Battery pole pieces and cells

A battery pole piece and pole piece technology, which is applied to battery electrodes, electrode carriers/collectors, secondary batteries, etc., to achieve the effect of reducing battery weight and improving battery safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

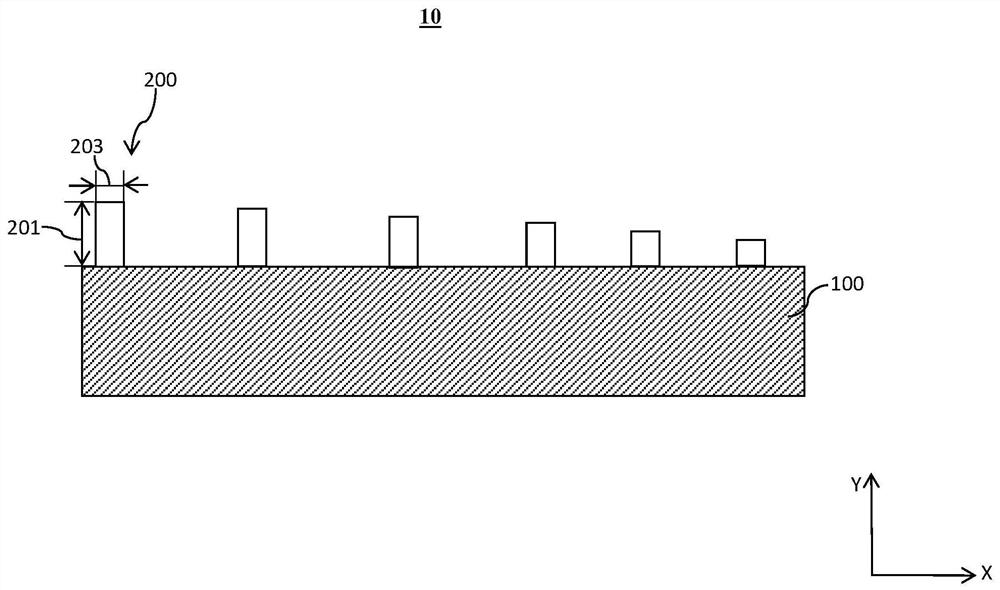

Embodiment 1

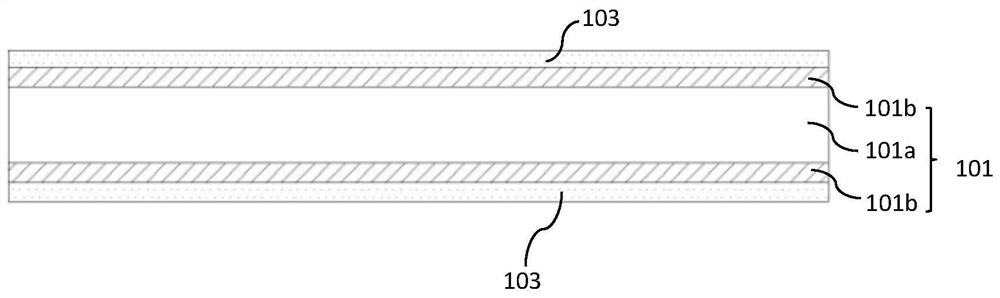

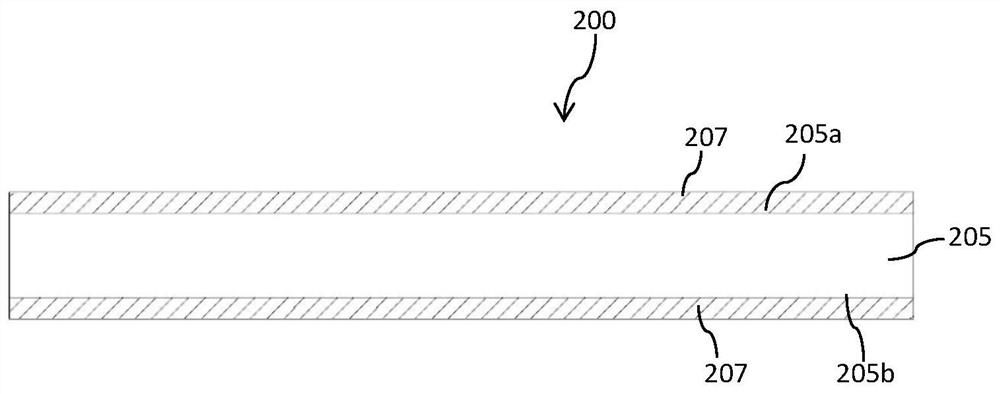

[0047] A positive current collector is composed of PET with a thickness of 12um as the polymer layer and Al with a thickness of 0.5um as the metal layer. The positive electrode active material lithium cobaltate (LiCoO2), conductive carbon black (Super P), and polyvinylidene fluoride (PVDF) were mixed according to a weight ratio of 97.5:1.0:1.5, and N-methylpyrrolidone (NMP) was added as a solvent. Prepare a slurry with a solid content of 0.75 and stir evenly. The slurry was evenly coated on the positive electrode current collector, leaving a 15 cm blank area on both sides of the positive electrode current collector. After the coating is completed, it is dried and cold pressed. By adjusting the parameters of laser die-cutting and cutting off the redundant empty foil area, five pole pieces with a width of 10mm and lengths of 14mm, 12mm, 10mm, 8mm and 6mm were obtained.

[0048] Using copper foil as the negative electrode current collector, mix the negative electrode active mat...

Embodiment 2

[0051] A positive current collector is composed of PET with a thickness of 12um as a polymer layer and Al with a thickness of 1.0um as a metal layer. The positive electrode active material lithium cobaltate (LiCoO2), conductive carbon black (Super P), and polyvinylidene fluoride (PVDF) were mixed according to a weight ratio of 97.5:1.0:1.5, and N-methylpyrrolidone (NMP) was added as a solvent. Prepare a slurry with a solid content of 0.75 and stir evenly. The slurry was evenly coated on the positive electrode current collector, leaving a 15 cm blank area on both sides of the positive electrode current collector. After the coating is completed, it is dried and cold pressed. By adjusting the parameters of laser die-cutting and cutting off the redundant empty foil area, five pole pieces with a width of 10mm and lengths of 14mm, 12mm, 10mm, 8mm and 6mm were obtained.

[0052] Using copper foil as the negative electrode current collector, mix the negative electrode active materia...

Embodiment 3

[0055] A positive current collector is composed of PET with a thickness of 12um as the polymer layer and Al with a thickness of 0.5um as the metal layer. The positive electrode active material lithium cobaltate (LiCoO2), conductive carbon black (Super P), and polyvinylidene fluoride (PVDF) were mixed according to a weight ratio of 97.5:1.0:1.5, and N-methylpyrrolidone (NMP) was added as a solvent. Prepare a slurry with a solid content of 0.75 and stir evenly. The slurry was evenly coated on the positive electrode current collector, leaving a 15 cm blank area on both sides of the positive electrode current collector. After the coating is completed, it is dried and cold pressed. By adjusting the parameters of laser die-cutting and cutting off the redundant empty foil area, five pole pieces with a width of 10mm and lengths of 14mm, 13mm, 12mm, 11mm and 10mm were obtained.

[0056] Using copper foil as the negative electrode current collector, mix the negative electrode active m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com