Pored-tube filling and high-pressure impacting extruding grouting method

A high-pressure, hole-pipe technology, applied in the field of high-pressure punching "grouting," hole-pipe sealing, can solve the problems of low strength, poor grouting, poor effect, etc., and achieve the effect of high strength and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

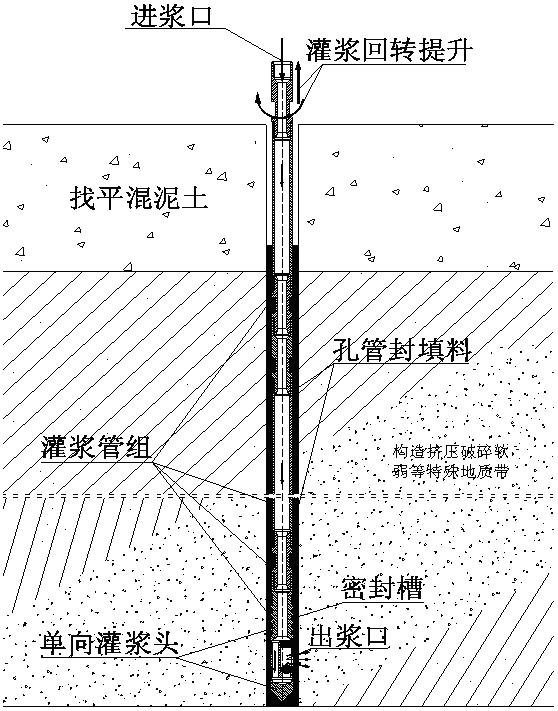

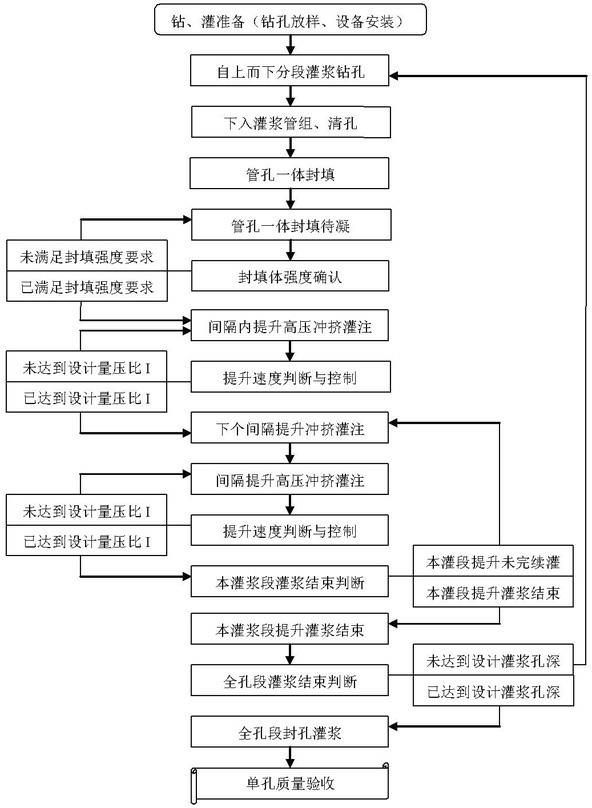

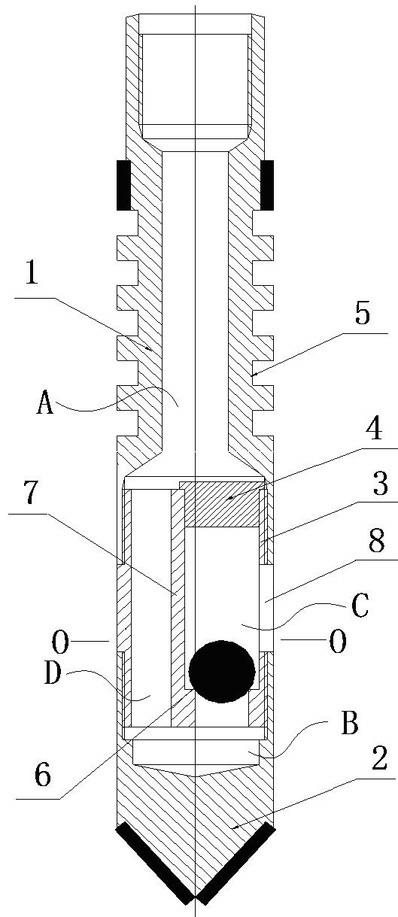

[0032] A method of grouting with the above-mentioned "hole tube sealing and high pressure squeezing", the specific steps are:

[0033] (1) Drilling and grouting lifting adopt full hydraulic power head drilling rig; squeeze grouting should adopt special high-pressure (≥10MPa) single-cylinder single-acting grouting pump, or use the current domestic three-cylinder high-pressure grouting pump to retain a plunger (unloading Go to two plungers) to realize single-cylinder single-action squeezing grouting, the appropriate amount of single squeezing is 0.3-1L, and the squeezing frequency is 30 times / min--100 times / min.

[0034] (2) The drilling segment is determined according to the stability of the hole wall and the capacity of the equipment and machinery. The length of a grouting segment is taken as a grouting segment with a full hole once or every 10m-50m from top to bottom. The grouting hole diameter adopts Φ75mm or Φ91mm. After the grouting section is drilled, flush the hole in the ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com