Test probe, test probe module and test device

A technology for testing probes and needle valves, applied in the field of integrated circuit testing, to achieve the effect of saving the budget for mechanical rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

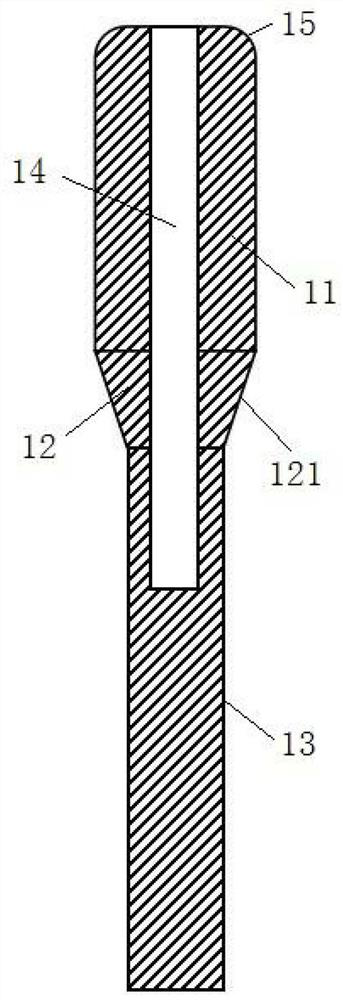

[0046] This embodiment provides a test probe 10 for contacting each alignment contact 31 on the carrier board 30 , wherein the alignment contact 31 may be a metallized through hole. The test probe 10 comprises a head 11 , a transition 12 and a tail 13 , wherein the head 11 and the tail 13 form the main body of the test probe, and the transition 12 is arranged between the head 11 and the tail 13 .

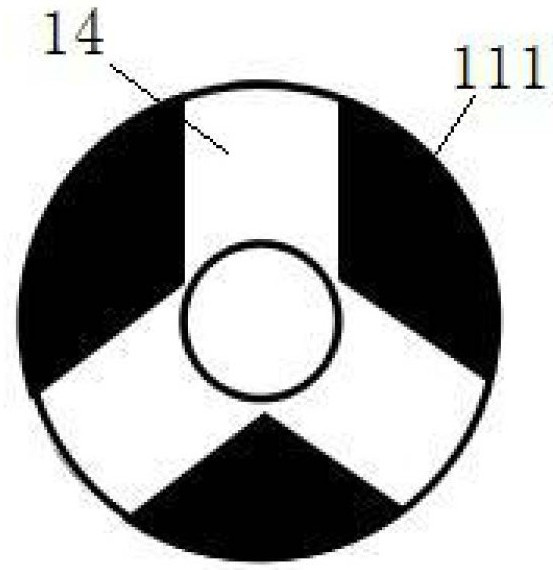

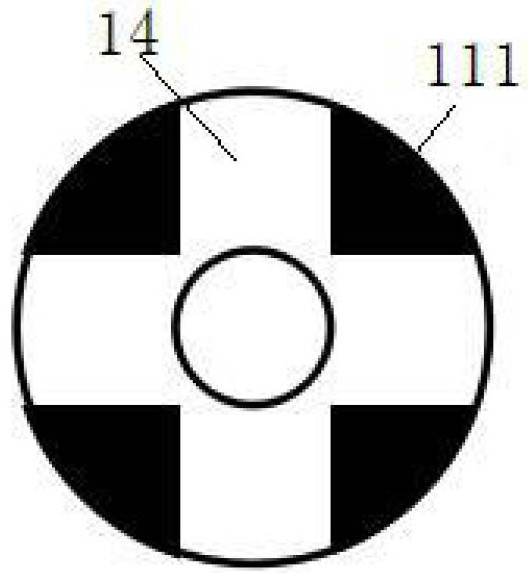

[0047] see figure 1 As shown, the above-mentioned head 11 includes at least two needle flaps 111 that can be opened or closed. The area surrounded by the needle flaps 111 in the opened state has a first area, and the area surrounded by the needle flaps 111 in the closed state has The second area, and the first area is larger than the inner hole area of the metallized through hole, and the second area is smaller than the inner hole area of the metallized through hole. In a natural state, at least two needle petals 111 are in an open state.

[0048]Above-mentioned transition part...

Embodiment 2

[0057] see Figure 5 and Image 6 As shown, this embodiment provides a test probe module, on which the probe array is used to contact the alignment contacts 31 on the carrier board 30 , wherein the alignment contacts 31 may be metallized through holes. The test probe module includes a probe array, a pinhole set and ejector pins 24 .

[0058] The above-mentioned probe array includes at least two test probes 10 as in the first embodiment. The specific structure of the test probes 10 has been described in detail in the first embodiment, and will not be repeated here in this embodiment.

[0059] The above-mentioned pinhole kit includes a movable plate 21, a fixed plate 22 and an extruded part 23. The movable plate 21 includes a first through hole 211 capable of accommodating the test probe 10 moving therein, and the inner side wall of the first through hole 211 is provided with The extruding part 23 that cooperates with the inclined surface 121 on the transition part 12 of the t...

Embodiment 3

[0070] An embodiment of the present invention provides a test device, including a test machine and a test probe module as in Embodiment 2, where the test probe module is assembled on the test machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com