Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

113results about How to "Have a synergistic effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite leavening agent combining xylanase with multiple strains and method for fermenting straw feed

InactiveCN102048025ASolve labor intensitySolve easy-to-contaminate bacteriaAnimal feeding stuffAccessory food factorsRetention periodBiotechnology

The invention discloses a composite leavening agent combining xylanase with multiple strains and a method for fermenting a straw feed. The leavening agent consists of the following components in part by weight: 4 parts of xylanase, 2 parts of lactobacillus acidophilus, 2 parts of propionibacterium, 2 parts of saccharomyces cerevisiae, 3 parts of bacillus subtilis, 1 part of lactobacillus plantarum and 1 part of bacillus coagulans, wherein the xylanase can quickly degrade cell walls of straw plants and release nutrient substances; and under the synergistic effects of a plurality of microorganisms, fermentation speed is increased, fermentation period is shortened, fermentation activity is enhanced, protein conversion rate is increased and fermentation cost is lowered. The prepared fermented straw feed has low cellulose content, high protein content, high viable count, long retention period, soft and wet feel, strong acid incense, high palatability and high nutritional value. The problem of low resource utilization ratio of crops such as straws and the like is solved; simultaneously, environmental pollution is reduced; and the leavening agent and the method have high economic benefit and social benefit.

Owner:天津科建科技发展有限公司

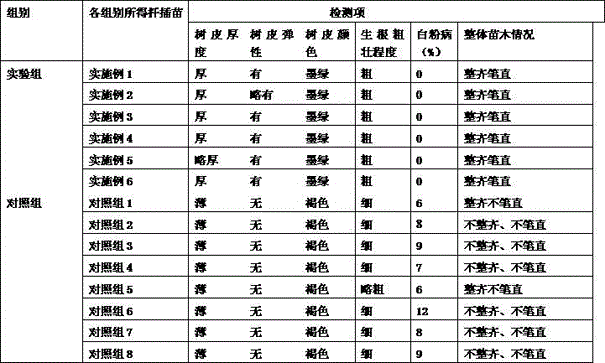

Method for hardening and transplanting savatier monochasma herb

ActiveCN110352804ALow survival ratePromote growth and developmentGrowth substratesCulture mediaFertilizerTransplanting

The invention relates to a method for hardening and transplanting savatier monochasma herb. A savatier monochasma herb tissue culture rooting seedling is taken as a test material, and research is carried out from the aspects of a rooting bottle seedling domestication transition method, shading and moisturizing treatment, transplanting matrix screening, matrix ratio, water and fertilizer retentionmanagement and the like. The technical problems of low survival rate and poor transplanting growth adaptability of the savatier monochasma herb rooting seedling in transition in the seedling stage e transplanting into a container are solved, an appropriate seedling hardening technology is provided for the heliophilous savatier monochasma herb rooting seedlings, the savatier monochasma herb rootingseedling smoothly gets through the seedling stage, and a good growth environment is further provided for the transplanted savatier monochasma herb seedling by selecting a high-quality cultivation container, a cultivation medium and a water and fertilizer management mode.

Owner:江西环境工程职业学院 +1

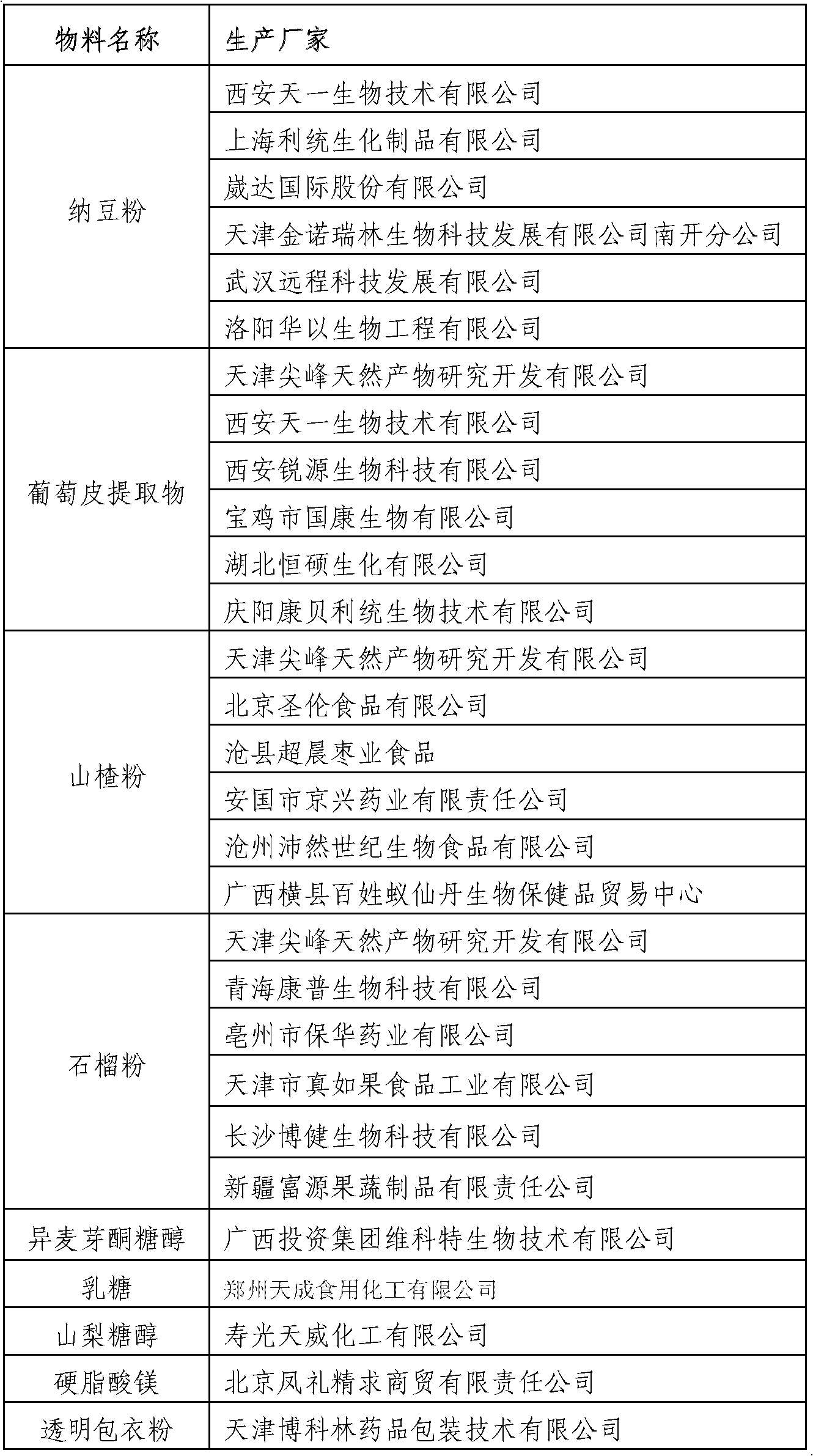

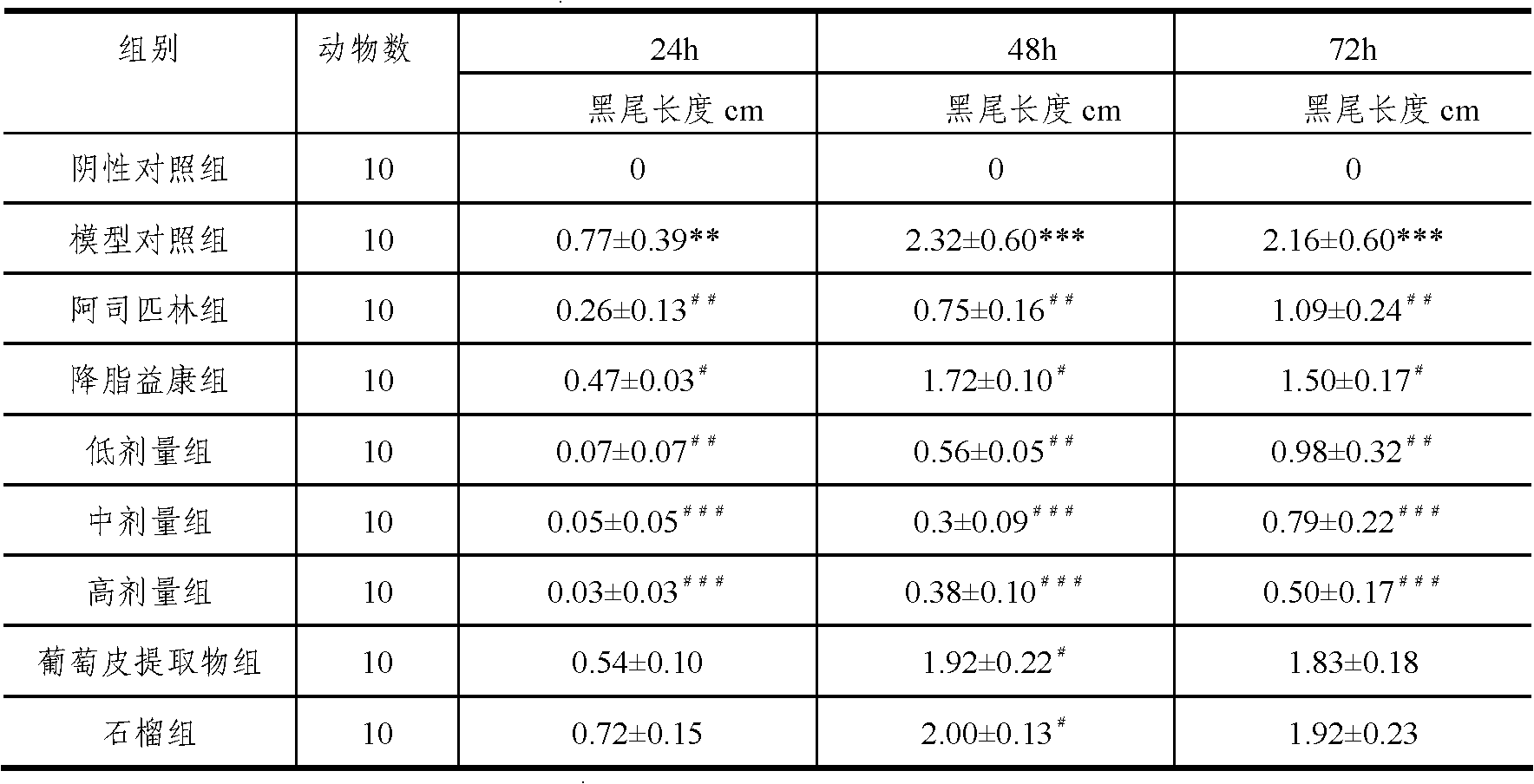

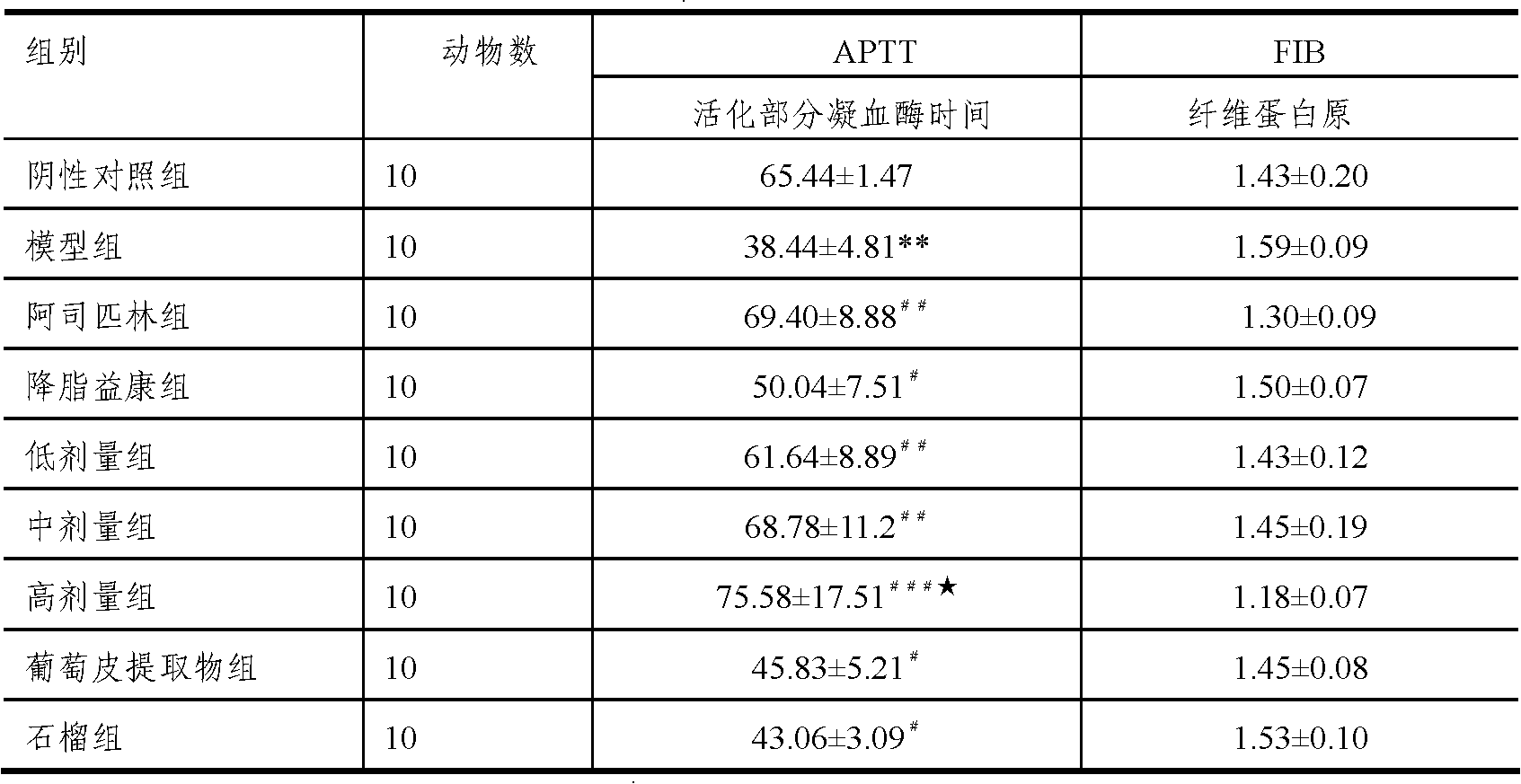

Health care product for preventing microthrombus from forming and preparation method thereof

ActiveCN102349963ABlock different pathwaysEasy to carryBlood disorderFood preparationDiseaseMedicine

The invention relates to a heath care product for preventing microthrombus from forming and a preparation method thereof. The health care product comprises the following components in part by weight: 1-3 parts of natto powder, 0.8-3 parts of grape skin extract, 8-25 parts of hawthorn powder and 3-15 parts of pomegranate powder. The health care product provided by the invention is rich in various biological active substances, such as natto kinase, resveratrol, flavone, various vitamins and minerals and the like; the biological active substances are scientifically matched to exert cooperative and synergistic action, block off different paths of forming the microthrombus and establish a defensive line for preventing cardiovascular and cerebrovascular diseases.

Owner:NEW ERA HEALTH IND GRP +1

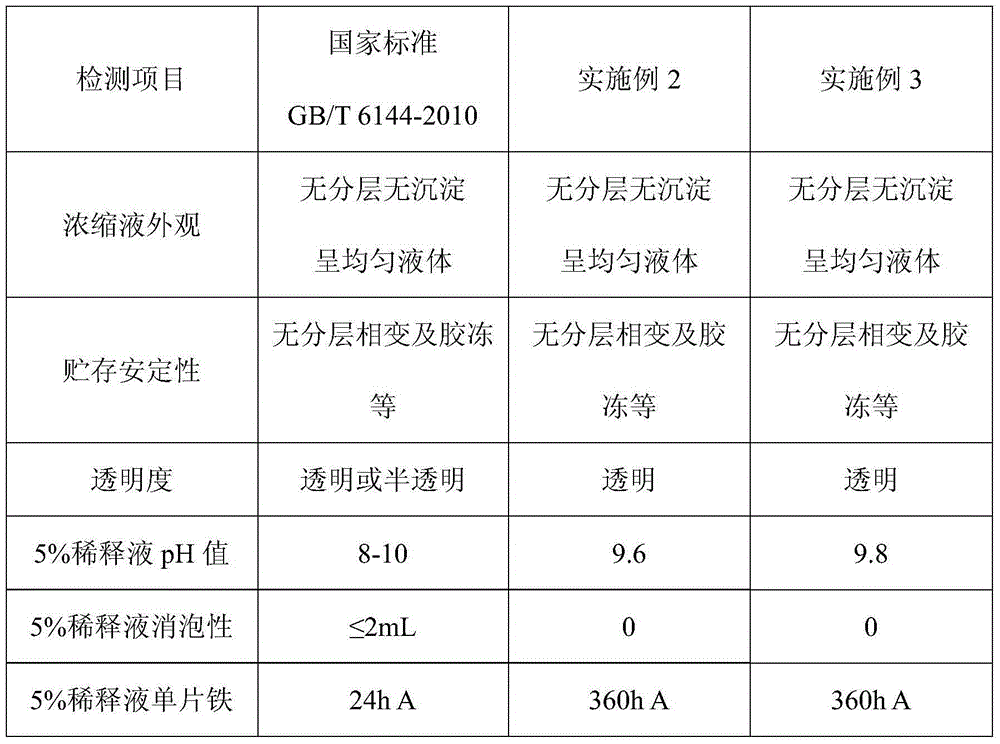

Honing solution and preparation method thereof

InactiveCN104911015AHas a cleaning effectImprove the lubrication effectLubricant compositionWater basedRust converter

The invention provides a honing solution and a preparation method thereof. The honing solution is prepared from the following components in percentage by mass: 10%-25% of extreme pressure additive, 10%-25% of penetrating agent, 5%-10% of anti-rusting agent, 0.5%-3% of bactericide, 0.1%-0.5% of softener, 0.1%-0.2% of defoamer and the balance of water. The metal processing solution is good in lubrication effect, excellent in anti-corrosion performance, and good in cooling property and cleaning property; various defects of products in the prior art can be solved; as the raw materials of the honing solution completely include no oily component, the pollution source is eliminated from the source; the honing solution is a real water-based product; the industrial production cost is greatly reduced; and besides, the honing solution is green and environment-friendly, friendly to the human body and the environment, and applicable to honing processing completely instead of oil based products.

Owner:SHAANXI YUHANG CHEM ENG

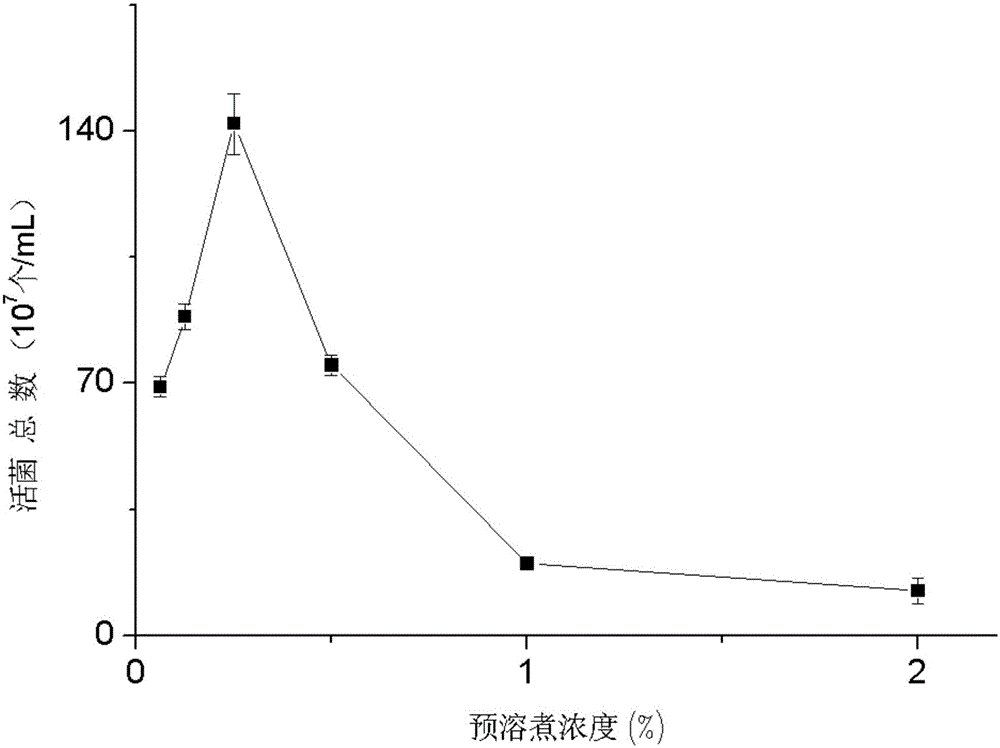

Formula of compound biological bacterial fertilizer and preparation process and application thereof

ActiveCN105130684ALow costPromote conversion absorptionFertilizer mixturesBacillus thuringiensisAzotobacter chroococcum

The invention relates to a formula of a compound biological bacterial fertilizer and a preparation process and application thereof. The formula of the compound biological bacterial fertilizer comprises, by weight, 10-60 parts of pre-cooking fluid, 10-25 parts of azotobacter chroococcum inoculum, 10-25 parts of bacillus mucilaginosus inoculum, 10-25 parts of bacillus megaterium inoculum and 10-25 parts of bacillus thuringiensis inoculum, wherein the pre-cooking fluid is a nutrient solution obtained by treating industrial wastewater produced in the edible fungi canning and processing process. The formula of the compound biological bacterial fertilizer has the following advantages that the formula is capable of saving energy and is environmentally friendly; the applying quantity of a chemical fertilizer is effectively decreased; the bacterial fertilizer can prevent soil hardening; the bacterial fertilizer further has the insect prevention and controlling effects; the preparation process is simple and is suitable for industrial production; the compound biological bacterial fertilizer can be stored for a long period of time and does not easily inactivate.

Owner:MINNAN NORMAL UNIV

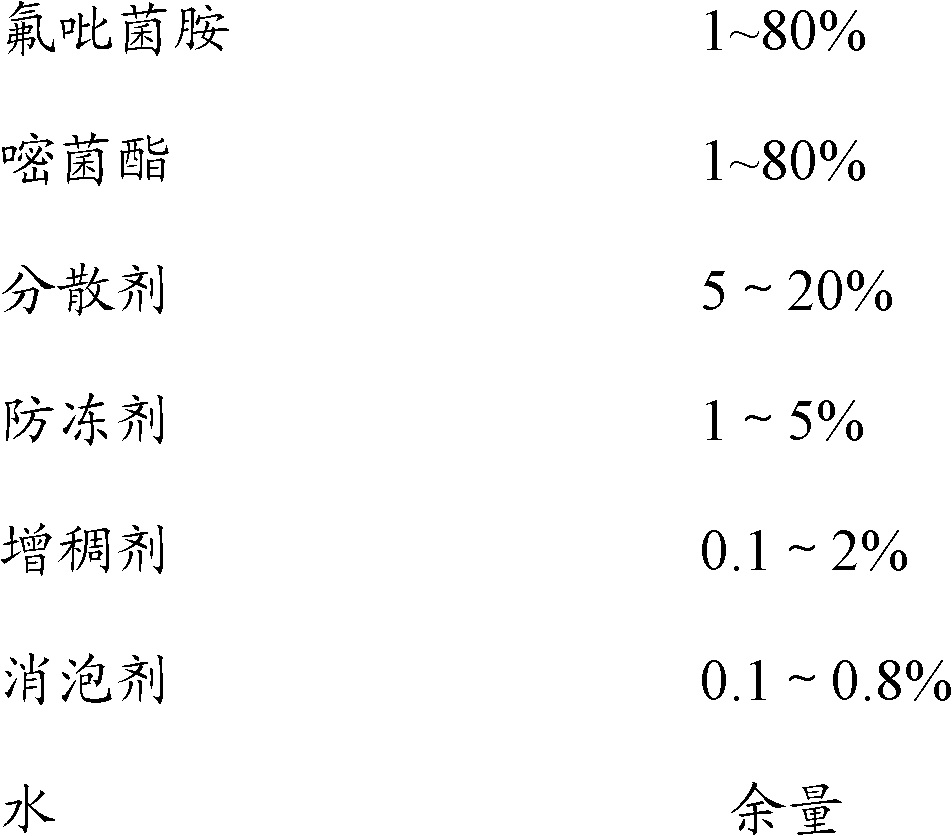

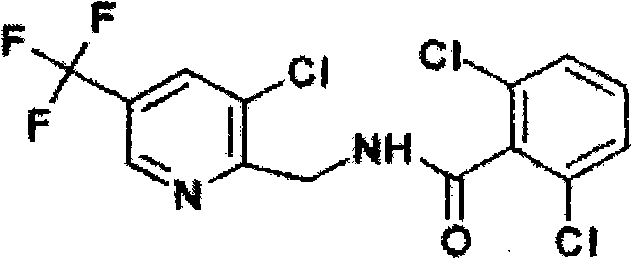

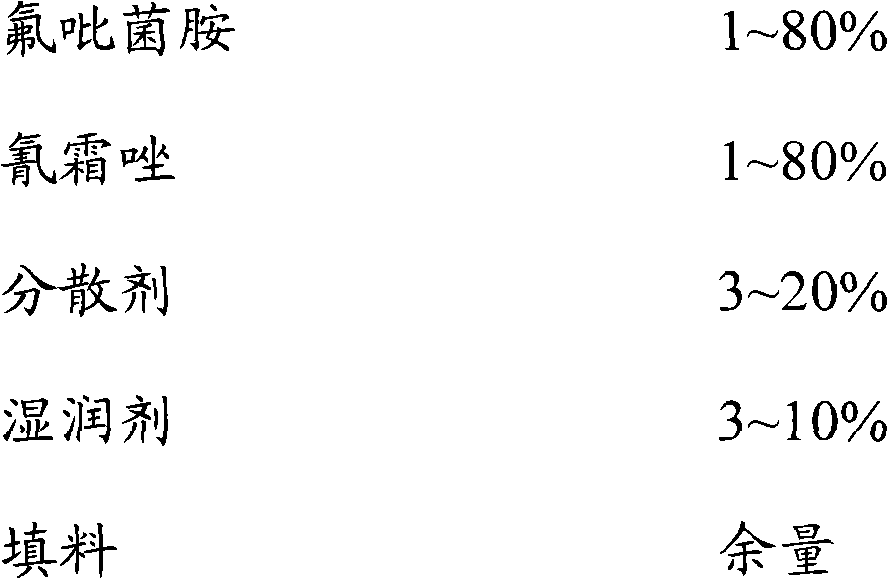

Antibacterial composition containing fluopicolide and azoxystrobin

The invention relates to a compound antibacterial agent. The active components of the compound antibacterial agent include fluopicolide and azoxystrobin, which are in a mass percentage ratio of (1-80):(80-1), and the compound antibacterial agent contains 1 to 80 percent of fluopicolide and azoxystrobin. The compound antibacterial agent can be prepared into formulations such suspension, wettable powder, water dispersion granules, water emulsion, microemusion and the like by methods known by the technicians in the field. The antibacterial composition can be used for preventing and controlling various diseases in crops, particularly diseases caused by fungi in oomycete, such as downy mildew, epidemic disease, late blight and damping off.

Owner:HAILIR PESTICIDES & CHEM GRP

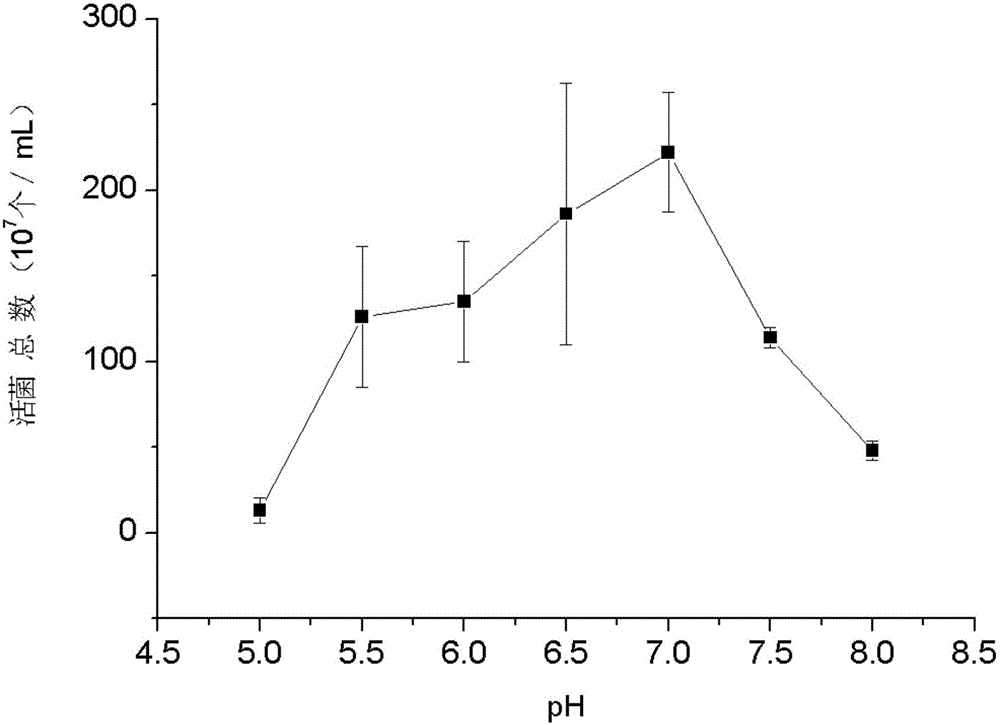

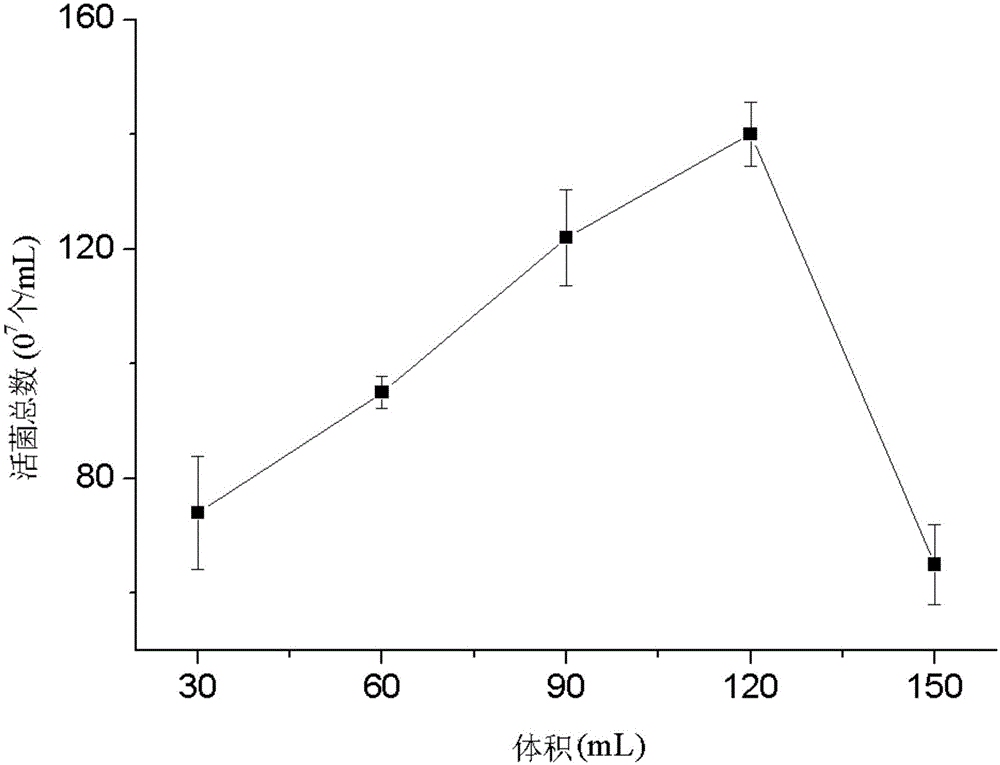

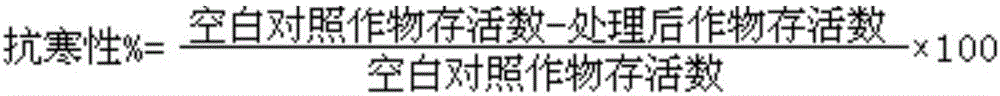

Composition for preventing and treating soil-borne disease and improving cold resistance of crops

ActiveCN106135291AEfficient killingInhibition of germinationBiocidePlant growth regulatorsPlant diseaseCold resistance

The invention discloses a mixture for preventing and treating a soil-borne disease and protecting plants from cold. The composition is a bacillus subtilis and amino-oligosaccharin composition. After the composition is mixed with a wetting agent, a thickening agent, a dispersing agent and a carrier, the mixture can be used as a drug for effectively preventing and treating the soil-borne disease. The composition can effectively kill harmful germs in soil and improves cold resistance of crops, and is used in crops such as vegetables, strawberries, flowers, melons, nursery gardens, orchards, tea gardens, graperies, woods and Chinese herbal medicines.

Owner:HAINAN JINYUFENG BIOLOGICAL ENG

Fermentation film containing rich lactobacillus plantarum and preparation method thereof

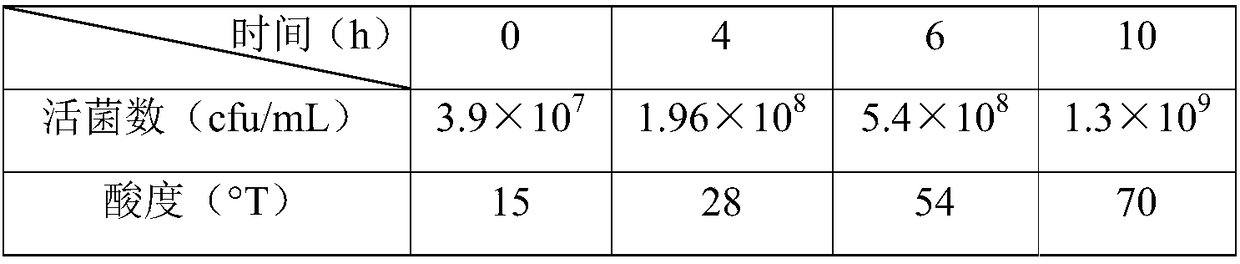

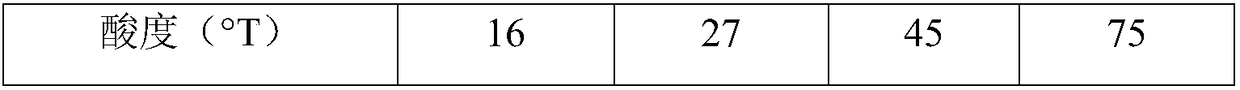

ActiveCN109497135AAchieve multiplicationShorten fermentation timeMilk preparationLactobacillusCultured milkCow milk

The invention discloses a fermentation film containing rich lactobacillus plantarum and a preparation method thereof, and belongs to the technical field of microbes and the technical field of fermentation. According to the method, the lactobacillus plantarum is inoculated into raw material milk added with proliferation factor for fermentation so as to obtain the fermentation milk. By using the method provided by the invention, the proliferation and the fermentation of the lactobacillus plantarum in the cow milk fermentation system are successfully realized; in addition, the fermentation time of the lactobacillus plantarum in the cow milk fermentation system can be greatly shortened. When the method provided by the invention is used for preparing the fermentation milk, the viable count of the lactobacillus plantarum in the fermentation milk can reach 1.2*10<9>CFU / g after the fermentation for 10 to 12h; in addition, the fermentation milk is prepared by using the method; the problem of poor flavor (beany flavor or bitter taste) of products due to the use of yeast powder, soybean protein, soy peptone or hydrolyzed soybean protein as accelerators for accelerating the fermentation of thelactobacillus plantarum in the cow milk is solved; the large-scale application of the lactobacillus plantarum in the fermented milk product is greatly promoted.

Owner:JIANGNAN UNIV +1

Fiber resin composite scalpel handle and preparing method thereof

The invention discloses a fiber resin composite scalpel handle and a preparing method thereof. The fiber resin composite scalpel handle is prepared from, by weight, 9-11 parts of carbon fibers, 4-6 parts of polytetrafluoroethylene fibers, 5-7 parts of polycrystal mullite fibers, 2-4 parts of alkali-resistant glass fibers, 6-8 parts of hexagonal boron nitride, 1-3 parts of titanium diboride, 10-13 parts of hollow glass beads, 88-90 parts of polydimethylsiloxane, 10-12 parts of di-tert-butyl peroxide, 9-11 parts of China wood oil, 7-9 parts of silicon dioxide, 2-4 parts of sodium silicate, 1-3 parts of zirconium dioxide, 50-52 parts of thermoset phenolic resin, 18-20 parts of polymerized rosin and 25-27 parts of terpene resin. The fiber resin composite scalpel handle is hard, low in weight and capable of being sterilized at high temperature.

Owner:张霞

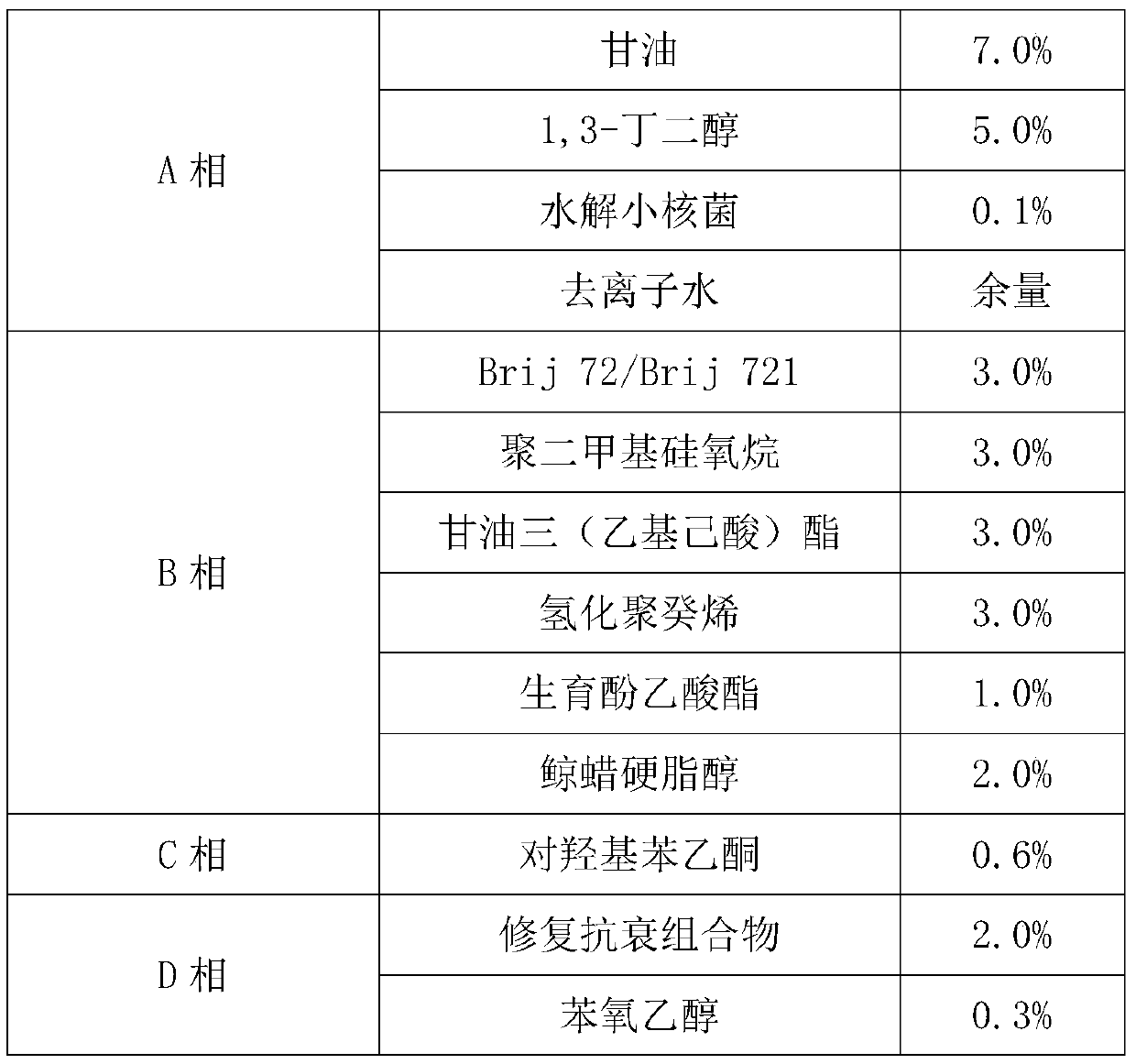

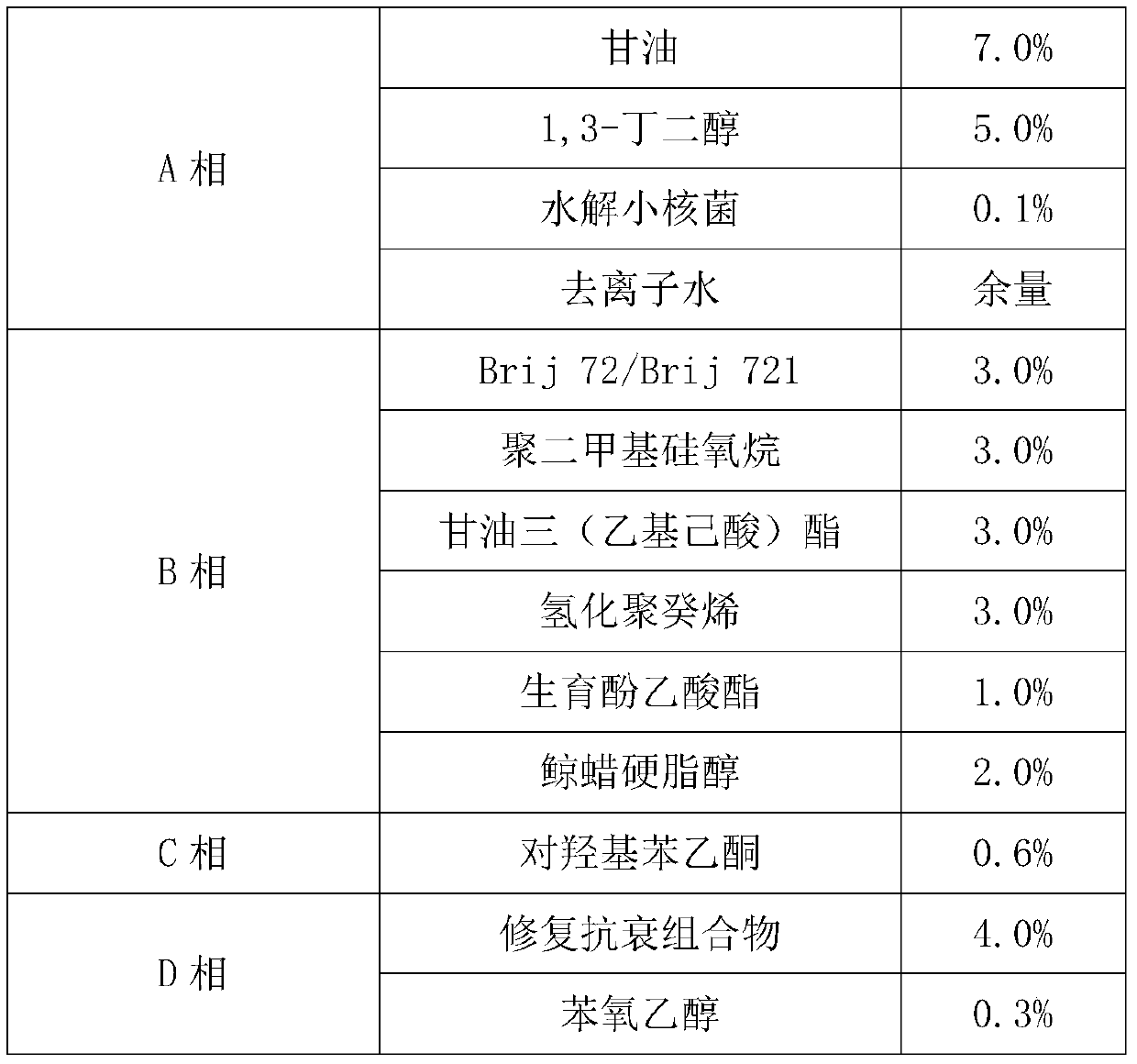

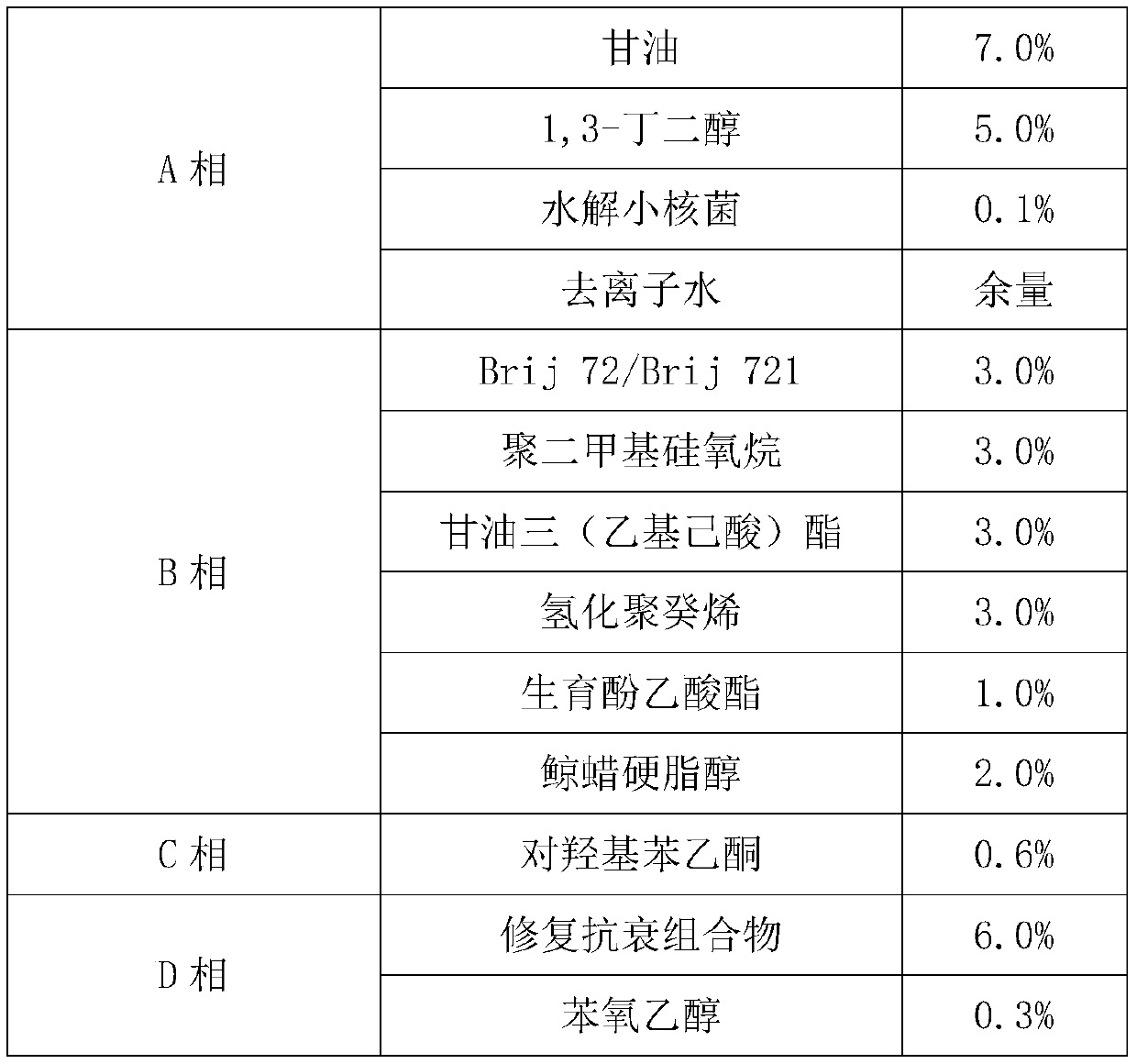

Repairing and aging resistance compound containing multiple plant extracts, preparation method and application

PendingCN110215423APromote generationReduce secretionCosmetic preparationsToilet preparationsCentella asiatica extractAging resistance

The invention provides a repairing and aging resistance compound containing multiple plant extracts, a preparation method and application. The repairing and aging resistance compound containing multiple plant extracts is prepared from, by mass, 1%-10% of a moisturizing agent, 3%-10% of a repairing and aging resistance agent, 0.1%-5% of a preservative and the balance deionized water. The olive leafextract and the centalla asiatica extract are cooperatively used and can achieve a synergistic effect, the epidermal barrier capacity is effectively improved, the damaged skin is effectively repaired, and aging resistance is effectively improved. It is proved through an experiment result that cooperative use of the two extracts can achieve the best use effect.

Owner:珠海远大美业生物科技有限公司

Lutein-containing salad sauce and preparation method thereof

The invention belongs to the technical field of food processing, and in particular relates to lutein-containing salad sauce and a preparation method thereof. The lutein-containing salad sauce comprises the following raw materials in parts by weight: 2 to 4 parts of lutein oil suspension liquid, 50 to 100 parts of mustard oil, 2500 to 6000 parts of vegetable oil, 2000 to 4000 parts of water, 200 to 1000 parts of whole egg liquid, 100 to 400 parts of concentrated fruit juice, 100 to 700 parts of acetic acid, 20 to 200 parts of aginomoto, 20 to 150 parts of salt, 300 to 1000 parts of a sweetening agent, 0.5 to 10 parts of a preservative, 100 to 800 parts of an thickening agent, 0.5 to 10 parts of an antioxidant and 50 to 100 parts of an emulsifier. The lutein-containing salad sauce provided by the invention is exquisite, viscous and high in stability, the appearance is pink, the product can reduce the loss of the lutein in the production process through reasonable formula and proper process, and the product has good color, taste and high stability within the shelf life.

Owner:YUNNAN RAINBOW BIO TECH

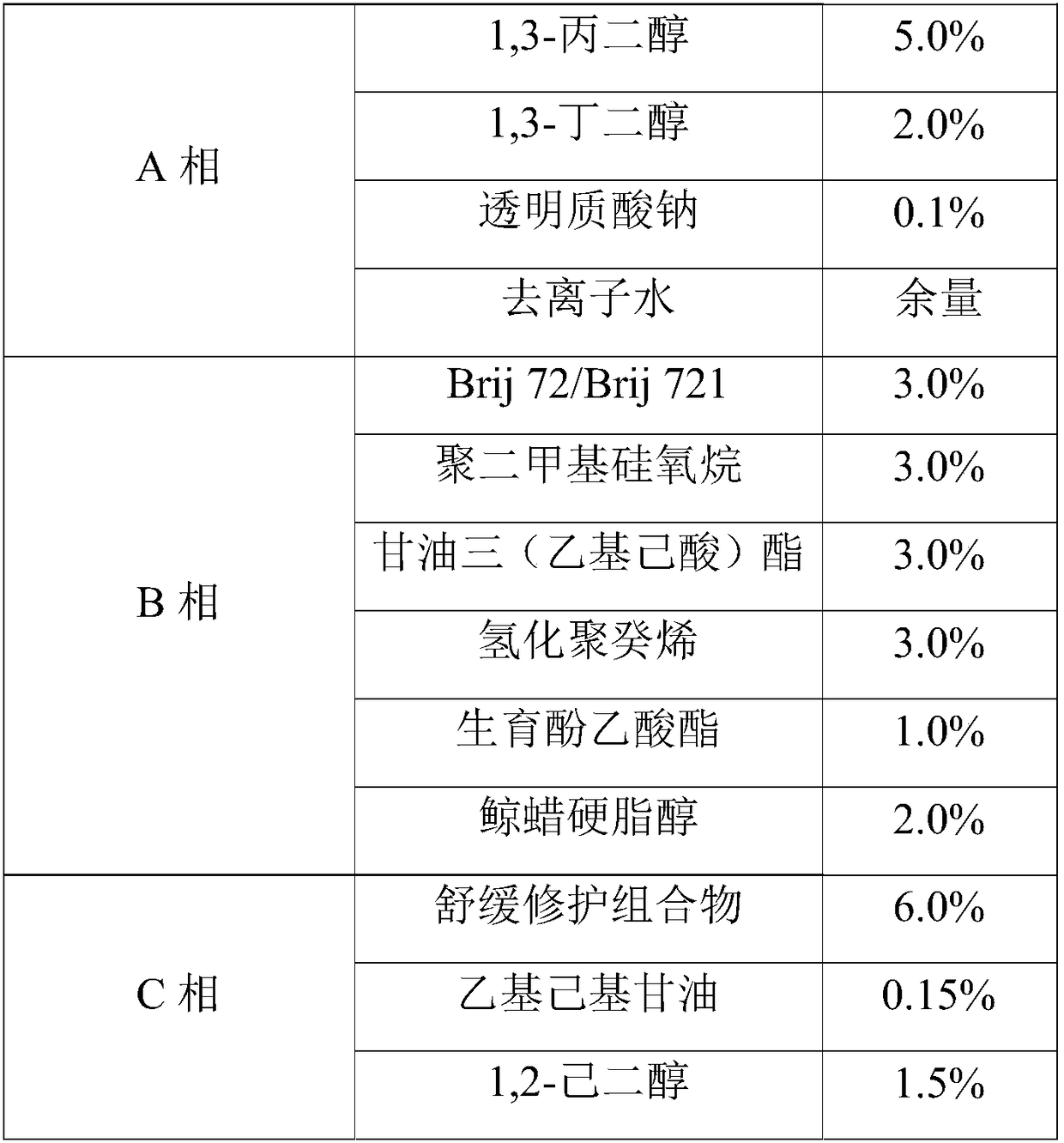

Relieving and repairing composition containing various plant extracts

ActiveCN109394615AInhibition releaseImprove defense systemCosmetic preparationsToilet preparationsPreservativeIrritation

The invention discloses a relieving and repairing composition containing various plant extracts, and belongs to the technical field of cosmetics formulas. The relieving and repairing composition is prepared from the following components in percentages by weight: 1-10% of a moisturizer, 3-10% of a relieving and repairing agent, 0.1-3% of a preservative and the balance of deionized water. The relieving and repairing agent comprises hydrolyzed lupine protein, a long carob fruit extract and a jasminum officinale extract. The composition has a remarkable relieving and repairing effect, can effectively relieve problems of redness, swelling, paining and itching, papule and desquamation and the like of skin after the skin is irritated, meanwhile can rapidly repair a damaged barrier function of theskin, and improves the ability of the skin resisting harm of the outside. According to difference of dosage forms of products, the suggested adding amount of the relieving and repairing composition is 2-8%, and the composition has the advantages of naturalness, no irritation, obvious relieving and repairing effect and the like.

Owner:珠海远大美业生物科技有限公司

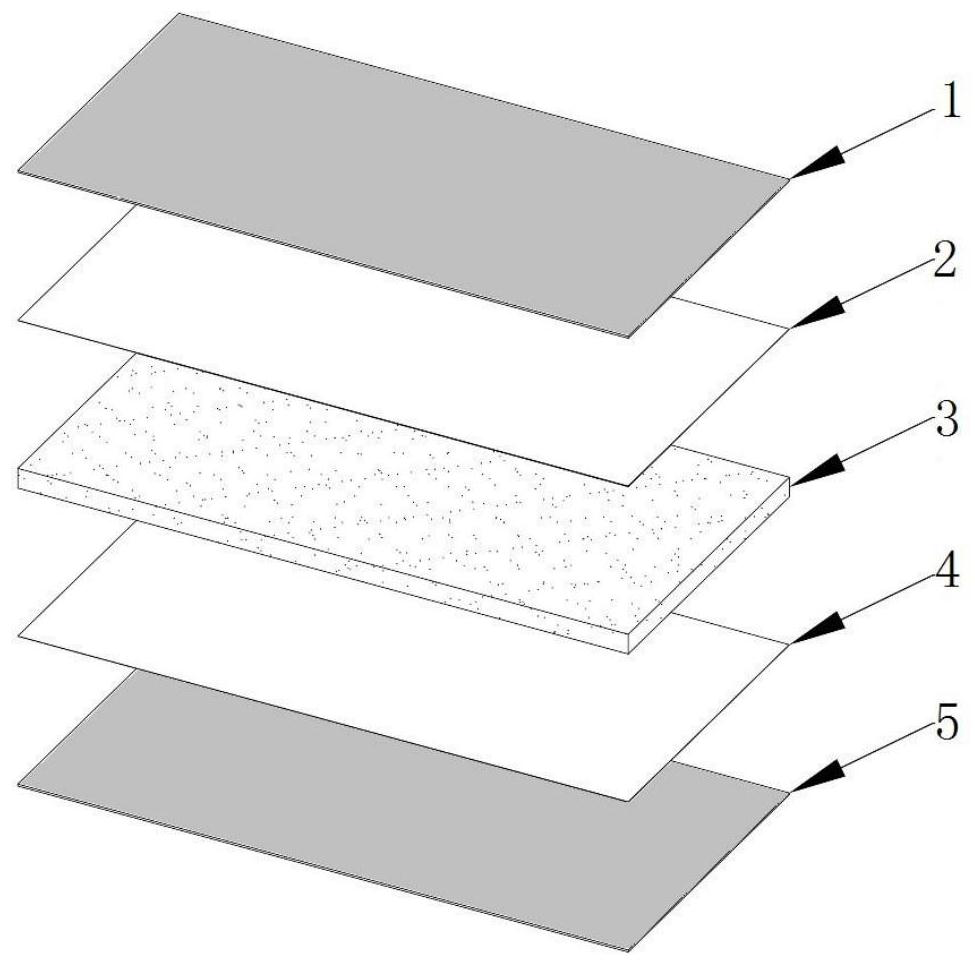

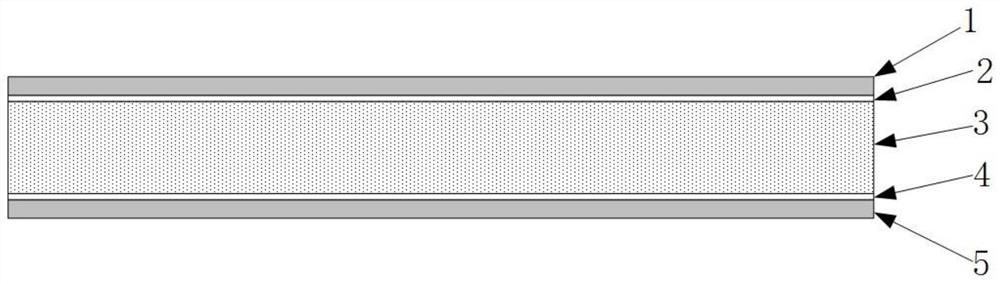

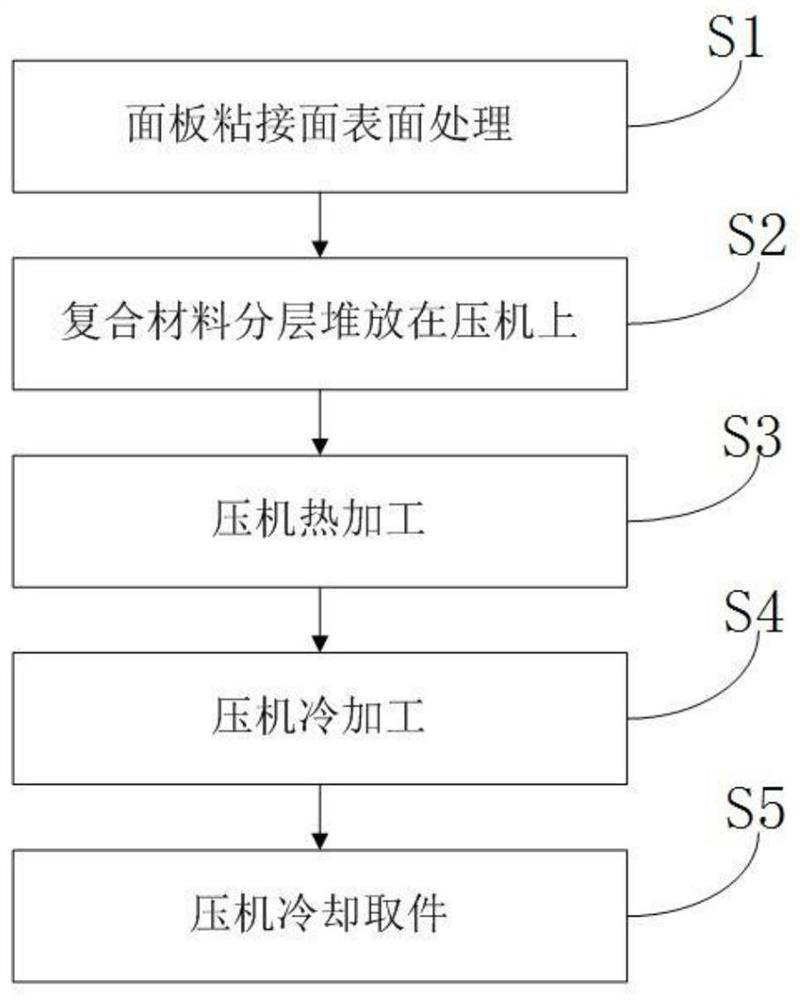

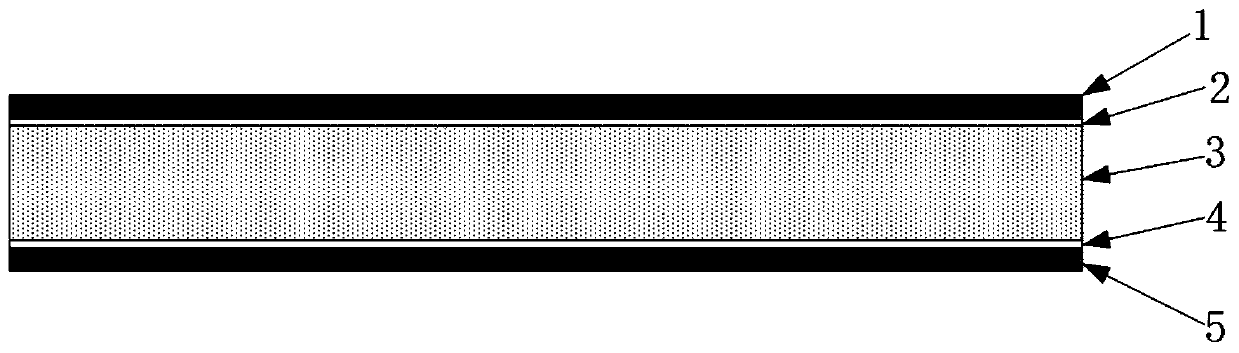

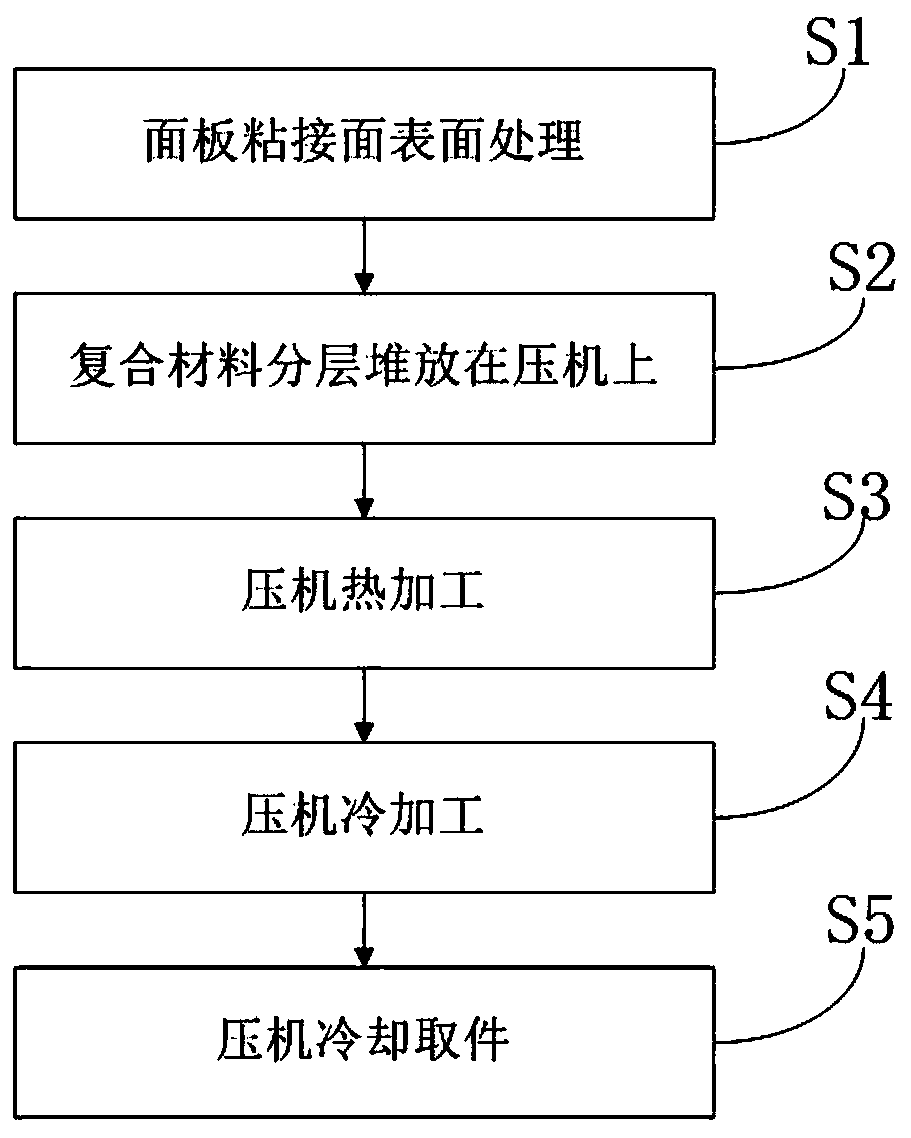

A kind of production process of aluminum foam composite plate and plate

ActiveCN109747237BImprove sound insulationGood heat insulationLaminationLamination apparatusAdhesive glueComposite plate

Owner:SAFENET NINGBO NEW MATERIAL TECH CO LTD

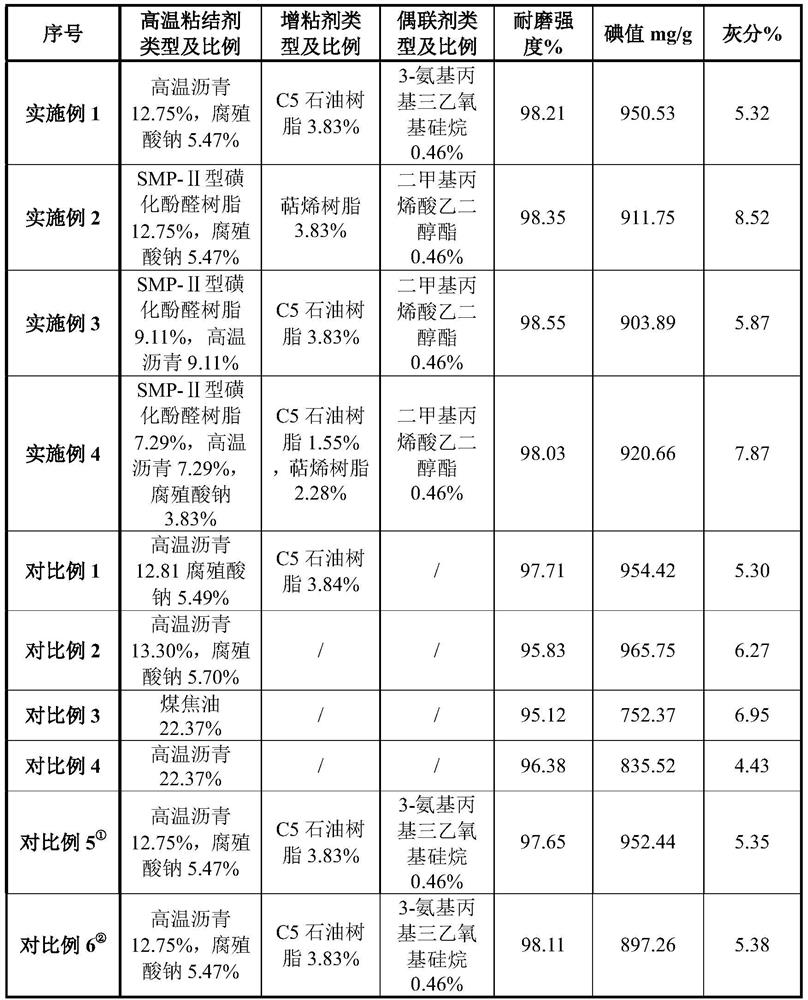

Activated carbon and preparation method thereof

The invention relates to activated carbon. The activated carbon is prepared from the following raw materials in parts by mass: 70-80 parts of wood charcoal powder, 1-6 parts of a normal-temperature binder, 15-20 parts of a high-temperature binder, 3-5 parts of a tackifier, 0.5-1 part of an extrusion aid, 0.1-0.5 part of a coupling agent and water accounting for 35-45% of the total mass of the components. The invention also relates to a preparation method of the activated carbon. The preparation method comprises the following steps of: pulverizing, screening, proportioning, mixing, kneading, aging, carrying out extrusion molding, drying, carbonizing and activating at the same time. High-temperature asphalt, sodium humate and sulfonated phenolic resin are used for replacing dangerous chemical coal tar to serve as adhesives, VOCs gas emission in the preparation process is reduced, environmental pollution is reduced, the adhesion effect of the adhesives is improved through a tackifier anda coupling agent, the abrasion resistance and the adsorption capacity of the activated carbon are improved, the abrasion resistance of the activated carbon reaches 98%, the iodine value of the activated carbon can reach 900 mg / g, the ash content of theactivated carbon is smaller than 10%. The method can be used for some application scenes with high requirements for the abrasion resistance and theadsorption capacity of the activated carbon, such as desulfurization and denitrification catalysts and gold extraction.

Owner:北京中科恩吉科科技发展有限公司

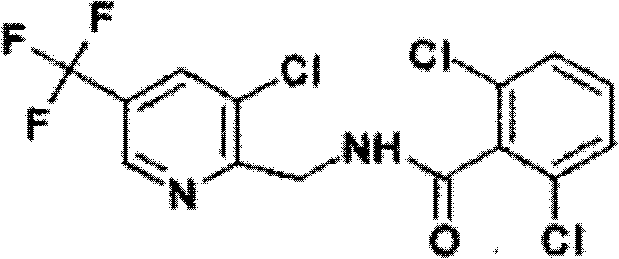

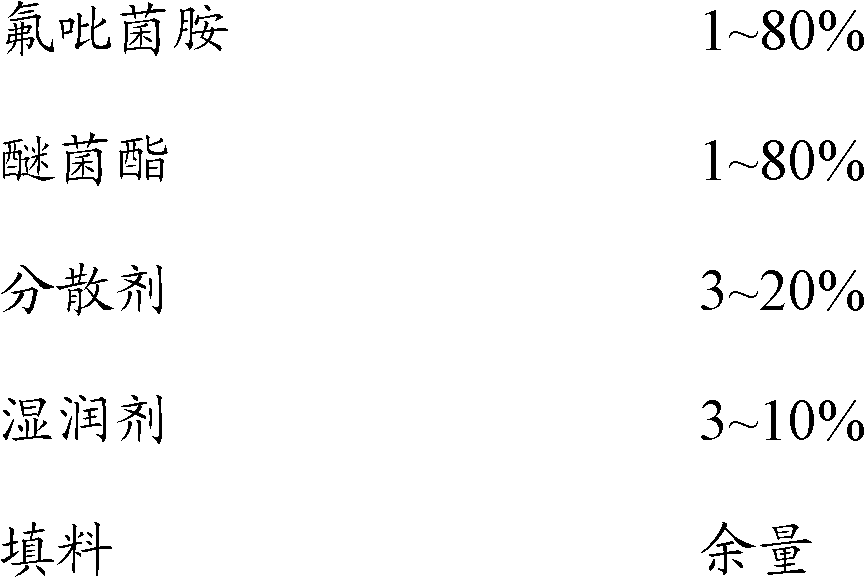

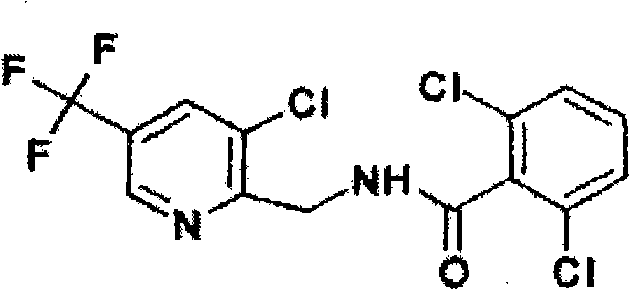

Bactericidal composition containing fluopicolide and cyazofamid

InactiveCN102726401AGood control effectHave a synergistic effectBiocideFungicidesDiseaseFluopicolide

The invention relates to a complex bactericide, which comprises the effective components of fluopicolide and cyazofamid. The mass percentage of fluopicolide to cyazofamid is 1-80:80-1, the content of the fluopicolide and cyazofamid in the complex bactericide is 1-80%. The complex bactericide can be prepared to a suspending agent, a wettable powder, a water dispersible granule, an emulsion in water, a micron emulsion and the like by a widely-known method for the technicists in the field. The bactericidal composition can be used for preventing and treating a plurality of crop diseases, and possesses outstanding effects on various diseases caused by Oomycete, such as downy mildew, epidemic disease, late blight, damping off diseases and the like.

Owner:QINGDAO KYX CHEMICAL CO LTD

Cinnamon oil containing burn medicine

InactiveCN104873723APromote regenerationStrong sterilization and disinfection abilityDermatological disorderPlant ingredientsMYRRH TINCTURECurative effect

The invention relates to cinnamon oil containing burn medicine which is prepared from the following raw materials in parts by weight: 2-5 parts of cinnamon oil, 2-5 parts of lavender essential oil, 7-10 parts of aloe extracting solution, 2-5 parts of mint oil, 4-7 parts of myrrh, 7-10 parts of licorice extract and 4-7 parts of frankincense. The effective constituents of the cinnamon oil containing burn medicine are mainly from pure natural plants and compounded in a scientific manner and have the synergistic effect and high sterilization, anti-inflammation and analgesic effects; the wound can heal quickly and is unlikely to infection; the therapy cost is low, and scar can be avoided after the wound heals; the cinnamon oil containing burn medicine is pure traditional Chinese medicine preparation, simple, convenient and feasible in preparation, precise in curative effect and free of stimulation and curative effect, can shorten the curing time, and deserves clinical popularization and application.

Owner:闭炳春

Daily chemical essence with flower fragrance and preparation method thereof

PendingCN112210438AReduce volatilityReduce evaporation rateEssential-oils/perfumesBenzoic acidPhenethyl alcohol

The invention relates to the field of daily chemical essences, and particularly discloses a daily chemical essence with flower fragrance and a preparation method thereof. The daily chemical essence with the flower fragrance comprises 0.6%-1.4% of B ionone. 0.2%-0.7% of n-amyl salicylate; 0.05%-0.15% of cis-jasmonic ketone; 0.5%-1.5% of convallaldehyde; 6%-10% of benzyl acetate; 1%-3% of methyl dihydrojasmonate; 0.1%-0.5% of methyl benzoate; 0.5%-1.5% of indole; 0.1%-0.3% of leaf alcohol; 0.1%-0.5% of salicylic acid leaf alcohol ester; 1%-3% of phenethyl alcohol; and the balance of dipropyleneglycol, wherein the total mass percentage is 100%. The preparation method comprises the following steps: mixing B-ionone, n-amyl salicylate, cis-jasmonate, convaleraldehyde, benzyl acetate, methyl dihydrojasmonate, methyl benzoate, indole, leaf alcohol, geraniol, leaf alcohol salicylate, phenethyl alcohol and dipropylene glycol in proportion, heating to 45-55 DEG C while stirring, and standing for45-55 minutes to obtain the daily chemical essence with flower fragrance. The daily chemical essence with the flower fragrance has the advantages that the fragrance lasting time of the daily chemicalessence is prolonged, and the cost is relatively low.

Owner:广东芬豪生物科技有限公司

Cinnamon oil containing externally applied medicine for treating traumatic injury

InactiveCN104873615AEffective in treating bruisesGood effectAntipyreticAnalgesicsBULK ACTIVE INGREDIENTPharmaceutical Substances

The invention relates to cinnamon oil containing externally applied medicine for treating traumatic injury. The medicine is prepared from the following raw materials in parts by weight: 6-9 parts of cinnamon oil, 6-9 parts of mint oil, 4-7 parts of safflower carthamus, 4-7 parts of radix zanthoxyli, 4-7 parts of pseudo-ginseng, 4-7 parts of ligusticum wallichii, 4-7 parts of corydalis tuber and 8-10 parts of 75% ethyl alcohol in volume fraction. Based on the theory of traditional Chinese medicine, the crude drugs are selected, sealed and soaked in mixed powder and mixed essential oil for one week and then soaked in absolute ethyl alcohol to enable active ingredients in the cinnamon oil containing externally applied medicine to be extracted, so that the cinnamon oil containing externally applied medicine has the efficacities of promoting blood circulation to remove blood stasis, relaxing tendon and activation collaterals, and relieving swelling and pain to realize the purpose of treating traumatic injury.

Owner:闭炳春

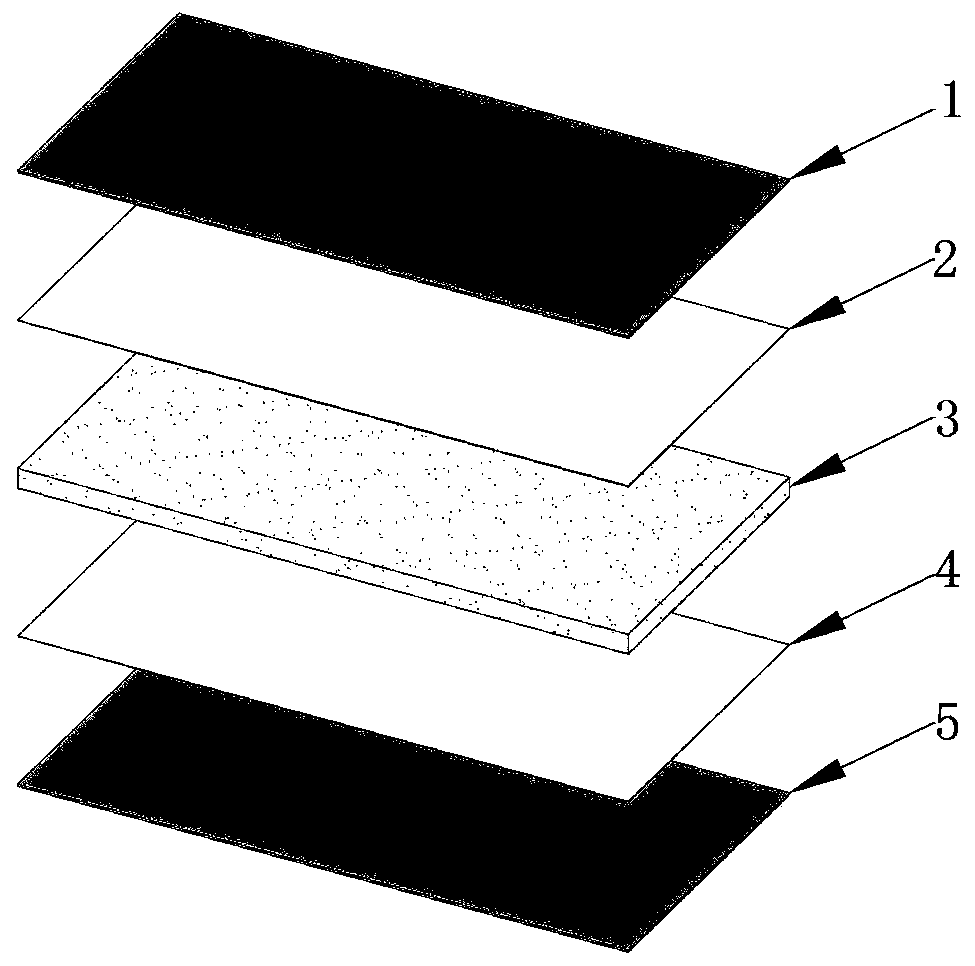

Foamed aluminum composite sheet material production process and sheet material

ActiveCN109747237AImprove sound insulationGood heat insulationLaminationLamination apparatusAluminum compositesBonding strength

The invention discloses a foamed aluminum composite sheet material production process and the sheet material. The foamed aluminum composite sheet material comprises a formed aluminum plate and face plates arranged on two sides of the foamed aluminum plate; the face plates are bonded with the formed aluminum plate through adhesive films; the face plates on the two sides are respectively taken as afirst face plate and a second face plate; a first adhesive film is arranged between one side of the formed aluminum plate and the first face plate; and a second adhesive film is arranged between the other side of the formed aluminum plate and the second face plate. The face plates on the two sides of the formed aluminum composite sheet material provided by the invention are bonded with the formedaluminum plate through the adhesive films, and the traditional bonding mode of liquid glue is replaced, so that glue is prevented from entering into pores of the foamed aluminum, and the composite sheet material is lighter in weight; the stress distributed at each point between the adhesive films and the bonding surfaces of the face plates is uniform, so that the bonding strength among the layersof the composite sheet material is improved.

Owner:SAFENET NINGBO NEW MATERIAL TECH CO LTD

Antibacterial composition containing fluopicolide and ethofenprox

InactiveCN102204537AGood control effectIt has the effect of preserving leaves and increasing yieldBiocideFungicidesDiseasePlant disease

The invention relates to a compound antibacterial agent. The active components of the compound antibacterial agent are fluopicolide and ethofenprox in a mass percentage ratio of (1-80):(80-1), and the compound agent contains 1 to 80 percent of the fluopicolide and ethofenprox. The compound antibacterial agent disclosed by the invention can be prepared into formulations including suspension, wettable powder, water dispersion granules, water emulsion, microemulsion and the like by methods known by the technicians in the field. The antibacterial composition can be used for preventing and controlling various diseases in crops, particularly diseases caused by fungi in oomycete, such as downy mildew, epidemic disease, late blight and damping off.

Owner:HAILIR PESTICIDES & CHEM GRP

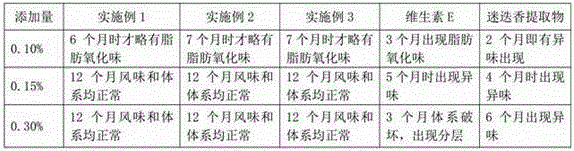

Preparation method of antioxidant

InactiveCN106036355ASimple preparation processEquipment investment is simpleCosmetic preparationsToilet preparationsSolventEmulsion

The invention discloses a preparation method of an antioxidant. The preparation method of the antioxidant mainly comprises the following steps: taking a rosemary extract, VE, polyglycerol esters, an auxiliary solvent and water as the raw materials; and performing shearing on the raw materials so as to prepare a stable and uniform antioxidant emulsion. The preparation method is simple in technologies; and the stable water-soluble antioxidant emulsion can be immediately prepared by a simple shearing process, and no high-pressure homogenization is required; thus, the preparation method is simple in equipment investment and low in cost. The antioxidant prepared according to the preparation method disclosed by the invention is very strong in antioxidant capacities, and has bacteriostatic effects; thus, the antioxidant is free of microbial growth and reproduction after long-term storage, and is stable in effects and wide in application ranges. The antioxidant is capable of saving equipment investment of the downstream enterprises; moreover, the antioxidant is low in dosage, so that the production costs of the food and cosmetic enterprises can be reduced.

Owner:陈爱梅

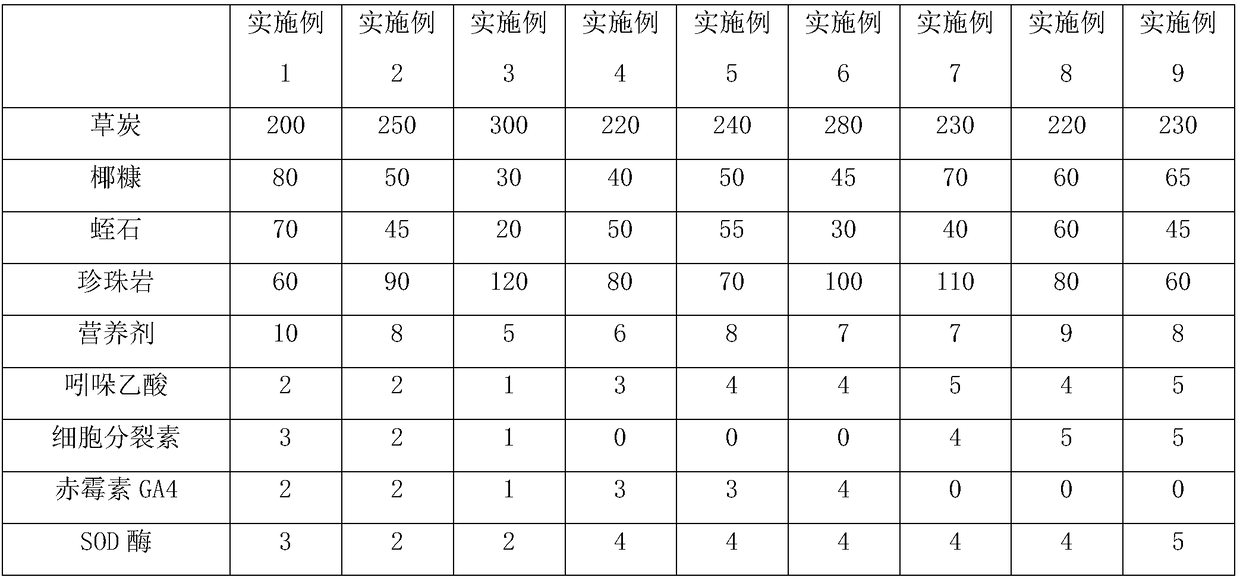

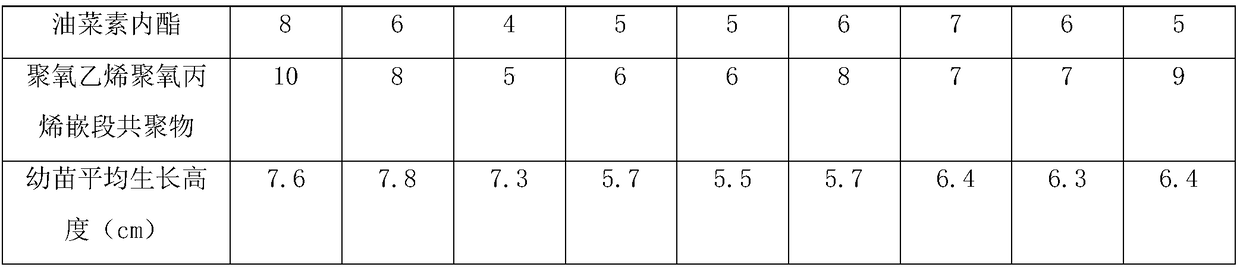

Seedling-growing substrate and preparation method thereof

InactiveCN108059541AFast growthImprove survival rateBioloigcal waste fertilisersGrowth substratesFiberMicrobial agent

The invention discloses a seedling-growing substrate and a preparation method thereof. According to parts by weight, the material is prepared from the following components: 200 to 300 parts of peat; 30 to 80 parts of coconut shell powder; 20 to 70 parts of vermiculite; 60 to 120 parts of perlite; 5 to 10 parts of nutrition agent; 10 to 15 parts of microbial agent; and 4 to 8 parts of brassinolide;and the microbial agent is prepared from heteroauxin. Both brassinolide and heteroauxin can induce plant growth gene expression, having the effect of promoting the growth of plants, brassinolide canregulate the polar transport of heteroauxin, having the effect of synergistic promotion, and thereby the growth speed of plants is increased. The coconut shell powder is coconut shell powder fiber powder, and is a purely natural organic medium which comes off in the process of processing coconut shells at a limited position, and the processed coconut shell powder is highly suitable for growing plants, and has high air permeability. With an adsorbing effect and high water-retaining capability, the vermiculite can adsorb nutrient substances and the microbial agent, preventing the loss of the nutrient substances and the microbial agent, and thereby the requirement of plants on nutrition is met.

Owner:厦门市银农种苗有限公司

Spraying-free polycarbonate composition and preparation method thereof

InactiveCN106280378AImprove surface topographyImprove surface strengthAmmonium polyphosphatePolycarbonate

The invention provides a spraying-free polycarbonate composition and a preparation method thereof. According to the preparation method, active ammonium polyphosphate, red phosphorus, a compound antioxidant, melamine cyanurate, a light stabilizer and the like are added into a formula, the melamine cyanurate and the active ammonium polyphosphate are mixed with a mixture No. 1 and a mixture No. 2, the stirring time and the stirring speed of three-stage stirring are strictly controlled, and the melamine cyanurate and the active ammonium polyphosphate can achieve a synergistic effect together with the mixture No. 1 and the mixture No. 2, so that the surface morphology of the spraying-free polycarbonate composition is improved, and the spraying-free polycarbonate composition prepared by the method not only has good surface strength and surface glossiness, but also has higher flame retardant property and longer heat resisting time; tests prove that the highest flame retardant property reaches up to level V-0, and the spraying-free polycarbonate composition has the heat resistance that the composition has a color change phenomenon only after being baked for 22min in the environment of 150+ / -5 DEG C.

Owner:福建华塑新材料有限公司

White marble sand composite resin material and preparation method thereof

The invention discloses a white marble sand composite resin material. The white marble sand composite resin material comprises the following raw materials in parts by weight: 30 to 40 parts of white marble sand, 60 to 70 parts of polypropylene, 0.3 to 0.5 part of lead sulfate tribasic, 4 to 5 parts of polyethylene wax, 1 to 2 parts of octyl isothiazolinone, 2 to 4 parts of double decarboxyl alcohol ester, 0.1 to 0.2 part of 1-ethoxy-2-oleic imidazoline, 1 to 2 parts of zinc diricinoleate, 0.5 to 1 part of glycerin monostearate, 0.3 to 1 part of stannous octoate, 2 to 3 parts of ethoxylated alkyl phenol ammonium sulfate, 10 to 12 parts of a carbon nano-tube and 6 to 9 parts of phosphorylated cellulose. The lead sulfate tribasic, the stannous octoate and the zinc diricinoleate are added, sothat the heat-resistant stability of the finished product is effectively improved and the comprehensive performance of the finished product is improved.

Owner:宿松汉邦新型建材有限公司

Composite feed additive for improving reproduction performance of egg breeder cock and application method thereof

InactiveCN103829086AImprove qualityEnhance the immune function of the bodyAnimal feeding stuffBiotechnologyAnimal science

The invention relates to a composite feed additive for improving reproduction performance of an egg breeder cock and an application method thereof. The feed additive comprises 40 to 60% of taurine, 25 to 40% of arginine and 20 to 35% of soybean peptide. When the egg breeder cock is 40 weeks old, the additive weighing 1.0 to 1.5% of the daily ration for the egg breeder cock is uniformly mixed with the cooperative daily ration, and the mixed daily ration is fed to the egg breeder cock until the egg breeder cock is eliminated. The additive provided by the invention accords with the rule of reproduction performance of the egg breeder cock, improves seminal fluid quality and immunity of the egg breeder cock, allows sperm viability to be improved by more than 15% and effectively prolongs the service life of the egg breeder cock.

Owner:沈阳荌瑞福客生物科技有限公司

Regulator for cutting seedling and transplanting of aceraceous plants such as red maple and planting method thereof

InactiveCN106417371AImprove survival ratePest controlBiocideMagnesium fertilisersRoot systemInstability

The invention belongs to the technical field of forestry breeding and discloses a regulator for cutting seedling and transplanting of aceraceous plants such as red maple and a planting method thereof. According to the regulator for cutting seedling and transplanting of the aceraceous plants such as red maple, provided by the invention, extensive plantation can be performed by rapidly dipping the cuttings into the regulator only, and the regulator is particularly applied to industries such as gardens, municipal administration, road and landscaping. The regulator disclosed by the invention is capable of nourishing the bark, controlling leaf yellowing, leaf spots and powdery mildew and high in cutting survival rate, and the quality of cuttings in the same area is large; moreover, the problems of irregular roots, instability, fewer roots, root puffing, root system callus and multiple calluses are solved.

Owner:许伟琦

Solvent type strippable plastic film antirust agent and preparation method thereof

ActiveCN106833844AEasy to removeInhibition of oxygen absorption corrosionAnti-corrosive paintsLubricant compositionPlasticizerBenzotriazole

The invention discloses a solvent type strippable plastic film antirust agent and a preparation method thereof. The solvent type strippable plastic film antirust agent comprises the following components in percentage by weight: 15.5-20.0% of polyvinyl chloride powder, 6.0-8.0% of a plasticizer, 1.0-3.0% of a corrosion inhibitor, 0.2-0.4% of organic alkali, 1.0-2.0% of an antioxidant and 66.8-76.3% of tetrahydrofuran. The antirust agent has the following advantages and effects: tetrahydrofuran is adopted as a solvent for dissolving the polyvinyl chloride powder, and the plasticizer promotes the film formation of polyvinyl chloride; when in use, a solvent type strippable plastic film forms a layer of plastic film which is attached to the surface of a metal product, and the plastic film is simply torn and stripped for removal; and moreover, by adding the organic alkali (benzotriazole) and the antioxidant (tert-butyl p-cresol), a synergistic effect can be realized, the antirust property of the solvent type strippable plastic film antirust agent is remarkably enhanced, and the effects of convenient removal and improvement of antirust property are realized.

Owner:SHANGHAI XINPING FINE CHEM CO LTD

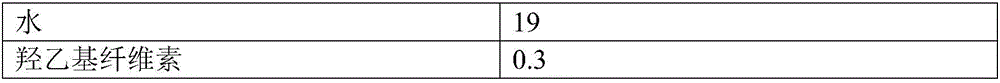

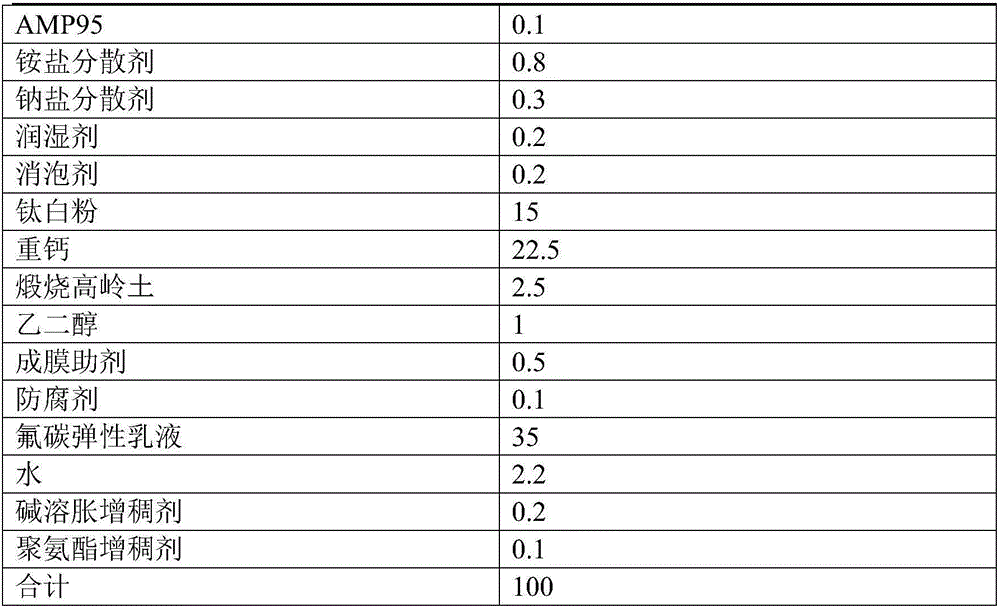

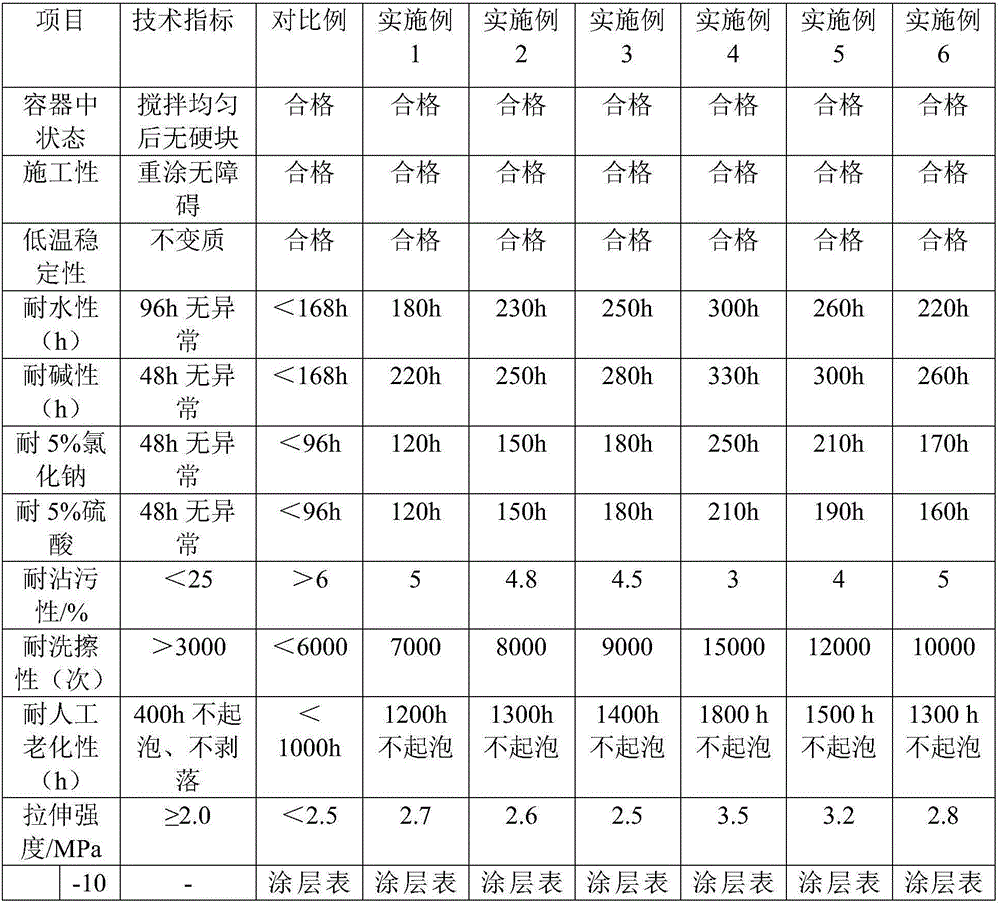

Fluorocarbon elastic emulsion and preparation method thereof

The invention discloses a fluorocarbon elastic emulsion, and belongs to the technical field of emulsions. The fluorocarbon elastic emulsion is prepared from the following components in mass percent: 35-55% of water, 1-3% of an emulsifying agent, 5-30% of a fluorine-containing monomer, 20-30% of butyl acrylate, 5-10% of methyl methacrylate, 1-3% of acrylic acid or methylacrylic acid, 0-5% of benzophenone, 0-5% of vinylalkoxy phosphate, 0-5% of ethylene glycol dimethacrylate, and 0-3% of persulfate. The invention further provides a preparation method of the fluorocarbon emulsion. Compared with a common elastic emulsion, the elastic emulsion disclosed by the invention not only has the advantages of being high in weather resistance, chemical corrosion resistance, water resistance, stain resistance and artificial ageing resistance, but also can improve the wetting and dispersing ability on pigments and fillers, and the adhesive force and water resistance of a paint film are further improved.

Owner:GUANGDONG HENGGUANG CHEM CO LTD

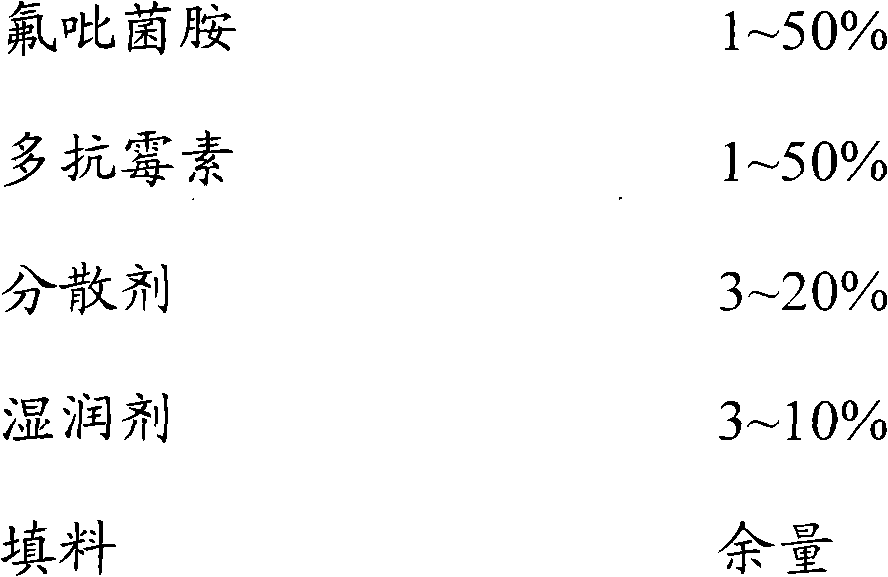

Bactericidal composition containing fluopicolide and polyoxin

InactiveCN102726426AReduce dosageDelays the development of fungicide resistanceBiocideFungicidesDiseaseMicrobicide

The invention relates to a complex bactericide, which comprises the effective components of fluopicolide and polyoxin. The mass percentage of fluopicolide to polyoxin is 1-50:50-1, the content of the fluopicolide and polyoxin in the complex bactericide is 1-80%. The complex bactericide can be prepared to a suspending agent, a wettable powder, a water dispersible granule, an emulsion in water, a micron emulsion and the like by a widely-known method for the technicists in the field. The bactericidal composition can be used for preventing and treating a plurality of crop diseases, and possesses outstanding effects on various diseases caused by Oomycete, such as downy mildew, epidemic disease, late blight, damping off diseases and the like.

Owner:QINGDAO KYX CHEMICAL CO LTD

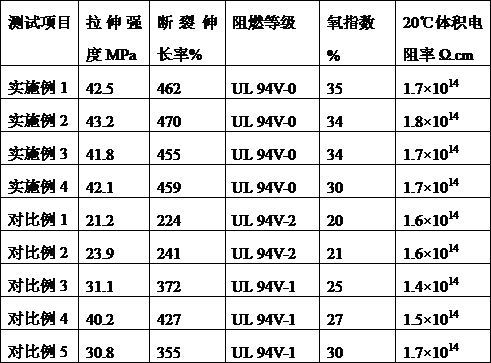

Cable material composition for automobile wire harness and preparation method thereof

InactiveCN114456480ANo loss of toughness strengthDoes not compromise tensile strengthPlastic/resin/waxes insulatorsCarbon nanotubeAnoxomer

The invention discloses a cable material composition for an automobile wire harness and a preparation method of the cable material composition. The cable material composition is prepared from the following raw materials in parts by weight: 30-80 parts of ethylene propylene diene monomer; 60 to 120 parts of an ethylene-vinyl acetate copolymer; 70 to 160 parts of a silicon-aluminum compound inorganic flame retardant; 0.4 to 3 parts of an antioxidant; 2-10 parts of a plasticizer; and 0.5-5 parts of a coupling agent. According to the invention, the carbon nano tube is used as a carrier to load part of the silicon dioxide microspheres, and can be connected with part of the silicon dioxide microspheres in a surface bonding manner to form a carbon nano tube-silicon dioxide composite carrier, and through the synergistic enhancement effect of the carbon nano tube and the silicon dioxide microspheres, the loading capacity can be increased, and the dispersion performance can be improved; the carbon nanotubes, the silicon dioxide microspheres and the Al (OH) 3 / Al2O3 are complementarily enhanced, so that the mechanical properties such as toughness and tensile strength of the polymer can be improved while the flame retardant property of the polymer is improved.

Owner:南通华海电气有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com