Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Good electrical conduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

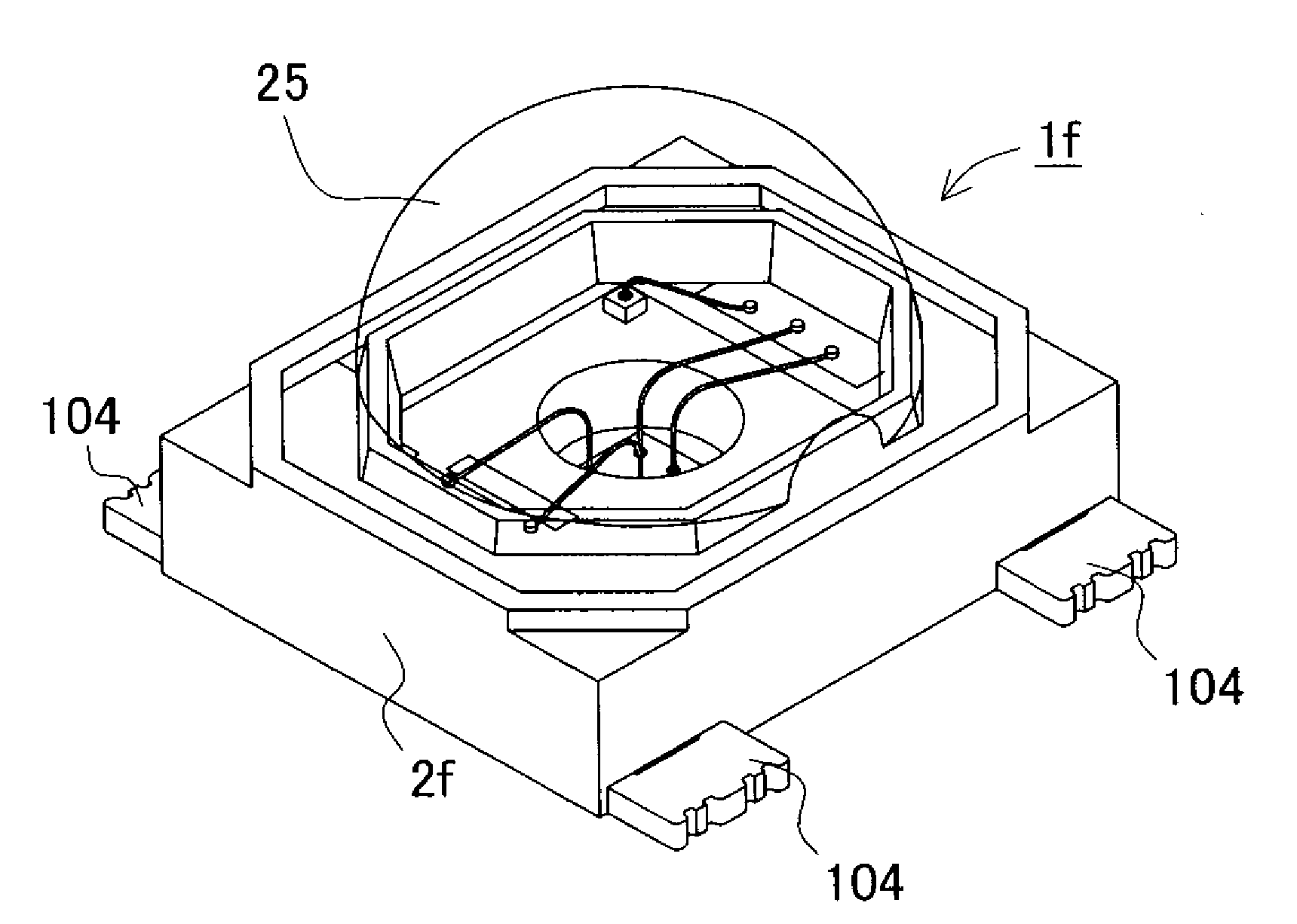

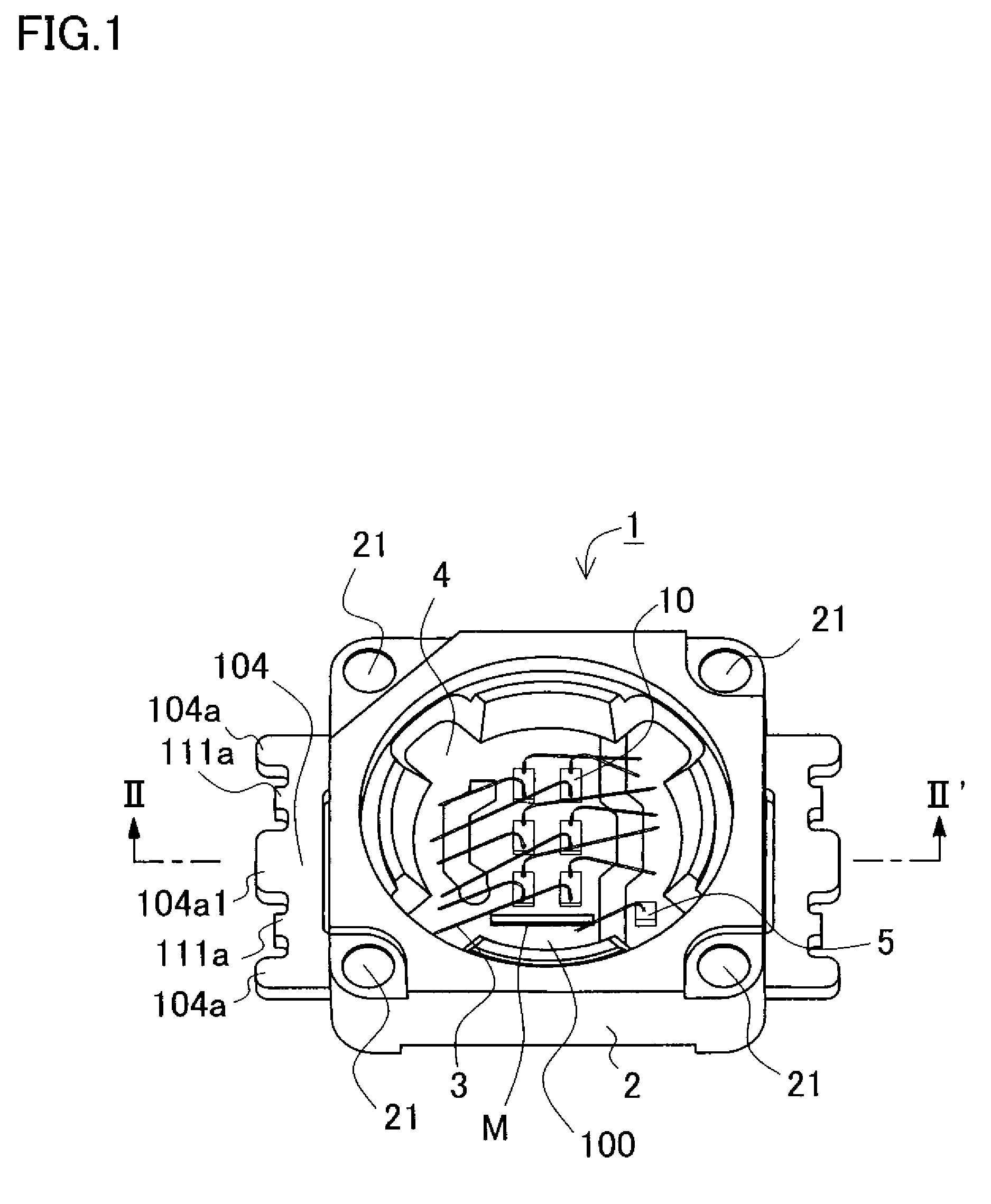

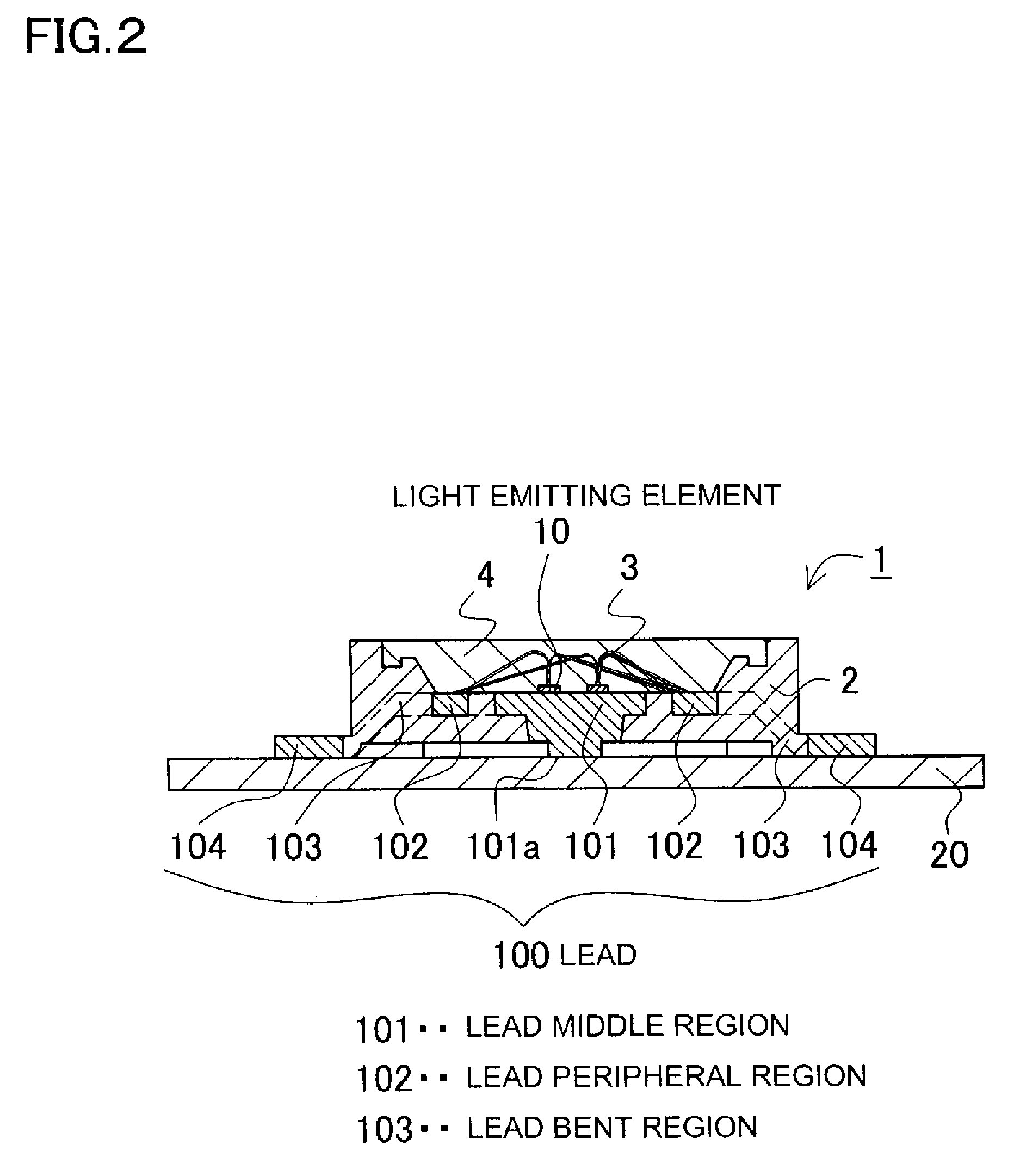

Semiconductor light emitting device and a method for producing the same

ActiveUS20070262328A1Avoid damageReduce the possibility of damageSolid-state devicesSemiconductor devicesEngineeringLight emitting device

Both ends of the lead arrangement project outward from side surfaces of a package to form outer lead regions. Each of the outer lead regions includes a pair of outer lead projections and lead terminal smaller projections that are located between the outer lead projections. The outer lead projections and lead terminal smaller projections project outward. Adjustment is made to the projection amount of end surfaces of the lead smaller projections lying in a plane perpendicular to a longitudinal direction of the lead arrangement, whereby the end surfaces projecting less than end surfaces of the outer lead projections. Thus, cut surfaces of lead connection portions with edged corners are not exposed. This arrangement prevents that the cut surfaces damage other devices.

Owner:NICHIA CORP

Environment-friendly electrode silver slurry of zinc oxide varistor suitable for two soldering technologies and preparation method of electrode silver slurry

ActiveCN104934103AGuaranteed normal transmissionReduce interface contact resistanceNon-conductive material with dispersed conductive materialCable/conductor manufactureSlurryResistor

The invention discloses an environment-friendly electrode silver slurry of zinc oxide varistor suitable for two soldering technologies and a preparation method of the electrode silver slurry. The silver slurry is composed of 60-80% silver powder, 1-5% of metal oxide, 2-5% of leadless glass powder and 10-37% of organic carriers by weight. The preparation method comprises the steps that the leadless glass powder is prepared by that raw materials are mixed well, placed in a platinum crucible and melt, and the melt material is removed and dried to obtain the leadless glass powder; the organic carriers are prepared by adding an organic solvent into a stainless steel container, adding organic resin, carrying out heating, and carrying out cooling and adding a surfactant after the resin is completely dissolved; and the silver slurry is prepared by mixing the silver powder, the metal oxide, the leadless glass powder and the organic carriers, and stirring and grinding the mixture in a vacuum manner. The preparation method is simple and suitable for both the reflow soldering and immersed soldering technologies, the solderability and the soldering resistance are high, the silver slurry can be used to prepare common type as well as lightning protection type varistor, the adhesion force, the conductivity and the electrical performance are high, and the performance completely reach the using requirements.

Owner:GUIYAN DETECTION TECH YUNNAN CO LTD

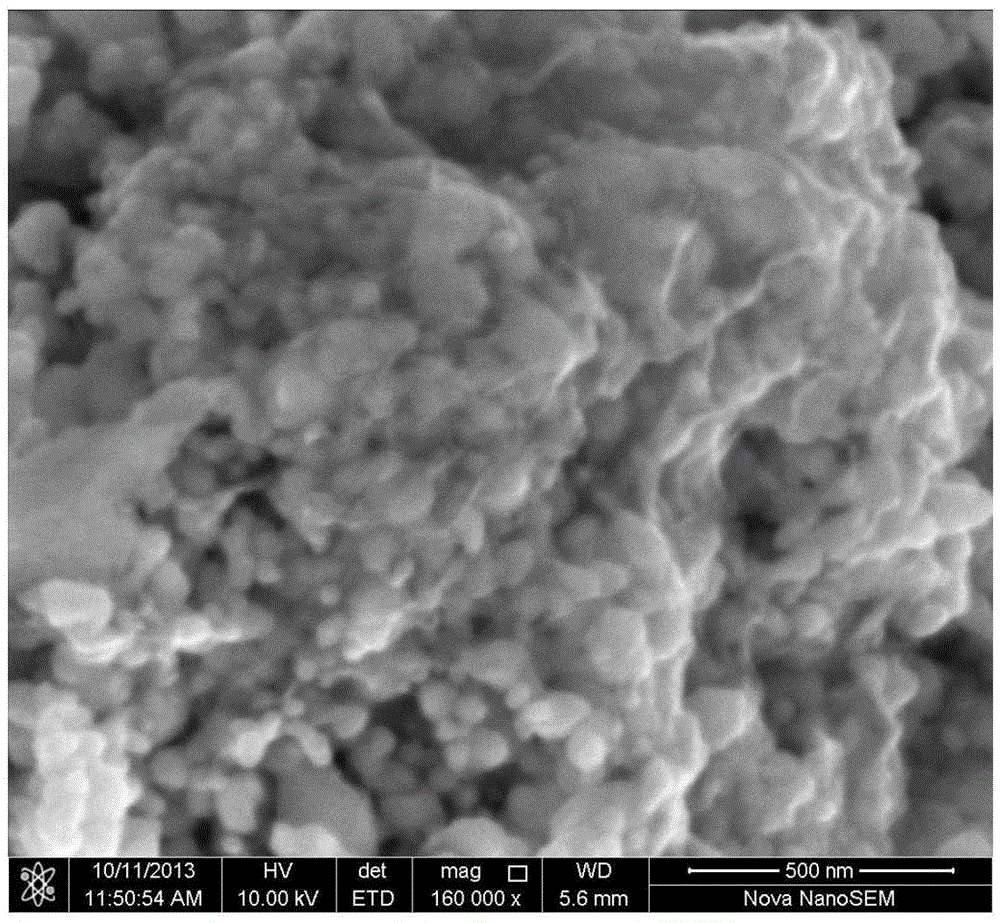

Electrocondution slurry and preparation method and application of electrocondution slurry

InactiveCN103839605AAvoid affecting charge transportGuaranteed normal transmissionNon-conductive material with dispersed conductive materialCable/conductor manufactureCross-linkMoisture resistance

The invention discloses electrocondution slurry and a preparation method and application of the electrocondution slurry. The slurry comprises, by mass percent, 30-40% of silver-graphene composite materials, 30-48% of organic resin, 5-10% of cross-linking agents and 12-26% of thinning agents. The method that the silver-graphene composite materials are prepared are as follows: graphite oxide and organic silver are added to a mixed system formed by organic solvents and deionized water, and ultrasonic dispersion is carried out on the mixture; hydrazine hydrate is dripped to the mixed system while the mixed system is stirred; after stirring is carried out for 20-30 min at room temperature, the temperature rises to 60-70 DEG C, reaction is conducted for 2-3 h, the mixture is cooled to be at the room temperature, filtered and rinsed by the deionized water, vacuum drying is carried out on the mixture, and the silver-graphene composite materials are obtained. The electrocondution slurry can meet the demands of photovoltaic devices for the electrical property under low silver content conditions and is suitable for flexible substrates, good in temperature and moisture resistance and excellent in filament printing performance, adhesive force of the electrocondution slurry and substrate ITO materials is high, and production cost of the slurry is remarkably reduced.

Owner:HUAZHONG UNIV OF SCI & TECH +1

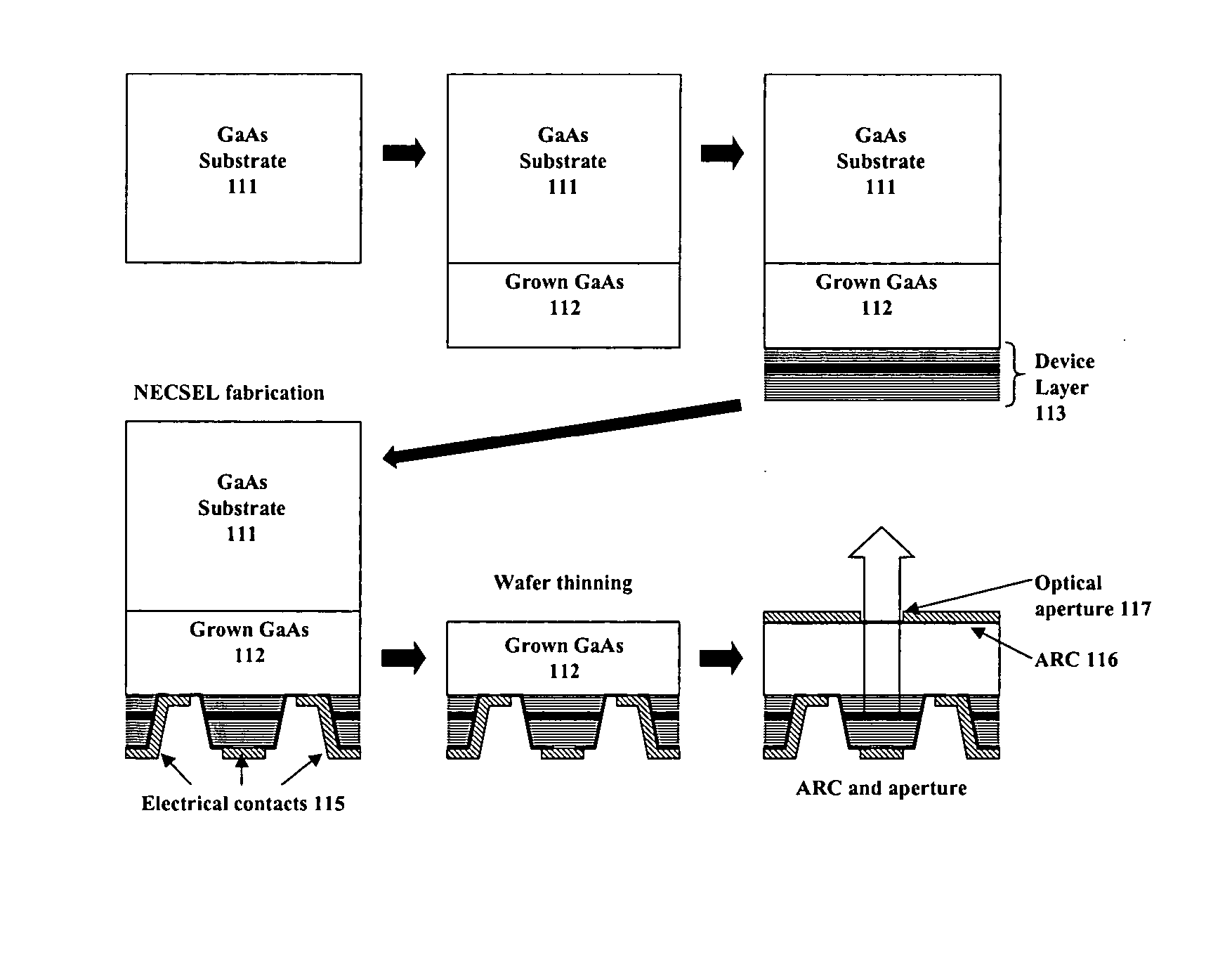

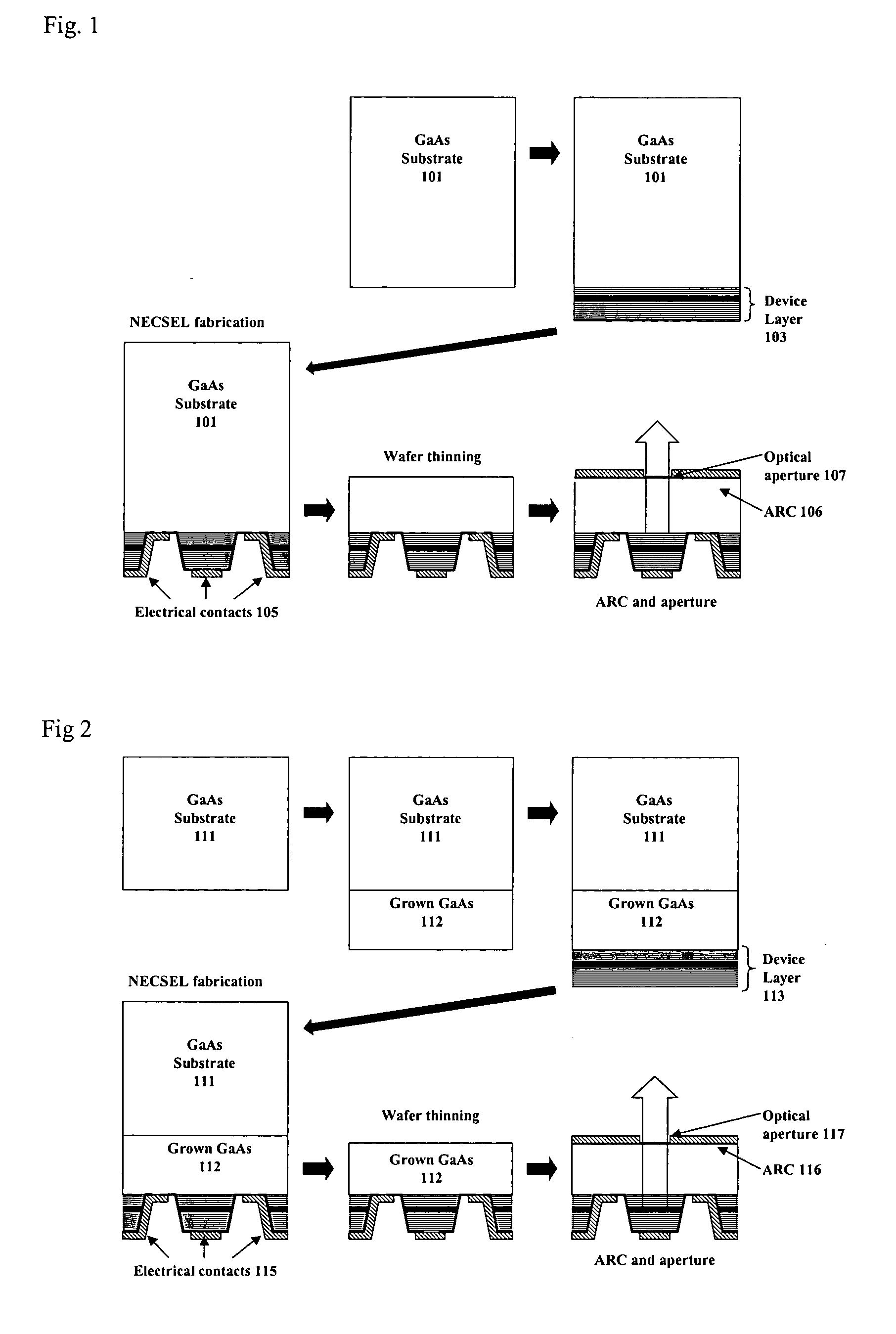

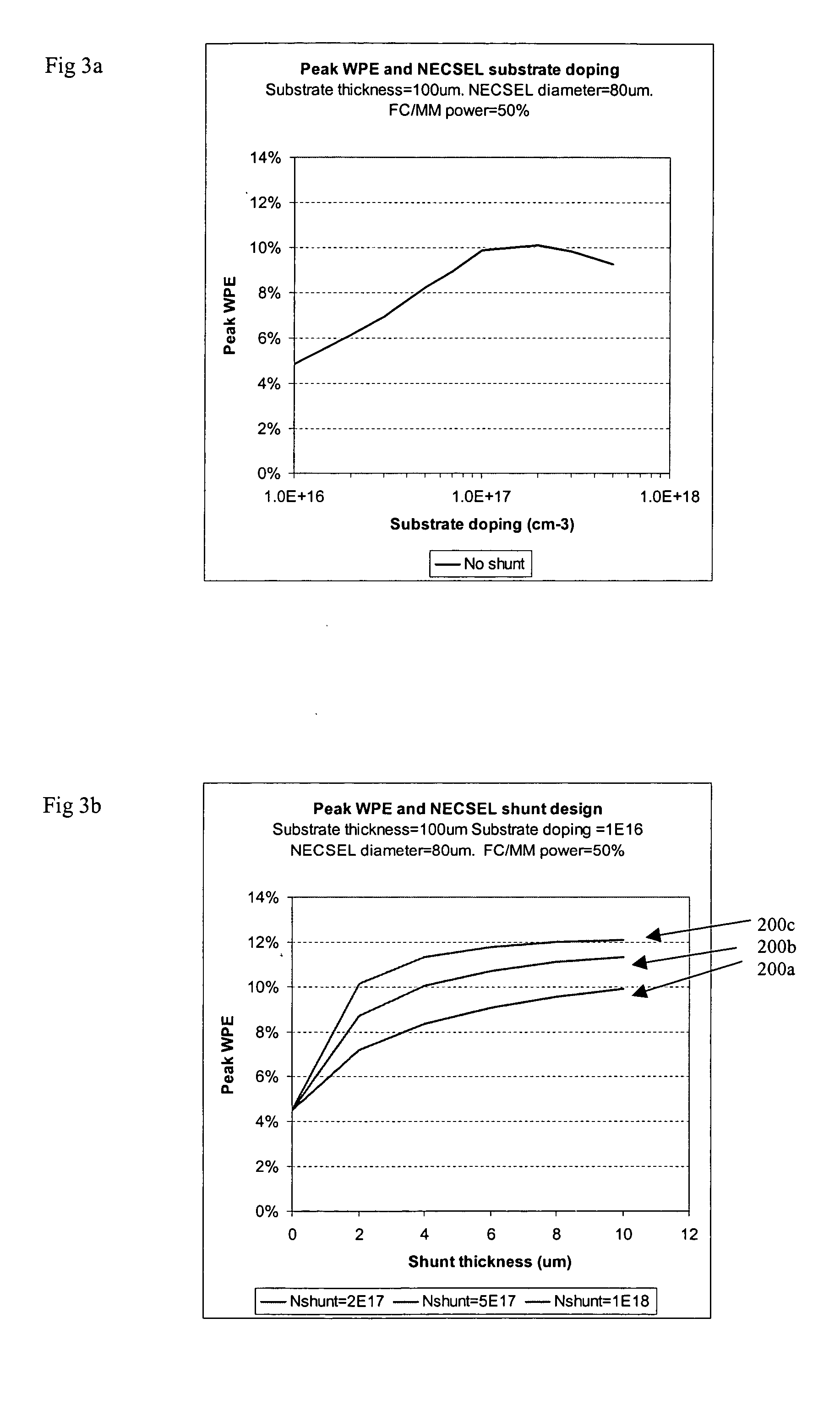

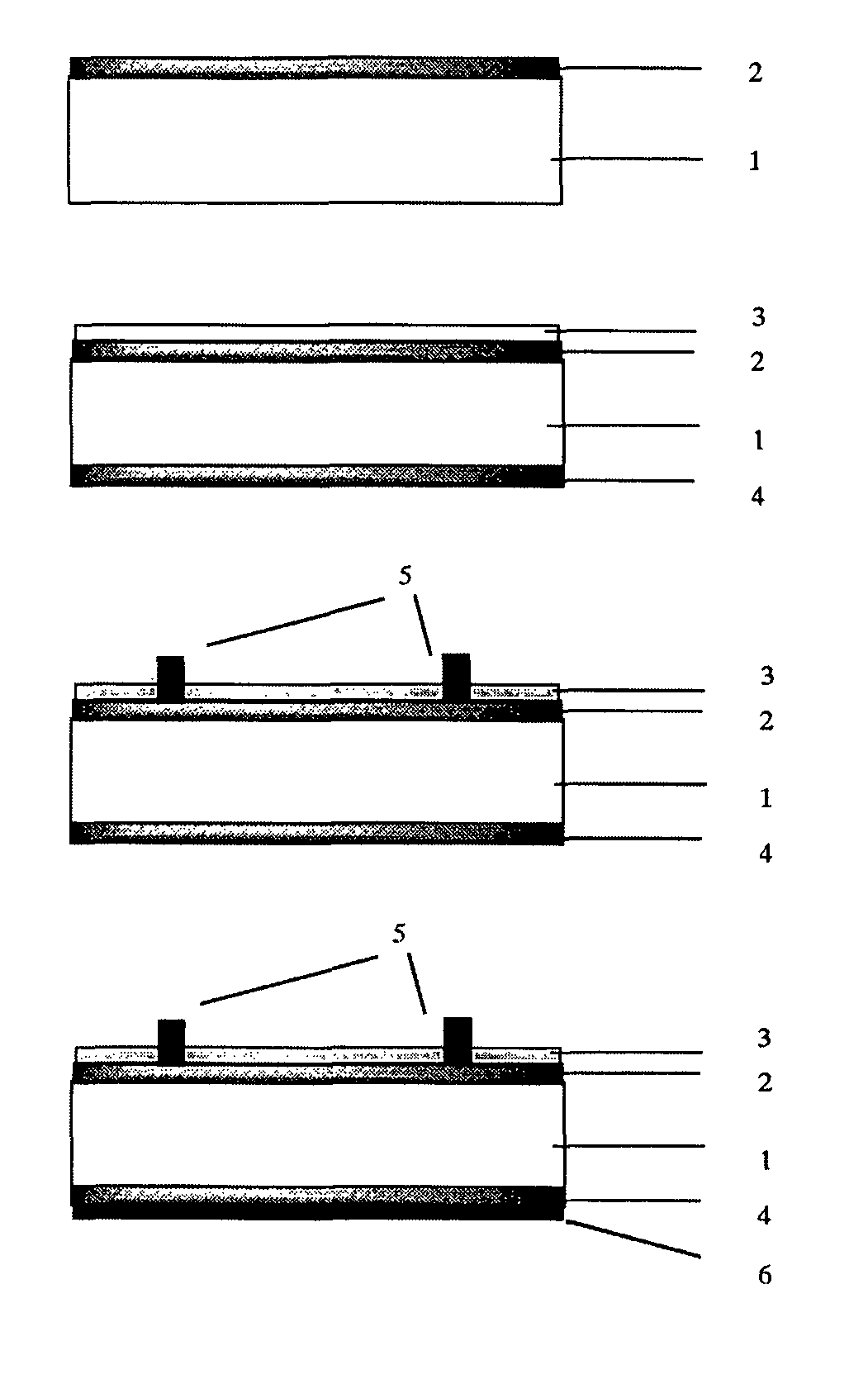

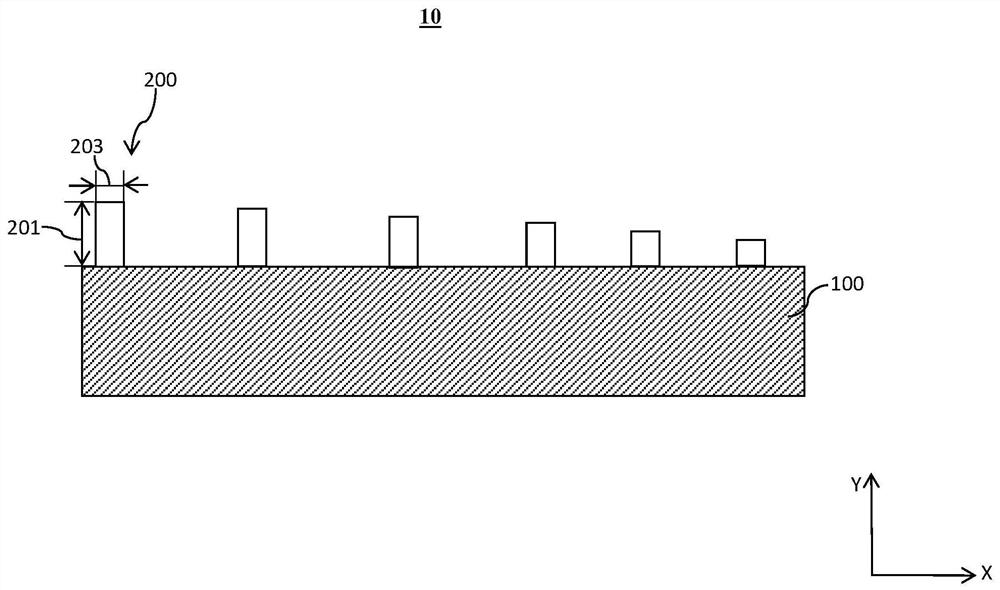

Method of fabrication of a support structure for a semiconductor device

ActiveUS20050014349A1Good electrical conductionOptimal device performanceLaser detailsFrom solid stateEngineeringElectrical conductor

A method of fabricating a semiconductor device is described. In this method, a starting substrate of sufficient thickness is selected that has the required defect density levels, which may result in an undesirable doping level. Then a semiconductor layer having a desired doping level is formed on the starting substrate. The resulting semiconductor layer has the required defect density and doping levels for the final product application. After active components, electrical conductors, and any other needed structures are formed on the semiconductor layer, the starting substrate is removed leaving a desired thickness of the semiconductor layer. In a VECSEL application, the active components can be a gain cavity, where the semiconductor layer has the necessary defect density and doping levels to maximize wall plug efficiency (WPE). In one embodiment, the doping of the semiconductor layer is not uniform. For example, a majority of the layer is doped at a low level and the remainder is doped at a much higher level. This can result in improved WPE at particular thicknesses for the higher doped material.

Owner:ARASOR ACQUISITION +1

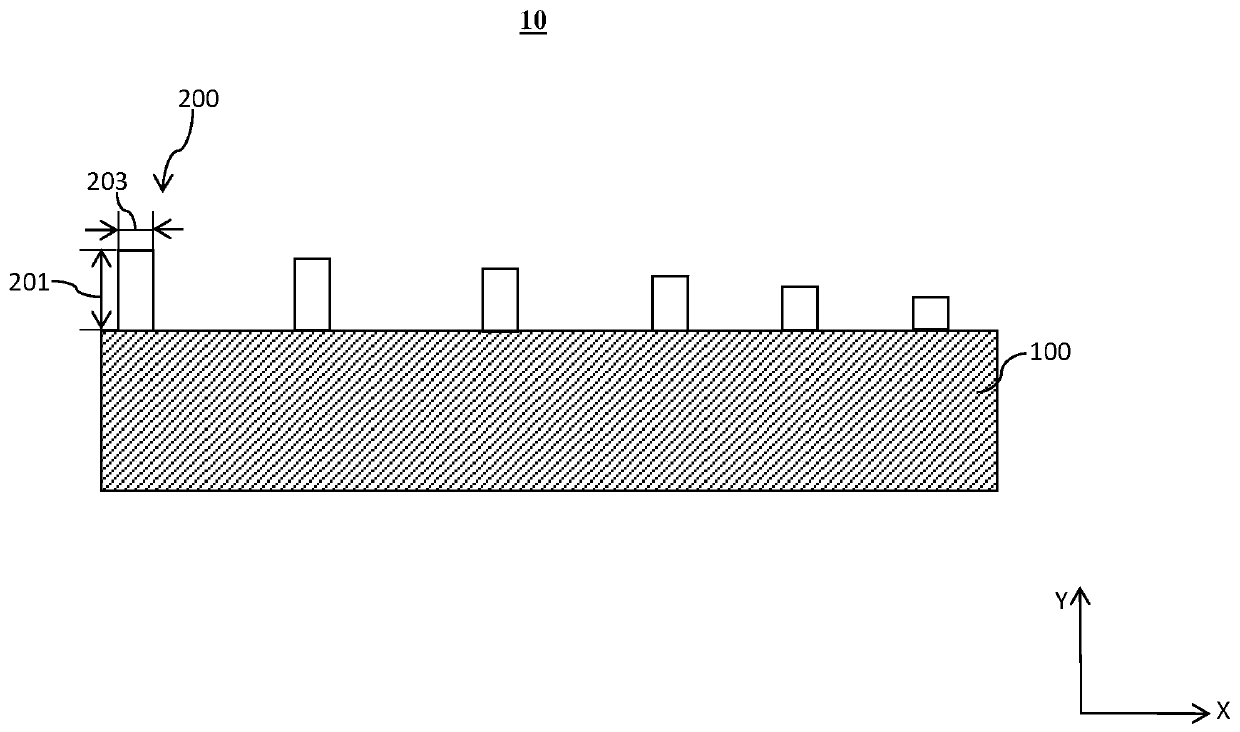

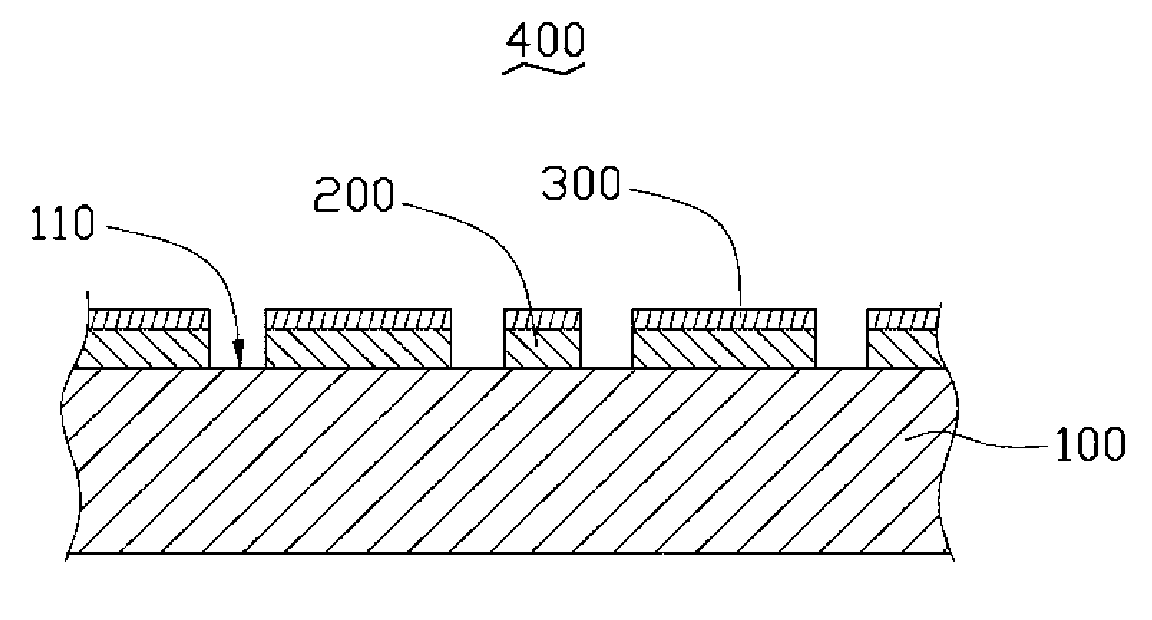

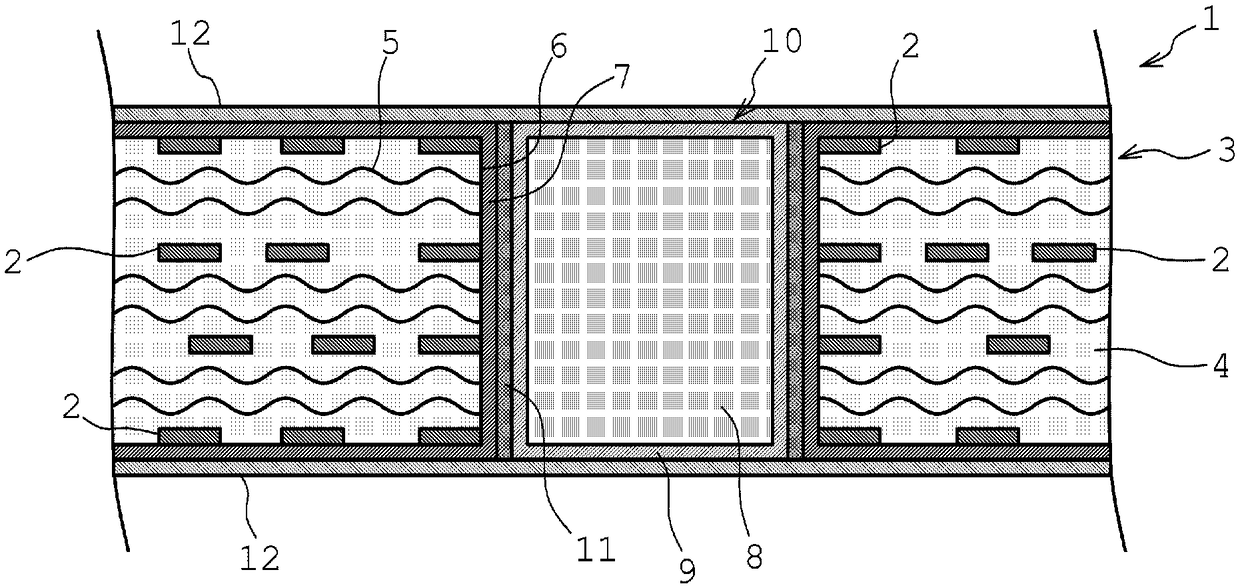

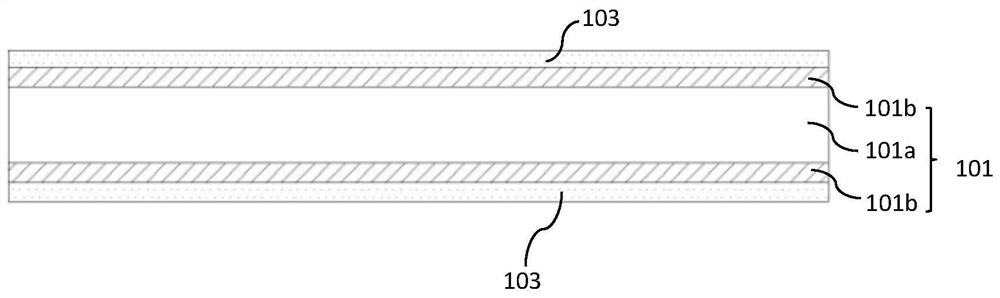

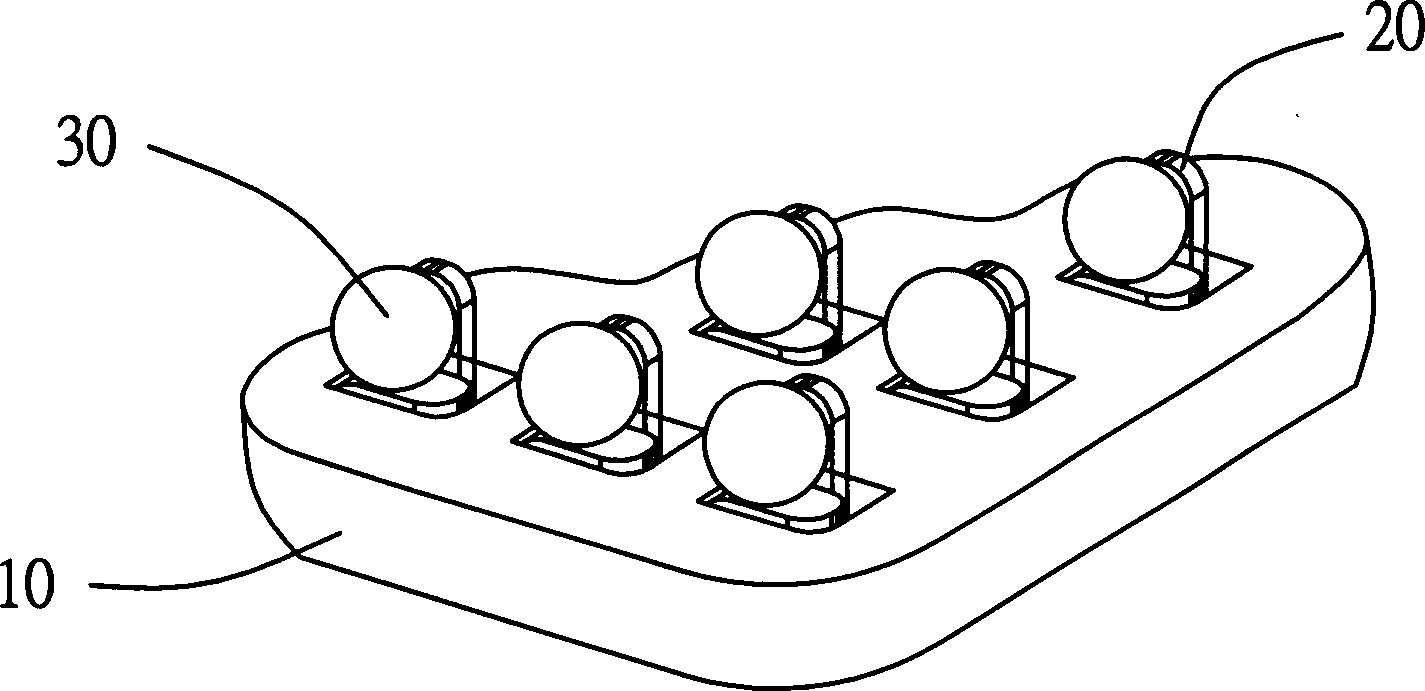

Battery pole piece and cell

ActiveCN110061182AImprove battery safety performanceReduce battery weightFinal product manufactureElectrode carriers/collectorsEngineeringPole piece

Embodiments of the invention relate to a battery pole piece and a cell. The battery pole piece according to an embodiment comprises a pole piece body having a length direction and a width direction perpendicular to the length direction, and a plurality of tabs connected to the pole piece body, wherein each of the plurality of tabs has a width in the width direction, and a length in the length direction, wherein the widths or lengths of the tabs are different. According to the battery pole piece and the cell provided by the embodiments of the invention, the battery safety performance is improved, the battery weight can be reduced, and it is guaranteed that each tab in the battery pole piece can be electrically communicated with the outside well.

Owner:NINGDE AMPEREX TECH

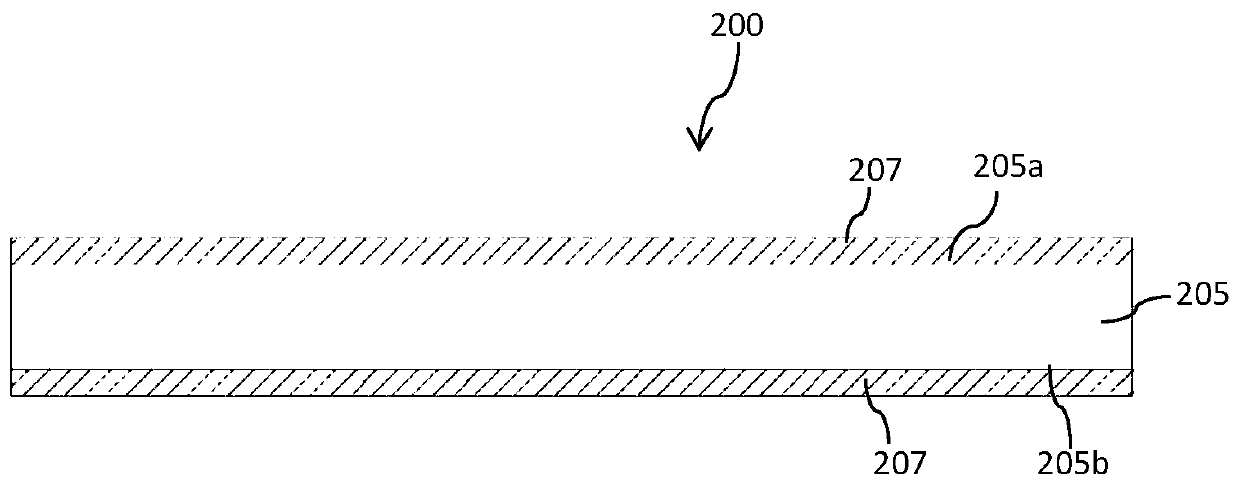

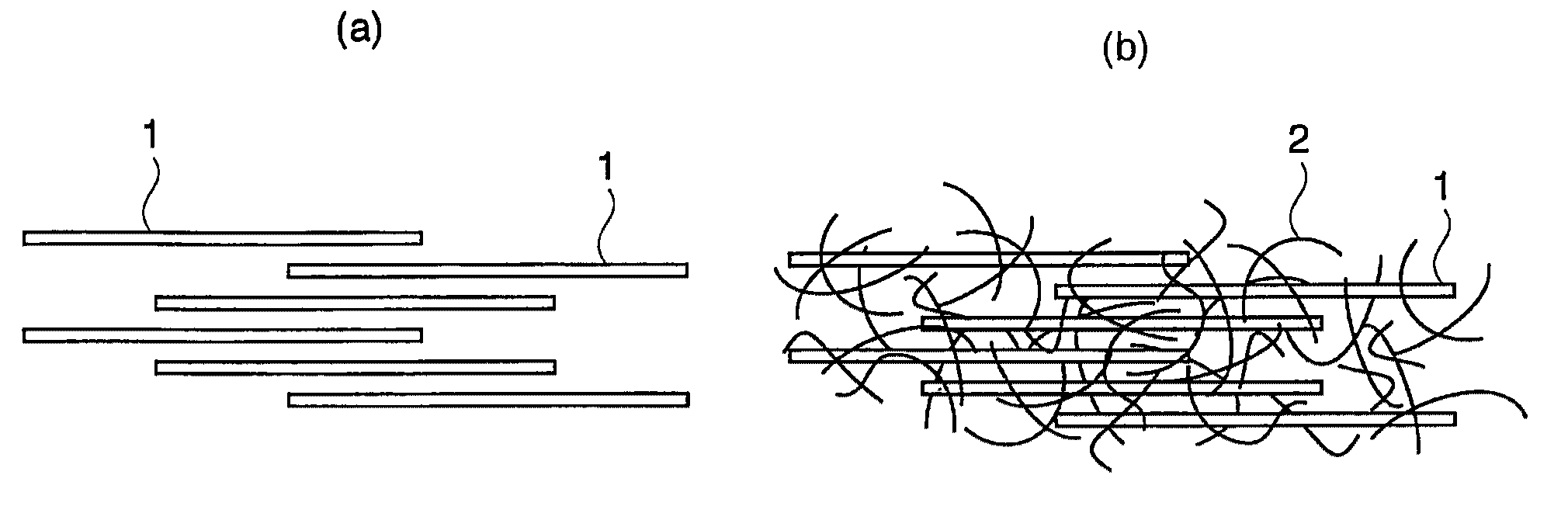

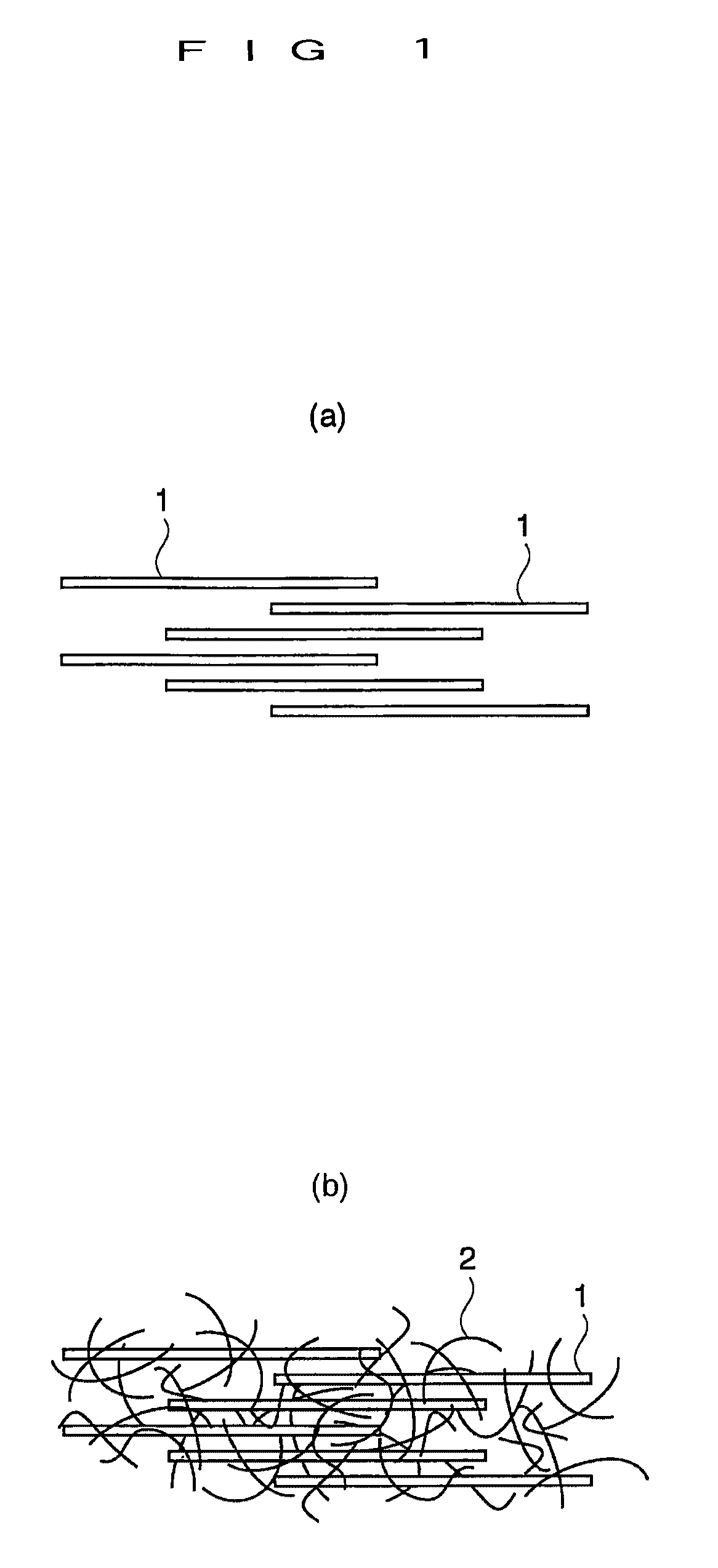

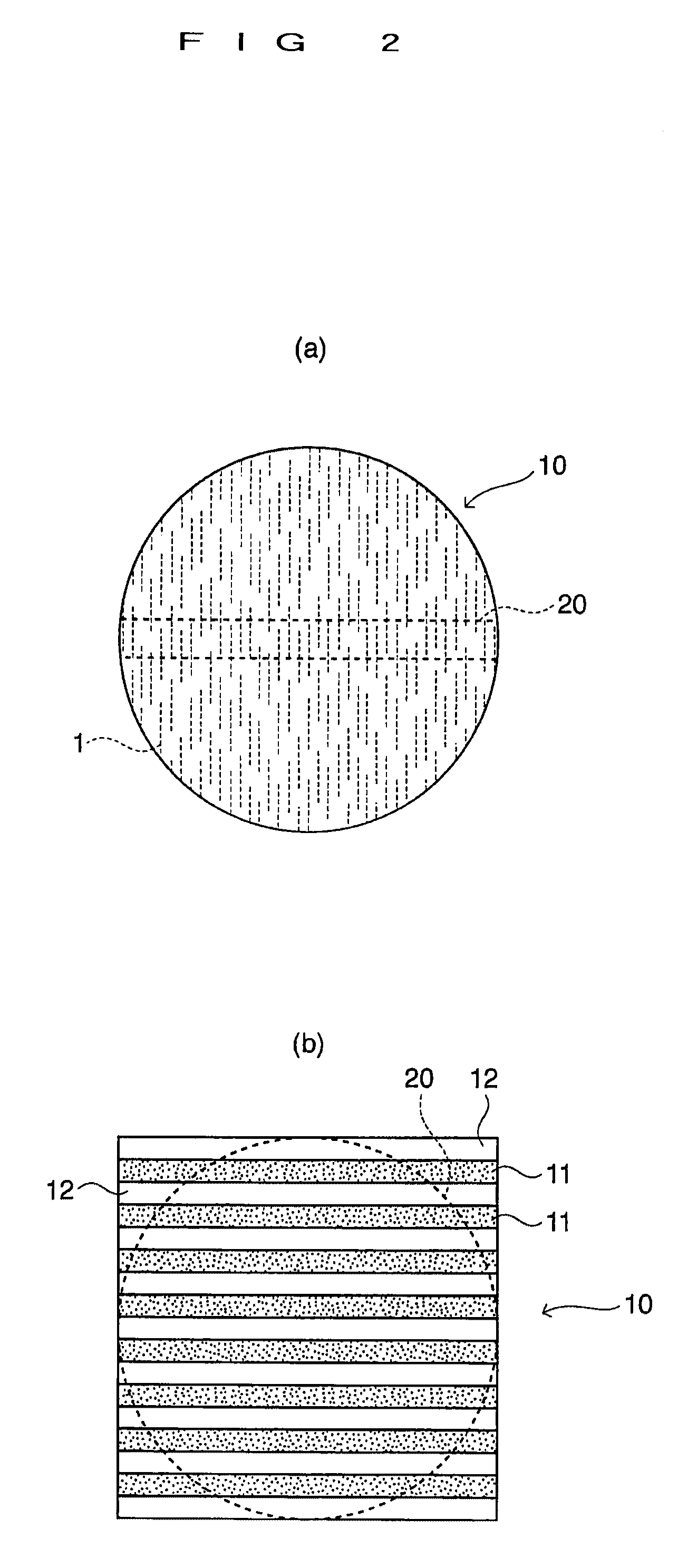

High heat conduction composite material

InactiveUS20100143691A1Improve corrosion resistanceGood electrical conductionMaterial nanotechnologyBottlesFiberMetal powder

A composite material being excellent in heat conductivity is provided. In order to realize this, a fibrous carbon material made of fine tube form structures constituted with single-layer or multiple-layer graphene is present to form a plurality of layers within a substrate made from a spark plasma sintered body of a metal powder, a mixed powder of a metal and ceramics, or a ceramic powder. The fibrous carbon material constituting each layer is made of a mixture obtained by mixing a small amount of a small diameter fiber 2 having an average diameter of 100 nm or less with a large diameter fiber 1 having an average diameter of 500 nm to 100 μm.

Owner:LOCAL INC ADMINISTATIVE AGENCY TECH RES INST OF OSAKA PREFECTURE +1

Surface scale eliminating method for anode guide rod in aluminium electrolysis

The present invention features that the crimping surfaces of the bus bar and anode guide rod are cleaned with the cleaning liquid comprising dodecyl benzene sulfonic acid 1-20 wt%, alkali metal hydroxide 0.5-12 wt%, triethanolamine, 1-25 wt%, JFC 0.1-10 wt%, calgon 0.5-10 wt%, ethanol 5-10 wt%, non-ionic surfactant 1-18 wt% and butylcellusolve 5-10 wt% and water (the balance). Washing the anode guide rod with the cleaning liquid can reduce the electrode voltage obviously, lower the power consumption of electrolyzing aluminium greatly.

Owner:GUANGXI UNIV

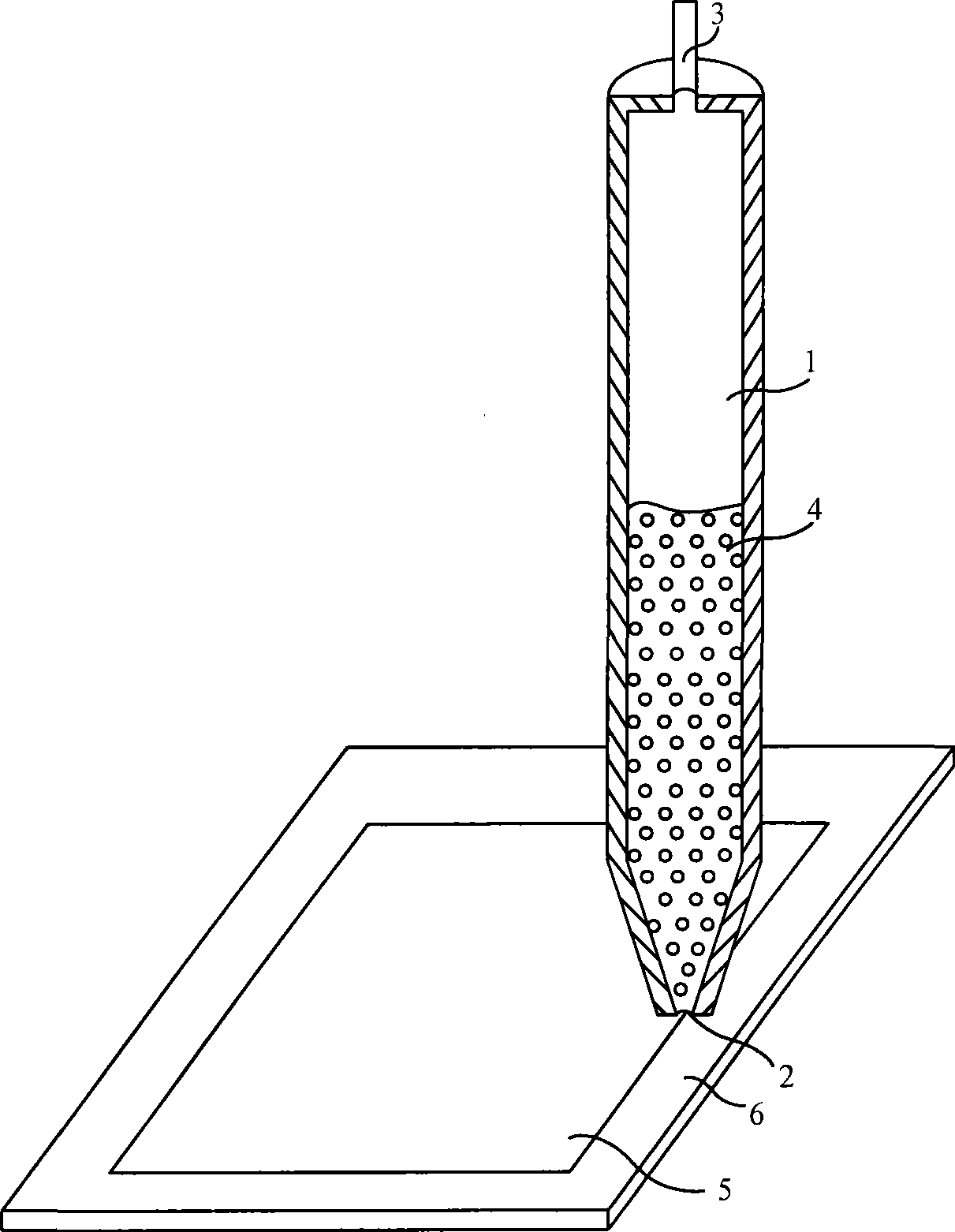

Frame enclosing gum coating apparatus

InactiveCN101452157AGood electrical conductionThe process steps are simpleNon-linear opticsAdhesiveEngineering

The present invention relates to a frame-enveloping adhesive coating device which comprises the following components: a first storing chamber which is used for storing conductive frame-enveloping adhesive; a second storing chamber which is used for storing insulated frame-enveloping adhesive; a nozzle which is respectively connected with the first storing chamber and the second storing chamber and is used for coating frame-enveloping adhesive; and a first controller which is connected with the first storing chamber and is used for controlling the outflow capacity of conductive frame-enveloping adhesive. The frame-enveloping adhesive coating device according to the invention realizes the separated coating of conductive frame-enveloping adhesive and insulated frame-enveloping adhesive, simplifies the technical process and increases the production efficiency. Simultaneously the conductive frame-enveloping adhesive is coated properly. The generation of electrostatic breakage phenomenon is prevented. The qualified rate of product is increased and the product cost is reduced.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Functional paste

InactiveUS8257617B2Stable removalLower resistanceLiquid surface applicatorsConductive materialOrganic solventEngineering

Owner:MERCK PATENT GMBH

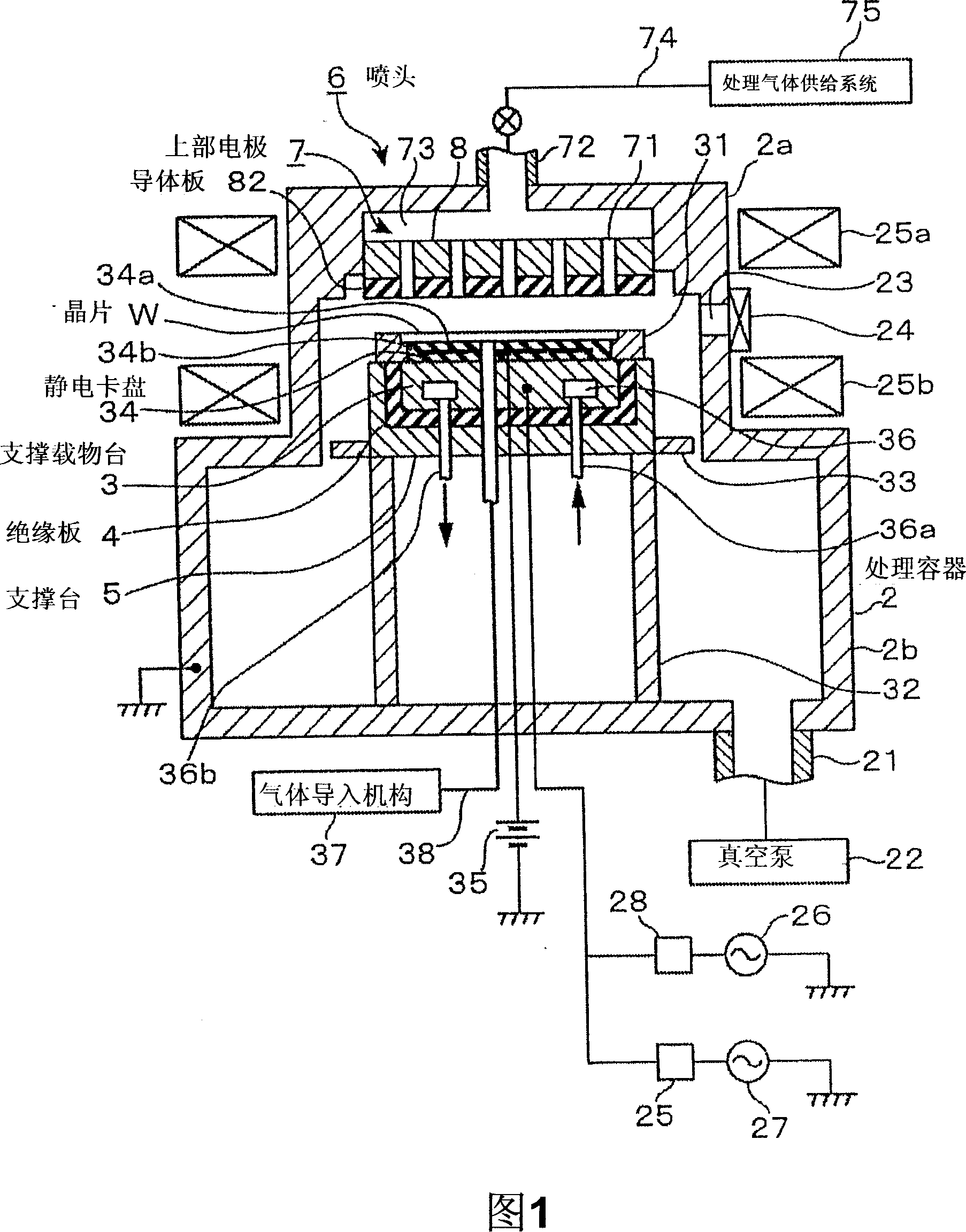

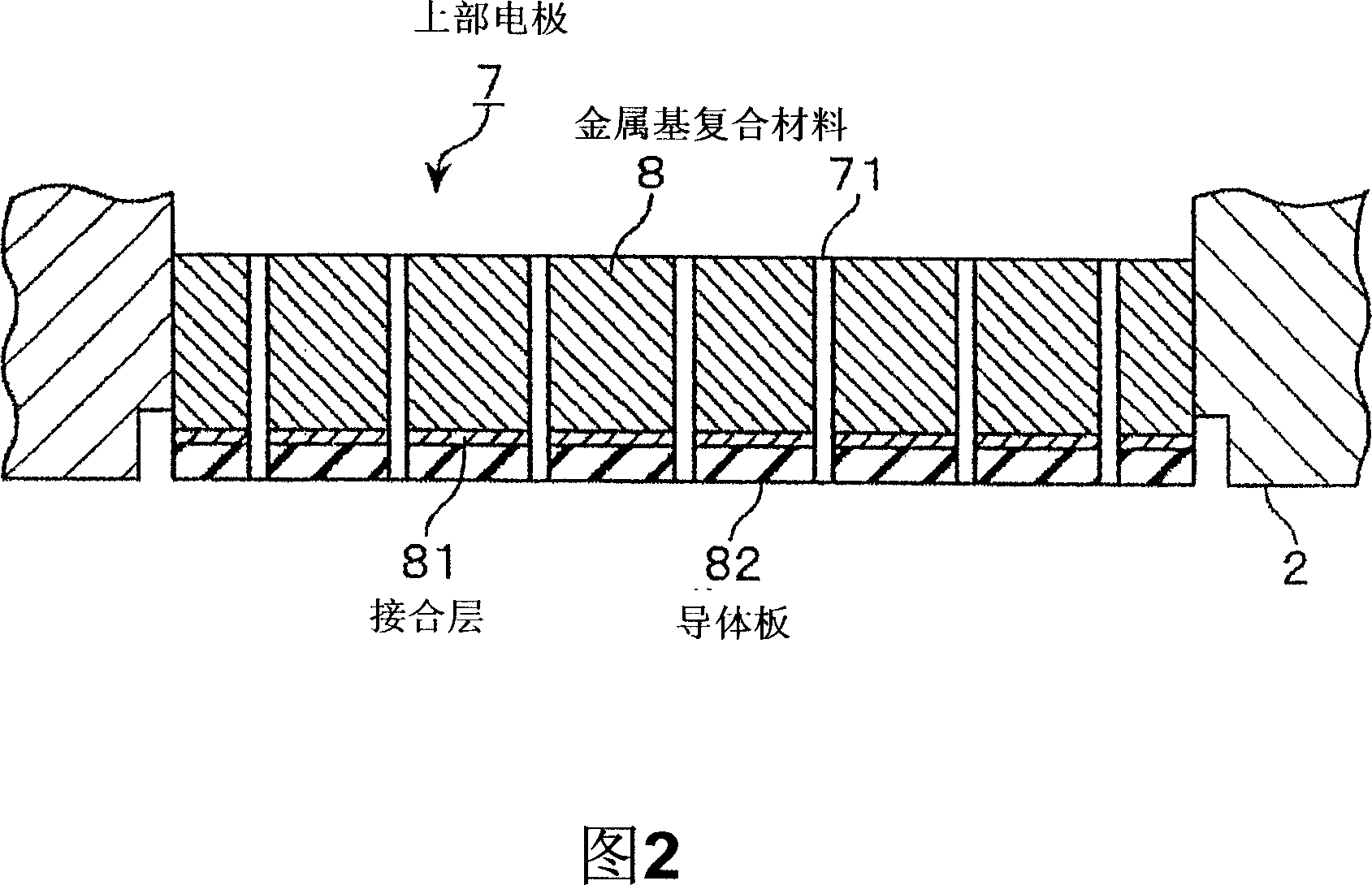

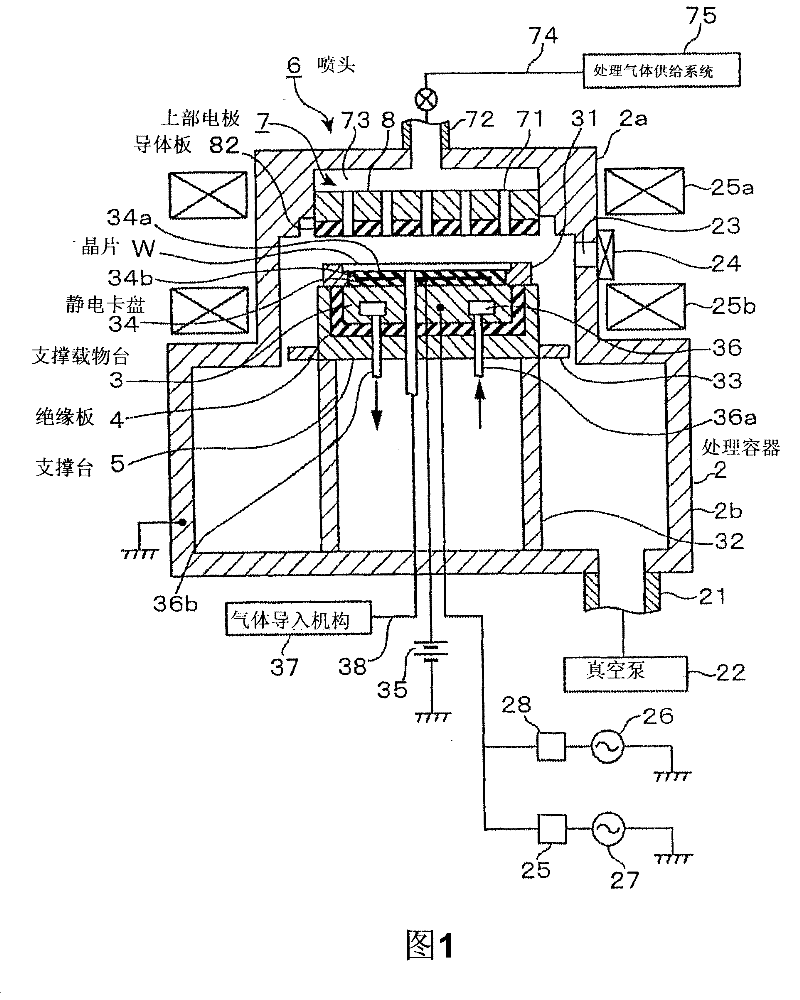

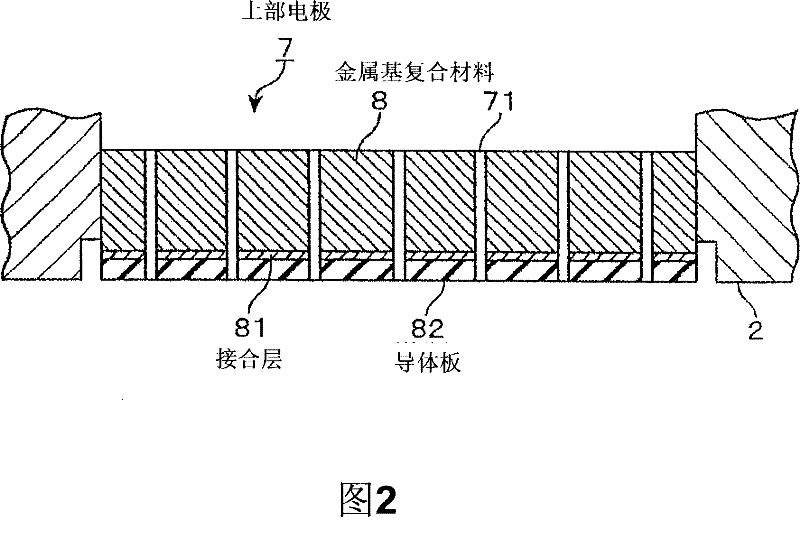

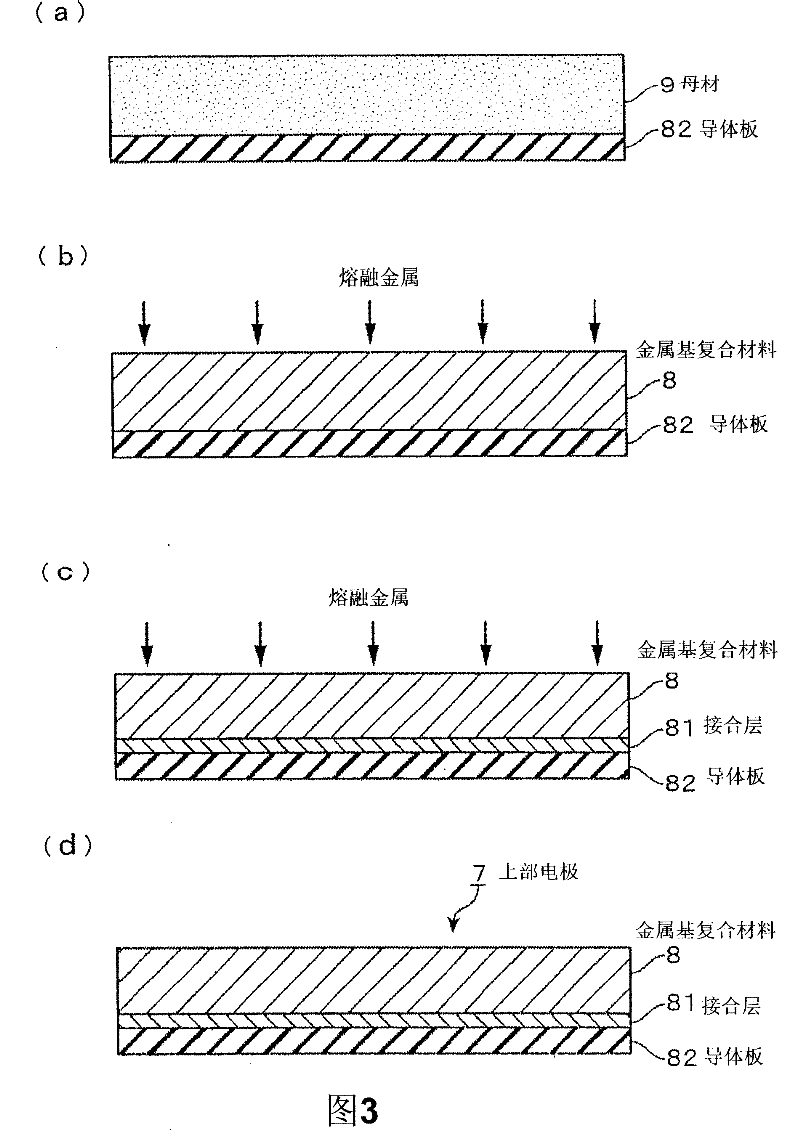

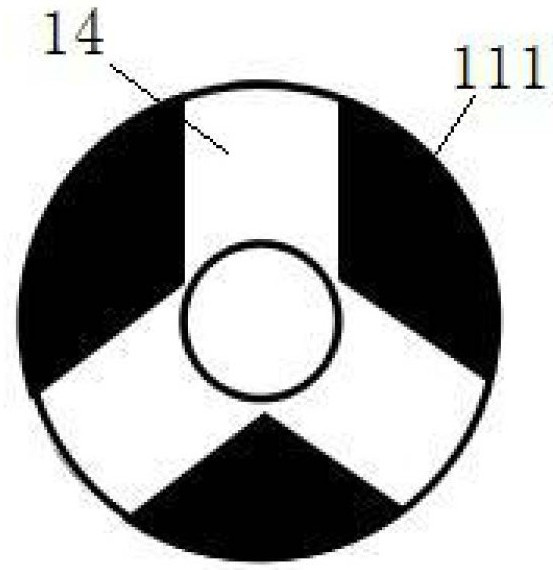

Electrode for generating plasma and plasma processing apparatus using same

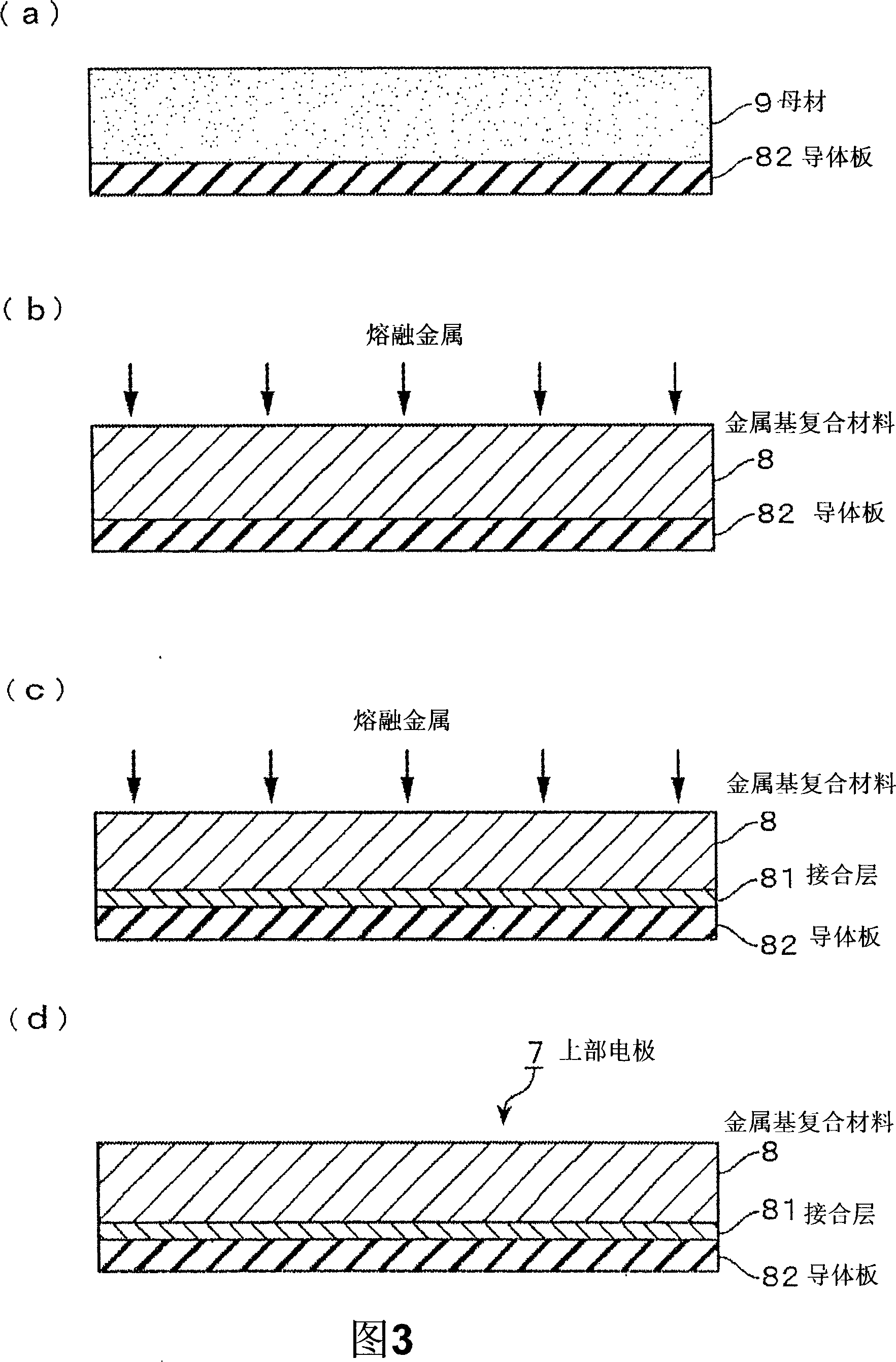

ActiveCN101005727ALittle risk of ruptureLess prone to individual differencesMolten spray coatingElectric discharge tubesMetal matrix compositeSilicon

An electrode for generating plasma and a plasma process apparatus are provided to prevent generation of excessive local stress due to a thermal expansive coefficient difference by using a metal-group composite material. A plasma generation electrode includes a metal-group composite material(8) and a conductive plate(82). The metal-group composite material has a junction surface facing a surface to be processed of a substrate by impregnating silicon into silicon carbide(9) of a porous ceramic. The conductive plate is made of a plasma-resistant material melt-joined on a junction surface of the metal-group composite material by a metal.

Owner:TOKYO ELECTRON LTD

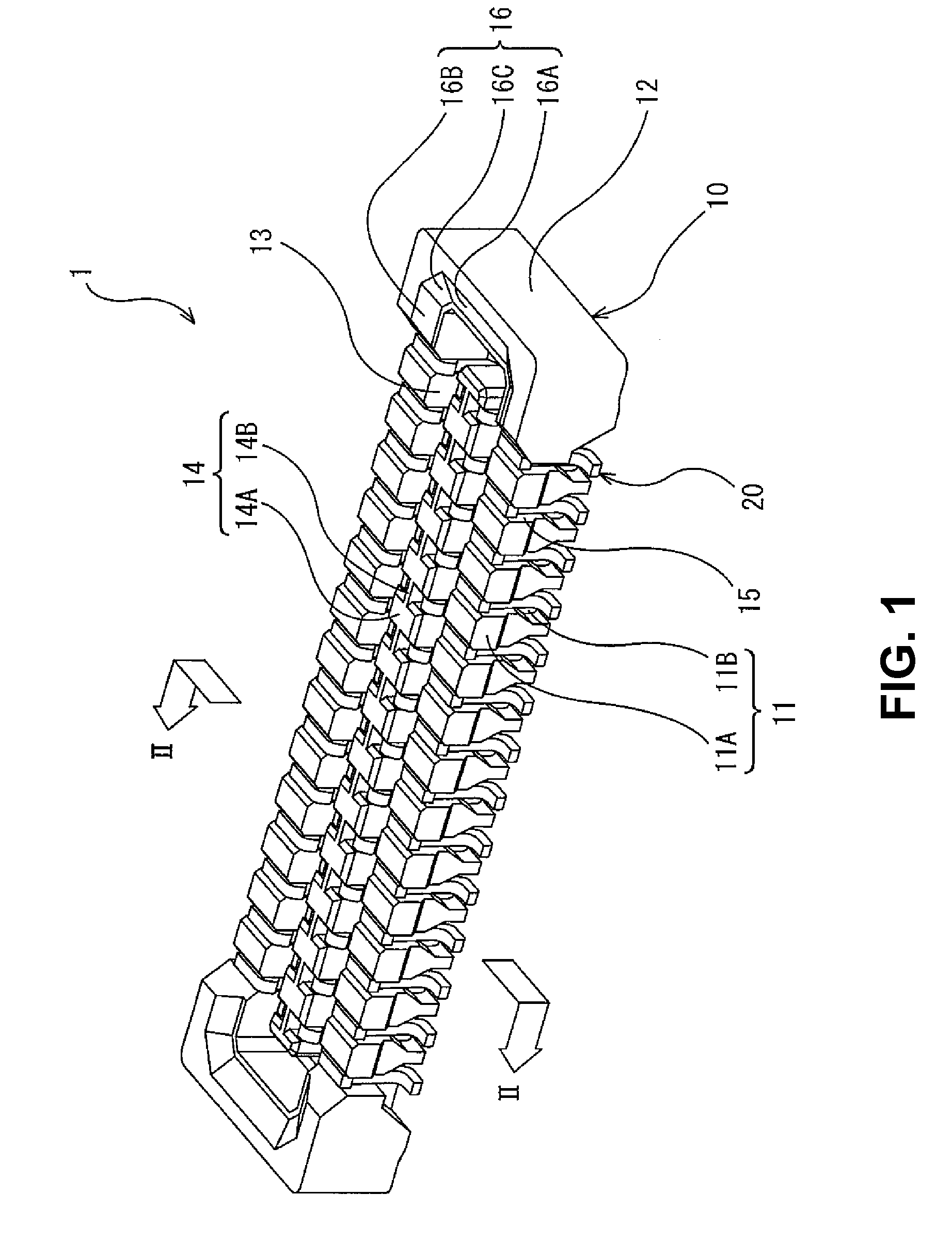

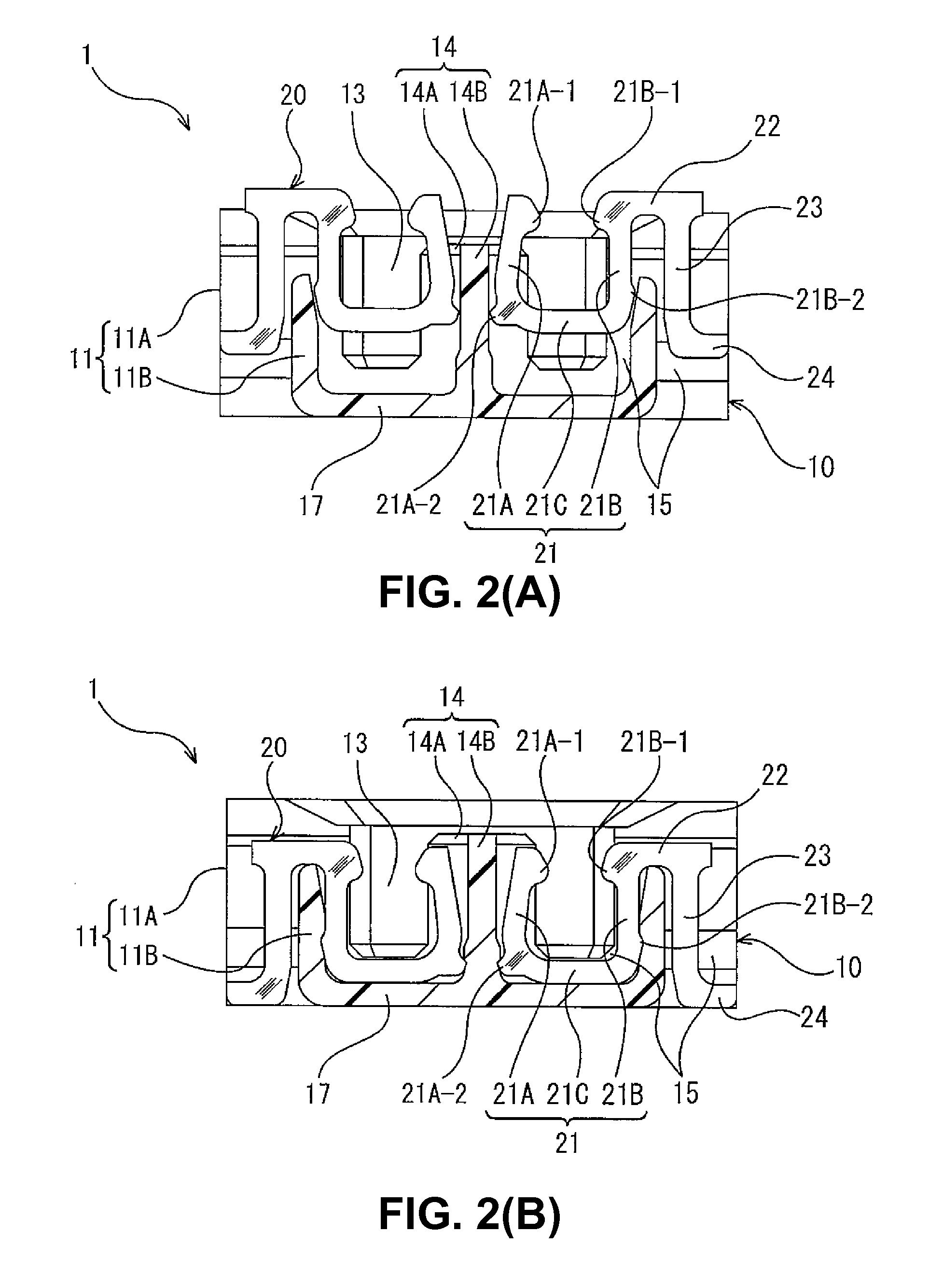

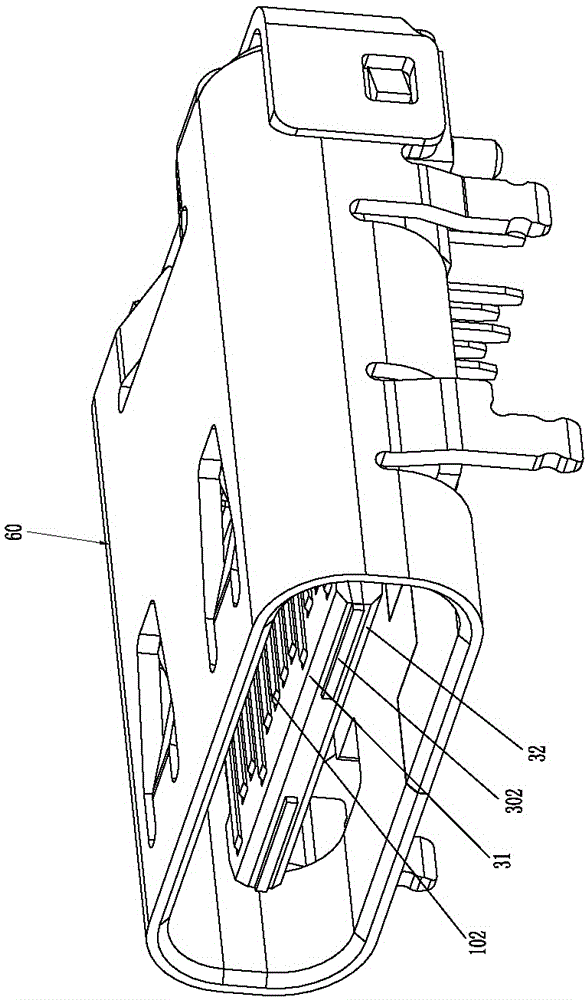

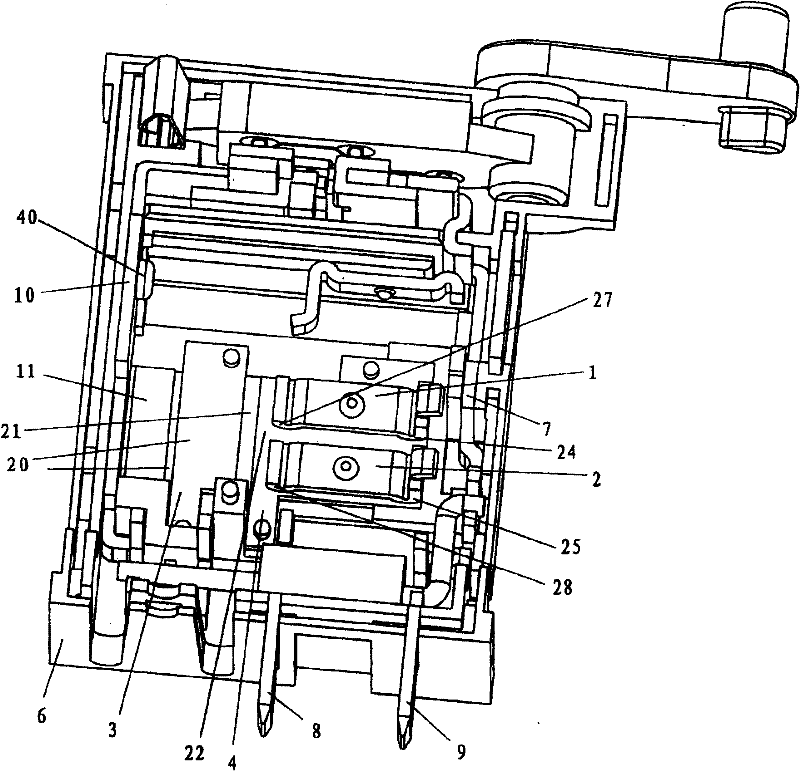

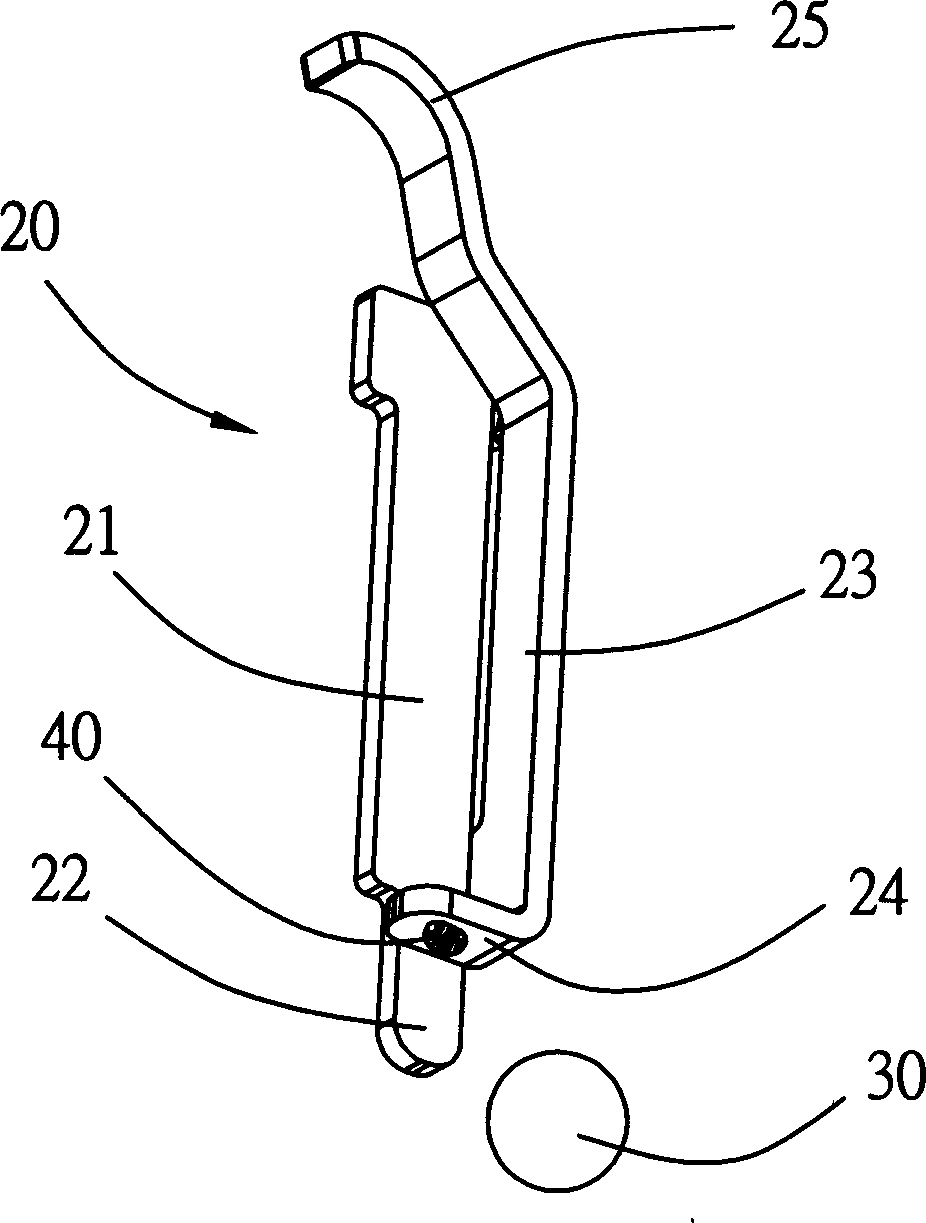

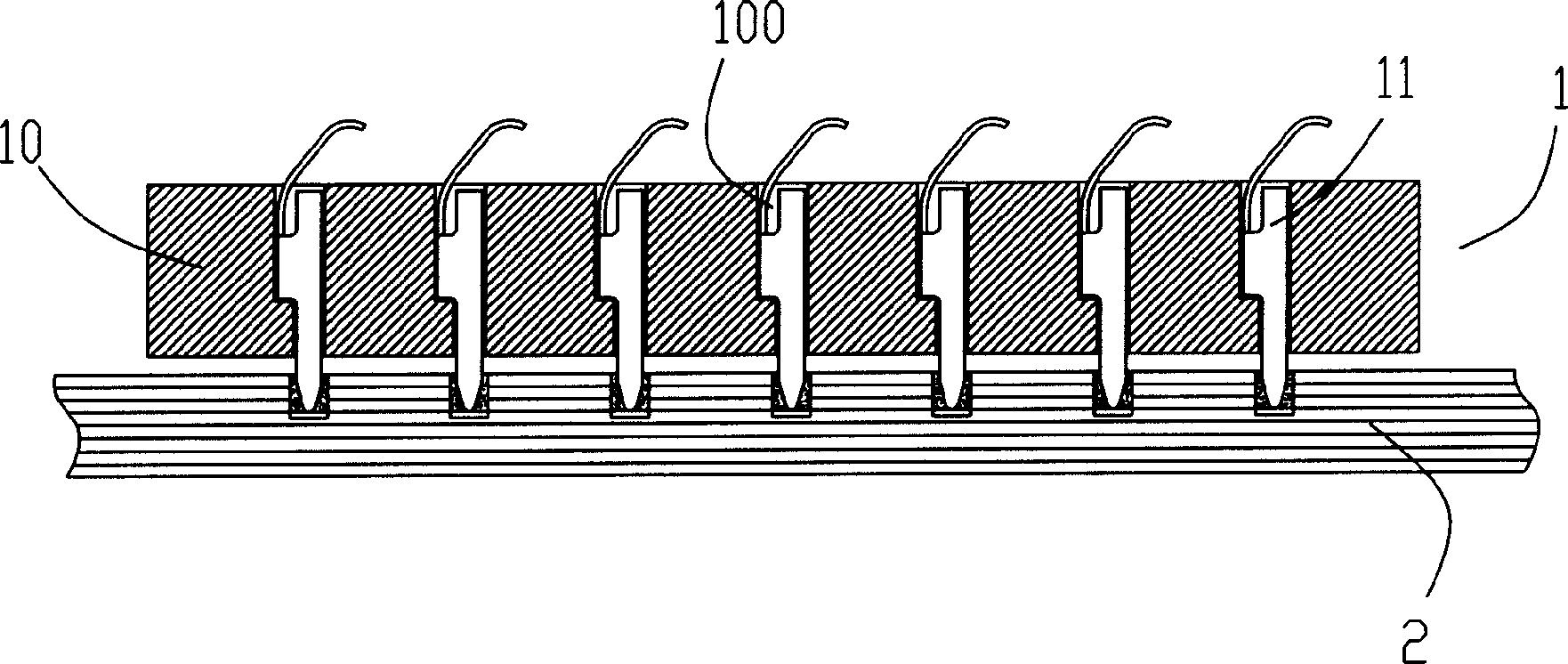

Electrical connector

ActiveUS20110045708A1Good electrical conductionReduce pressureElectric discharge tubesCoupling device detailsEngineeringMechanical engineering

An electrical connector includes a housing to be disposed on a circuit board, a receiving recess portion formed in the housing for receiving a mating connector, and a terminal arranged in the housing. The terminal includes a U-shape portion, an extending portion extending outside the receiving recess portion a first sidewall facing outside, and a connecting portion. The U-shape portion includes a first arm portion and a second arm portion. The first arm portion is fitted along the sidewall and the second arm portion is fitted along a second sidewall. The first arm portion and the second arm portion include locking portions for being fixed against an inner surface of the receiving recess portion, respectively. The extending portion is arranged to be away from the first sidewall to form a space in between.

Owner:HIROSE ELECTRIC GROUP

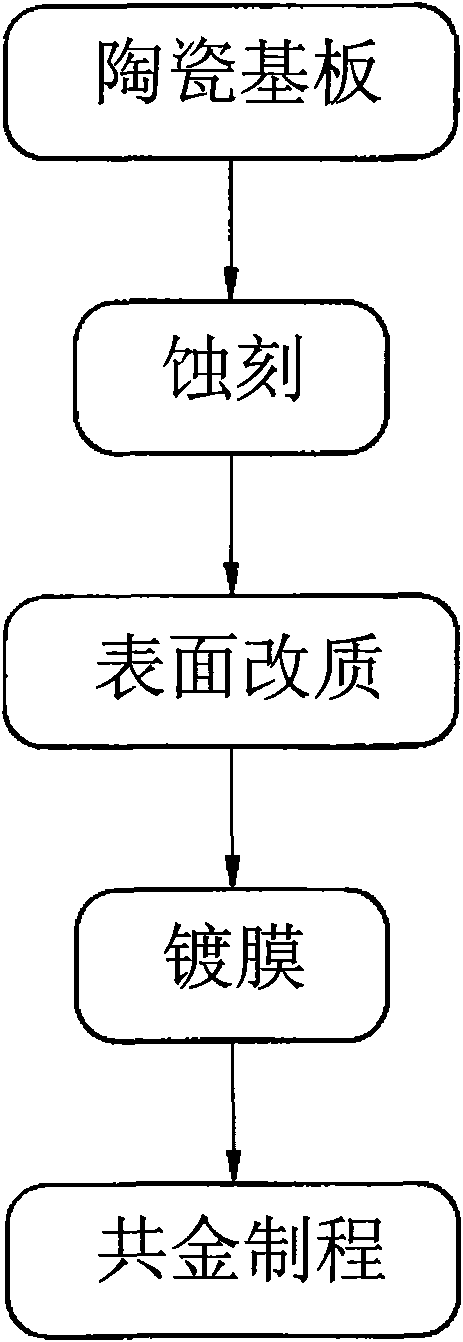

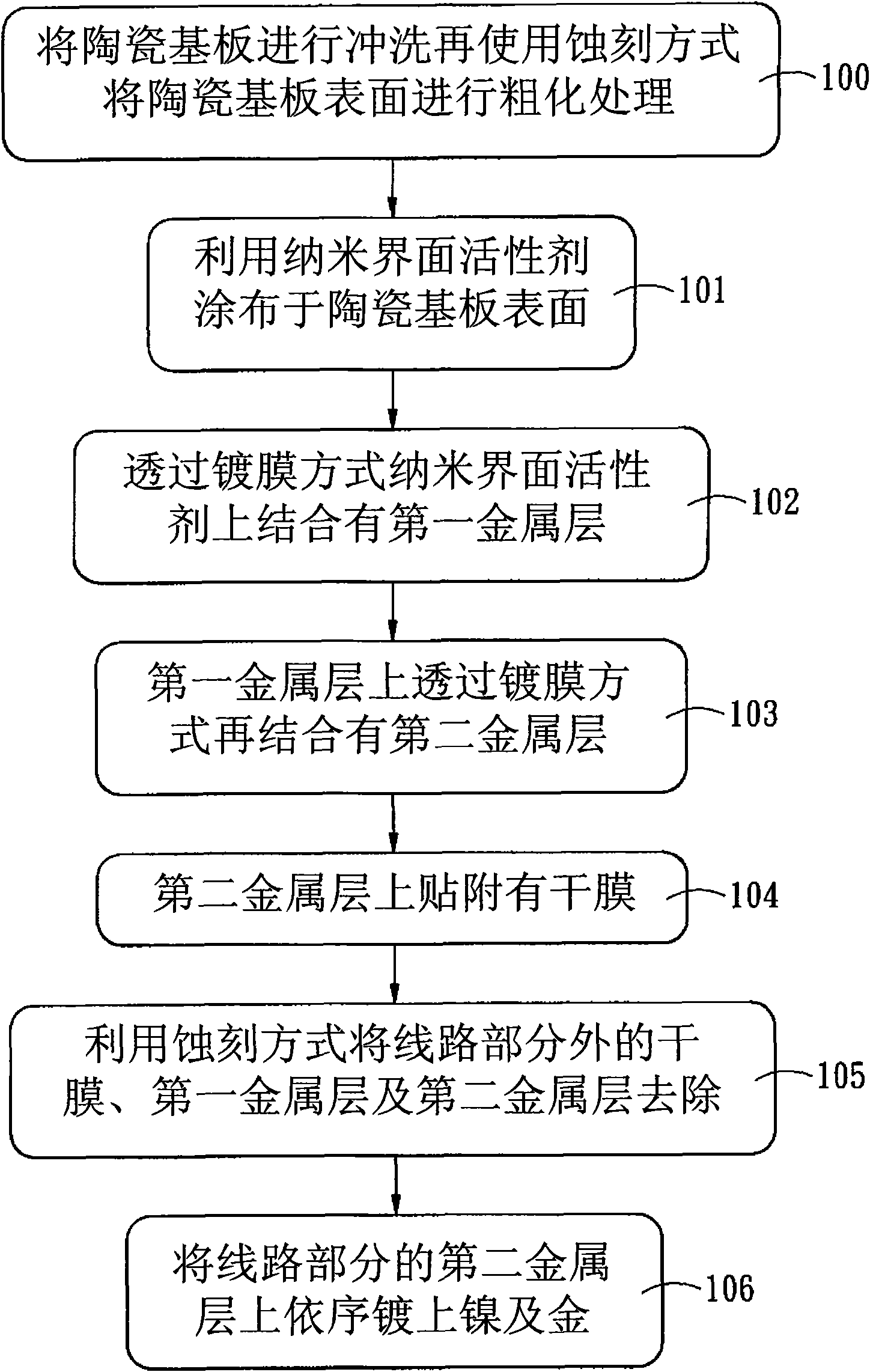

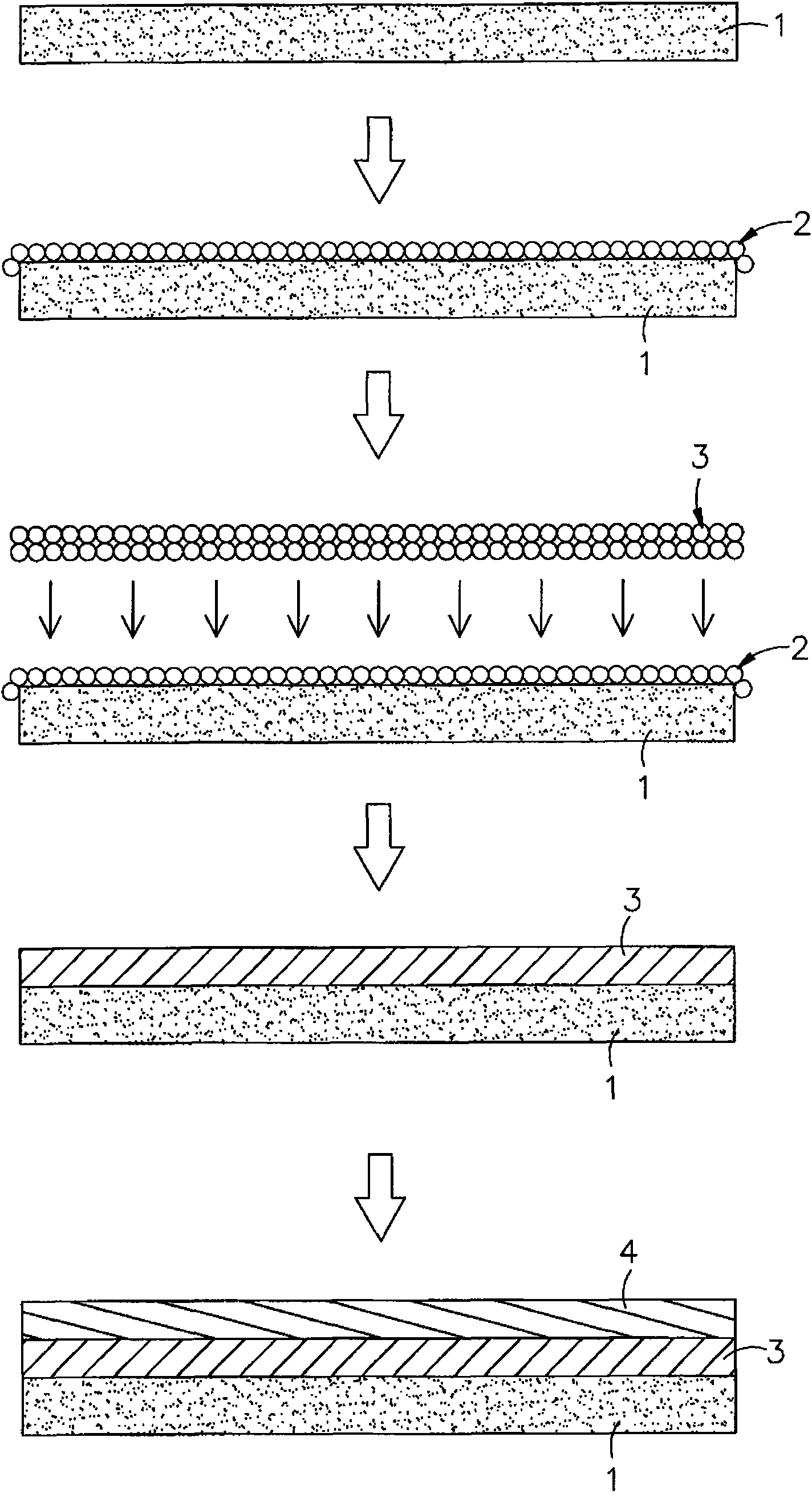

Metallizing manufacturing method of ceramic substrate

InactiveCN102010233AImprove thermal conductivityStrong reliabilityManufacturing cost reductionSURFACTANT BLEND

The invention provides a metallizing manufacturing method of a ceramic substrate, in particular to a film coating manufacturing way utilized because the ceramic substrate is an inorganic substance without any positive and negative electrical property and is very difficult to joint with metal. The film coating manufacturing way comprises the following steps of: firstly cleaning the ceramic substrate; carrying out roughening treatment on the surface of the ceramic substrate in a micro-etching way; and coating nanometer grade Si-containing surfactants on the surface of the ceramic substrate to enable the surface of the ceramic substrate, without electric polarity, to generate negative electrode effect. Therefore, a positively charged first metal layer which has thinner thickness and is easy to joint with ceramic can be deposited on the nanometer grade Si-containing surfactants in the film coating way, and the effect of effectively reducing the manufacturing cost of the ceramic substrate, which has fine heat positively charged, good electrical property, high reliability and strong bonding force, can be achieved.

Owner:HOLY STONE ENTERPRISE

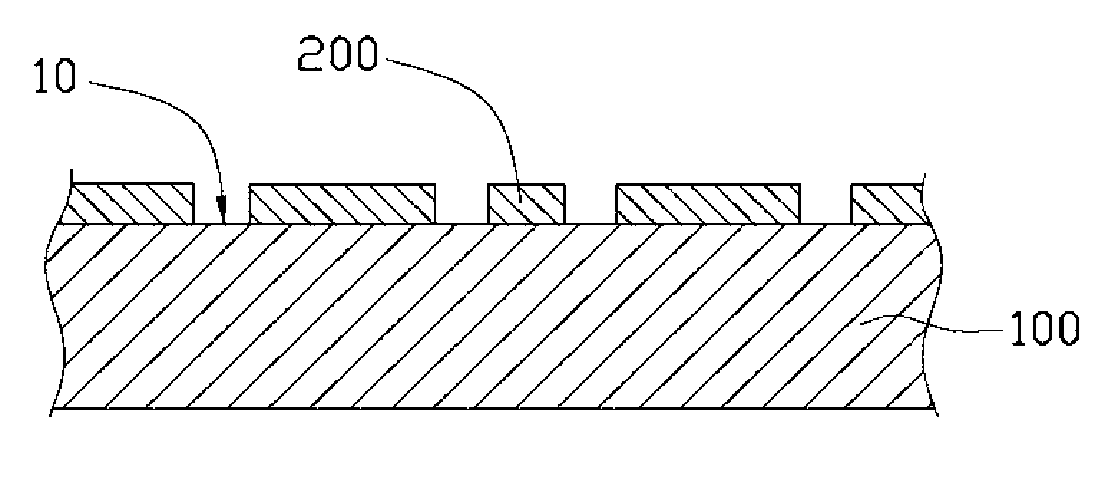

Circuit base plate and manufacturing method thereof

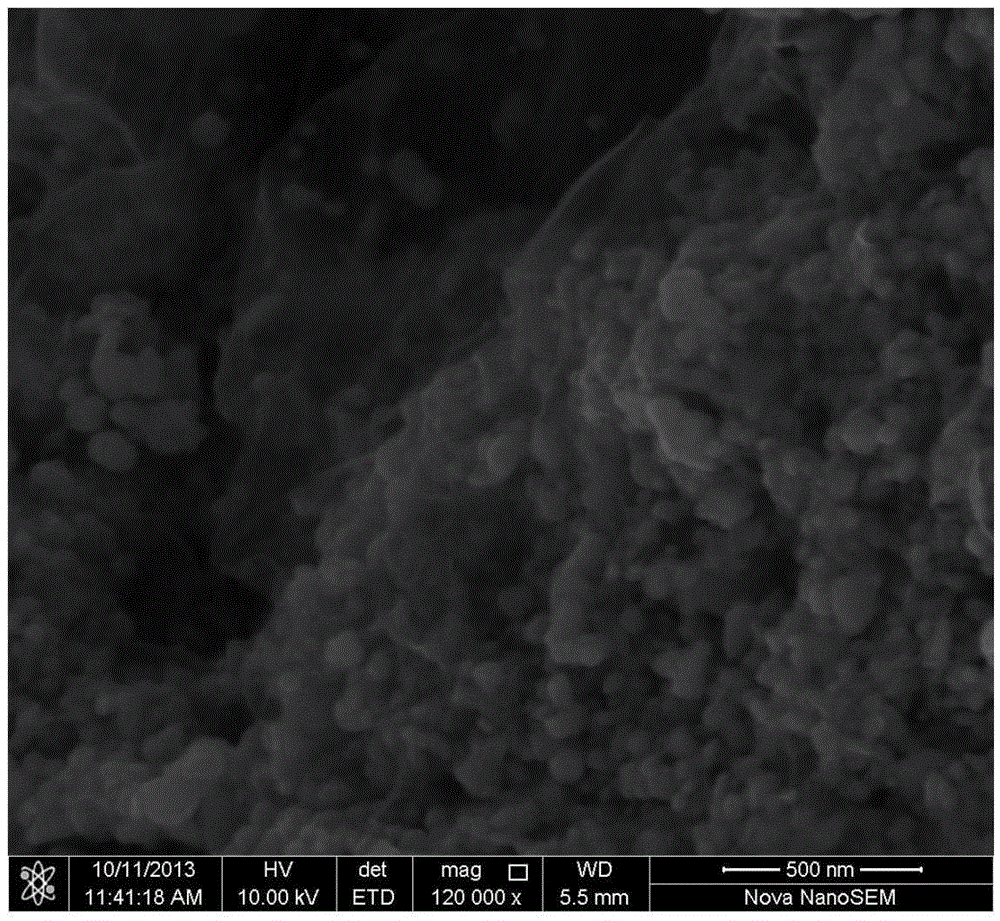

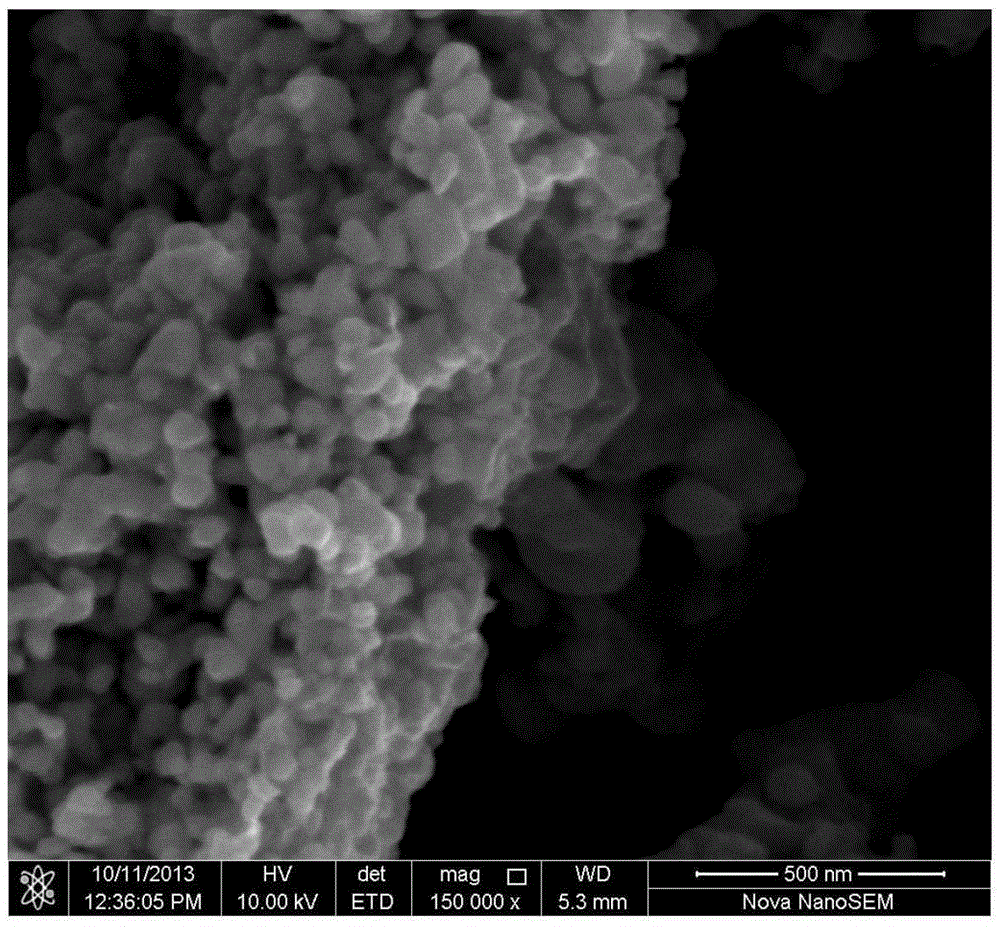

ActiveCN101553084ANot easy to warpInfluence influenceNanoinformaticsPrinted circuit aspectsCarbon nanotubeNanometre

The invention provides a circuit base plate which comprises base materials and a conductive circuit formed on the surface of the base plate, wherein the conductive circuit comprises a compound of a carbon nano tube and metal nano-particles as well as a metal plated on the surface of the compound. The plating metal is filled in a clearance between two adjacent metal nano-particles so as to cause the two metal nano-particles to be completely combined by the metal, thus realizing good electric conduction. The invention also provides a manufacturing method of the circuit base plate. The circuit base plate has good conductivity, and the difference of expanding and shrinkage degree between the conductive circuit and the base materials is reduced.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

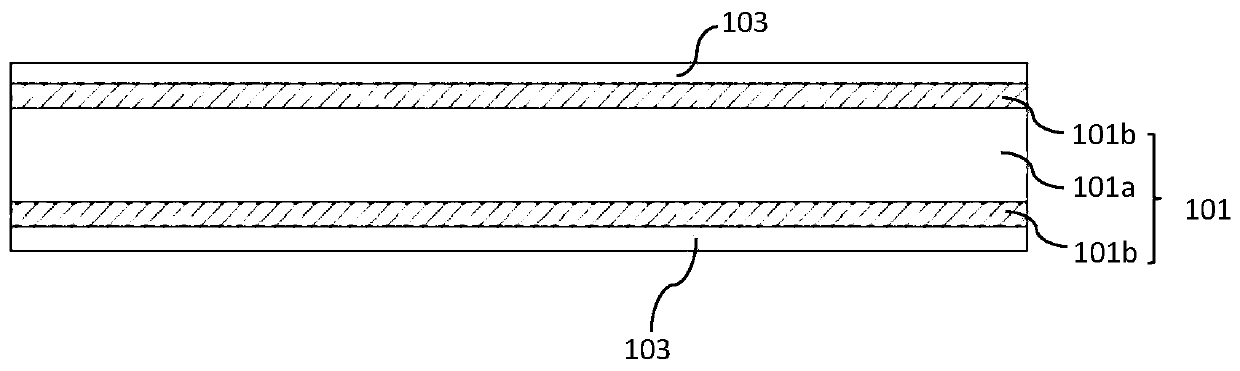

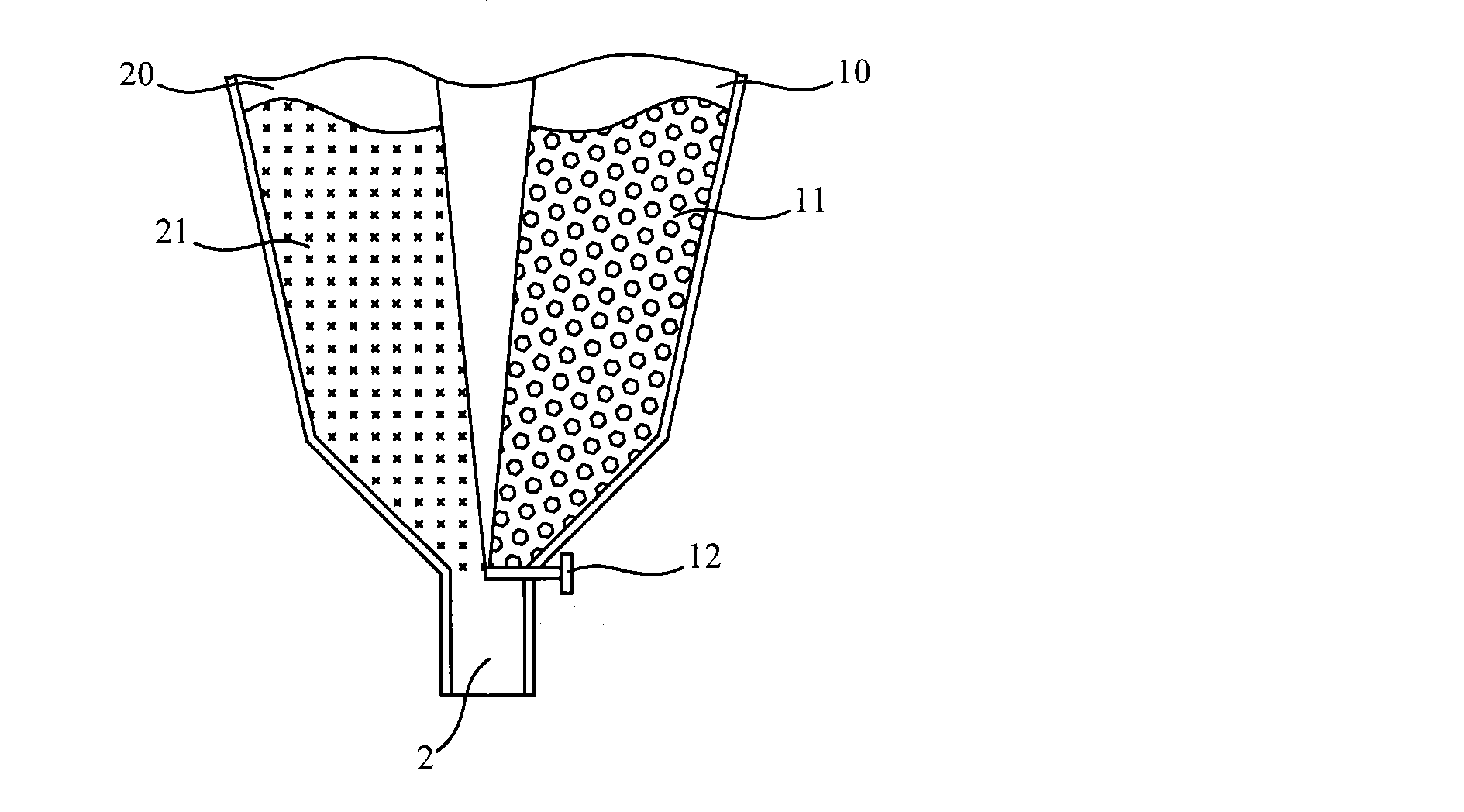

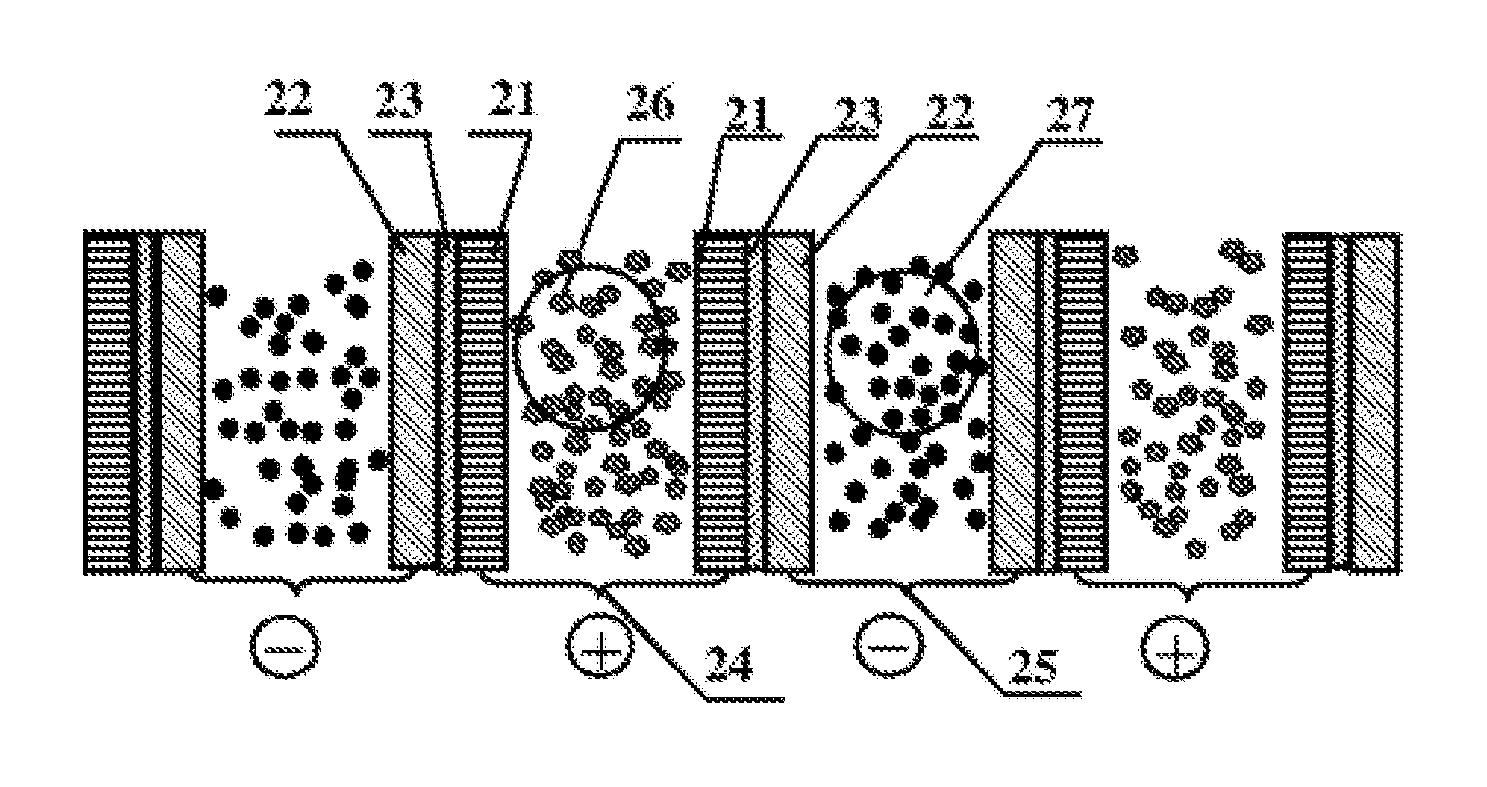

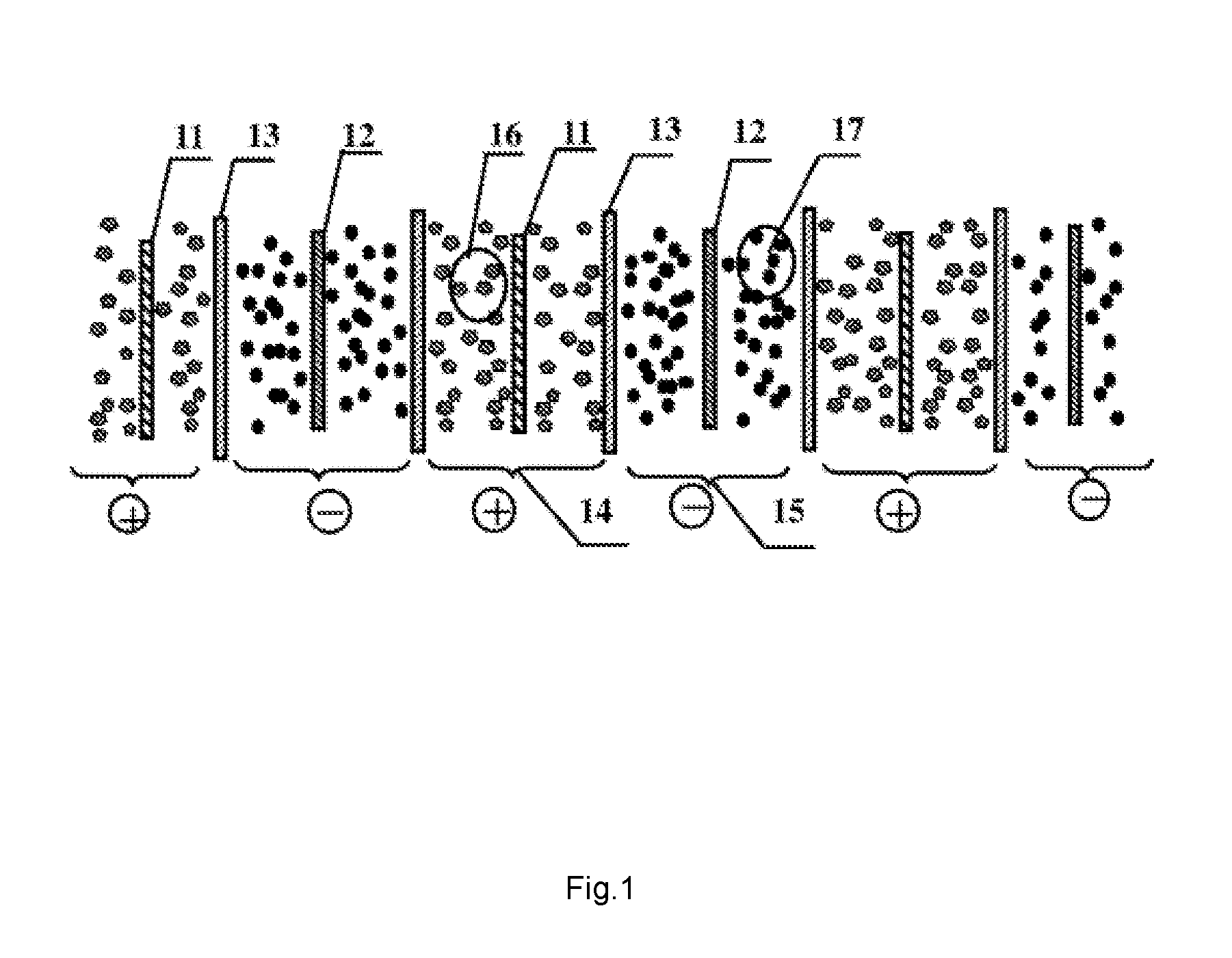

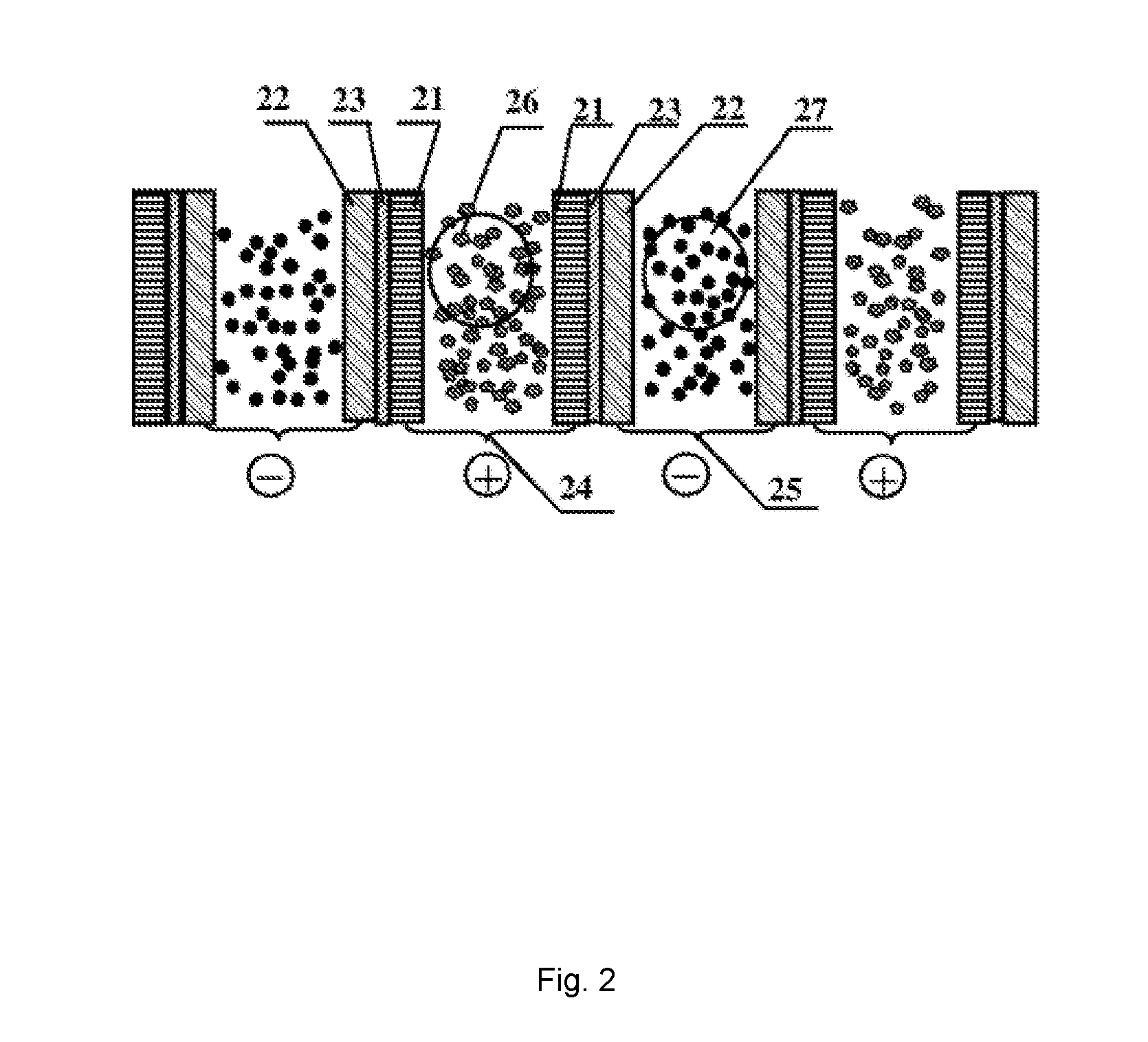

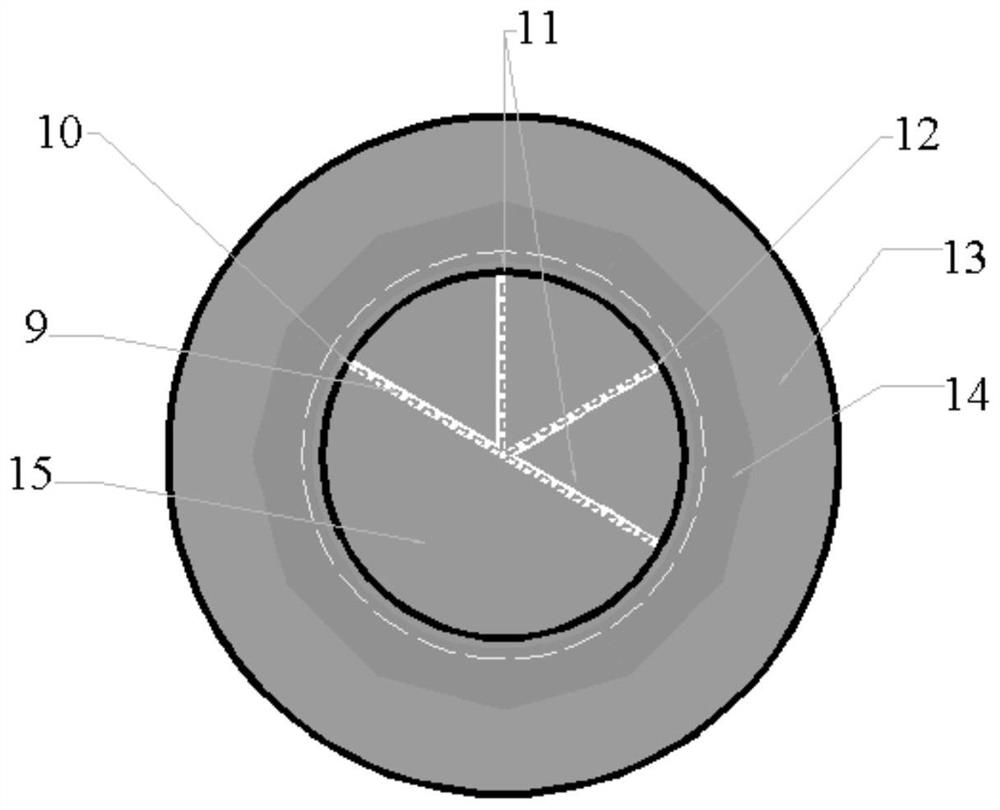

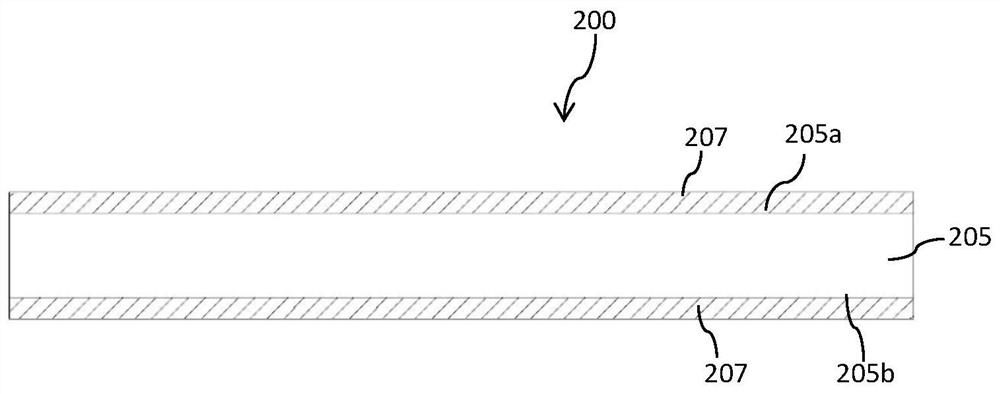

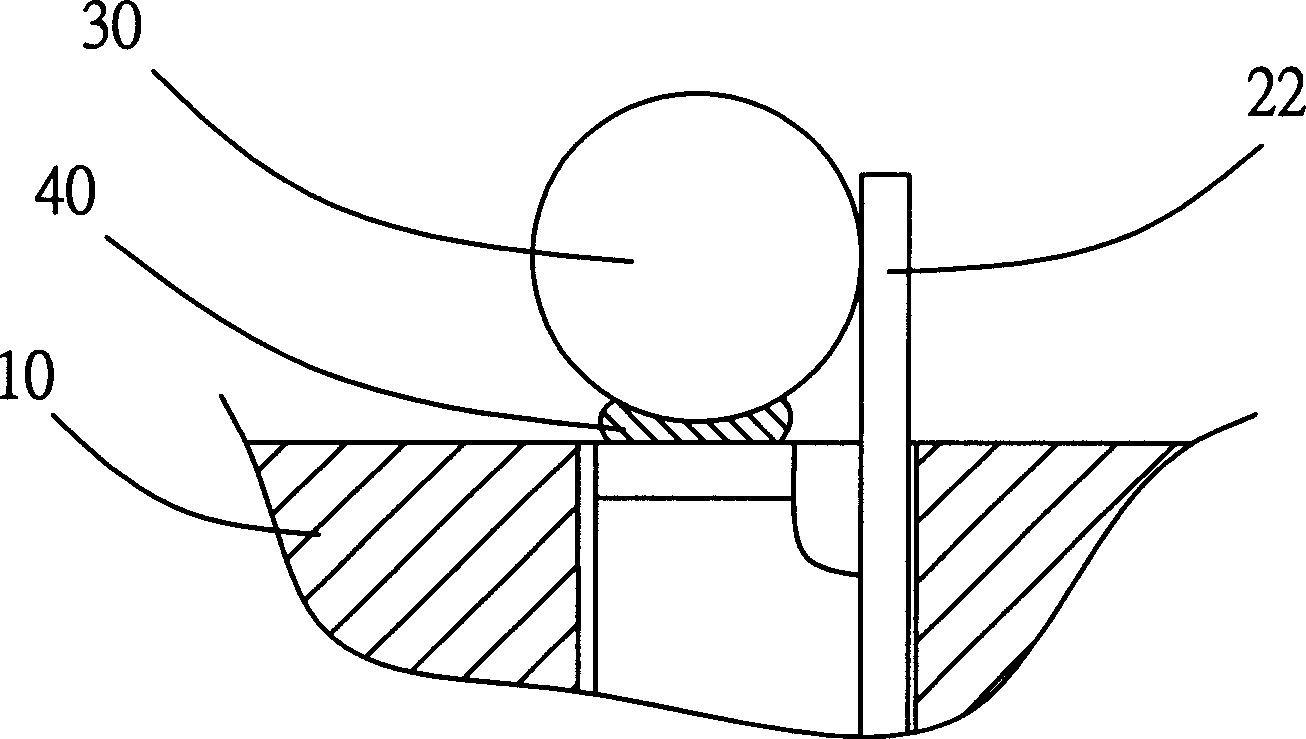

A novel lithium ion flow battery

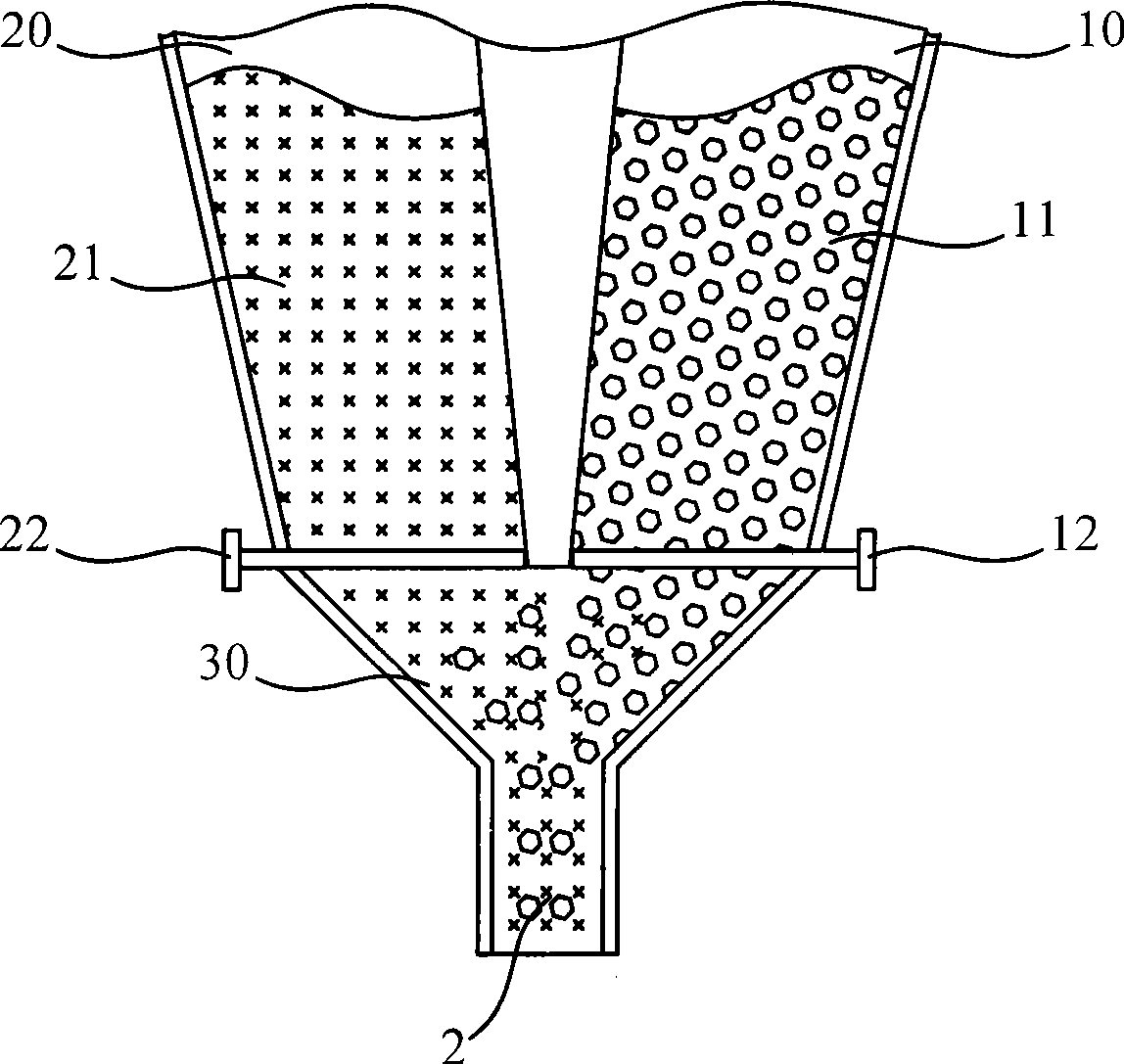

ActiveUS20160329569A1Current is limitedGood electrical conductionElectrolyte holding meansCell electrodesInternal resistanceElectrical polarity

A lithium ion flow battery comprising cathode current collectors (21), an anode current collector (22), a cathode reaction chamber (24), an anode reaction chamber (25), a separator (23), a cathode suspension solution (26) and an anode suspension solution (27), wherein the cathode and anode current collectors are located at both sides of the separator respectively and are in close contact with the separator to form sandwich composite structure layers of the cathode current collector, the separator and the anode current collector; and in that several sandwich composite structure layers are arranged in sequence in an order that current collectors with the same polarity are oppositely arranged, and the electrode suspension solution continuously or intermittently flows in a battery reaction chamber between adjacent sandwich composite structure layers. Thus, the size of the battery reaction chamber can be flexibly designed according to the viscosity of the electrode suspension solution without increasing the polarization internal resistance of the battery, thereby solving the restriction conflict existing in the existing lithium ion flow battery between the size of the battery reaction chamber and the polarization internal resistance of the battery.

Owner:BEIJING HAWAGA POWER STORAGE TECH

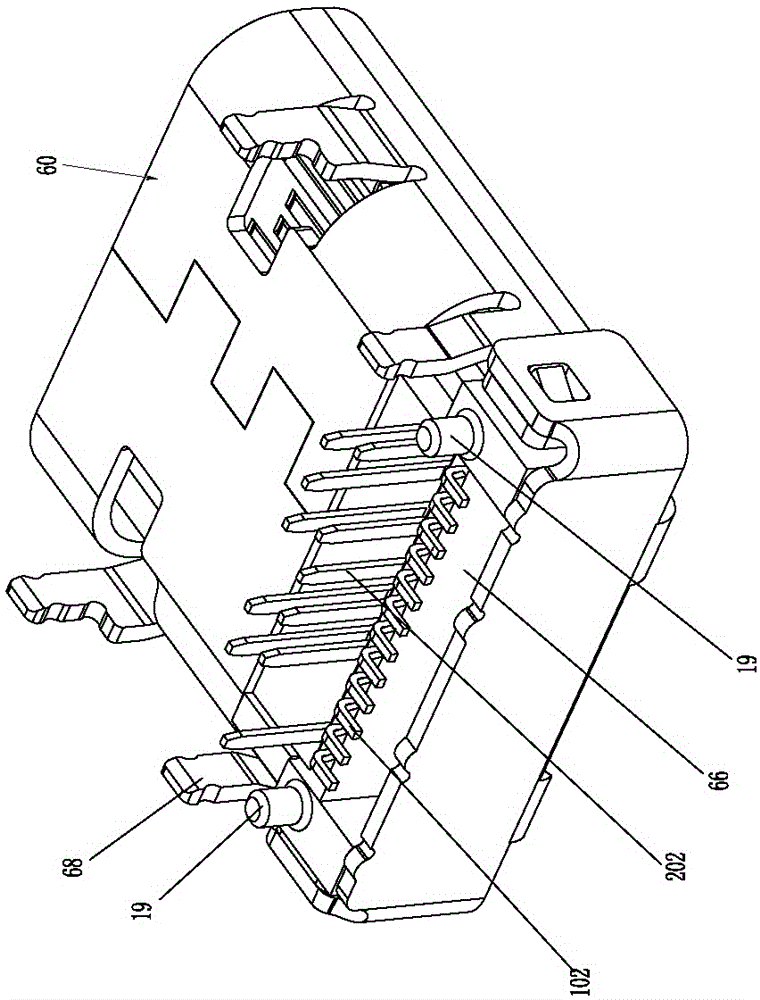

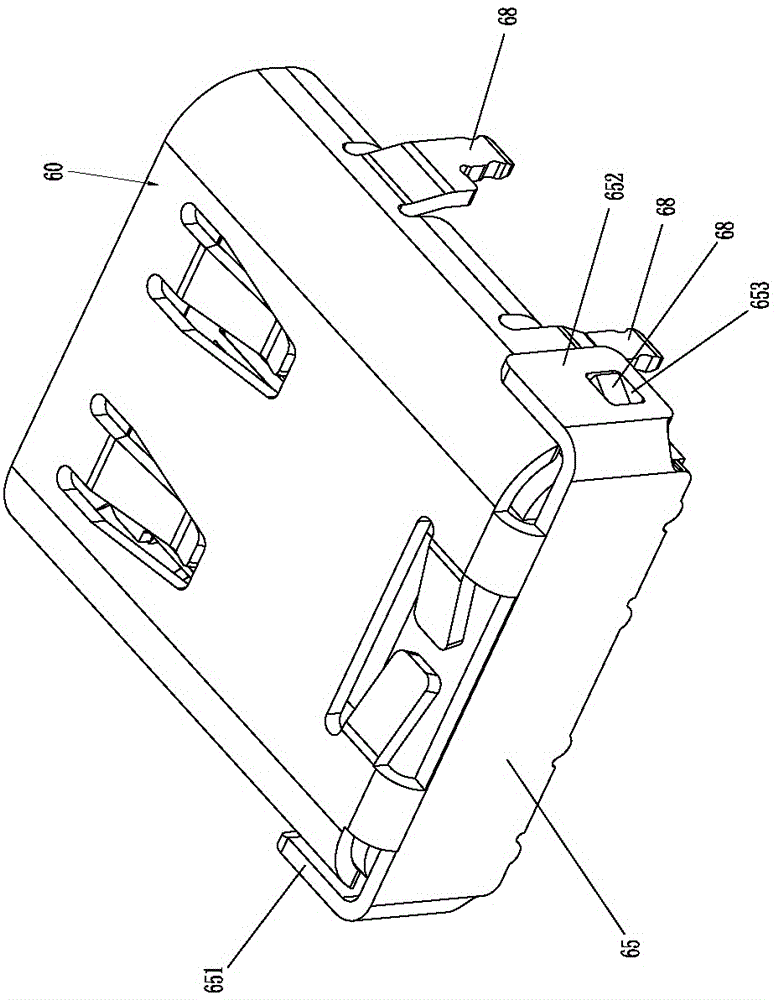

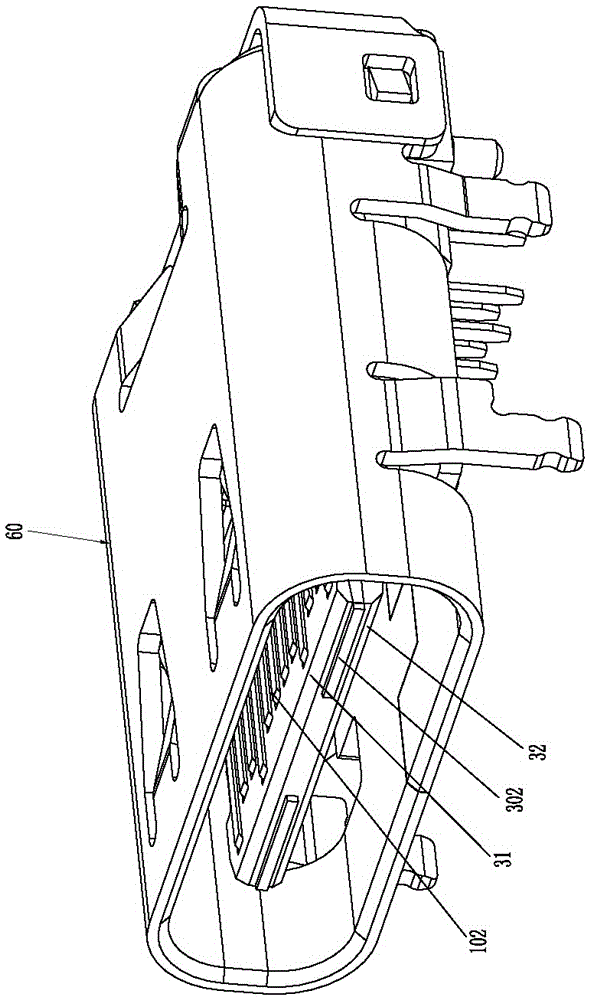

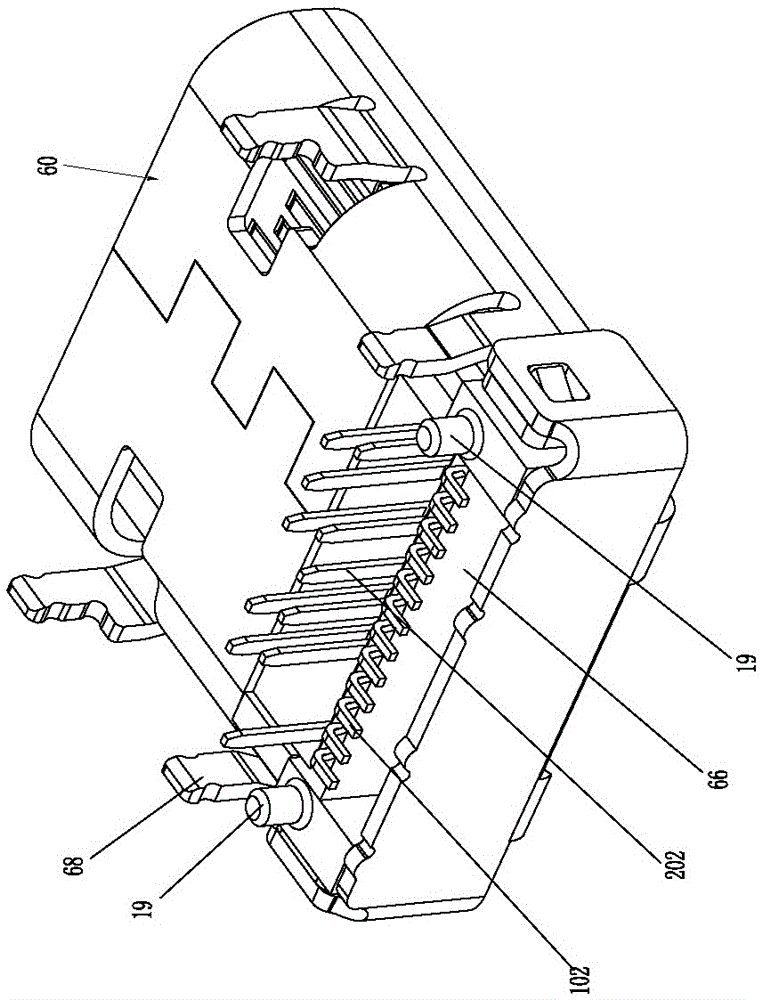

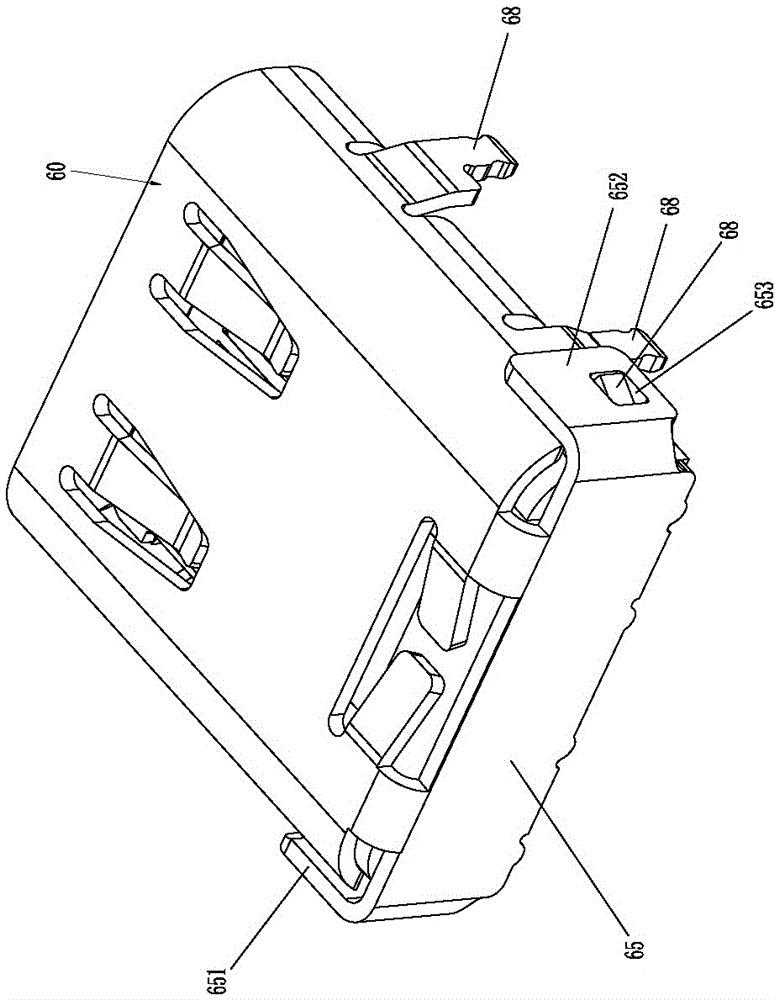

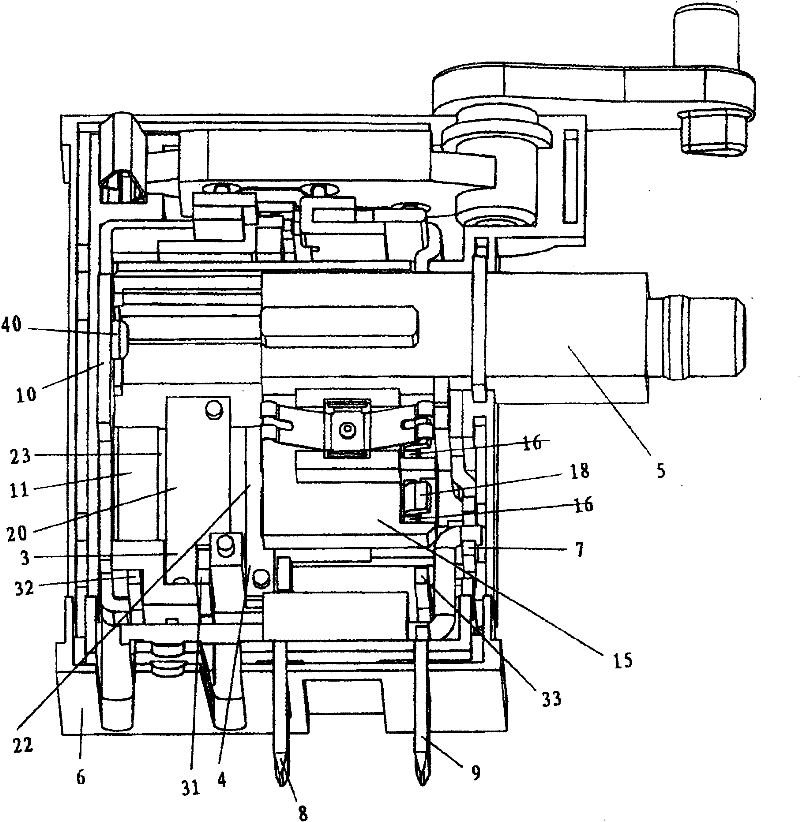

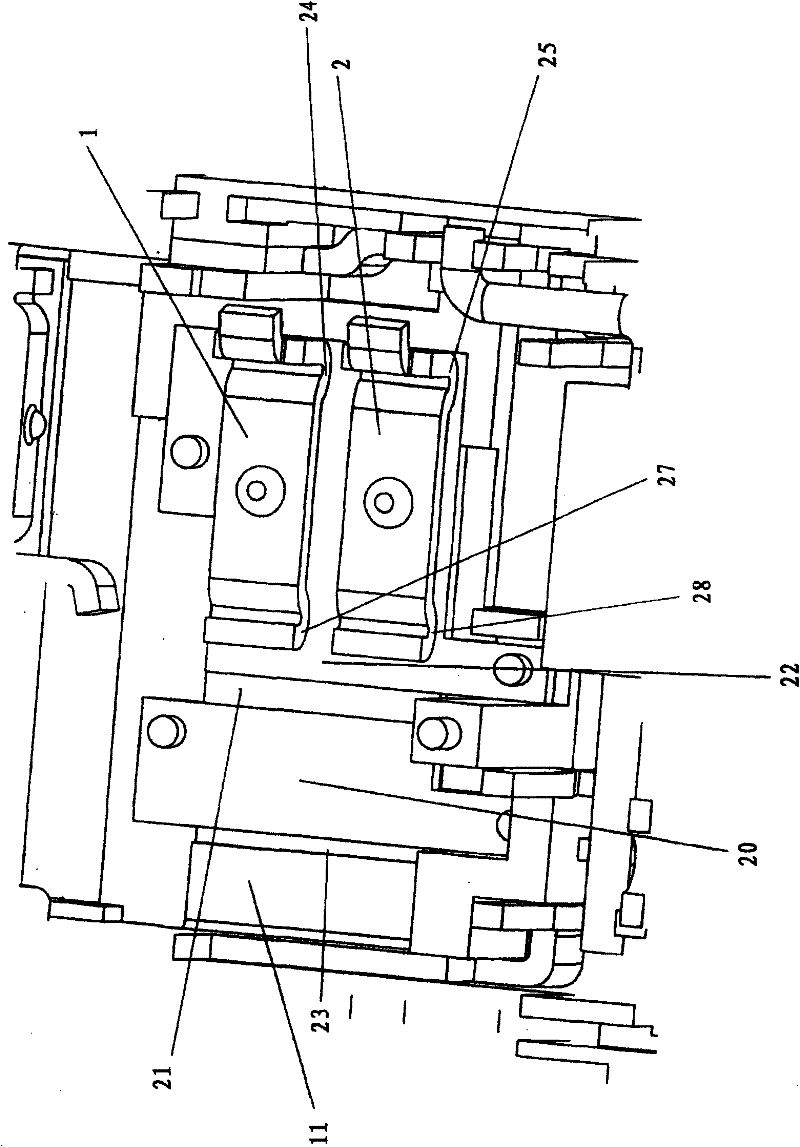

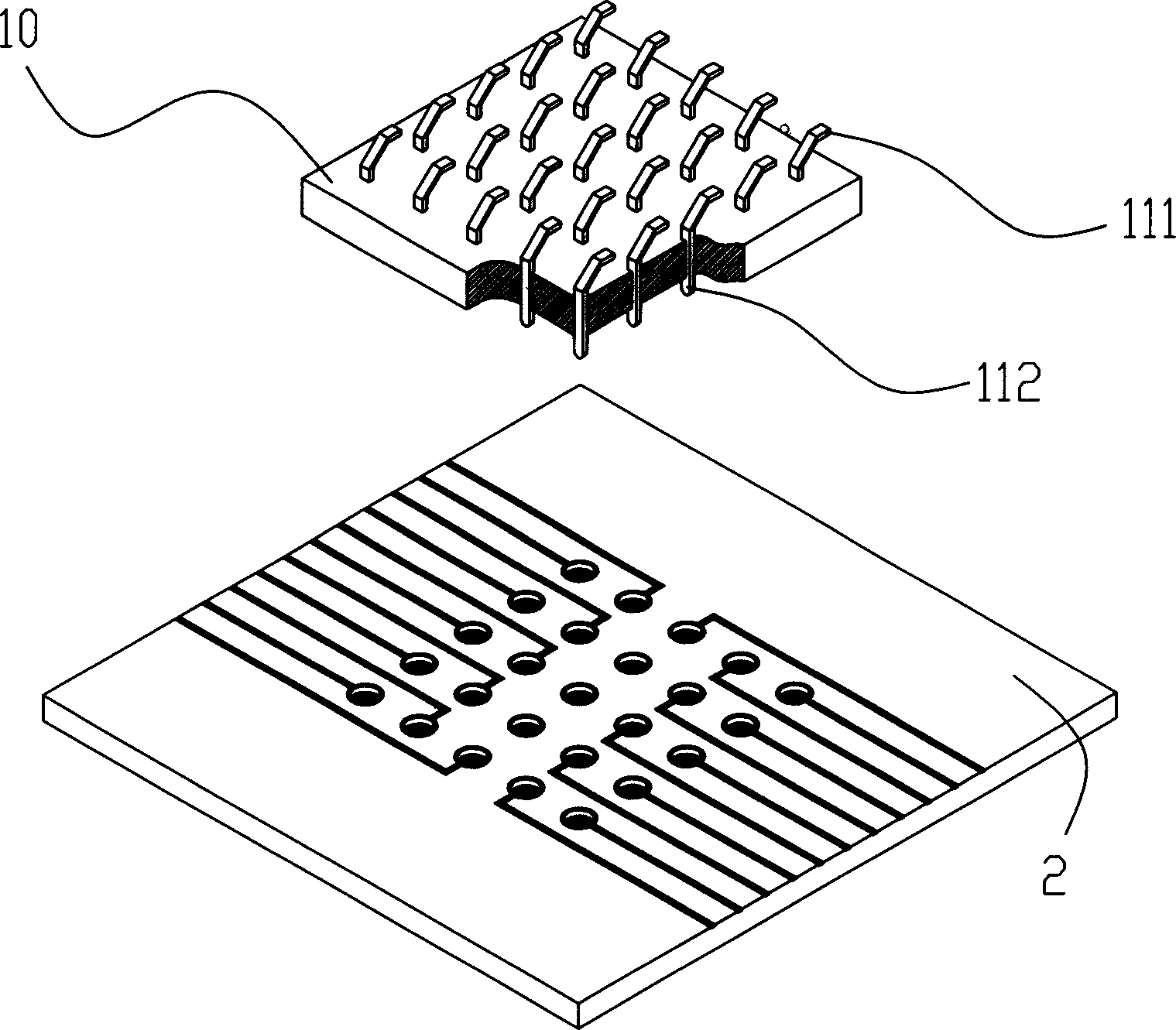

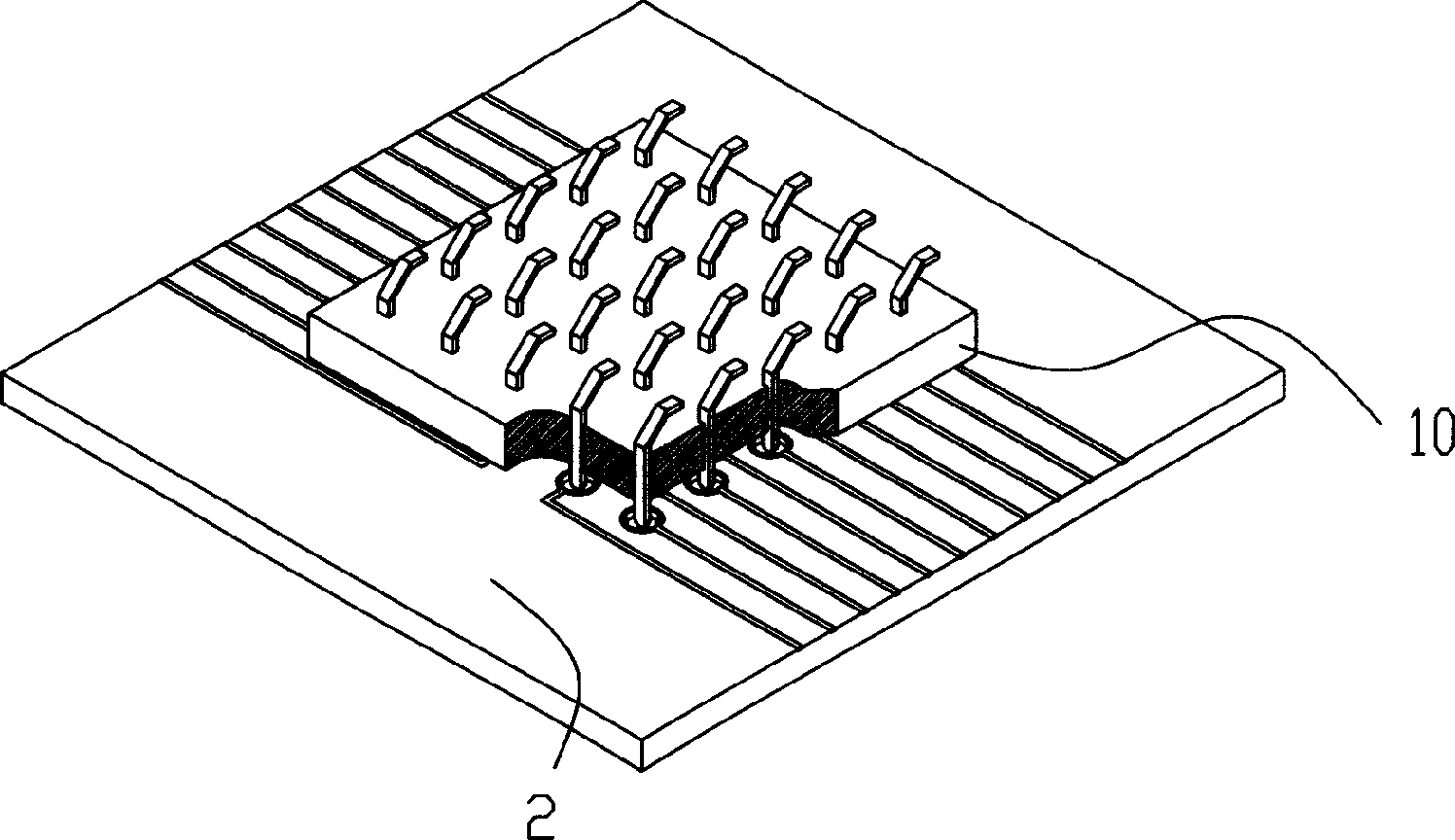

USB3.1 (universal serial bus) connector socket with full-automatic manufacturing process and assembly manufacturing method for USB3.1 connector socket

ActiveCN104953397ARealize fully automated processSimple designContact member assembly/disassemblyCoupling device detailsEngineeringSurface-mount technology

The invention discloses a USB3.1 (universal serial bus) connector socket with a full-automatic manufacturing process and an assembly manufacturing method for the USB3.1 connector socket. The connector socket comprises an SMT (surface mount technology) terminal module, a DIP (double in-line package) terminal module, a separator module, an upper EMI (electro-magnetic interference) sheet, a lower EMI sheet and a shielding case; the SMT terminal module, the DIP terminal module and the separator module are superposed vertically; the SMT terminal module, the DIP terminal module and the separator module are assembled and positioned by buckling the upper EMI sheet and the lower EMI sheet to form an inner core whole, and then, the shielding case covers the inner core whole to form the connector socket product. The USB3.1 connector socket is simple in structure and skillful and reasonable in design; the full-automatic manufacturing process of the whole connector socket product is effectively realized, so that the production efficiency is greatly increased; the processing quality is easy to control in the manufacturing process of the connector socket, so that the product quality and the product yield are improved; moreover, through a special structural design of the upper EMI sheet, the lower EMI sheet and the separator of the USB3.1 connector socket, not only is steady assembly and positioning ensured but also good electrical conduction is ensured; the anti-EMI effect of the USB3.1 connector socket is better than that of a connector in the traditional technology.

Owner:SHENZHEN LITKCONN TECH

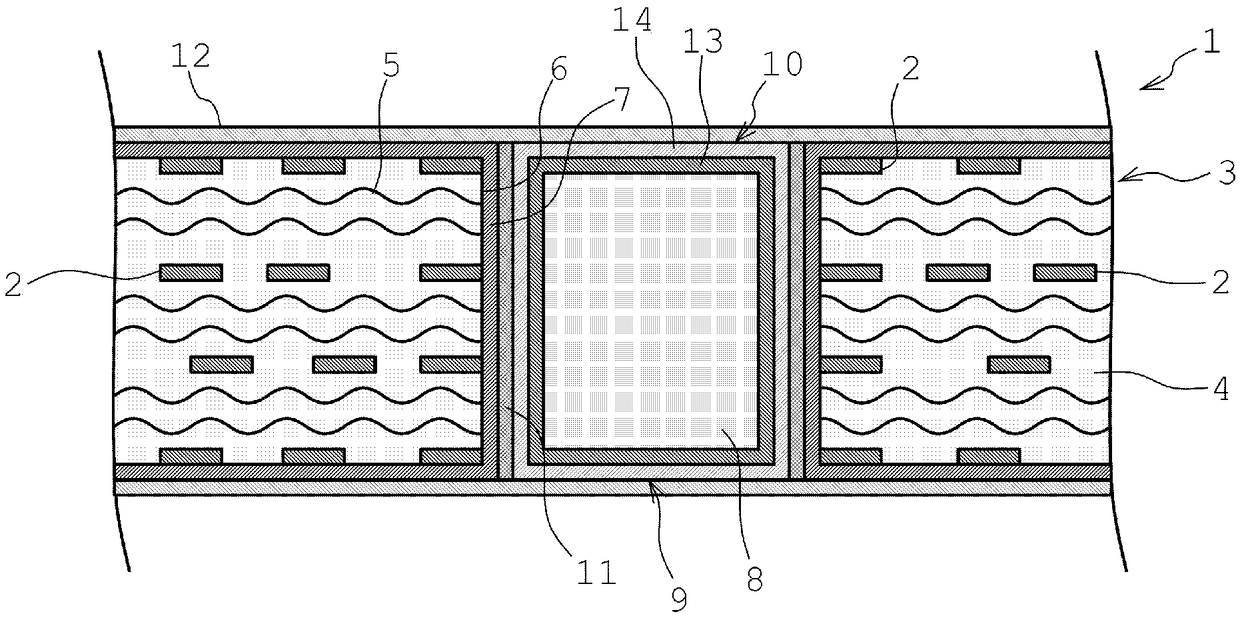

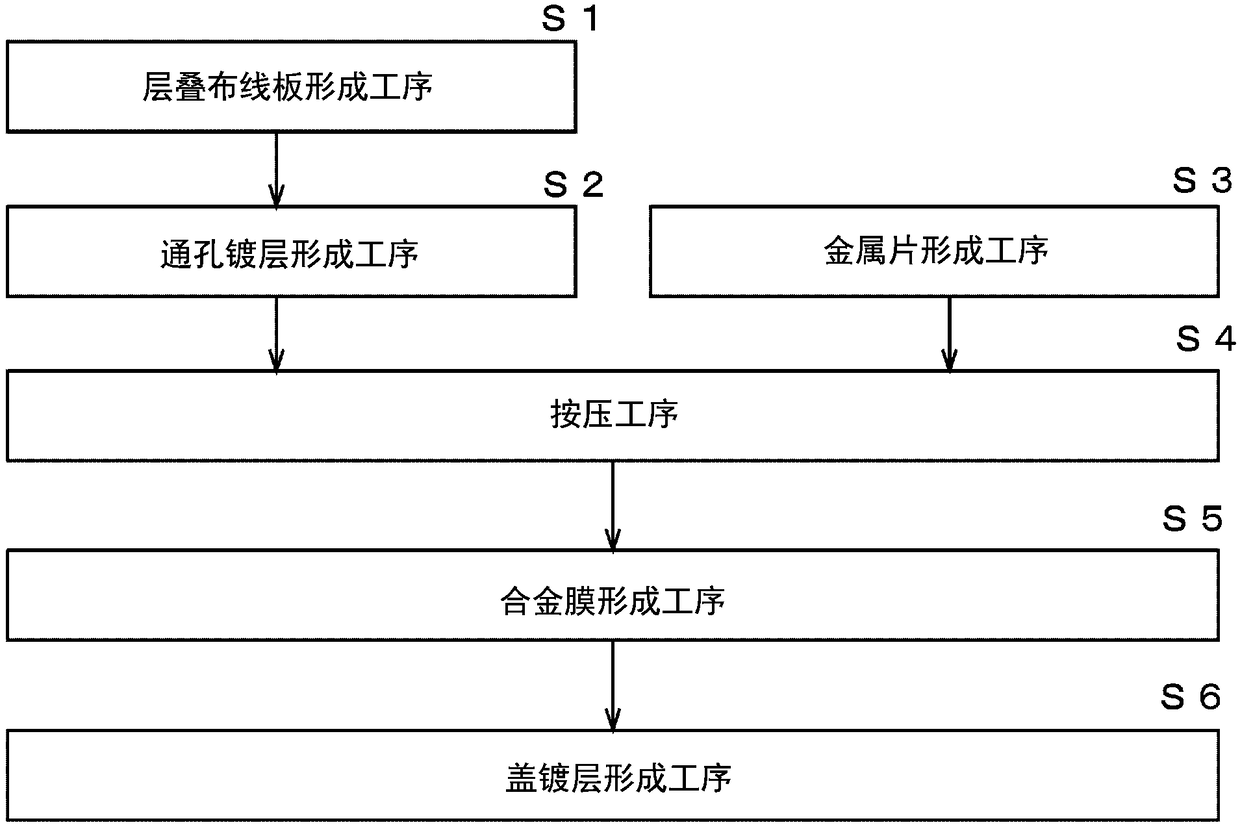

Substrate and method for manufacturing substrate

InactiveCN108353498AEasy to integrateInhibit sheddingElectrical connection printed elementsMultilayer circuit manufactureAlloyEngineering

A substrate (1) is provided with: a laminated wiring board (3) on which a plurality of conductive layers (2) are formed; a through hole (6) formed by penetrating the laminated wiring board (3); a through hole plating (7), which covers the inner wall of the through hole (6), and is electrically connected to the conductive layers (2); a metal piece (10), which is disposed on the inner side of the through hole plating (7), and is configured from a core section (8), and a film section (9) covering the whole surface of the core section (8); and an alloy film (11), which is disposed between the filmsection (9) and the through hole plating (7), and is formed of metals which the film section (9) and the through hole plating (7) are respectively formed of.

Owner:MEIKO ELECTRONICS CO LTD

A fully automated manufacturing process usb3.1 connector socket and assembly method thereof

ActiveCN104953397BRealize fully automated processSimple designContact member assembly/disassemblyCoupling device detailsSurface-mount technologyMechanical engineering

The invention discloses a USB3.1 (universal serial bus) connector socket with a full-automatic manufacturing process and an assembly manufacturing method for the USB3.1 connector socket. The connector socket comprises an SMT (surface mount technology) terminal module, a DIP (double in-line package) terminal module, a separator module, an upper EMI (electro-magnetic interference) sheet, a lower EMI sheet and a shielding case; the SMT terminal module, the DIP terminal module and the separator module are superposed vertically; the SMT terminal module, the DIP terminal module and the separator module are assembled and positioned by buckling the upper EMI sheet and the lower EMI sheet to form an inner core whole, and then, the shielding case covers the inner core whole to form the connector socket product. The USB3.1 connector socket is simple in structure and skillful and reasonable in design; the full-automatic manufacturing process of the whole connector socket product is effectively realized, so that the production efficiency is greatly increased; the processing quality is easy to control in the manufacturing process of the connector socket, so that the product quality and the product yield are improved; moreover, through a special structural design of the upper EMI sheet, the lower EMI sheet and the separator of the USB3.1 connector socket, not only is steady assembly and positioning ensured but also good electrical conduction is ensured; the anti-EMI effect of the USB3.1 connector socket is better than that of a connector in the traditional technology.

Owner:SHENZHEN LITKCONN TECH

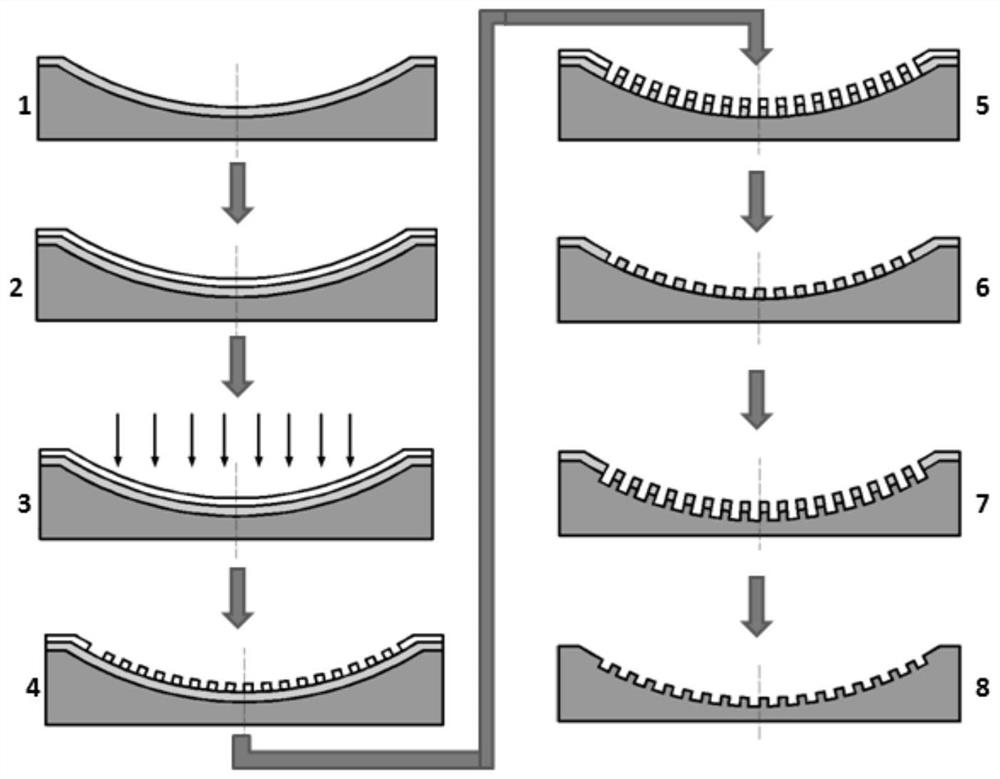

A high-precision etching transfer method for micro-nano structure patterns on curved substrates

ActiveCN111517274BSolve the problem of uneven etching transferPotential consistentMaterial nanotechnologyElectric discharge tubesEvaporation (deposition)Nano structuring

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Switch component

ActiveCN101699594BGood effectVoltage polarity is differentContact electric connectionContact failureEngineering

The invention particularly relates to a switch and is used to improve the structure at the contact part used for turning on and off in a switch to reduce current in each contact point and total contact resistance. The problem of poor contact at the pin joint position of a pin joint contact rod and a supporting part in the conventional switch is solved by arranging an additional elastic metal plate on the pin joint contact rod. Due to the contact part arranged on a rotary contact device at the position of a forward / reverse conversion mechanism, the total contact area is increased, current in each contact point is further reduced, and the total contact resistance and heat generation between the rotary contact device at the position of the forward / reverse conversion mechanism and an internalinput and an external output are reduced.

Owner:SHANGHAI BAICHENG ELECTRONICS

Battery pole pieces and cells

ActiveCN110061182BImprove securityReduce weightFinal product manufactureElectrode carriers/collectorsPole pieceMechanical engineering

Owner:NINGDE AMPEREX TECH

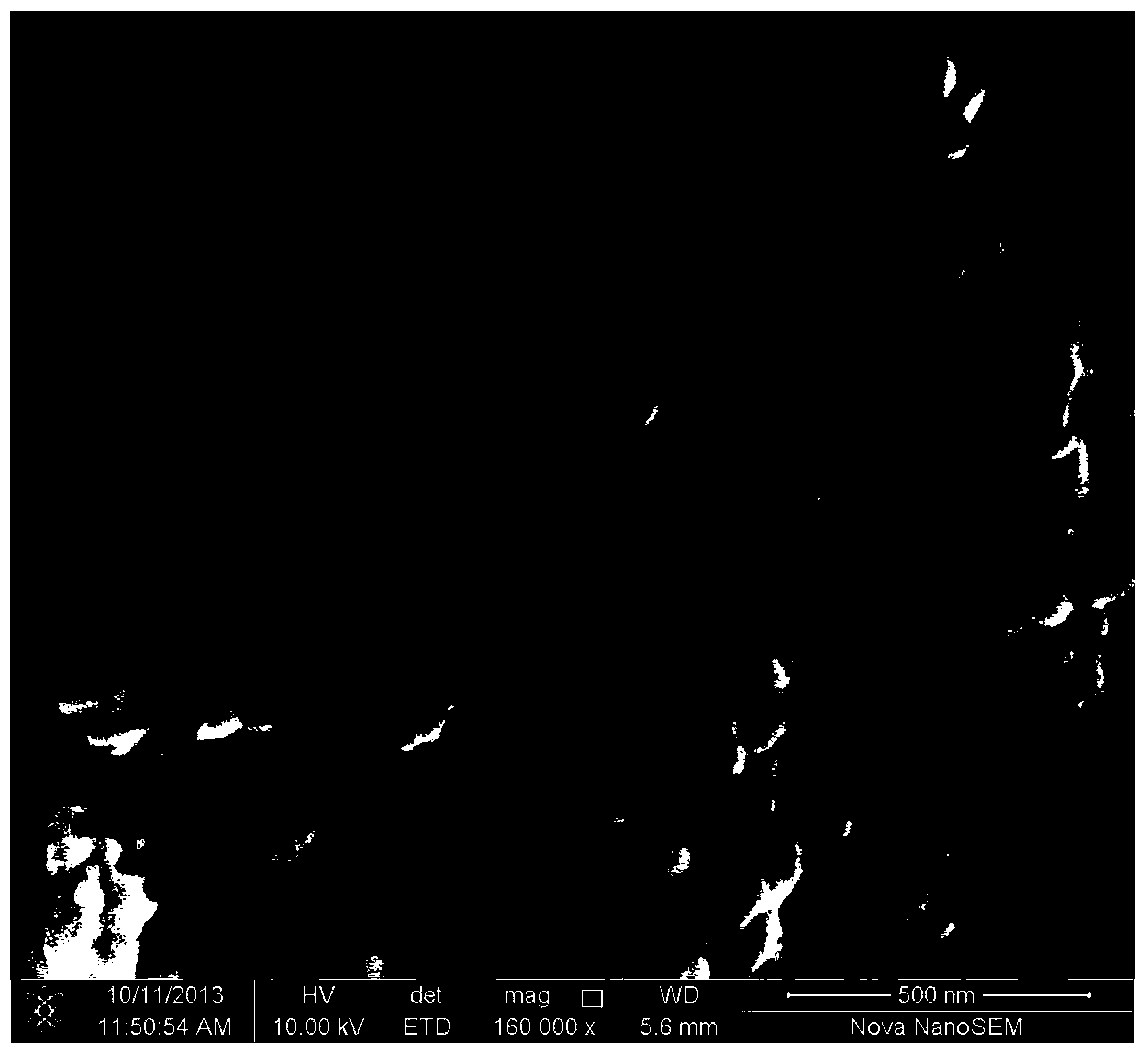

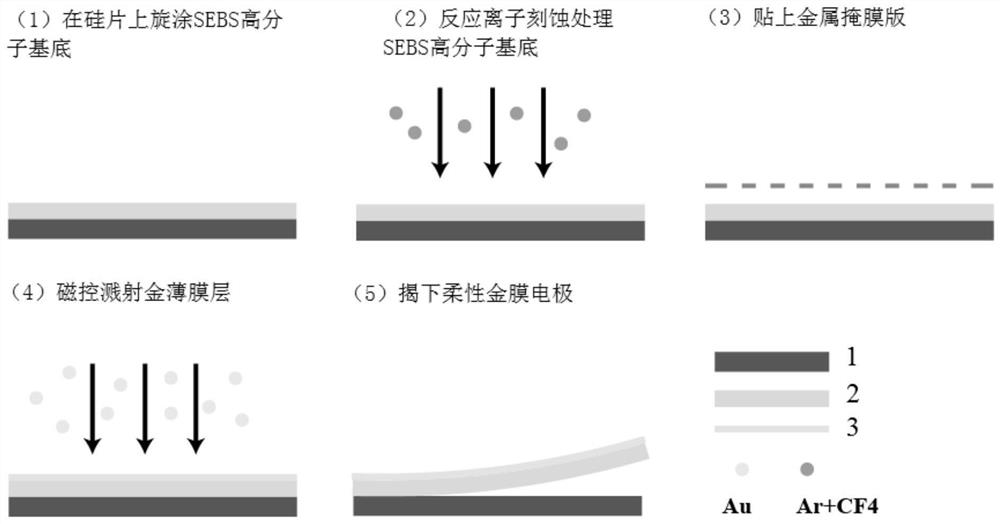

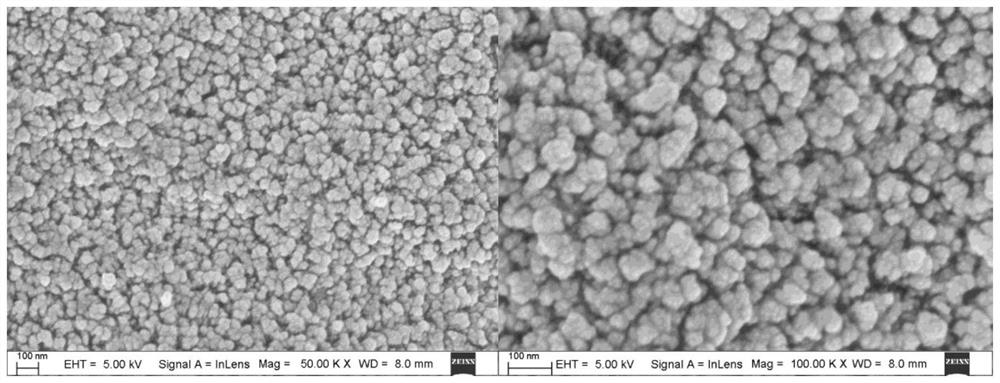

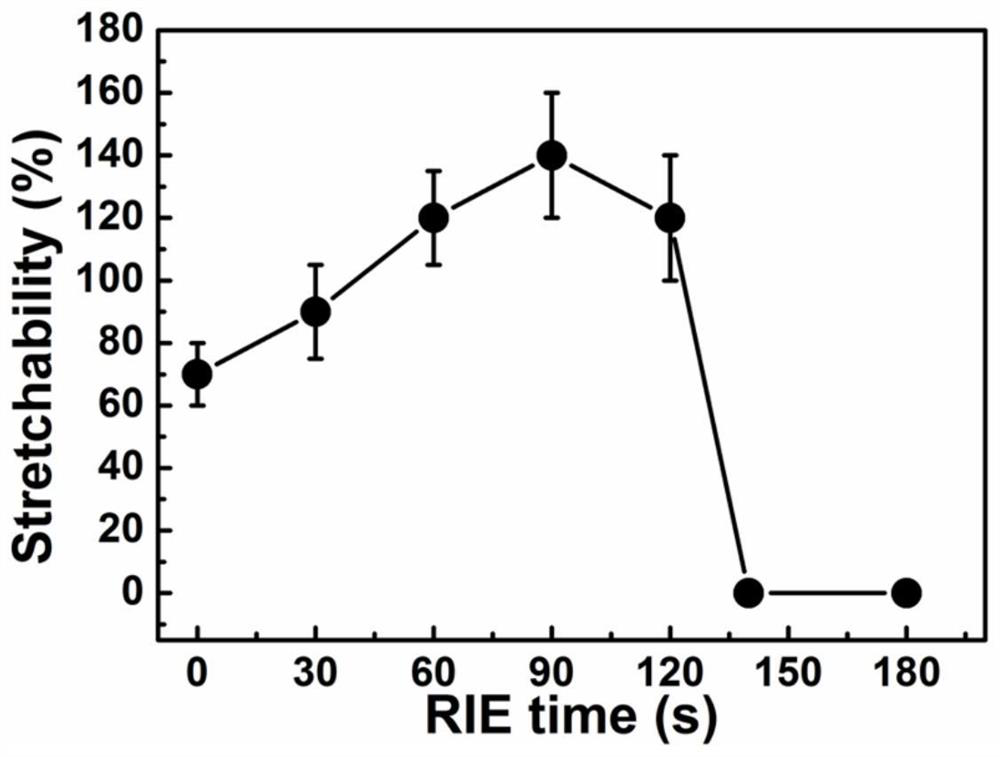

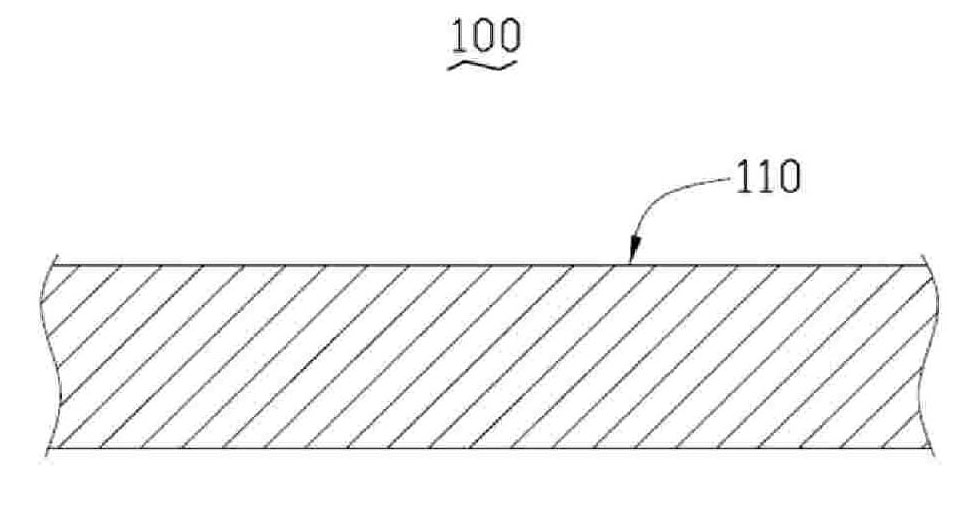

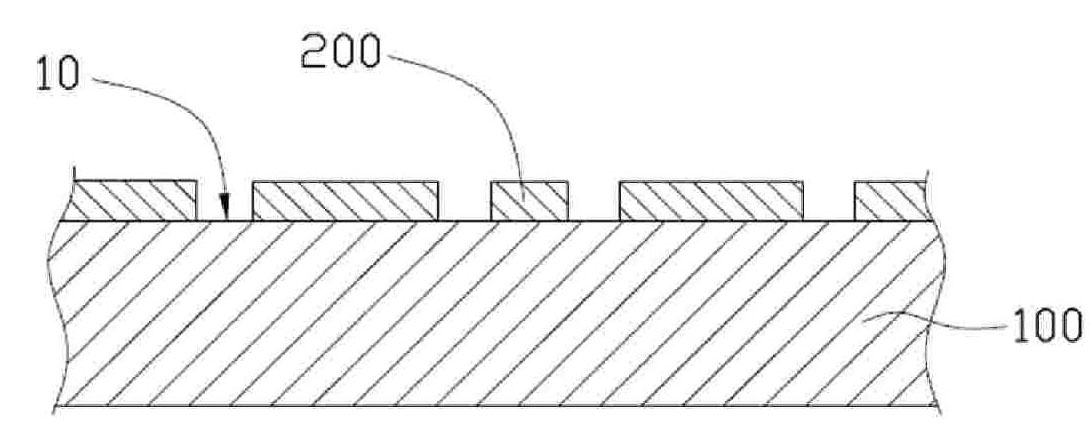

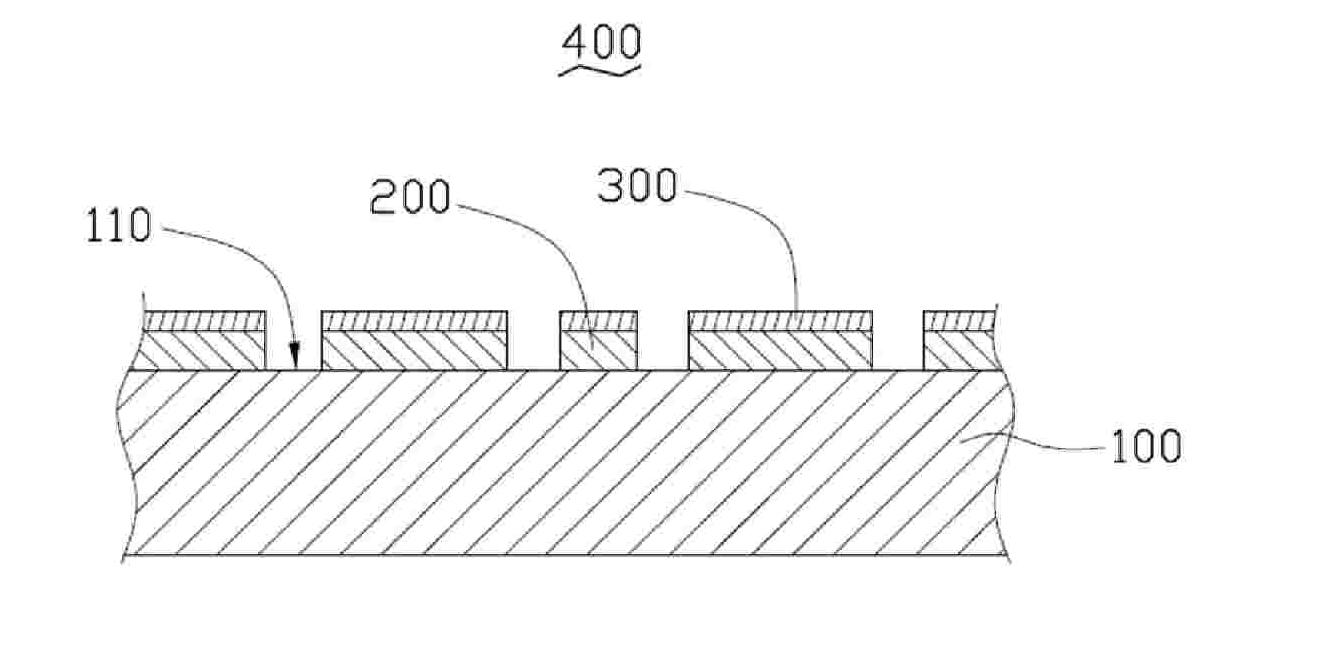

Flexible stretchable gold film electrode based on reactive ion etching and preparation method thereof

PendingCN114107922AGood stretchabilityEnsure electrical continuityVacuum evaporation coatingSputtering coatingSputteringThin membrane

The invention discloses a flexible stretchable gold film electrode based on reactive ion etching and a preparation method thereof, and relates to the technical field of electrode materials. The preparation method comprises the following steps: carrying out magnetron sputtering on the surface of a high-molecular flexible substrate treated by a reactive ion etching process to form a layer of gold film; wherein the thickness of the gold thin film is 10-40 nanometers, and the gold thin film is provided with a crack structure with a micron scale and / or a nano scale. The method is used for improving the tensile property of the flexible gold film electrode.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Circuit base plate and manufacturing method thereof

ActiveCN101553084BNot easy to warpInfluence influenceNanoinformaticsPrinted circuit aspectsCarbon nanotubeNanometre

The invention provides a circuit base plate which comprises base materials and a conductive circuit formed on the surface of the base plate, wherein the conductive circuit comprises a compound of a carbon nano tube and metal nano-particles as well as a metal plated on the surface of the compound. The plating metal is filled in a clearance between two adjacent metal nano-particles so as to cause the two metal nano-particles to be completely combined by the metal, thus realizing good electric conduction. The invention also provides a manufacturing method of the circuit base plate. The circuit base plate has good conductivity, and the difference of expanding and shrinkage degree between the conductive circuit and the base materials is reduced.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

Electrode for generating plasma and plasma processing apparatus using same

ActiveCN101005727BLittle risk of ruptureLess prone to individual differencesMolten spray coatingElectric discharge tubesResistMetal matrix composite

The invention provides an electrode for plasma emergence. In the electrode for plasma emergence set opposed to a base plate and composed by matal base and conductor plate without broken danger of conductor plate, ensuring combination state with good uniformity between electric conduction of matal base and conductor plate and heat conduction in surface. The electrode is composed by following material: dipping metal such as Si in base metal formed by porous multiple ceramics such as silicon carbide, having metal base compound material of junction surface at least opposed to whole processed surface of the base plate; a conductor plate such as CVD-silicon carbide formed by resist plasma material melting connecting on junction surface of the metal base compound material via metal. In this condition, dipping metal in the base metal, melting connecting the conductor plate on the metal base compound material via the metal.

Owner:TOKYO ELECTRON LTD

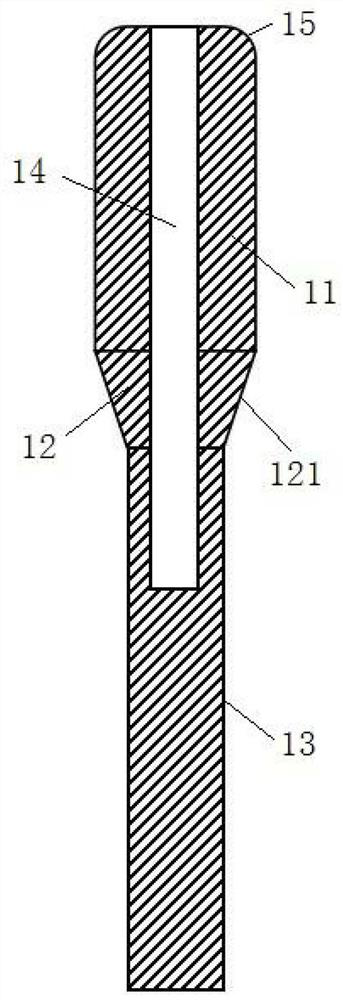

Test probe, test probe module and test device

ActiveCN113466504ASave the budget for mechanical rigidityAvoid the problem of poor contact caused by easy deformation and warpingElectronic circuit testingElectrical measurement instrument detailsPhysicsMechanical engineering

The present invention relates to a test probe comprising: a head comprising at least two needle flaps that can be opened or closed; a tail part which forms a main body of the test probe; and a transition part which comprises two ends, wherein one end is connected with the head part, the other end is connected with the tail part, and the transverse size of the end connected with the head part is larger than that of the end connected with the tail part, so that the outer wall of the transition part is provided with an inclined surface shrinking from the head part to the tail part; when the extrusion piece moves from the tail part to the head part along the inclined surface, the transition part is subjected to extrusion force to drive the at least two needle flaps to be closed, so that the closed head part can enter the metalized through hole in the carrier plate; and when the extrusion force is removed, the at least two needle petals expand naturally so as to abut against the inner wall of the metalized through hole in the carrier plate. Therefore, the problem of poor contact caused by easy deformation and warping of the contact surface of the carrier plate or the test probe module due to increase of the number of the probes can be avoided, and the budget of mechanical rigidity of an installation mechanism is omitted.

Owner:绅克半导体科技(苏州)有限公司

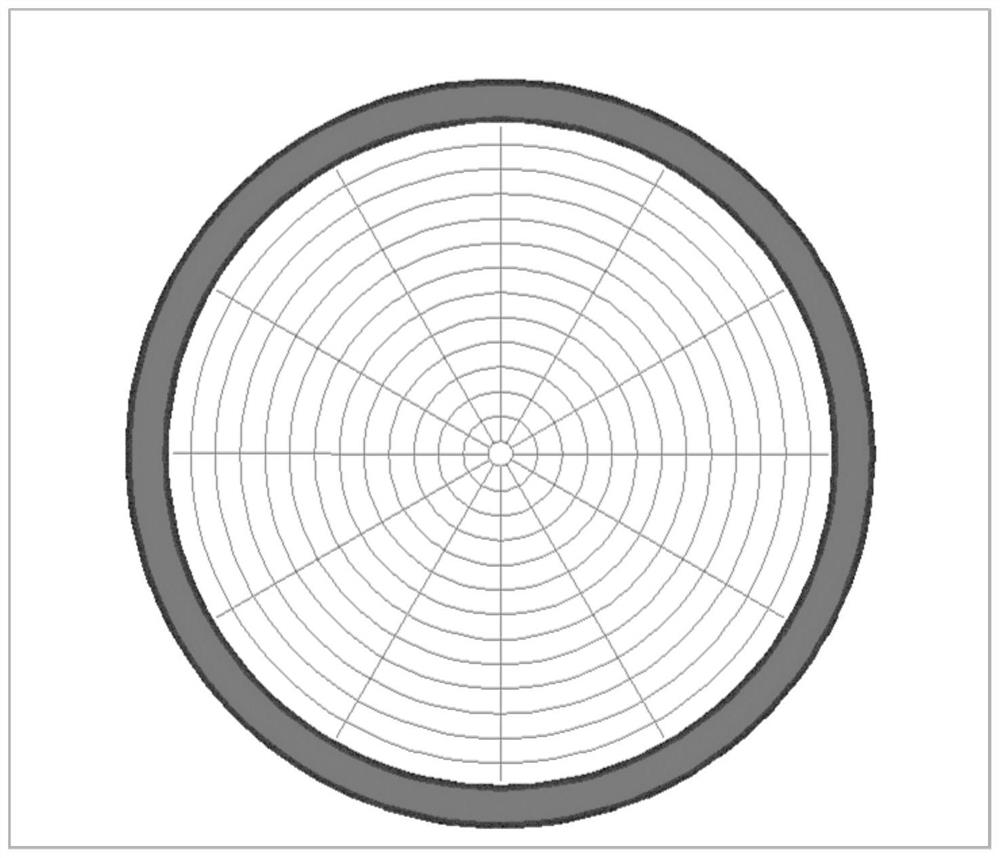

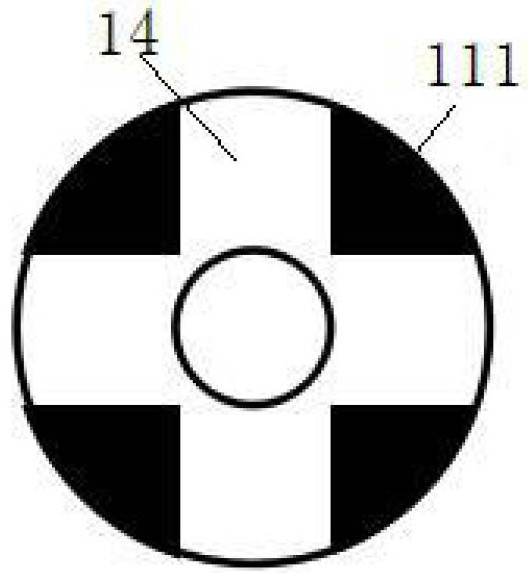

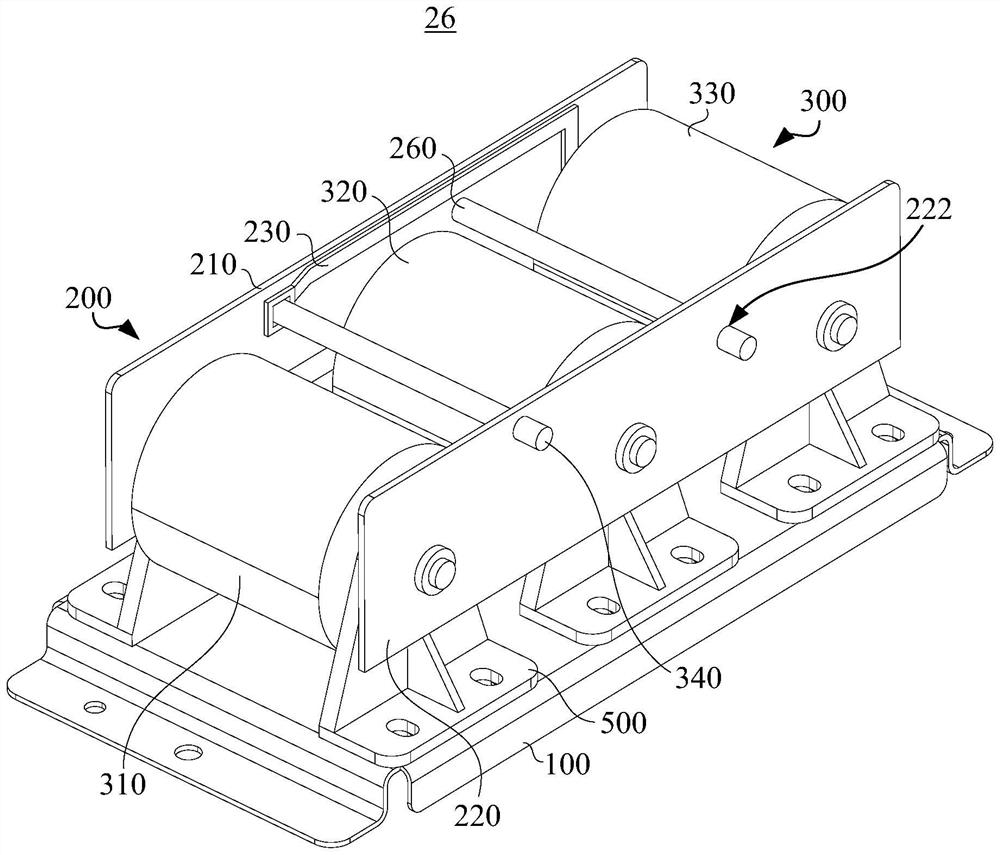

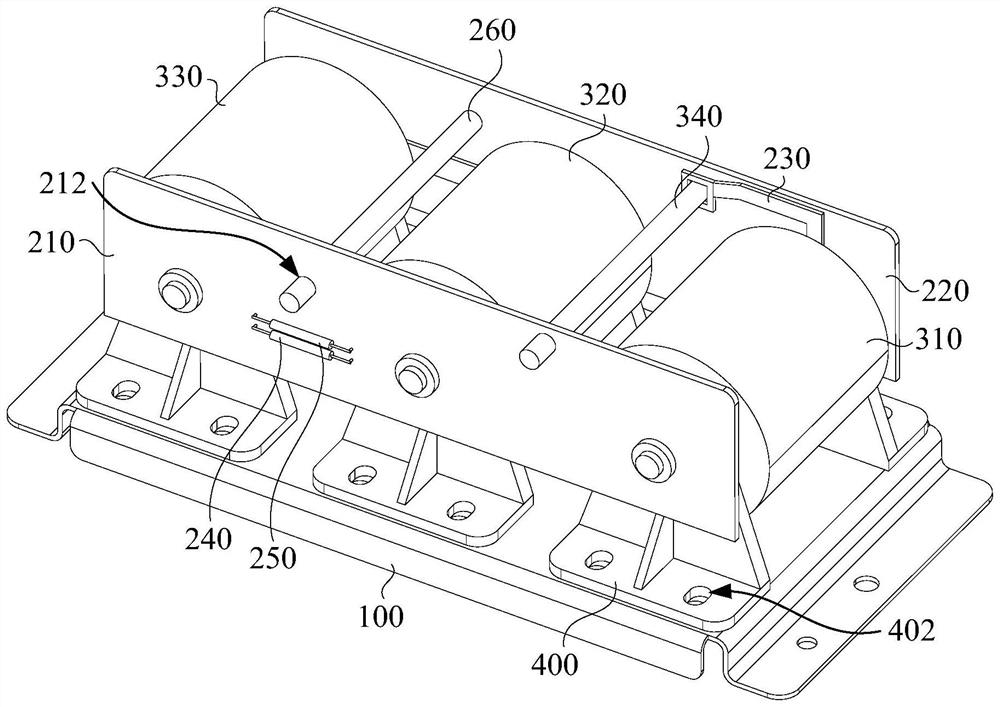

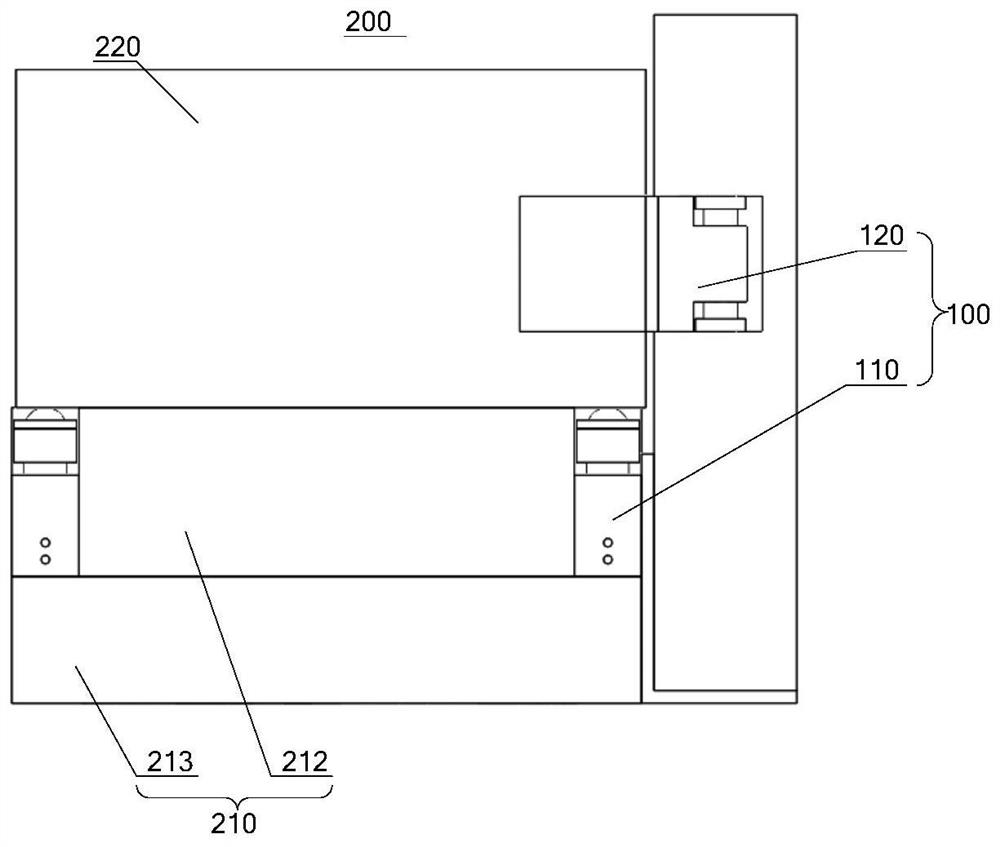

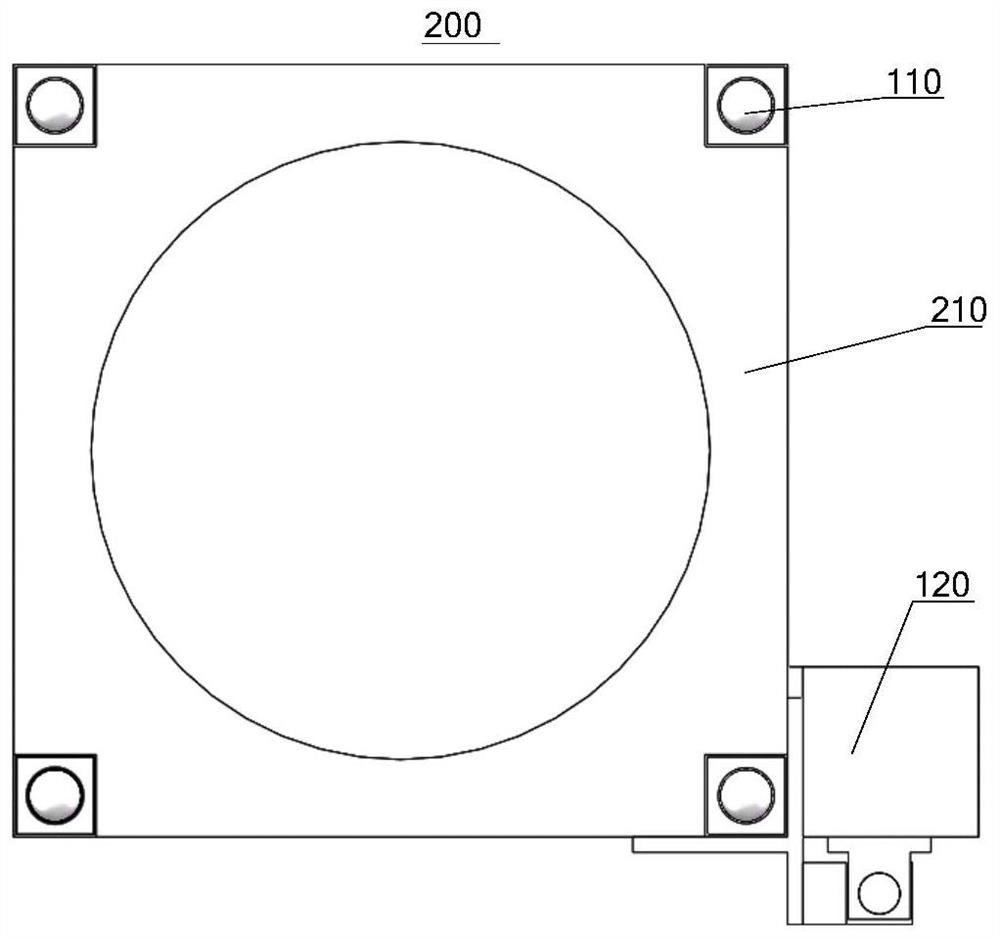

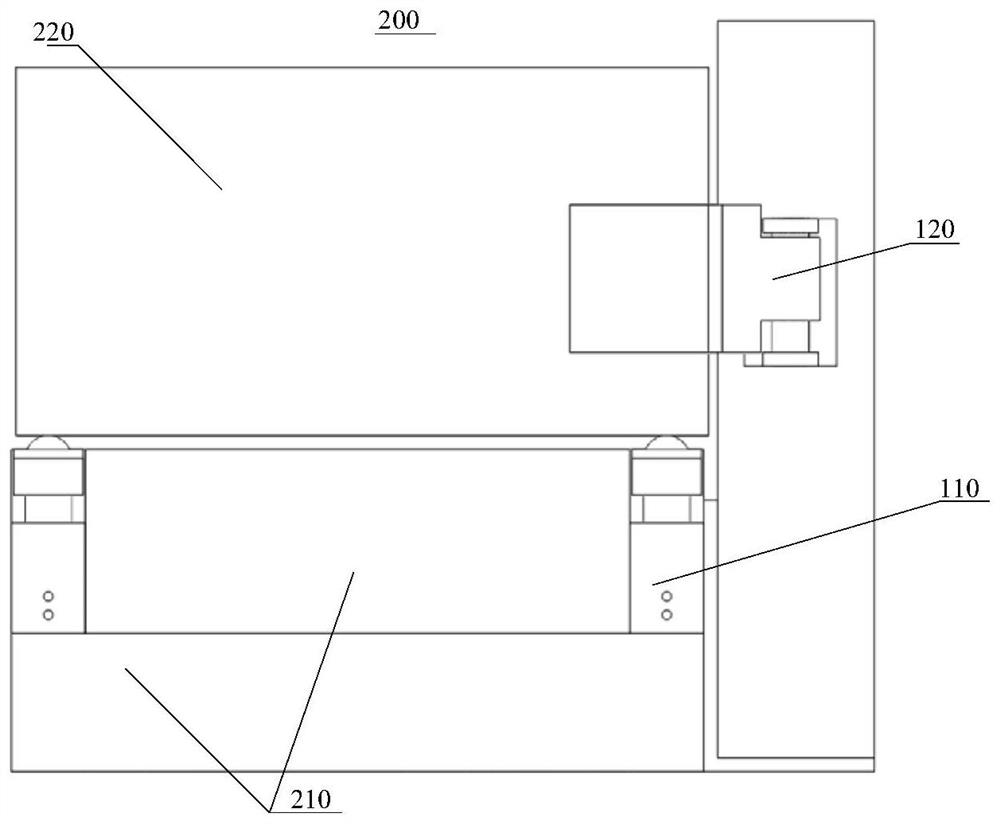

Capacitor wiring device

PendingCN114038686ASimple structureEasy to batchCoupling device connectionsMultiple fixed capacitorsCapacitanceEngineering

The invention provides a capacitor wiring device. The capacitor wiring device comprises a wire board assembly and a capacitor assembly. The circuit board assembly comprises a first circuit board and a second circuit board which are oppositely arranged, and a plurality of conductive circuits are arranged in the first circuit board and the second circuit board; the capacitor assembly comprises a first electrodeless capacitor, a second electrodeless capacitor, a third electrodeless capacitor and a first bridge type conductive piece, the first end of the first electrodeless capacitor is electrically connected with the first end of the second electrodeless capacitor, and the second end of the second electrodeless capacitor is electrically connected with the second end of the third electrodeless capacitor; the first end of the first bridge type conductive piece is connected with the first end of the third electrodeless capacitor, and the second end of the first bridge type conductive piece is connected with the second end of the first electrodeless capacitor. The electrodeless capacitors are connected through the conductive circuits on the circuit board and do not need to be connected through wires in an interpenetrating mode.

Owner:惠州市先锋电镀设备有限公司

Upper electrode uncovering structure and semiconductor processing equipment

ActiveCN111640690AAvoid lateral forcesGood electrical conductivityFinal product manufactureSemiconductor/solid-state device manufacturingRadio frequencyMechanical engineering

The invention discloses an upper electrode uncovering structure and semiconductor processing equipment. The uncovering structure comprises a first lifting mechanism located below the upper electrode,wherein the first lifting mechanism can independently drive the upper electrode to ascend and descend in the vertical direction in a preset first lifting stage and keep the whole upper electrode in ahorizontal state, so that the upper electrode is switched between a process position and an initial cover opening position; a second lifting mechanism which is located on the side of the upper electrode and connected with the upper electrode, wherein the second lifting mechanism can independently drive the upper electrode to ascend and descend in the vertical direction in a preset second lifting stage, so that the upper electrode is switched between the initial uncovering position and the target uncovering position, and the initial uncovering position is located between the process position and the target uncovering position. The conductive function of the induced coil can be remarkably improved, good electrical conduction between the upper electrode and the cavity is effectively guaranteed, meanwhile, radio frequency leakage can be avoided, and the process result is improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

A kind of environment-friendly zinc oxide varistor electrode silver paste suitable for two kinds of welding processes and its preparation method

ActiveCN104934103BGuaranteed normal transmissionReduce interface contact resistanceNon-conductive material with dispersed conductive materialCable/conductor manufactureSlurryVaristor

The invention discloses an environment-friendly electrode silver slurry of zinc oxide varistor suitable for two soldering technologies and a preparation method of the electrode silver slurry. The silver slurry is composed of 60-80% silver powder, 1-5% of metal oxide, 2-5% of leadless glass powder and 10-37% of organic carriers by weight. The preparation method comprises the steps that the leadless glass powder is prepared by that raw materials are mixed well, placed in a platinum crucible and melt, and the melt material is removed and dried to obtain the leadless glass powder; the organic carriers are prepared by adding an organic solvent into a stainless steel container, adding organic resin, carrying out heating, and carrying out cooling and adding a surfactant after the resin is completely dissolved; and the silver slurry is prepared by mixing the silver powder, the metal oxide, the leadless glass powder and the organic carriers, and stirring and grinding the mixture in a vacuum manner. The preparation method is simple and suitable for both the reflow soldering and immersed soldering technologies, the solderability and the soldering resistance are high, the silver slurry can be used to prepare common type as well as lightning protection type varistor, the adhesion force, the conductivity and the electrical performance are high, and the performance completely reach the using requirements.

Owner:GUIYAN DETECTION TECH YUNNAN CO LTD

Method for connecting conductor and solder and electronic element in said connecting method

InactiveCN1555216AAvoid pollutionGood electrical conductionConductive pattern reinforcementButt jointAdhesive

This invention discloses a connection method for a electric conductor and a solder which is stuck on the conductor or an insulation body containing the conductor by adhesives, then to heat the solder to be melted to solder the conductor and the butt-joint electronic elements including the insulation body and several conductors and solders in the insulation body, adhesives are put between the tin sweat and conductor or the insulation body for fixing them.

Owner:DEYI PRECISION ELECTRONIC IND CO LTD PANYU

A kind of conductive paste and its preparation method and application

InactiveCN103839605BAvoid affecting charge transportGuaranteed normal transmissionNon-conductive material with dispersed conductive materialCable/conductor manufactureCross-linkMoisture resistance

The invention discloses electrocondution slurry and a preparation method and application of the electrocondution slurry. The slurry comprises, by mass percent, 30-40% of silver-graphene composite materials, 30-48% of organic resin, 5-10% of cross-linking agents and 12-26% of thinning agents. The method that the silver-graphene composite materials are prepared are as follows: graphite oxide and organic silver are added to a mixed system formed by organic solvents and deionized water, and ultrasonic dispersion is carried out on the mixture; hydrazine hydrate is dripped to the mixed system while the mixed system is stirred; after stirring is carried out for 20-30 min at room temperature, the temperature rises to 60-70 DEG C, reaction is conducted for 2-3 h, the mixture is cooled to be at the room temperature, filtered and rinsed by the deionized water, vacuum drying is carried out on the mixture, and the silver-graphene composite materials are obtained. The electrocondution slurry can meet the demands of photovoltaic devices for the electrical property under low silver content conditions and is suitable for flexible substrates, good in temperature and moisture resistance and excellent in filament printing performance, adhesive force of the electrocondution slurry and substrate ITO materials is high, and production cost of the slurry is remarkably reduced.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Welding method and circuit board using same

InactiveCN1676259AGood electrical conductionPrinted circuit assemblingLine/current collector detailsEngineeringElectronic component

The present invention relates to a welding method capable of welding two electronic elements together, in which on one electronic element a needle welding end is set, on another electronic element several holes with weltable portion and welding compound correspondent to the holes, the needle welding end can be inserted into the hole, and can be welded with described weltable portion by heating welding compound. Said invention can make two electronic elements be connected together stably.

Owner:DEYI PRECISION ELECTRONIC IND CO LTD PANYU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com