Self-piercing rivet die

A technology of self-piercing riveting and mold, which is applied in the direction of rivets, screws, connecting components, etc., and can solve problems such as the weakening of self-piercing rivet connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

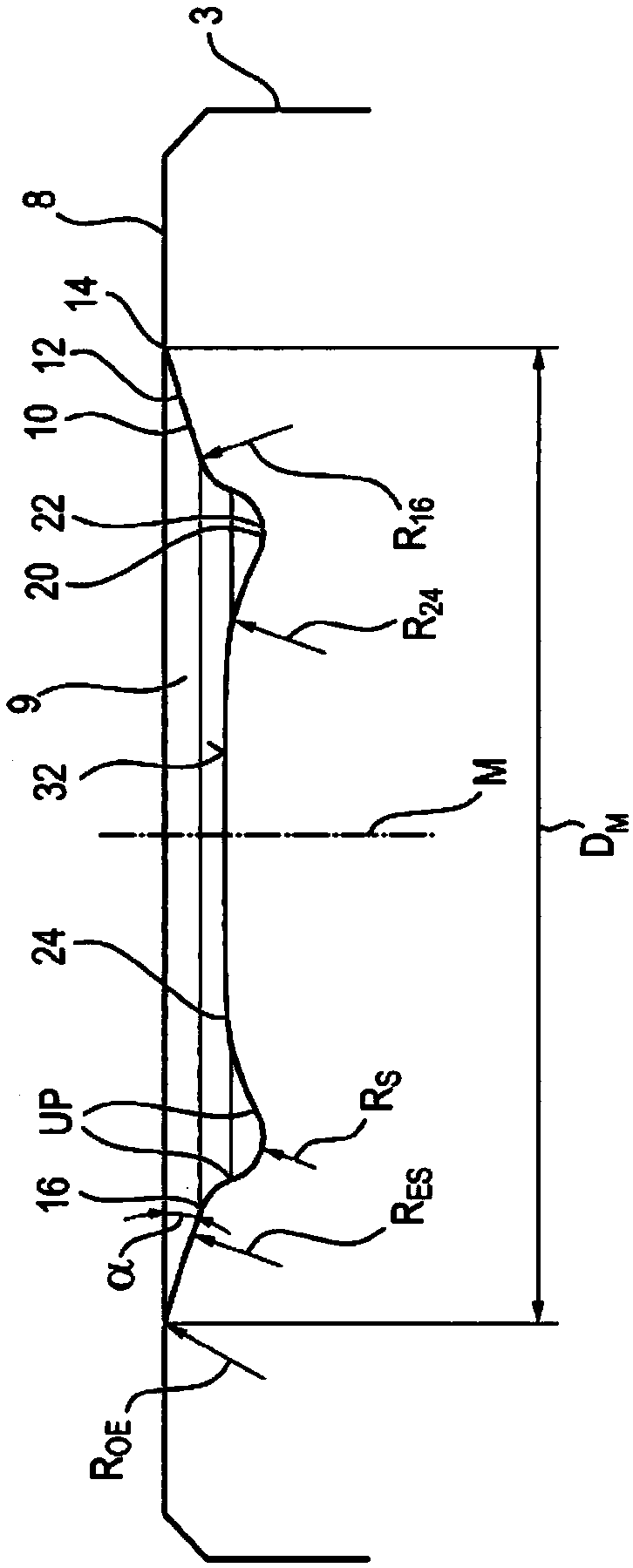

[0066] similar to image 3 The mold form of , with the following geometric data

[0067] D. M =12.2mm

[0068] D. 20 =8.395mm

[0069] ∝=18°

[0070] R OE =0.5mm

[0071] R ES =10.4mm

[0072] R S =0.2mm

[0073] R 24=11.17mm

[0074] R 16 =0.6mm

[0075] T RK =0.9mm

example 2

[0077] similar to image 3 The mold form of , with the following geometric data

[0078] D. M =12.2mm

[0079] D. 20 =7.3mm

[0080] ∝=18°

[0081] R OE =0.5mm

[0082] R ES =10.4mm

[0083] R S =0.8mm

[0084] R 24 =1.44mm

[0085] R 16 =0.6mm

[0086] T RK =1.3mm

example 3

[0088] similar to Figure 9 The mold form of , with the following geometric data

[0089] D. M =12.2mm

[0090] D. 20 =8.395mm

[0091] ∝=18°

[0092] R OE =0.5mm

[0093] R ES =10.4mm

[0094] R S =0.2mm

[0095] R 24 =11.17mm

[0096] R 16 =0.6mm

[0097] T RK =0.9mm

[0098] D. A =3.6mm

[0099] T A =0.9mm

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com