Size preparation method, size and paper made of size

A slurry and high-consistency refining technology, used in pulp beating/refining methods, papermaking, textiles and papermaking, etc., can solve the problem of fiber cutting, unfavorable to improve pulping yield, pulp strength, and fiber bundles are difficult to be dissociated. Brooming and other problems, to achieve the effect of improving strength, improving the rate of splitting and brooming, and fine surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

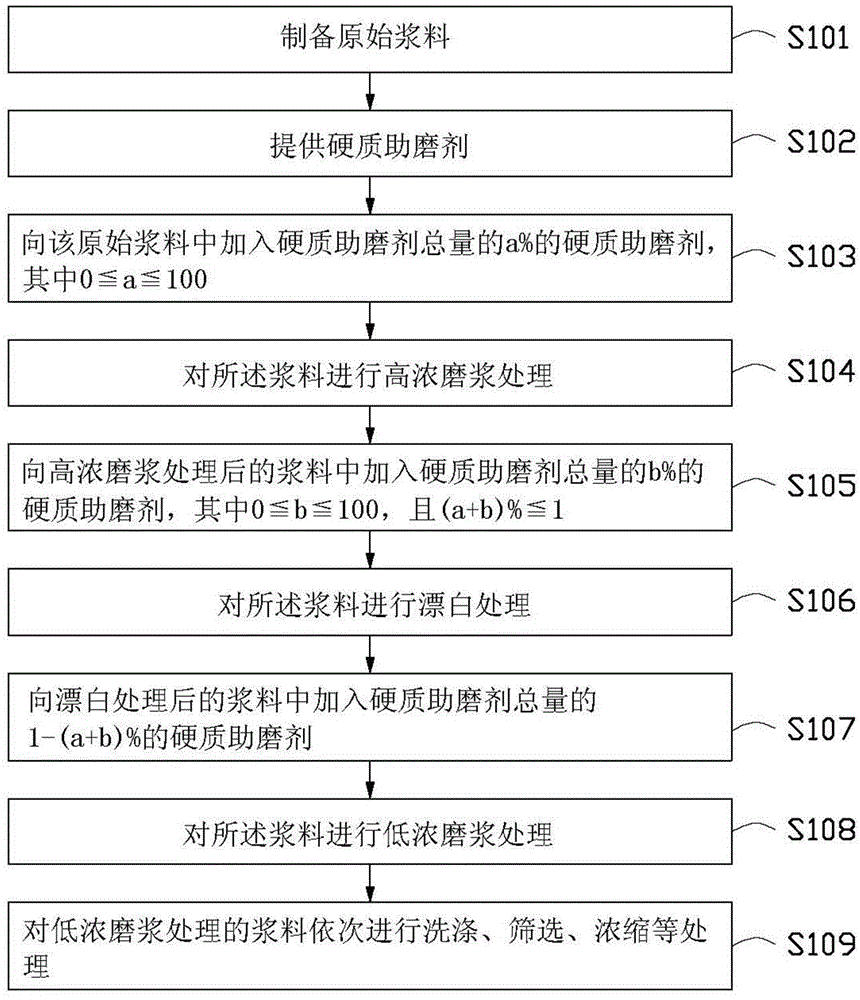

[0019] See figure 1 , a preferred embodiment of the present invention provides a kind of preparation method of slurry, mainly comprises the following steps:

[0020] S101: Prepare raw pulp, the specific method is as follows: use at least one of wood chips such as hardwood chips and coniferous wood chips as raw materials, and perform conventional washing, steaming, crushing, tearing and other treatments on the raw materials to obtain Original slurry. The raw stock mainly contains stock fibers 10 and water. The mass percentage of the original slurry is 25%-50%.

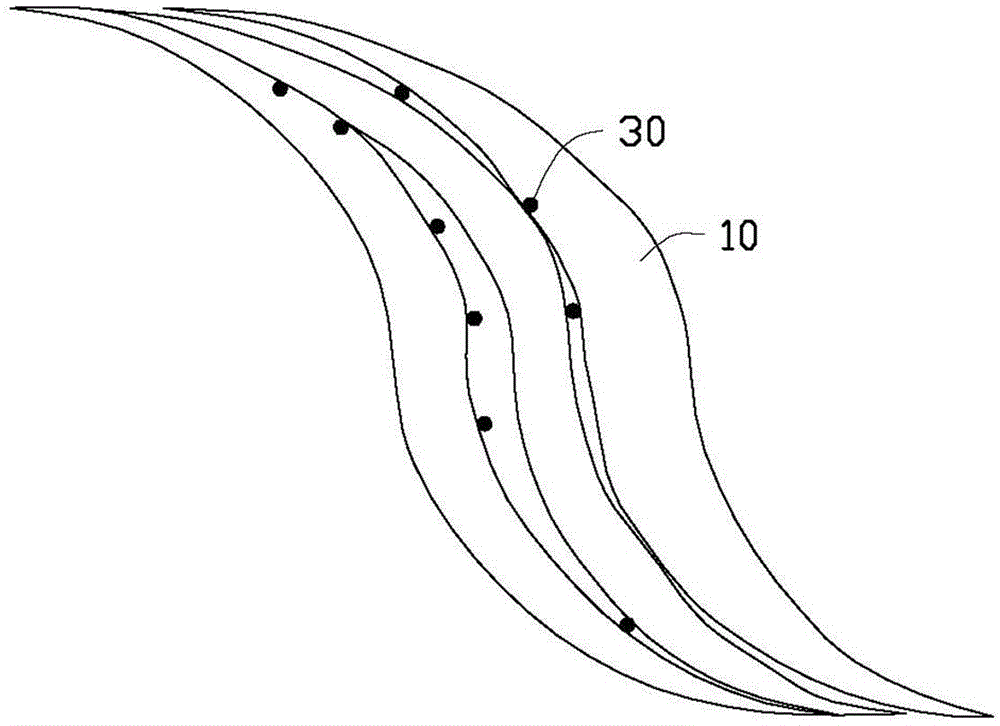

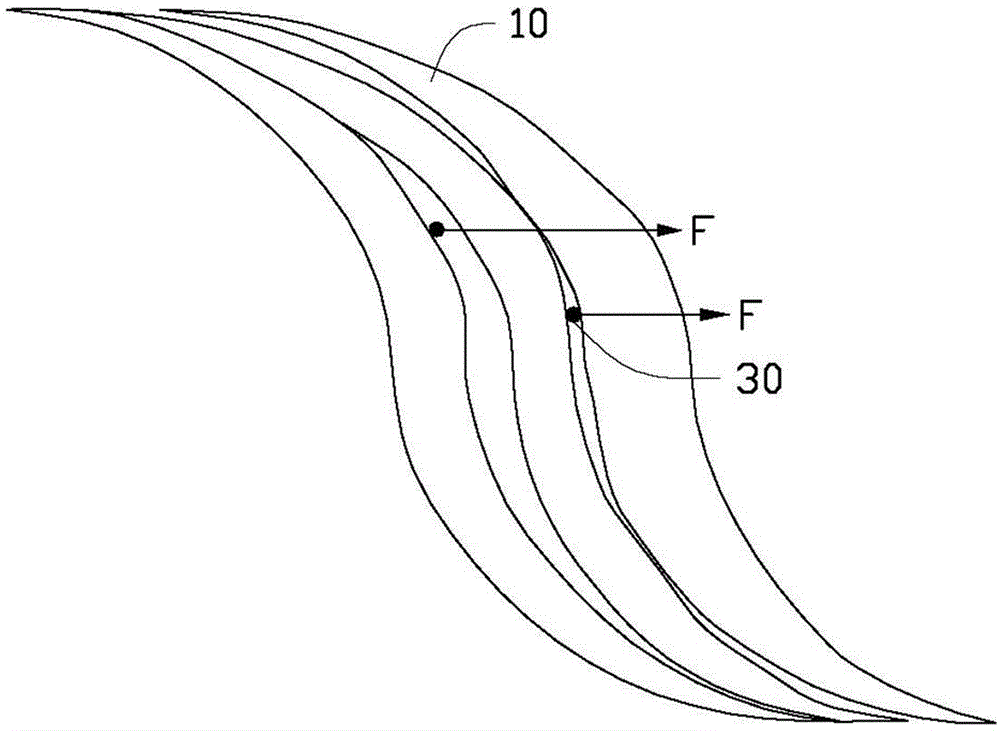

[0021] S102: Provide hard grinding aid 30 (see figure 2 ). The mass of the hard grinding aid 30 is 3%-20% of the absolute dry mass of the original slurry, preferably 6%-10%. The hard grinding aid 30 can be any one or a mixture of precipitated calcium carbonate (PCC), ground calcium carbonate (GCC), talc (Talc) and titanium dioxide. The particle size of the above-mentioned hard grinding aid 30 is 0.2-50 μm. Among...

Embodiment 1

[0039] The original slurry was prepared, the raw material of the original slurry was poplar wood chips, and the mass percentage of the original slurry was 45%. A hard grinding aid 30 is provided, and the hard grinding aid 30 is grade 65 GCC. Add 8% 65-grade GCC of the dry weight of the original slurry to the original slurry and mix evenly to obtain a mixed slurry. The mixed pulp is subjected to high-consistency refining treatment. The power of the refiner is 18MW. After the high-consistency refining treatment, the mixed pulp is bleached, low-consistency refined, washed, screened, and slag-removed to obtain the required pulp. And before the screening and slag removal treatment, the fiber bundle content and the quality of the slurry in the slurry were tested by sampling.

Embodiment 2

[0047] The steps and process parameters of Example 1 are basically the same, the difference is that in this embodiment, the filler grade PCC with an absolute dry mass of 10% of the original slurry is added to the original slurry. During the high-consistency refining process, the refiner The power is 25MW.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com