Tobacco stem pulp sheet as well as preparation method and application thereof

A technology of tobacco stems and paddles, applied in the field of tobacco, can solve the problems of low processing efficiency, low yield of tobacco stem pulp, high cost, etc., and achieve the effect of high pulping yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

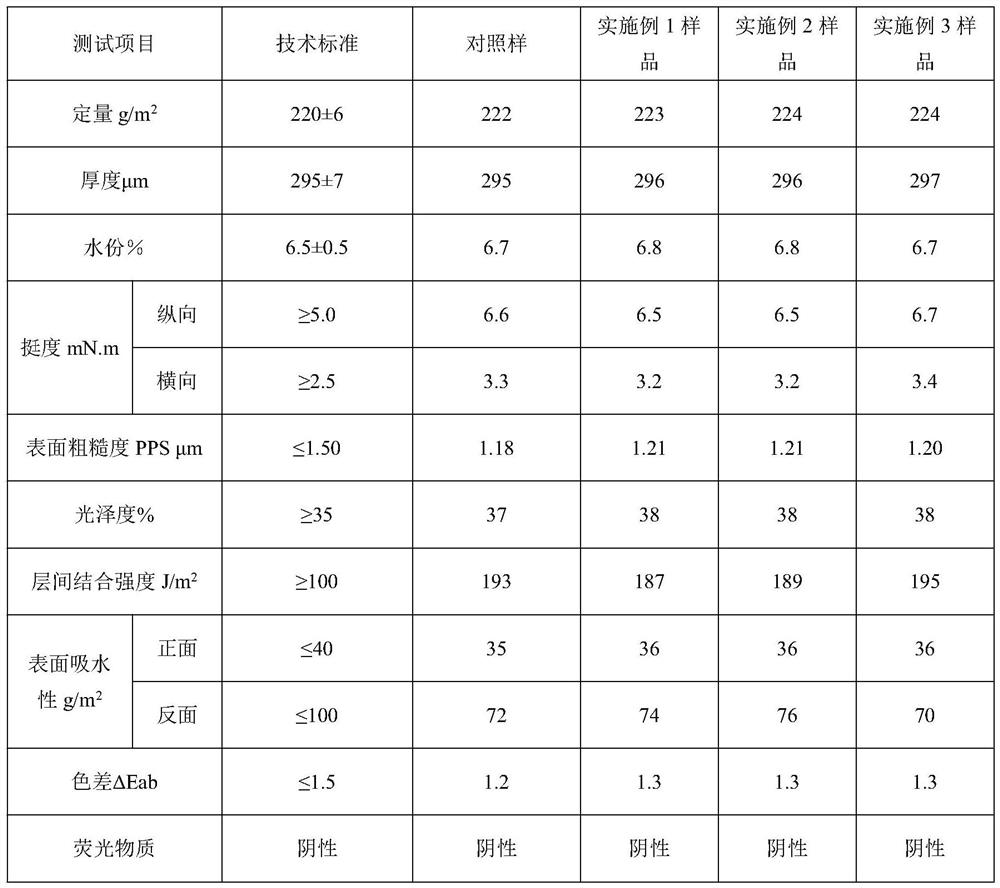

Examples

Embodiment 1

[0032] The preparation method of the tobacco stem pulp sheet of the present embodiment is prepared through the following steps:

[0033] Step (1): Heat reflux extraction of tobacco stem raw materials with a length of 5mm in water, the solid-to-liquid ratio of the extraction is 1:4, the extraction temperature is 90°C, and the extraction time is 60 minutes;

[0034] Step (2): The material in step (1) is subjected to solid-liquid separation, and the solid phase part is subjected to pressure filtration treatment, and the water content of the solid after pressure filtration is 75wt%;

[0035] Step (3): The solid matter after pressure filtration in step (2) is subjected to three-stage high-concentration pulping. The grinding gap is 0.3mm, the freeness of the high consistency pulp of tobacco stems after pulping is 500ml, and the water content of the high consistency pulp of tobacco stems is 85wt%;

[0036] Step (4): The tobacco stem high-consistency pulp of step (3) is made into 4wt...

Embodiment 2

[0042] The preparation method of the tobacco stem pulp sheet of the present embodiment is prepared through the following steps:

[0043] Step (1) Extraction: heat reflux extraction of tobacco stem raw materials with a length of 10mm in water, the extraction solid-to-liquid ratio is 1:7, the extraction temperature is 60°C, and the extraction time is 30 minutes;

[0044] Step (2) solid-phase pressure filtration: the material extracted in step (1) is subjected to solid-liquid separation, and the solid phase part is subjected to pressure filtration treatment, and the moisture content of the solid after pressure filtration is 70wt%;

[0045] Step (3) high-consistency pulping: the solid matter after pressure filtration in step (2) is subjected to three-stage high-consistency pulping, the first-stage pulping disc mill gap is 0.5mm, and the second-stage pulping disc mill gap is 0.3mm, The three-stage pulping disc grinding gap is 0.1mm, the freeness of the high consistency pulp of toba...

Embodiment 3

[0052] The preparation method of the tobacco stem pulp sheet of the present embodiment is prepared through the following steps:

[0053] Step (1) Extraction: heat reflux extraction of tobacco stem raw materials with a length of 20mm in water, the extraction solid-liquid ratio is 1:6, the extraction temperature is 85°C, and the extraction time is 40 minutes;

[0054] Step (2) solid phase filter press: the material extracted in step (1) is subjected to solid-liquid separation, and the solid phase part is subjected to press filter treatment, and the moisture content of the solid after press filter is 72wt%;

[0055] Step (3) high-consistency pulping: the solid matter after pressure filtration in step (2) is subjected to three-stage high-consistency pulping, the first-stage pulping disc mill gap is 0.6mm, and the second-stage pulping disc mill gap is 0.4mm, The three-stage pulping disc grinding gap is 0.2mm, the freeness of the high-consistency tobacco stem pulp after pulping is 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com