Frame enclosing gum coating apparatus

A coating device and sealing glue technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of low product yield, low production efficiency, electrostatic breakdown, etc., to simplify process steps, improve production efficiency, The effect of avoiding electrostatic breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

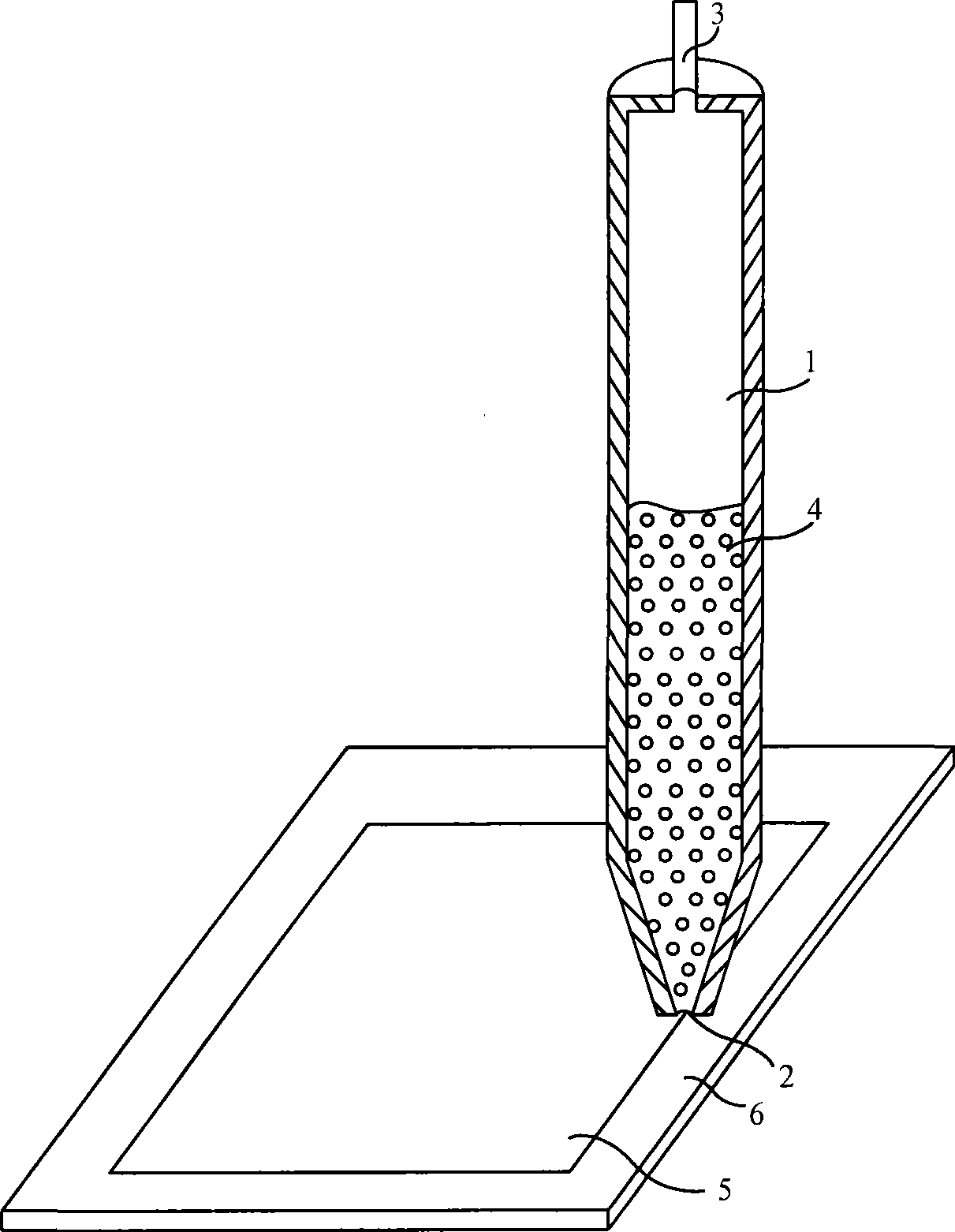

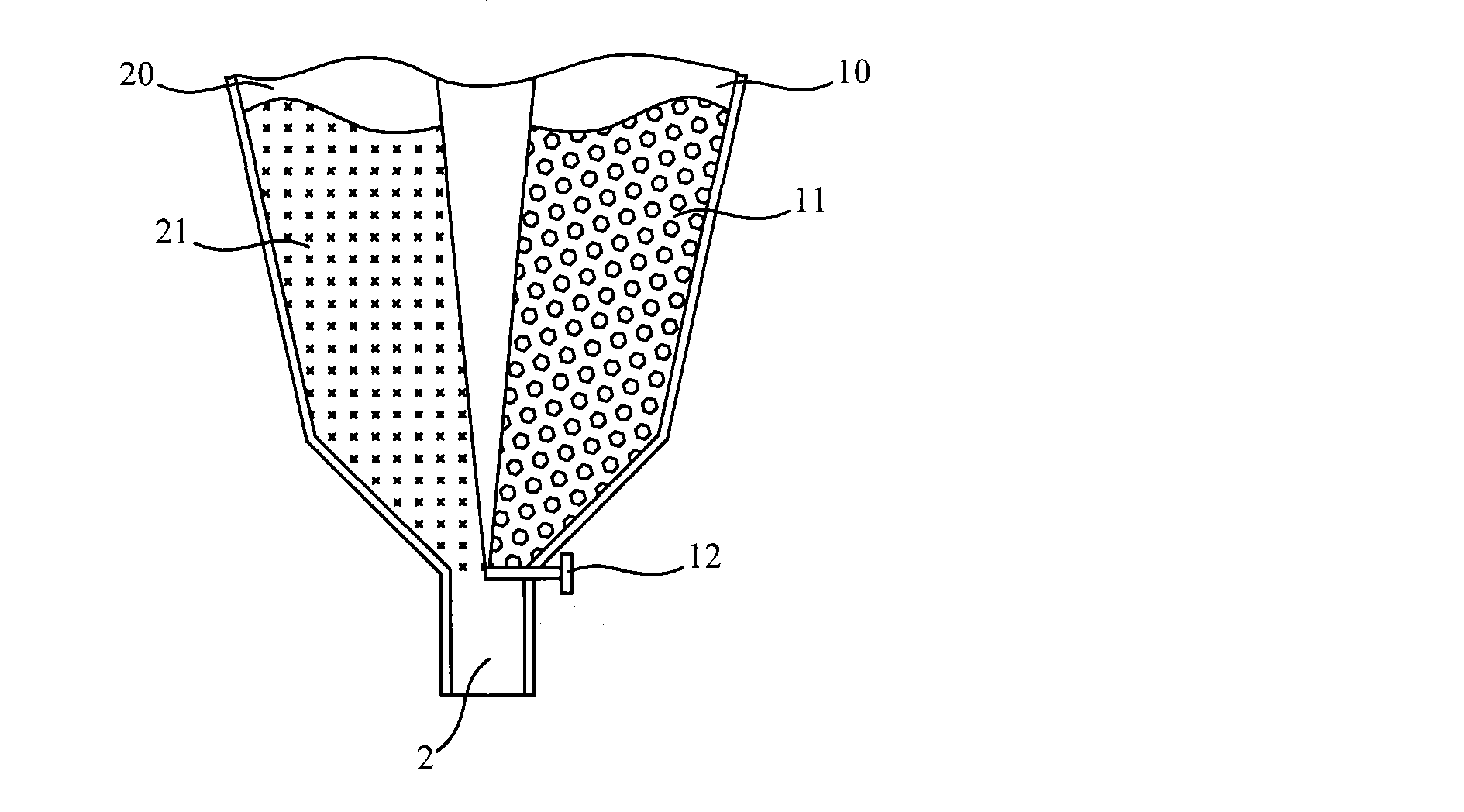

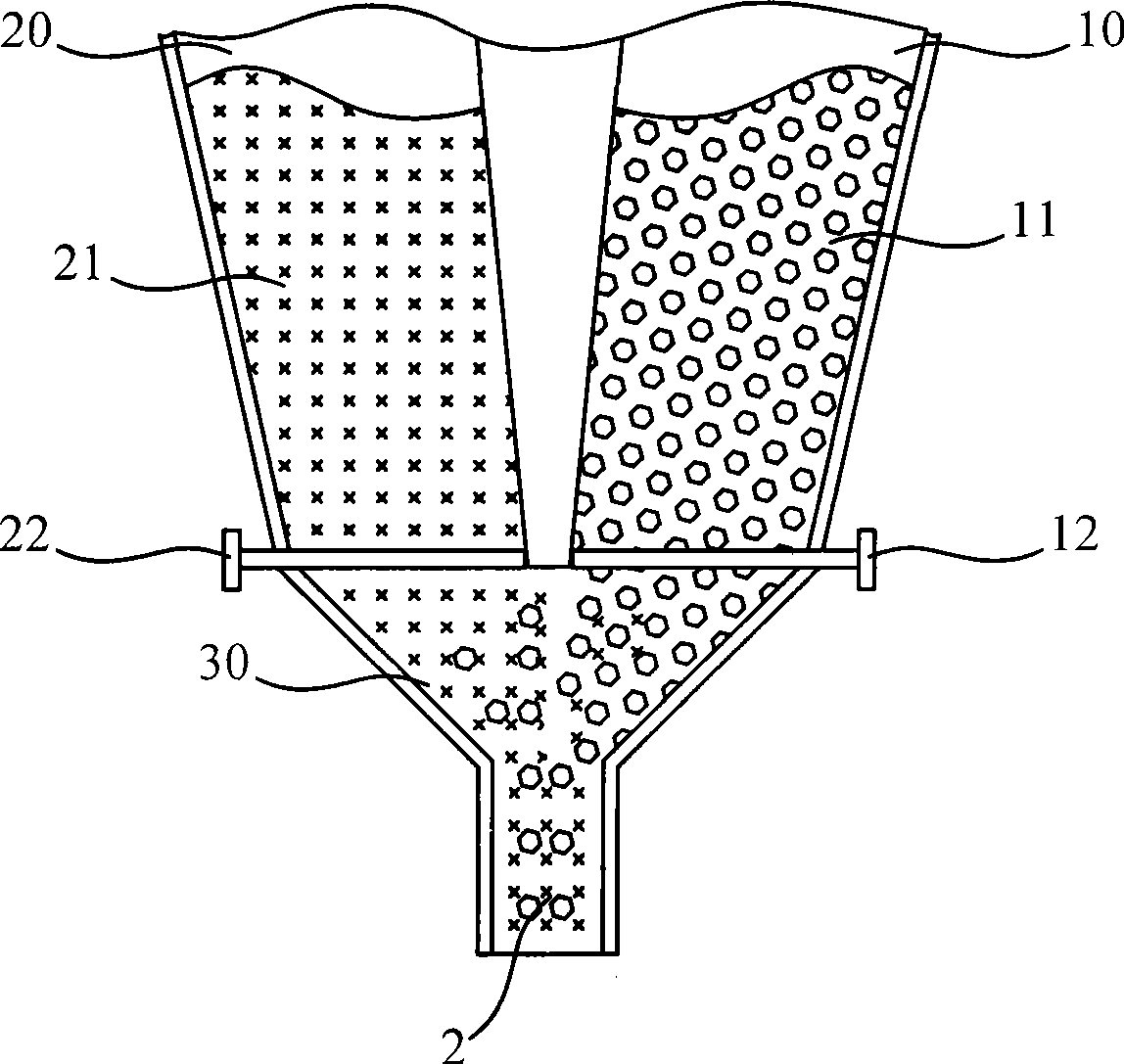

[0014] Embodiment 1 of the sealing glue coating device

[0015] Such as figure 2 Shown is a schematic structural diagram of a specific embodiment 1 of the frame sealing glue coating device of the present invention. The device specifically includes a first storage chamber 10, a second storage chamber 20, a nozzle 2 and a first control valve 12. The first storage chamber 10 is used for For storing the conductive frame sealant 11, the conductive frame sealant 11 is a frame sealant with a conductive function, such as a frame sealant mixed with conductive microspheres; the second storage chamber 20 is used to store the insulating frame sealant 21, the insulating frame sealant Glue 21 is the sealant that has no conductive function or is not mixed with conductive microspheres; the spout 2 is respectively connected to the first storage cavity 10 and the second storage cavity 20, and is used to guide the conductive sealant 11 and / or insulate The sealant 21 flows out so as to be coate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com