Anti-jamming pneumatic slide plate gate of pulverized coal pipeline and work method based on anti-jamming pneumatic slide plate gate

A technology for pulverized coal pipelines and sliding door, which is applied in the direction of valve operation/release devices, sliding valves, engine components, etc. It can solve the problem of increasing the frictional resistance between the sliding plate and the sealing gasket, making the control system instructions impossible to implement, and affecting the safety of the unit Economical operation and other issues, to achieve the effect of good sealing, tight shut-off, and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

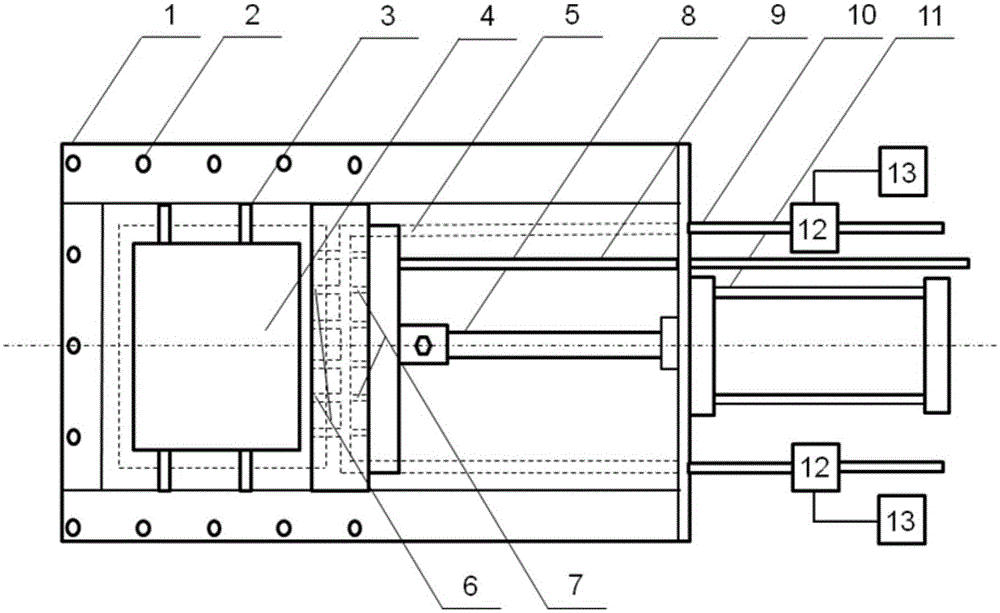

[0064] Such as Figure 1-4 As shown, a pulverized coal pipeline pneumatic sliding door that can prevent jamming includes:

[0065] Rectangular frame body 1, described rectangular frame body 1 is connected with pulverized coal pipeline by fastening bolt 2; In the middle of rectangular frame body 1, there is an inserting plate 4 capable of blocking the airflow of pulverized coal pipeline,

[0066] The rectangular frame body 1 includes: a front side frame, a rear side frame, a left side frame and a right side frame; the front side frame is parallel to the rear side frame, and the left side frame is parallel to the right side frame, wherein the left side frame and the right side frame are parallel The right side frame is provided with sliding tracks, the front side frame is provided with a right-angled triangle notch, and the rear side frame is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com