Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "High initial adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

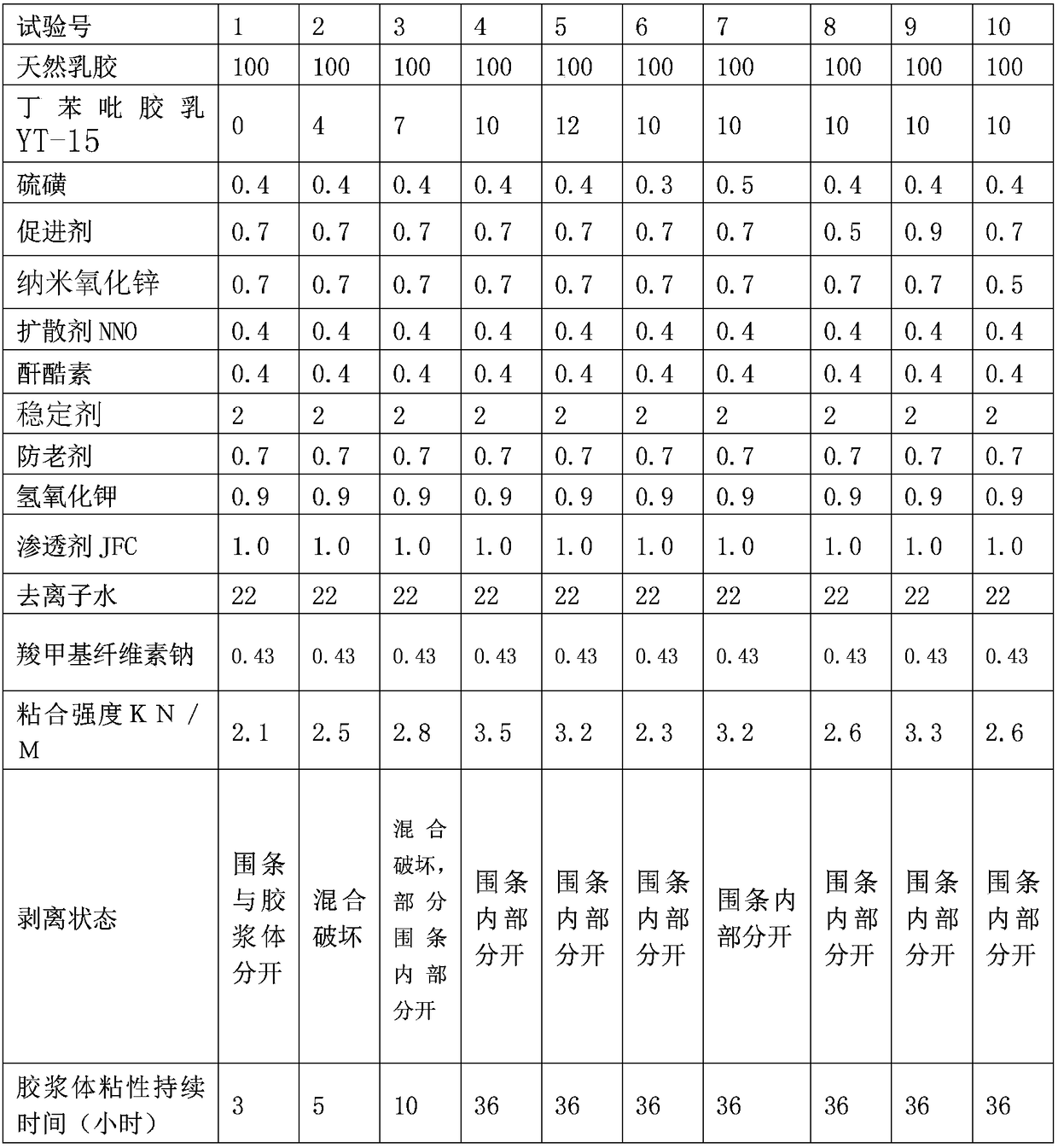

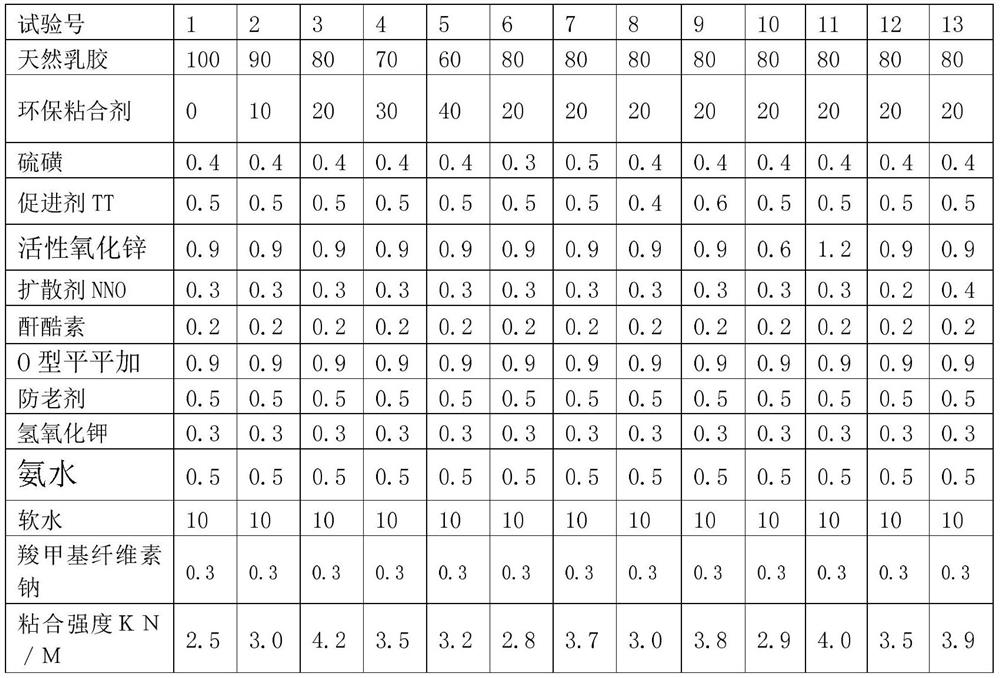

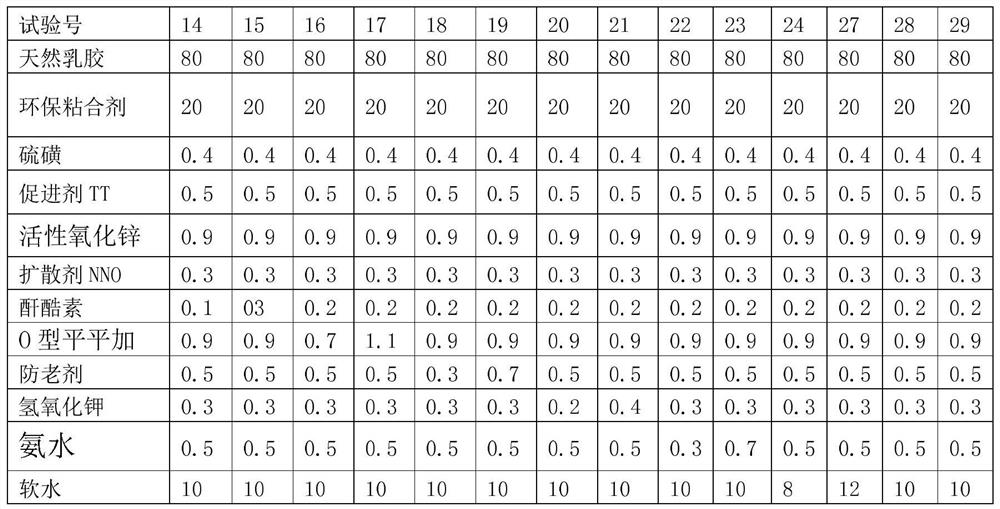

Water soluble adhesive and preparation method thereof

ActiveCN101486882APrevent agingMaintain performanceNatural rubber adhesivesFootwearNon toxicityPolymer science

The invention provides a water-soluble adhesive and a preparation method thereof. The water-soluble adhesive is prepared mainly by natural latex, soft water, a vulcanizing agent, a vulcanization accelerator, a vulcanizing activator, a dispersant, anhydride casein, borax, a stabilizer, a wetting agent, ammonia and potassium hydroxide. In order to improve the performance of the water-soluble adhesive, carboxymethyl cellulose sodium, the wetting agent, an age inhibitor, an antifoaming agent and a mildew inhibitor also can be added; the obtained water-soluble adhesive is an environment-friendly material which is used for shoes, has the processing advantages of low energy consumption, non-toxicity, good processing property, simple operation and the like in the preparation process, strengthens self deterioration resistance, greatly prolongs the storage stabilization period of slurry, improves the intrinsic performance of the adhesive, and fundamentally realizes the demand of high adhesive strength on rubber shoes.

Owner:际华制鞋工业有限公司

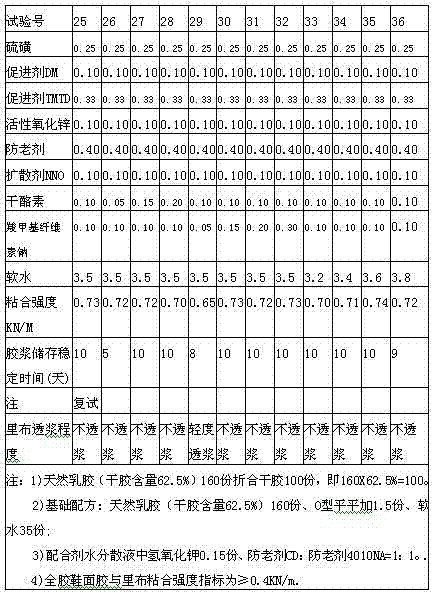

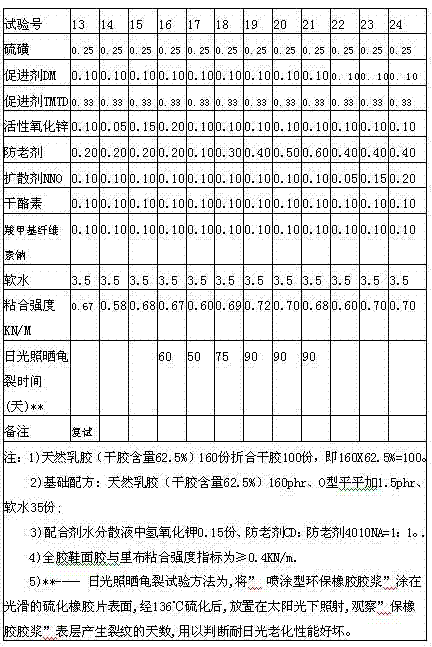

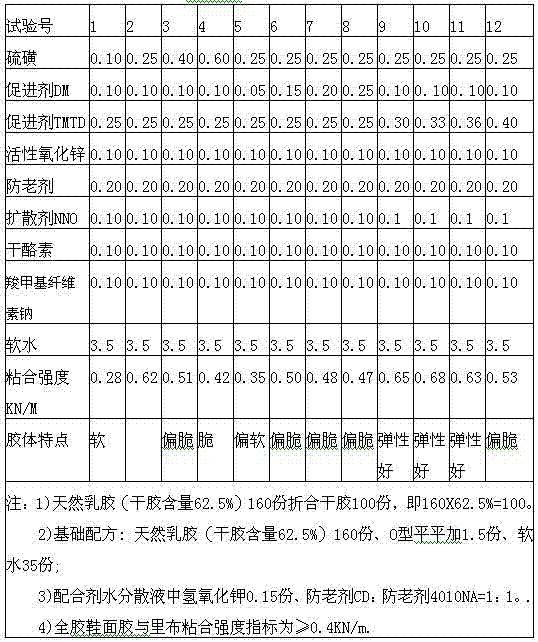

Spraying-type environment-friendly rubber adhesive cement and preparation method thereof

ActiveCN102807830AOvercome the quality problems of degummingPrevent agingNatural rubber adhesivesNon-macromolecular adhesive additivesEmulsionOxide

The invention discloses a spraying-type environment-friendly rubber adhesive cement and a preparation method of the rubber adhesive cement. The spraying-type environment-friendly rubber adhesive cement comprises the following components by weight parts: natural emulsion containing 62.5% of dry glue content, O-type peregal, soft water, and compounding agent aqueous dispersion, wherein the compounding agent aqueous dispersion comprises sulphur, an accelerant DM (2,2'-dibenzothiazoledisulfde), an accelerant TMTD (tetramethyl thiuram disulfide), active zinc oxide, anti-aging agent CD, anti-aging agent 4010NA, mildew preventive BCM, dispersing agent NNO, potassium hydroxide, casein and soft water. By using the natural emulsion as the main material and due to the fact that the original condition of the molecules of the natural emulsion are kept basically, the high initial bonding property of the environment-friendly rubber adhesive cement is ensured; the vulcanized and cross linked adhesive cement and the bonded rubber component form a strong unity, so that the product has a high final bonding property. The manufacturing process disclosed by the invention has the advantages of low energy consumption, no toxic, excellent processing property, simple operation, and the like. In addition, the deterioration resistance of the binder is enhanced, the storage stationary phase of the cement is prolonged greatly, and the internal property of the binder is improved.

Owner:际华制鞋工业有限公司

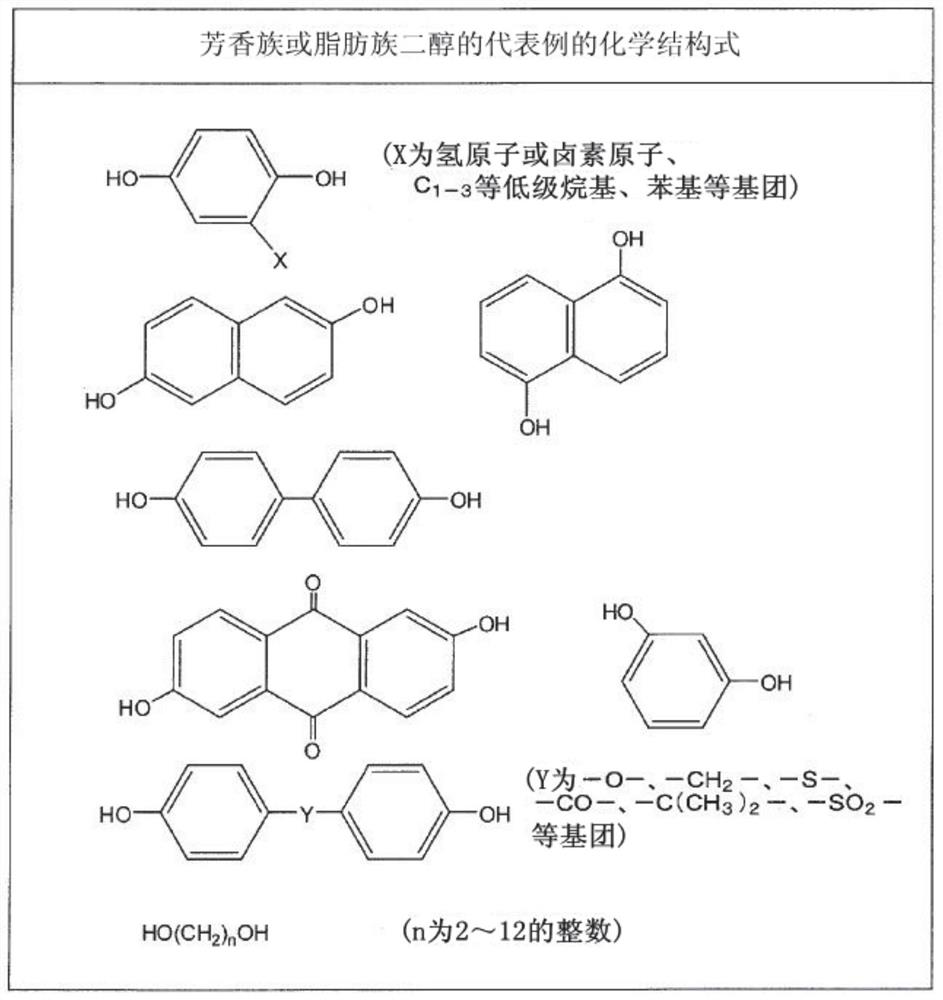

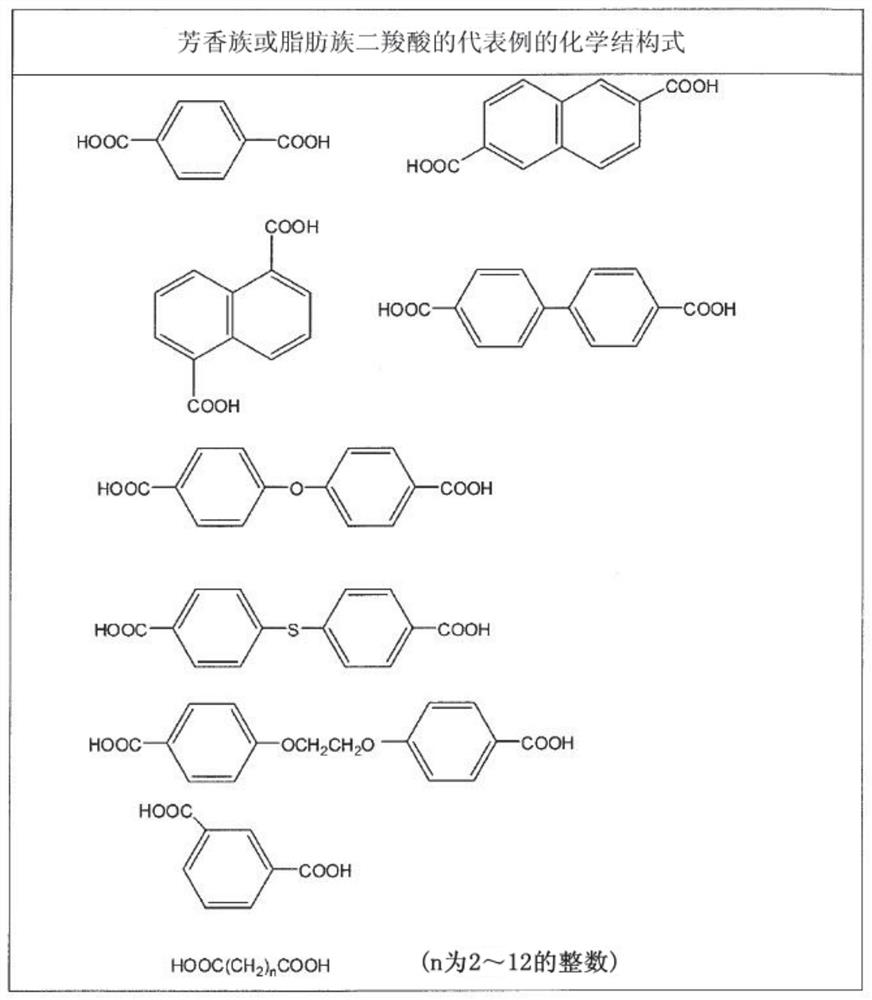

Aqueous silylated urethane composition, aqueous adhesives for wrapping, and aqueous contact adhesives

InactiveCN1788030AImprove securityHigh initial adhesionPolyureas/polyurethane adhesivesWater basedPolyol

The silylated polyurethane water-based composition can be used as a water-based adhesive that is highly safe, takes a short time to express an excellent adhesive force, and is excellent in initial adhesiveness. The aforementioned silylated polyurethane-based aqueous composition is characterized in that the composition contains the following (A) component, (B) component, and (C) component: (A) polyol compound (A1) not containing anionic groups , polyol compound (A2) containing anionic group, compound (A3) containing tertiary amino group and isocyanate-reactive group, polyisocyanate compound (A4), alkoxysilane compound (A5) containing isocyanate-reactive group ), and an alkoxysilyl-terminated polyurethane prepolymer containing anionic groups and tertiary amino groups obtained by reacting with an amine chain extender (A6), (B) a basic compound, and (C) water.

Owner:KONISHI CO

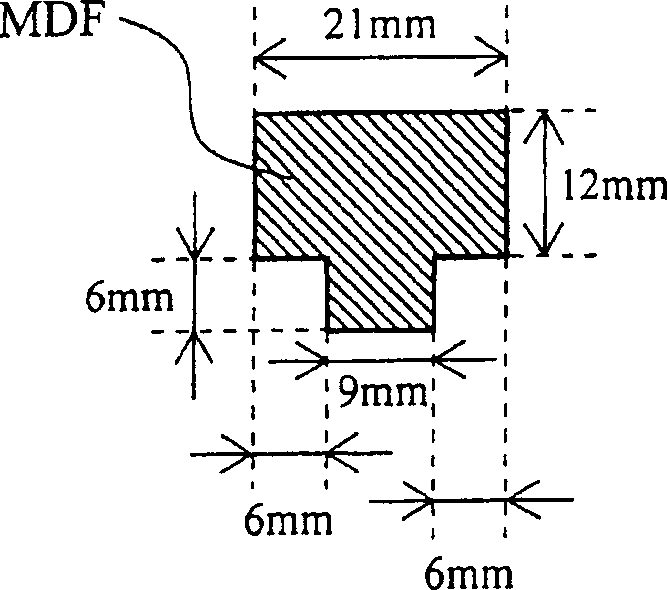

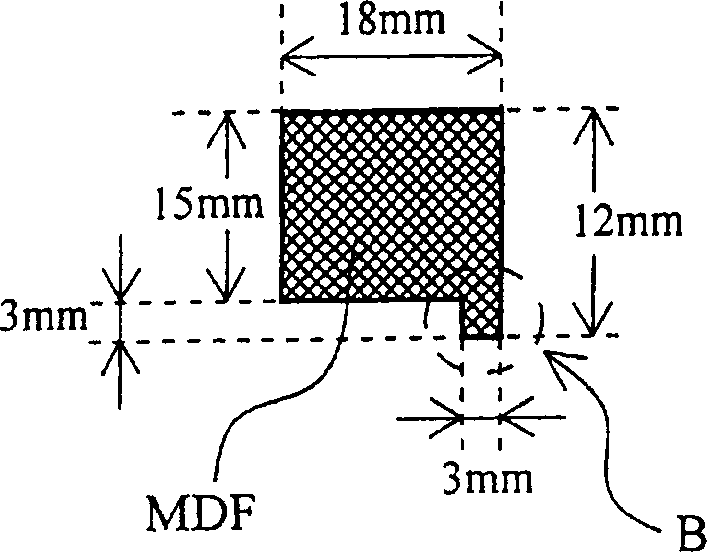

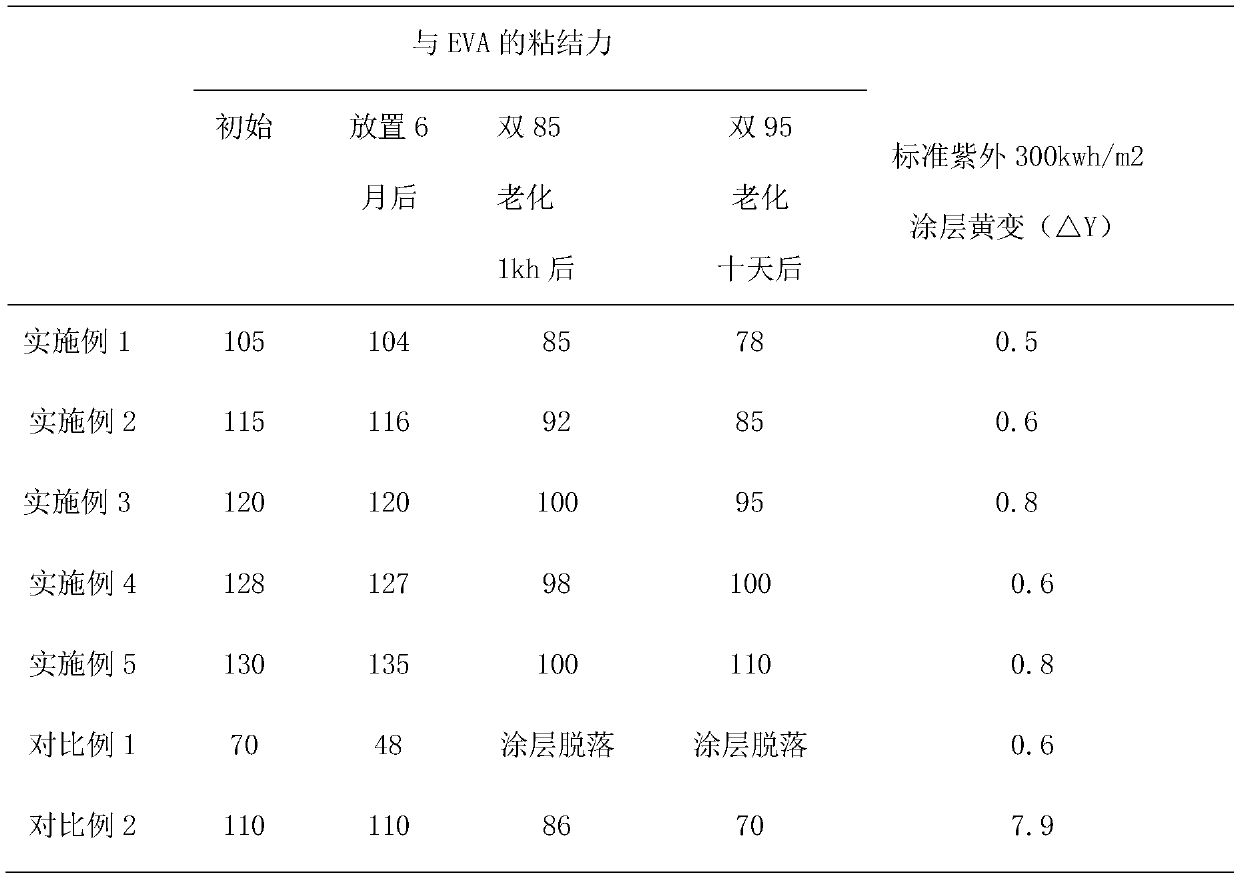

Coating for solar cell back plates

ActiveCN109735177AGood interlayer forceEasy to degradeCoatingsPhotovoltaic energy generationWeather resistanceAcrylic resin

The invention relates to coating for solar cell back plates. The coating comprises, by mass percentage, 9.2-14.4% of fluorocarbon resin, 3.6-9.2% of acrylic resin, 20.5-25.3% of pigment, 37.6-48.1% ofsolvent, 0.6-1% of auxiliaries and an isocyanate curing agent, wherein the mole ratio of hydroxyl in the fluorocarbon resin and the acrylic resin to the isocyanate in the curing agent is 0.8-1.6, andthe total mass percentage of the components is 100%. The coating has the advantages that the coating is good in interlayer performance, a coating layer after hydrothermal aging is good in bonding force with EVA, and the problem that fluorocoating cannot give consideration to both weather resistance and cohesiveness is solved.

Owner:乐凯胶片股份有限公司

Room-temperature rapid-curing polyurea adhesive and preparation method thereof

InactiveCN103694939AGel fastRapid viscosity increasePolyureas/polyurethane adhesivesPolymer sciencePolyol

The invention relates to a room-temperature rapid-curing polyurea adhesive and a preparation method thereof. The polyurea adhesive comprises A and R components, wherein the A component comprises polyether polyol and polyisocyanate; the R component comprises amino polyether and an amine chain extender. The polyurea adhesive is applied to the surface of bonded buoyancy material modules, has the effects of rapid curing and rapid tackifying, is higher in primary adhesive force and can reach the machining strength in the short time; the modules do not need to be clamped and fixed in splicing, bonding and curing processes and can be bonded on machining site, and the operation is convenient and reliable.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

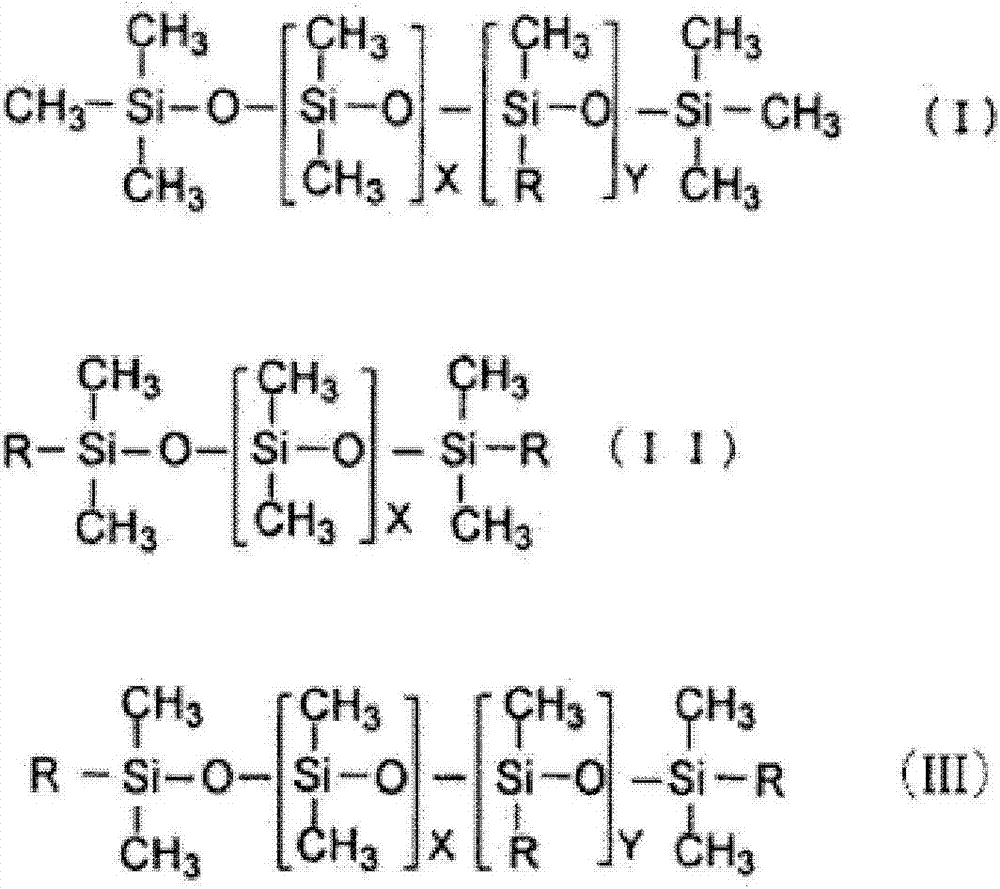

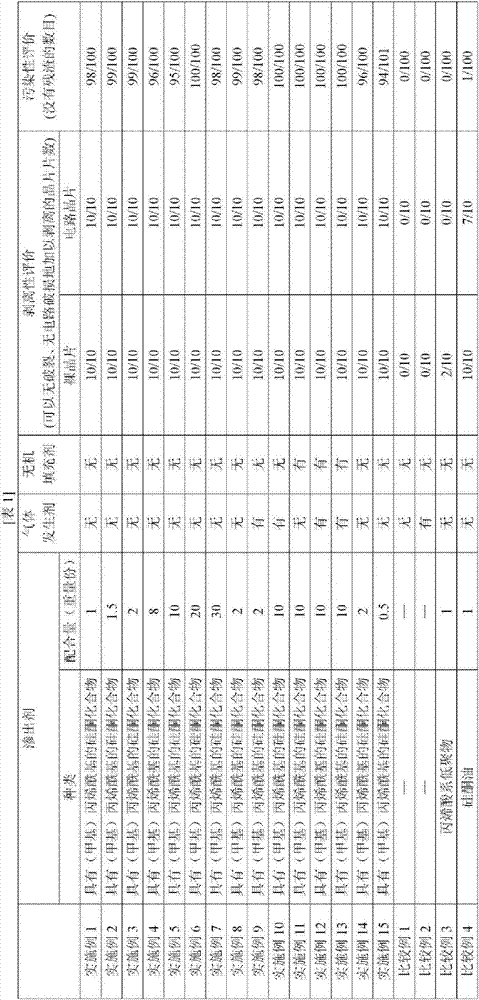

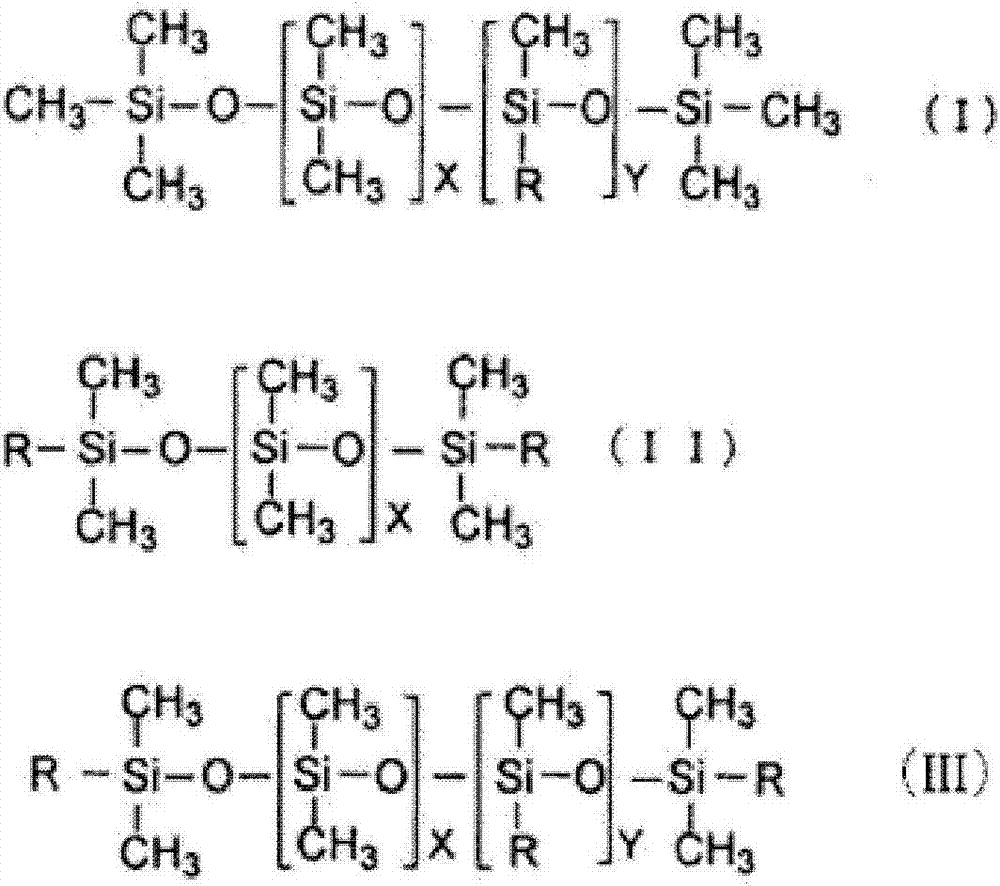

Pressure-sensitive adhesive compound, pressure-sensitive adhesive tape, and wafer treatment method

ActiveCN103097485AEasy to fixHigh initial adhesionLamination ancillary operationsSolid-state devicesLight irradiationPhotoinitiator

The present invention aims to provide an adhesive composition which has high initial adhesion and can strongly fix an adherend, while can be peeled off easily by light irradiation even after undergoing a high-temperature process at 200°C or higher. The present invention also aims to provide an adhesive tape produced from the adhesive composition, and wafer treatment method using the adhesive composition. The present invention provides an adhesive composition including an adhesive component, a photoinitiator, and a silicone compound containing a functional group that is crosslinkable with the adhesive component.

Owner:SEKISUI CHEM CO LTD

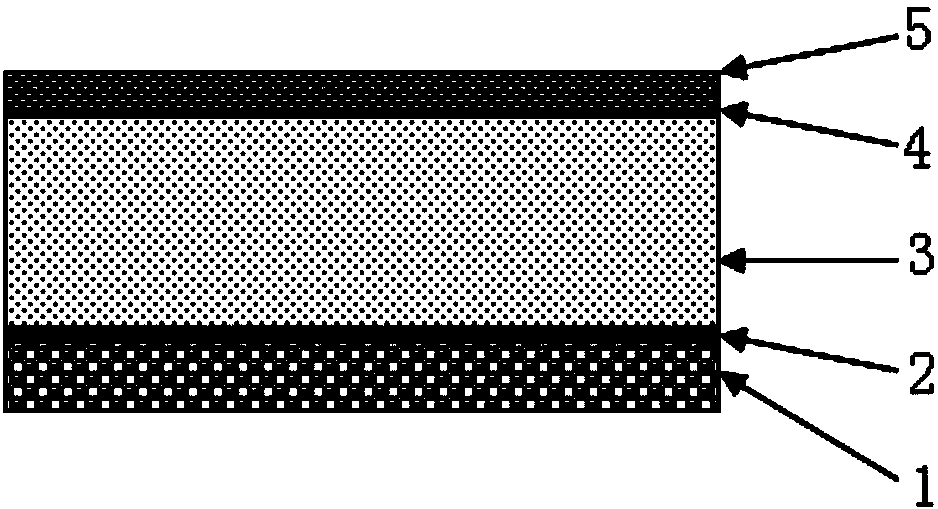

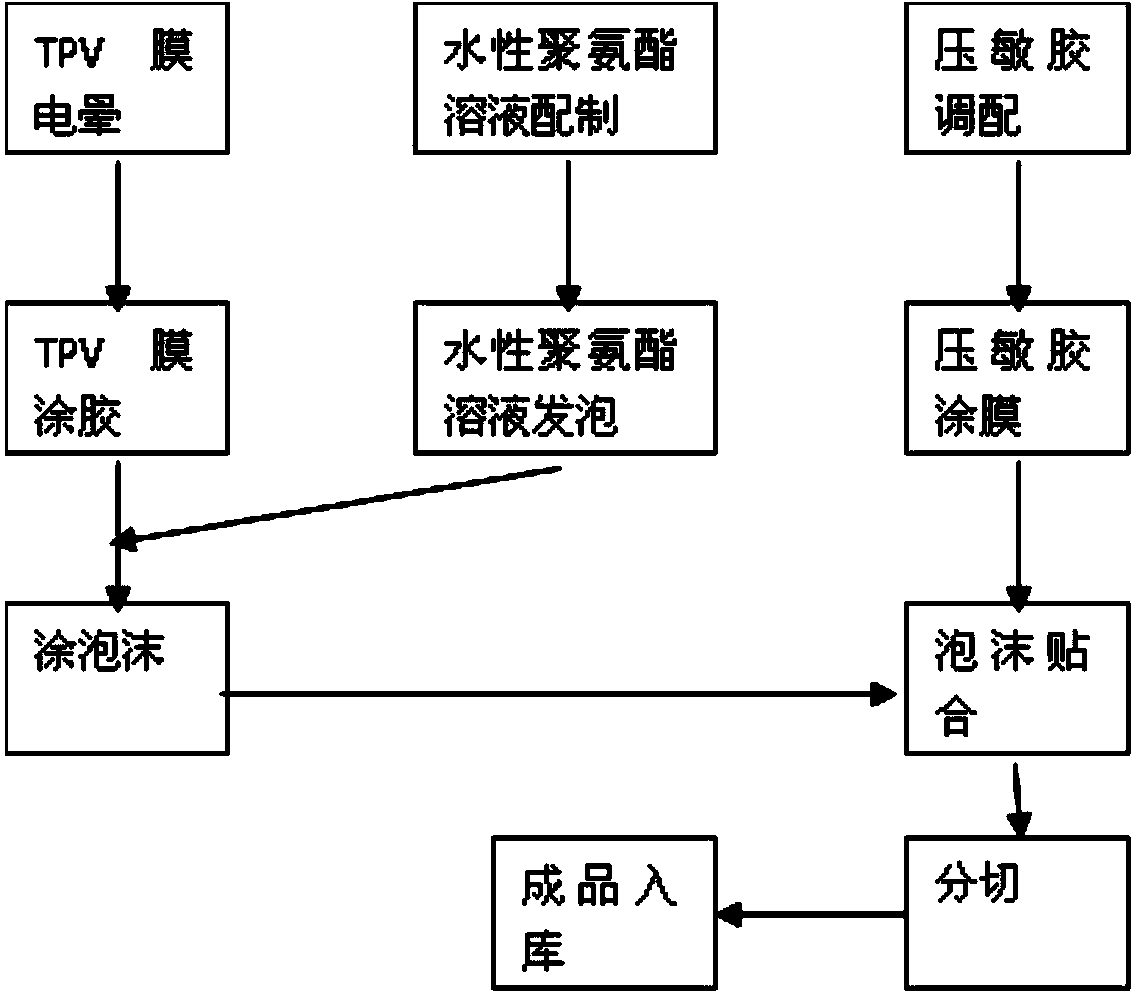

Foam adhesive tape and preparation method thereof

ActiveCN104371584AImprove sealingIncrease elasticityFilm/foil adhesivesPolyureas/polyurethane adhesivesThermoplasticPolyurethane adhesive

The invention discloses a production method of a foam tape. The foam tape comprises a TPV (Thermoplastic Vulcanizate) film, a bonding layer, a foam layer, a pressure-sensitive adhesive layer and a PE (Poly Ethylene) film. The production method comprises the following steps: a) performing polyurethane affinity treatment on the TPV film, and coating the surface of the TPV film with a single-component polyurethane adhesive to obtain the bonding layer; b) sequentially adding 10-30% of anti-hydrolysis component and 1-2% of foam regulation agent into waterborne polyurethane emulsion to form a polyurethane mixed liquid; c) performing polyurethane release treatment on the PE film; d) under a temperature condition of 100-120 DEG C, foaming the polyurethane mixed liquid to form the foam layer on the TPV film; e) coating the foam layer with the pressure-sensitive adhesive so that the PE film and the polyurethane foam are bonded. By adopting the method disclosed by the invention, the produced waterborne polyurethane foam tape has good rebound resilience, high elongation, high strength and long anti-aging time, and is environment-friendly.

Owner:SHANGHAI 3N CHEM

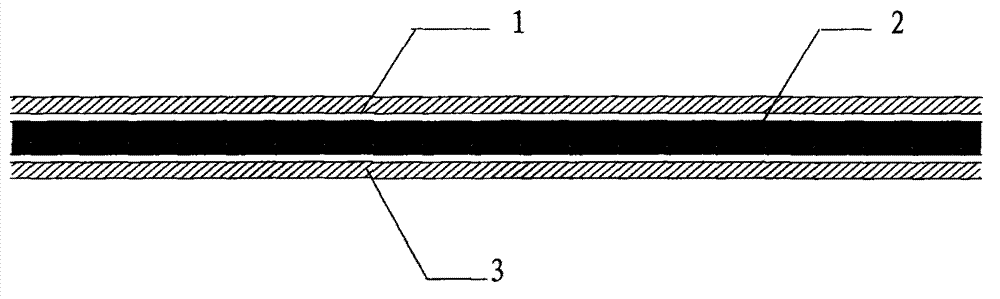

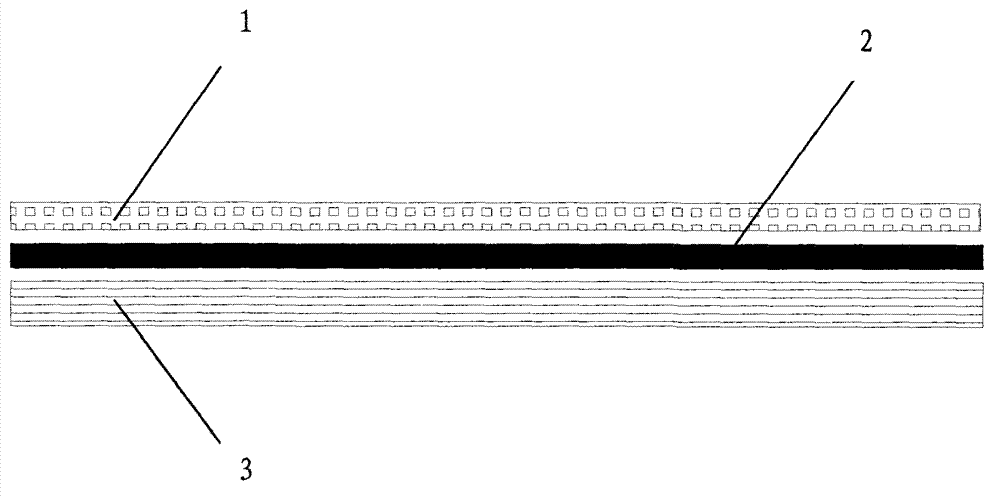

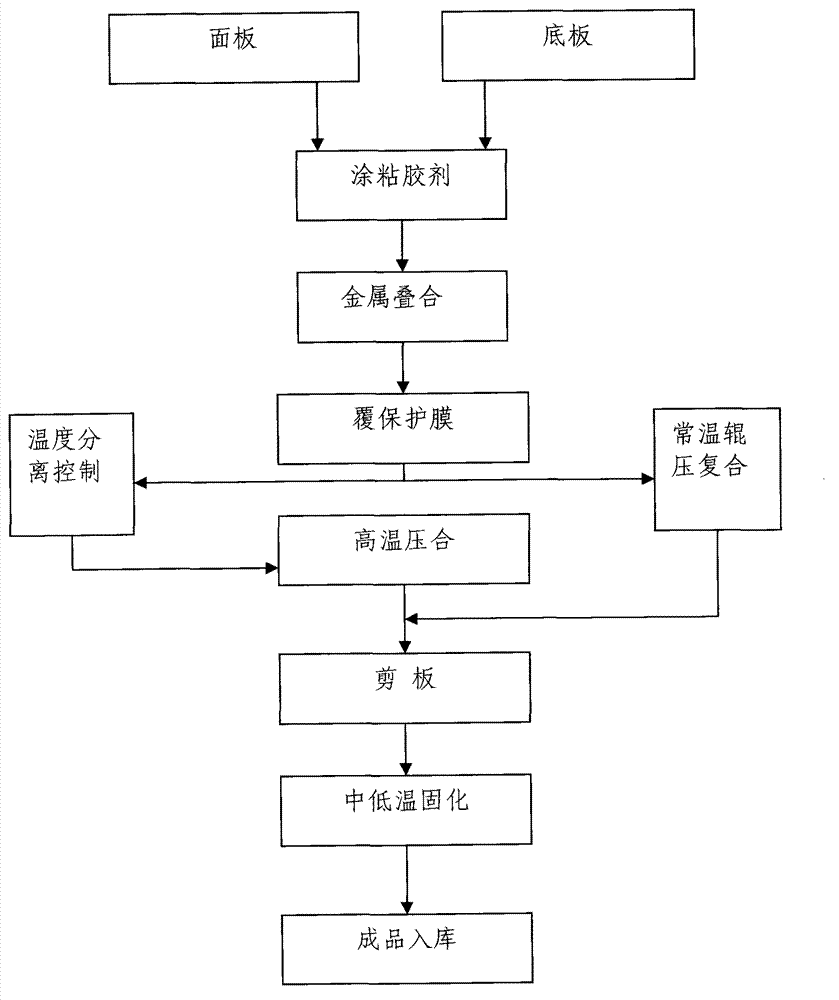

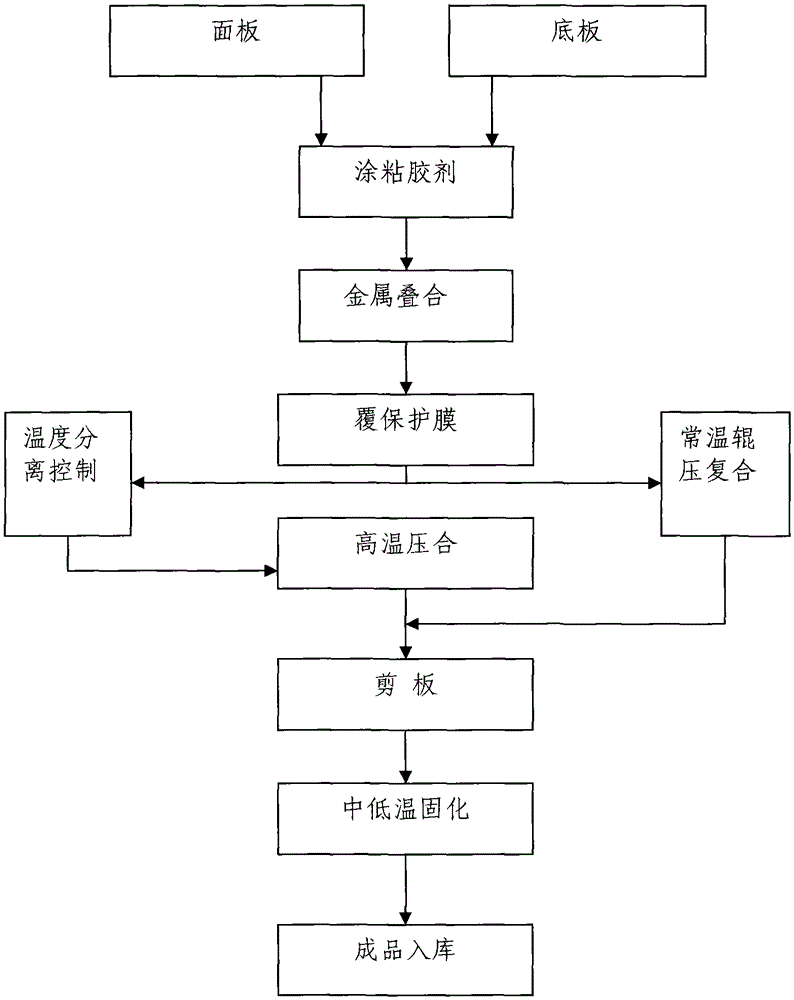

Bimetallic composite plate material and manufacturing process thereof

InactiveCN102873936AImprove creep resistanceImprove fatigue resistanceLaminationLamination apparatusSurface layerPolyurethane adhesive

The specification discloses a bimetallic composite plate material and a manufacturing process thereof; the bimetallic composite plate material comprises a surface layer metal and a bottom layer metal; a polyurethane adhesive layer is disposed between the surface layer metal and the bottom layer metal. The manufacturing process of the bimetallic composite plate material comprises the following steps: a. uniformly coating a polyurethane adhesive between the surface layer metal and the bottom layer metal; b. superposing the surface layer metal and the bottom layer metal; c. coating a protection film on the surface layer metal; d. performing normal temperature rolling compounding or heating rolling compounding of the surface layer metal and the bottom layer metal; e. shearing the plate; f. curing at a medium or low temperature.

Owner:广东晟力新材料有限公司

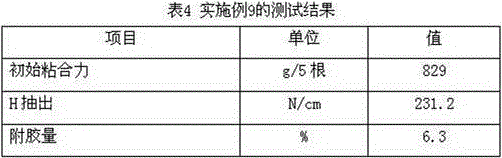

Method for improving initial adhesive force of nylon 66 dipped tyre cord fabric

ActiveCN105937185AIncrease milk contentHigh initial adhesionLiquid surface applicatorsFibre typesNylon 66Engineering

The invention discloses a method for improving the initial adhesive force of nylon 66 dipped tyre cord fabric. The method includes the steps of: 1) passing a non-dipped nylon 66 cord fabric through a dip solution at a speed of 50-120m / min; and 2) passing the dipped nylon 66 cord fabric through a drying area 1A, a drying area 1B, a drafting area and a shaping area in order at a speed of 50-120m / min, and then conducting packaging and storage. The dip solution is prepared by mixing 0.9-2.8 parts of resorcinol, 1.4-4.1 parts of formaldehyde, 0.1 part of caustic soda, 2.9-25.7 parts of natural latex, 8.6-51.5 parts of butadiene vinyl-pyridine rubber latex, 1.3-3.9 parts of ammonia water, and 28.9-79.2 parts of low purity water at 5-35DEG C for 5-9h. According to the invention, the dip solution greatly increases the natural latex content, the initial adhesive force of the prepared nylon 66 dipped tyre cord fabric finished product is increased to 500-1000g / 5 threads, and the production cost is low, therefore the method is easy for industrialization.

Owner:PINGDINGSHAN SHENMA TIRE CORD FABRIC DEV CO LTD

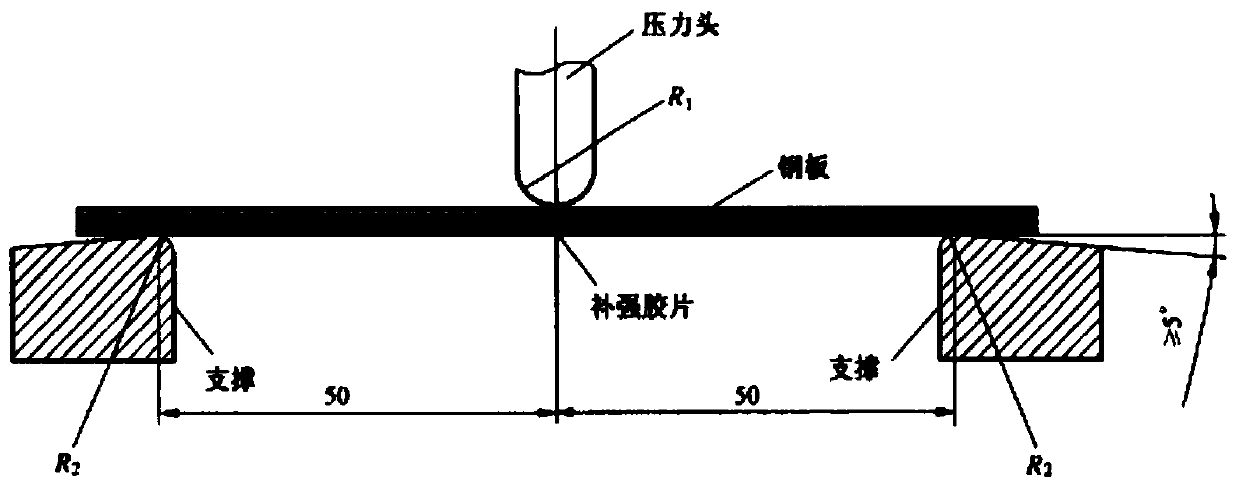

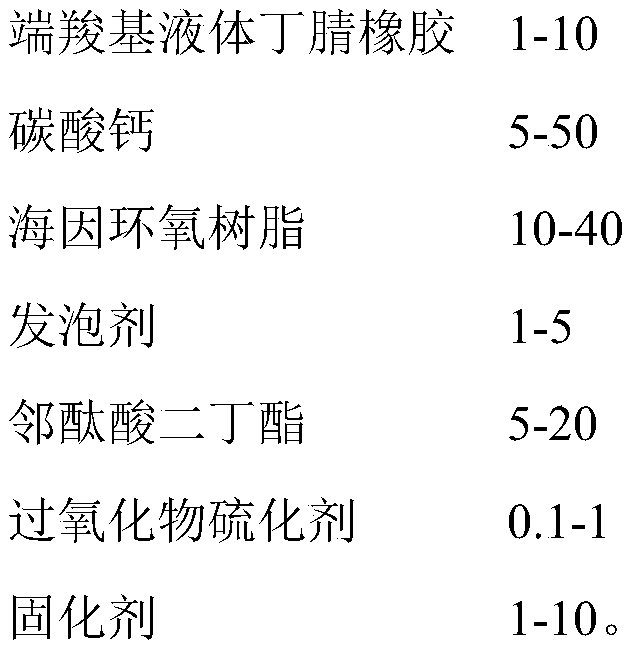

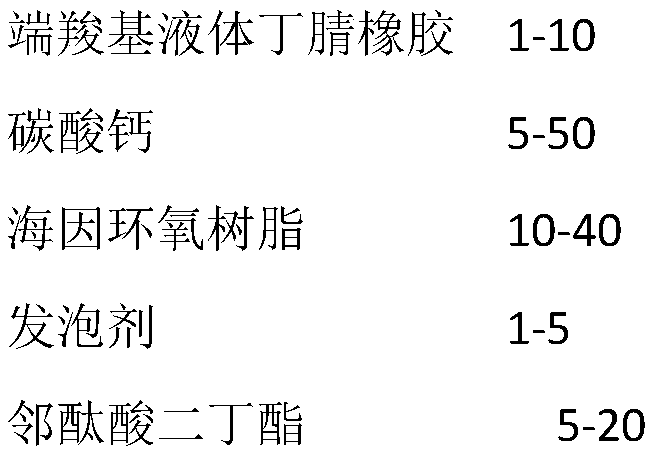

High-foaming reinforcing rubber sheet

ActiveCN111423836AGood compatibilityHigh initial adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceNitrile rubber

In order to solve the problems of fixed thickness and unsatisfactory reinforcing effect of conventional automobile reinforcing rubber sheets, the invention provides a high-foaming reinforcing rubber sheet. The reinforcing rubber sheet is composed of the following substances in parts by mass: 1-10 parts of carboxyl-terminated liquid nitrile rubber, 5-50 parts of calcium carbonate, 10-40 parts of hydantoin epoxy resin, 1-5 parts of a foaming agent, 5-20 parts of dibutyl phthalate, 0.1-1 part of a peroxide vulcanizing agent and 1-10 parts of a curing agent. The reinforcing rubber sheet of the invention has the advantages that the reinforcing rubber sheet is lighter and is beneficial for promoting lightweighting of an automobile; the strength of the reinforcing rubber sheet can be improved through microcellular foaming, and under a foaming condition, reinforcing multiplying power can also reach 5-6 times; meanwhile, due to the existence of a mesoporous structure, damping effect is better,the stress of the reinforcing rubber sheet during epoxy curing can be dispersed due to the existence of micropores; the reinforcing rubber sheet has better conformability during application, and doesnot causes deformation of a steel plate.

Owner:重庆钧业新材料科技股份有限公司

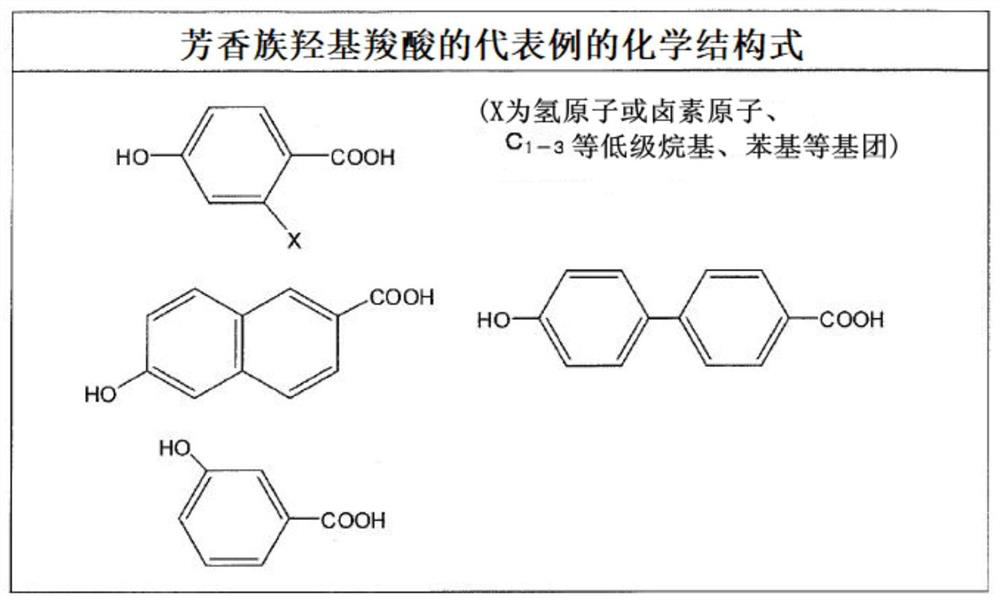

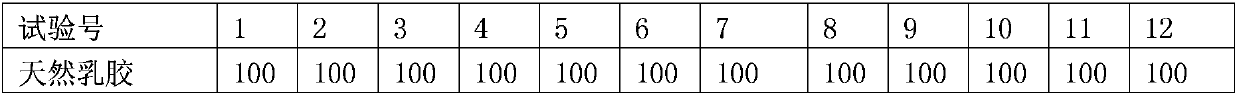

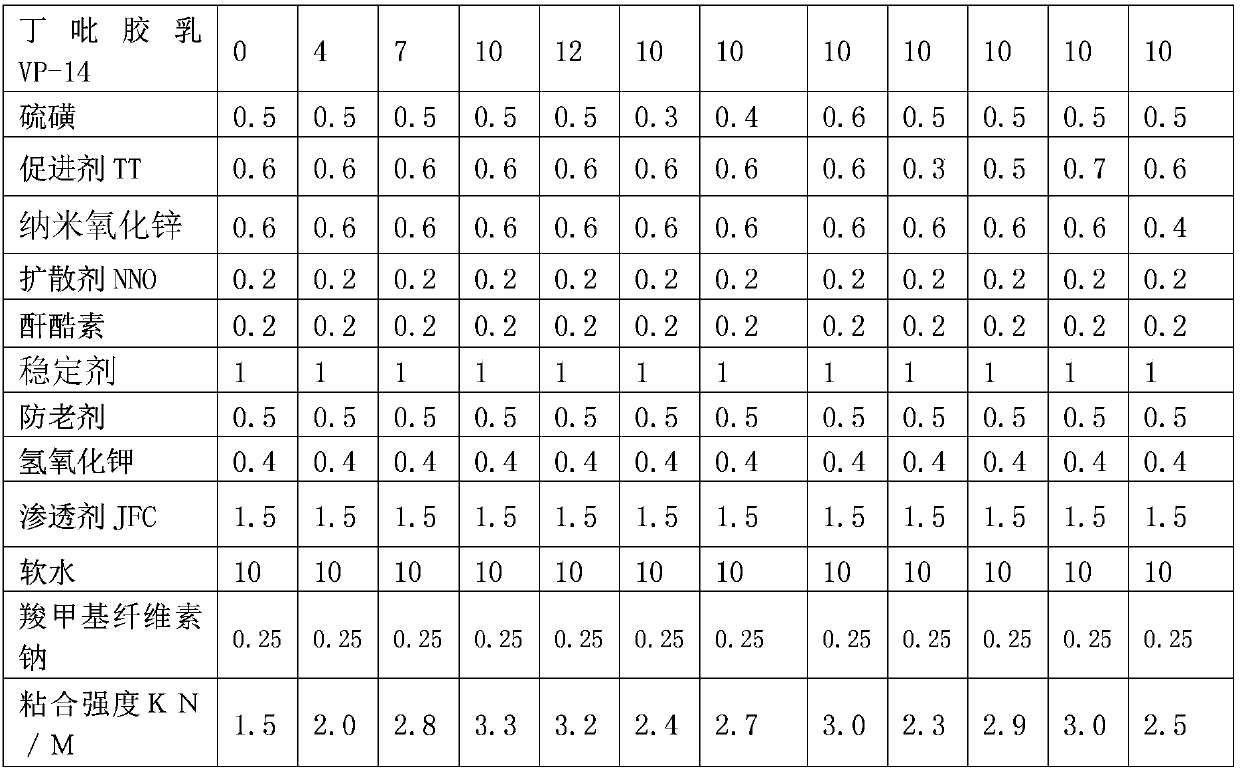

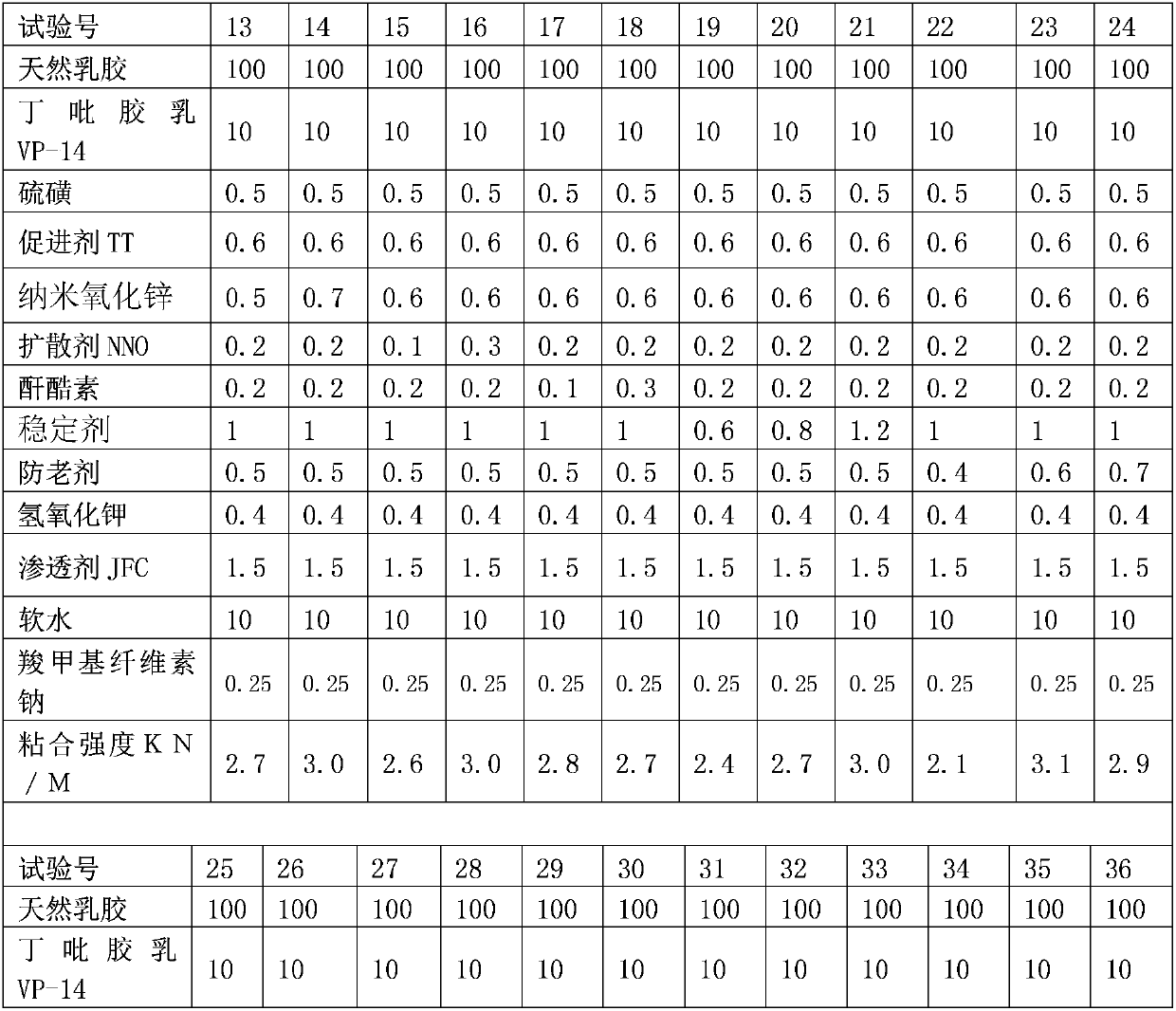

Water-borne rubber cement for cotton canvas rubber shoe foxing bonding and preparation method thereof

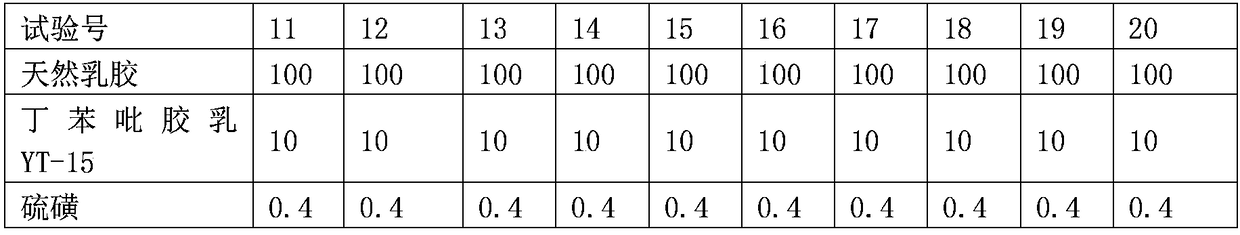

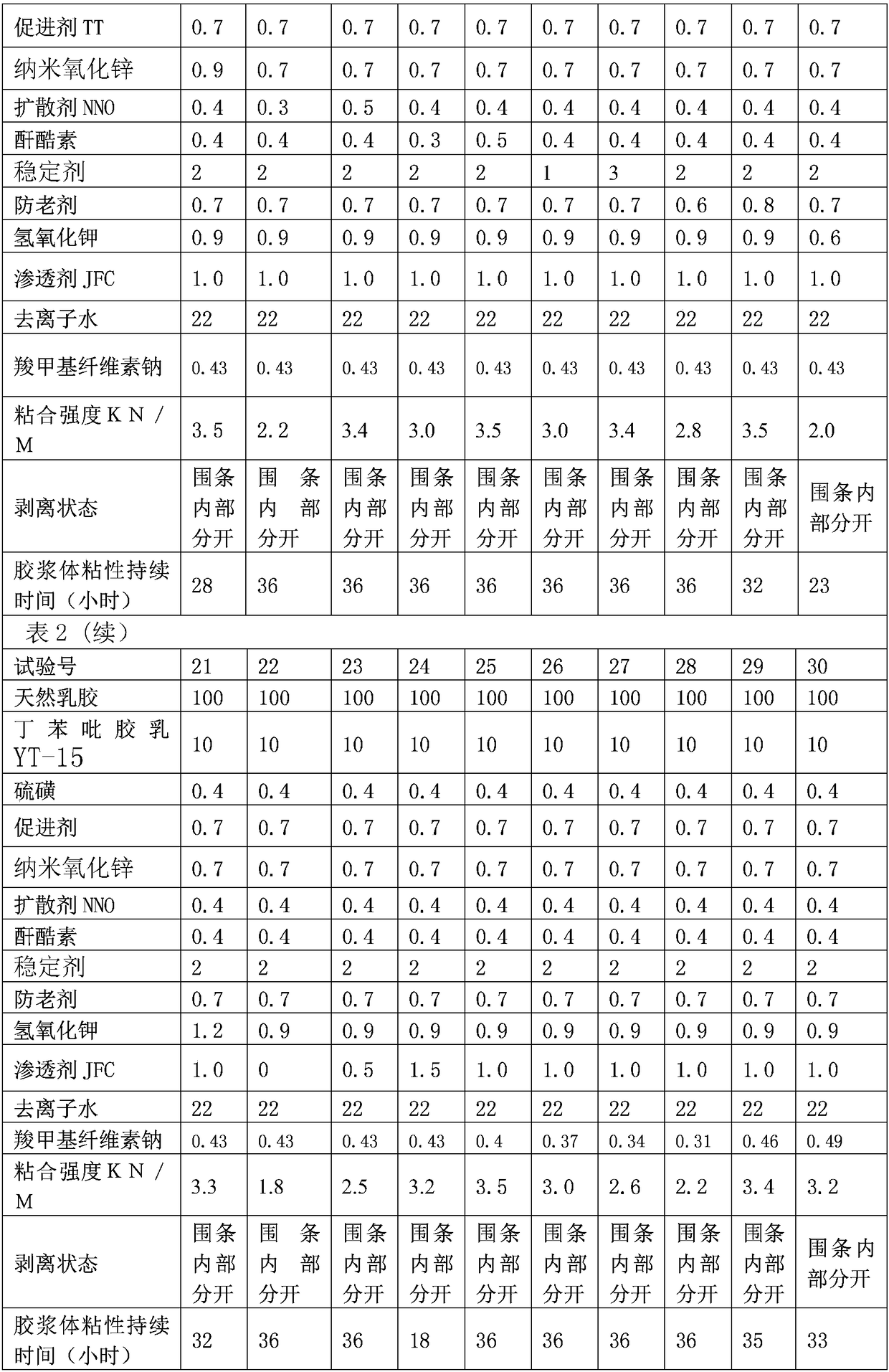

InactiveCN109294478AUniform vulcanizationConsistent vulcanizationNatural rubber adhesivesNon-macromolecular adhesive additivesFiberRubber material

The invention discloses a water-borne rubber cement for cotton canvas rubber shoe foxing bonding and a preparation method thereof. A combination of natural latex and pyridine-styrene-butadiene rubberlatex is adopted as the host material, a vulcanized and cross-linked adhesive, a bonded part and cotton canvas fiber form a high strength and uniform adherend, and the final bonding strength is high.The rubber cement has long-lasting surface stickiness, has low temperature requirement for the bonded part, and lowers the requirement of the bonded rubber material for thermal insulation performance.The three major quality problems of cotton canvas rubber shoes, i.e. lace delamination, base fabric disengaging and undersole delamination are effectively solved, and the quality defect of glue failure during use of cotton canvas rubber shoes can be thoroughly eliminated.

Owner:JIHUA 3537 SHOE MAKING

Single-component high-heat-resistance vacuum forming adhesive and preparation method thereof

InactiveCN111718682ASlow heatingSave cooling timeMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesPolymer scienceAdhesive

The invention discloses a single-component high-heat-resistance vacuum forming adhesive and a preparation method thereof. The vacuum forming adhesive comprises the following components in parts by weight: 20 to 50 parts of a VAE emulsion, 40 to 60 parts of a PUD emulsion, 2 to 10 parts of a modified VAE emulsion, 5 to 8 parts of waterborne blocked isocyanate, 2 to 5 parts of polycarbodiimide resin, 0 to 0.1 part of a pH regulator, 0.1 to 0.2 part of a defoaming agent, 0.1 to 0.2 part of a dispersing agent and 0.3 to 0.5 part of a thickening agent. The vacuum forming adhesive can be used and stored in a single-component manner, has no active period limitation and is convenient to operate; after closed isocyanate is heated, activated and unsealed, a final product has heat resistance of 80 DEG C, which exceeds the heat resistance temperature of a double-component vacuum forming adhesive. The activation temperature of the single-component high-heat-resistance vacuum forming adhesive is about 55 DEG C, so heating and cooling discharging time of a workpiece is saved in practical application, and working hours are reduced. The single-component high-heat-resistance vacuum forming adhesiveis small in particle size, good in atomization effect and good in the surface effect of formed highlight PVC.

Owner:顶立新材料科技股份有限公司 +2

Thermoplastic liquid crystal polymer molding and method for manufacturing same

PendingCN112533985AHigh initial adhesionImprove long-term reliabilityLamination ancillary operationsAdhesive processes with surface pretreatmentPolymer sciencePolymer chemistry

Owner:KURARAY CO LTD

Environment-friendly type high-bonding heat-vulcanization rubber overshoes water-emulsion adhesive and preparation method thereof

InactiveCN107674610AEnhance anti-deterioration abilityImprove intrinsic performanceNatural rubber adhesivesNon-macromolecular adhesive additivesPolymer scienceVulcanization

The invention discloses an environment-friendly type high-bonding heat-vulcanization rubber overshoes water-emulsion adhesive and a preparation method thereof. According to the invention, natural latex and styrene-butadiene latex are used as main materials, the latex molecules basically keep an original state, high initial bonding capability of an environment-friendly type high-bonding heat-vulcanization rubber overshoes water-emulsion bonding system can be ensured, rubber polymer is not changed, the vulcanized crosslinked adhesive and a to-be-bound part form a high-tenacity unity, the unity has high final-bonding intensity, the surface viscosity requirement of the to-be-bound part is not high, the temperature requirement of the to-be-bound part is low, and the thermal-insulation performance requirement of the to-be-bound part is reduced. The initial bonding force of the adhesive and the to-be-bound part as well as affinity are increased, plastic flowing of the molecules on a bonding surface of high temperature vulcanized initial rubber part is prevented, and the rubber part and a shoe upper part are firmly bound, so that three quality problems of lace delamination, base fabric disengaging, and large base elastic edge of the rubber overshoes can be effectively solved.

Owner:JIHUA 3537 SHOE MAKING

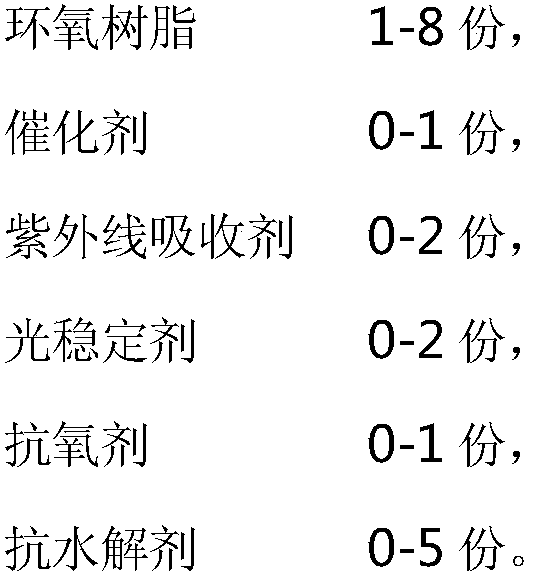

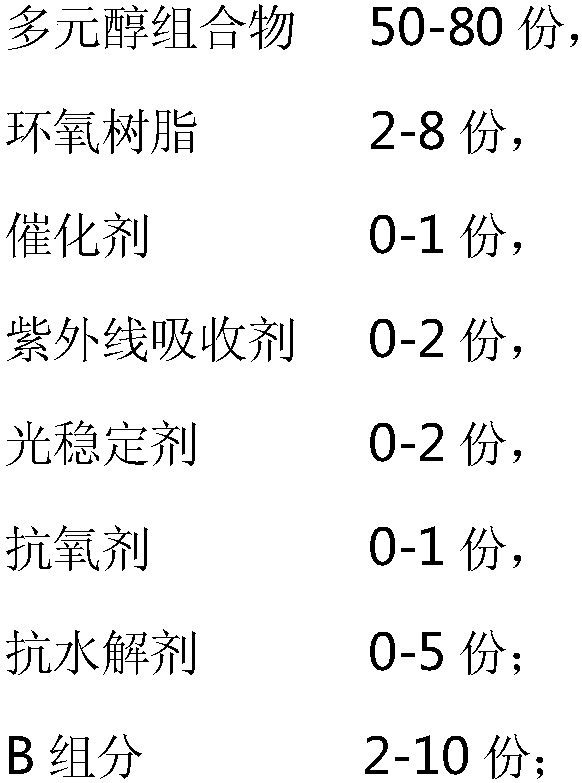

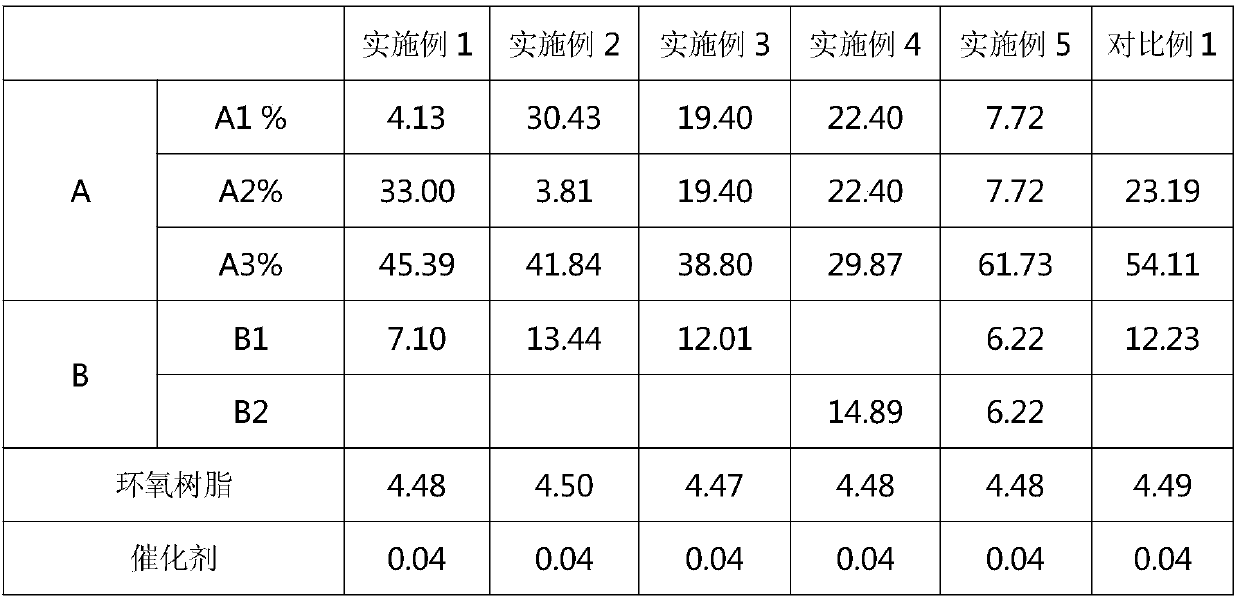

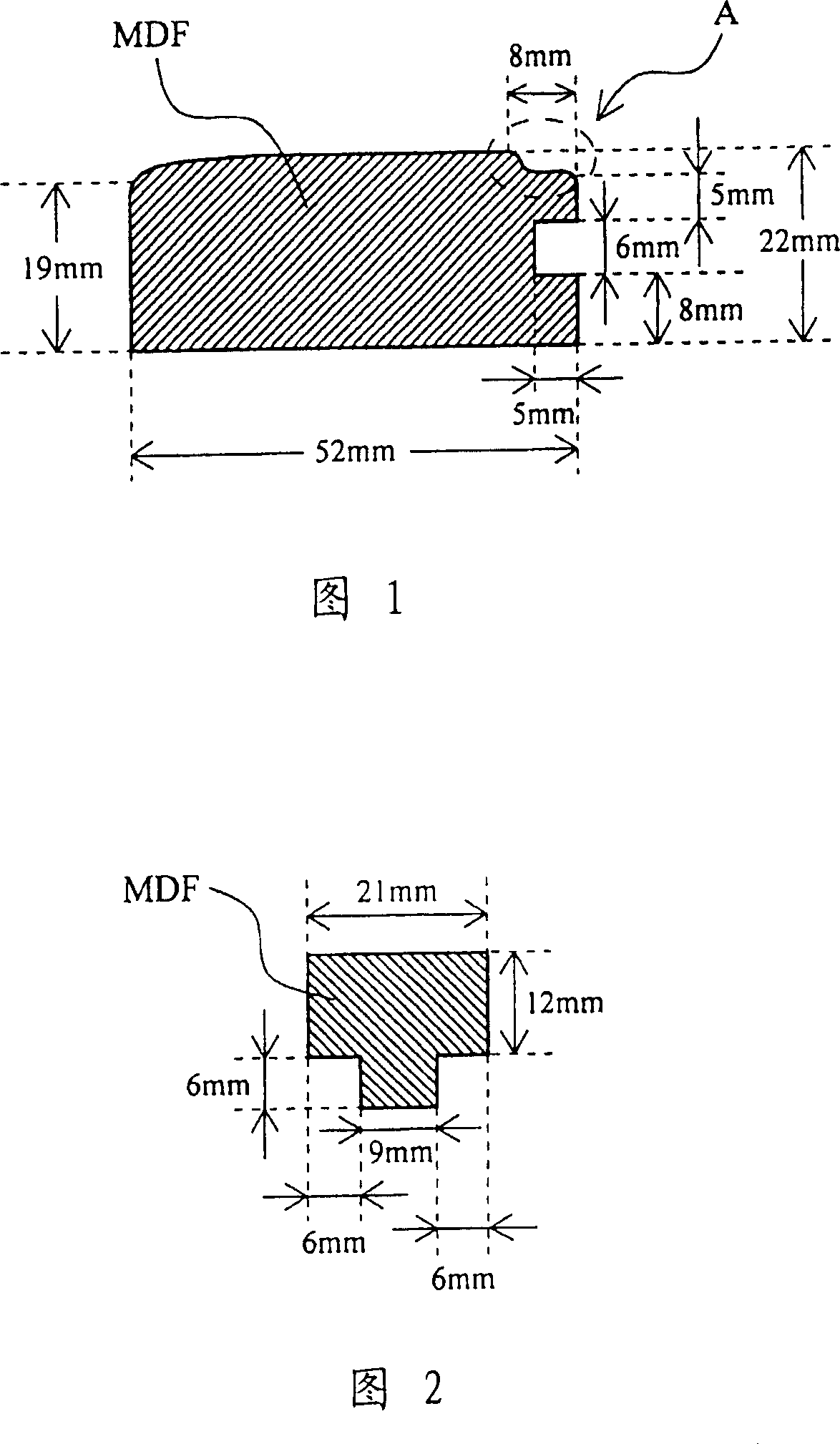

A weather-resistant adhesive and its application on solar cell backplanes

ActiveCN105907354BHigh initial adhesionImprove adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterWeather resistance

The invention discloses a weather resistance adhesive. The weather is a dual-component polyurethane adhesive comprising a component A and a component B, wherein the component A is composed of polyester polyol, acrylic polyol, polyether polyol and auxiliaries, and the component B is mainly composed of isocyanate. The obtained adhesive has the better initial stripping resistance, can keep the good adhesion stress on the poor environment condition, xanchochromia is not likely to occur, and the weather resistance adhesive can be applied to occasions with the requirement for high weather resistance.

Owner:CHINA LUCKY FILM CORP

Aqueous silylated urethane composition, aqueous adhesives for wrapping, and aqueous contact adhesives

InactiveCN1330681CImprove securityHigh initial adhesionPolyureas/polyurethane adhesivesPolyolPrepolymer

An aqueous silylated urethane composition useful as an aqueous adhesive which is highly safe, develops excellent tack in a short time, and is excellent in initial bond strength. The aqueous silylated urethane composition is characterized by comprising (A) an alkoxysilyl-terminated urethane prepolymer having an anionic group and a tertiary amino group which prepolymer is produced by reacting a polyol compound (A1) free from anionic groups, a polyol compound (A2) having an anionic group, a compound (A3) having a tertiary amino group and an isocyanate-reactive group, a polyisocyanate compound (A4), an alkoxysilane compound (A5) having an isocyanate-reactive group, and an amine chain extender (A6), (B) a basic compound, and (C) water.

Owner:KONISHI CO

High-flame-resistant foam tape

InactiveCN107325746AHigh elongationHigh initial adhesionFilm/foil adhesivesEmulsionUltimate tensile strength

The invention belongs to the technical field of high-flame-resistant foam material, and especially relates to a preparation method of a high-flame-resistant foam tape. The high-flame-resistant foam tape comprises a TPV film, a bonding layer, a foam layer, a pressure-sensitive adhesive layer, and a PE film. The preparation method comprises following steps: 1, the TPV film is subjected to polyurethane affinity treatment, and the surface of the TPV film is coated with a single-component polyurethane glue to form the bonding layer; b, 10 to 30% of a hydrolysis resistant ingredient and 1 to 2% of a foam regulator are added into an aqueous polyurethane emulsion successively so as to obtain a polyurethane mixed solution; c, the PE film is subjected to polyurethane release treatment; d, foaming of the polyurethane mixed solution on the TPV film is carried out at 100 to 120 DEG C so as to form the foam layer; and e, the foam layer is coated with the pressure-sensitive adhesive so as to bond the PE film with the polyurethane foam layer. The aqueous polyurethane foam tape prepared via the preparation method is excellent in elastic resilience, and high in percentage elongation and strength, and is friendly to the environment; and anti-aging time is long.

Owner:东莞市哲华电子有限公司

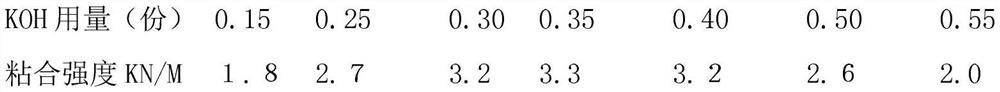

Preparation method of coating for pasting household wallpaper

InactiveCN109913152AImprove permeabilityReduce penetrationNon-macromolecular adhesive additivesBenzoyl peroxideDibenzoyl Peroxide

The invention provides a preparation method of a coating for pasting household wallpaper. The coating is prepared from a main binder, an auxiliary binder, filler, a crosslinking agent and a mildewproof agent, wherein the main binder is prepared from polyvinyl alcohol, formaldehyde, ammonium persulfate and sodium bisulfite with a pre-emulsification and semi-continuous emulsion polymerization processes, and the concentration of formaldehyde is 0.37 mol / L; the auxiliary binder is prepared from a water-soluble sodium hydroxide solution with the concentration of 0.3 mol / L; the filler adopts expandable quartz sand particles which are not prone to pulverization; the crosslinking agent is prepared from a benzoyl peroxide material; the mildewproof agent is prepared from an ammonium persulfate material. The main binder is prepared with the pre-emulsification and semi-continuous emulsion polymerization processes, so that adhesion strength of the wallpaper coating is improved effectively, follow-up edge warping is prevented, and by adding the mildewproof agent, edge warping damage under conditions of dampness and bacterial corrosion of the wallpaper due to long use time of the coating is prevented effectively.

Owner:桐城市桐佳装饰有限公司

Bimetal composite plate and its manufacturing process

InactiveCN102873936BConducive to castingLow initial viscosityLaminationLamination apparatusPolyurethane adhesiveSurface layer

The specification discloses a bimetallic composite plate material and a manufacturing process thereof; the bimetallic composite plate material comprises a surface layer metal and a bottom layer metal; a polyurethane adhesive layer is disposed between the surface layer metal and the bottom layer metal. The manufacturing process of the bimetallic composite plate material comprises the following steps: a. uniformly coating a polyurethane adhesive between the surface layer metal and the bottom layer metal; b. superposing the surface layer metal and the bottom layer metal; c. coating a protection film on the surface layer metal; d. performing normal temperature rolling compounding or heating rolling compounding of the surface layer metal and the bottom layer metal; e. shearing the plate; f. curing at a medium or low temperature.

Owner:广东晟力新材料有限公司

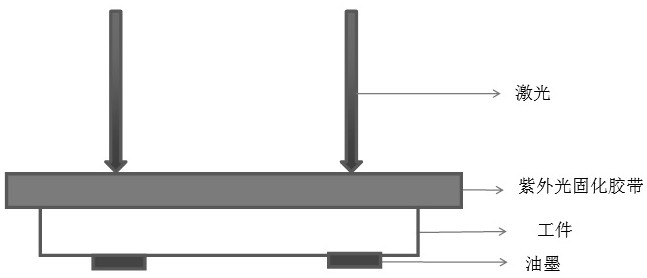

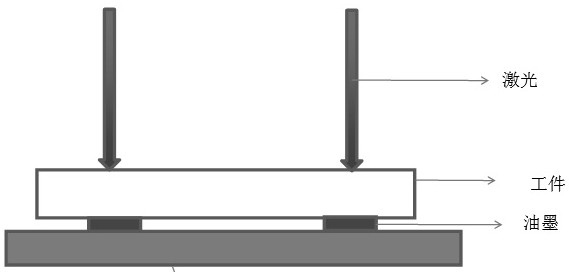

Ultraviolet curing adhesive tape for invisible cutting as well as preparation method and application of ultraviolet curing adhesive tape

PendingCN113214746AGood optical performanceIncrease profitFilm/foil adhesive primer layersPressure sensitive film/foil adhesivesOptical propertyUltraviolet

The invention provides an ultraviolet curing adhesive tape for invisible cutting and a preparation method and application thereof. The ultraviolet curing adhesive tape comprises a using layer and a protective layer, the using layer is composed of a base material layer and an acrylic acid pressure-sensitive adhesive layer, when the ultraviolet curing adhesive tape is used, the protective layer is removed, the using layer composed of the base material layer and the pressure-sensitive adhesive layer is attached to a workpiece, and the using layer has the good optical characteristic, and laser can penetrate through the adhesive tape to cut a workpiece. The obtained ultraviolet curing adhesive tape for invisible cutting has good optical performance, can ensure that laser penetrates through the adhesive tape to cut a workpiece, has high initial adhesive force, can ensure that the whole processing procedure is free of chip falling and water seepage, has very low adhesive force after ultraviolet curing, and is easy to reverse a film and take a chip.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Novel water-based adhesive for polyester filament canvas shoes and preparation method thereof

InactiveCN112341953AEnhance anti-deterioration abilityImprove intrinsic performanceNatural rubber adhesivesNon-macromolecular adhesive additivesPolyesterAdhesive cement

The invention discloses a novel water-based adhesive for polyester filament canvas shoes and a preparation method thereof. A combined body of natural latex and an environment-friendly adhesive is usedas a main body material, and molecules of the latex are basically kept in the original shape, so that the higher initial adhesion capacity of the novel water-based adhesive for the polyester filamentcanvas shoes is ensured; asthe rubber polymer does not change, the vulcanized and cross-linked adhesive and an adhered adhesive part form a high-strength unified body and have relatively high final adhesion strength, so that the requirement on the surface viscosity of the adhered adhesive part is not high, the requirement on the temperature of the adhered adhesive part is low, and the requirementof an adhered adhesive material on the thermal insulation property is reduced. Due to the fact that the initial bonding force and affinity with the adhered adhesive part are improved, plastic flowingof molecules on the bonding surface of the adhesive part in the initial stage of high-temperature vulcanization is prevented, the adhesive part and the upper are firmly bonded together through the adhesive, and therefore the three quality problems of lace delaminating, base cloth disengaging and outsole elastic edges of the rubber shoes are effectively solved.

Owner:JIHUA 3537 SHOE MAKING

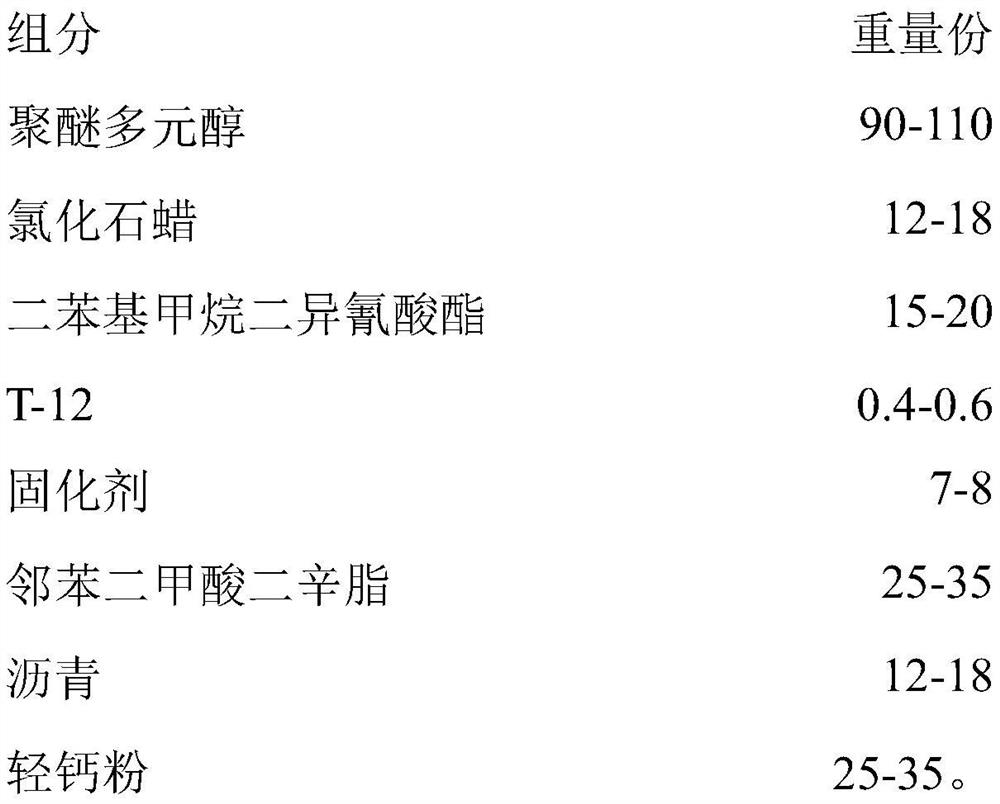

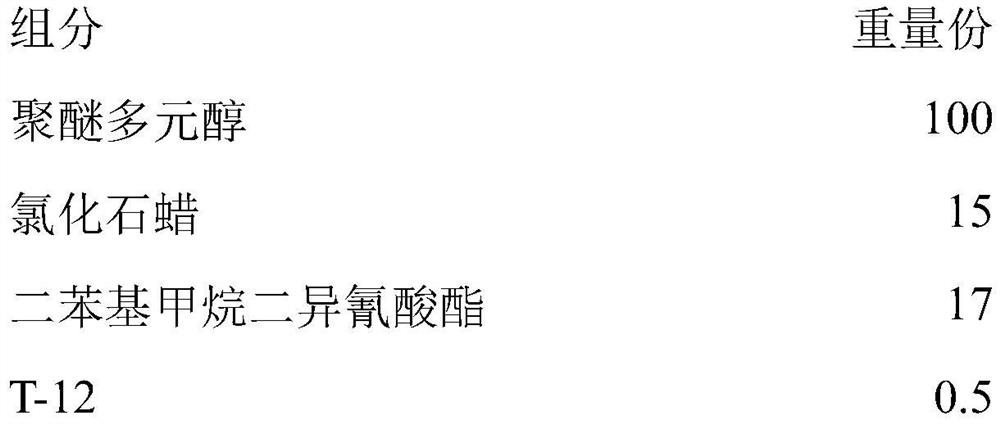

A kind of polyurethane single-component road liquid joint glue and preparation method thereof

ActiveCN110028924BHigh elongationHigh tensile strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPtru catalystFirming agent

The invention belongs to the technical field of highway engineering, and specifically relates to a polyurethane single-component road liquid joint glue and a preparation method thereof. The polyurethane single-component road liquid joint glue proposed by the invention includes diphenylmethane diisocyanate, poly Ether polyol, chlorinated paraffin, dioctyl phthalate, asphalt, catalyst, curing agent and other materials are prepared by reaction. Traditional solid joint glue needs to be heated before use, and heating will inevitably produce harmful gases to pollute the environment. , the most important traditional solid joint glue has the problems of environmental protection, aging resistance and poor wear resistance, and its aging cycle is about one year. If it exceeds this cycle, it will inevitably produce multiple repairs, and it will appear easy to flow at high temperature and easy to flow at low temperature. Brittle problem. The polyurethane one-component liquid joint glue of the present invention can solve all the above-mentioned problems and can completely replace the solid joint glue. It not only has strong adhesion but also has excellent physical properties, which cannot be replaced by other joint glue.

Owner:河北德瑞公路工程有限公司

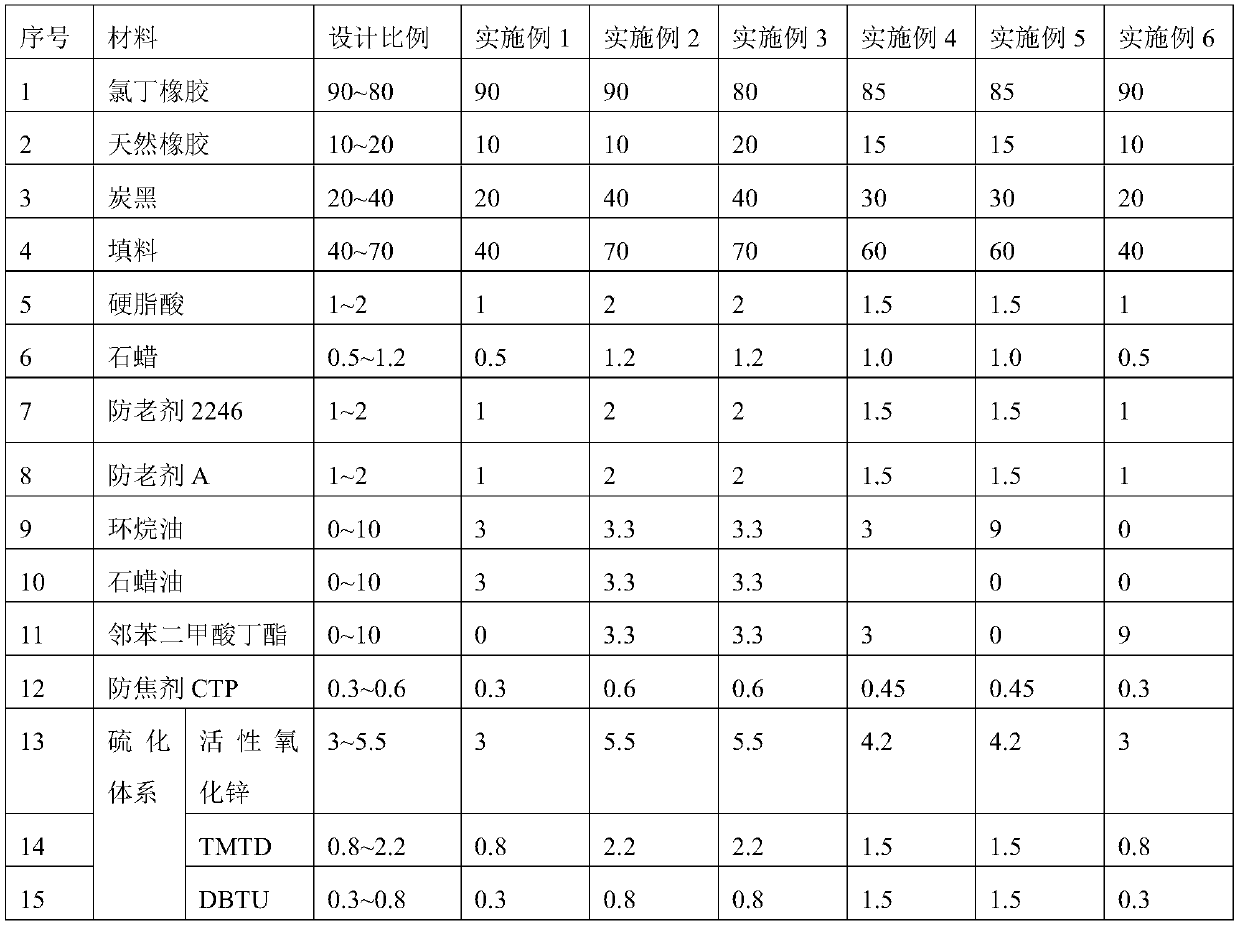

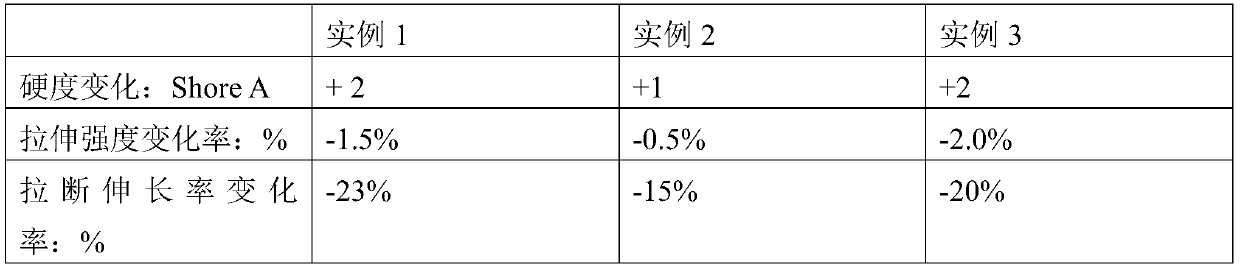

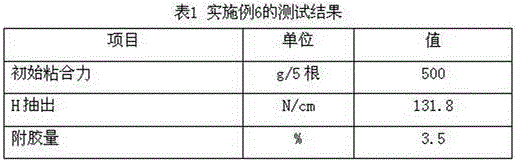

Self-vulcanized chloroprene rubber/natural rubber lining composition and application method thereof

The invention discloses a self-vulcanized chloroprene rubber / natural rubber lining composition and an application method thereof. The lining composition comprises, by weight, 80-90 parts of chloroprene rubber and 10-20 parts of natural rubber, and a zinc oxide-low-temperature overspeed accelerator vulcanization system and a sulfur-free vulcanization system are adopted for co-vulcanization. The lining is adhered to a device, and can be self-vulcanized at 25-40 DEG C without heating vulcanization, and can be pasted and constructed on the device site; the lining material is softer than a pre-vulcanized chloroprene rubber lining and softer than a chloroprene rubber lining free of natural rubber, so the lining material is suitable for pasting a large-scale device, an immovable device and complex devices with rib plates and perforated plates; and additionally, the product has the advantages of excellent corrosion resistance, excellent aging resistance, good oil resistance, excellent cohesiveness and very high initial cohesive force, and is suitable for corrosion prevention of nuclear power devices with a very long service life and rubber lining and onsite repairing of the complex devicessuch as perforated plates.

Owner:SHANGHAI SHUANGPU ANTICORROSION RUBBER LINING

A method for improving the initial adhesion of nylon 66 dipped cord fabric

ActiveCN105937185BIncrease milk contentHigh initial adhesionLiquid surface applicatorsFibre typesAgricultural engineeringNylon 66

The invention discloses a method for improving the initial adhesive force of nylon 66 dipped tyre cord fabric. The method includes the steps of: 1) passing a non-dipped nylon 66 cord fabric through a dip solution at a speed of 50-120m / min; and 2) passing the dipped nylon 66 cord fabric through a drying area 1A, a drying area 1B, a drafting area and a shaping area in order at a speed of 50-120m / min, and then conducting packaging and storage. The dip solution is prepared by mixing 0.9-2.8 parts of resorcinol, 1.4-4.1 parts of formaldehyde, 0.1 part of caustic soda, 2.9-25.7 parts of natural latex, 8.6-51.5 parts of butadiene vinyl-pyridine rubber latex, 1.3-3.9 parts of ammonia water, and 28.9-79.2 parts of low purity water at 5-35DEG C for 5-9h. According to the invention, the dip solution greatly increases the natural latex content, the initial adhesive force of the prepared nylon 66 dipped tyre cord fabric finished product is increased to 500-1000g / 5 threads, and the production cost is low, therefore the method is easy for industrialization.

Owner:PINGDINGSHAN SHENMA TIRE CORD FABRIC DEV CO LTD

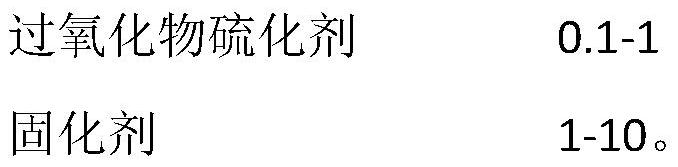

A kind of high foaming reinforced film

ActiveCN111423836BGood compatibilityHigh initial adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceNitrile rubber

In order to solve the problem that the thickness of the existing automotive reinforcing film is fixed and the reinforcing effect is not ideal, the invention proposes a high-foaming reinforcing film. The reinforcing film is composed of the following parts by mass: carboxyl-terminated liquid nitrile rubber 1-10; calcium carbonate 5-50; hydantoin epoxy resin 10-40; foaming agent 1-5; Butyl ester 5‑20; peroxide curing agent 0.1‑1; curing agent 1‑10. The advantage of the present invention is that the reinforcing film applied with the reinforcing film is lighter, which is beneficial to promote the weight reduction of automobiles. And its microcellular foaming can increase the strength of the reinforced film itself. In the case of foaming, the reinforcement ratio can reach 5-6 times. At the same time, due to the existence of the mesopore structure, the damping and shock absorption effect is better, and the existence of micropores can disperse the stress of the reinforcing film when the epoxy is cured. When the reinforcing film is applied, it has better conformability and will not make the steel plate deformed.

Owner:重庆钧业新材料科技股份有限公司

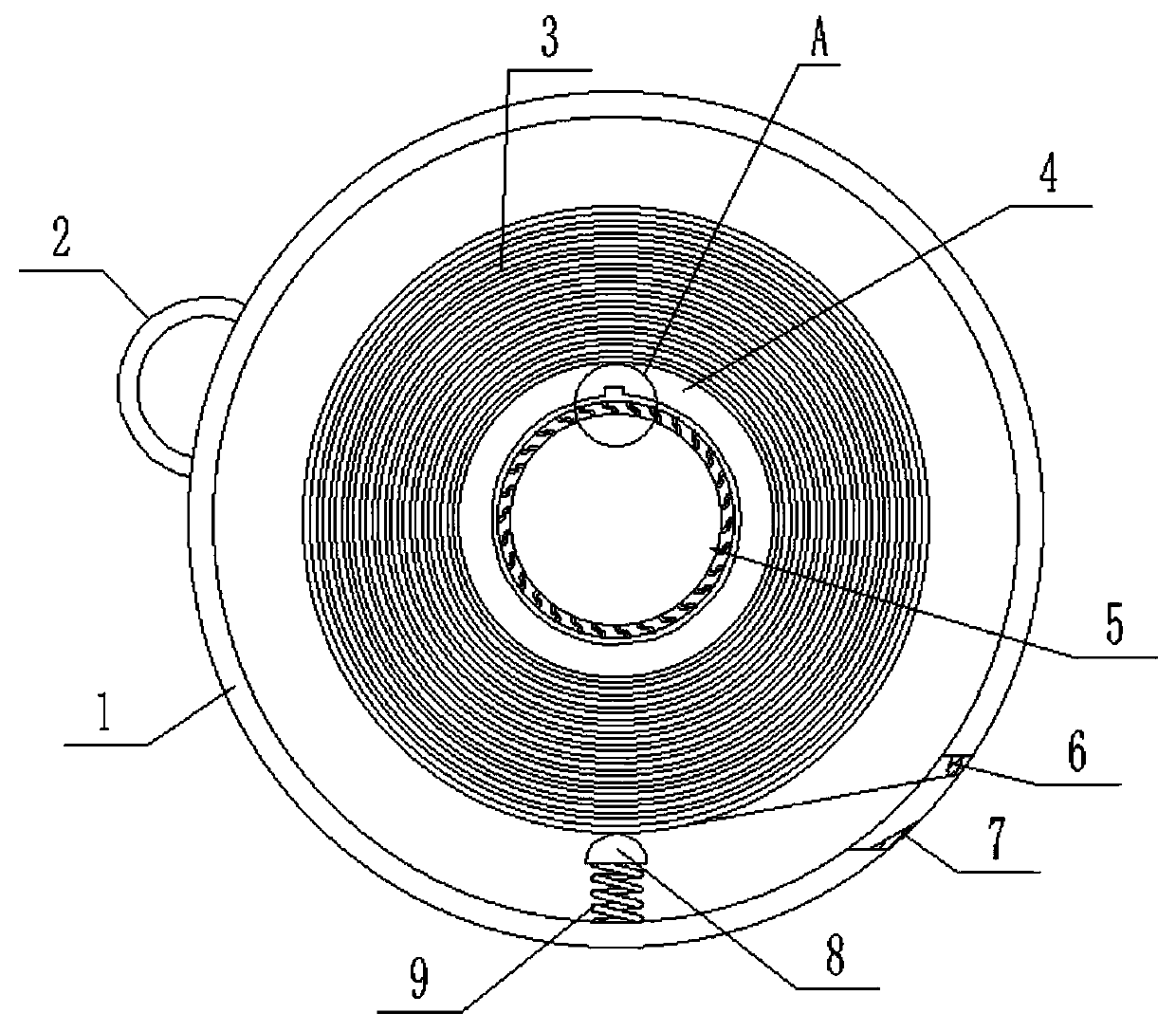

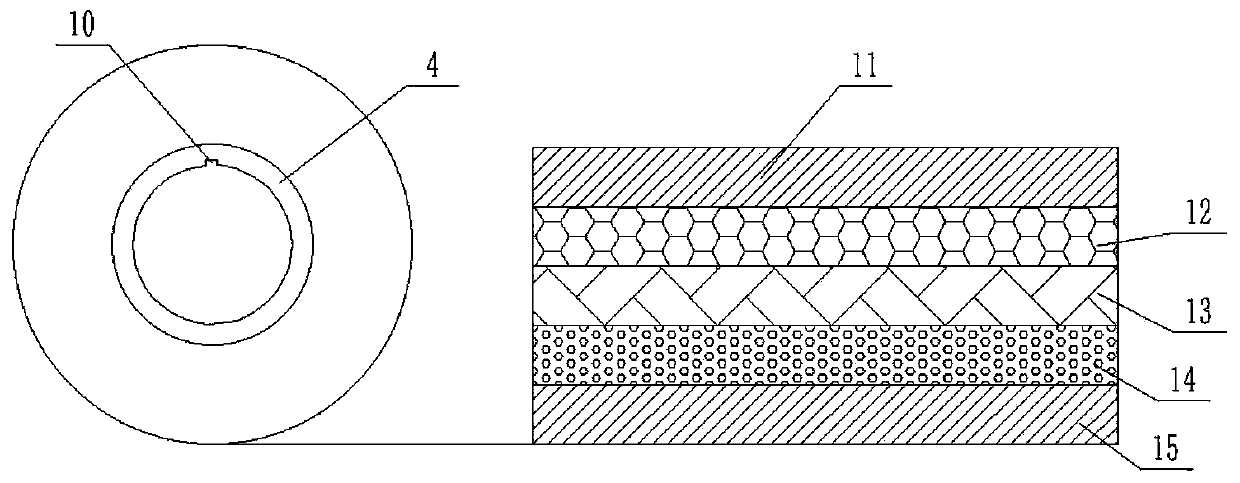

Conveniently uncoiled industrial double-sided adhesive tape

The invention belongs to the technical field of industrial double-sided adhesive tapes, in particular to a conveniently uncoiled industrial double-sided adhesive tape. The conveniently uncoiled industrial double-sided adhesive tape comprises a shell. An inner shaft is arranged on the inner wall of the shell, an inner ring is rotatably connected to the outer wall of the inner shaft, an adhesive tape ring sleeve is connected to the outer wall of the inner ring in a sleeving manner, an adhesive tape body is connected to the outer wall of the adhesive tape ring sleeve in a coiling manner, the adhesive tape body comprises a nonflammable cotton base material, first nonflammable acrylic acid glue and second nonflammable acrylic acid glue are separately arranged on two sides of the nonflammable cotton base material, first release paper is arranged on one side of the first nonflammable acrylic acid glue and second release paper is arranged on one side of the second nonflammable acrylic acid glue. The adhesive tape ring sleeve can be fixed by way of clamping, so that the adhesive tape ring sleeve is prevented from swinging. A first protecting tooth and a second protecting tooth are mounted to prevent reverse rotation of the adhesive tape ring sleeve, so that the adhesive surface has a relatively large adhesive space for the convenience of uncoiling when the adhesive tape is fetched nexttime.

Owner:HUNAN PROVINCE PURUIDA INTERIOR MATERIAL CO LTD

Epoxy anti-corrosive paint for underwater construction and preparation method

InactiveCN101311233BHigh speed dispersionInternal cohesionAntifouling/underwater paintsPaints with biocidesSolvent freeSolvent

The present invention relates to a smearing epoxy anti-corrosion coating for underwater concrete and steel structure and the preparation thereof, comprising the blending of component A and component B. The present invention is characterized in that the Component A consists of 20-40wt percent of solvent-free epoxide resin, 0-6wt percent of glycidyl ether epoxy active diluent, 13-50wt percent of barite powder, 0-30wt percent of titanium pigment, 0.5-2wt percent of modified polyamide thixotropic agent, 0.2-0.5wt percent of dispersant, 0.2-0.5wt percent of defoamer and 1-4wt percent of resin acceptor; the preparation viscosity is 40000-120000cP and the proportion is 1.5-2.5. The component B consists of 10-30wt percent of C5-C20 hydrocarbon chain Mannich di-benzene-ring epoxy curing agent, 2-10 percent of reaction typed promoter, 2, 4, 6-tri-dialkyl amine alkylamine methyl phenol. The coating of the invention has the advantages of strong adhesive attraction at the initial stage, excellent initial adhesive attraction under dynamic water, quick solidification in underwater construction and no drain and spalling, and can resist the impact of water with the speed of 1m per second, realize initial set in an hour to reach 30-50 percent of the design strength and reach more than 1MPa of bond strength in 24 hours, thereby overcoming the disadvantage of difficult coating under dynamic water of the existing epoxy coating.

Owner:无锡市南雅化工有限公司

Heat-vulcanized water-soluble adhesive of unvulcanized rubber and vulcanized rubber and preparation method of heat-vulcanized water-soluble adhesive

InactiveCN112126376AReduce energy consumptionGood workmanshipNatural rubber adhesivesNon-macromolecular adhesive additivesCellulosePolymer science

The invention provides a heat-vulcanized water-soluble adhesive of unvulcanized rubber and vulcanized rubber and a preparation method of the heat-vulcanized water-soluble adhesive. The heat-vulcanizedwater-soluble adhesive is mainly prepared from natural latex, soft water, a vulcanizing agent, a vulcanization accelerator, nano zinc oxide, a dispersing agent, anhydride casein, borax, a stabilizer,ammonia water and potassium hydroxide. In order to improve the performance of the heat-vulcanized water-soluble adhesive of the unvulcanized rubber and the vulcanized rubber, sodium carboxymethyl cellulose, an anti-aging agent, a defoaming agent and a mildew preventive can also be added, and the obtained heat-vulcanized water-soluble adhesive of the unvulcanized rubber and the vulcanized rubber is an environment-friendly bonding material for shoes. The adhesive has the processing advantages of low energy consumption, no toxicity, excellent process performance, simplicity in operation and thelike in the manufacturing process; the deterioration resistance of the adhesive is enhanced; the storage stable period of slurry is greatly prolonged; the internal performance of the adhesive is improved; the requirements of rubber shoe foxing strips on high adhesive strength of the secondary vulcanized soles of rubber shoes are fundamentally met; the technical problem of bonding adhesive removalis solved, and potential safety hazards of spontaneous combustion in a rubber shoe manufacturing process are eliminated.

Owner:JIHUA 3537 SHOE MAKING

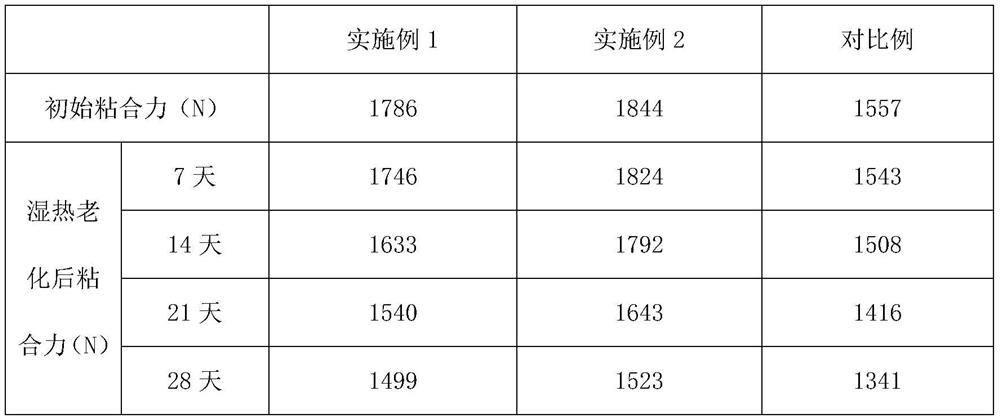

Cobalt-containing composite coating for steel cord and preparation method of cobalt-containing composite coating

PendingCN114807936AIncrease productivityShort preparation timeLiquid surface applicatorsMolten spray coatingGrindingCobalt

The invention discloses a cobalt-containing composite coating for a steel cord and a preparation method of the cobalt-containing composite coating. The specific preparation method comprises the following steps that 1, a coating production technology principal conducts preparation scheme review and puts forward questions and answers, technicians compile special preparation schemes and pay attention to details, and technical disclosure is conducted to workers; secondly, a sand bag grinding tool is used for conducting overall rough grinding and surface accurate grinding treatment on the steel cord steel wire base body; thirdly, the steel cord steel wire base body is cut into sections through a hydraulic clamp; polishing scum on the surface is purged through high-pressure gas; according to the cobalt-containing composite coating for the steel cord and the preparation method of the cobalt-containing composite coating, rare earth is added, the coating structure is refined, and the atomic activity is improved; the initial bonding performance of the Cu-Zn-Co coating and rubber is improved, meanwhile, more excellent aging bonding performance and damp-heat aging bonding performance can be achieved, and the possibility of industrial application of the cobalt-free sizing material is increased.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

Rare earth-containing Cu-Zn-Co steel cord coating and preparation method thereof

PendingCN114574915AReduce voidsImprove corrosion resistanceRolling resistance optimizationCopper platingCobalt

The invention discloses a rare earth-containing Cu-Zn-Co steel cord coating and a preparation method thereof. The preparation method specifically comprises the following steps: step 1, paying off a smooth steel wire; 2, pickling the steel wire with diluted hydrochloric acid, wherein the concentration of the hydrochloric acid is 150 + / -50g / L; thirdly, the steel wire treated in the second step is washed and dried; fourthly, the steel wire treated in the third step is subjected to copper electroplating through a copper plating tank and cobalt electroplating through a cobalt plating tank, and a plating solution contains a rare earth additive; fifthly, Zn powder is sprayed on the surface of the steel wire obtained in the fourth step through a plasma spray gun; sixthly, the steel wire obtained in the fifth step passes through an intermediate frequency furnace, so that coating metal is diffused, and the steel wire containing the rare earth Cu-Zn-Co coating is obtained; according to the rare earth-containing Cu-Zn-Co steel cord coating and the preparation method thereof, rare earth is added, the coating structure is refined, the initial bonding performance of the coating and rubber is improved, meanwhile, the coating can have more excellent damp-heat aging bonding performance, the use of Co elements in rubber products can be reduced, rubber cracking and aging are retarded, and the durability of rubber is improved.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com