Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Good tempering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metallurgical reduction production method for titanium containing slag

InactiveCN106755658ARealize quenching and temperingIncrease the specific surface area for chemical reactionsCement productionRecycling and recovery technologiesAlkalinityMolten state

The invention provides a metallurgical melting reduction production method for titanium containing slag and belongs to the field of non-blast furnace ironmaking and resource comprehensive utilization. The metallurgical melting reduction production method comprises the steps that (1) vanadium containing slag or vanadium-titanium containing steel slag is added into a melting reaction device, reducing agents are sprayed into the melting reaction device while iron containing materials and / or vanadium-titanium containing materials are sprayed into the melting reaction device with oxidizing gas, reaction mixed slag is obtained, heated to be in a molten state and monitored in real time, and the situations that the reaction slag temperature is within the set range, and the reaction slag alkalinity CaO / SiO2 ratio is 0.6-2.0 are ensured at the same time through adjustment and control, so that the reaction slag is fully mixed, and reduced and oxidized slag is obtained; and (2) separating and recycling are conducted. According to the metallurgical melting reduction production method for the titanium containing slag, the recycling rate of metallic iron is 92%-96%; heat compensation is not needed or a small quantity of heat compensation is needed; the operability is high; the production cost is low; no solid waste is produced in the whole process; the reaction conditions are mild; energy saving and emission reduction are achieved; and the metallurgical melting reduction production method is an environment-friendly metallurgical process.

Owner:NORTHEASTERN UNIV

Phase-separated soda-lime-silica glass

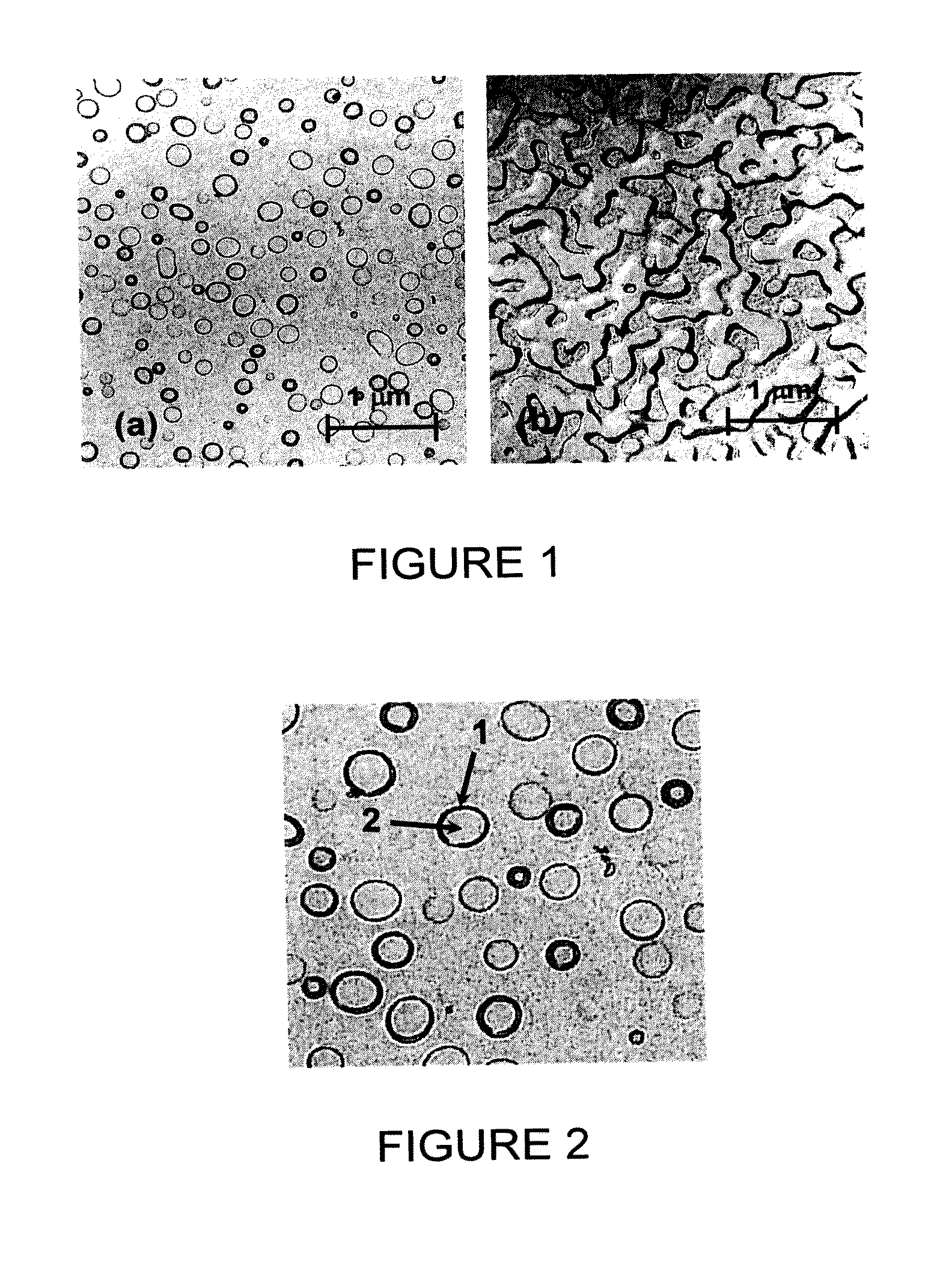

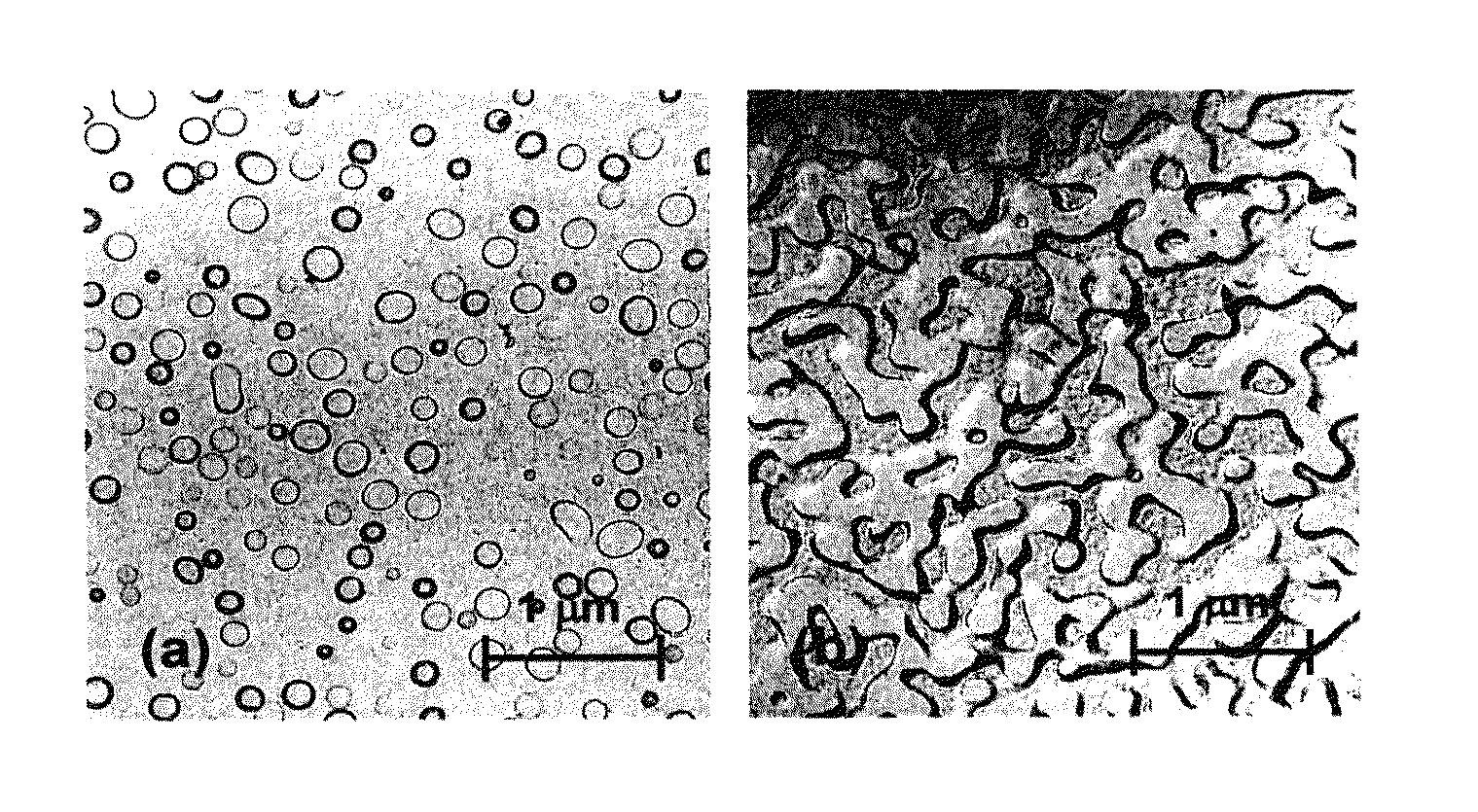

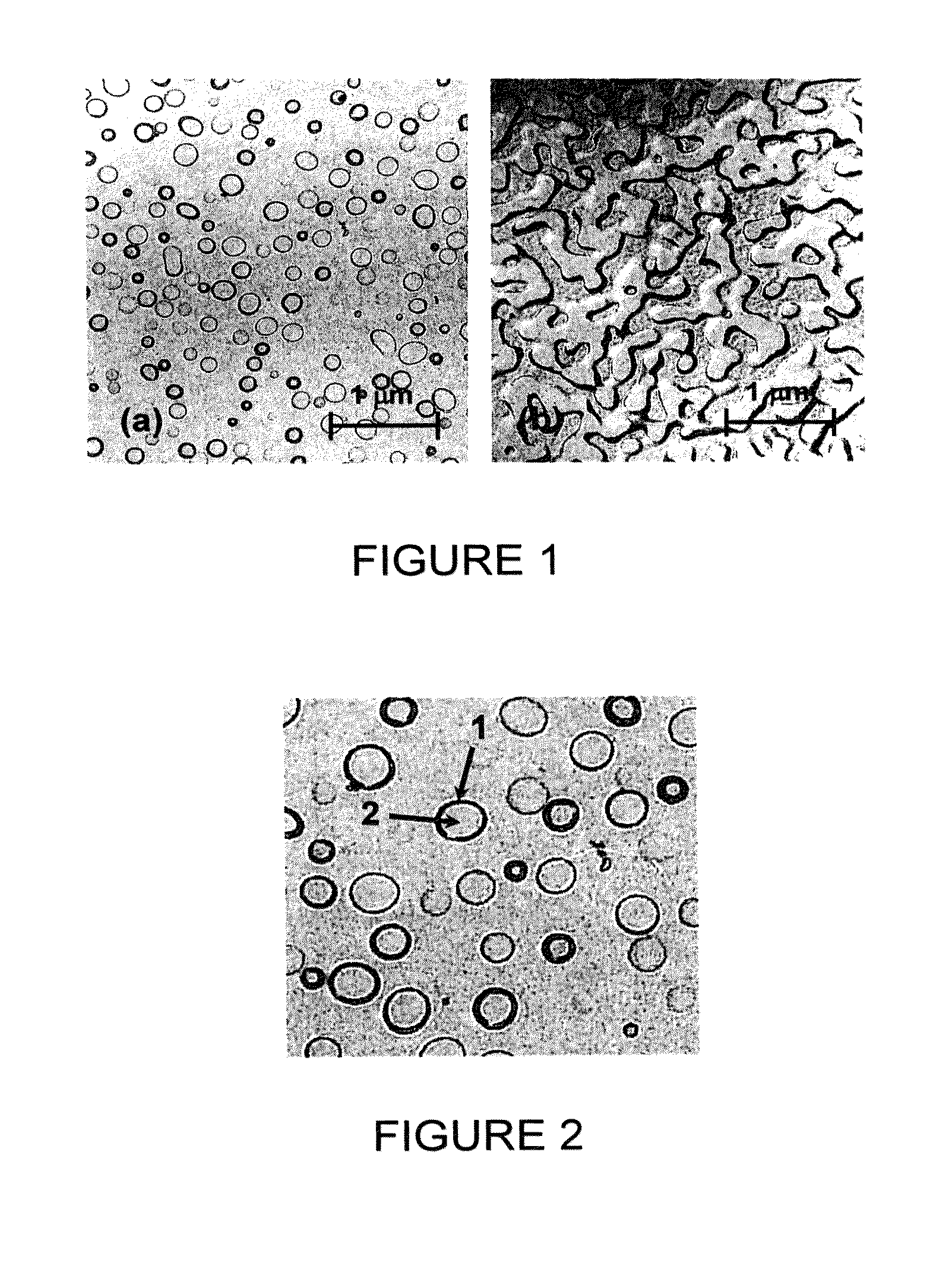

InactiveUS20120196735A1Improve mechanical propertiesGood resistance to scratch propagationMaterial nanotechnologyGlass productionAmorphous phaseSilica gel

The invention relates to a glass having SiO2, Na2O and CaO as main components, which comprises two amorphous phases having different compositions, one of the two phases being in the form of inclusions dispersed in the volume of the other phase and comprising crystalline particles. Such a glass has good mechanical strength, in particular good resistance to scratch propagation and allows improved tempering. This glass furthermore has a pleasant aesthetic appearance.

Owner:AGC GLASS EUROPE +1

Duck fattening feed and preparation method thereof

InactiveCN104171711AHigh energyHigh fat levelsFood processingAnimal feeding stuffSodium bicarbonateThreonine

The invention provides a duck fattening feed and a preparation method thereof, aiming at the condition that current cherry valley ducks are relatively low in fat deposition generally after being fed by a feed. The duck fattening feed comprises the following raw materials in parts by weight: 40-60 parts of corns, 10-30 parts of wheat, 3-8 parts of bean meal, 2-6 parts of cottonseed meal, 2-6 parts of flour, 0-6 parts of wheat bran, 2-5 parts of corn gluten meal, 3-6 parts of rapeseed meal, 0-6 parts of corn distillers grains, 2-5 parts of lard oil, 0.2-0.6 part of lysine hydrochloride, 0.05-0.2 part of methionine, 0.05-0.2 part of threonine, 0.2-0.4 part of table salt, 0.1-0.3 part of various vitamins, 0.6-1.5 parts of rock flour, 0.6-1.2 part of calcium hydrophosphate, 0.1-0.3 part of sodium bicarbonate and 0.2-0.5 part of a premix. The duck fattening feed is high in energy level, high in content of starch and high in content of saturated fatty acid, and is capable of remarkably improving the carcass fat deposition effect of the cherry valley ducks, greatly reducing the production cost of roast ducks, and improving the production performance of the cherry valley ducks.

Owner:TONGWEI

Method for producing low-iron high-pervious self-cleaning ultra-white rolling glass

The invention discloses a method for producing low-iron high-pervious self-cleaning ultra-white rolling glass. Prepared materials comprise components in parts by mass as follows: 68% to 75% of SiO2, 9% to 15% of Na2O, 8% to 12% of CaO, 1% to 3% of Al2O3 and 2% to 5% of MgO, a compound strong oxidant accounting for 0.1% to 1.0% of the prepared materials is added, iron contents of the materials are controlled to be within 50ppm, and the rolling glass is formed through mixing, melting, rolling, annealing, cut loading, coating, tempering and coating curing. According to the method, the iron contents of the materials and the mass ratio of the materials are controlled, the strong oxidant is added, glass sheets are manufactured by a natural gas total oxygen combustion technology, and photoelectric properties and physical properties of the rolling glass can be improved remarkably after two times of coating, tempering and curing, so that the sunlight transmittance is improved by 2.5% to reach more than 94.5%, the photoelectric conversion efficiency of the rolling glass can be improved, a self-cleaning function is provided, and industrial application of solar ultra-white rolling glass is facilitated.

Owner:江西省速睿科技有限责任公司

Phase-separated soda-lime-silica glass

InactiveUS8853109B2Improve mechanical propertiesGood resistance to scratch propagationGlass productionAmorphous phaseSilica gel

The invention relates to a glass having SiO2, Na2O and CaO as main components, which comprises two amorphous phases having different compositions, one of the two phases being in the form of inclusions dispersed in the volume of the other phase and comprising crystalline particles. Such a glass has good mechanical strength, in particular good resistance to scratch propagation and allows improved tempering. This glass furthermore has a pleasant aesthetic appearance.

Owner:AGC GLASS EUROPE SA +1

Total mixed ration for fattening sheep and production process and application thereof

InactiveCN108935992AIncrease production capacityImprove digestibilityFood processingAnimal feeding stuffBiotechnologyHordeum vulgare

The invention discloses a total mixed ration for fattening sheep and a production process and application thereof. The total mixed ration comprises the following components in parts by weight: 260-340parts of corn, 50-70 parts of soybean meal, 35-45 parts of germ meal, 15-25 parts of wheat middlings, 10-30 parts of bran, 55-65 parts of barley roots, 40-60 parts of stevia, 90-150 parts of peanut seedlings and 45-55 parts of wheat bran, 35-45 parts of yeast and yeast culture, 130-180 parts of gunite corn bran, 75-85 parts of premix and 3-5 parts of soybean oil. The total mixed ration can: maintain the normal internal environment of the rumen, reduce the production of methane and maintain the maximization of effective micoorganisms in the rumen; improve the production performance of fattening sheep; improve the digestibility of the fattening sheep to nutrient substances and increase the utilization rate of effective nutrients; and improve the slaughter performance and meat quality of thefattening sheep, reduce the deposition of fat under the skin and viscera and improve the quality of mutton.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

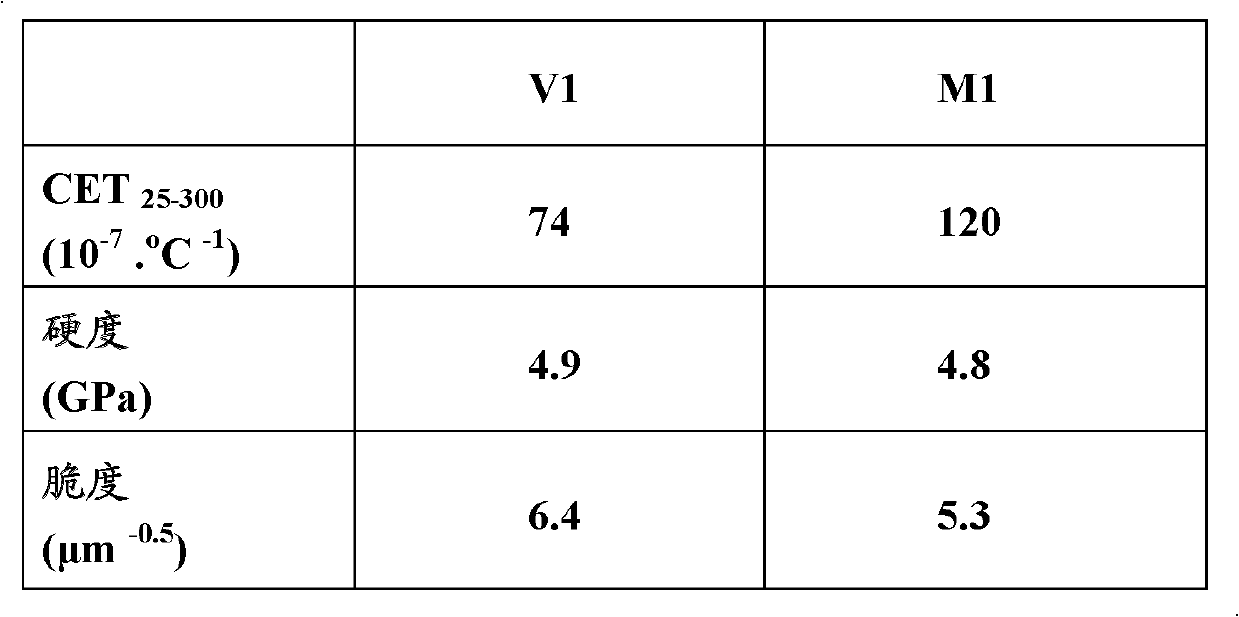

Silico-sodo-calcic glass-ceramic material

InactiveCN102596836AImprove mechanical propertiesGood resistance to scratch propagationAmorphous matrixUltimate tensile strength

The invention relates to a glass-ceramic material having, as main components, SiO2, Na2O and CaO, and including crystalline SiO2 particles homogenously dispersed in the space of an amorphous matrix. Such a material has good mechanical strength, in particular good resistance to the propagation of scratches, and enables improved tempering. Said material furthermore has a pleasant aesthetic appearance.

Owner:AGC GLASS EUROPE SA +1

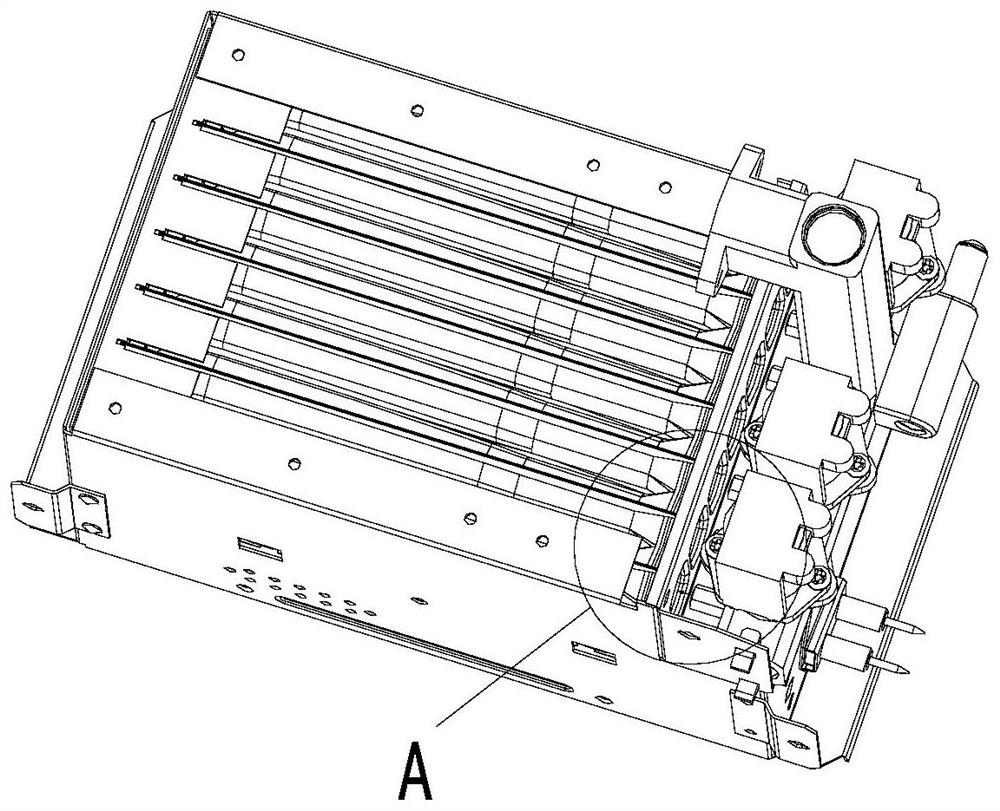

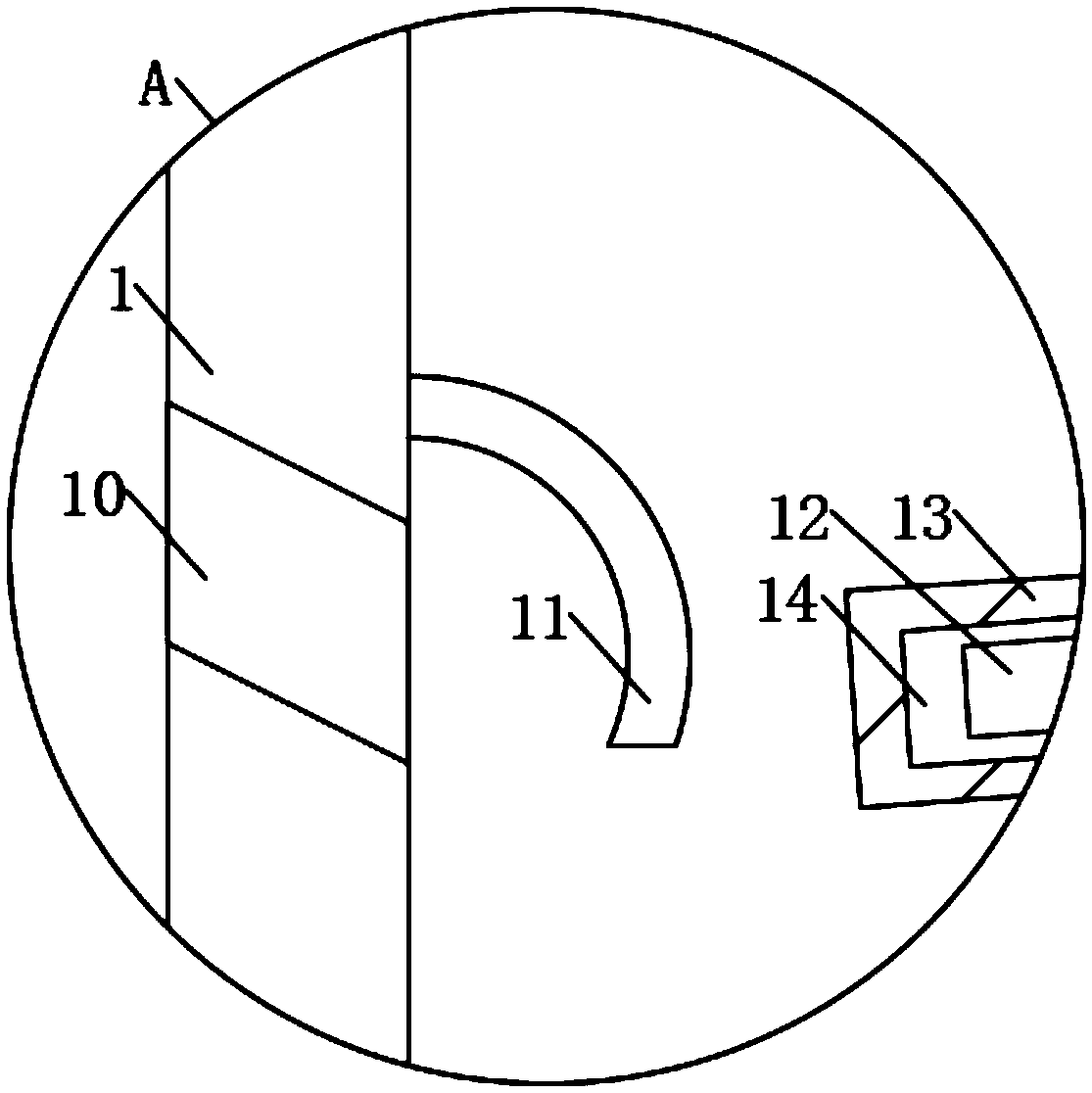

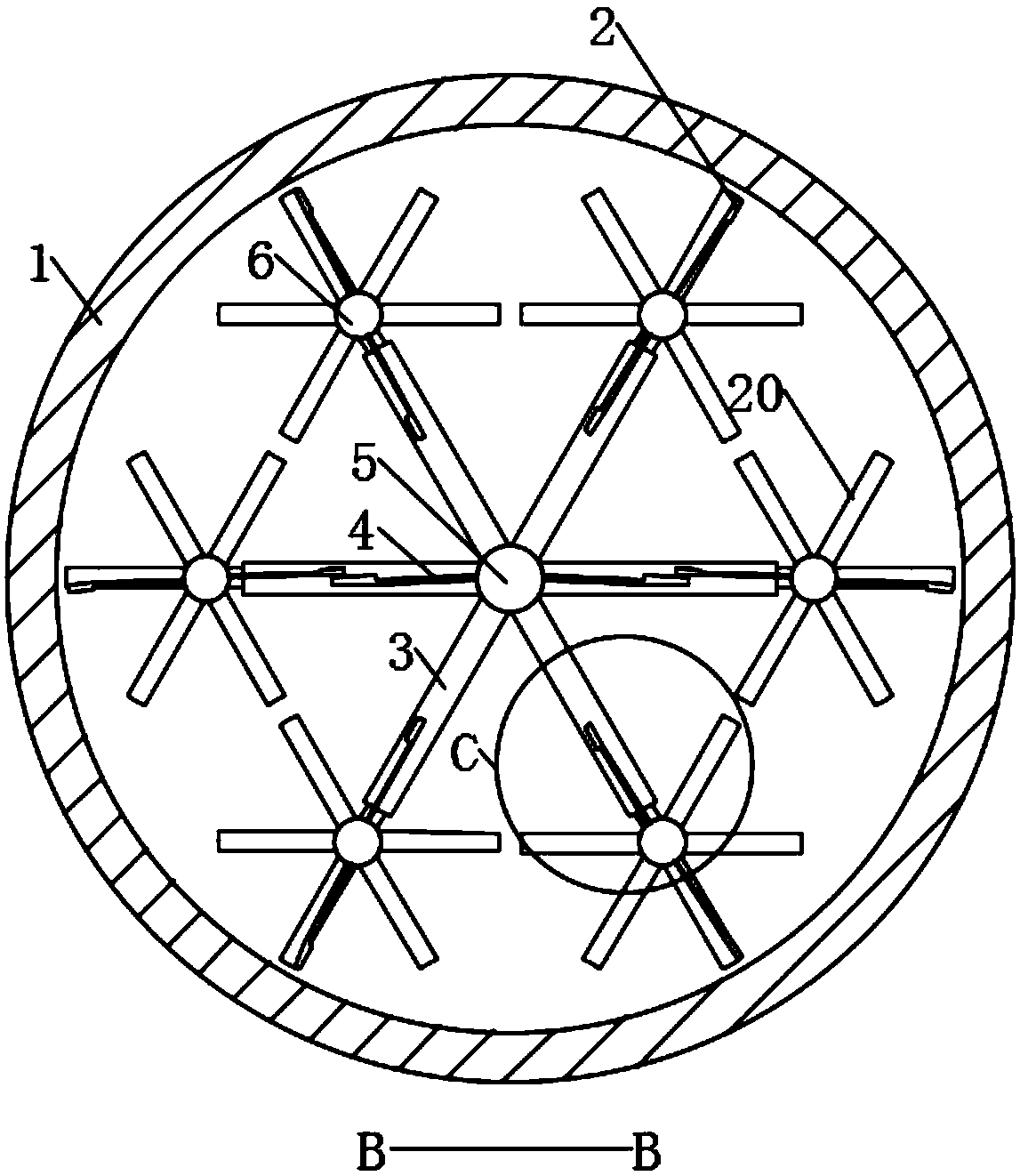

Sectional type pyrolysis and gasification device

PendingCN107903948AImprove pyrolysis efficiencyImprove heat transfer efficiencyGasifier feeding meansChemical industryProcess engineeringPyrolysis

The invention discloses a sectional type pyrolysis and gasification device, which comprises a first furnace body, a first feeding hole, a first discharging hole, a first main shaft, a second main shaft, a first groove-type air distribution board, a second groove-type air distribution board, a first driving speed controller, a second driving speed controller, a plurality of first blades, a plurality of second blades, a second discharge hole, a first clapboard and a first gasification agent inlet, wherein the plurality of first blades and the plurality of second blades which are distributed at equal intervals are respectively arranged on the first main shaft and the second main shaft; the second discharge hole is arranged on one side of the first groove-type air distribution board; the firstclapboard is arranged between the second groove-type air distribution board and the inner wall of the furnace body; the first gasification agent inlet is arranged on the furnace body of one side of the corresponding second groove-type air distribution board; the first furnace body is provided with a first fuel outlet. The sectional type pyrolysis and gasification device has high pyrolysis efficiency and stable and even reaction, heat exchange efficiency is improved, reaction remaining time is prolonged, handling capacity is improved, investment cost is saved, and an effect on greatly saving separation, refining and purification cost in a subsequent production utilization process can be realized.

Owner:常州至拓新能源开发有限公司

Manufacturing technology for ultrathin glass protective film

InactiveCN107032627AGuaranteed aestheticsGood temperingFlexible article cleaningGlass tempering apparatusTectorial membraneManufacturing technology

The invention discloses a manufacturing technology for an ultrathin glass protective film. The technology comprises the following steps: (3) using a thinning solution for only one time; (4) airing the product for 4-6min for cleaning the product again; (6) cleaning the product before tempering under the cleaning condition of detergent concentration of 5%, temperature at 50-60 DEG C, cleaning for 3min and drying for 3min that is convenient for subsequent tempering, wherein the thickness of the tempering in the step (6) is 0.05MM; (8) checking the finished products and then performing spot check on the products, thereby increasing the yield of the products. The glass protective film manufactured according to the manufacturing technology is thinner, can be perfectly fit with the present electronic products, has no step feeling in the use process and can guarantee the beautiful appearance of the electronic products.

Owner:SHENZHEN FANCY OPTICAL MATERIAL TECH CO LTD

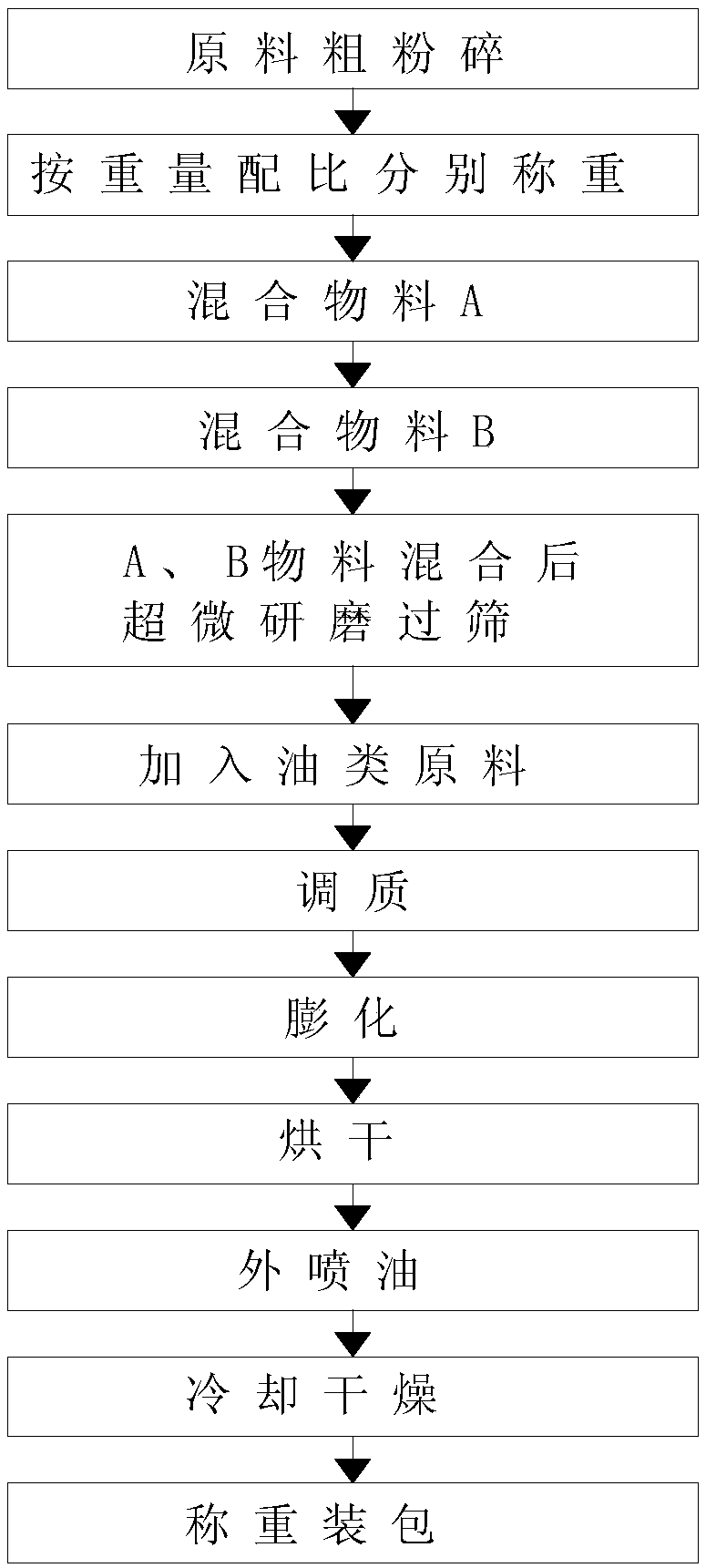

Preparation process for fattening cream river crab compound feed

InactiveCN109221803AWell mixedFacilitates the ripening processFood processingClimate change adaptationDiseaseCompound organic

The invention relates to a preparation process for a fattening cream river crab compound feed and belongs to the technical field of agricultural breeding. The compound feed is prepared from the following materials: high protein flour, peeled expanded bean pulp, fermented bean pulp, fish meal, chicken powder, shrimp powder, sleeve-fish paste, phospholipid oil, soya-bean oil, fish oil, spirulina, choline chloride, zeolite powder, monocalcium phosphate, table salt, yeast hydrolysate, antibacterial peptides, chitosan compound vitamins, compound organic microelements and astaxanthin. By roughly crushing the materials first and then carrying out ultraomicro crushing on the materials, the materials are fine enough. The materials are mixed in grade and can be fully mixed, so that the fusing degreeof the powder and the oil is improved, and follow-up tempering and expanding operations are facilitated. The longer the tempering time is, the longer the contact and mix time of vapor and the powderyfeed is, and the more the added vapor amount is, the more favorable the curing of the river crab feed is. The tempered materials are extruded and expanded, so that starch is fully cured, the proteinsare deteriorated, the antinutritional factors in different feed raw materials are deactivated, and insects are killed and bacteria are sterilized, and therefore, the digestive absorption utilizationof the feed by the river crabs is improved, the intestinal tract irritation is reduced, diseases are reduced, and the water quality is improved.

Owner:HUAIAN ZHENGCHANG FEED

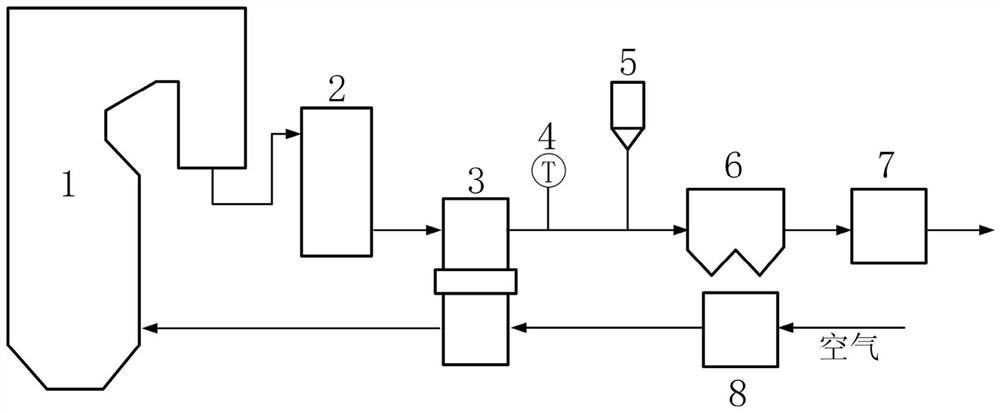

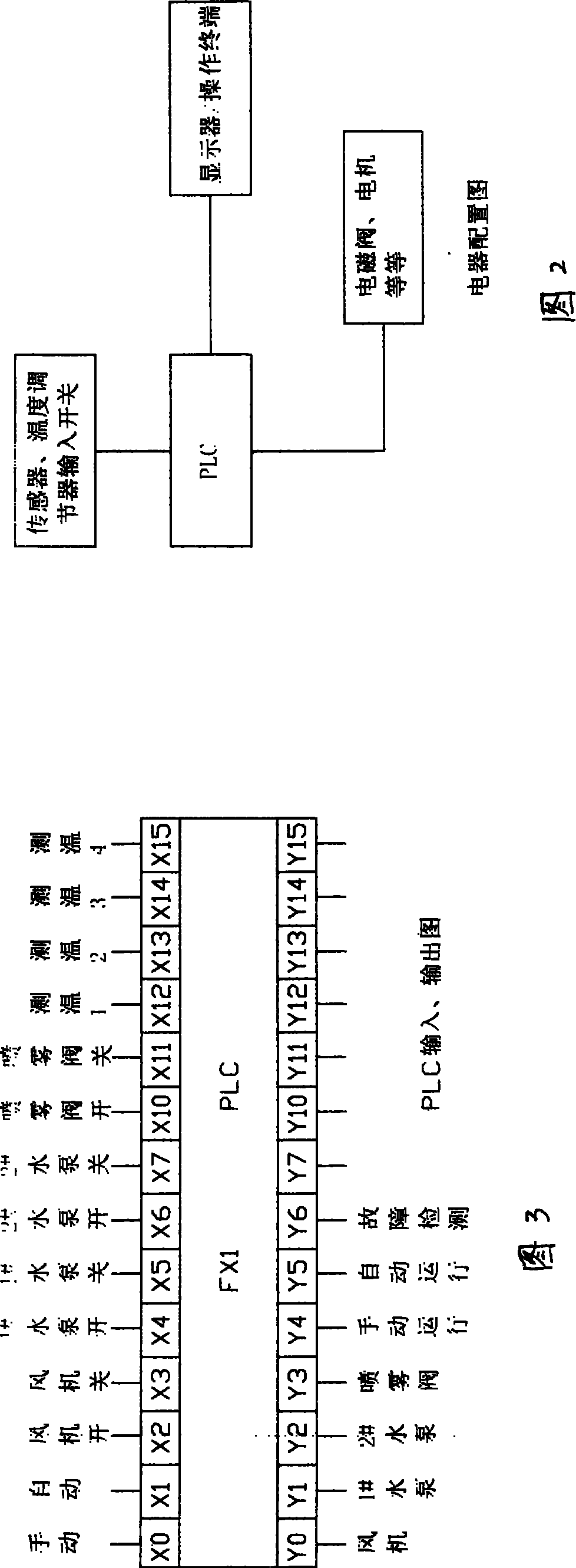

System and method for simultaneously removing sulfur trioxide, ammonia gas, and fly ash in flue gas after SCR

ActiveCN109821409AGuaranteed uptimeGood temperingCombustion processDispersed particle separationAir preheaterFlue gas

The invention discloses a system and method for simultaneously removing sulfur trioxide, ammonia gas, and fly ash in flue gas after SCR. A rotary air preheater and an auxiliary flue gas conditioning system are taken as the basis of the system. The system mainly comprises the rotary air preheater, a flue gas online monitoring system, the auxiliary flue gas conditioning system, an electrostatic deduster, a flue gas deep cooler, and a pre-posed air heater. The heat exchange area of the rotary air preheater is reduced, the temperature of the flue gas outlet of the rotary air preheater is raised tothe dew point temperature of ammonium bisulfate or so, ammonia gas and sulfur trioxide in flue gas are used to modify flue gas; at the same time, the auxiliary flue gas conditioning system can adjustand optimize the flue gas conditioning process in real time according to the flue gas information provided by the flue gas online monitoring system. The provided simultaneous removal method can improve the dedusting efficiency of an electric deduster, is capable of removing sulfur trioxide and SCR escaped ammonia gas in flue gas, and solves the problem that a downstream heat-absorbing surface isobstructed and corroded by deposited ash.

Owner:XI AN JIAOTONG UNIV

Method for the production of optical components with increased stability, components obtained thereby and their use

InactiveUS6855380B2Improve production yieldComponent stabilityElectric discharge heatingVacuum evaporation coatingThree dimensional shapeBiomedical engineering

A method is described for the production of optical components, particularly of crystalline base material, with elevated stability and an optically active three-dimensional shape, which is defined by its surfaces, of high fit accuracy, by shaping the base material into a blank with a desired three-dimensional shape, and applying a covering layer to the surface of the thus-formed three-dimensional shape and the fit accuracy is obtained by abrasion of the covering layer.

Owner:CARL ZEISS SMT GMBH

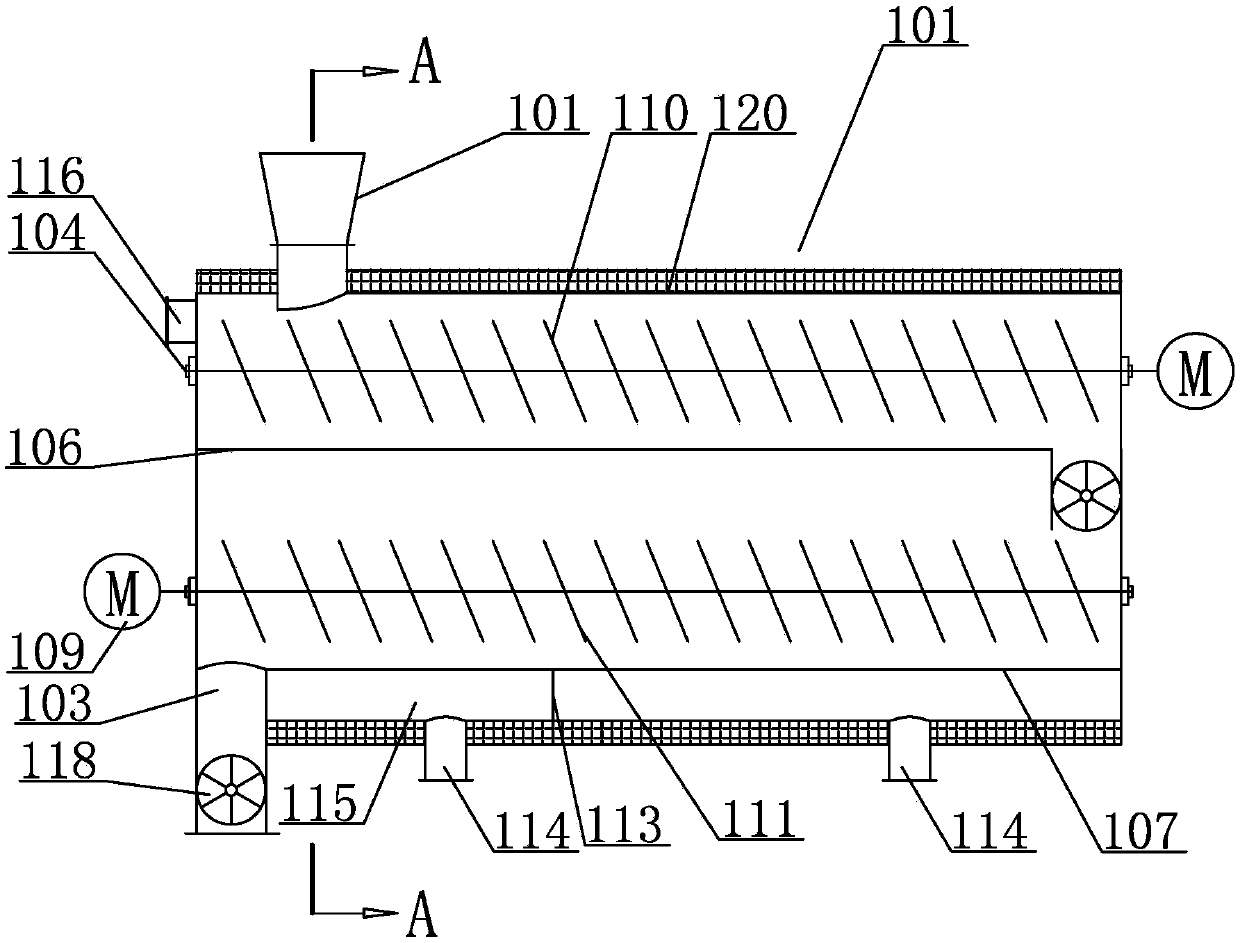

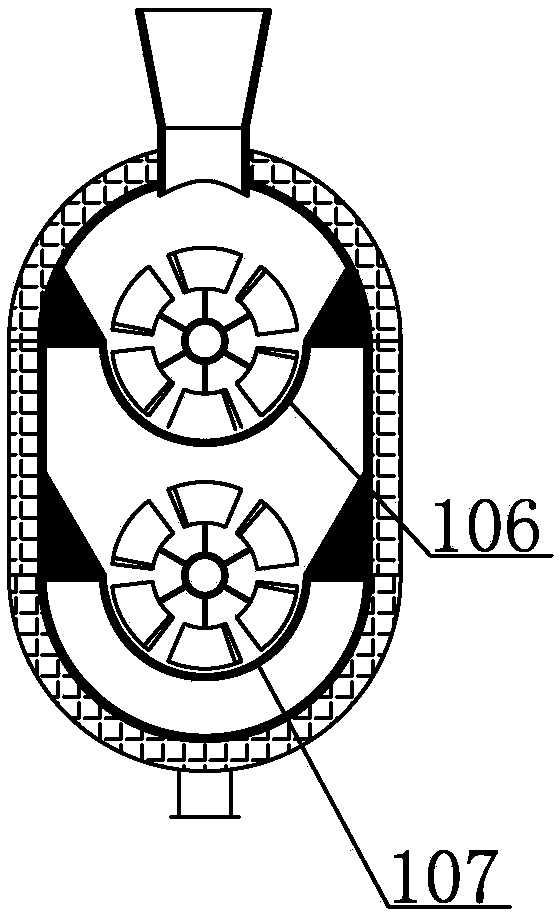

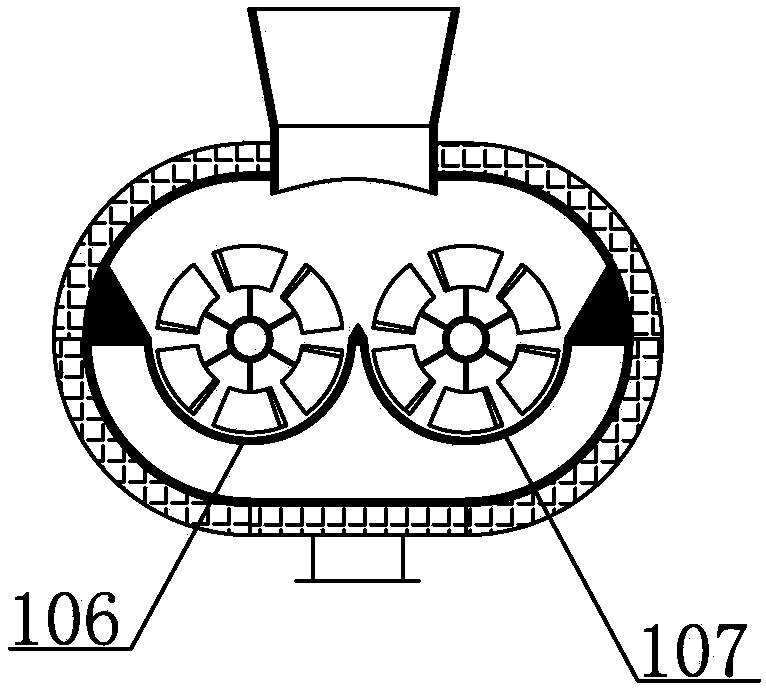

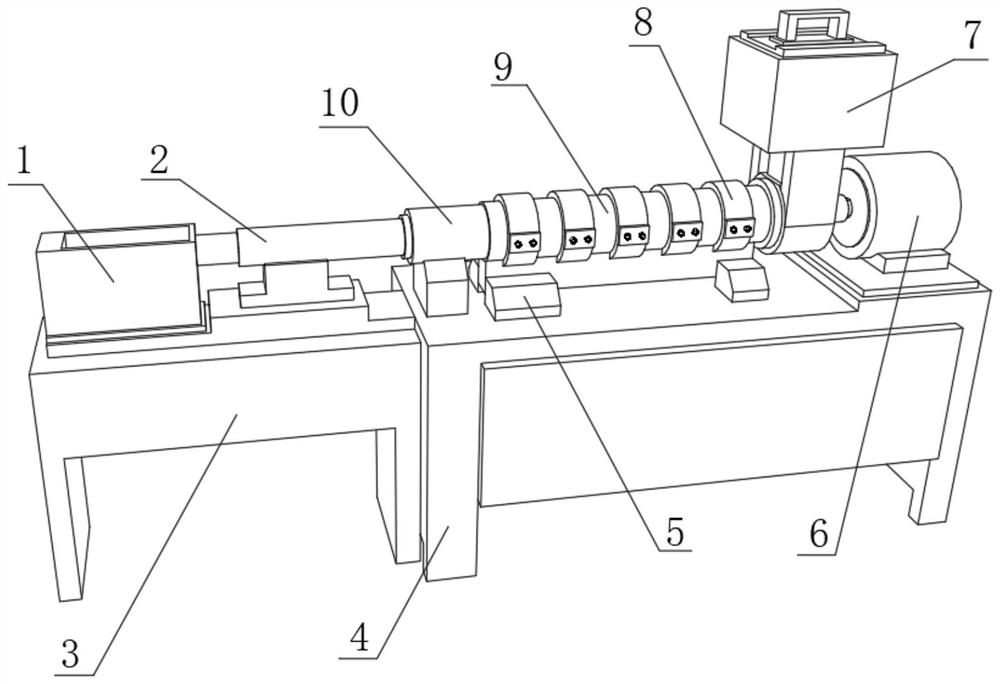

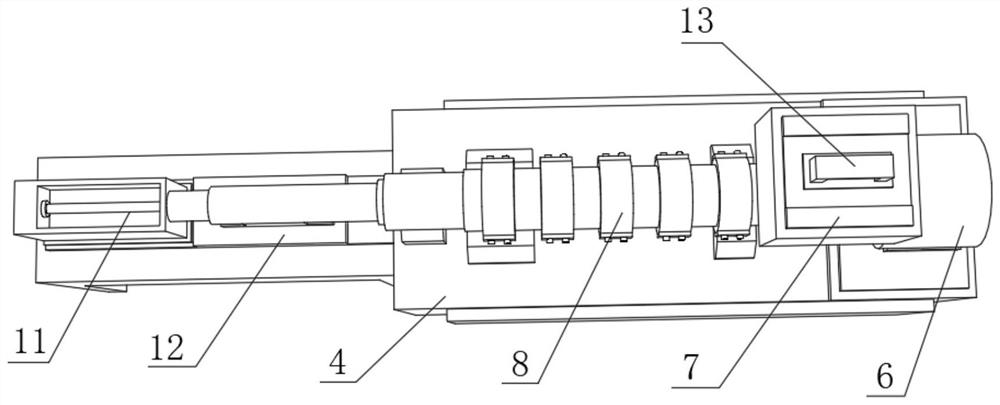

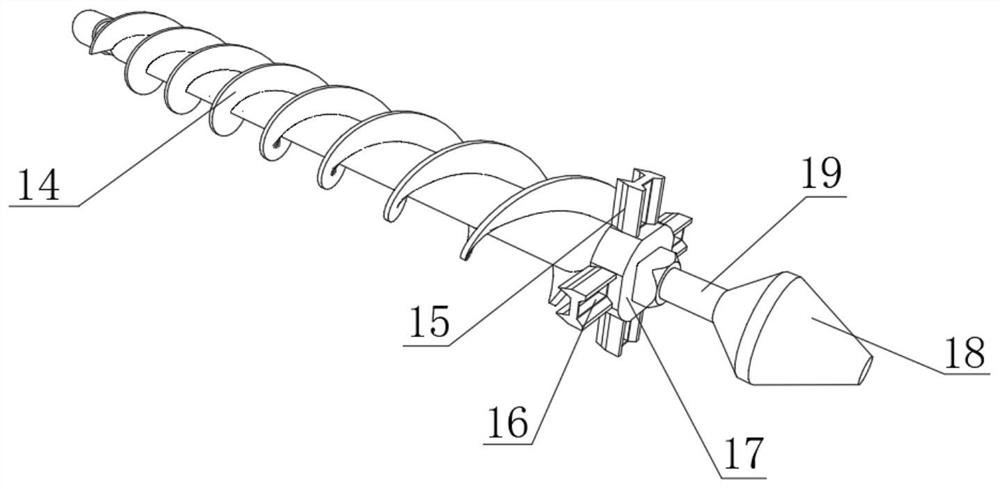

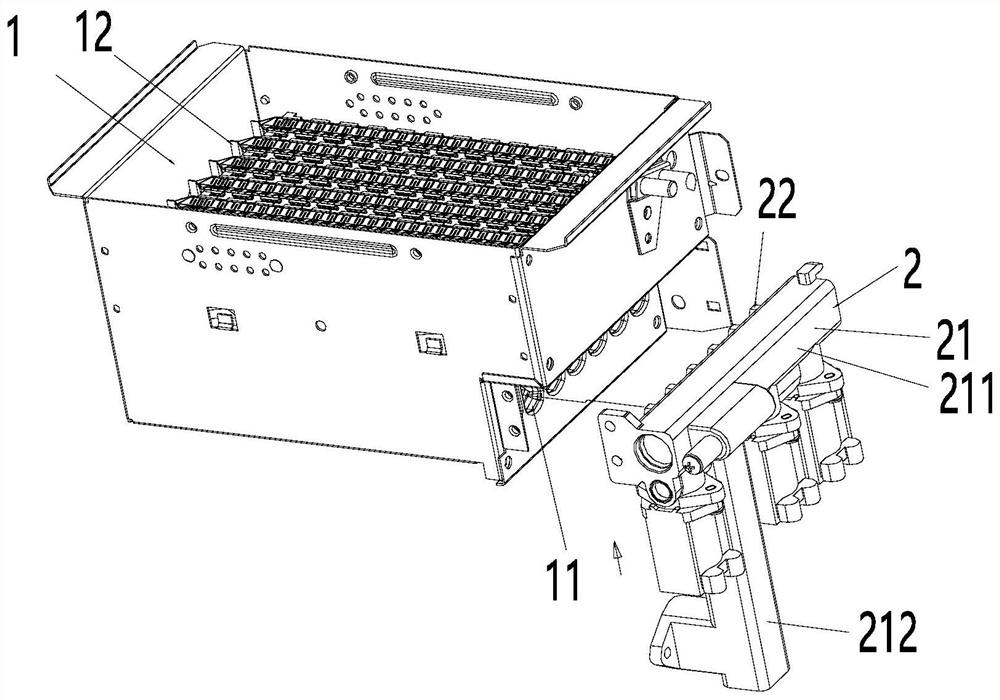

Conditioning device for feed production

InactiveCN111871329ASolve agglomerationSolve the blockageFeeding-stuffGranulation by pressingTemperingElectric machinery

The invention discloses a conditioning device for feed production, and relates to the technical field of feed production conditioning. The invention aims to solve the problem of fusion degree betweenmixed materials of feed. The device specifically comprises a first workbench and a second workbench, wherein four mounting blocks are fixed to the outer wall of the top of the second workbench throughbolts; one hardening and tempering cylinder is fixed to the outer walls of the tops of the four mounting blocks through limiting plates, and heating rings distributed at equal intervals are connectedto the outer wall of the circumference of the hardening and tempering cylinder in a sleeving mode; one end of the hardening and tempering cylinder is sleeved with a feeding cylinder through a sealingring, supporting plates are welded to the outer walls of the two sides of the feeding cylinder, the same feeding box is fixed to the outer walls of the opposite sides of the two supporting plates through bolts, and a box cover is arranged on the outer wall of the top of the feeding box; a motor is fixed to the outer wall of one side of the top of the second workbench through a support, wherein the output end of the motor is connected with a mounting shaft through a coupler, and the mounting shaft is inserted into the feeding cylinder. According to the invention, a problem of caking of the mixed material in the mixing and stirring process is effectively avoided.

Owner:江苏大地动物保健品有限公司

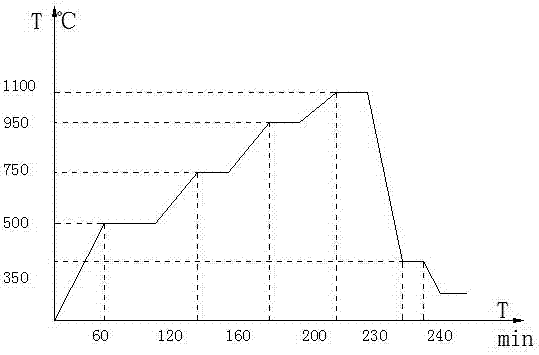

Micro-deformation controlling heat treatment process for forming position of special-shaped curved surface part

InactiveCN107447085AMeet the hardness requirementsSimple processFurnace typesHeat treatment furnacesFurnace temperatureHardness

The invention discloses a micro-deformation controlling heat treatment process for a forming position of a special-shaped curved surface part. The process comprises the following steps of: S1, preliminary working of forming; S2, charging; S3, temperature raising: raising the temperature at a uniform speed till the furnace temperature reaches 500-600 DEG C, continuously raising the temperature to 750-850 DEG C at the uniform speed, continuously raising the temperature to 950-1000 DEG C at the uniform speed and continuously raising the temperature to 1100-1200 DEG C at the uniform speed; S4, micro-deformation heat treatment: introducing protective gas for cooling, performing quick cooling to 300-400 DEG C, and performing discharge at a constant temperature for 5-10min; S5, high-temperature tempering treatment; S6, deep cooling treatment; S7, hard control tempering; S8, stable structure tempering; and S9, polishing treatment. The process disclosed by the invention has the beneficial effects that the problem that the micro-deformation of the forming position of the special-shaped curved surface part which is high in hardness and hard to process is hard to control; the machining process of the special-shaped curved surface part is simplified, and the processing efficiency is increased.

Owner:CHENGDU LIANYU PRECISION MACHINERY

Low-magnesium superwhite glass

The invention discloses low-magnesium superwhite glass. The low-magnesium superwhite glass comprises the following components in percent by mass: 65-75% of SiO2, 1-4% of Al2O3, 11-17% of Na2O, 7-13% of CaO, 0-1.5% of MgO and 0-2% of K2O. Compared with the prior art, the low-magnesium superwhite glass has the advantages and effects as follows: due to adjustment of the MgO content to 0.2-0.5%, reduction in the weatherability of the glass due to use of high-content MgO for controlling the crystallization speed of the glass is avoided; due to increase of Al2O3 content, the crystallization trend is reduced, and the chemical stability of the superwhite glass is improved; due to adjustment and control of the alkali metal content, the expansion coefficient of the glass is increased and the glass is easily tempered; due to decrease of the liquid phase temperature, the adaptability to floating production of the glass is higher.

Owner:CHINA LUOYANG FLOAT GLASS GROUP

System and method for synergistic removal of sulfur trioxide, ammonia and fly ash in SCR flue gas

ActiveCN109821409BGood temperingImprove removal efficiencyCombustion processDispersed particle separationAir preheaterDust control

The invention discloses a system and method for simultaneously removing sulfur trioxide, ammonia gas, and fly ash in flue gas after SCR. A rotary air preheater and an auxiliary flue gas conditioning system are taken as the basis of the system. The system mainly comprises the rotary air preheater, a flue gas online monitoring system, the auxiliary flue gas conditioning system, an electrostatic deduster, a flue gas deep cooler, and a pre-posed air heater. The heat exchange area of the rotary air preheater is reduced, the temperature of the flue gas outlet of the rotary air preheater is raised tothe dew point temperature of ammonium bisulfate or so, ammonia gas and sulfur trioxide in flue gas are used to modify flue gas; at the same time, the auxiliary flue gas conditioning system can adjustand optimize the flue gas conditioning process in real time according to the flue gas information provided by the flue gas online monitoring system. The provided simultaneous removal method can improve the dedusting efficiency of an electric deduster, is capable of removing sulfur trioxide and SCR escaped ammonia gas in flue gas, and solves the problem that a downstream heat-absorbing surface isobstructed and corroded by deposited ash.

Owner:XI AN JIAOTONG UNIV

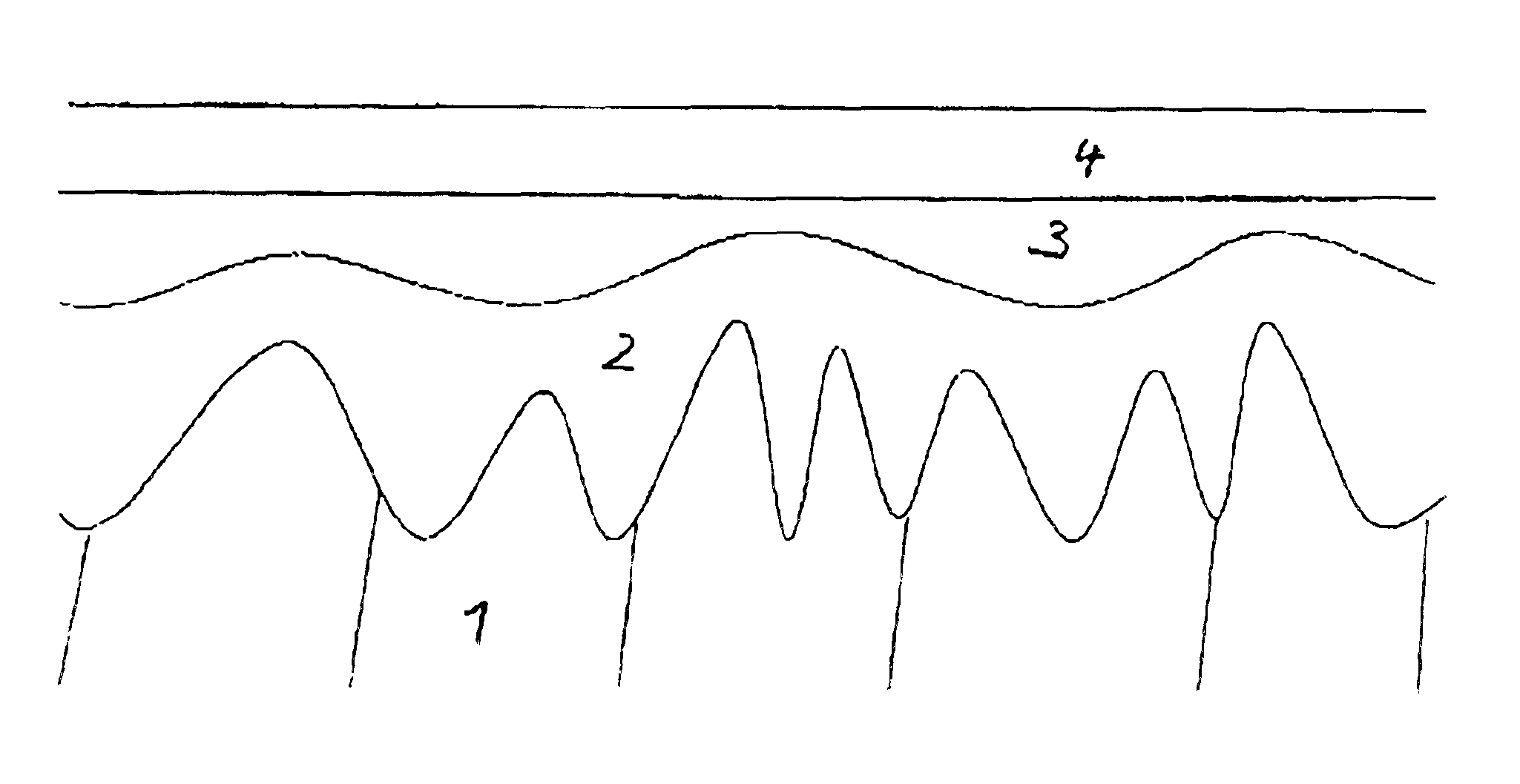

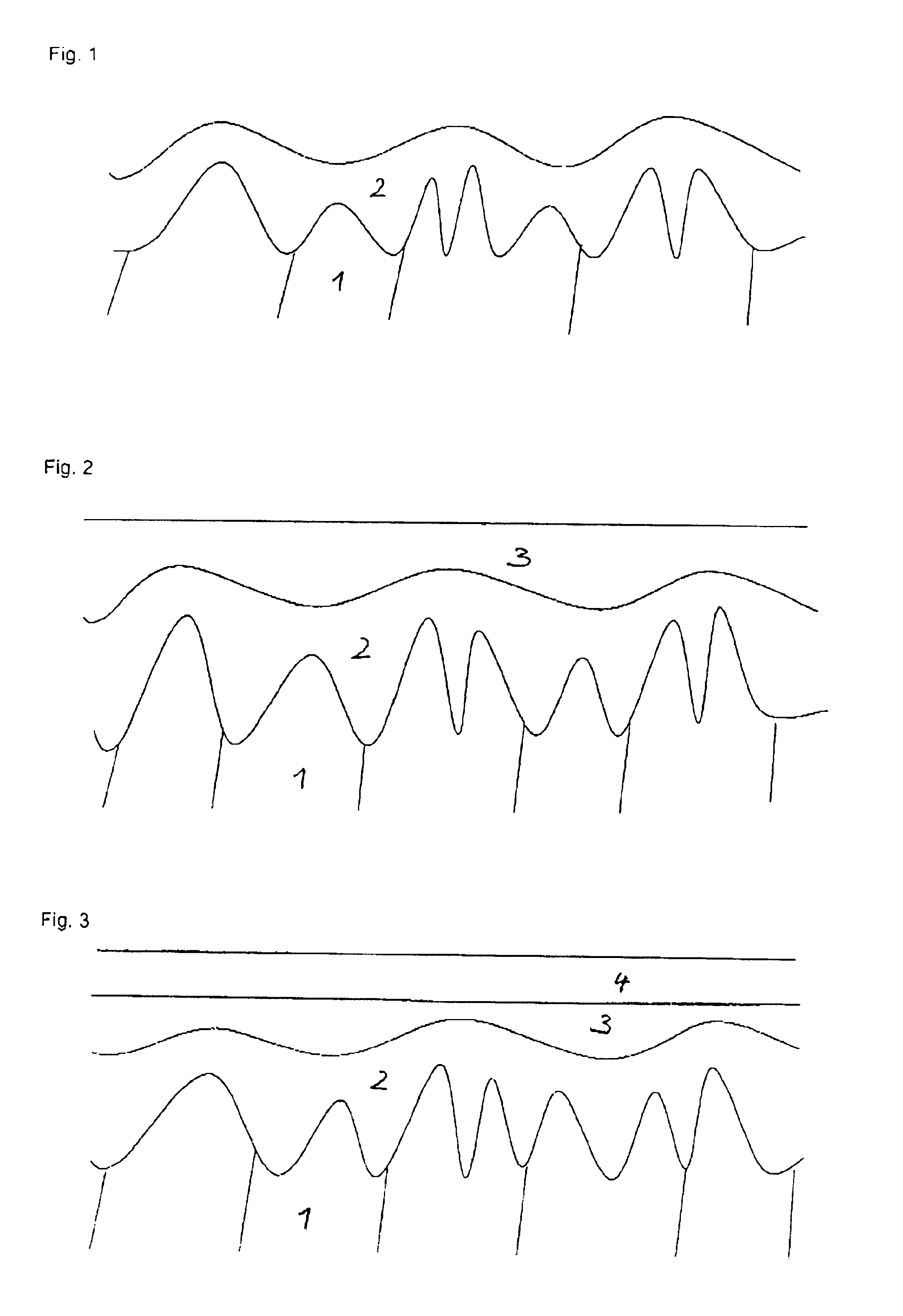

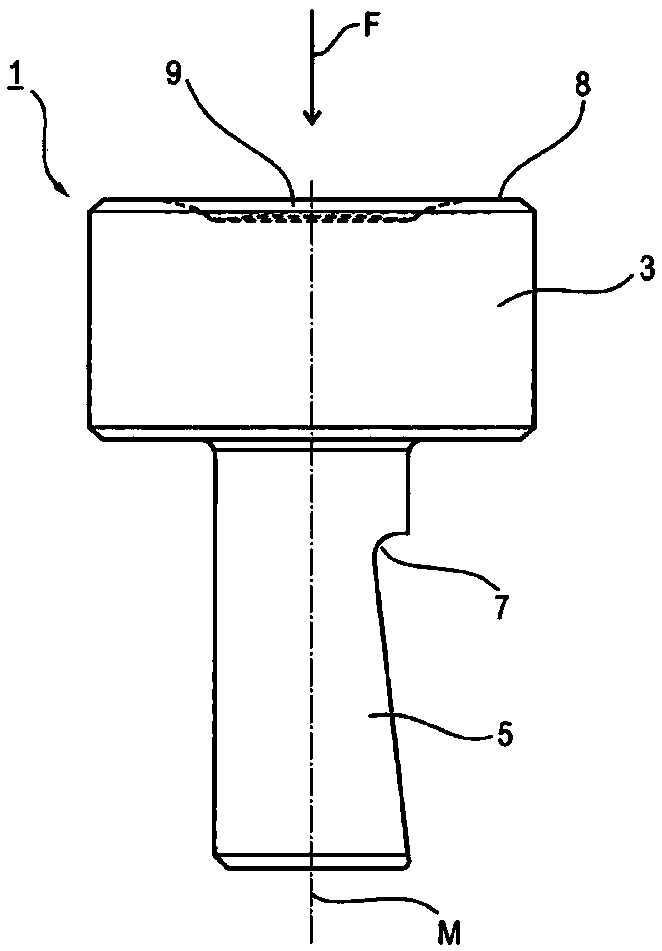

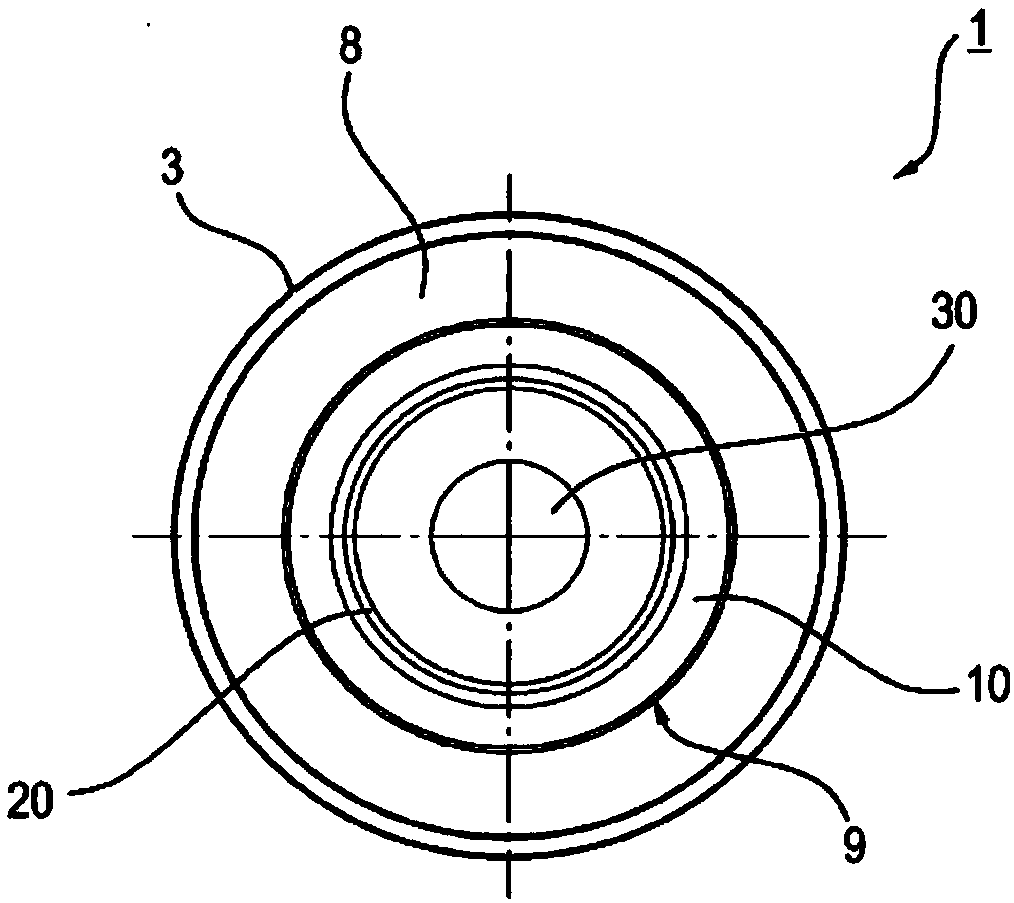

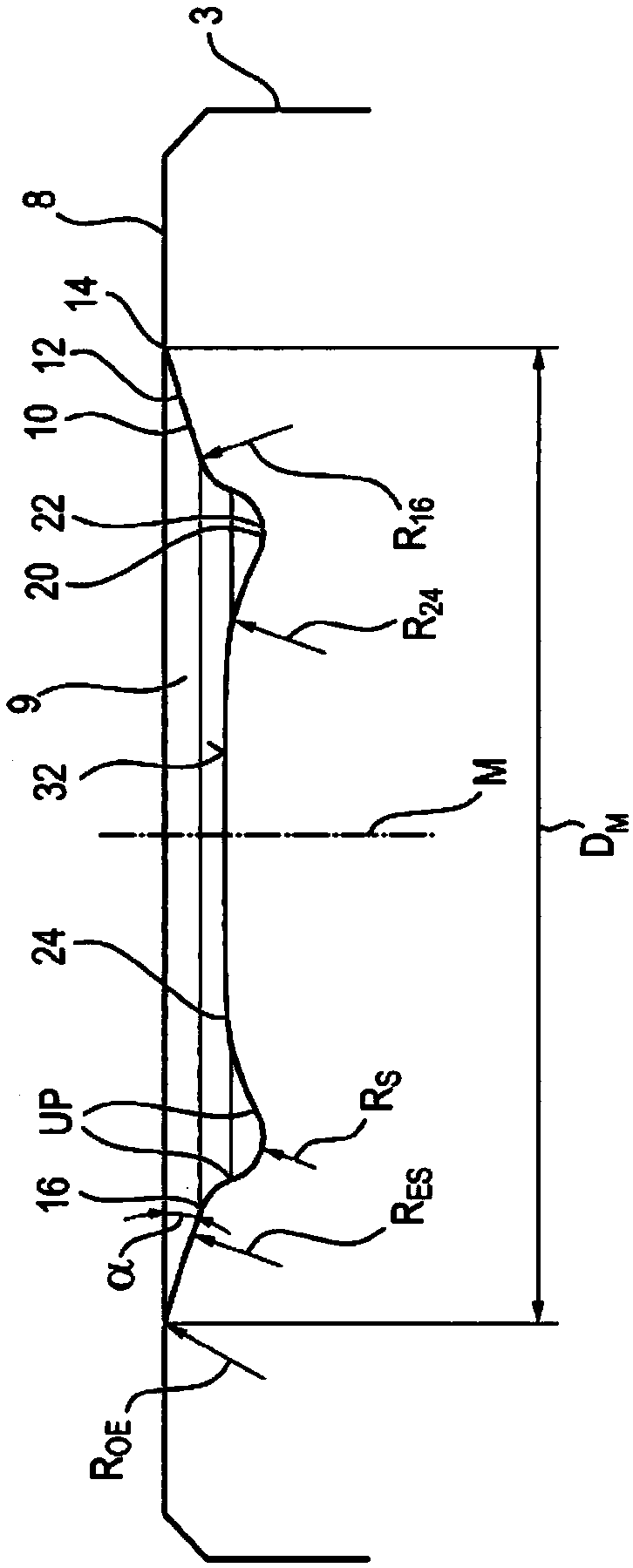

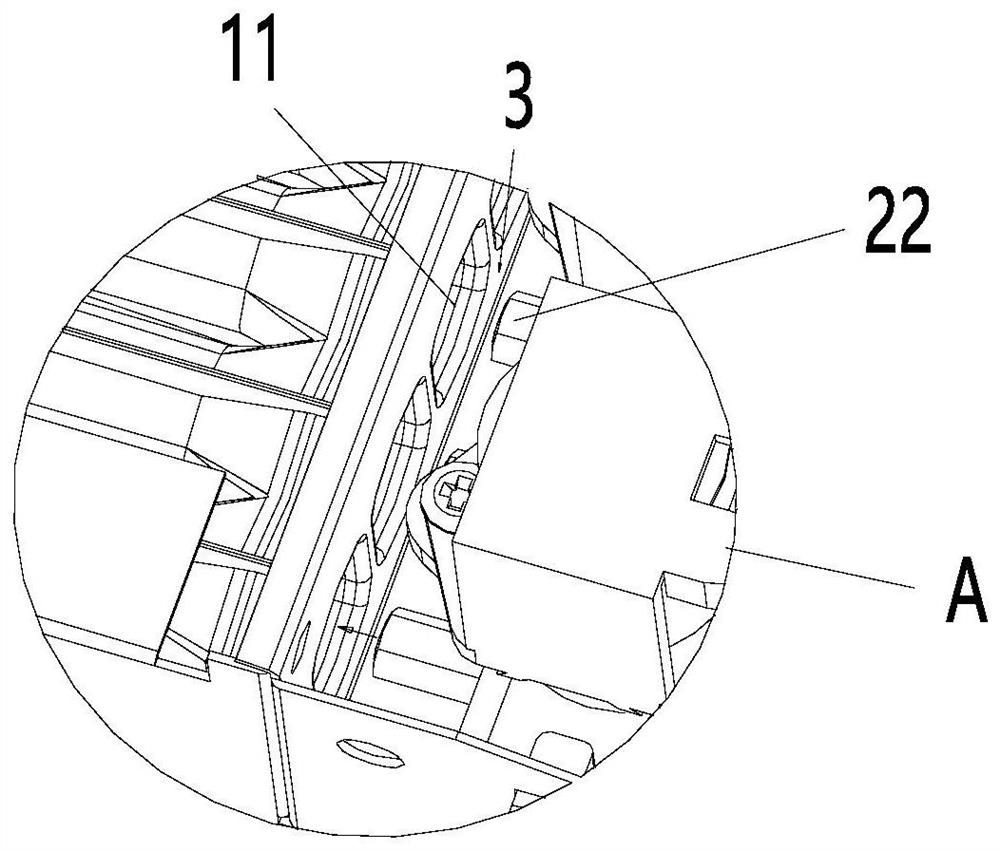

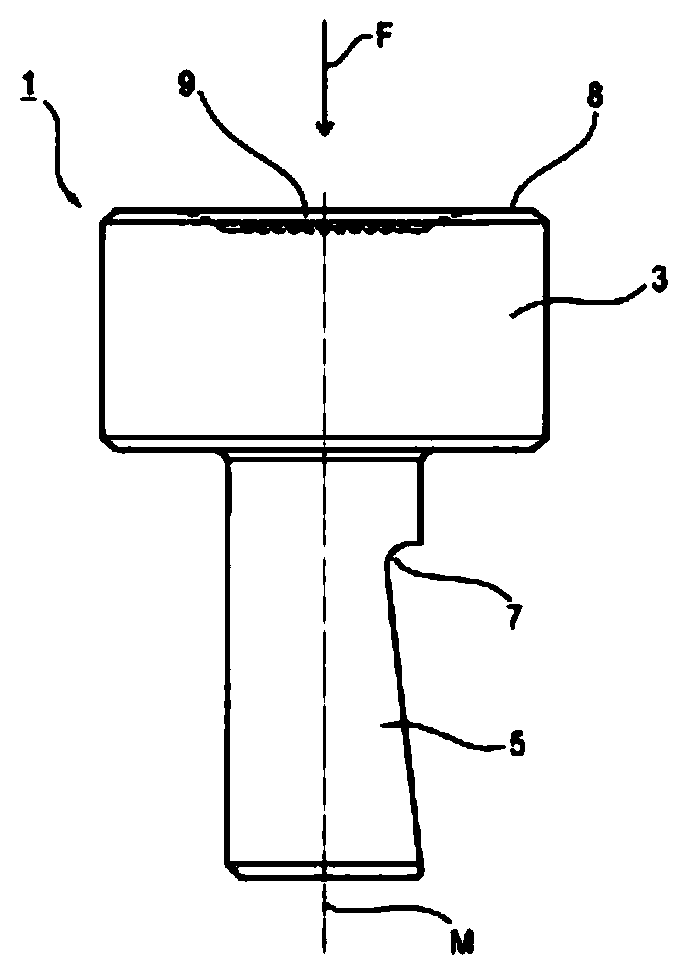

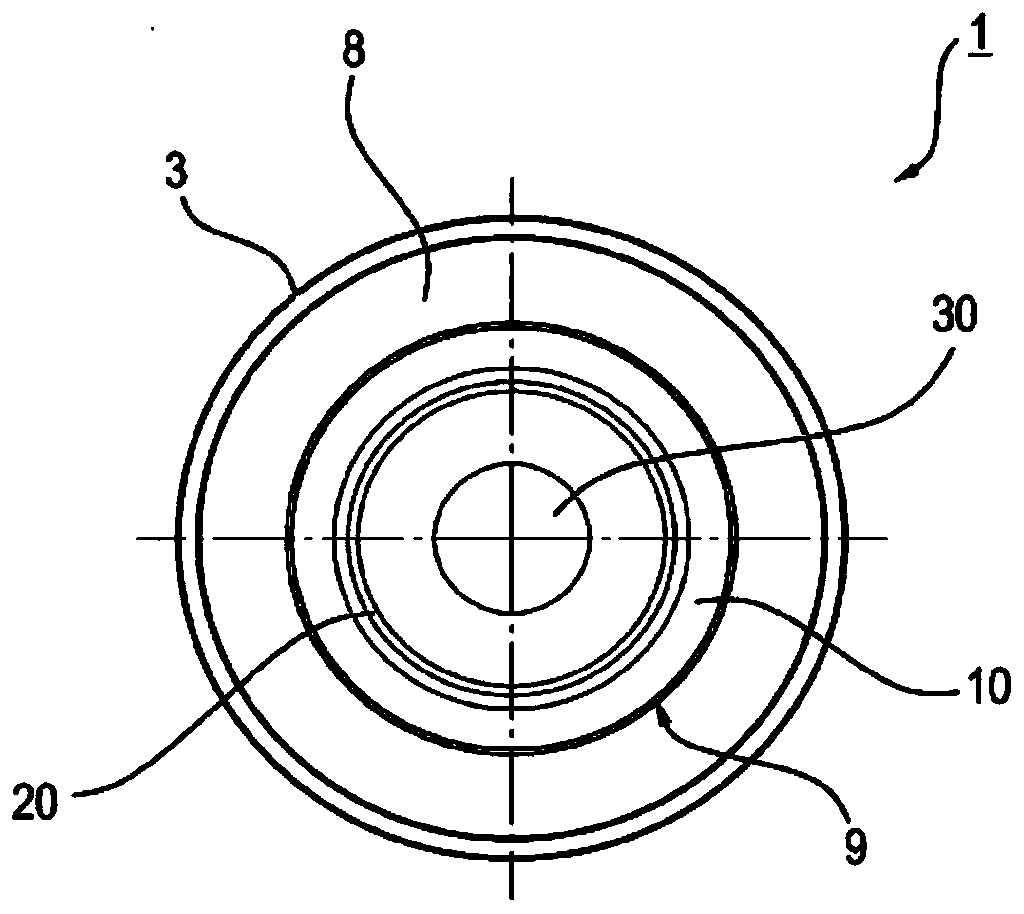

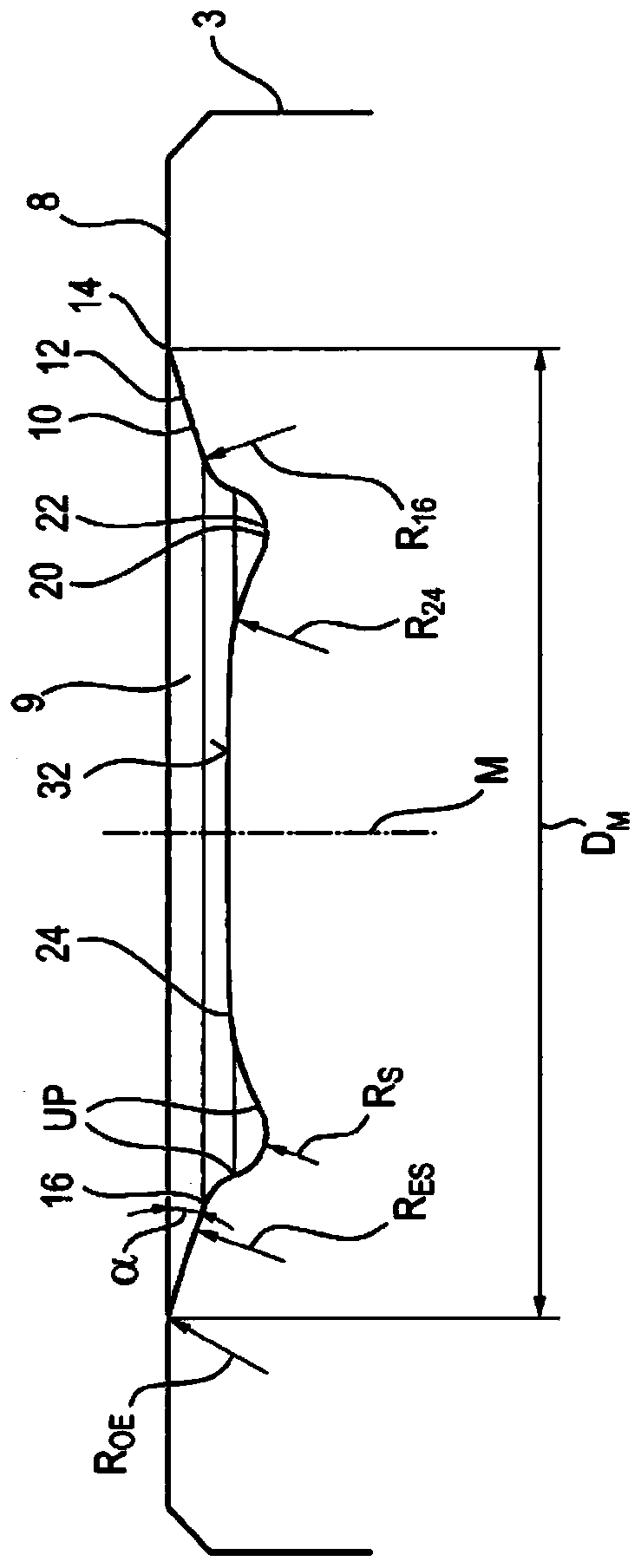

Self-piercing rivet die

The present invention describes a self-piercing rivet die for a rivet gun, by which die a self-piercing rivet connection can be produced in a plurality of components by formation of a closing head. This self-piercing rivet die (1) is characterised by a main body (3) with a top face (8) and a recess (9) which is formed thereon and is arranged rotationally symmetrically relative to a central axis Mof the self-piercing rivet die 1. In the cross-section of the self-piercing rivet die (1) the recess (9) has a draft angle (12) of the draft section (10) which merges radially via a step (16) into anarcuate depression (22) of the annular channel section (20), wherein radially inwards the arcuate depression (22) rises in a rectilinear or arcuate or curvilinear manner to the die base (30).

Owner:BOLLHOFF VERBINDUNGSTECHNIK GMBH

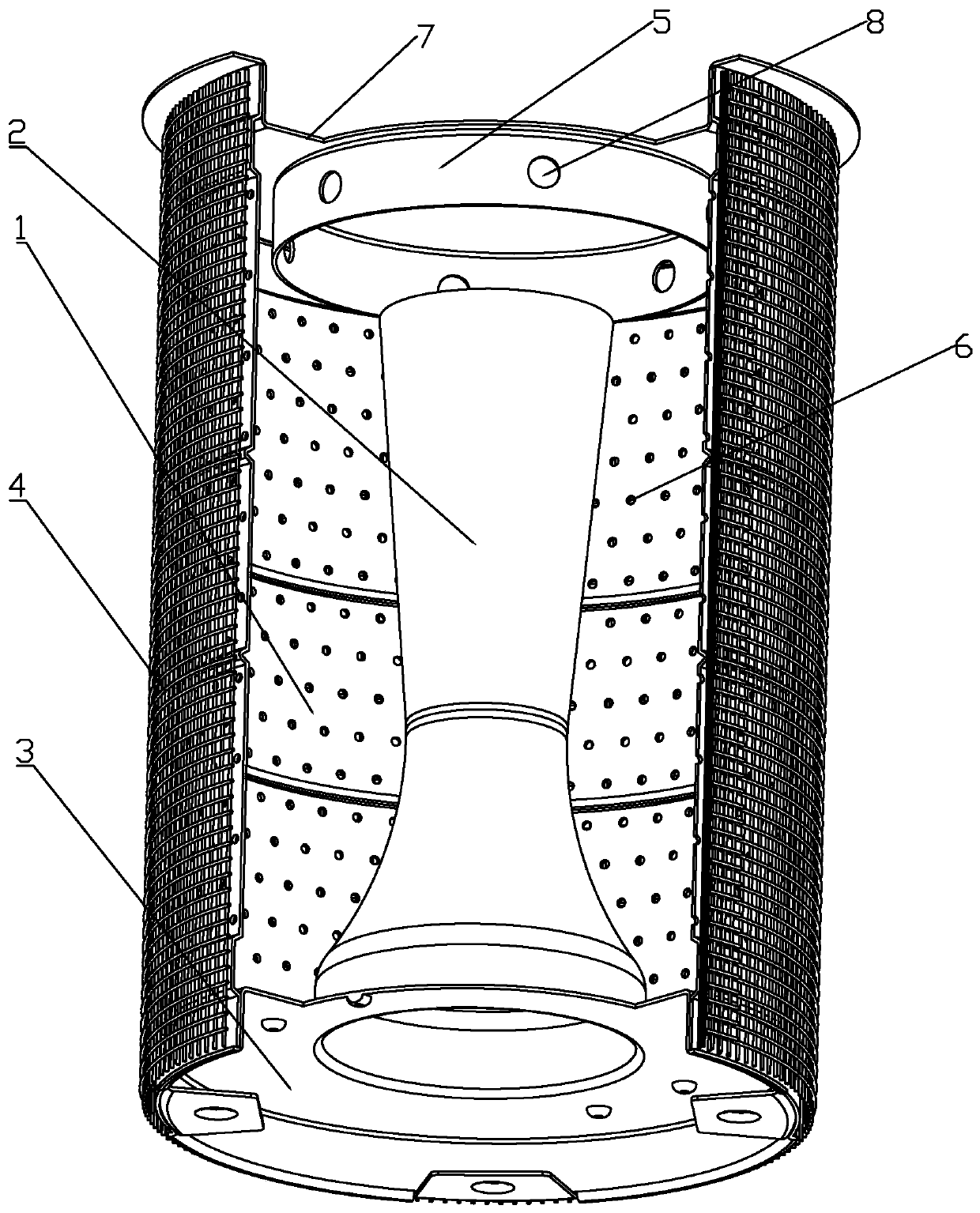

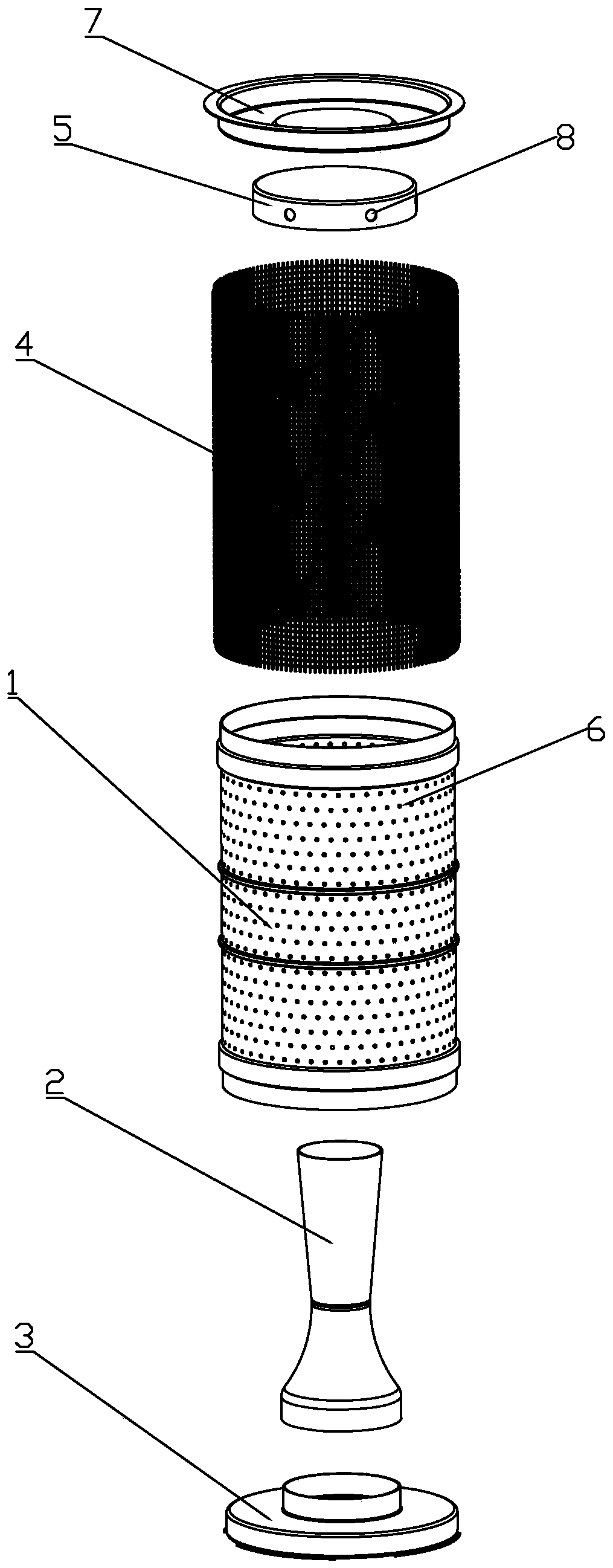

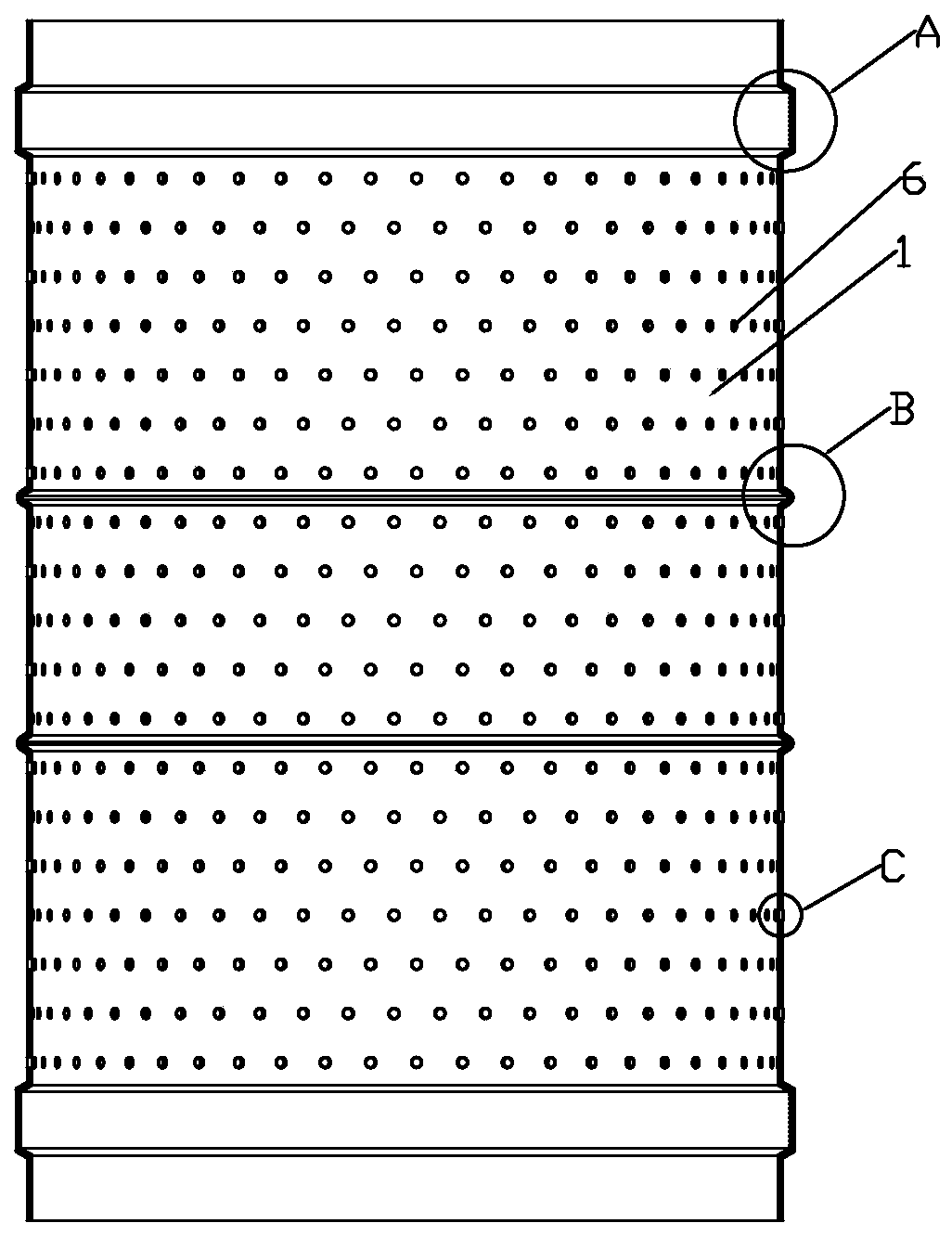

Combustor

The invention relates to a combustor. The combustor comprises a cylindrical combustion cylinder made of metal, an injection pipe is arranged in the combustion cylinder, a lower cover is arranged at alower end opening of the injection pipe, a combustion net is arranged on the outer surface of the circumference of the combustion cylinder, fire holes are evenly distributed in the surface of the combustion cylinder in the 360-degree direction, an air adjusting ring fixed to the inner wall of the combustion cylinder is arranged above the injection pipe, an upper cover is arranged above the air adjusting ring, the diameter of the fire hole is R, the wall thickness of the combustion cylinder is B, and the ratio of the diameter R of the fire hole to the wall thickness B of the combustion cylinderranges from 1.4 to 1.9. Through the arrangement, the combustion effect, the service life and the heat radiation efficiency of the combustor are all optimal.

Owner:中山市三诺燃气具有限公司

Electric actuator of central air-conditioning centrifuge set

InactiveCN102797894ANo oil leakageSimple internal structureOperating means/releasing devices for valvesPortable liftingElectric machineCopper

The invention discloses an electric actuator of a central air-conditioning centrifuge set, comprising a housing frame in which a motor and a potentiometer are arranged, wherein the motor is connected to a gear box; a gear and a bearing are arranged in the gear box; the potentiometer comprises an angle sensor; and the motor is a reversible speed reducing motor. After optimization, the lubrication way of the gear box is a grease sedimentation lubrication way; the bearing is a copper-based solid inlaid self-lubricating bearing; the gear is prepared from a 40Cr material; a limiting switch is a photoelectric switch; and the angle sensor of the potentiometer is prepared from conducting plastics. The electric actuator of the central air-conditioning centrifuge set has the following advantages that no oil leakage occurs, the internal structure is simple and the size is small, the gear and the bearing are not easy to damage; and the potentiometer is long in service life and accurate to control.

Owner:NINGBO JIECHENG ELECTROMECHANICAL EQUIP ENG

Combustor and water heater with same

PendingCN113654044APrimary air ratio is reasonableBurn fullyFluid heatersGaseous fuel burnerFuel gasHome appliance

The invention relates to the technical field of household appliances, and discloses a combustor and a water heater with same. The combustor comprises a combustor body and an air distribution rod assembly, wherein an injection hole is formed in the combustor body; the air distribution rod assembly is connected with the combustor body, and comprises an air inlet pipe cavity and a nozzle which is arranged on the outer side of the air inlet pipe cavity and communicates with the interior of the air inlet pipe cavity; the air outlet section of the nozzle faces the injection hole, and the air outlet section and the injection hole are arranged at intervals; and an auxiliary air inlet hole communicating with an inner cavity of the nozzle is formed in the nozzle. The combustor has the advantages that the mixing ratio of air to fuel gas is reasonable, combustion is sufficient, and generated carbon monoxide is less.

Owner:GREE ELECTRIC APPLIANCES INC

Production method for corncob glycosyl medicinal carrier and production system

ActiveCN109675046AEfficient removalImprove liquidityFood processingPharmaceutical non-active ingredientsEngineeringCrusher

The invention belongs to the field of medicines and particularly relates to a production method for a corncob glycosyl medicinal carrier and a production system. The production method for the corncobglycosyl medicinal carrier, provided by the invention, comprises the following steps: (1) carrying out rolling crushing; (2) carrying out coarse crushing; (3) carrying out vibratory screening; (4) carrying out micro-powdering; (5) carrying out quenching and tempering; (6) carrying out granulating. Xylon can be separated from corncob integers so as to prepare the high-quality glycosyl carrier whichis good in fluidity, high in adsorption force, proper in pH value and good in palatability and can be completely degraded. The production system provided by the invention comprises double-row rollers, a coarse crusher, a vibratory screen and a fine crusher which are sequentially connected; the production system can be used for separating the xylon from the corncob integers and has the characteristic of high production efficiency.

Owner:青岛海科生物技术有限公司

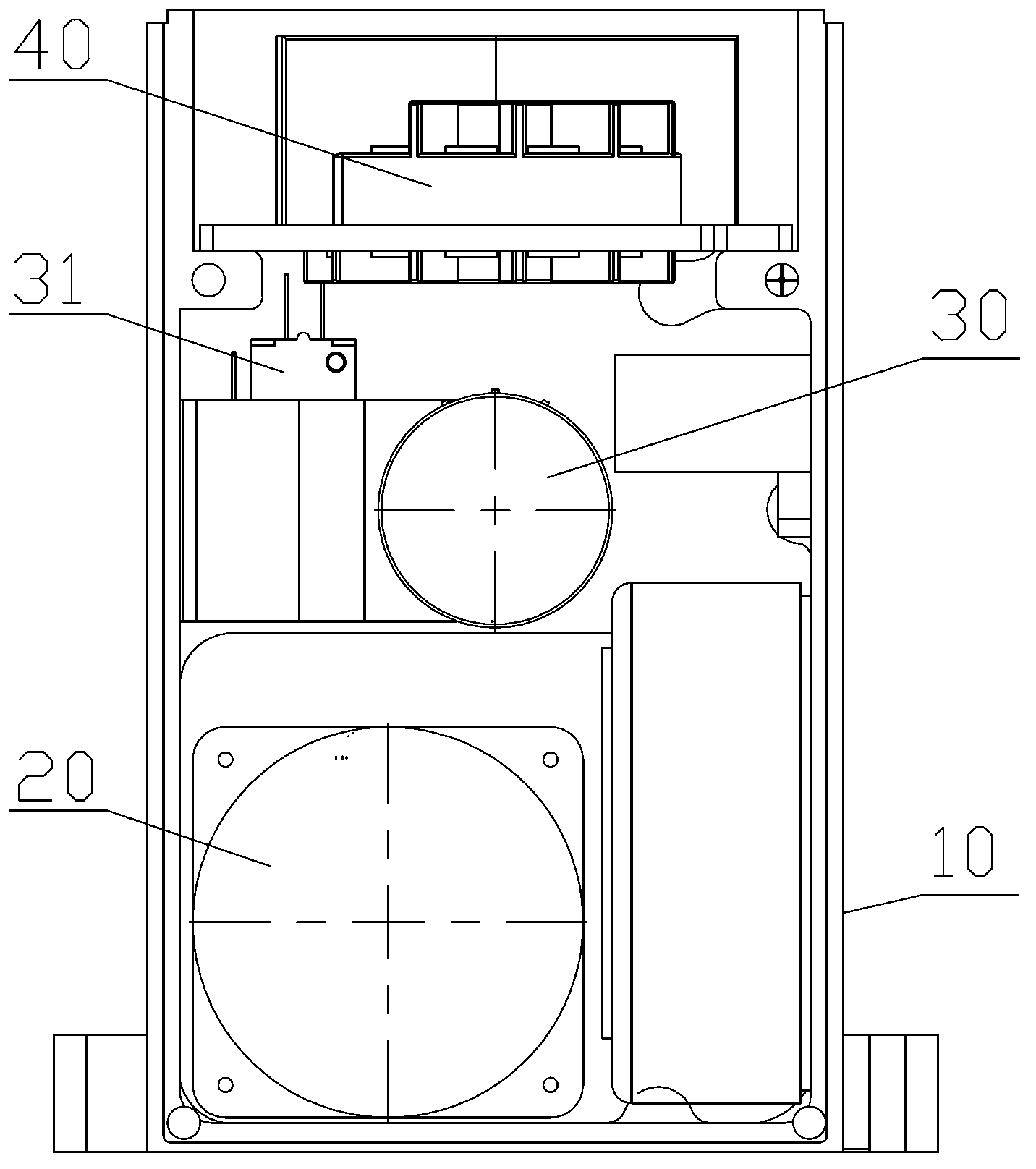

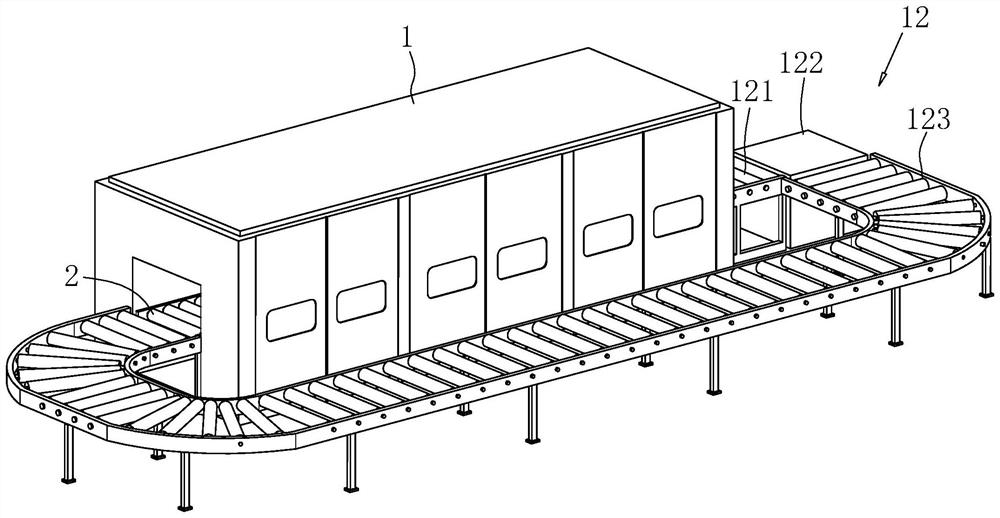

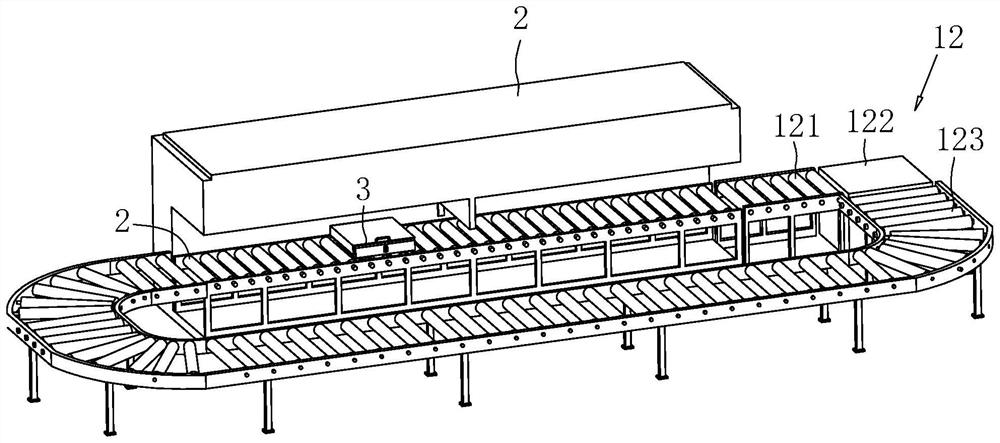

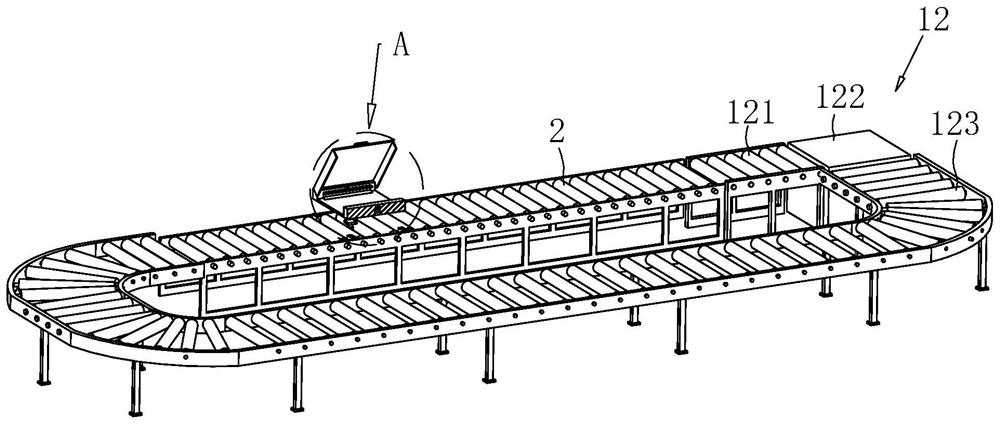

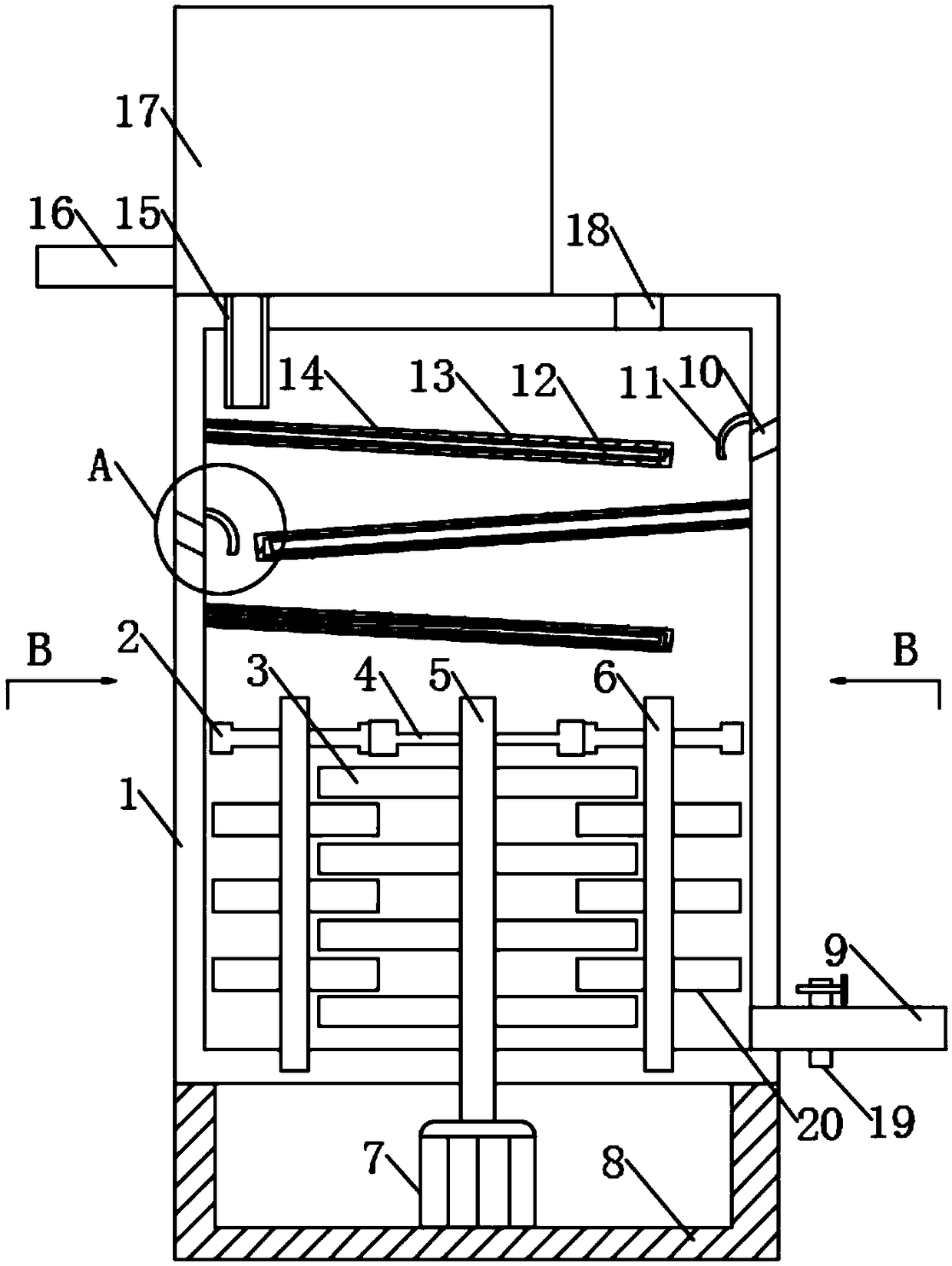

Tempered glass production line

PendingCN114149172AEvenly heatedGood temperingGlass transportation apparatusGlass tempering apparatusProduction lineTempering

The invention relates to a tempered glass production line, and belongs to the technical field of tempered glass production, the tempered glass production line comprises a tempering furnace, a conveying roller used for conveying glass is arranged in the tempering furnace, the tempered glass production line further comprises a storage box used for storing the glass, and the storage box is located on the conveying roller; a feeding port and a discharging port are formed in the face, in the conveying direction of the conveying rollers, of the storage box, a lifting device is arranged in the storage box, and the lifting device is used for driving glass in the storage box to be in a suspended state. A suspension part is arranged in the toughening furnace and is used for driving the storage box entering the toughening furnace to be in a suspended state. The glass softening agent has the advantage of improving the glass softening effect.

Owner:四川雄港玻璃有限公司

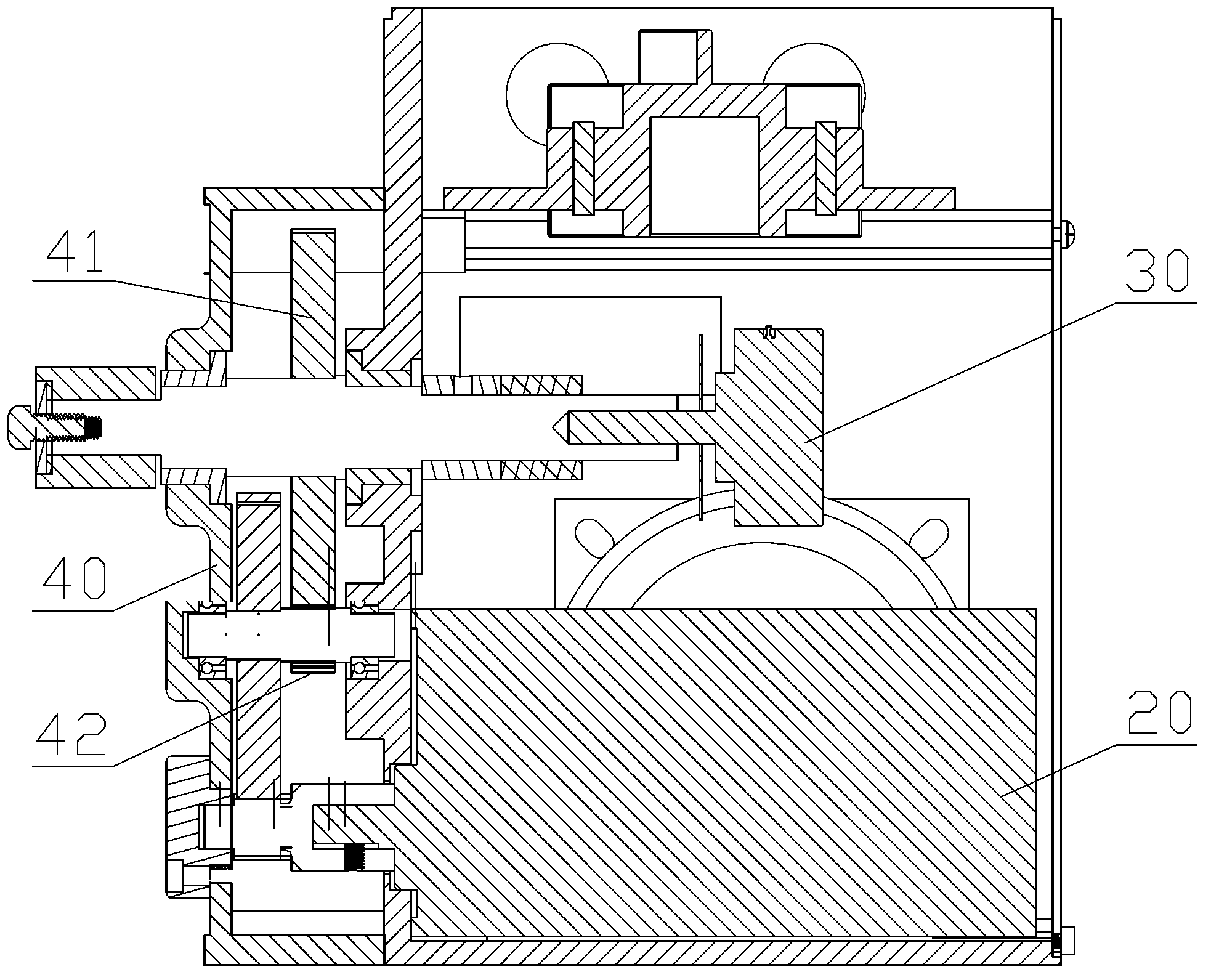

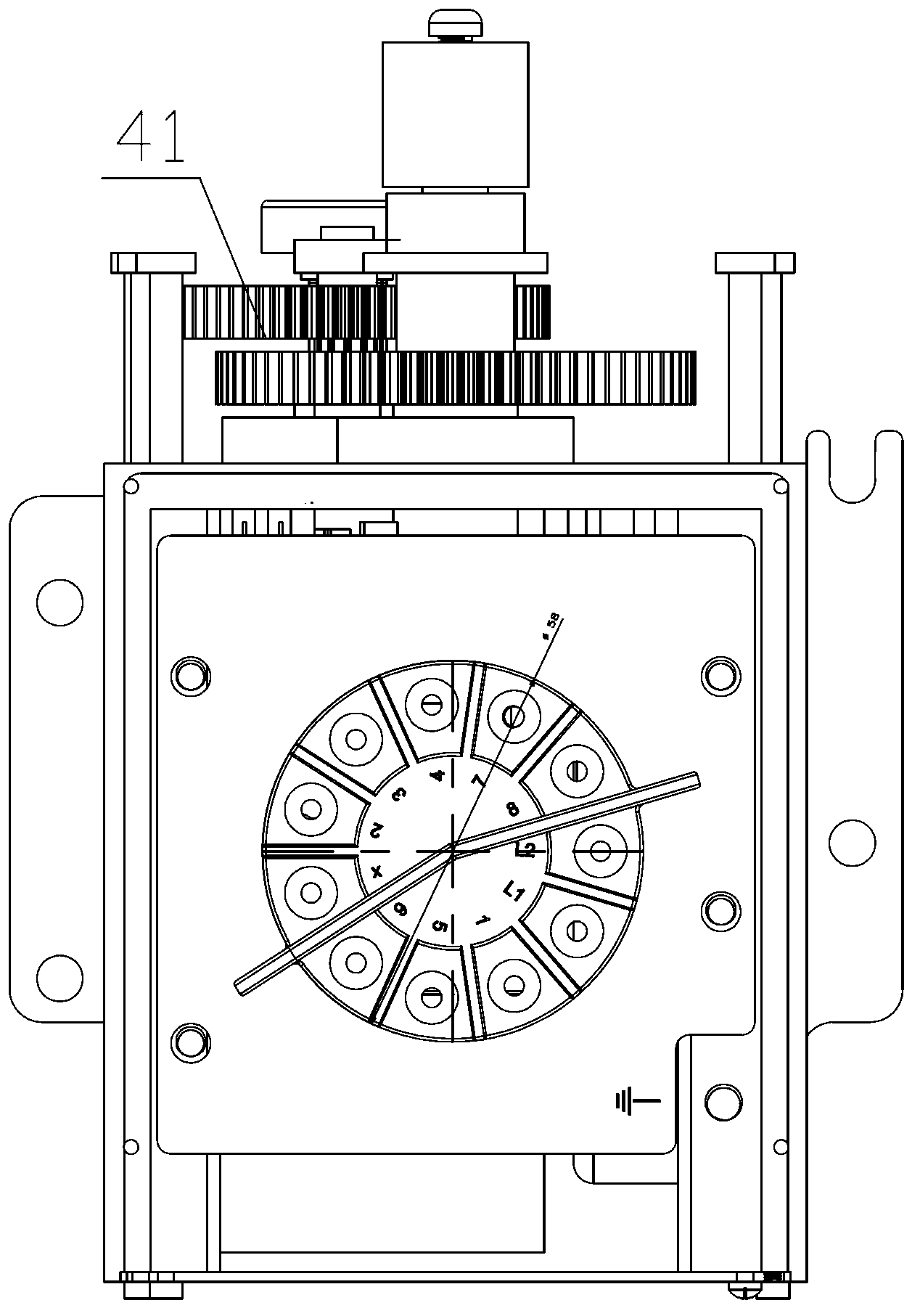

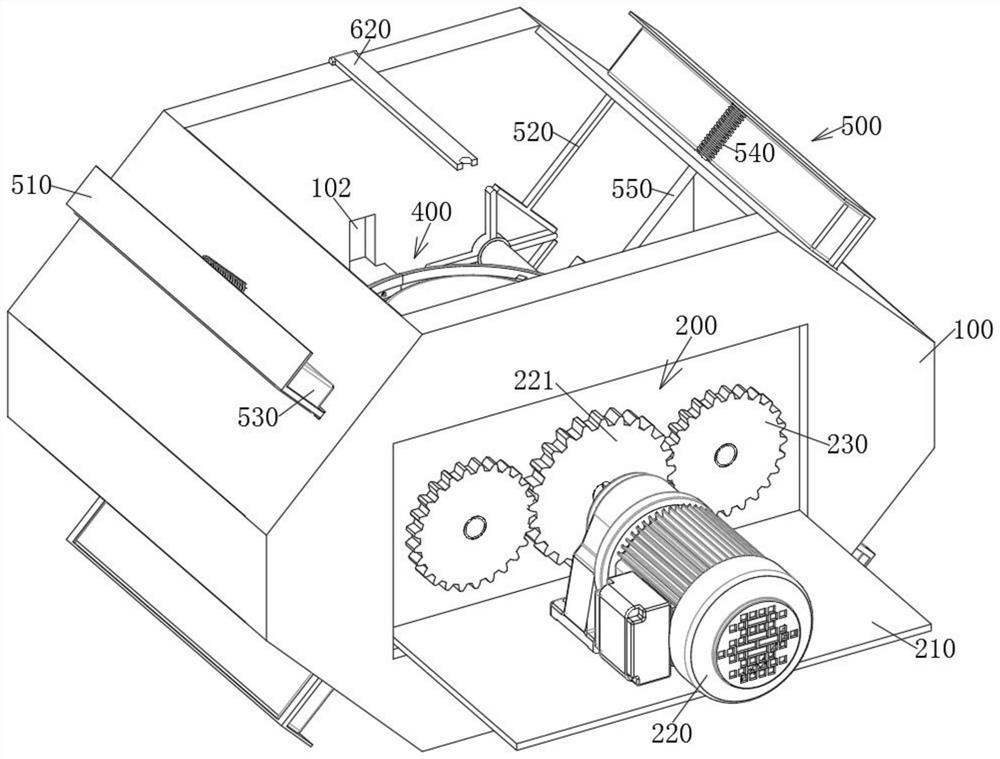

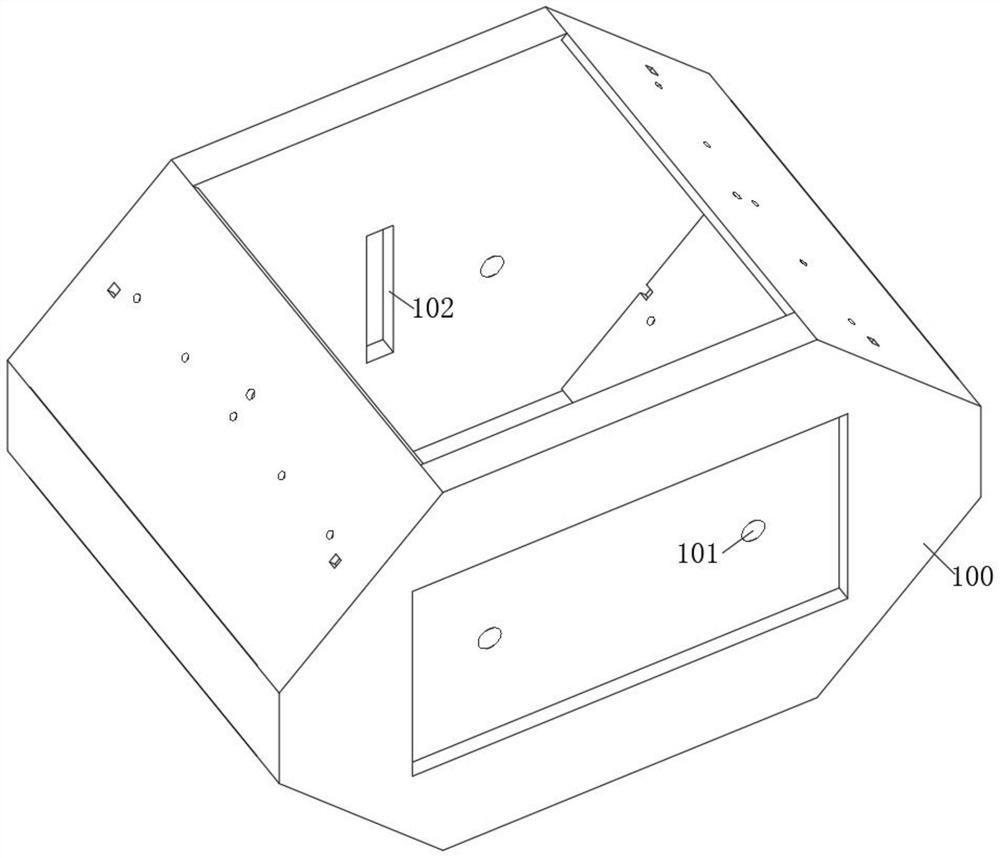

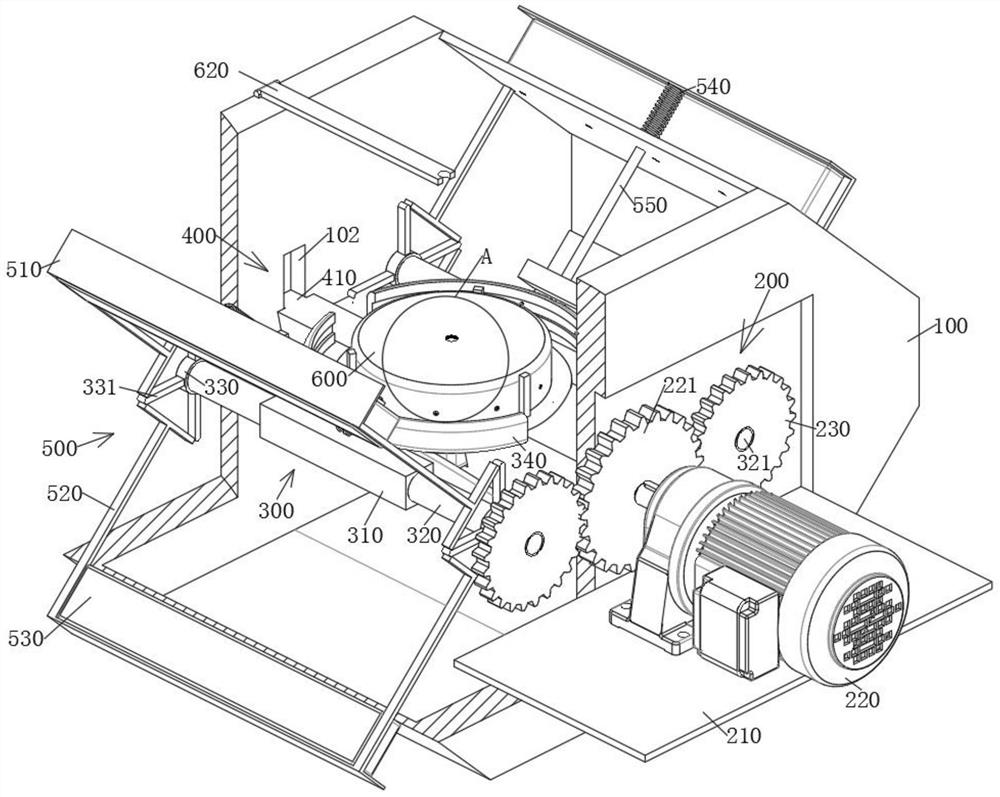

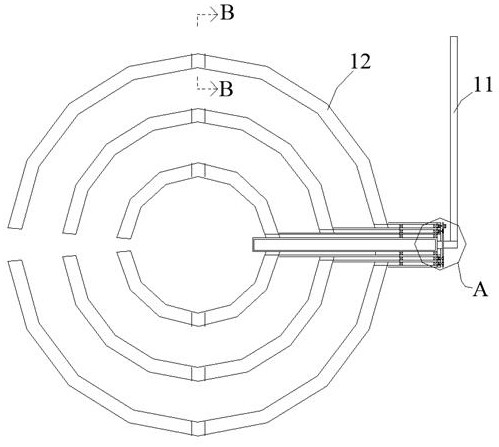

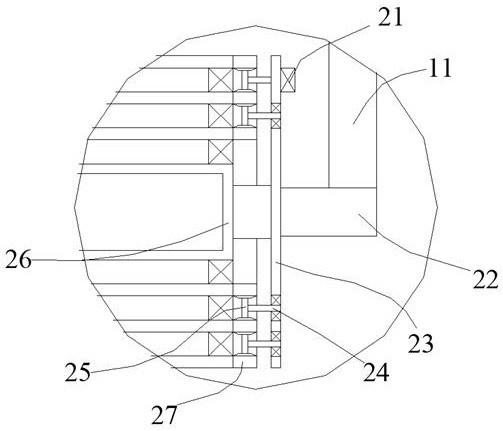

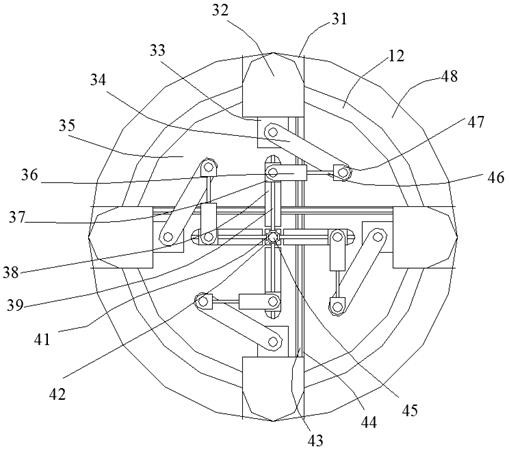

Bearing raceway surface quenching device and method

PendingCN114672629AGood temperingImprove quenching effectFurnace typesHeat treatment furnacesGear driveGear wheel

The invention relates to the technical field of bearing production, in particular to a bearing raceway surface quenching device and method.The bearing raceway surface quenching device comprises a shell, two exchange mechanisms used for cooling and heating a bearing raceway are symmetrically arranged in the shell, and a lifting mechanism used for containing a bearing is arranged between the two exchange mechanisms; and auxiliary mechanisms are arranged at four corners of the shell. According to the bearing replacing device, a bearing is placed on a tray, then a driving motor is started, the driving motor drives a main gear to rotate, the main gear drives two auxiliary gears on the two sides to synchronously rotate in the opposite direction, and the two auxiliary gears drive two replacing mechanisms to rotate in the opposite direction; the lifting mechanism and the four auxiliary mechanisms are started through abutting of the supporting arms while the two exchange mechanisms rotate, the bearing raceway is integrally heated and cooled, and overall tempering can be achieved, so that the bearing quenching effect is improved, bearing tempering is facilitated, and the bearing production efficiency is improved.

Owner:DALIAN OCEAN UNIV

Self-piercing rivet mold

Owner:BOLLHOFF VERBINDUNGSTECHNIK GMBH

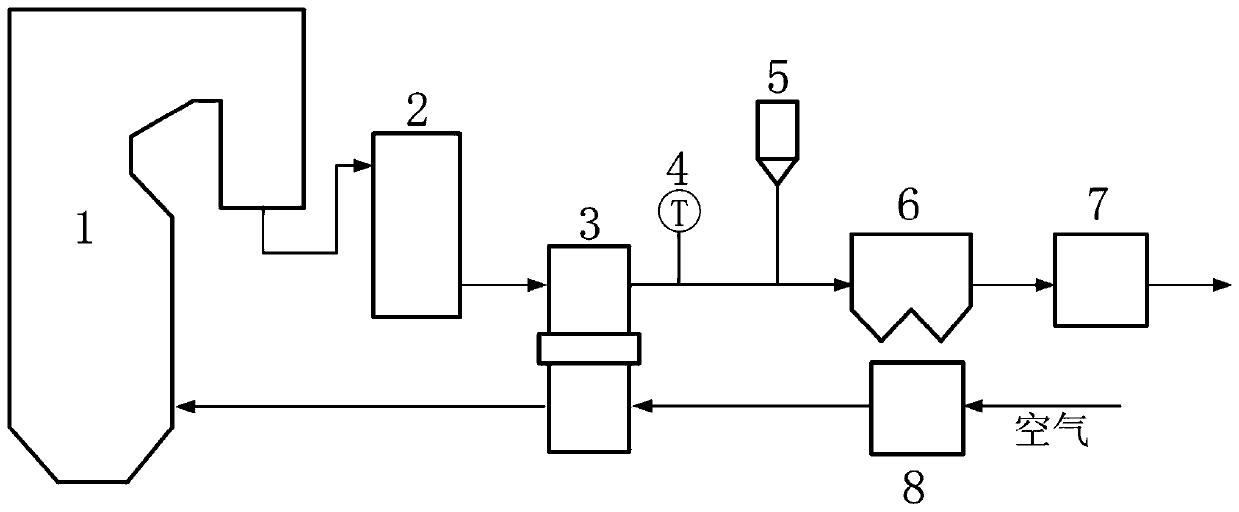

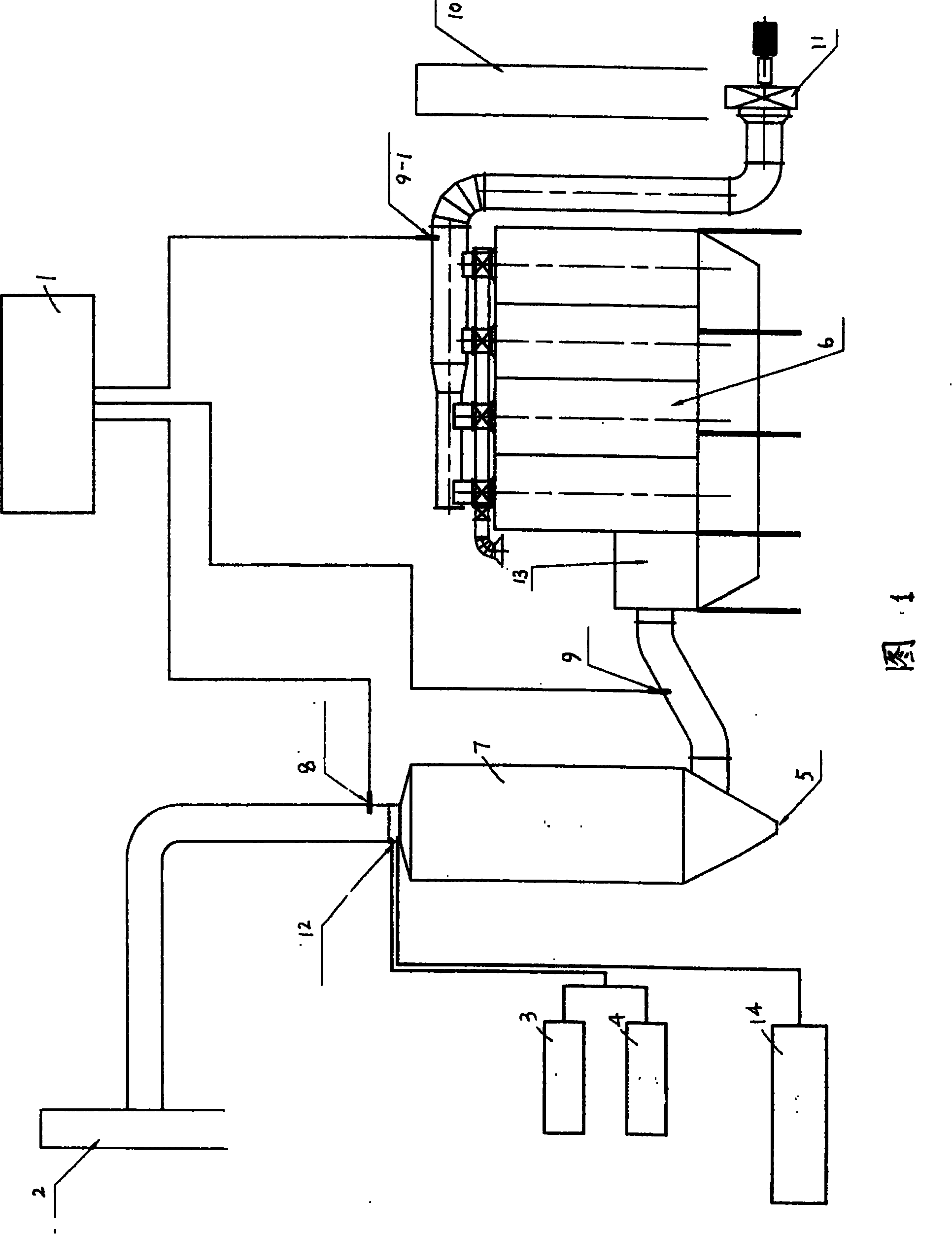

Low pressure double flow spray method and system for high temperature fume quenching and tempering and dust processing

InactiveCN100384509CShorten evaporation timeReduce areaCombination devicesUsing liquid separation agentFrostSpray nozzle

The invention relates to a method for treating the low-pressure dual-flow spray high-temperature smoke modified dust. The method comprises: spraying to treat the high-temperature smoke inside the spray tower; the smoke is feed into the spray tower from the chimney; the spray tower uses low-pressure dual-flow spray to treat the high-temperature smoke; inside the spray tower, the high-temperature dust gas contacts the water frost sprayed by injector to be mixed and eliminate the sparkle in the high-temperature; the large grains of gas are directly discharged at the lower part of spray tower via the dedust function of water frost; the cooled gas via the channels enters into following dedusting process. The invention utilizes low-pressure dual-flow spray, to uniform the frost grain injected by the injector via the compressed air and water; reduces the time of vaporizing the smoke and the area of spray tower. And it has less area, reduced resistance and lower energy consumption.

Owner:张锡麟

Method for producing low-iron high-pervious self-cleaning ultra-white rolling glass

The invention discloses a method for producing low-iron high-pervious self-cleaning ultra-white rolling glass. Prepared materials comprise components in parts by mass as follows: 68% to 75% of SiO2, 9% to 15% of Na2O, 8% to 12% of CaO, 1% to 3% of Al2O3 and 2% to 5% of MgO, a compound strong oxidant accounting for 0.1% to 1.0% of the prepared materials is added, iron contents of the materials are controlled to be within 50ppm, and the rolling glass is formed through mixing, melting, rolling, annealing, cut loading, coating, tempering and coating curing. According to the method, the iron contents of the materials and the mass ratio of the materials are controlled, the strong oxidant is added, glass sheets are manufactured by a natural gas total oxygen combustion technology, and photoelectric properties and physical properties of the rolling glass can be improved remarkably after two times of coating, tempering and curing, so that the sunlight transmittance is improved by 2.5% to reach more than 94.5%, the photoelectric conversion efficiency of the rolling glass can be improved, a self-cleaning function is provided, and industrial application of solar ultra-white rolling glass is facilitated.

Owner:江西省速睿科技有限责任公司

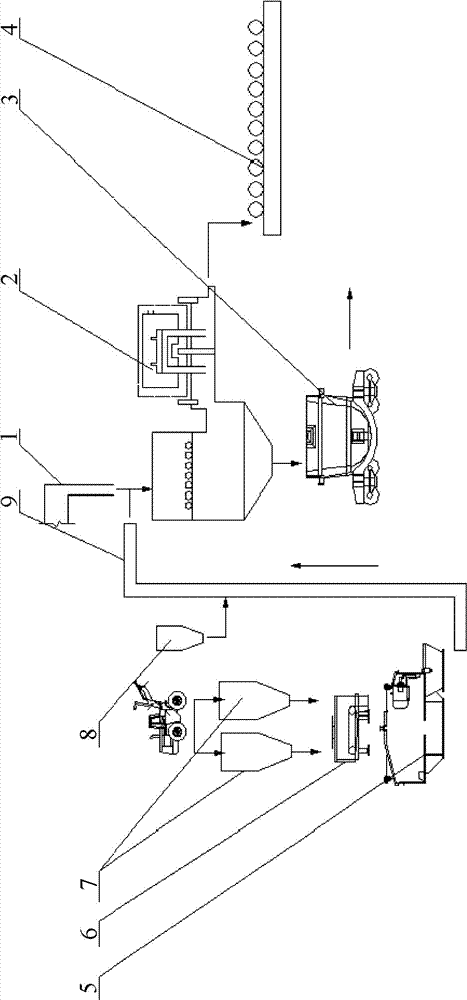

Refining device for silicon-manganese alloy tailings and method of using the same

ActiveCN103866133BReduce production capacityShorten the extraction processProcess efficiency improvementSlagResource utilization

The invention relates to the field of treatment of slag produced in production or refining of metals, specifically to a refining apparatus for silicon manganese alloy tailings and an application method thereof. The refining apparatus for silicon manganese alloy tailings comprises a silicon manganese alloy slag outlet (1), a melting furnace (2), a metal casting machine (3) and a microcrystalline glass molding machine (4), wherein the discharge outlet of the silicon manganese alloy slag outlet (1) is arranged just above the feed inlet of the melting furnace (2). The refining apparatus is characterized by further comprising a mixer (5), a fixed-weight feeder (6), an accessory material bin (7), a reducing agent warehouse (8) and an elevator (9). The application method for the refining apparatus is characterized in that an accessory material, a reducing agent and slag are heated to at least 1600 DEG C in the melting furnace (2) and calcined, and molten ferromanganese and slag are respectively discharged through the iron outlet and the slag outlet of the melting furnace (2). With the apparatus and the method in the invention, the utilization rate of energy and resources is high, and good environmental protection performance is realized.

Owner:SHANGHAI BAOSTEEL ENERGY TECH

A sludge reaction tank having a high efficiency

InactiveCN108996874AImprove drying effectSpread evenlySludge treatment by de-watering/drying/thickeningTransportation and packagingSludgePulp and paper industry

A sludge reaction tank having a high efficiency is disclosed. The reaction tank includes a sludge reaction tank main body, main stirring plates, slide plates and a dehydration case. The lower end of the tank main body is connected to a motor through a motor fixing seat. A main rotation shaft at the upper end of the motor movably penetrates the middle of the lower surface of the tank main body. Sludge in the dehydration case enters the slide plates after dehydration and is heated and dried, and the sludge uniformly slides downward on the surfaces of the slide plates and falls down after passingthrough three groups of the slide plates so that sludge drying effects are good, and the sludge is evenly spread during drying and is uniformly dried. The sludge is fully mixed through rotation of the main stirring plates and auxiliary stirring plates. Driving blades above the main stirring plates drive driven blades to rotate so that the auxiliary stirring plates rotate, and the one motor is utilized for driving operation, thus saving the power. Six groups of the auxiliary stirring plates are disposed around the main stirring plates, and the stirring plates completely cover the lower end ofthe tank main body, thus improving the degree of sufficiency of sludge mixing and facilitating sludge quality adjusting.

Owner:JIANGSU XINGXIN SEPARATION EQUIP MFR

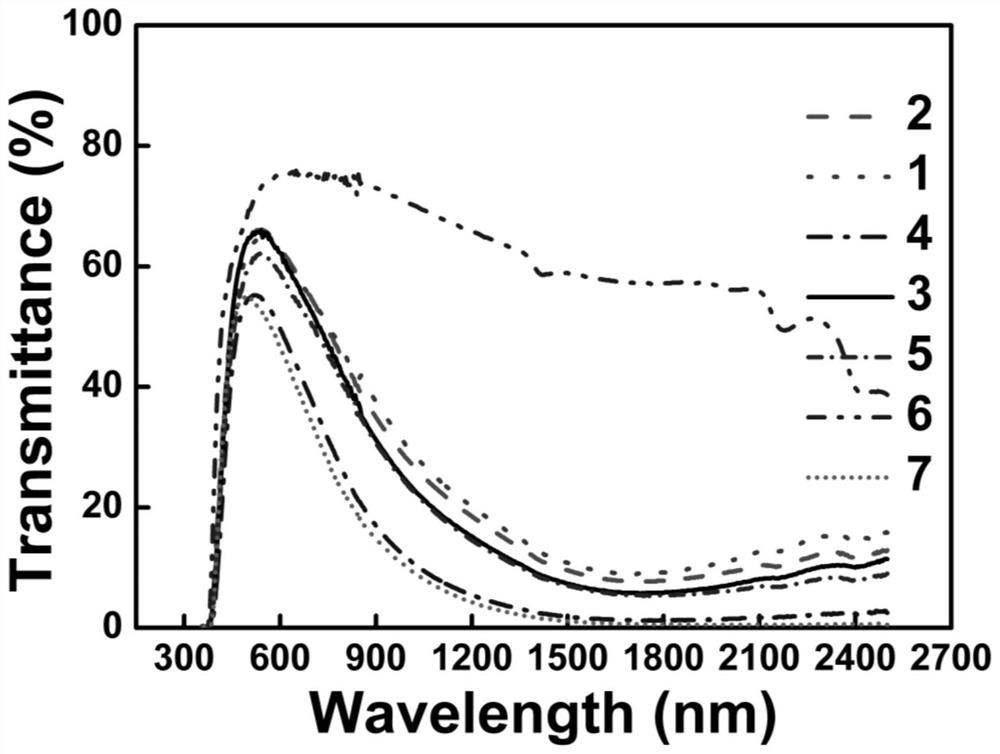

Preparation method of energy-saving glass

ActiveCN111268904BLow costStrong near-infrared shielding effectGlass shaping apparatusRenewable energy source integrationUltraviolet lightsNon oxidative

The invention discloses a preparation method of energy-saving glass, which uses tungsten bronze or low-valent tungsten oxide, tungstic acid, boric acid, silicon dioxide, alkali metal halide or alkali metal carbonate, antimony trioxide as raw materials; Each raw material is melted and processed in a non-oxidizing atmosphere furnace in a non-oxidizing atmosphere at a set temperature after mixing the raw materials. After the melting is completed, the molten glass obtained by melting is taken out, and then The glass liquid is quenched and formed, and then the glass sheet is put into an annealing furnace for annealing. After annealing, the required non-coated heat-insulating energy-saving glass with light transmittance and near-infrared shielding performance is obtained. The energy-saving glass prepared by the method of the invention can not only shield near-infrared and ultraviolet light to achieve energy-saving effect, but also has a simpler and more economical production process and a longer service life compared with products of the same type.

Owner:SHANGHAI UNIV

Gear heat treatment processing equipment

ActiveCN111893288BFull heat processingSimple structureFurnace typesHeat treatment furnacesGear wheelEngineering

The invention discloses gear heat treatment processing equipment, which comprises a vertical rod, a bottom rod is arranged on the lower side of the vertical rod, a side plate is arranged on one side of the bottom rod, and several outer cylinders are arranged on one side of the bottom rod. The outer cylinders are stacked on top of each other, ring blocks are arranged on one side of the outer cylinders at different positions, and a number of clamping devices are arranged in the ring blocks to facilitate clamping gears of various specifications from the inside. The ring blocks and A rotating device is installed between the outer cylinders so that the outer cylinders at different positions can be rotated relative to each other so that the gears are fully heat-processed. This equipment adopts the method of fixing the gears on the ring blocks respectively. The relative rotation of the block makes the gear fully heat-processed.

Owner:嘉兴特威金属科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com