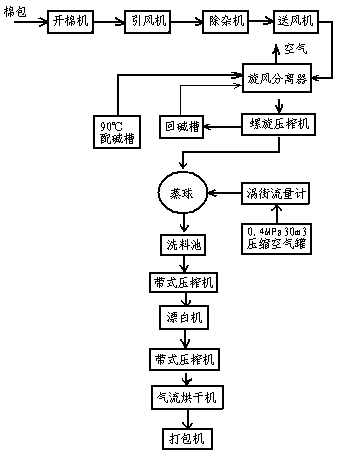

Cotton linter alkali-compressed air pulping method and device

A technology of compressed air and linter alkali, applied in pulping with inorganic alkali, pulp bleaching, pretreatment with alkaline compounds, etc., can solve the problems of unsatisfactory treatment effect, small application range, environmental pollution, etc., and achieve emulsification and detoxification Good miscellaneous effect, increased reaction effect, high economic value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

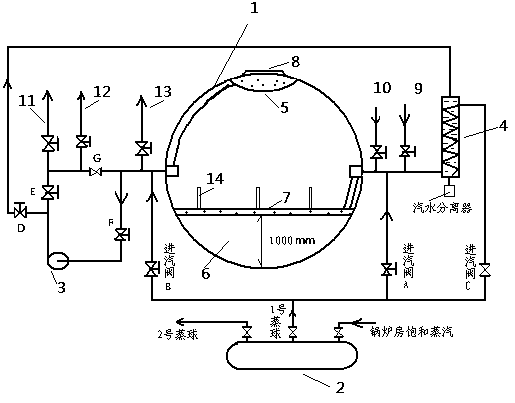

[0041] Such as image 3 As shown, at this time, the pressure of the steam bag ≥ the pressure inside the ball, therefore, the steam can be input into the steam ball and can be used for heating.

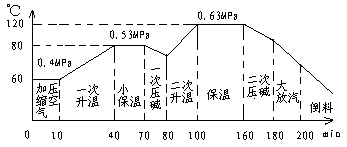

[0042] After feeding, start the steaming ball, open the compressed air valve, enter the compressed air at 0.4MPa, pass in the steam for a 30-minute temperature rise, so that the temperature rises to 80°C, and keep the heat for 30 minutes, and then carry out a 10-minute pressure of the alkali, (the extruded alkali The liquid is used to mix the alkali) to make the liquid ratio in the ball ≤ 3, the liquid ratio is small, the slurry can better follow the steaming ball to rotate and stir, so that the slurry is in the vapor phase space, the temperature distribution is uniform, and the cooking uniformity is good. After the first caustic press, heat up to 120°C for the second time, keep the temperature for 60 minutes, carry out the second caustic press for 20 minutes, let off steam for 20 minu...

Embodiment 2

[0046] Such as Figure 4 As shown, when the steam drum pressure is less than the internal pressure of the ball, after adding compressed air, the internal pressure of the ball is greater than the steam drum pressure. Under this working condition, the heater can only be used for indirect heating.

[0047] After feeding, start the steaming ball, stop the steam release grate at the bottom, pass in compressed air to control the pressure at 0.4MPa, then turn on the circulation pump to heat up the heater once so that the temperature of the lye reaches 80°C, keep it for 40 minutes, and pass it through the heater again The second temperature rise makes the temperature of the lye reach 120°C, keep it warm for 60 minutes, pressurize the alkali for 20 minutes, release the steam for 20 minutes, and finish the pouring.

[0048] The heater heats up and circulates the lye, which improves the uniformity of lye penetration and the uniformity of temperature distribution. After the first tempera...

Embodiment 3

[0051] If the production unit is equipped with circulation pump and heater equipment, it can be steamed, bleached and pulped by heating up first and then adding compressed air.

[0052] Such as Figure 5 As shown, after the steaming ball is turned cold for 10 minutes, let the lye and cotton linters mix below, and then heat up to 100°C once, stop inputting steam, and change to compressed air, so that the pressure rises to 0.4MPa, due to normal temperature compressed air Entering, the temperature inside the steaming ball drops from 100°C to 90°C, keep warm for 40 minutes, pressurize the alkali for 10 minutes, make the liquid ratio in the ball ≤ 3.0, and after 10 minutes of steam release, carry out a second temperature rise to 130°C, and the pressure inside the ball is 0.165MPa. On the basis of 0.165MPa, enter compressed air, when the pressure rises to 0.4MPa, the temperature drops to 120°C, keep warm for 60min, press alkali for 20min, release steam for 20min, dump the material, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com