Device and method for making refined cottons through performing high-concentration hydrogen peroxide bleaching on cotton linters

A technology of high-concentration hydrogen peroxide and cotton linters, which is applied in the field of cotton linter pulping, can solve the problems of low pulping yield, harm to human health and ecological environment, and decrease in the degree of polymerization of cotton fibers, so as to accelerate mass transfer. The effect of increasing the rate, improving the utilization rate, and increasing the concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

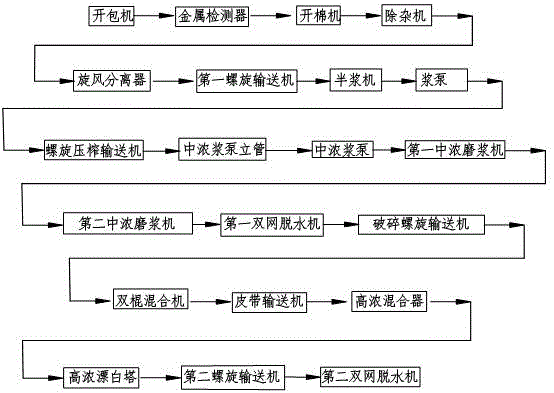

[0040] Such as figure 1 As shown, the device for preparing refined cotton by bleaching cotton linters with high-concentration hydrogen peroxide, including bale opener, metal detector, cotton opener, impurity remover, cyclone separator, first screw conveyor, half pulper, installation and decontamination The first medium-consistency refiner with a type grinding disc, the second medium-consistency refiner with a refining disc, the first double-net dehydrator, crushing screw conveyor, double-roll mixer, belt conveyor, high-consistency mixer , a high-concentration bleaching tower, a second screw conveyor, and a second double-net dehydrator, wherein the linters are connected by a belt conveyor between the bale opener, the metal detector and the cotton opener, and the cotton linters are connected between the opener, the metal detector, and the cotton opener. The impurity remover and the cyclone separator are connected by an air delivery pipeline, the outlet of the cyclone separator i...

Embodiment 2

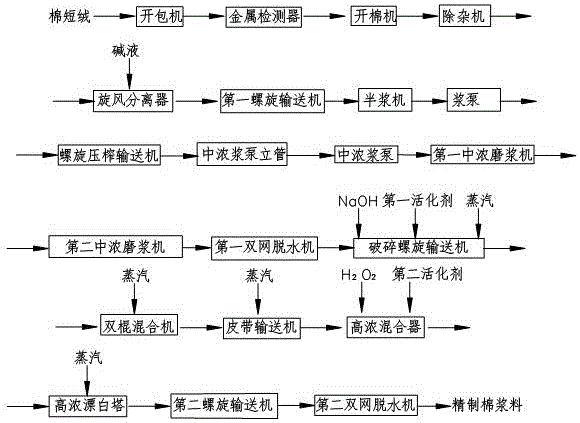

[0048] Such as figure 2 Shown, the method for preparing refined cotton by bleaching cotton linters with high-concentration hydrogen peroxide, adopting type III cotton linters as raw material, comprises the following steps:

[0049] 1) Cotton opening and impurity removal. After the cotton linters are unpacked by the bale opener, they are checked by a metal detector and metal objects are removed, and then the cotton linters are opened and shredded into flocculent small pieces by the cotton opener. Remove some impurities, and then transport them to the impurity remover to further remove foreign impurities such as dust and cotton seed hulls; the content of foreign mechanical impurities carried by cotton linters after treatment is less than 4%;

[0050] 2) Pre-infiltrated, washed and refined, the cotton linters after cotton opening and impurity removal are mixed with NaOH solution at a temperature of 40°C and a mass concentration of 5% in a cyclone separator, and then enter the fi...

Embodiment 3

[0057] Such as figure 2 Shown, the method for preparing refined cotton by bleaching cotton linters with high-concentration hydrogen peroxide, adopting type III cotton linters as raw material, comprises the following steps:

[0058] 1) Cotton opening and impurity removal. After the cotton linters are unpacked by the bale opener, they are checked by a metal detector and metal objects are removed, and then the cotton linters are opened and shredded into flocculent small pieces by the cotton opener. Remove some impurities, and then transport them to the impurity remover to further remove foreign impurities such as dust and cotton seed hulls; the content of foreign mechanical impurities carried by cotton linters after treatment is less than 4%;

[0059] 2) Pre-infiltrated, washed and refined, the cotton linters after cotton opening and impurity removal are mixed with NaOH solution at a temperature of 80°C and a mass concentration of 2% in a cyclone separator, and then enter the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com