Production method for corncob glycosyl medicinal carrier and production system

A production method and corn cob technology, applied in the field of medicine, can solve the problems of undisclosed internal sponge core separation, etc., and achieve the effects of saving manpower, suitable pH and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below through specific embodiments.

[0038]The production method of a kind of corncob sugar-based pharmaceutical carrier that the present embodiment adopts, comprises the following steps:

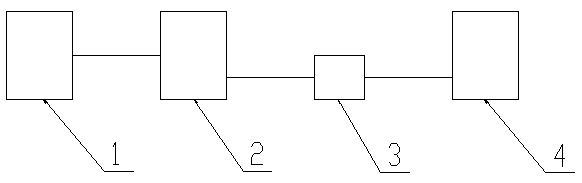

[0039] Step 1: Roller crushing: the whole corncob is crushed by double-row rollers, the double-row rollers rotate relatively, the number of double-row rollers is 20-30 pairs, and the roller gap is gradually reduced from 30-40mm to 15- 10mm;

[0040] Step 2: Coarse crushing: After rolling and crushing, the whole corncob is coarsely crushed through a pulverizer;

[0041] Step 3: Vibration screening: After coarse crushing, the whole corn cob is screened through a vibrating screen. The vibration frequency of the vibrating screen is 4-10 times per second, and the sieve hole is 20-30 mesh. After removing the material on the sieve, collect the under-sieve materials;

[0042] Step 4: Micropowder: further pulverize the undersieve to 60-80 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com