Electrode for generating plasma and plasma processing apparatus using same

A plasma and electrode technology, which is applied in the direction of plasma, circuit, discharge tube, etc., can solve the problems of no prompting, etc., and achieve the effects of not being easy to individual difference, suppressing the generation of dust, and uniform electrical conduction and heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

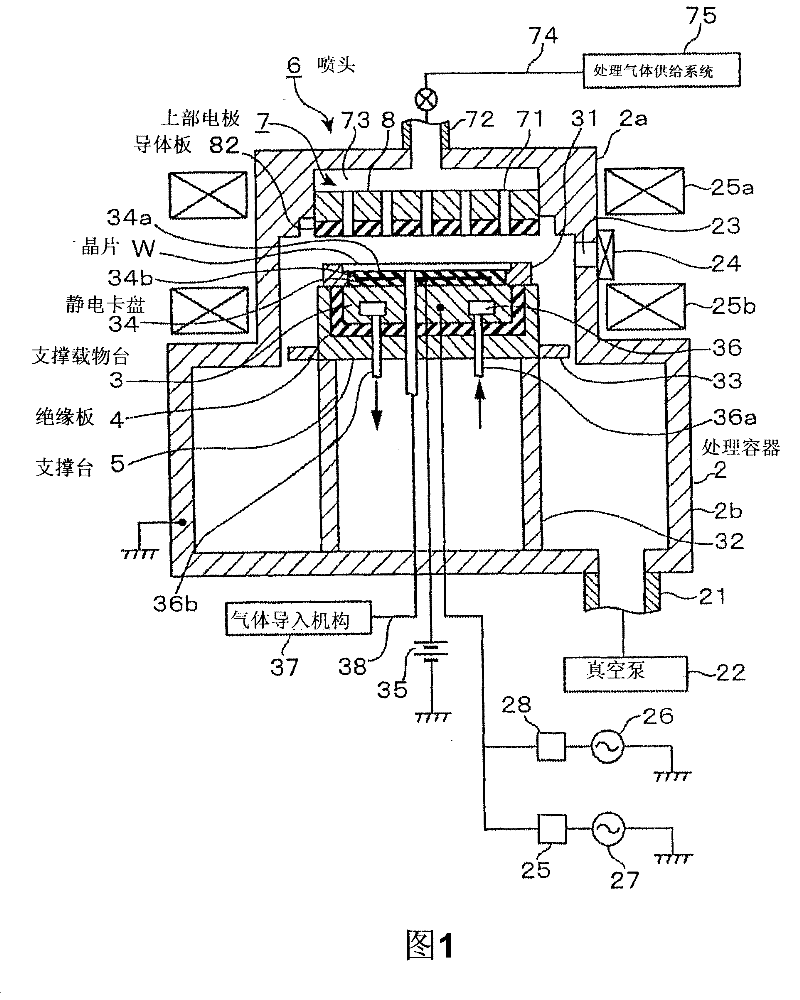

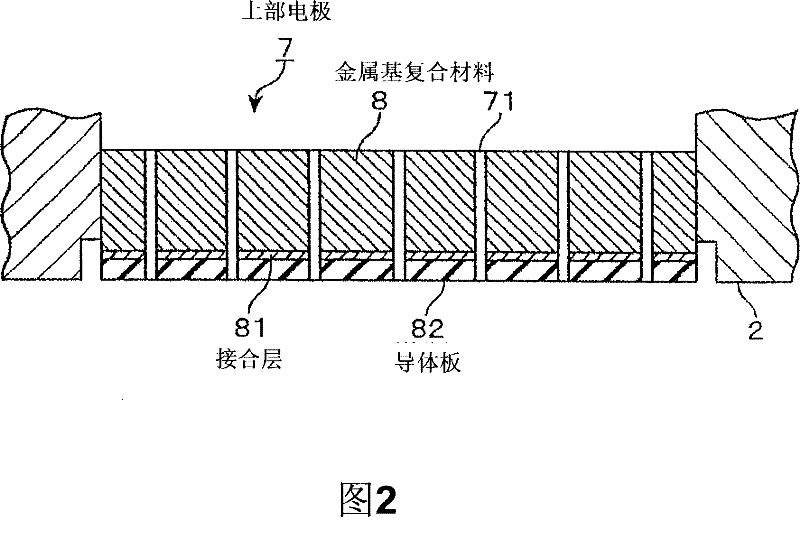

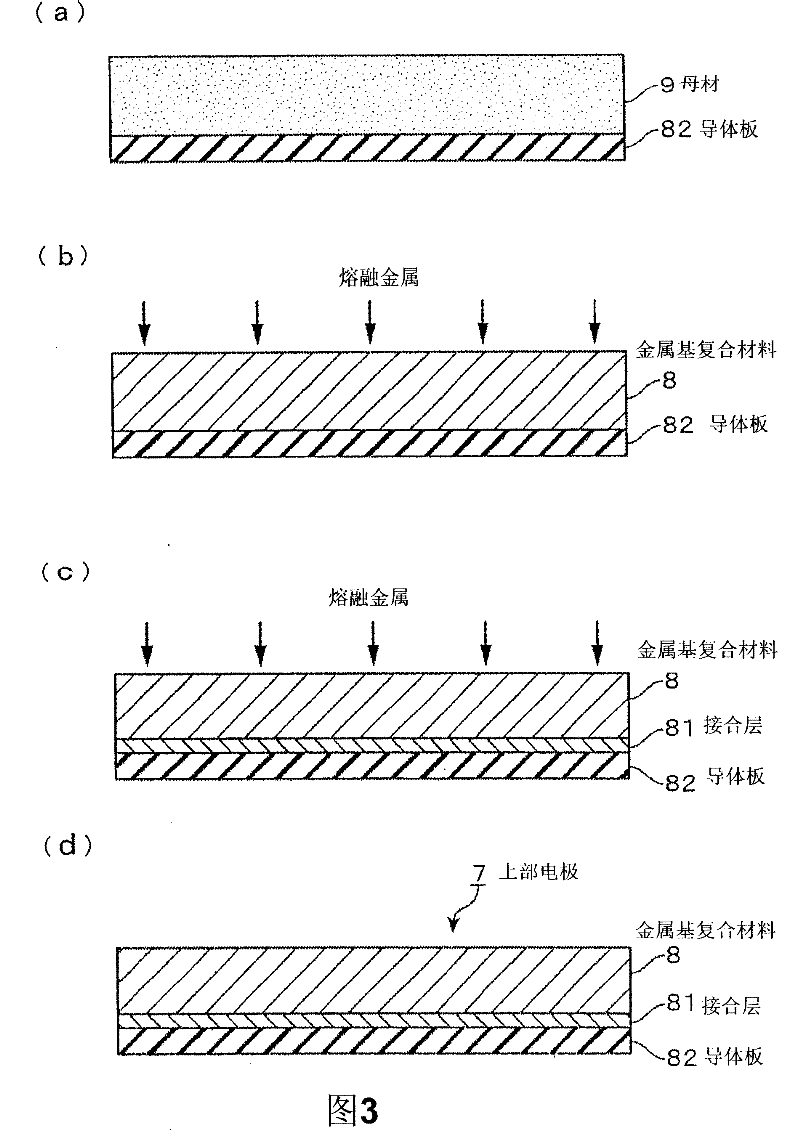

[0039]Next, embodiments of the present invention will be described. figure 1 It is a cross-sectional view showing an RIE (Reactive Ion Etching) plasma etching apparatus to which an electrode according to an embodiment of the present invention is applied as a plasma processing apparatus as an upper electrode. figure 1 2 in is a processing container (vacuum chamber) made of, for example, aluminum. The processing container 2 is an airtight structure composed of a small-diameter cylindrical upper portion 2a and a large-diameter cylindrical lower portion 2b. The processing container 2 is provided with a supporting stage 3 which horizontally supports a semiconductor wafer W (hereinafter referred to as a wafer) as a substrate to be processed and is a mounting table which functions as a lower electrode. The supporting stage 3 is made of, for example, aluminum, and is supported by a conductor supporting base 5 via an insulating plate 4 . In addition, on the outer periphery above th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com