Apparatus for preparing refined cotton from cotton linter by bleaching

A technology of refined cotton and cotton linters, applied in the field of refined cotton preparation, can solve the problems of decreased polymerization degree of cotton fiber, human health and ecological environment hazards, highly toxic chlorine-containing organic compounds, etc., and achieve the goal of improving the effect and improving the utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

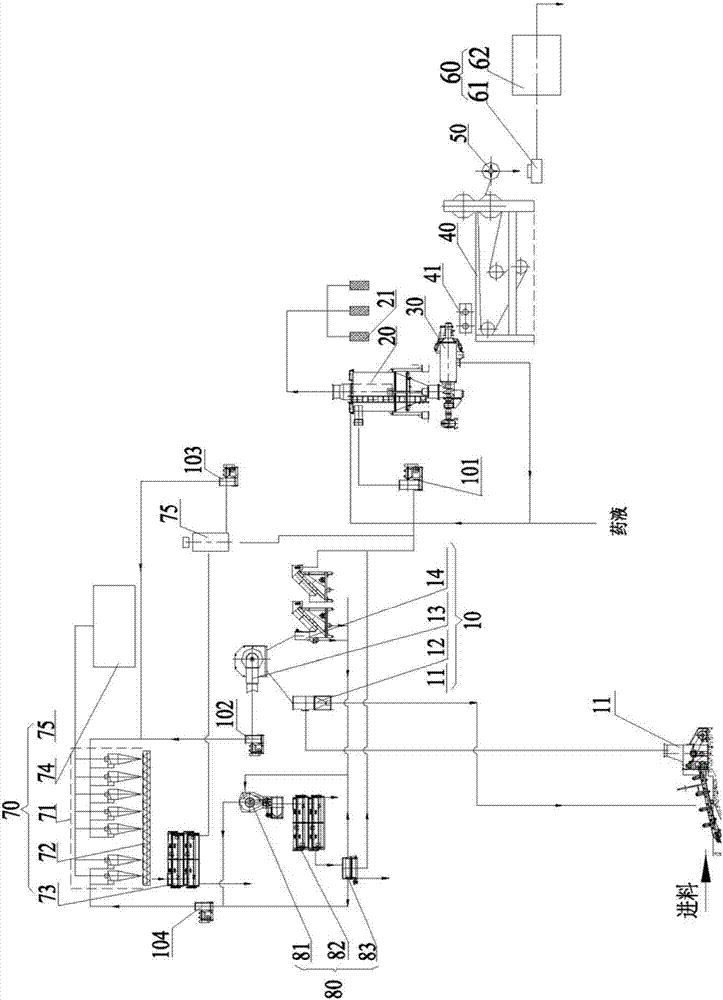

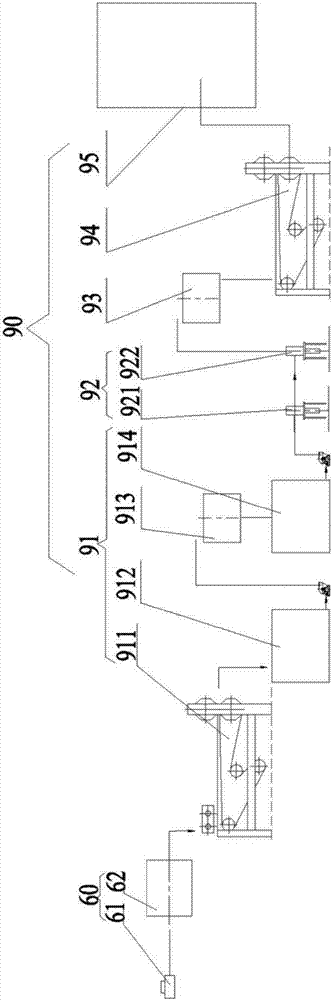

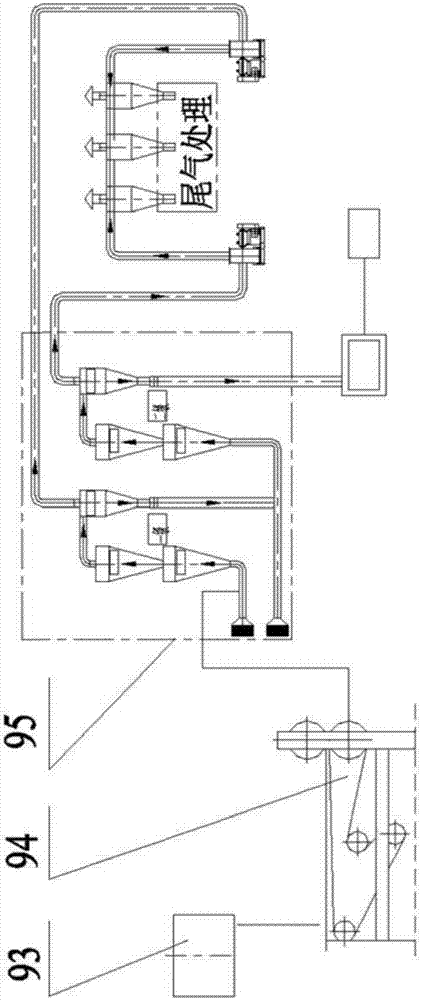

[0041] The invention aims at the problem of high production cost due to the need for steaming and cooking in the preparation process of refined cotton in the prior art. A kind of equipment for preparing refined cotton by bleaching cotton linters is provided, such as figure 1 As shown, the equipment includes a material preparation and removal device 10, a cyclone separator 20, a squeezer 30, a press machine 40, a crusher 50 and a bleaching device 60 arranged in sequence along the material direction, and the bleaching device includes sequentially arranged along the material direction. High concentration mixer 61 and continuous oxygen bleaching machine 62. Wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com