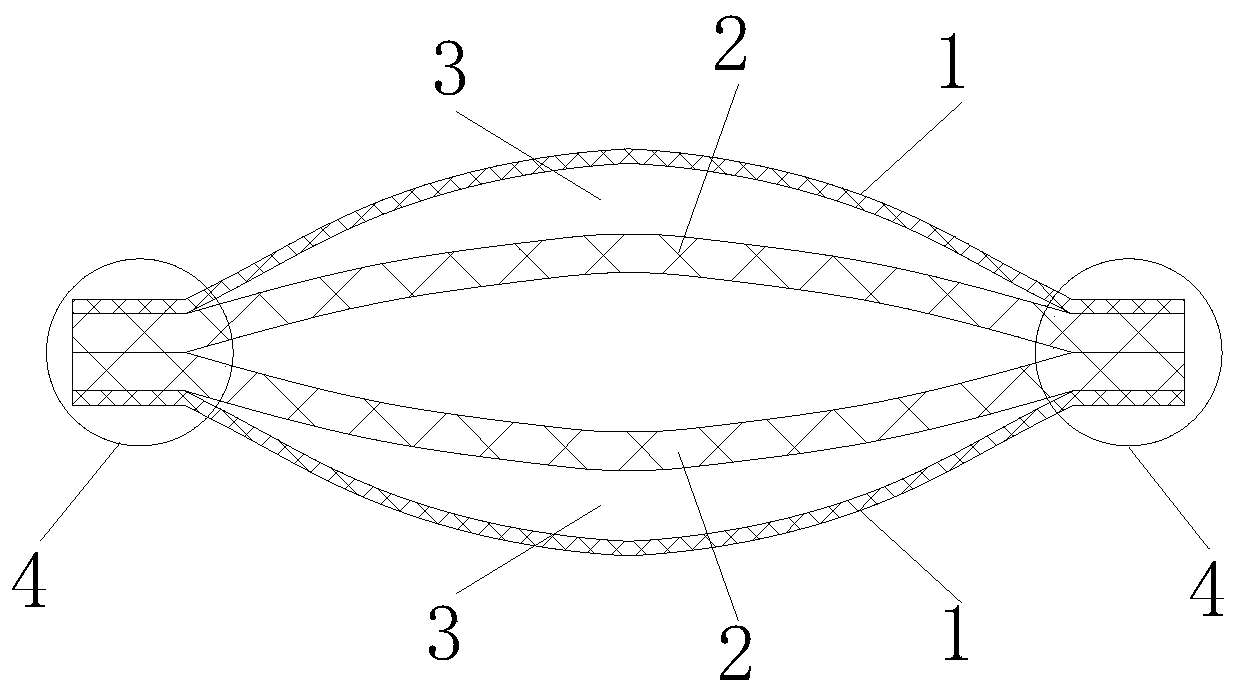

Yarn and fabric with electrostatic load characteristics

ActiveCN109610172BStable and uniform high voltage electrostatic loadIncrease load capacityVegetal fibresYarnDielectric layer

The invention belongs to the field of textile fabrics and provides yarns and fabrics with electrostatic load characteristics. The yarn with electrostatic load characteristics includes a yarn base and a multilayer film structure covering the surface of the yarn base, and the multilayer film structure includes at least one of a conductive layer and a dielectric layer. Fabrics prepared from this yarn can achieve stable and uniform high-voltage electrostatic loading, and maintain a long-lasting loading effect after being subjected to molding, installation, use and cleaning.

Owner:DONGHUA UNIV

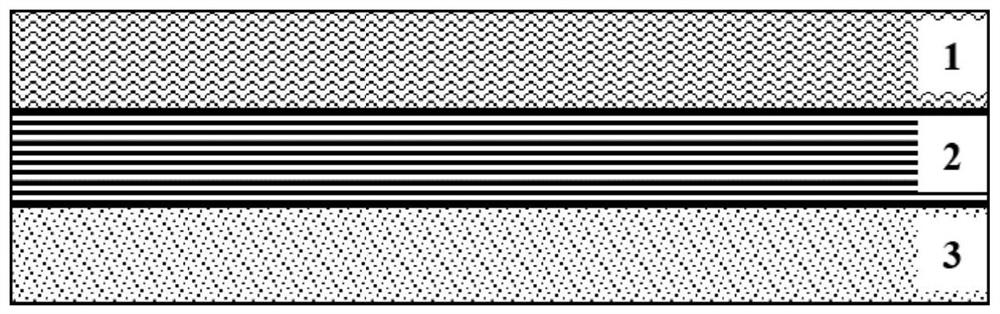

Composite non-woven fabric and printing pressing method thereof

PendingCN110027264AUniform clarityImprove composite fastnessLamination ancillary operationsSynthetic resin layered productsWoven fabricSurface layer

The invention relates to a composite non-woven fabric and a printing pressing method thereof, wherein the composite non-woven fabric comprises a non-woven fabric surface layer and a printing substratelayer, a plurality of ink regions are printed on the top surface of the printing substrate layer, and are arranged at intervals, the non-woven fabric surface layer is compounded on the top surface ofthe printing substrate layer, and forms pressing regions with the top surface of the printing substrate layer, and the pressing regions and the ink regions are overlapped each other. According to thepresent invention, the composite non-woven fabric can ensure the clarity uniformity of the patterns in the ink regions, is beautiful, and has the improved compounding fastness.

Owner:科思达(厦门)卫生制品有限公司

Polypropylene film for cold mounting composite film, preparation method of polypropylene film and cold mounting composite film

PendingCN114311898AReduce surface tensionEasy to unwindSynthetic resin layered productsFlat articlesPolymer scienceComposite film

The invention relates to a polypropylene film for a cold mounting composite film, a preparation method of the polypropylene film and the cold mounting composite film. The polypropylene film for the cold laminating composite film comprises a first surface layer, a core layer and a second surface layer which are sequentially arranged, the first surface layer comprises a polymethylpentene copolymer, the polymethylpentene copolymer is an olefin copolymer based on 4-methyl-1-pentene, the content of 4-methyl-1-pentene is 95-100 wt%, and the content of 4-methyl-1-pentene is 20-30 wt%. The surface tension of the first surface layer is less than 29mN / m, and the surface of the second surface layer is subjected to corona or flame treatment. The invention further provides a preparation method of the polypropylene film for the cold mounting composite film and the cold mounting composite film. The polypropylene film for the cold mounting composite film is easy to unroll, the preparation method is simple, and the prepared cold mounting composite film does not need release backing paper and is easy to unroll.

Owner:GUANGDONG DECRO PACKAGE FILMS +1

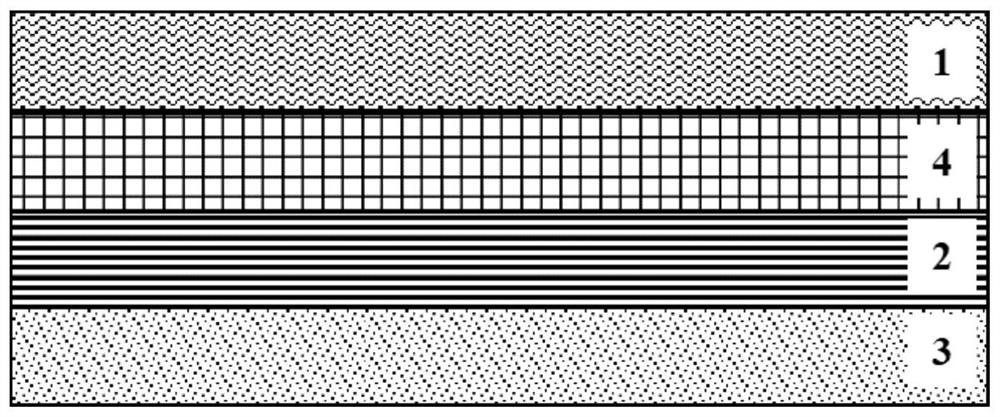

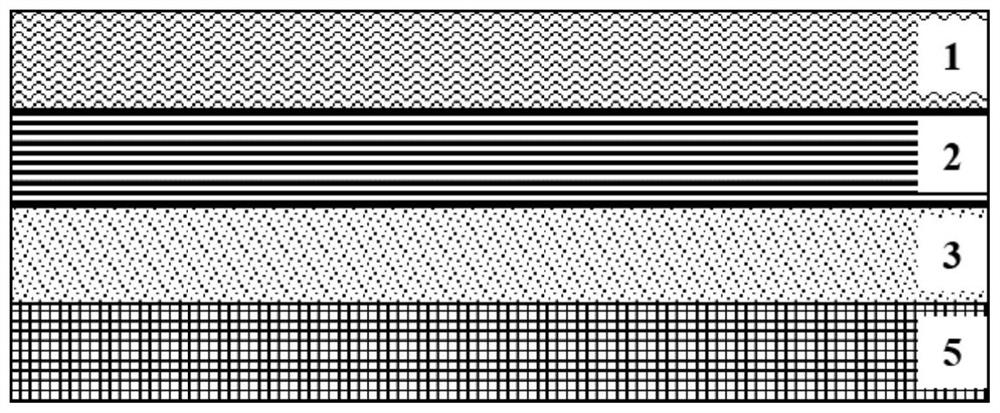

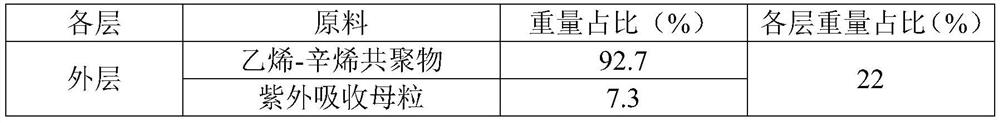

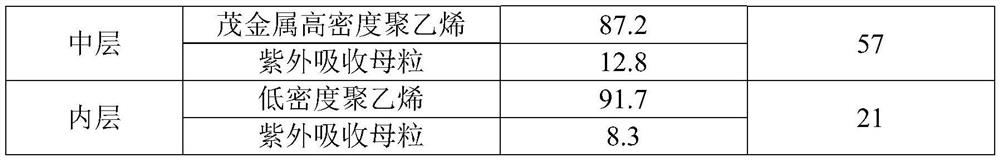

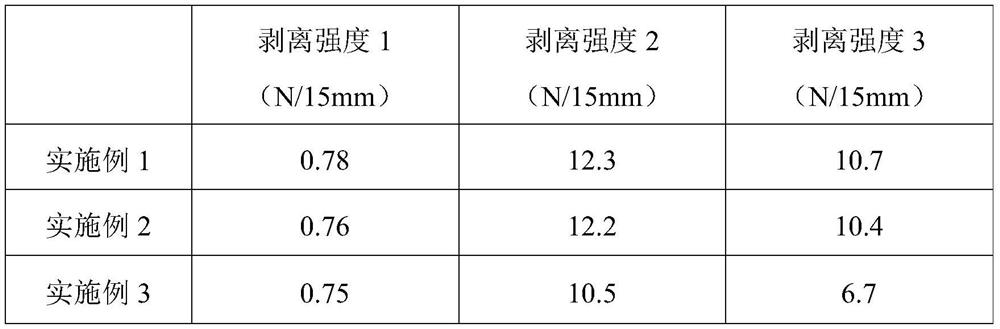

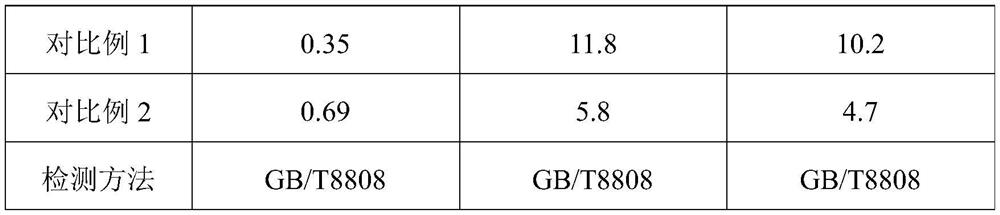

A solar cell backsheet film with high composite fastness

ActiveCN110948977BReduce the chance of delaminationAdhesivelySynthetic resin layered productsElectrical equipmentPolyolefinPhysical chemistry

The invention relates to a solar cell backboard film, which is composed of outer layer, middle layer and inner layer materials. The material of the outer layer is olefin copolymer, the material of the middle layer is metallocene polyolefin, and the material of the inner layer is polyolefin. Wherein the outer layer of the solar cell back sheet, between the middle layer and the inner layer material, between the inner layer material and the EVA layer of the solar cell back sheet, and between the outer layer material and the middle layer PET of the solar cell back sheet due to the synergistic effect. It has tight composite fastness, which minimizes the chance of delamination of solar cell backsheets. Moreover, the materials of the outer layer, the middle layer and the inner layer of the solar battery backplane film have strong intermolecular forces among each other, thereby improving the water resistance and water vapor corrosion resistance of the solar battery backplane film.

Owner:JIANGMEN PENGJIANG HUALONG PACKING MATERIAL

Preparation method of gold-containing three-layer micro-profile electrical contact material

ActiveCN104384186BAchieve precisionNo diffusionTemperature control deviceMetal rolling arrangementsElectricitySurface layer

Owner:CHONGQING CHUANYI AUTOMATION

Coating type BOPP pre-coating film capable of embossing and preparation method of coating type BOPP pre-coating film

PendingCN114736412AIncrease the number ofLower melting temperatureFilm/foil adhesivesMacromolecular adhesive additivesDiphenylmethanePolymer science

The invention discloses a coating type BOPP pre-coating film capable of embossing. The coating type BOPP pre-coating film comprises a base material layer, a hot melt adhesive layer and a coating layer which are arranged in sequence, the hot melt adhesive layer is prepared from the following raw materials: an ethylene-vinyl acetate polymer and N, N-4, 4-diphenylmethane type bismaleimide resin; the coating layer is prepared from a modified polyurethane solution, and the modified polyurethane solution is prepared by reacting the following raw materials in a solvent: a polyurethane prepolymer, dimethyl triphenyl ethane sulfonic acid isocyanate and maleic anhydride. The invention also discloses a preparation method of the pre-coating film. The technical problems that in the prior art, a common coating film is insufficient in binding force and compounding fastness and high in use temperature are solved, and the compounding fastness of the prepared pre-coating film and paper can be remarkably improved.

Owner:ANHUI GUOFENG PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com