Micro-deformation controlling heat treatment process for forming position of special-shaped curved surface part

A technology for micro-deformation and parts, applied in the field of heat treatment, can solve the problems of difficult processing and difficult micro-deformation, and achieve the effects of easy tempering, simplified processing technology, and improved processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A heat treatment process controlled by micro-deformation at the forming position of curved surface special-shaped parts, which includes the following steps:

[0030] S1. Preliminary molding processing: processing the curved surface and irregular size at the point to be formed of the part, reducing the tolerance level of its size by 1;

[0031] S2. Furnace loading: put the processed parts into a vacuum heating furnace, and vacuumize to make the pressure at 0.1Pa;

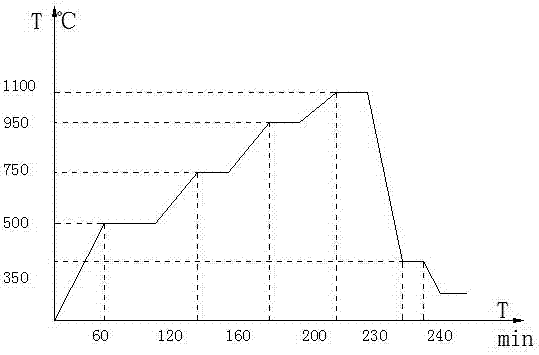

[0032] S3, such as figure 1 As shown, the heating treatment includes the following heating steps: a. Heating up at a uniform speed until the furnace temperature reaches 550°C, the heating rate is 1.5°C / s, and holding for 50 minutes; 30min; c. Continue to heat up to 1000°C at a constant speed, with a heating rate of 8°C / min, and hold for 30 minutes; d. Continue to heat up to 1120°C at a constant speed, with a heating rate of 5°C / min, and hold for 25 minutes;

[0033] S4. Micro-deformation heat treatment: Intr...

Embodiment 2

[0040] A heat treatment process controlled by micro-deformation at the forming position of curved surface special-shaped parts, which includes the following steps:

[0041] S1. Preliminary processing of forming: processing of curved surface and special-shaped size at the point to be formed of the part, the tolerance level of the size is required to be reduced by 2 levels;

[0042] S2. Furnace loading: put the processed parts into a vacuum heating furnace, and vacuumize to make the pressure at 0.001Pa;

[0043] S3. Heating treatment, including the following heating steps: a. Heating up at a constant speed until the furnace temperature reaches 500°C, with a heating rate of 1°C / s, and holding for 55 minutes; b, continuing to heat up at a uniform speed to 750°C, with a heating rate of 8°C / min, and holding for 35 minutes ; c. Continue to heat up to 950°C at a constant speed, with a heating rate of 10°C / min, and keep warm for 35 minutes; d, continue to heat up to 1100°C at a constan...

Embodiment 3

[0051] A heat treatment process controlled by micro-deformation at the forming position of curved surface special-shaped parts, which includes the following steps:

[0052] S1. Preliminary processing of forming: processing of curved surface and special-shaped size at the point to be formed of the part, the tolerance level of the size is required to be reduced by 2 levels;

[0053] S2. Furnace loading: put the processed parts into a vacuum heating furnace, and vacuumize to make the pressure at 0.02Pa;

[0054] S3. Heating treatment, including the following heating steps: a. Heating up at a constant speed until the furnace temperature reaches 600°C, with a heating rate of 2°C / s, and holding for 60 minutes; b, continuing to heat up at a constant speed to 850°C, with a heating rate of 10°C / min, and holding for 40 minutes ; c. Continue to heat up to 980°C at a constant speed, with a heating rate of 9°C / min, and hold for 40 minutes; d, continue to heat up to 1200°C at a constant spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com