Tempered glass production line

A tempered glass and production line technology, which is applied in glass tempering, glass manufacturing equipment, glass transportation equipment, etc., can solve the problems affecting the softening effect of ordinary glass, and the temperature difference between the contact surface and the non-contact surface, so as to facilitate heating, softening and heating Uniform and improve softening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

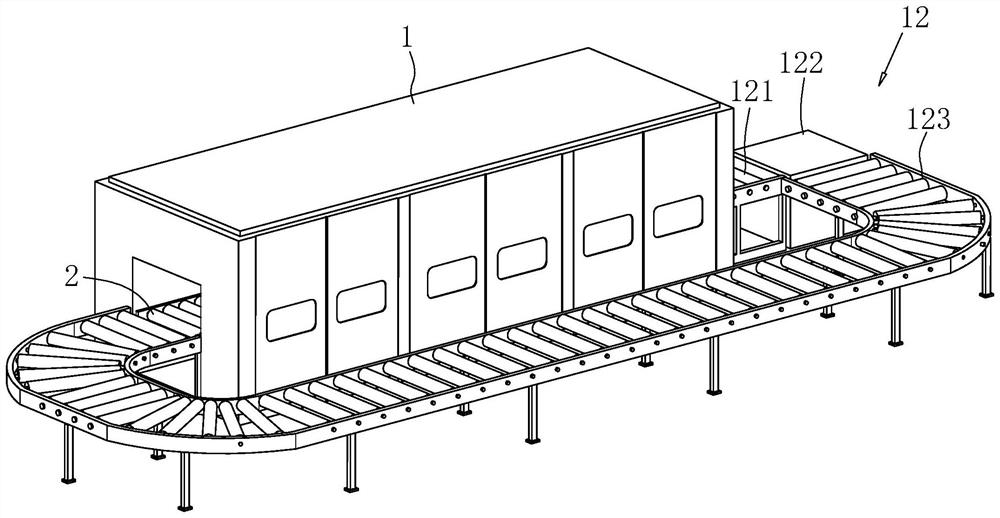

[0042] The following is attached Figure 1-6 The application is described in further detail.

[0043] The embodiment of the present application discloses a tempered glass production line. refer to figure 1 The tempered glass production line includes a tempering furnace 1. The tempering furnace 1 is a known technology and will not be described too much here. The tempering furnace 1 is used to soften and rapidly cool the glass, and then convert ordinary glass into tempered glass. Inside the tempering furnace 1 A conveying roller 2 for conveying glass is provided; the ordinary glass is placed on the conveying roller 2, conveyed to the inside of the tempering furnace 1 through the conveying roller 2, and heated to 700° by the tempering furnace 1 to soften; then the softened glass is conveyed to the tempering furnace In the cooling zone of the furnace 1, the temperature of the glass is rapidly cooled to 60°, and then tempered glass is formed.

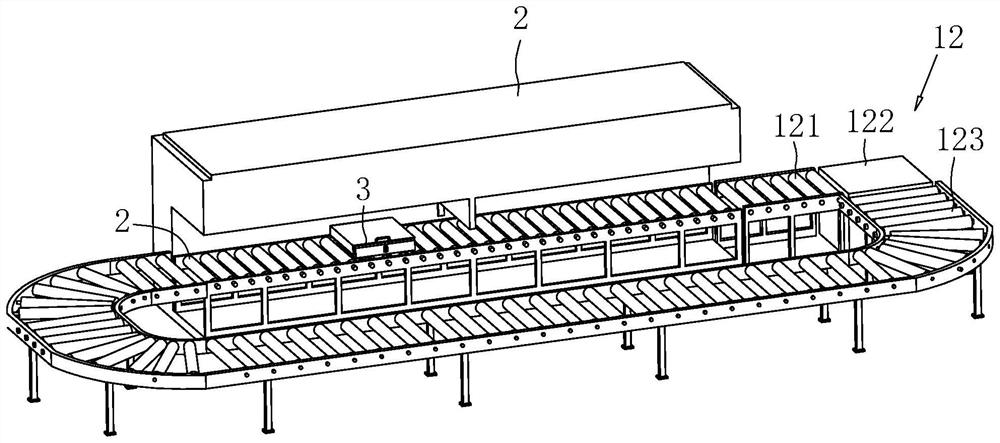

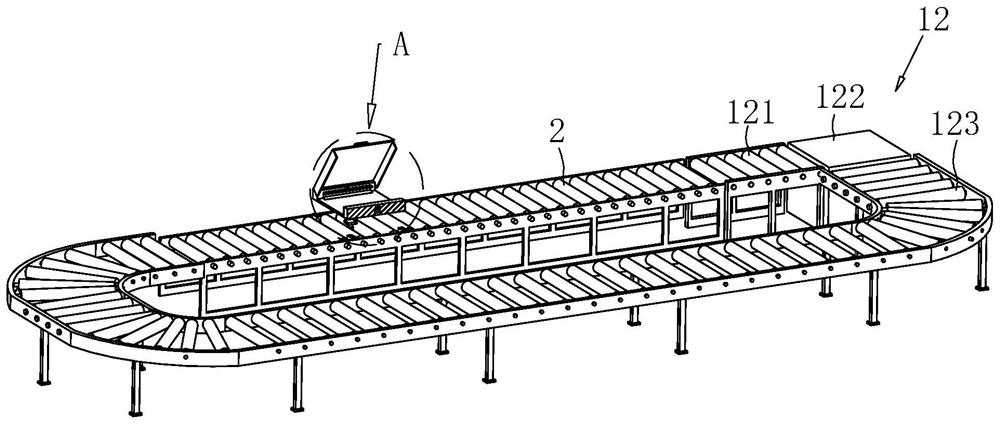

[0044] refer to figure 2 , ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com