A kind of polyurethane single-component road liquid joint glue and preparation method thereof

A technology of polyurethane single and seam-filling glue, applied in the direction of polyurea/polyurethane adhesives, adhesives, non-polymer adhesive additives, etc., can solve the problems of brittleness, long curing time, and inconvenient use, and achieve excellent Elongation ratio and tensile strength, avoid the expansion of cracks, the effect of simple and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

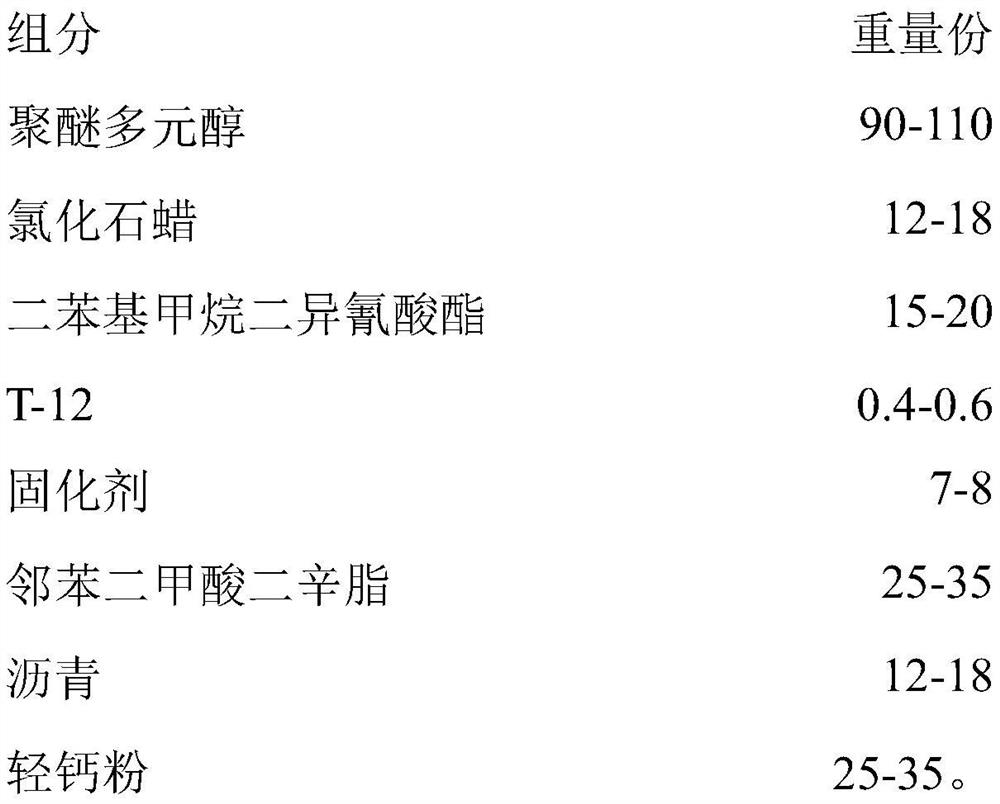

[0056] The preparation method of the polyurethane one-component road liquid joint glue, comprises the following steps:

[0057] g. Weigh polyether polyol, chlorinated paraffin, asphalt, and dioctyl phthalate according to the formula and add them to the reaction kettle, start stirring, and start heating;

[0058]h. When the temperature reaches 100-120°C, close the reaction kettle, turn on the vacuum pump to start vacuuming, start timing when the vacuum gauge reads 1200mmHg column, control the temperature at about 120°C, and keep it under negative pressure for 3 hours; stop heating at the same time, and Turn off the vacuum pump;

[0059] i. When the temperature drops to 80°C, turn on the vacuum pump, add diphenylmethane diisocyanate through negative pressure extraction, turn off the vacuum pump, control the temperature at 75-80°C, and keep the temperature for 2 hours;

[0060] d. Open the closed system of the reactor, turn off the heating system, add T-12 and curing agent LCA-3...

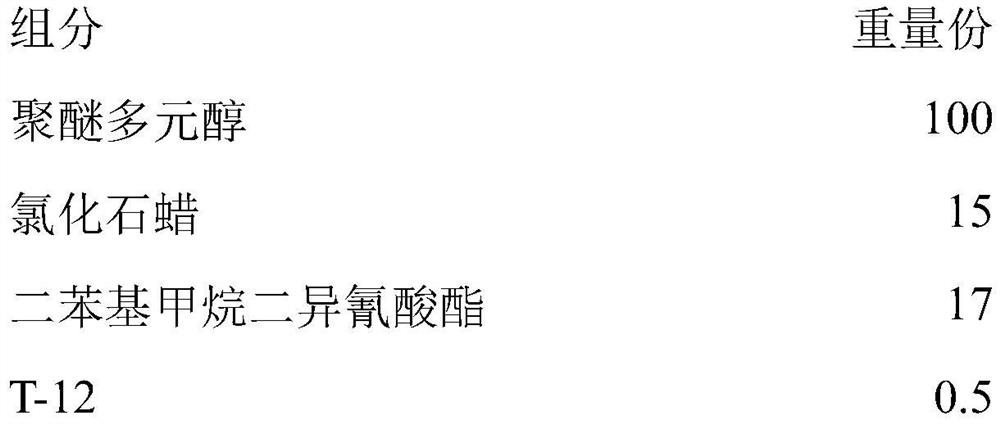

Embodiment 1

[0071]

[0072] Weigh 100Kg of polyether polyol, 15Kg of chlorinated paraffin, 15Kg of asphalt, and 30Kg of dioctyl phthalate into the reaction kettle, start stirring, and start heating; when the temperature reaches 100°C, close the reaction kettle, turn on the vacuum pump and start pumping. Vacuum, start timing when the reading of the vacuum gauge is 1200mmHg column, control the temperature at about 120°C, keep the negative pressure for 3 hours, stop heating at the same time, and turn off the vacuum pump; when the temperature drops to 80°C, turn on the vacuum pump, and add two Phenylmethane diisocyanate 17Kg, turn off the vacuum pump, the temperature should be controlled at 80°C, keep the temperature and stir for 2 hours; open the closed system of the reactor, turn off the heating system, when the temperature drops to 50°C, add 0.5Kg of T-12 catalyst, curing agent LCA -3000 7.5Kg, keep warm and stir for 30 minutes; stop heating and add 30Kg of light calcium powder, stir for...

Embodiment 2

[0074]

[0075] Weigh 80Kg of polyether polyol, 10Kg of chlorinated paraffin, 15Kg of asphalt, and 20Kg of dioctyl phthalate into the reaction kettle, start stirring, and start heating; when the temperature reaches 100°C, close the reaction kettle, turn on the vacuum pump and start pumping. Vacuum, start timing when the reading of the vacuum gauge is 1200mmHg column, control the temperature at about 120°C, keep the negative pressure for 3 hours, stop heating at the same time, and turn off the vacuum pump; when the temperature drops to 80°C, turn on the vacuum pump, and add two Phenylmethane diisocyanate 12Kg, turn off the vacuum pump, the temperature should be controlled at 80°C, keep the temperature and stir for 2 hours; open the closed system of the reactor, turn off the heating system, when the temperature drops to 50°C, add 0.2Kg of T-12 catalyst, curing agent LCA -3000 6Kg, keep warm and stir for 30 minutes; stop heating and add 20Kg of light calcium powder, stir for 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com