Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "High pulping yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pulping and papermaking process through multiple-composition biological enzyme method

InactiveCN102345244AReduce consumptionImprove product qualityNon-fibrous pulp additionPaper/cardboardBlack liquorWastewater

The invention discloses a pulping and papermaking process through a multiple-composition biological enzyme method. The method is a biopulping method, which adopts a production process for preparing paper pulp through pulping and fermenting by using a multiple-composition biological enzyme method (phanerochaete, phanerochaete chrysosporium, xylanase, glucoamylase, yeast), adopts agricultural straws, rice and wheat straws, cotton stalks, rape stalks, reeds, bamboo, wood and the like as main raw materials, and comprises treatments of glass cutting, impurity removing, puffing, fermenting through multiple-composition biological enzyme, pulp washing, pulp selecting, defibrination and separation to form the pulp. According to the present invention, no black liquid is generated during the pulping process, the water from fermenting and pulping is recycled so as to achieve zero discharge of wastewater.

Owner:王凤忠

Method for preparing paper pulp by using biological enzyme

InactiveCN102978986AEasy to handleReduce energy consumptionCellulose material pulpingState of artFermentation

The invention relates to a preparation method of paper pulp, and further relates to a method for preparing the paper pulp through a biological enzyme method. The technical scheme is that the method comprises the following steps of: one, segment cutting; two, puffing; three, heat preservation fermentation; four, shoving; five, pulp washing; six, pulp selecting, wherein screened out coarse residues are put into the step three for fermentation again; seven, pulp grinding; and eight, screening, wherein the screened out pulp residues are put into the step seven for pulp grinding again. Compared with the prior art, the method has the advantages that the pulping and papermaking through the biological enzyme method has the characteristics of 'three highs and three lows' compared with the conventional process technology.

Owner:TIANJIN ZHIZHAN SCI & TECH

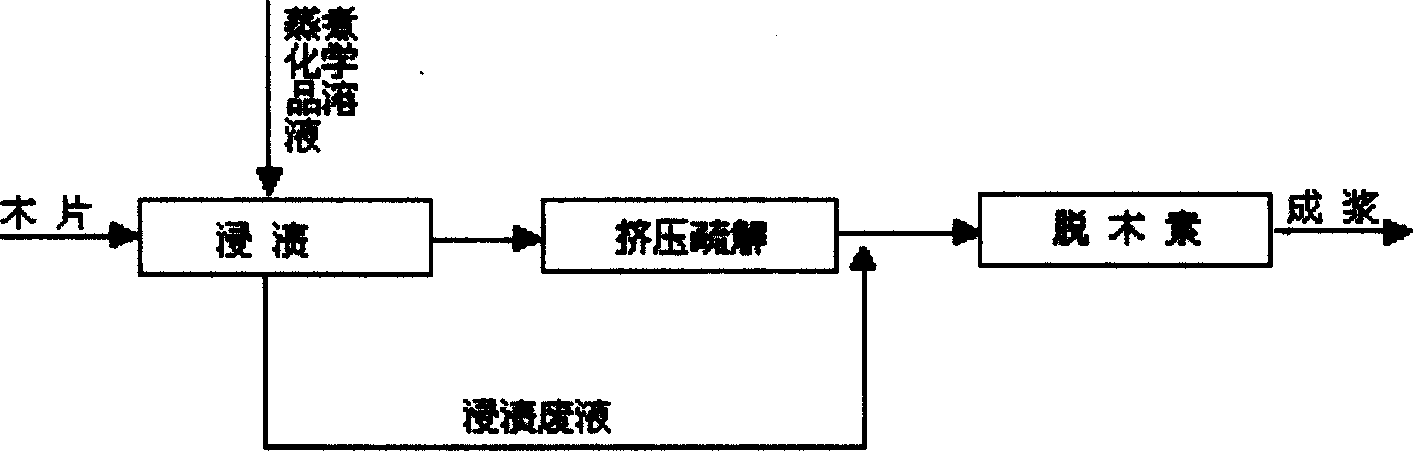

Method for producing chemical wood pulp

InactiveCN1563564AIncrease production capacityTake advantage ofCellulose material pulpingMaterials sciencePressed wood

This invention is a chemical wood pulp productive method. It contains following steps: 1) To soak, Put the thin piece wood plate into the soak liquid container, the soaking temperature is 50-90 deg.C. Soaking time is 15-50 minutes; the soak liquids use part or whole boiling liquid. 2) To relieve squeeze and press; relieve the pressed wood plate, the pressing ratio is 3-6:1. 3) To take-out lignin: put the pressing wood plate and its soak liquid into the boiler, boiling them to do the reaction of take-out lignin.

Owner:QILU UNIV OF TECH

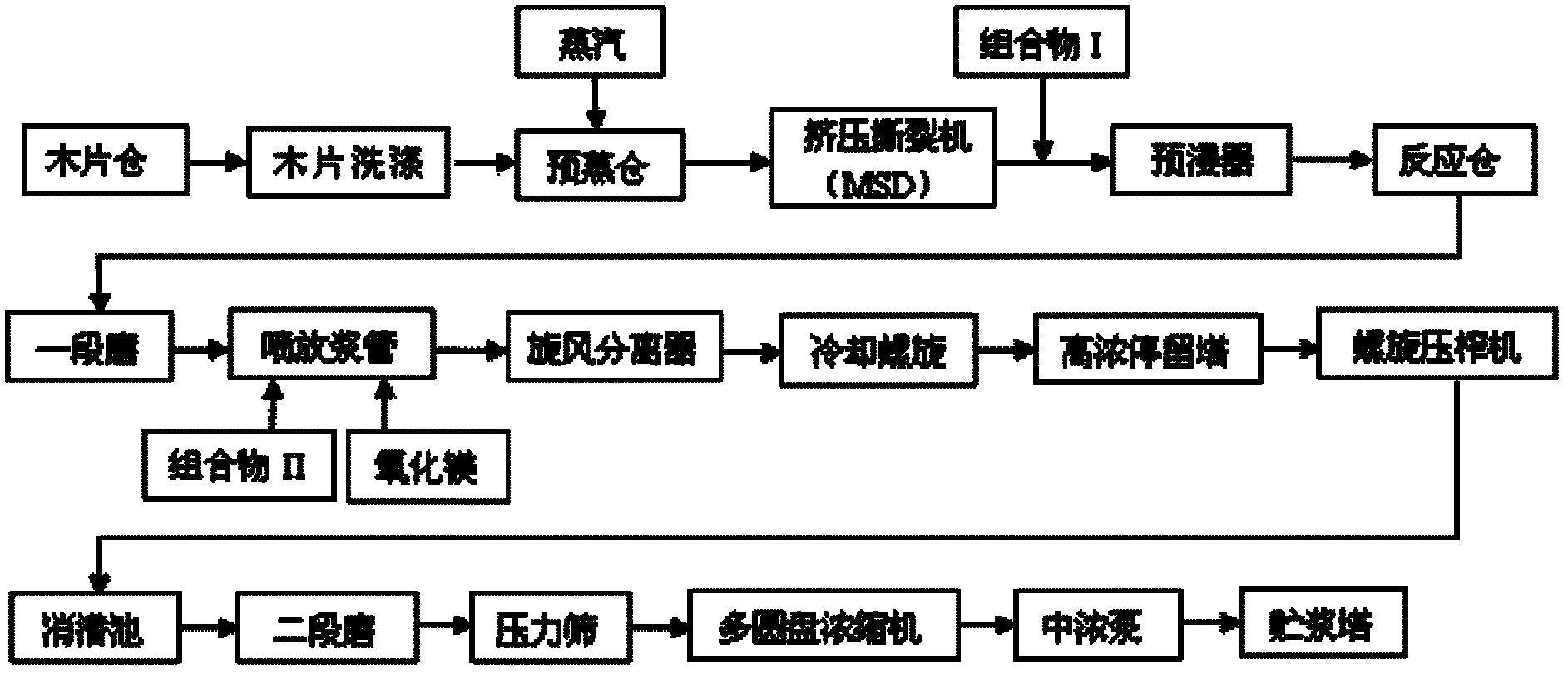

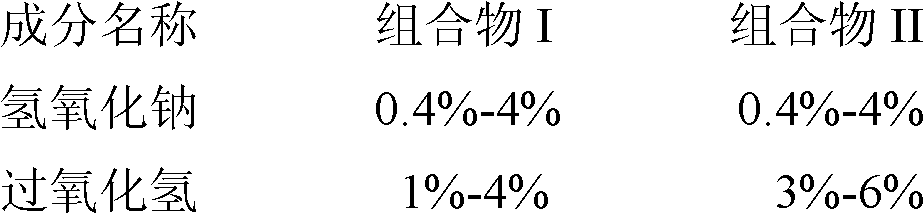

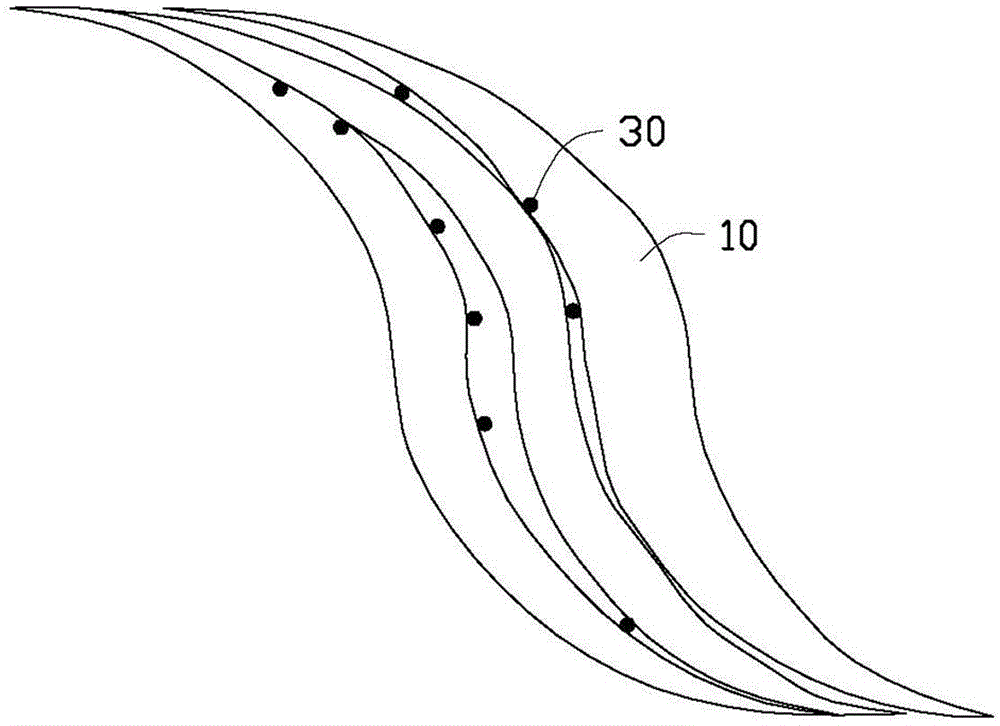

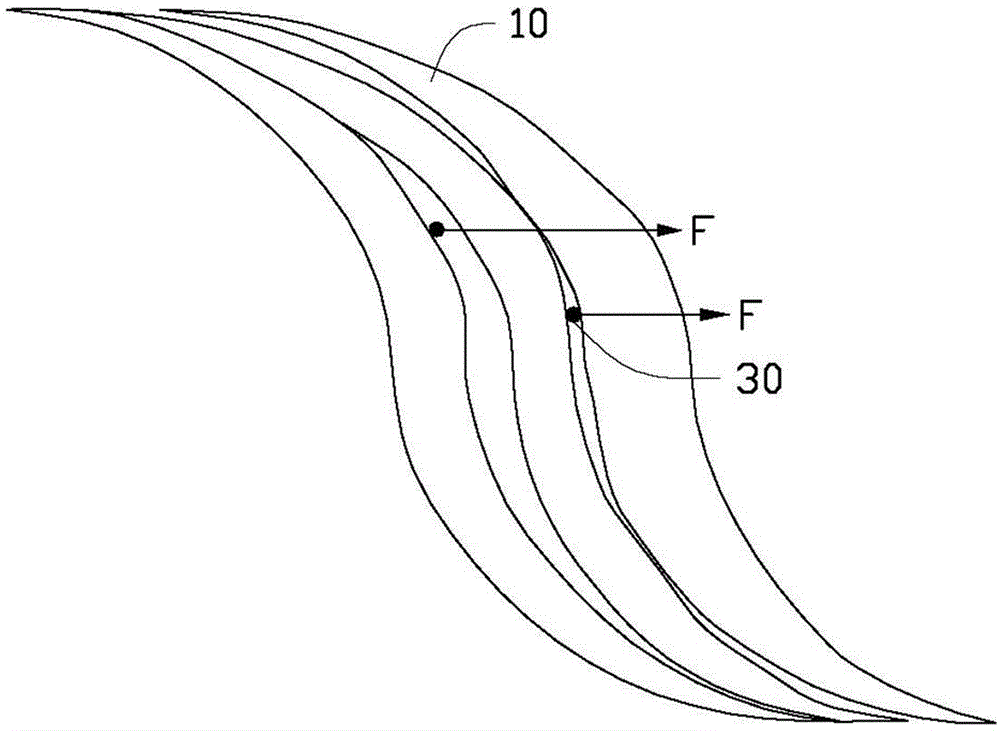

Deciduous wood P-RC APMP (pre-conditioning refiner chemical pretreatment alkaline peroxide mechanical pulp) pulping process using magnesium alkali

ActiveCN102535236AStrong maneuverabilityHigh pulping yieldPretreatment with alkaline reacting compoundsChemical/chemomechanical pulpPre conditioningChemistry

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for preparing biomechanical unbleached pulp from wheat straw

ActiveCN109577072AAvoid pollutionSave resourcesPretreatment with water/steamPretreatment with alkaline reacting compoundsState of artPapermaking

The invention belongs to the field of papermaking technologies and novel materials, and particularly relates to a method for preparing biomechanical unbleached pulp from wheat straw. The method includes pretreating grass by hot water and hot steam; adding trace alkali into the grass and carrying out hot water saturation softening treatment on the grass; adding alkaline biological enzymes into thegrass and carrying out enzyme treatment, pulping and washing. The grass is used as a raw material for the biomechanical unbleached pulp. The method has the advantages that alkali recycling can be omitted in integral production procedures, and environmental pollution can be prevented from the source; the method conforms to the national industry policy of resource conservation, economic cycle, energy conservation and emission reduction; the problems of difficulty in recycling straw pulp alkali wastewater and severe pollution in the prior art can be solved by the aid of the method; the method hasimportant significance in industrial production of straw pulp and the development of the papermaking industry.

Owner:QILU UNIV OF TECH

High-purity sulfate pulp, as well as production method and application thereof

ActiveCN102619126AHigh pulping yieldEmission reductionPulp bleachingPulping with inorganic basesSolubilityOxygen

The invention relates to high-purity sulfate pulp, as well as a production method and an application thereof. The high-purity sulfate pulp is prepared by stewing wood fiber raw material through a sulfate process for pulping, performing oxygen delignification and bleaching with DOEOPD1P, wherein the content of alpha cellulose in the pulp is not lower than 88% by weight; the content of pentosan is 4.5-6.5% by weight; the alkali solubility S18 of the pulp is 6.0-8.5% by weight; a DCM (dichloromethane) extract of the pulp is 0.1-0.30% by weight; the ash content is not higher than 0.15% by weight; the iron content is not higher than 20mg / kg; the SiO2 content is not higher than 50mg / kg; the inherent viscosity is 450-550dl / g; and the whiteness is not lower than 87% ISO, and the pulp is used for being mixed into dissolving pulp for producing viscose fiber.

Owner:湖南骏泰新材料科技有限责任公司

Method for removing adhesive matter from regenerated pulp

InactiveCN1395003AEfficient removalHigh pulping yieldPaper recyclingWaste paper working-upPulp and paper industryAdhesive materials

The method for removing adhesive material from regenerated pulp includes the following steps: firstly, using pressure slotted screen to screen the regenerated pulp, concentrating the screened tail pulp by using dewatering thickener to make it concentrate to a certain concentration, then using heat (cold) dispersing-pulp-grinding (dispersing) machine to make heat (cold) dispersing treatment. Said invention possesses good effect for removing adhesive material, and is high in pulp material recovery and is low in electric power consumption, so that it can be extensively used in the field of treating regenerated pulp containing adhesive material.

Owner:李风宁

Papermaking chemical mechanical pulp presoak softener and preparation method thereof

InactiveCN102660891AImprove physical strengthImprove softening effectInorganic compound additionPhosphoric Acid EstersSulfonate

The invention relates to a papermaking chemical mechanical pulp presoak softener and a preparation method thereof. The papermaking chemical mechanical pulp presoak softener is prepared from the following raw materials in percent by weight: 5-9% of alkyl sodium sulfonate, 10-16% of fatty alcohol-polyoxyethylene ether (2 ether-5 ether), 6-10% of alkyl phosphate, 1-4% of 98wt% concentrated sulfuric acid, 1-4% of anhydrous sodium sulfate and the balance of water. The invention also comprises the preparation method of the papermaking chemical mechanical pulp presoak softener; when being used for pulping, the papermaking chemical mechanical pulp presoak softener can reduce the power consumption by more than 2.3%, shorten the treatment time, improve the equipment efficiency and improve the productivity by more than 9%; and the yield of pulping can be improved by more than 2%.

Owner:湖南美莱精化有限公司

Method of producing corrugated paper with straw

InactiveCN104928958AHarm reductionHigh extraction ratePretreatment with acid reacting compoundsFibrous raw materialsEconomic benefitsProcess engineering

The invention discloses a method of producing corrugated paper with straw. The method includes the steps of preparing of raw materials, pretreatment of the straw, chemical pre-impregnating, primary hot grinding, tertiary hot grinding, screening, pulping, sheet making, and finishing. The short process is used in the production process, thus a washing and concentrating step is shortened and the pumping step is omitted. In the whole pulping process, power consumption is 10% lower than the power consumption for chemical pulps, water consumption is more than 70% higher than that for chemical pumps, boiling time is shorter, fuel consumption is decreased by 10% to 20%, the pulping rate is up to greater than 80%, and the production cost is lowered. On the basis of production of the high-strength corrugated paper, direct production cost of the paper is less than 1000 RMB per ton, and the economic benefit is excellent.

Owner:ZHANGJIAGANG XINFA PACKING

Method for preparing high-yield pulp for corrugating base paper from corn straws under normal pressure

InactiveCN106801356AHigh pulping yieldQuality improvementPulping with inorganic basesPulp beating/refining methodsCorn stoverPulverizer

The invention provides a method for preparing high-yield pulp for corrugating base paper from corn straws under normal pressure and relates to a preparation method of pulp for corrugating base paper. The problems that the corn straws are basically treated under the conditions of high temperature, high pressure and high medicine content in the existing pulping and paper-making industry, the pulping yield is low and the waste liquid cannot be treated are solved. The method comprises the following steps: 1, feeding the corn straws into a pulverizer, feeding the pulverized straws into a high-speed vibrating sieve by using a centrifugal fan, and separating skin and pith by virtue of a cyclone separator to obtain corn straw skin raw materials; 2, dipping the corn straw skin raw materials in a NaOH solution; and 3, grinding the dipped corn straw skin raw materials by a double-roll mill to obtain the high-yield pulp for the corrugating base paper. By the method, high pulping yield is obtained under the condition of normal pressure in the whole process and the yield reaches above 75 percent. The method is applied in the field of the corrugating base paper.

Owner:NORTHEAST FORESTRY UNIVERSITY

Biological compound enzyme and method thereof used for straw papermaking

InactiveCN107083711AReduce consumptionImprove product qualityWashing/displacing pulp-treating liquorsPulp beating/refining methodsBlack liquorPapermaking

The invention discloses a pulping and papermaking process through multiple combined biological enzymes. The process disclosed by the invention is a biological pulping method comprising the following steps: fermenting white-rot fungi, phanerochaete chrysosporium, xylanase, glucoamylase and saccharomycetes to prepare paper pulp; taking agricultural straws and the like as main raw materials, cutting grass, removing impurities, puffing, fermenting the combined biological enzyme fungi, pulp washing, pulp selecting, pulp grinding and separating, thereby obtaining the pulp. Black liquor is not produced in the pulping process, the fermentation water and pulping water can be recycled, and wastewater zero discharging can be achieved.

Owner:QILU UNIV OF TECH

Paper-making pulping method by using kenaf aggregate

ActiveCN102021859AReduce dosageReduce pollutionNon-woody plant/crop pulpCellulose material pulpingPulp (paper)Sodium silicate

The present invention relates to a paper-making pulping method by using kenaf aggregates. Concretely, the present invention provides a paper-making pulping method by using kenaf aggregates which comprises the following steps: (a) soaking the kenaf aggregates in water or an aqueous solvent at a temperature of 70-100 DEG C for 5-180 min, cooling the soaked kenaf aggregates to the temperature of 5-50 DEG C, and pulverizing to obtain the pulverized kenaf aggregates; (b) soaking the kenaf aggregates obtained through step (a) at a temperature of 70-90 DEG C for 60-300 min with the presence of 2.0-7.0 wt% of sodium hydroxide, 2.0-5.0 wt% of hydrogen peroxide, 0.05-3.0 wt% of sodium silicate, and 0.05-2.0 wt% of magnesium sulfate; (c) performing the refining and latency procedure to the chemically treated pulp so as to obtain kenaf aggregate paper pulp.

Owner:SHANGHAI ZHONGWEI BIOCHEM

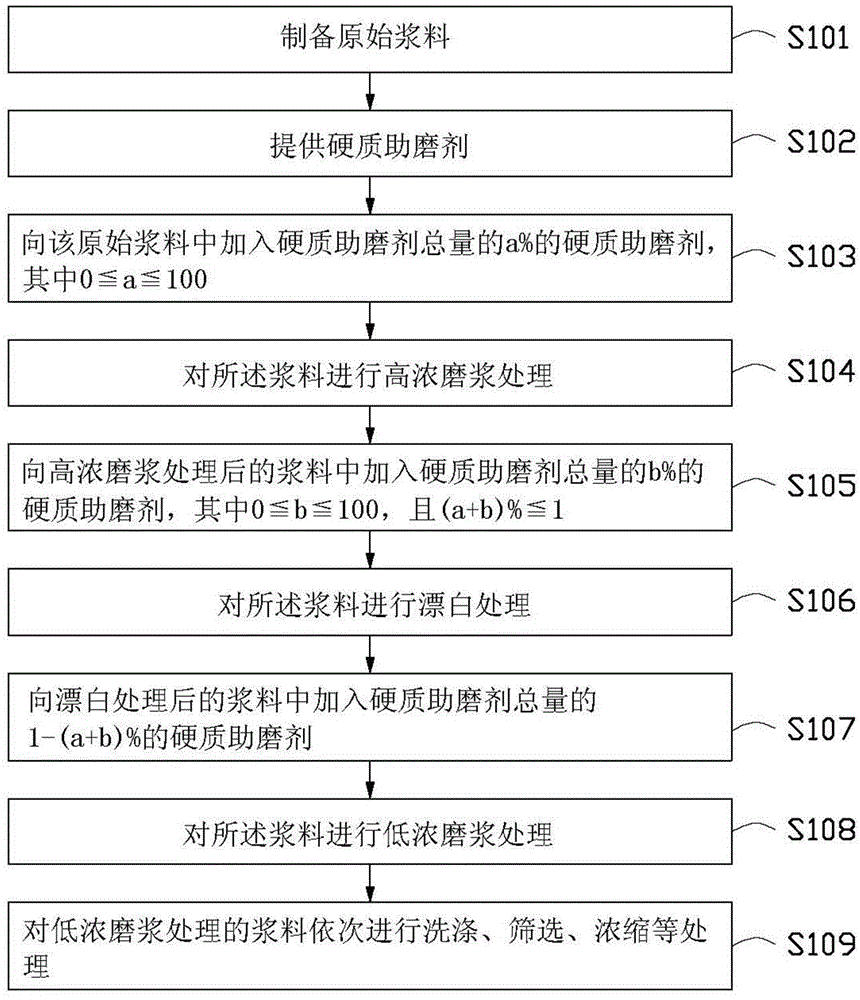

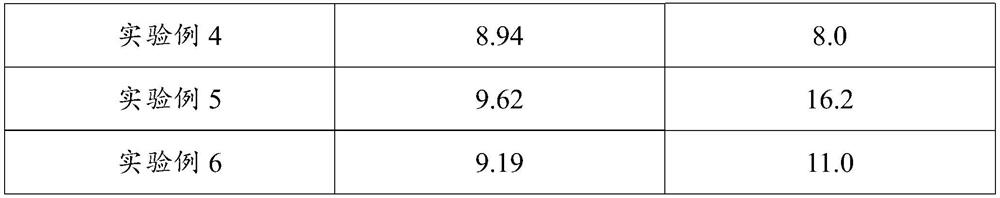

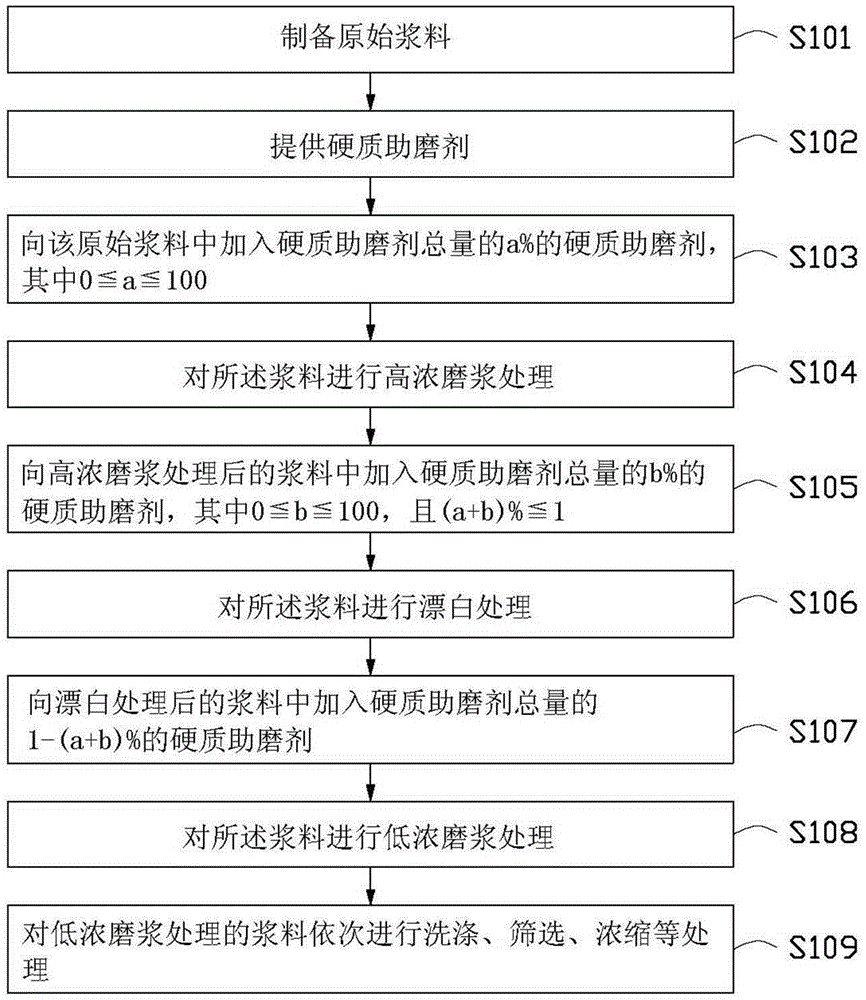

Size preparation method, size and paper made of size

ActiveCN102720087AReduce fiber contentLow fiber contentPulp beating/refining methodsPolymer scienceMicrometer

The invention provides a size preparation method. The size preparation method includes the following steps of providing raw size, subjecting the raw size to high-consistency size treatment, adding hard grinding aid by weight of 3-20% of that of completely dried raw size, wherein the grain diameter of the hard grinding aid ranges from 0.2-50 micrometers. The invention further provides size made by the size preparation method and paper made of the size.

Owner:GOLD EAST PAPER JIANGSU

Method for realizing micro fiberization of chemical mechanical pulp and for enhancing physical strength of paper

InactiveCN107653723AImprove applicabilityHigh pulping yieldPulping with inorganic basesPulp beating/refining methodsMicro nanoCellulose

The invention relates to a method for realizing micro fiberization of chemical mechanical pulp and for enhancing physical strength of paper. The method comprises the following steps: (1) preparing slurry; (2) concentrating the slurry; (3) preparing alkali-treated slurry; (4) preparing a slurry suspension; (5) performing an oxidation reaction; (6) adding a NaClO solution; (7) stopping the reaction;(8) performing washing; (9) performing homogenizing; and (10) adding cellulose micro-nano fibrils into the suspension liquid of raw materials of paper pulp to realize the micro fiberization of the chemical mechanical pulp and enhance the physical strength of paper. According to the method, the advantages of good raw material applicability of the chemical mechanical pulp, high pulping yield and low pollution load and the like are utilized, so that the chemical mechanical pulp can replace bleached chemical pulp for preparing cellulose micro-nano fibrils, and can be used to enhance the physicalstrength performance of the paper; the production cost is reduced, a raw material foundation for subsequent process, utilization or production of high-added-value products is provided, and the application field and range of the chemical mechanical pulp is expanded.

Owner:TIANJIN UNIV OF SCI & TECH

Bamboo pulping method

ActiveCN102154907AUniform moistureAccelerated cookingPretreatment with water/steamFinely-divided cellulose conservationPulp and paper industryDigestion

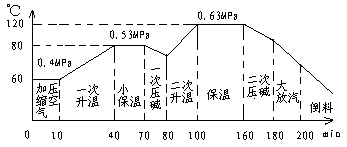

The invention discloses a bamboo pulping method, which comprises the following steps of: cutting and crushing bamboos to form bamboo chips; stacking and storing the bamboo chips obtained in the last step for 2 to 3 months; and washing the bamboo chips obtained in the last step, filling the bamboo chips into a digester, and then performing digestion under the conditions that: the alkali consumption amount (based on NaOH) of the digestion solution is 20 to 25 percent of the weight of the absolute dry bamboo chips, and the vulcanization degree of the digestion solution is 22 to 24 percent; in the temperature rise process, the initial temperature is raised to 130 to 140 DEG C for 30 to 40 minutes; the temperature is 125 to 135 DEG C after low exhaust and raised to 160 to 165 DEG C for 25 to 35 minutes; the temperature is raised to 170 to 175 DEG C for 40 to 50 minutes; the temperature of 170 to 175 DEG C is preserved for 20 to 30 minutes; and after the temperature preservation is finished, steam is exhausted through an exhaust port on the upper part of the digester, the pressure is reduced to 0.5 to 0.6MPa for 5 to 10 minutes, and the steam is blown after the pressure is reduced.

Owner:YUEYANG FOREST & PAPER CO LTD

Environmental-protection bio-enzyme explosion pulping method

InactiveCN101798767AGood physical propertiesImprove bleaching effectPulp bleachingRaw material divisionBlack liquorUltimate tensile strength

The invention discloses an environmental-protection bio-enzyme explosion pulping method. The method comprises the following steps: cutting a grass raw material into segments, removing dust, impregnating with water, and adding catalase accounting for 20-40 wt% of the raw material; after 40-60 minutes, conveying the mixture into an explosion device, and meanwhile, adding oxydol with the concentration of 50-60% into the explosion device; and exploding to obtain the pulp. The pulping method does not generate black liquor or pollute the environment. The pulping method requires a short production cycle and does not need cooking, thereby reducing the energy consumption. The pulping yield is high and can reach above 80%. The produced pulp has the advantages of favorable physical properties and bleaching properties, and can be used for producing high-whiteness high-strength high-grade paper sheets.

Owner:杨民玉

Pulping method of semi-chemical pulp made from reed

InactiveCN103046426AReduce loadHigh pulping yieldPulp de-wateringPulping with inorganic basesComposite materialChemical pulp

The invention discloses a pulping method of semi-chemical pulp made from reed. The pulping method comprises the steps of: preparing for the raw material, cooking, shoving by using a screw, pulp-grinding at a normal pressure, washing and screening. The pulping method is characterized by comprising the following steps: 1, the raw material is prepared by adopting a dry and wet process, to be specific, the reed with a length of 20-40mm and the percent of pass being more than 80 percent is provided; 2, cooking is carried out by adopting a caustic soda process, wherein the alkali charge is 5-10 percent by weight in the terms of NaOH, the liquid ratio is 1:(2.5-3.5) and the H factor is 500-1200, the yield of the pulp obtained by cooking is 60-80 percent and the Kappa value of the pulp is 50-100; 3, the pulp feeding concentration of a screw shoving machine is 8-12 percent, the pulp discharging concentration of the screw shoving machine is 20-40 percent; 4, the normal pressure pulp grinding concentration of one section is 10-40 percent, and the pulp beating degree is 20-30 DEG SR; and 5, the ring crush compression resistance of the reed semi-chemical pulp is good, the ring crush index is not less than 8.0N.m / g, and the fracture length of the pulp is not less than 4.5km. The pulping method is high in yield, and realizes effective utilization of the reed resources; and the produced reed semi-chemical pulp has high quality and can be used for producing high-grade fluting mediums and case boards.

Owner:YUEYANG FOREST & PAPER CO LTD

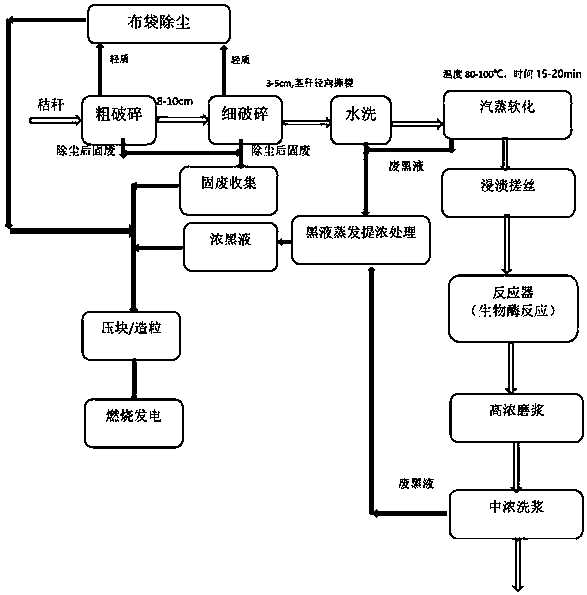

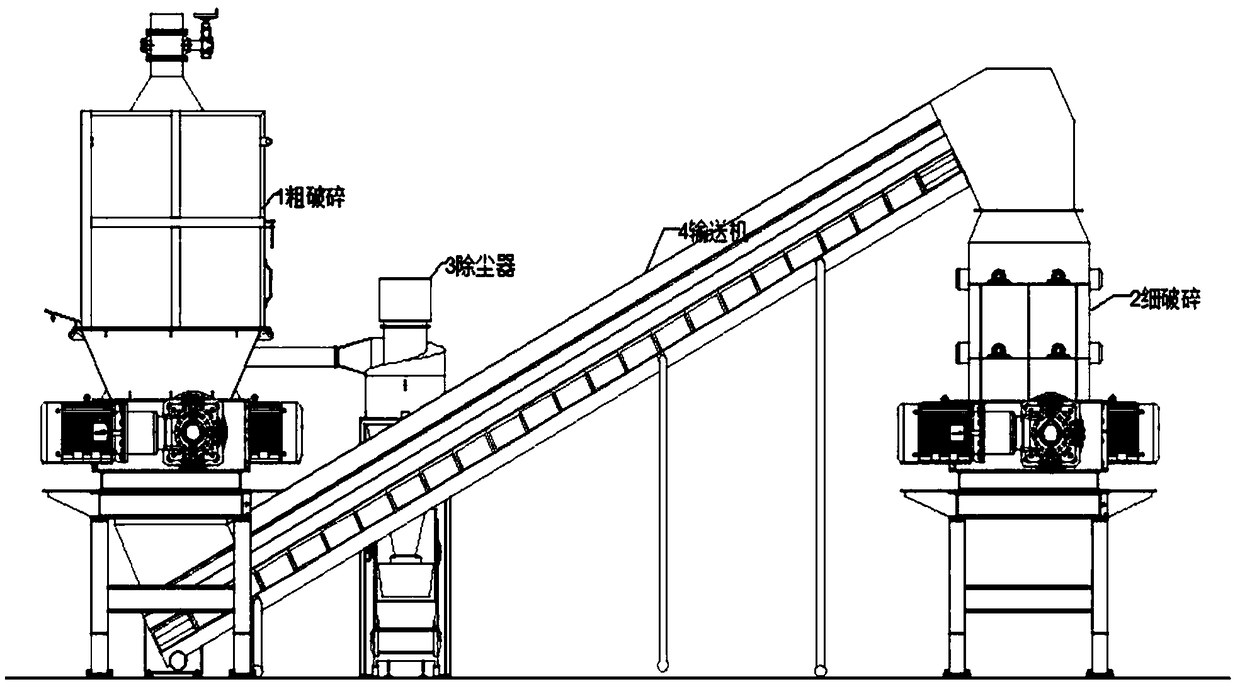

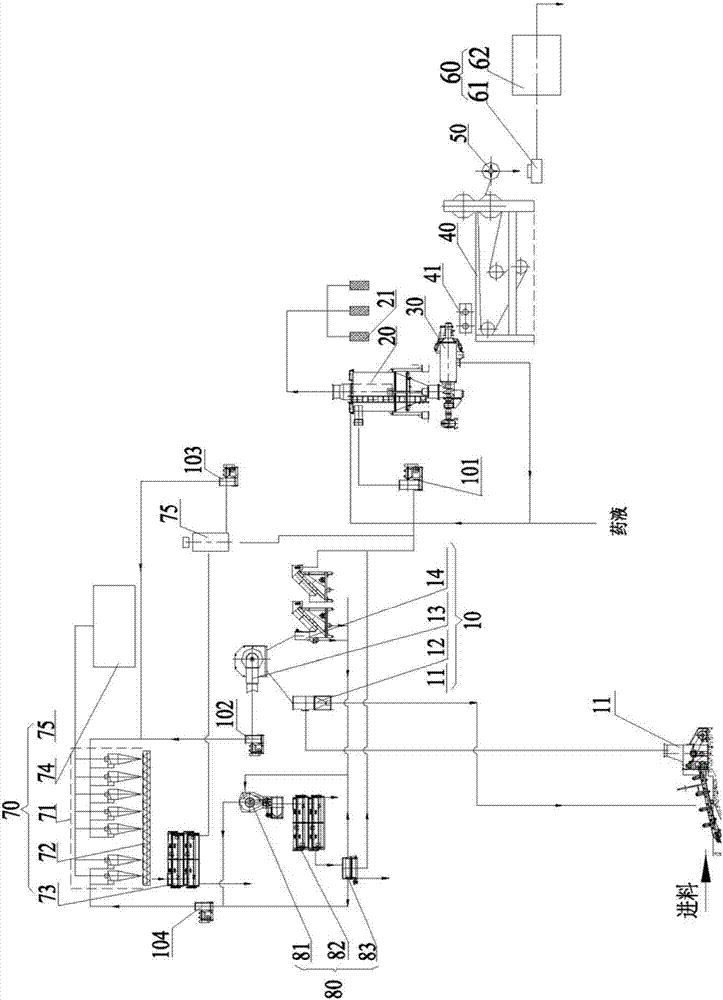

Closed loop environmental protection straw biomechanical pulping process

ActiveCN109338775AWill not polluteHigh pulping yieldPretreatment with water/steamFibrous raw materialsEnvironmental resistanceCombustion

The invention provides a closed loop environmental protection straw biomechanical pulping process, wherein straws are treated through coarse crushing, fine crushing, water washing, steam softening, dipping and rolling, bio-enzyme treatment, and high concentrated pulp grinding and the like. After mixing solid waste with waste liquid which is produced by a system and is concentrated, the solid wasteis pressed and pelleted and used for combustion power generation, and the straw pulping is achieved, and the process is a closed-loop and pollution-free treatment method, is environmental protection,and creates a new method of straw pulping and papermaking.

Owner:SHANDONG CENTURY SUNSHINE PAPER GROUP

Corrugated paper pulp with waterproof and fireproof characteristics

InactiveCN110804896AEasy to prepareFireproofInorganic fibres/flakesNatural cellulose pulp/paperVegetable oilPolyvinyl alcohol

The invention discloses corrugated paper pulp with waterproof and fireproof characteristics, and belongs to the technical field of papermaking. The corrugated paper pulp comprises plant fibers, ceramic fibers, aluminum hydroxide, ammonium chloride, rosin size, starch, chlorinated paraffin, dititanium trioxide, silicone oil, a flame retardant, titanium dioxide, polyvinyl alcohol, latex, a water repellent agent, paraffin, a softener, water and vegetable oil. A preparation method comprises the steps: firstly, uniformly stirring the plant fibers and the ceramic fibers, adding the rosin size and the starch into the mixture, and uniformly stirring; then adding an aqueous solution of aluminum hydroxide and ammonium chloride, and uniformly stirring; adding silicone oil, chlorinated paraffin and adititanium trioxide solution, and uniformly stirring; adding the flame retardant, titanium dioxide and water, and uniformly stirring; uniformly stirring the polyvinyl alcohol solution, the latex and ahydrophobic agent solution, adding a solution formed by paraffin, the softener and a proper amount of water into the obtained solution, and uniformly stirring to form the corrugated paper pulp. Corrugated board prepared from the corrugated paper pulp has the characteristics of fire resistance, flame retardancy, high temperature resistance, water resistance and moisture resistance.

Owner:鲍双铭

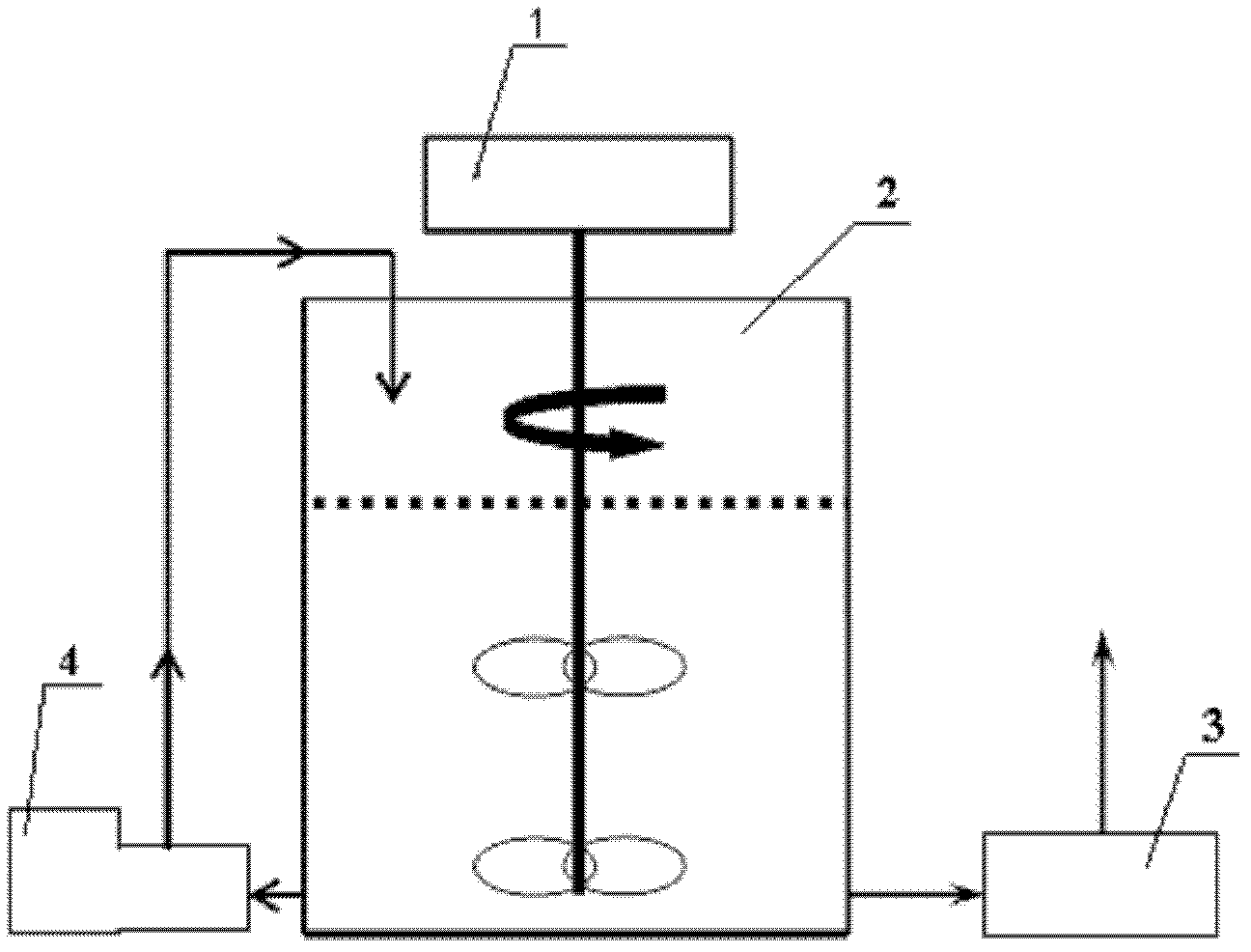

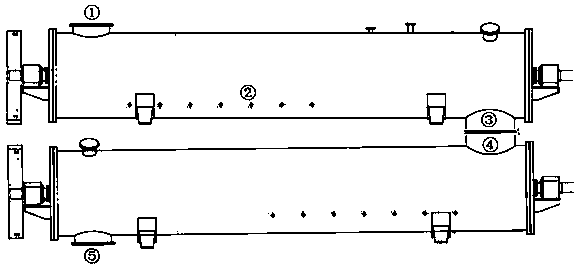

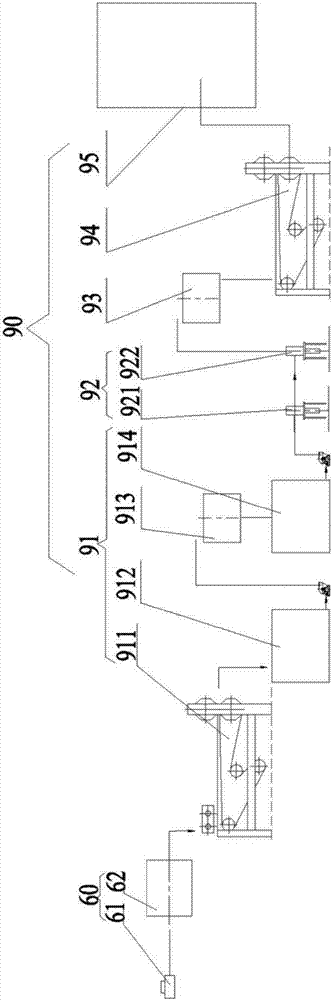

Apparatus for preparing refined cotton from cotton linter by bleaching

ActiveCN107287958AUniform penetrationFull penetrationPulp bleachingRaw material divisionHigh concentrationPulp and paper industry

The invention relates to the field of the preparation of refined cotton, and discloses an apparatus for preparing refined cotton from a cotton linter by bleaching. The apparatus comprises a stock impurity removal device, a cyclone separator, a press master, a presser, a crusher and a bleaching device, wherein the stock impurity removal device, the cyclone separator, the press master, the presser, the crusher and the bleaching device are arranged in sequence along a material trend; the bleaching device comprises a high-concentration mixer and a continuous oxygen bleacher which are arranged in sequence along the material trend. According to the apparatus for preparing the refined cotton from the cotton linter by the bleaching, the one-time pulping in a joint bleaching manner through adopting the high-concentration mixer and the continuous oxygen bleacher is achieved; a decoction process in the preparation process of the refined cotton is avoided; the production cost of the refined cotton is greatly decreased.

Owner:KUYTUN XINDALU CHEM +2

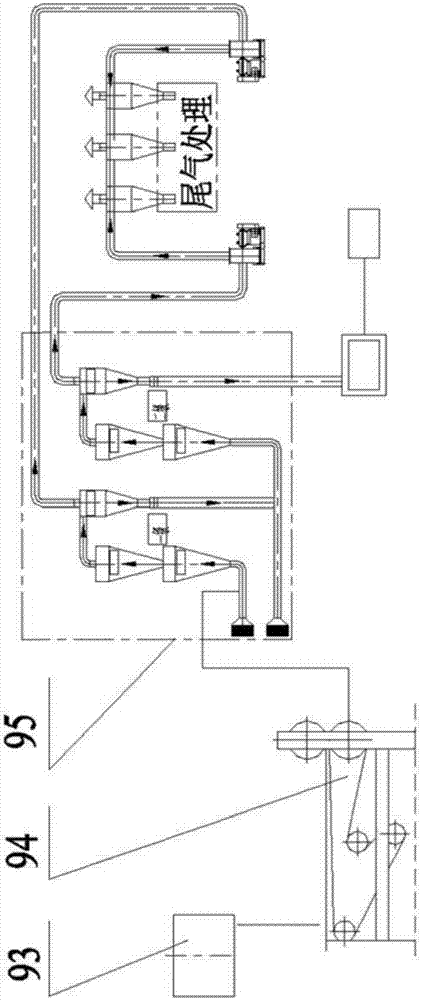

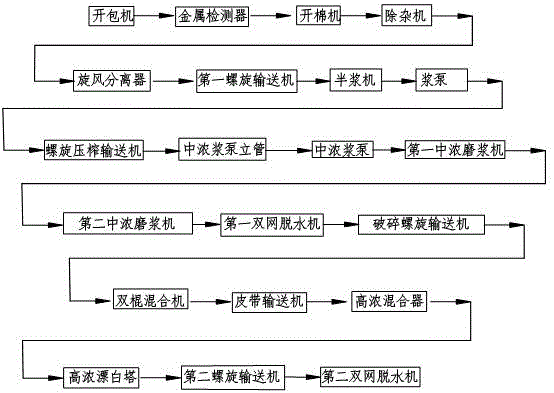

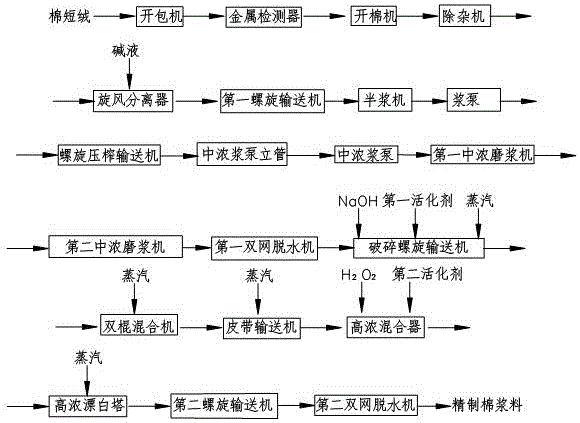

Device and method for making refined cottons through performing high-concentration hydrogen peroxide bleaching on cotton linters

InactiveCN105019286AIncrease profitImprove the effectPretreatment with water/steamPulp bleachingScrew conveyorProcess engineering

The invention discloses a device for making refined cottons through performing high-concentration hydrogen peroxide bleaching on cotton linters. The device comprises a bale opener, a metal detector, a cotton slitting machine, an impurity removal machine, a cyclone separator, a first spiral conveyor, a half stuff machine, a first medium-concentration stuff grinder where a defibering type grinding disc is installed, a second medium-concentration stuff grinder where a stuff-grinding type grinding disc is installed, a first double-net dehydrator, a crashing spiral conveyor, a double-rod mixer, a belt conveyor, a high-concentration mixer, a high-concentration bleaching tower, a second spiral conveyor and a second double-net dehydrator. The device is simple in structure and convenient to install and maintain. The invention further provides a method for making the refined cottons through performing high-concentration hydrogen peroxide bleaching on the cotton linters. By the utilization of the method, the quality of obtained products is high, impurities are few, the yield is high, the cost is low, and environment pollution is small.

Owner:SOUTH CHINA UNIV OF TECH +1

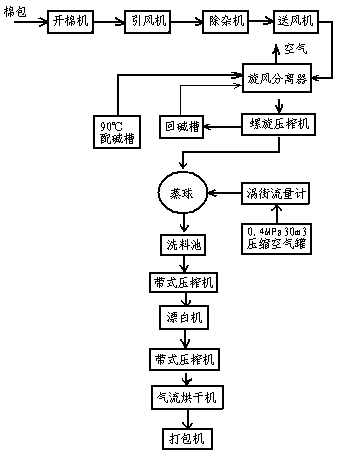

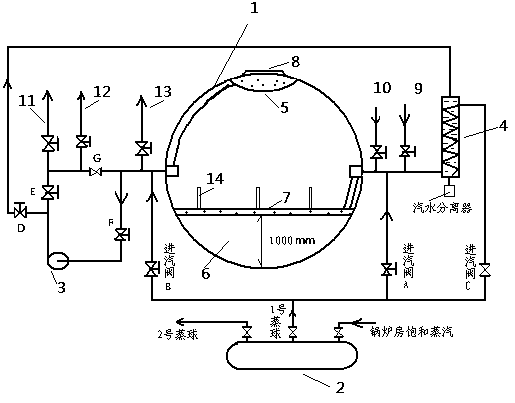

Cotton linter alkali-compressed air pulping method and device

InactiveCN108425263APromote absorptionEven temperaturePretreatment with alkaline reacting compoundsDigestersPulp and paper industryAir blower

The invention discloses a cotton linter alkali-compressed air pulping method and device. The method includes: primary mechanical impurity removal, cotton linter primary soaking, secondary soaking, compressed air pressurization steaming, washing and bleaching and drying and packing. The device comprises a cotton opener, an induced draft fan, an impurity remover, an air blower, a cyclone separator,a screw press, a spherical digester, a compressed air tank, a washing tank, a belt-type press, a bleaching machine, an airflow dryer and a packer. Through matched use of alkali liquid and compressed air, permeation effect and oxidation action of the alkali liquid are improved greatly, and consumption of the alkali liquid is reduced; compared with conventional steaming methods, treated cotton linter is high in whiteness, few in impurity, economical, environment-friendly and lower in cost.

Owner:薛润林

Method for preparing bamboo willow unbleached pulp

InactiveCN105178082AHigh pulping yieldQuality improvementPulping with inorganic basesFibrous raw materialsFiberPotassium hydroxide

The invention discloses a method for preparing bamboo willow unbleached pulp. The method comprises the following steps: (1) cutting bamboo willows which are two or three years old into material segments which are 40-50mm in length and 3-4mm in diameter with a rotary cutter; (2) feeding the material segments into a digester, adding 1.5%-2% of potassium hydroxide, 1.2%-1.5% of ammonium sulfite and 1%-1.5% of sodium tripolyphosphate on the basis of the oven dry weight of the material segments, and cooking the materials at 135-140 DEG C for 115-120 minutes; and (3) feeding the cooked materials into a twin-screw kneader, carrying out kneading and separating to obtain coarse pulp, and washing the coarse pulp to obtain the bamboo willow unbleached pulp. Compared with a traditional pulping method, according to the method disclosed by the invention, the pulping yield can reach 91%-93%; the length-width ratio of the fiber reaches 49.2; the BOD / COD ratio of sewage reaches about 0.5; biochemical treatment is very easy; and the pulping cost can be reduced by about 1 / 3.

Owner:XINJIANG GUOLIYUAN INVESTMENT

Tobacco stem pulp sheet as well as preparation method and application thereof

PendingCN113349407AEasy to storeEasy to transportTobacco preparationTobacco treatmentPulp and paper industryChemical pulp

The invention discloses a tobacco stem pulp sheet preparation method, and belongs to the field of processing and recycling of cigarette byproducts. The preparation method comprises the following steps: (1) extracting; (2) carrying out solid-phase filter pressing; (3) carrying out high-concentration pulping; (4) preparing pulp; (5)carrying out pulp screening; (6) forming on a net; and (7) drying. The invention further discloses the tobacco stem pulp sheet obtained through the preparation method and application of the tobacco stem pulp sheet. The tobacco stem pulp sheet belongs to mechanical pulp, compared with tobacco stem chemical pulp, chemicals are not needed in the production process, production is environmentally friendly, the pulping yield is high, and the tobacco stem pulp sheet is convenient to store and transport. The tobacco stem pulp disclosed by the invention can be added and used on a surface layer or a core layer or a bottom layer of a coated ivory board on line.

Owner:CHINA TOBACCO YUNNAN IND

Method for preparing flax stem unbleached pulp

InactiveCN105178080AGood fiber qualityRaise the ratioPretreatment with water/steamPretreatment with alkaline reacting compoundsSodium triphosphatePotassium hydroxide

The invention discloses a method for preparing flax stem unbleached pulp. The method comprises the following steps: (1) cutting a flax stem into material segments which are 30-40mm in length with a straw cutter, feeding the material segments into a steaming chamber and precooking the material segments at 90-95 DEG C for 10-15 minutes; (2) feeding the material segments into a digester, adding 2%-2.5% of potassium hydroxide, 1.5%-1.8% of ammonium sulfite and 1.2%-1.5% of sodium tripolyphosphate on the basis of the oven dry weight of the material segments, and cooking the materials at 135-140 DEG C for 95-100 minutes; and (3) feeding the cooked materials into a twin-screw kneader, carrying out kneading and separating to obtain coarse pulp, and washing the coarse pulp to obtain the flax stem unbleached pulp. Due to the adoption of the method disclosed by the invention, the pulping yield can reach 80%-83%; the mean fiber length reaches 3.26 microns; the BOD / COD ratio of sewage reaches about 0.5; and biochemical treatment is very easy.

Owner:XINJIANG GUOLIYUAN INVESTMENT

Method of preparing bamboo willow bleaching pulp

InactiveCN105200838AHigh pulping yieldReduce pulping costsPulp bleachingPulping with inorganic basesAnthraquinonesPotassium hydroxide

The invention discloses a method of preparing bamboo willow bleaching pulp. The method comprises the steps of cutting bamboo willow into segments, sending the segments into a digester, adding 2.5-3% potassium hydroxide and 0.2-0.3% anthraquinone, digesting the segments for 40-50 min at the temperature below 90-95 DEG C, sending digested materials into a double-screw pulp grinding machine, adding 2.2-2.5% PAM, 1-1.2% EDTA and 2.5-3% H2O2, controlling the outlet temperature at 100-105 DEG C, making the discharged materials react for 50-60 min, washing the materials, sending the materials into the double-screw pulp grinding machine again, adding 2.2-2.5% sodium tripolyphosphate, 1-1.2% magnesium sulfate and 5-5.5% H2O2, controlling the outlet temperature at 100-105 DEG C, making the discharged materials react for 50-60 min, washing the materials and obtaining the bamboo willow bleaching pulp. By the adoption of the method, the pulping yield is high, the BOD / COD ratio of sewage is high, and biodegradation is easy.

Owner:XINJIANG GUOLIYUAN INVESTMENT

Method for preparing bio-mechanical primary color pulp from wheat straw and fully utilizing byproducts

ActiveCN112779804AAvoid pollutionSave resourcesPretreatment with water/steamPretreatment with alkaline reacting compoundsThermal waterIndustrial engineering

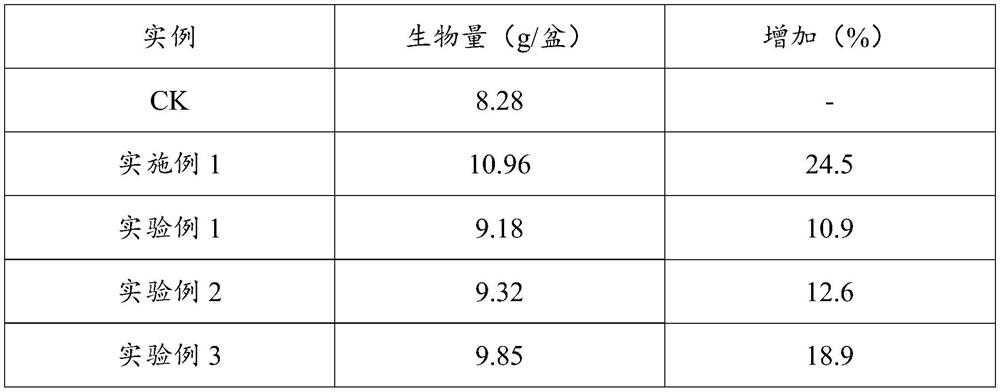

The invention belongs to the technical field of papermaking technology and comprehensive utilization of waste, and particularly relates to a method for preparing biological mechanical primary color pulp from wheat straw and fully utilizing byproducts. The method comprises the following steps of: by taking wheat straw as a pulping raw material, treating the wheat straw with hot water, then adding a trace amount of KOH, performing thermal saturation softening on the wheat straw, then adjusting the temperature of the wheat straw, adding alkaline compound enzyme for biological treatment, and finally grinding the wheat straw into pulp. The prepared mechanical pulp can meet the requirements for producing primary-color packaging paper and paper-based materials, meanwhile, byproducts of the mechanical pulp are recycled to prepare biomass compound fertilizer, solid waste is turned into wealth, and high-value full utilization of wheat straw is achieved. Therefore, the method has a good practical application value and a wide application prospect.

Owner:QILU UNIV OF TECH

Papermaking cooking assistant

InactiveCN104790243AImprove solubilityEnhanced complexationCellulose material pulpingPhosphatePapermaking

The invention relates to the technical field of papermaking, and particularly relates to a papermaking cooking assistant which is prepared from the following raw materials in parts by weight: 10-20 parts of green oxygen, 12-24 parts of sulfated castor oil, 20-30 parts of surfactant, 5-10 parts of phosphate, 5-10 parts of water retention agent and 60-90 parts of deionized water. The papermaking cooking assistant greatly enhances the cooking effect, enhances the raw material permeability, improves the cooking uniformity, quickly adsorbs alkali liquor, increases the transmission speed of the reaction product in the raw materials, accelerates cooking, obviously shortens the cooking time, and greatly improves the pulp quality and paper strength.

Owner:陈朝民

A kind of production method of environment-friendly and energy-saving household paper wood pulp

ActiveCN104389217BDip evenlyImprove cooking uniformityPulp bleachingCellulose material pulpingKappa numberSulfate

The invention relates to the technical field of living paper, particularly to a production method for an environment-friendly and energy-saving living paper wood pulp. The production method comprises the following steps: (1) material preparation; (2), enzyme treatment: adding enzymes in pulp which is extruded and dehydrated for treatment, wherein the treatment temperature is 40-60 DEG C, the treatment time is 1-2 hours, the concentration of the pulp is 5-15%, and pH is 6.5-7.5; (3) cooking: cooking the pulp which is treated by using the enzymes by a sulfate method cooking technology; (4), chlorination: chloridizing the cooked pulp; (5), oxygen delignification treatment: performing oxygen delignification treatment on the chloridized pulp, and removing 40-60% of lignin, wherein the kappa number of the pulp after the oxygen delignification is performed is 20-30; (6), acid treatment: adding pulp subjected to oxygen delignification in hydrochloric acid for acid treatment for 30-50 minutes. The method disclosed by the invention is simple in technology, and easy to operate; the produced wood pulp conforms to the production requirement of the living paper, and the method is energy-saving and environment-friendly.

Owner:ANHUI BILUN DOMESTIC PAPER CO LTD

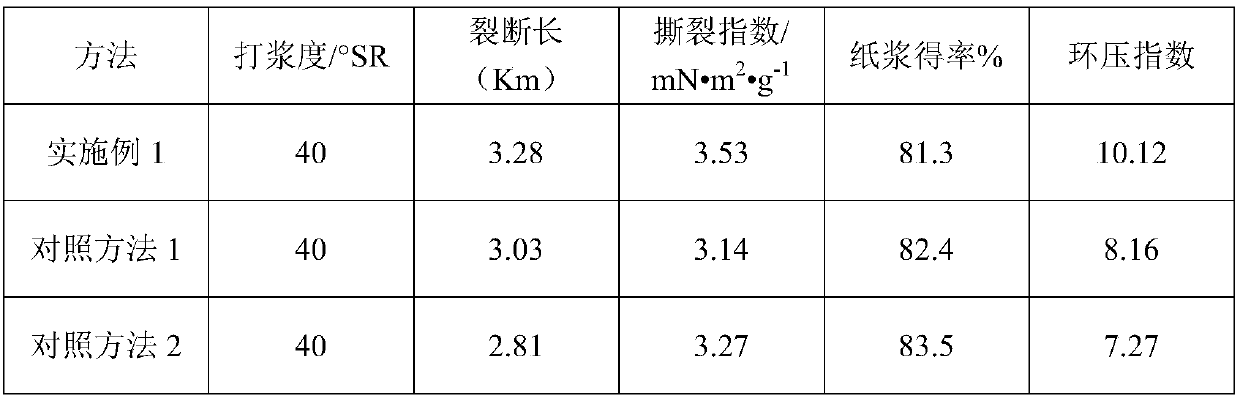

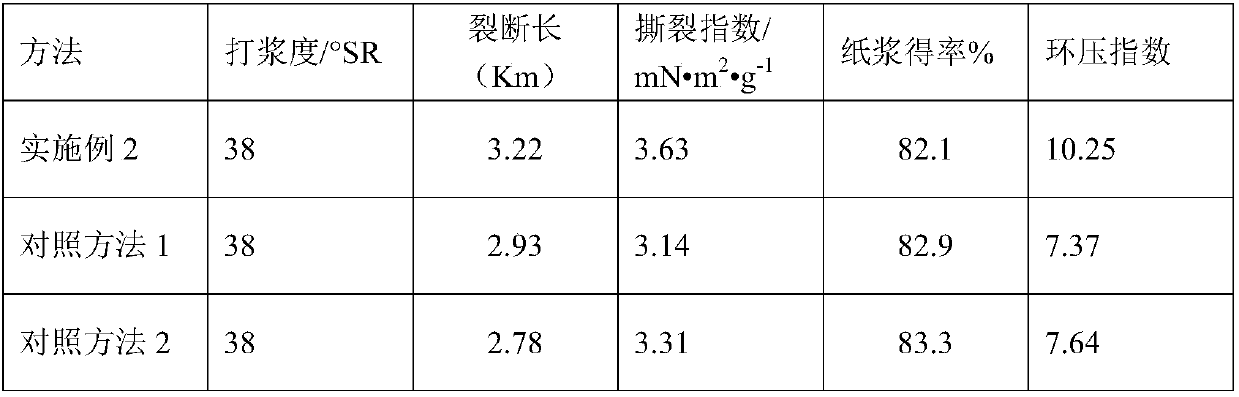

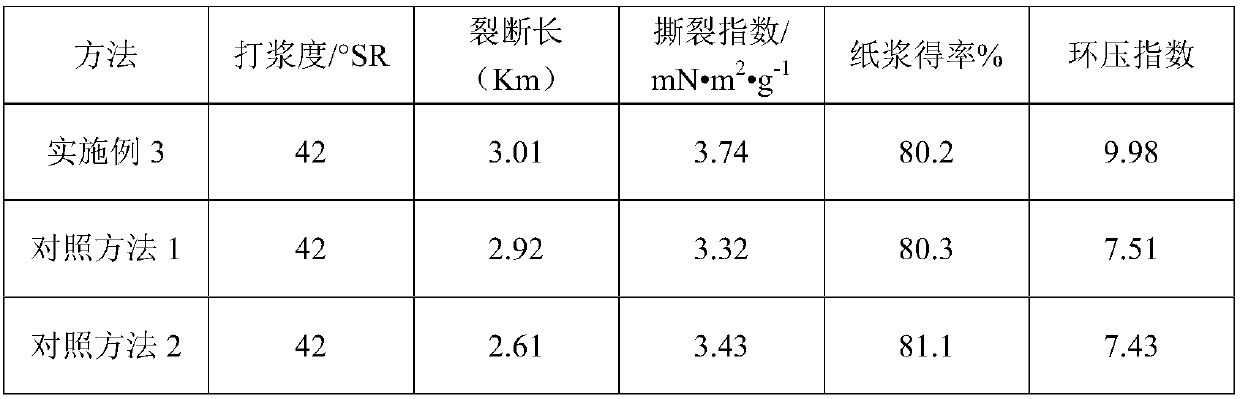

Method for preparing pulp, pulp and paper made therefrom

ActiveCN102720087BReduce fiber contentLow fiber contentPulp beating/refining methodsPolymer scienceMicrometer

The invention provides a size preparation method. The size preparation method includes the following steps of providing raw size, subjecting the raw size to high-consistency size treatment, adding hard grinding aid by weight of 3-20% of that of completely dried raw size, wherein the grain diameter of the hard grinding aid ranges from 0.2-50 micrometers. The invention further provides size made by the size preparation method and paper made of the size.

Owner:GOLD EAST PAPER JIANGSU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com