Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Fusible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

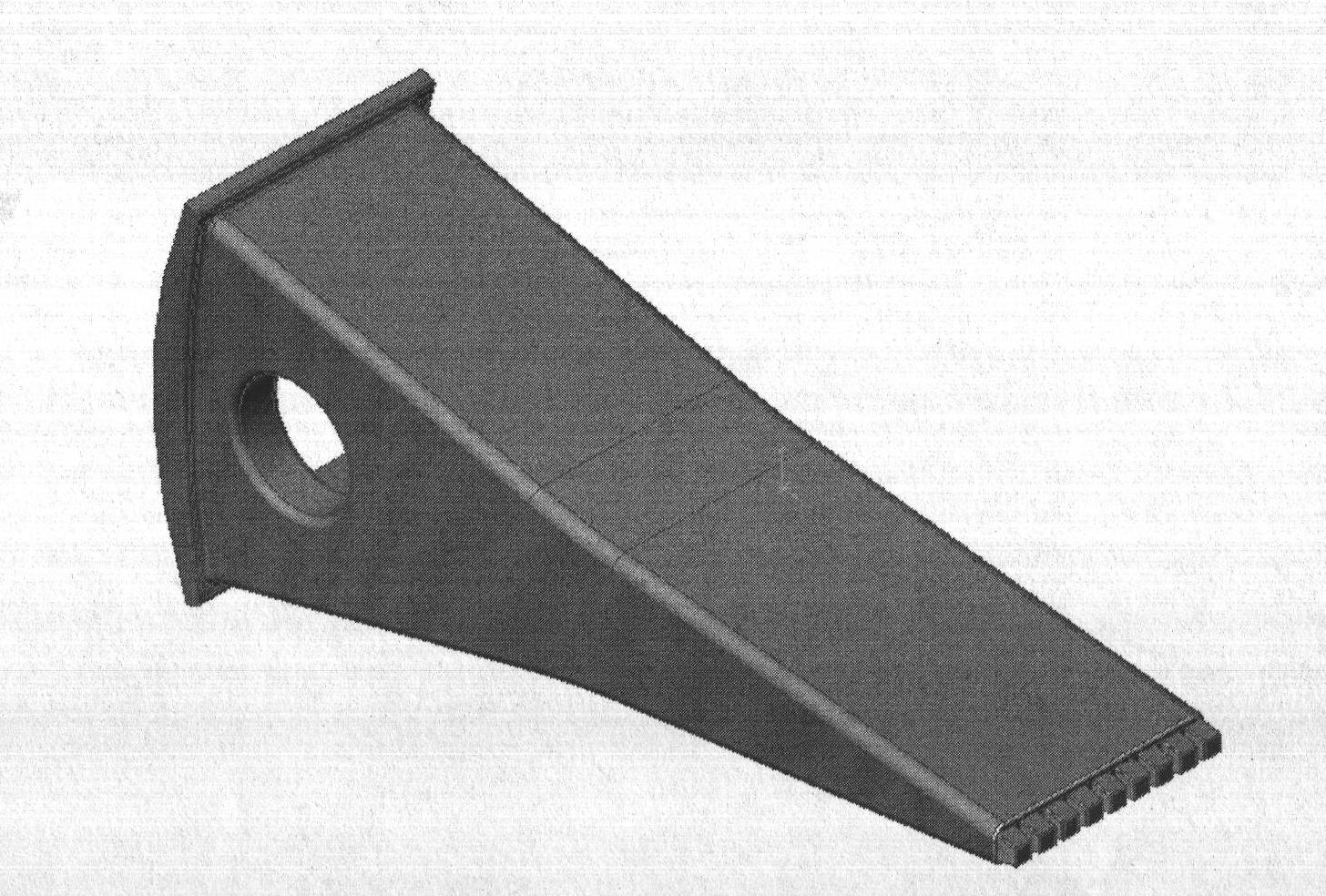

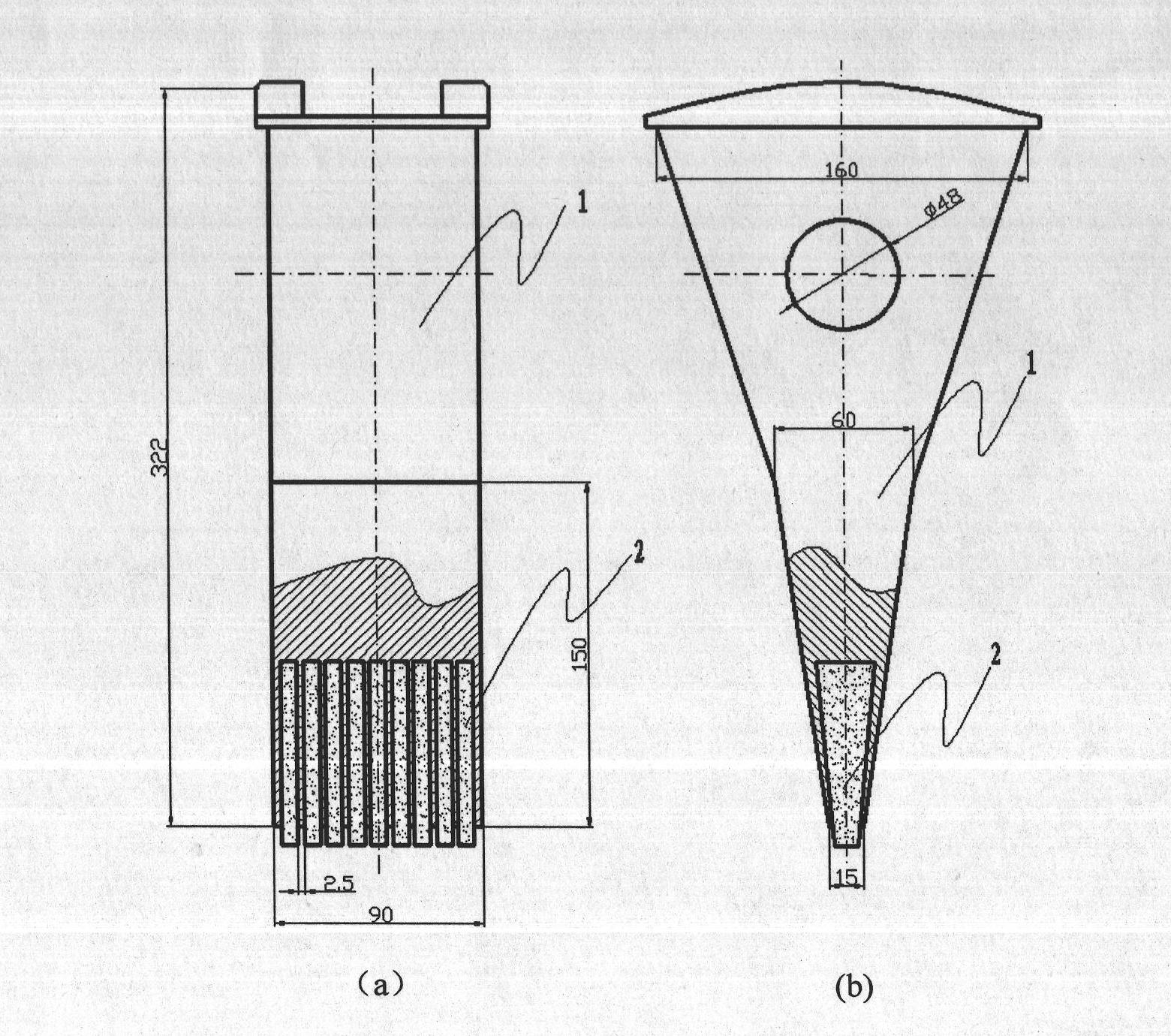

Composite dipper tooth of excavator and manufacturing method thereof

InactiveCN102182223AHigh hardnessHigh strengthSoil-shifting machines/dredgersExcavatorUltimate tensile strength

The invention relates to a composite dipper tooth of an excavator and a manufacturing method thereof, belonging to the field of high-tech engineering materials and application thereof. The novel composite dipper tooth comprises two parts of a bar type tooth tip (tooth bar) and a dipper tooth substrate (tooth substrate) and is formed by high temperature casting. The tooth bar material is novel high-rigidity and high-strength composite metal ceramics and comprises one or more of WC, TiCN, TiN or TiC-based composite metal ceramics; the tooth substrate is high / low chrome alloy steels or high manganese steels with higher rigidity and strength; a composite dipper tooth structure comprises a plurality of tooth bars of wedge shapes, the tooth bars are embedded at the front end of the tooth substrate, and a small section of each tooth bar is exposed out of a steel body, and a certain distance is arranged between tooth bars. The manufacturing method of the composite dipper tooth of the excavator sequentially comprises the following steps of: prefabricating the tooth bars; smelting alloy steels; casting the composite dipper tooth; and demolding. The tooth bar material is characterized by high rigidity, high strength and wearing resistance; the wearing resistance of the dipper tooth is improved and the consumption of wearing materials is reduced due to an intermittent structure, raw materials are saved, the cost is lowered, a contact area between the tooth bars and the tooth substrate is increased, the binding force is improved and the service life of the dipper tooth is prolonged.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

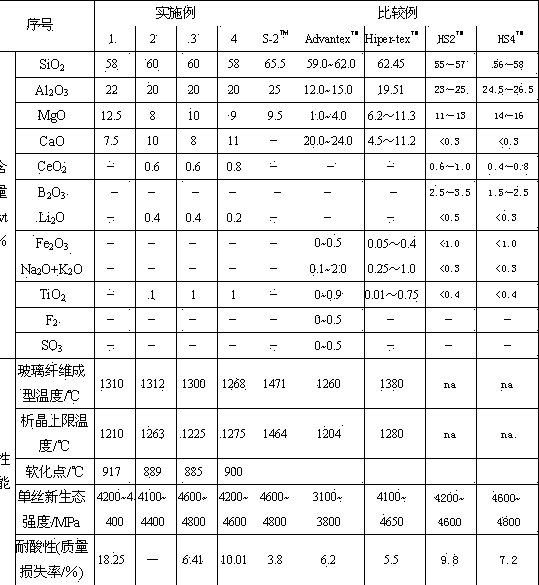

Composition for high-performance heat-resistant and corrosion-resistant glass fibers

ActiveCN102276153ASolve difficulties such as high manufacturing costsIncrease production capacityGlass fiberResin-Based Composite

The invention provides a composition for high-property heat-resisting corrosion-resisting glass fiber. The composition comprises the following components: 55-63wt% of SiO2, 18-23wt% of Al2O3, 8-16wt% of MgO, 7-13wt% of CaO, 0-1wt% of CeO2, 0-0.5wt% of Li2O, 0-0.4wt% of Fe2O3, 0-2wt% of TiO2, 0-0.5wt% of WO3 and 0-1.5wt% of Bi2O3, wherein the total content of SiO2, Al2O3, MgO and CaO is 94-98wt%; and CeO2, Li2O, Fe2O3, TiO2, WO3 and Bi2O3 are modifiers, the content of a single modifier is 0 at different times, and the total content of the modifiers is 2-6wt%. According to the invention, raw materials are adopted to produce the high-property heat-resisting corrosion-resisting glass fiber, thus the production difficulty is low, and the cost is low; and the produced glass fiber can be used as a reinforcing material and a heat-resisting heat-insulating material of a resin-based composite material and has the characteristics of high strength, corrosion resistance, high temperature resistance and light mass.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

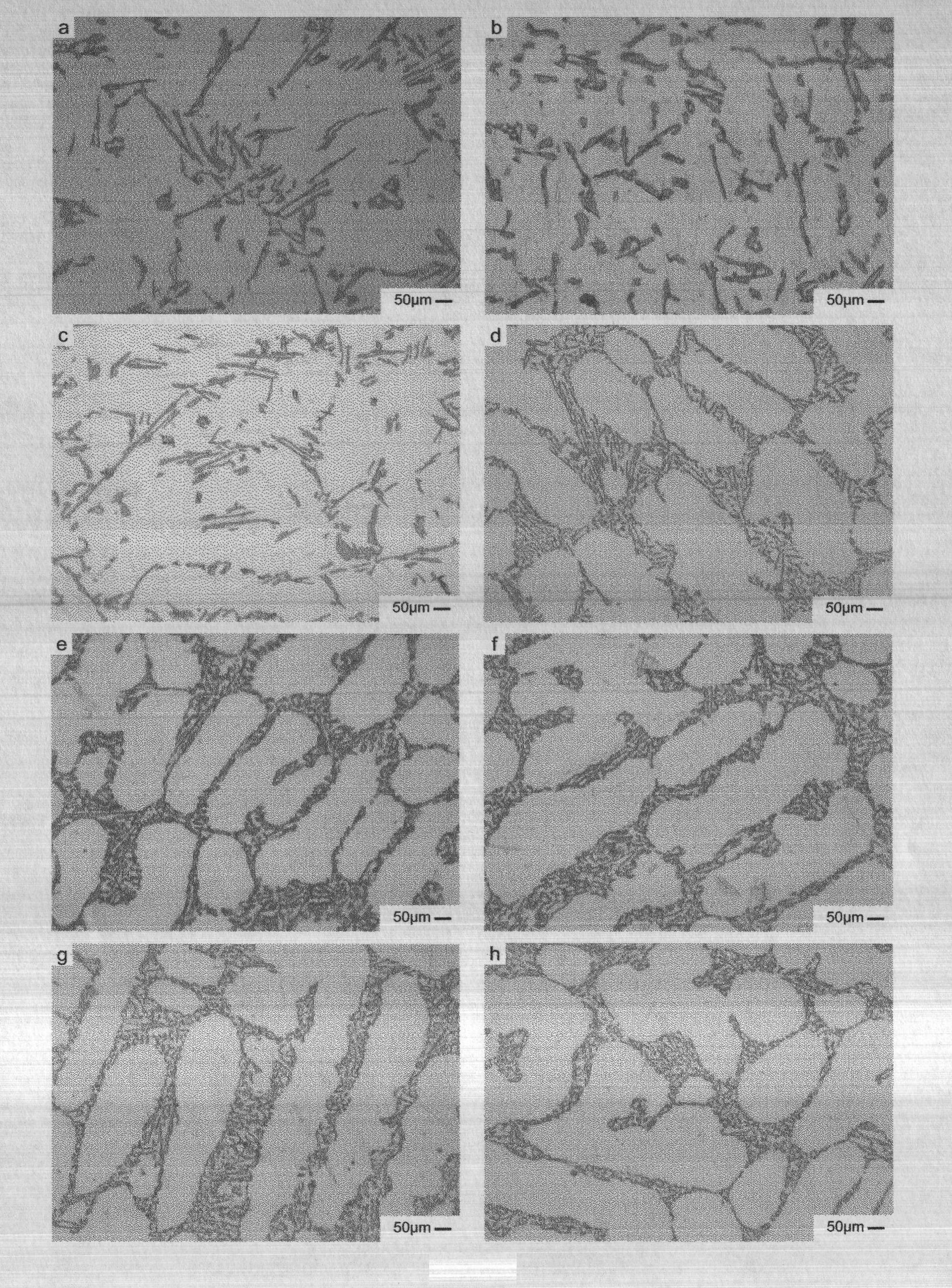

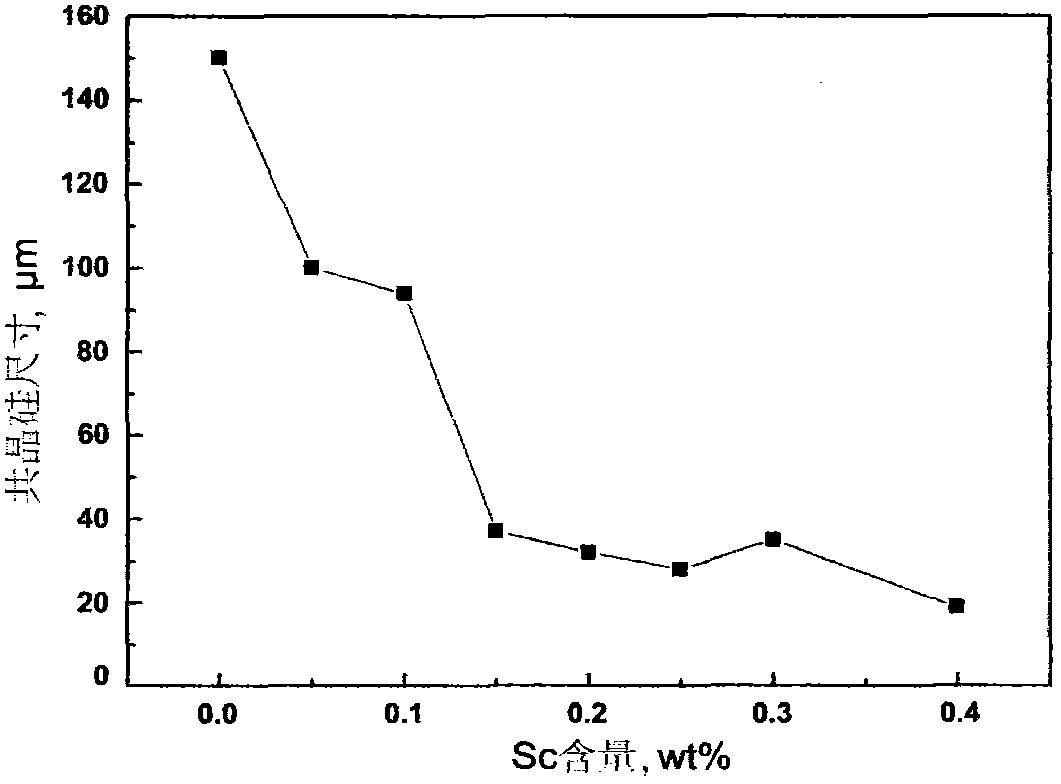

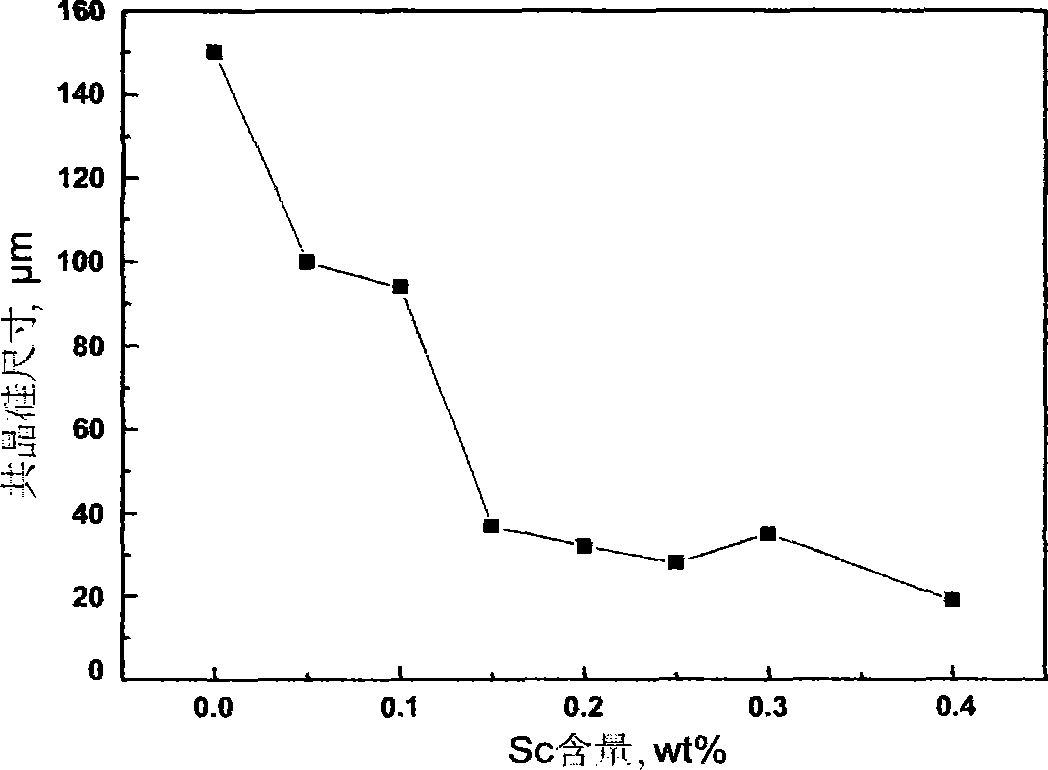

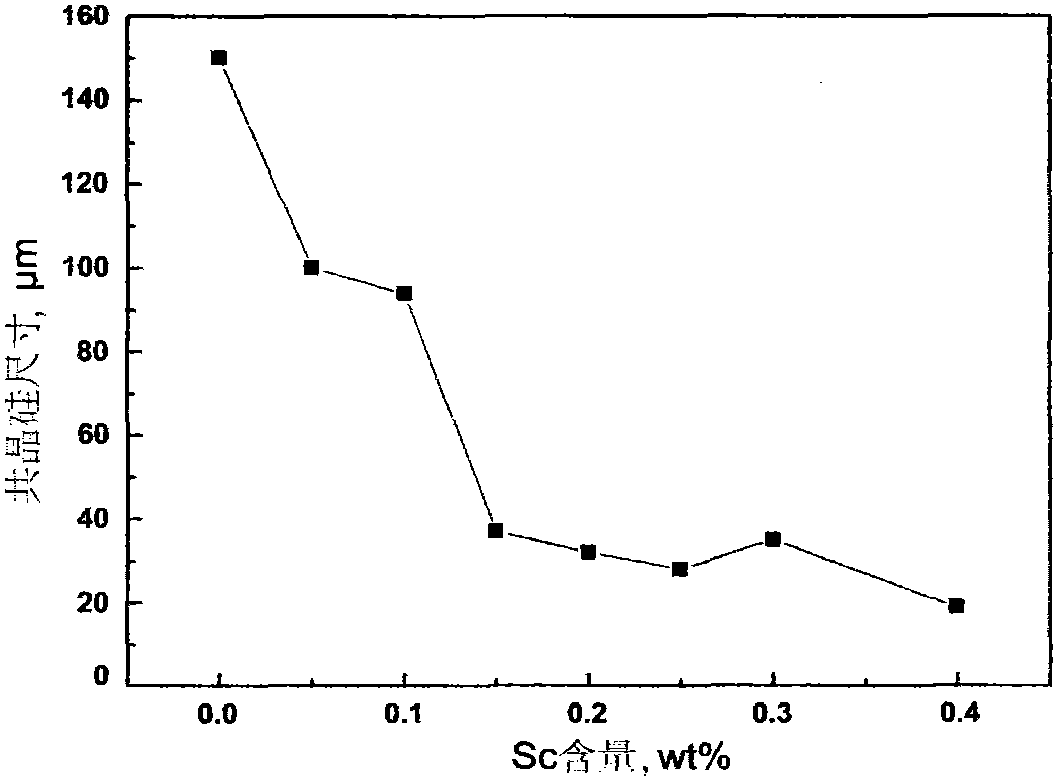

Metamorphic process of hypo eutectic casting aluminum-silicon alloy

The invention discloses a metamorphic process of a hypo eutectic casting aluminum-silicon alloy, which comprises the steps of: 1) dosing according to components of the hypo eutectic casting aluminum-silicon alloy; 2) cleaning, drying and placing the alloy and an intermediate alloy into a crucible resistance furnace which is 5kW in power, heating till completely being melted, and controlling the temperature of the melt at 700+ / -5 DEG C; 3) pressing pure Mg weighed in the step 1) into a melt obtained from the step 2) to stand for 3-5 minutes by a graphite bell jar with preheating temperature of 300 DEG C; 4) heating the melt obtained from the step 3) to be at 740-760 DEG C, adding weighed AlSc4 intermediate alloy till the intermediate alloy is completed melted, refining for 15 minutes by rotatably jetting high purity argon and drossing after standing for 10-20 minutes; 5) cooling the melt obtained from the step 4) to be at 680-700 DEG C and pouring into sand moulds, then cooling along with the mould to be at room temperature to obtain an as-cast structure containing fiberous and short-rod-shaped eutectic Si; and 6) performing heat treatment for cast obtained from the step 5) according to a T6 heat treatment process to obtain a particle eutectic silicon structure with good mechanical properties.

Owner:ZHONGBEI UNIV

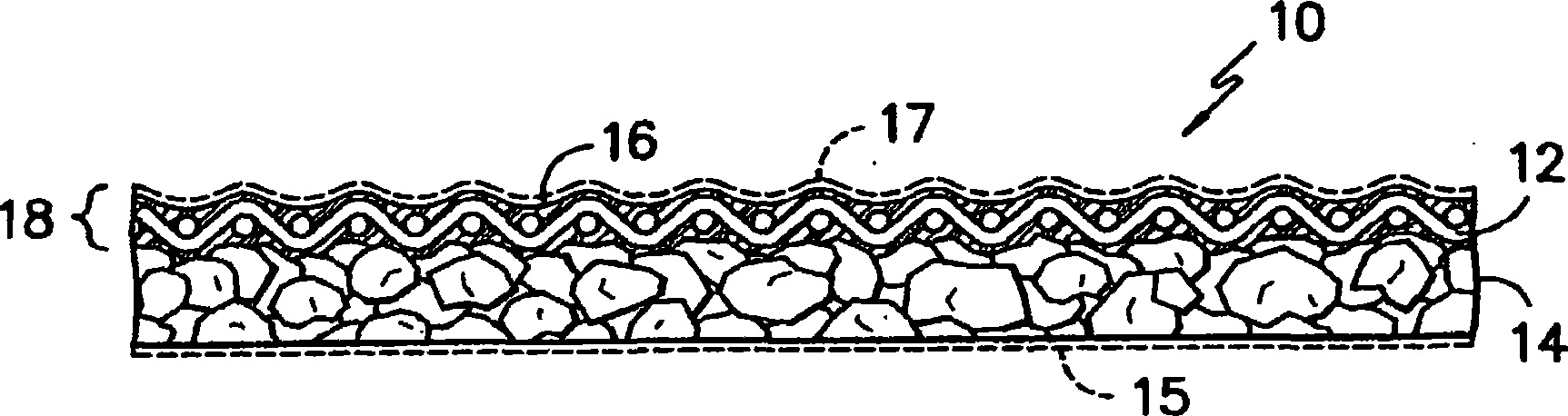

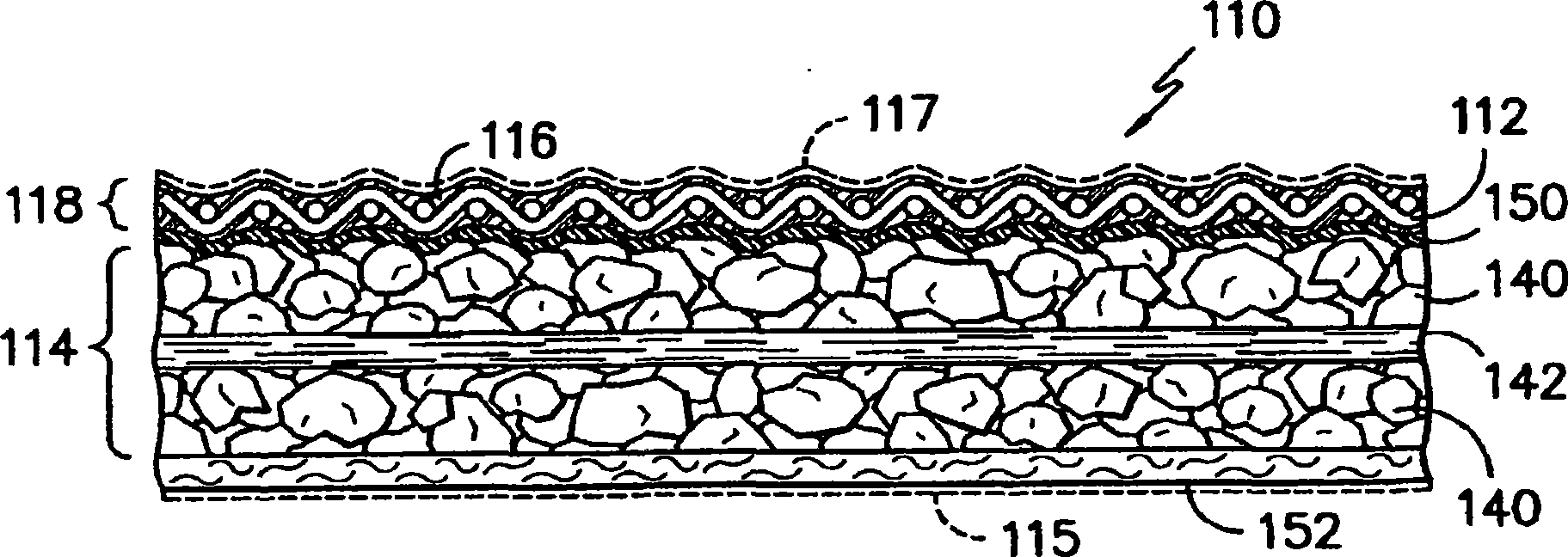

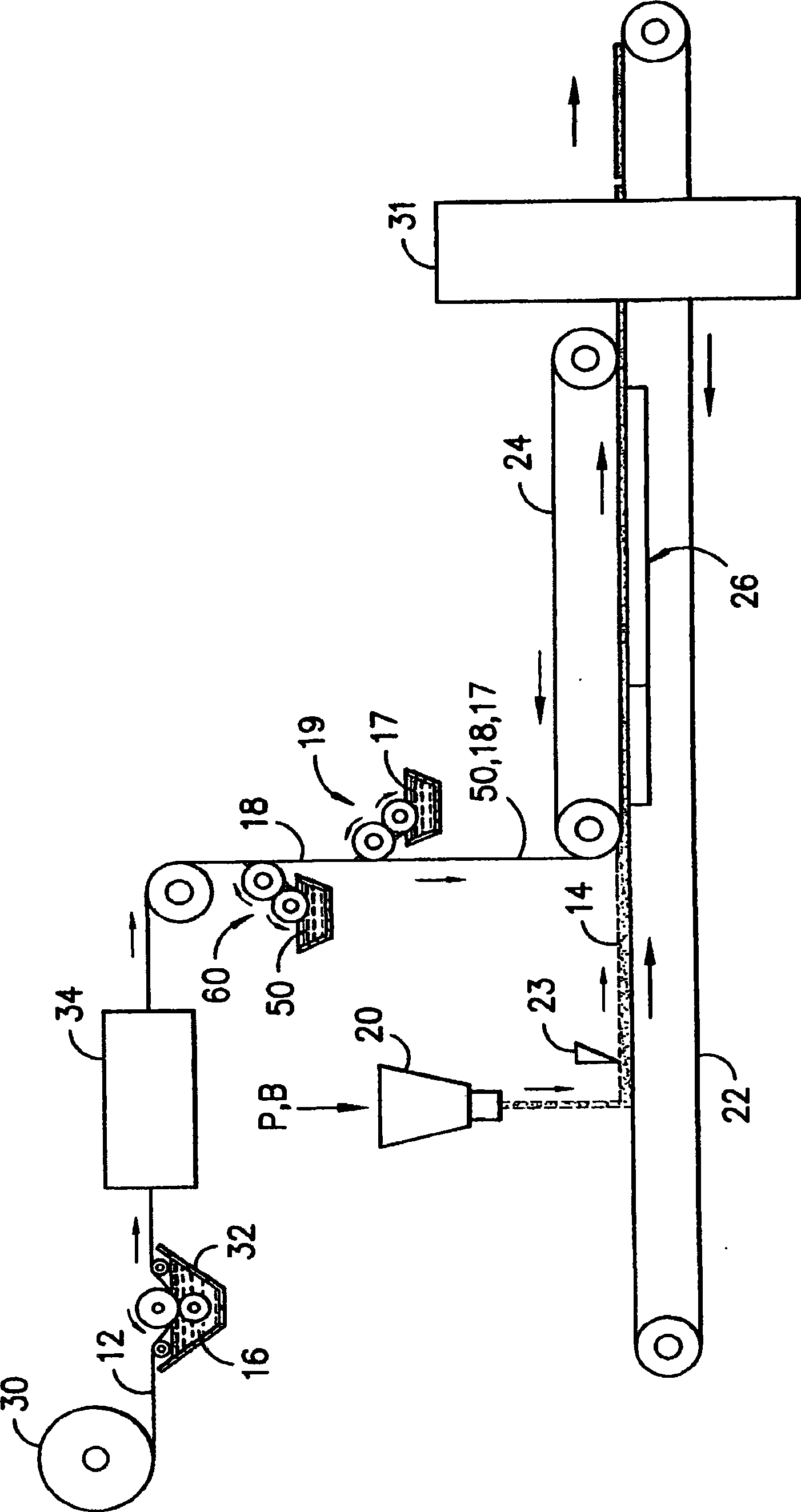

Surface coverings and methods

InactiveCN101501271AWear-resistantDirt-resistantLayered productsTextiles and paperTectorial membraneEngineering

A surface covering comprises a show surface, decorative layer, or face and an optional backing layer. The show surface, decorative layer, or face can comprise a decorative textile or fabric layer that is optionally saturated, covered, and / or coated with a protective film or film-forming composition. The backing can optionally comprise an agglomerated mass of particles, a foam, foam and particles, a felt, or a combination thereof. Methods for producing such surface coverings are also disclosed.

Owner:MILLIKEN & CO

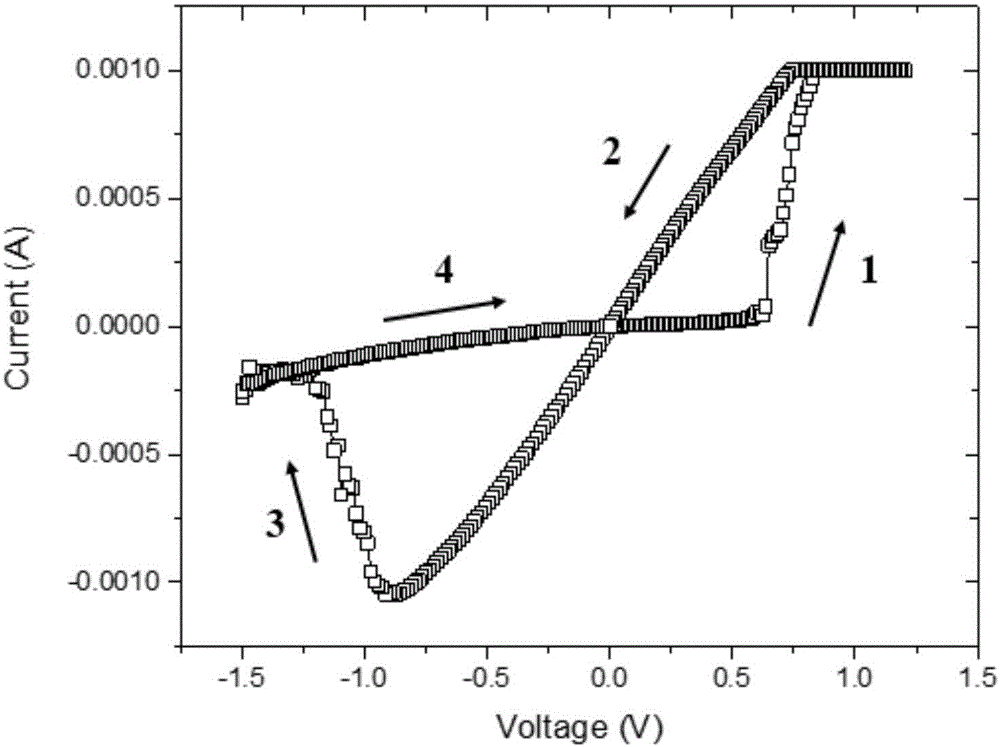

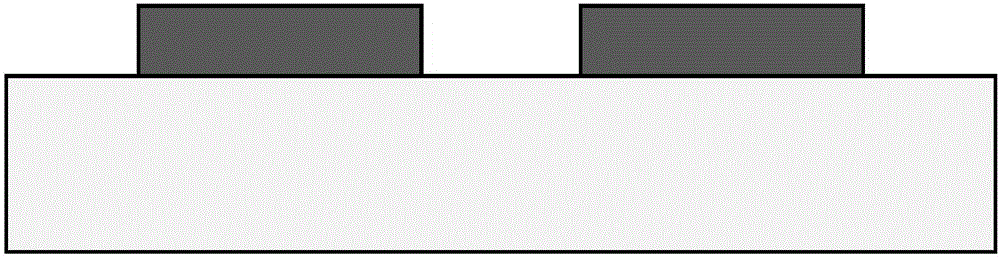

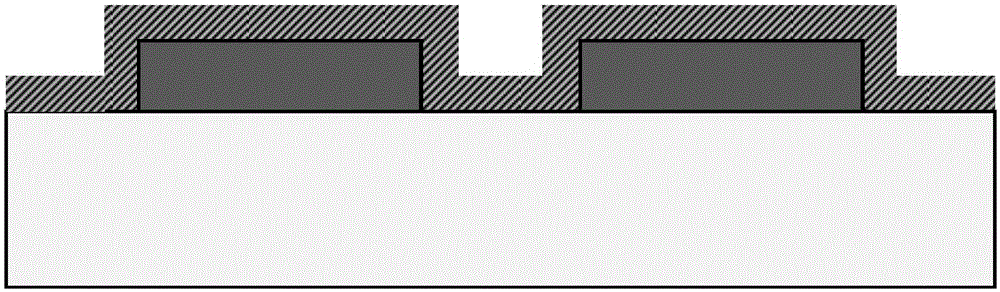

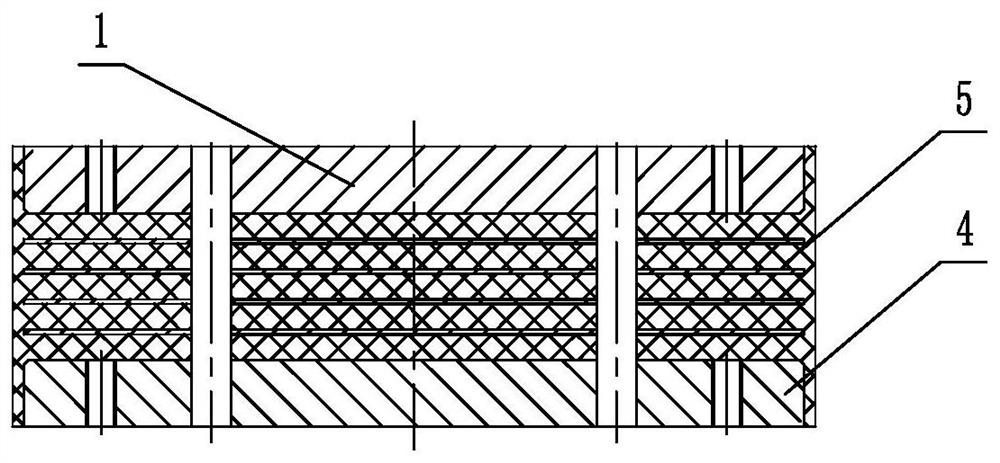

High consistency resistive random access memory and preparation method thereof

ActiveCN106229407AImprove consistencyImprove integration densityElectrical apparatusCMOSStatic random-access memory

The invention provides a high consistency resistive random access memory and a preparation method thereof, and belongs to the technical field of CMOS very large scale integration. The resistive random access memory comprises a substrate and a lower electrode-resistance variation film-upper electrode structure which is located on the substrate; the lower electrode is located on the substrate; the resistance variation film is located between the upper and lower electrodes; the resistance variation film is locally doped with metals; and the doped region is 50% to 10% of a device working area. A conducting channel of the resistive random access memory is more easily fused at a locally doped area, thus random generation and fusion of the conducting channel are limited in the locally doped area, the randomness of the conducting channel is effectively reduced, and the consistency of the resistive random access memory is improved.

Owner:PEKING UNIV

Ultrahigh-damping rubber support base and manufacturing method thereof

PendingCN111809739AStiffness controllable and adjustableEasy to makeBridge structural detailsProtective buildings/sheltersRubber materialPolymer science

The invention discloses an ultrahigh-damping rubber support base. A support base rubber sheet is a composite rubber sheet which is formed by a middle rubber layer and an encapsulated layer, wherein the composite rubber sheet is a composite rubber sheet I or a composite rubber sheet II; the middle rubber layer of the composite rubber sheet I is rubber A, and the encapsulated layer is rubber B or can be M layers of alternatively coated rubber B and rubber A; the middle rubber of the composite rubber sheet II is rubber B, and the encapsulated layer can be N layers of alternatively coated rubber Aand rubber B; the rubber A is high-energy-dissipation damping rubber, and the rubber B is highly-elasticity rubber, and the highly-elastic rubber accounts for 5%-90% of the total volume of the rubbersheet. A manufacturing method for the ultrahigh-damping rubber support base comprises the following steps: manufacturing a rubber A blank rubber sheet and a rubber B blank rubber sheet, manufacturinga support base rubber sheet and manufacturing a support base. The support base is simple in manufacturing, and is adjustable in performance; and the manufactured high-energy-dissipation damping rubber material is more uniform in rubber, is higher in tensile strength and elongation at break, and is affected slightly in performance by the temperature; and after external load is unloaded, the outerside surface of the support base is not liable to bulge and deform, so that scope of application is wide.

Owner:柳州东方工程橡胶制品有限公司

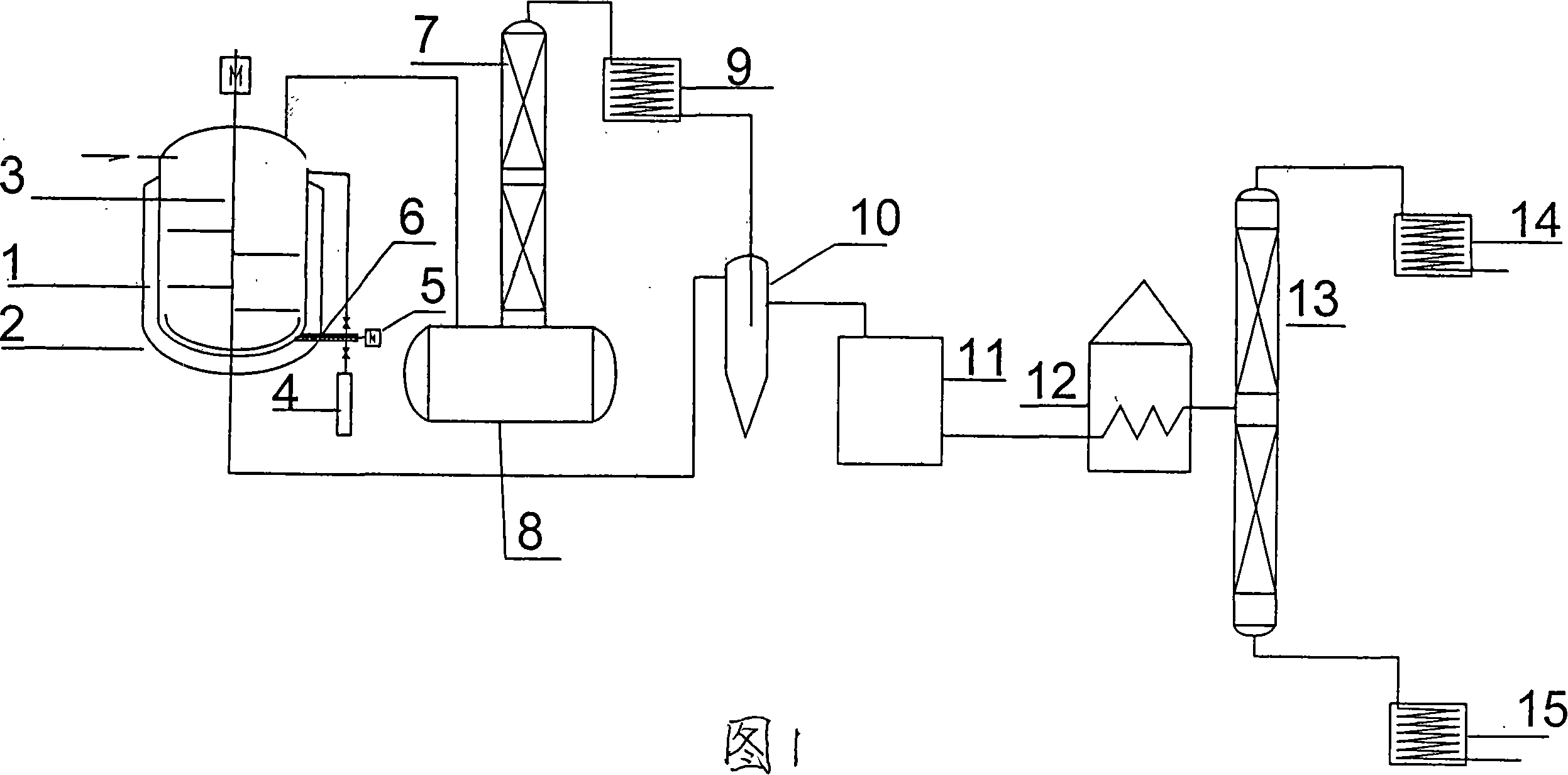

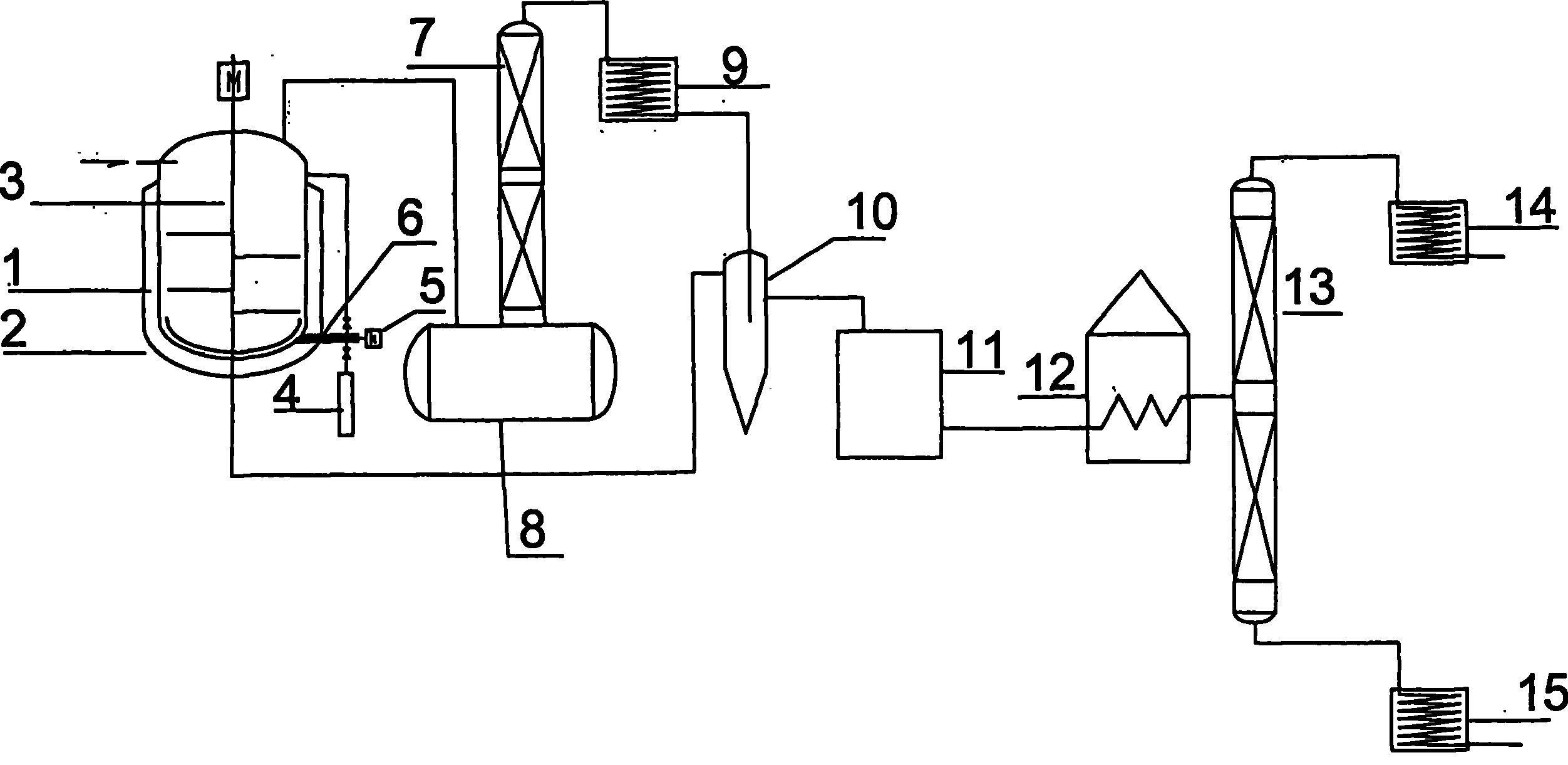

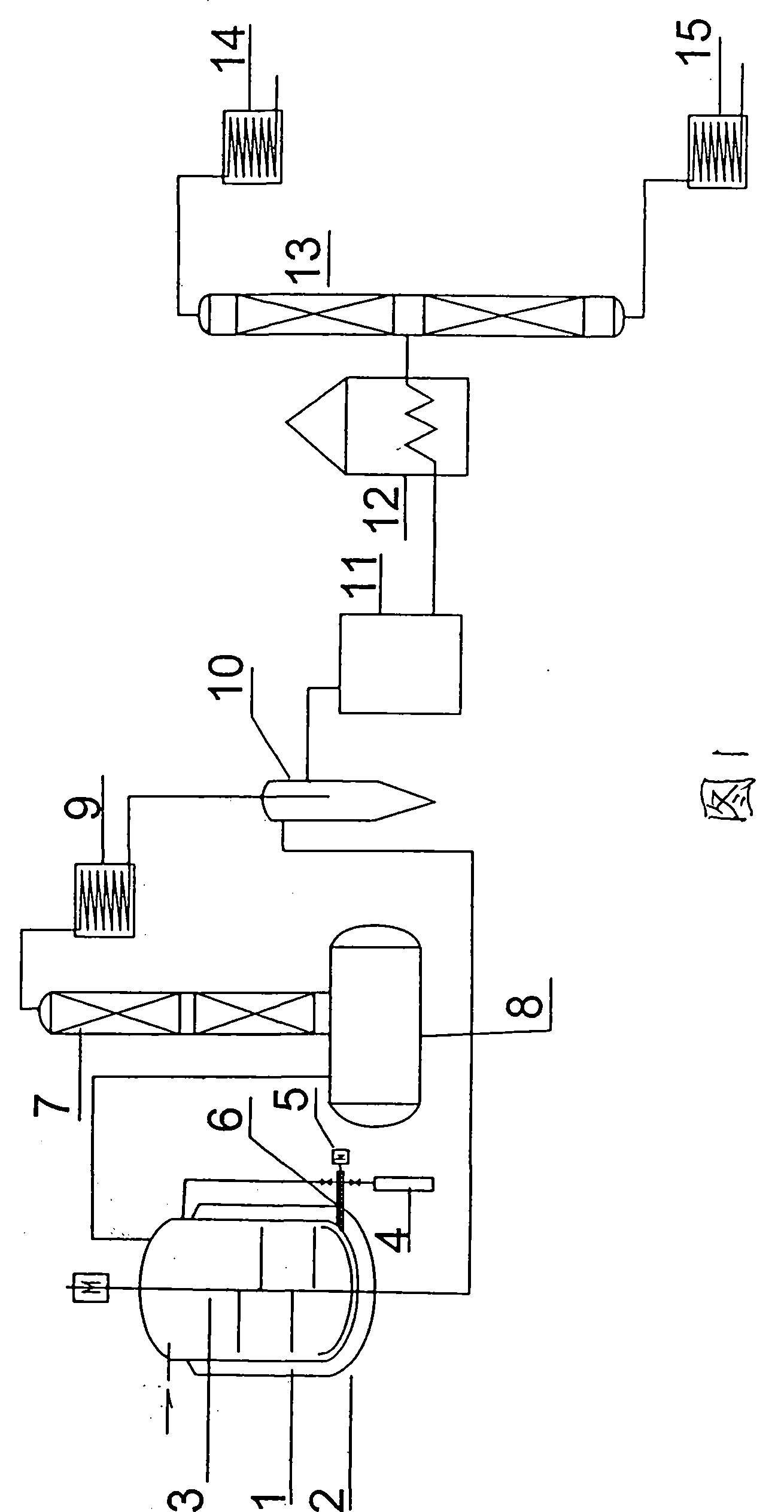

Industrialized method for producing fuel oil by using waste plastics

InactiveCN101117585AIncrease heat absorption areaImprove conversion rateLiquid hydrocarbon mixture productionDistillationHeat conducting

The present invention relates to an oil refining technology by utilizing waste plastic, in particular to an industrialized fuel oil producing method by utilizing the waste plastic. The present invention solves the shortcoming existed in the prior art that the effect for using the waste plastic to produce the fuel oil is bad. The steps includes: dehydrated mineral oil is used as the medium of liquidized waste plastic to be put into a reactor, the mineral oil being used for liquidizing the waste plastic is preheated in the reactor, the waste plastic is put into the reactor, the waste plastic in the reactor is stably heated and time-lapsed cracked, gaseous hydrocarbon produced from the reaction is fed into a flash distillation column, light distillated oil produced from the flash distillation column is distilled in the normal atmosphere. The present invention adopts molten salt as the heat-conducting medium, so as to enable the plastic being heated evenly, the operation temperature is controlled at 500 DEG C, the liquid liquidoid temperature inside the reactor is controlled at 370 DEG C for delaying the cracking operation and stabilizing the cracking temperature, the liquid inside the reactor is cracked under the stable condition, so as to overcome disadvantages in the prior art that using the coal fire to burn directly, the stability of the oil product is bad and the yield of the liquid is low.

Owner:党德润

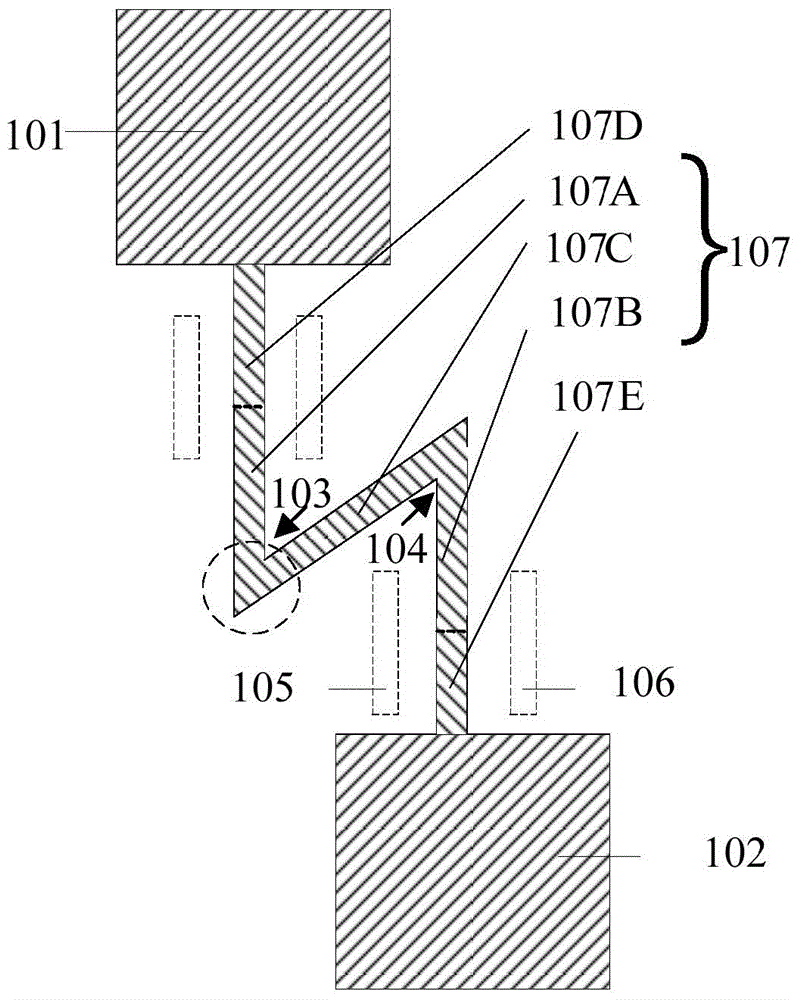

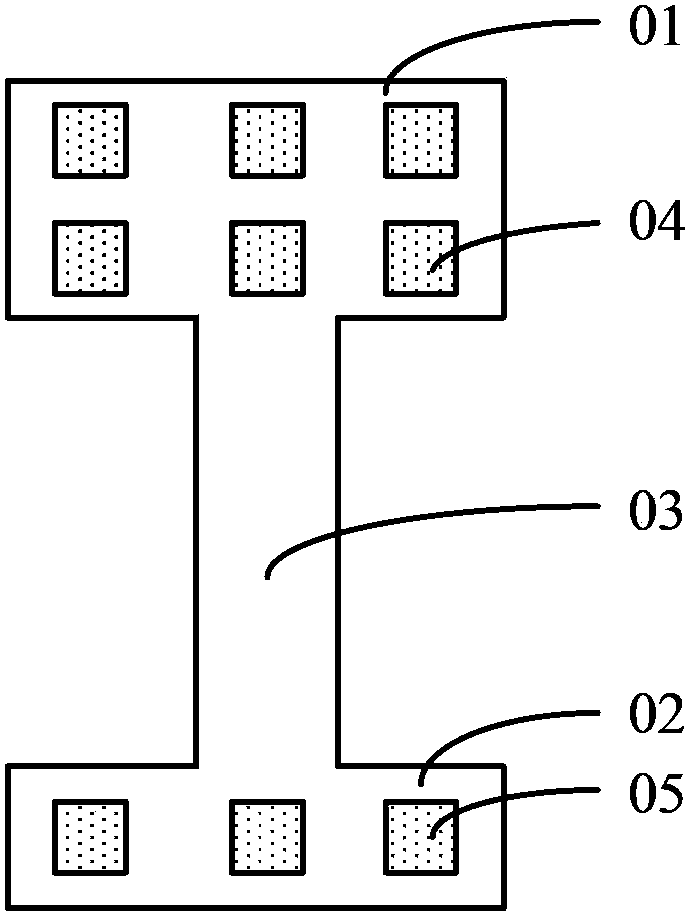

Electric fuse structure and formation method thereof

InactiveCN104617079ALower programming voltageFlexible electrical propertiesSemiconductor/solid-state device detailsSolid-state devicesElectricityElectric fuses

The invention provides an electric fuse structure and a formation method thereof. The electric fuse structure comprises an electric fuse, a base, an interlayer medium layer and other parts; the electric fuse comprises a first electrode, a second electrode, and a connecting fuse which is connected with the first electrode and the second electrode; the connecting fuse is equipped with at least one folding structure. According to the electric fuse structure, the current crowding effect occurs at the corner of the folding structure when loading voltage to the electric fuse, and the current density at the corner is more than that in other parts of the electric fuse, which is beneficial for the self-heating effect of the electric fuse; therefore, the connecting fuse is easily fused at the corner, and as a result, the programming voltage of the electric use can be reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP

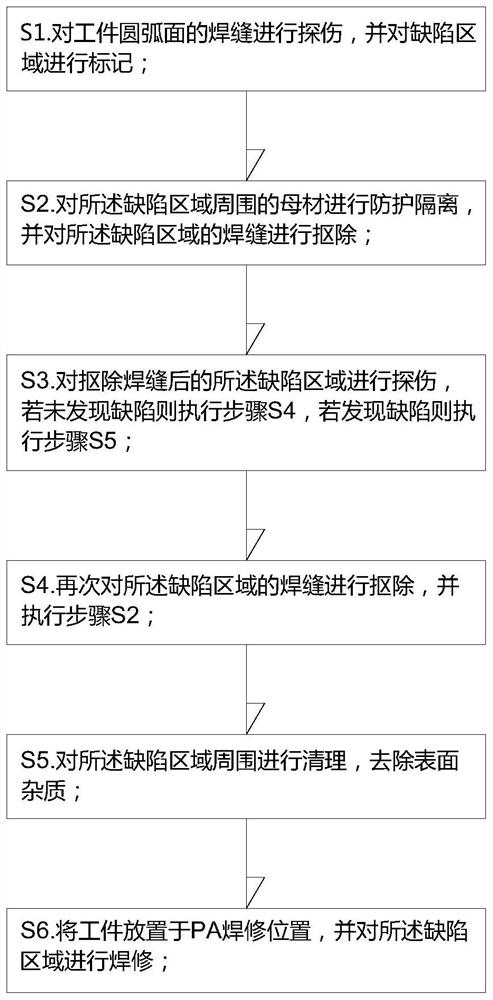

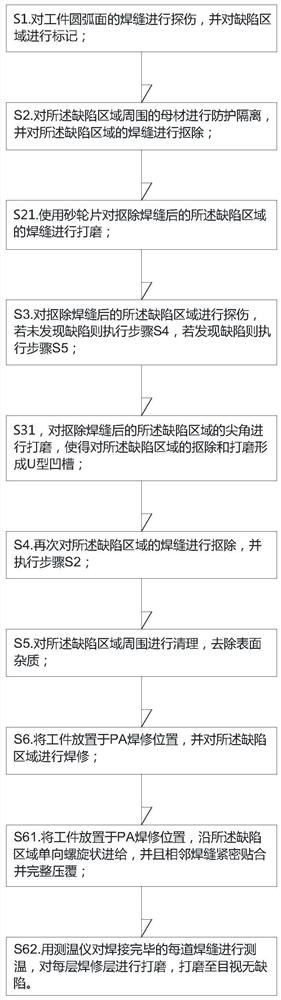

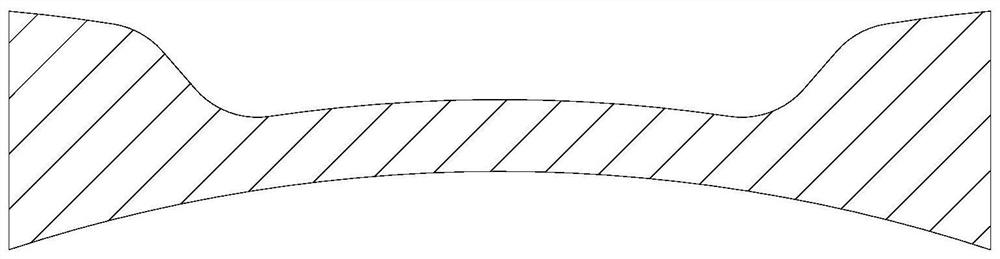

Defect repair welding process for arc-surface weld joint

InactiveCN112548382AReduce lossEffective control of penetrationWelding apparatusDefect repairStructural engineering

The invention discloses a defect repair welding process for an arc-surface weld joint. The process comprises the following steps that S1, flaw detection is conducted on the weld joint of an arc surface of a workpiece, and a defect area is marked; S2, base metal around the defect area is protected and isolated, and the weld joint of the defect area is dug out; S3, flaw detection is conducted on thedefect area with the weld joint dug out, if no defect is found, S4 is executed, and if a defect is found, S5 is executed; S4, the weld joint of the defect area is dug out again, and S2 is executed; S5, the periphery of the defect area is cleaned; and S6, the workpiece is placed at a PA repair welding position, and repair welding is conducted on the defect area. According to the defect repair welding process for the arc-surface weld joint, the interlayer penetration can be effectively controlled through a layer-by-layer repair welding method, the operation difficulty is reduced, the problem that parts are scrapped due to improper operation of a repair welding method is solved, internal defects of the weld joint are eliminated, consumable loss is reduced, and the production efficiency is improved.

Owner:CRRC QINGDAO SIFANG CO LTD

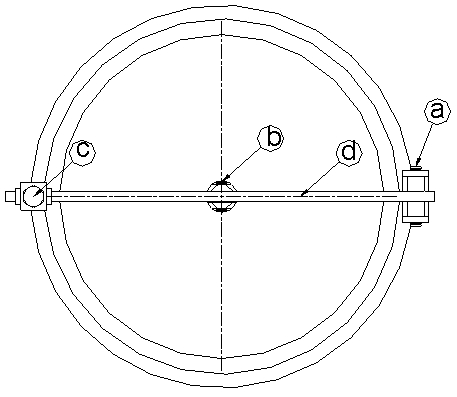

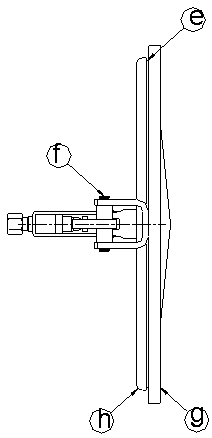

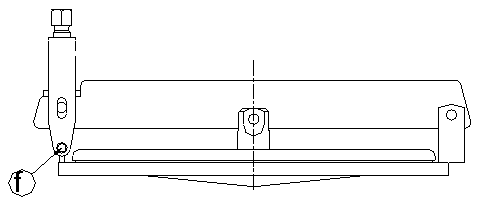

Inspection door for mechanical equipment

The invention discloses an inspection door for mechanical equipment. The door comprises a flange and a cover plate, an inspection port is formed in the center of the flange, the cover plate is arranged on the inspection port of the flange, and a sealing ring is arranged between the flange and the cover plate; a press rod is arranged on the cover plate and comprises an upper press rod body and a lower press rod body, the tail of the upper press rod and the tail of the lower press rod body are connected together, the cover plate is fixedly connected with the press rod through a middle connectionshaft, and the middle connection shaft penetrates through the portion between the upper press rod body and the lower press rod body; the end of the press rod is hinged to the flange through a movableshaft, and a manual switch device is arranged at the tail of the press rod; a step flange ring formed with the flange at a time is arranged at the outer circle of the flange, a 45-degree slope is arranged at the inspection port of an inner ring of the flange, the press rod is formed through edge folding of one-time formation, and the end of the upper press rod body, the end of the lower press rodbody and the movable shaft form a triangular strengthening structure. The inspection door is stable in structure, more convenient to operate and easy to clean. Sanitary dead corners are avoided, theinspection door better accords with the sanitation requirements, and hidden sanitation dangers are reduced to the greatest limit.

Owner:西恪丹分离技术(上海)有限公司

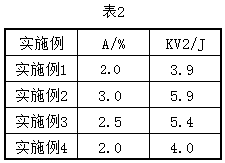

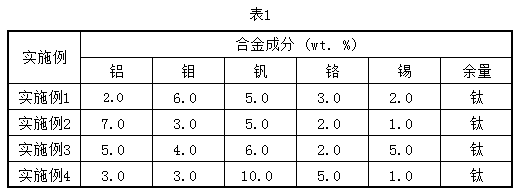

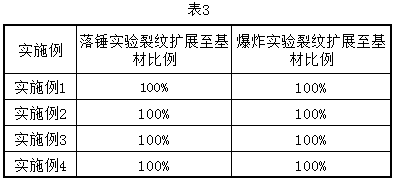

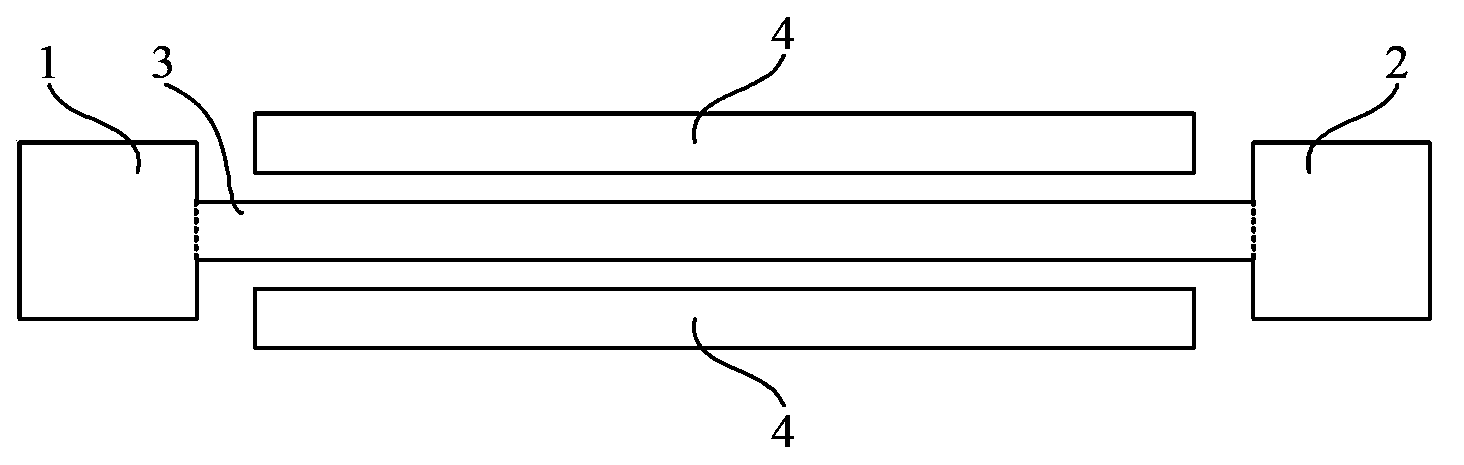

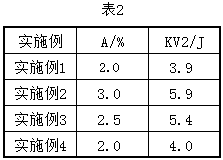

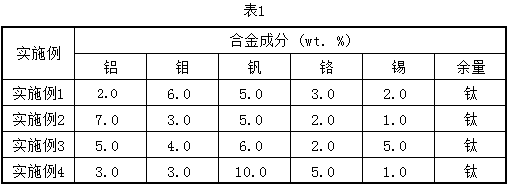

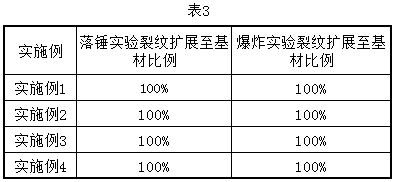

Brittle weld bead surfacing welding wire for crack source of titanium alloy applied to boat and preparation method of brittle weld bead surfacing welding wire

ActiveCN108284287AFix production issuesEasy to crackWelding/cutting media/materialsSoldering mediaDrop weightTitanium

The invention relates to the field of boat titanium alloy toughness investigation test materials applied to a boat titanium alloy application research and evaluation system, and particularly relates to a brittle weld bead surfacing welding wire for a crack source of titanium alloy applied to a boat and a preparation method of the brittle weld bead surfacing welding wire. The welding wire is prepared from the following elements and components in percentage by mass: 2.0-1.0 percent of aluminum, 3.0-6.0 percent of molybdenum, 5.0-10.0 percent of vanadium, 2.0-5.0 percent of chromium, 1.0-5.0 percent of tin and the balance of titanium. The welding wire provided by the invention can solve the problem about natural sharp cracks generated in a boat titanium alloy toughness investigation application process of a drop-weight test, an explosion test and the like, and thus the drop-weight test and explosion test methods for the titanium alloy applied to the boat can be improved, and the boat titanium alloy application research and evaluation system is more complete.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

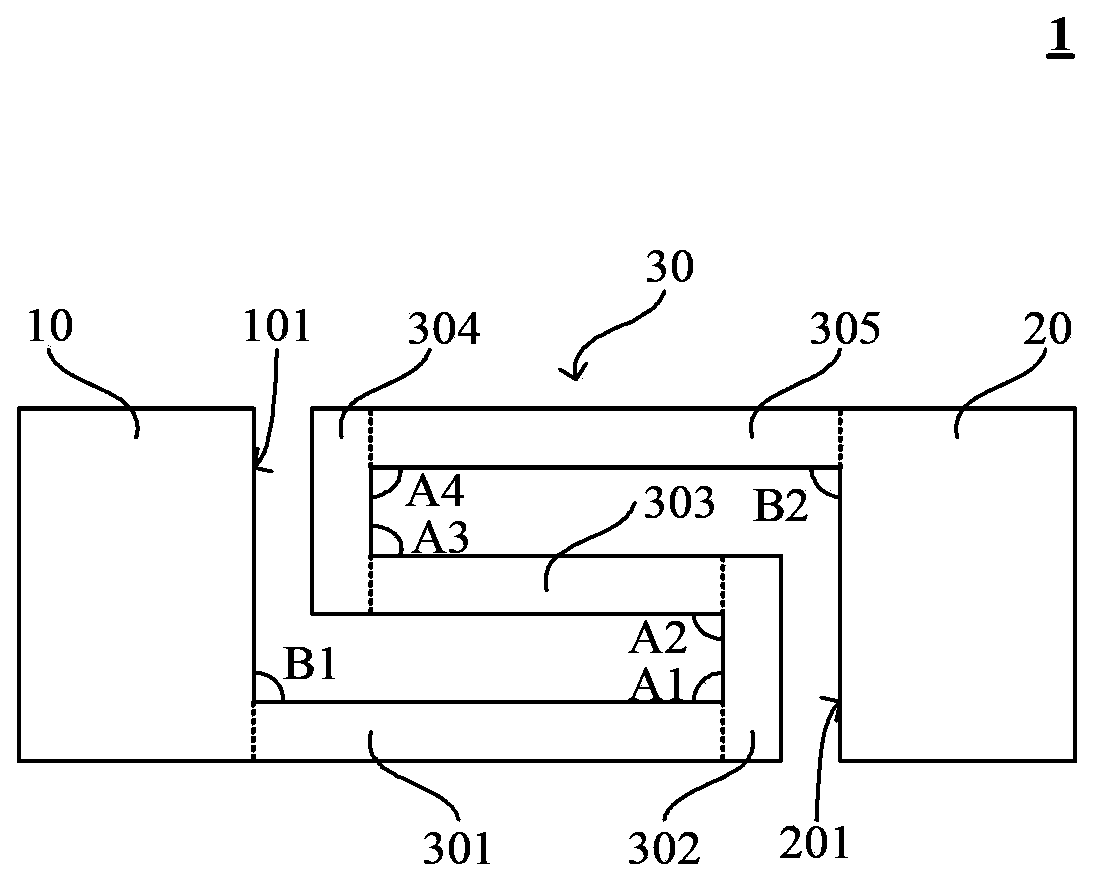

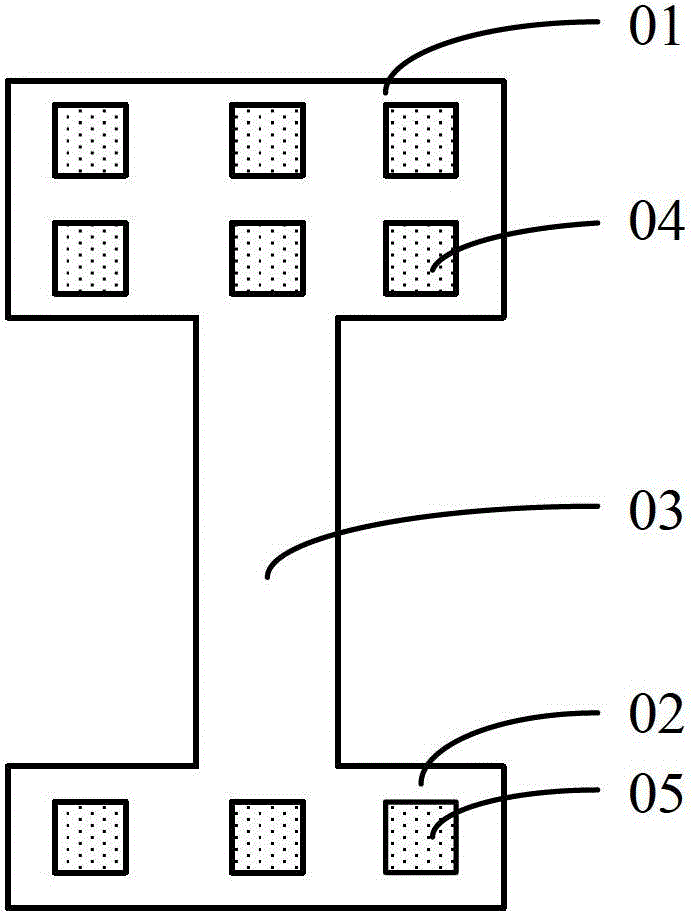

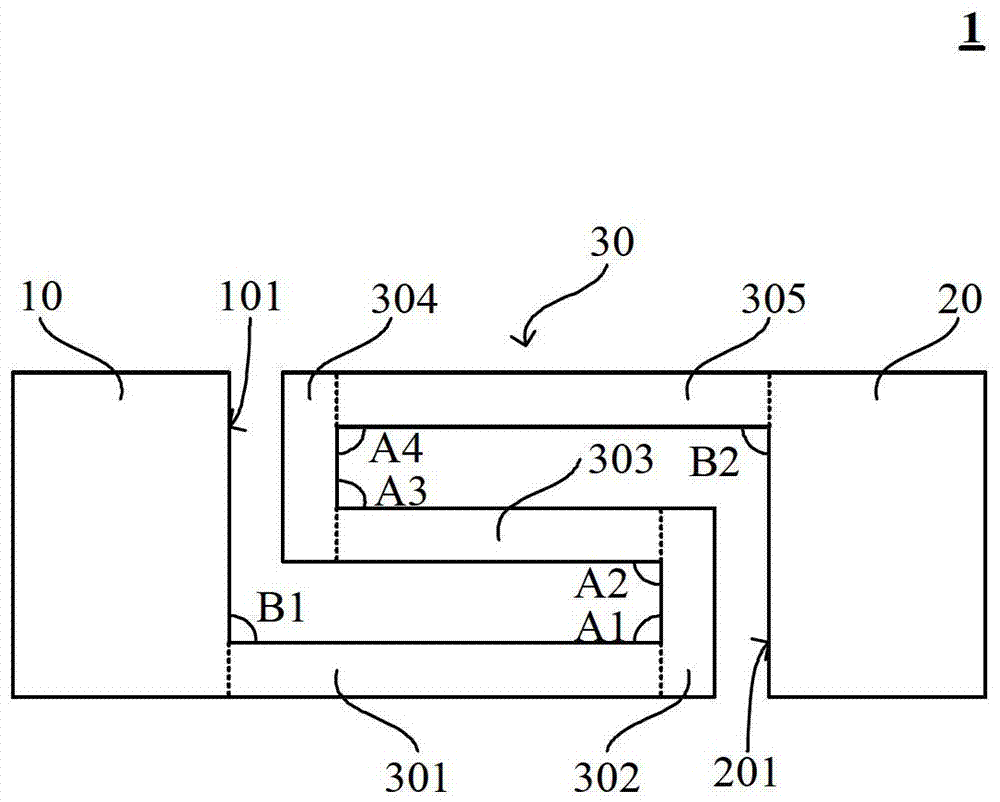

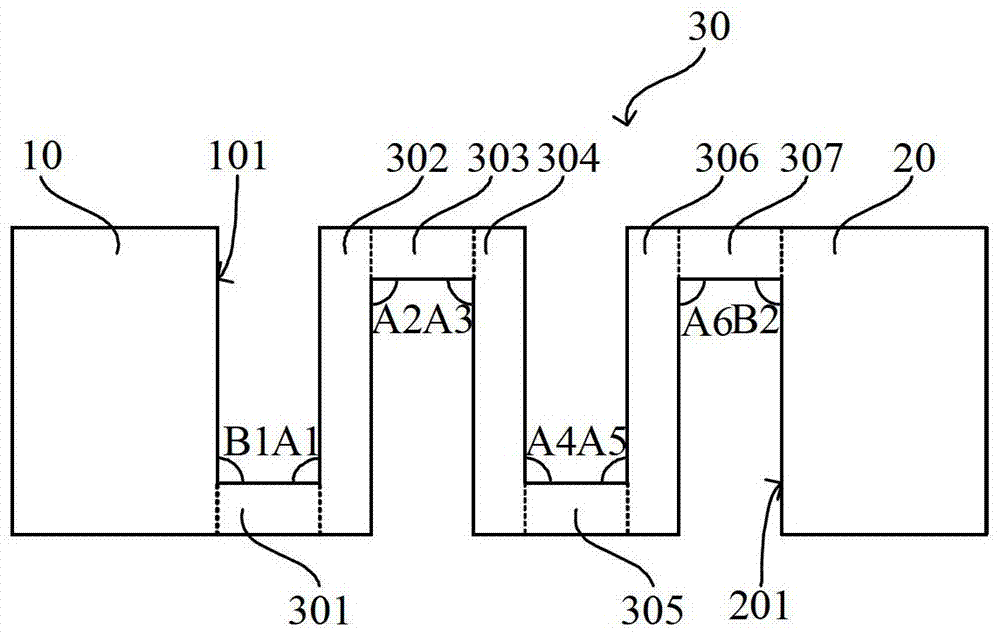

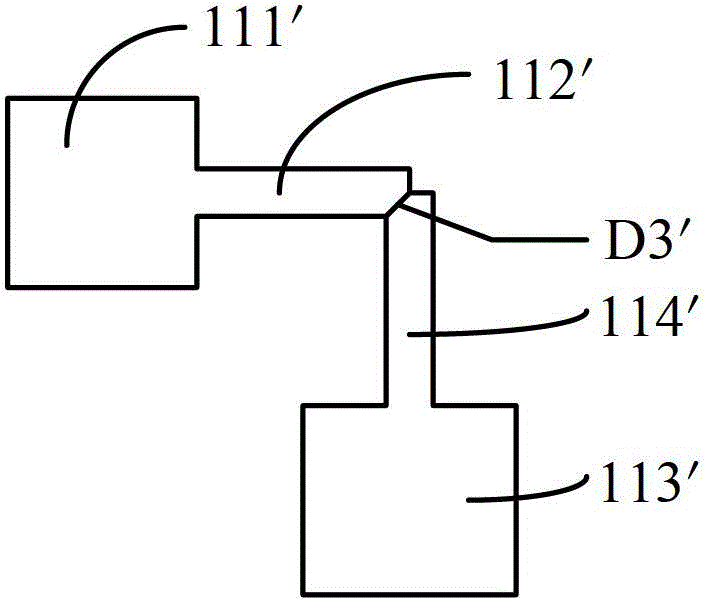

Electric fuse structure

ActiveCN104347588AReduce areaIncrease the lengthSemiconductor/solid-state device detailsSolid-state devicesIntegrated circuitElectricity

The invention discloses an electric fuse structure. The electric fuse structure comprises an electric fuse, and an anode and a cathode which are respectively arranged at two ends of the electric fuse and are connected with the electric fuse, wherein the electric fuse comprises at least three sub electric fuses which are mutually connected end to end, and included angles of every two end-to-end connected sub electric fuses are greater than 0 DEG and smaller than 180 DEG. The electric fuse is guaranteed to have enough large length to make the electric fuse be more easily fused while the distance between the anode and the cathode can be reduced, so the area occupied by the electric fuse structure in an integrated circuit chip can be reduced. When the electric fuse structure and metal interconnection wires are synchronously formed on the integrated circuit chip, layout design of the metal interconnection wires in the integrated circuit chip has more selections.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Protecting welding process with mixed Ar plus CO2 gas

InactiveCN101020273ALow splash rateReduce lossesArc welding apparatusWelding/cutting media/materialsMaterial consumptionProduct gas

The protected welding process with mixed Ar plus CO2 gas includes the following steps: selecting arc voltage in 20-26 V; selecting welding current in 200-230 A; selecting gas flow rate in 15-20 l / min; connecting to power source in correct polarity; selecting wire feeding speed in 5.25 m / min; determining wire extending length of 15 mm; feeding wire in equal speed; and continuously welding. The present invention has the advantages of excellent welding performance, lowered welding material consumption, high welding quality, etc. and may be used in welding rotor rack, machine foundation, etc.

Owner:SICHUAN DONGFENG ELECTRIC MACHINARY WORKS CO LTD

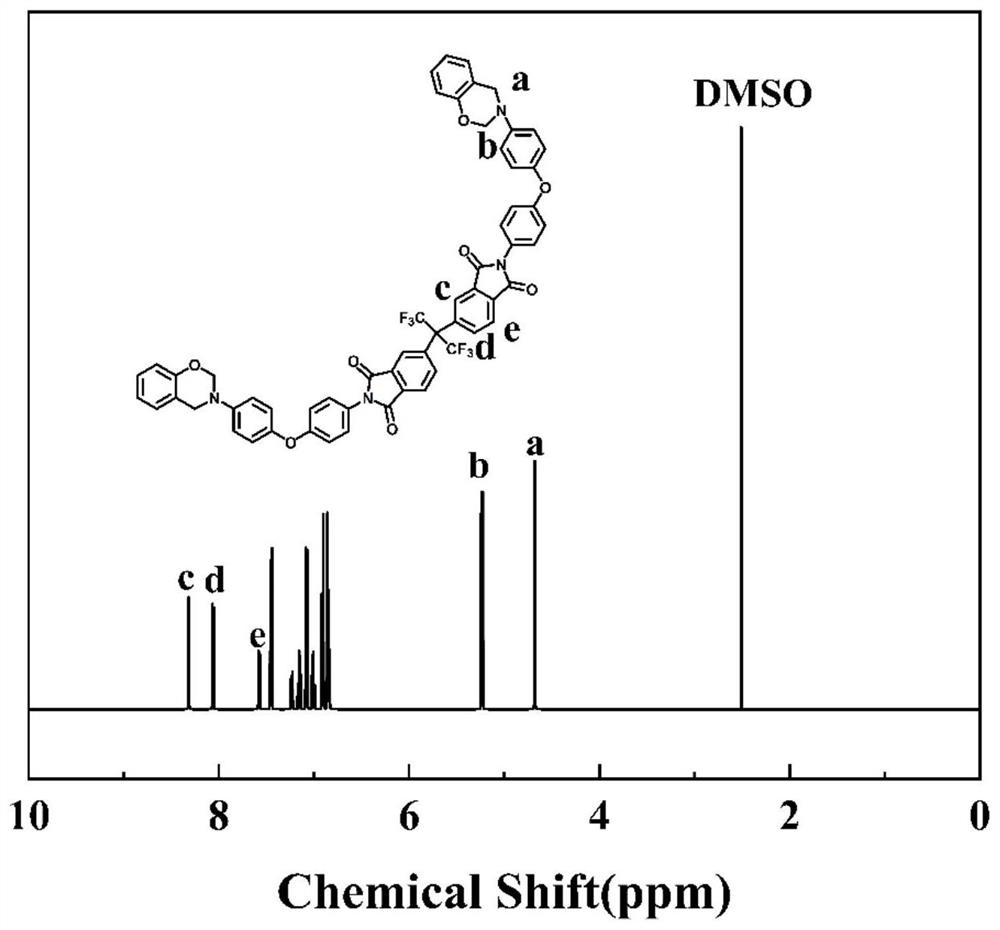

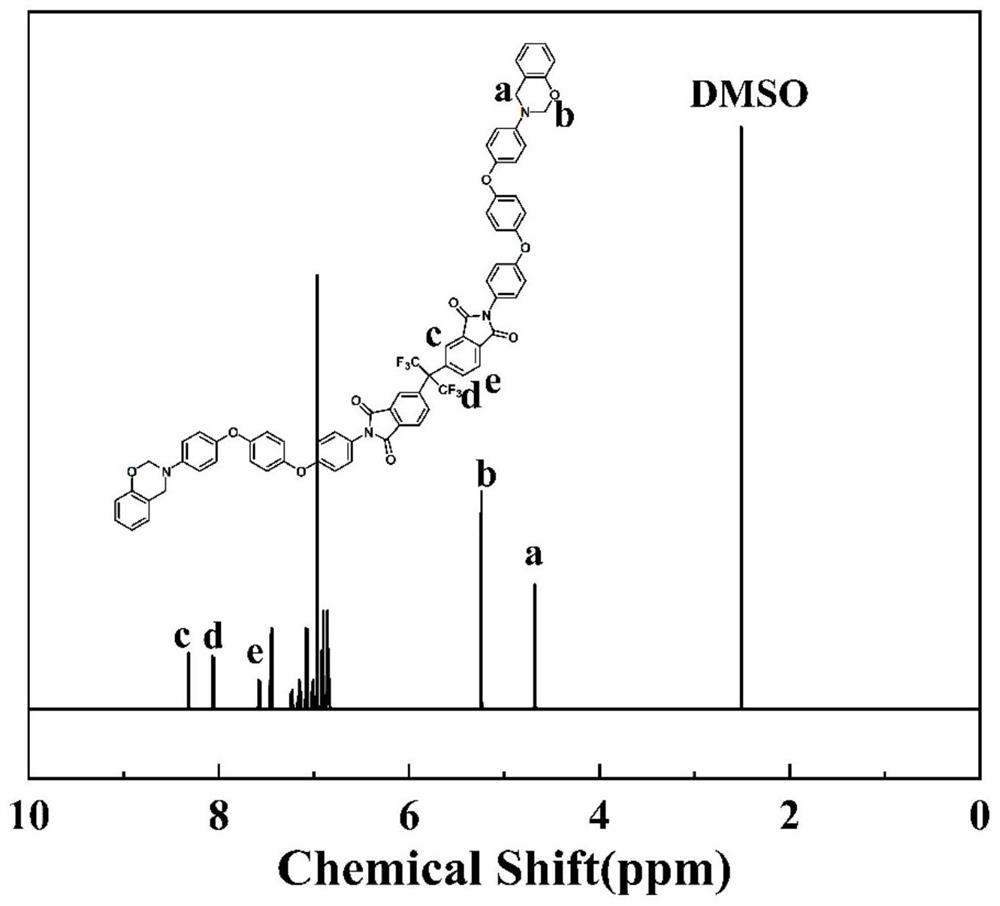

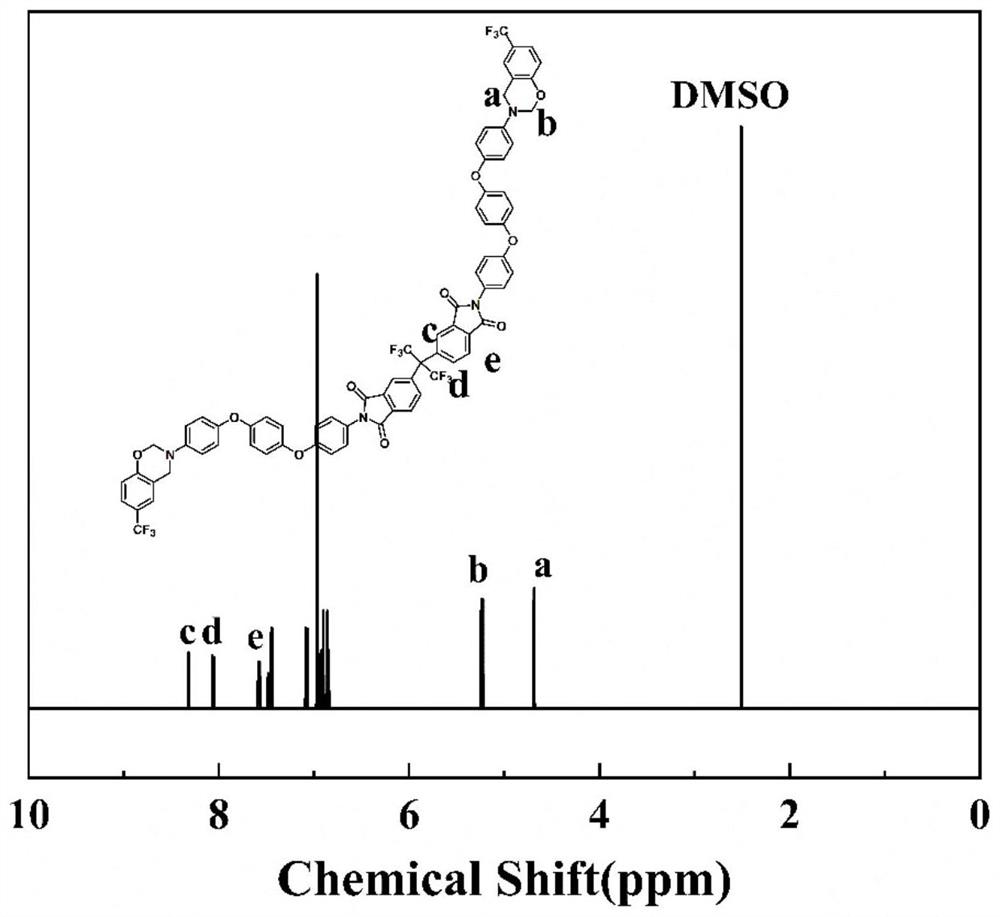

Benzoxazine-terminated imide, preparation method thereof and polybenzoxazine-terminated imide film

The invention discloses benzoxazine end-capped imide which is obtained by reacting diamine end-capped imide serving as an amine source with monohydric phenol and paraformaldehyde, the diamine-terminated imide is obtained by thermal cyclization of micromolecular polyamide acid in inert gas; the micromolecular polyamide acid is prepared by condensation reaction of a dianhydride monomer and a diamine monomer. The invention further discloses a preparation method of the benzoxazine end-capped imide and a polybenzoxazine end-capped imide film prepared from the benzoxazine end-capped imide. The invention further discloses a preparation method of the benzoxazine end-capped imide and a polybenzoxazine end-capped imide film prepared from the benzoxazine end-capped imide. The benzoxazine-terminated imide disclosed by the invention is fusible and soluble, and is easy to process; the polybenzoxazine-terminated imide film has the advantages of being excellent in mechanical property, thermal stability and flame retardant property.

Owner:SOUTH CHINA UNIV OF TECH

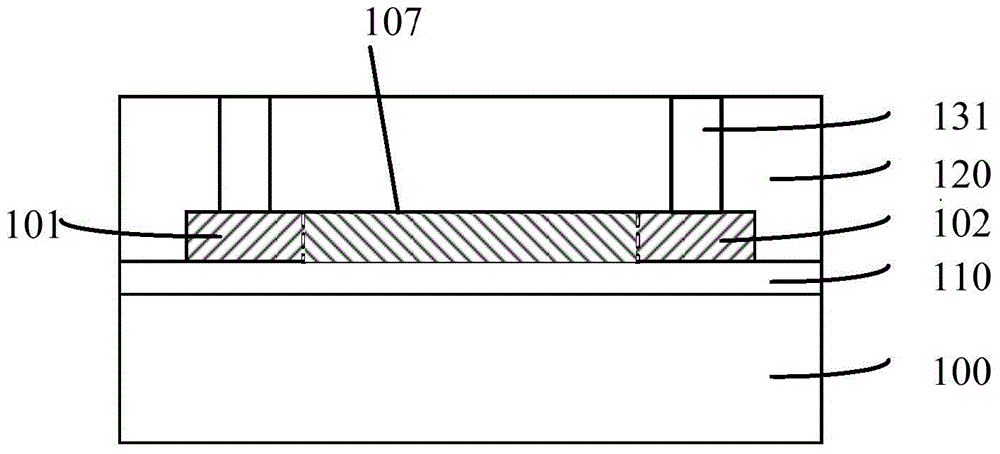

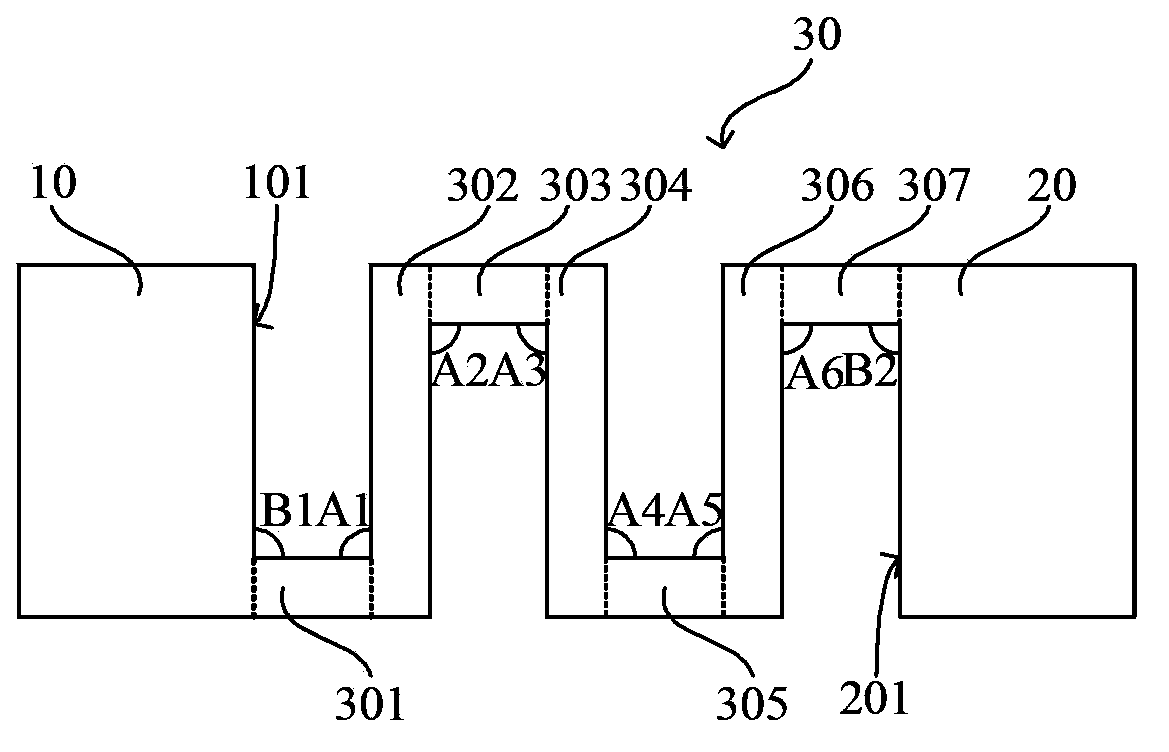

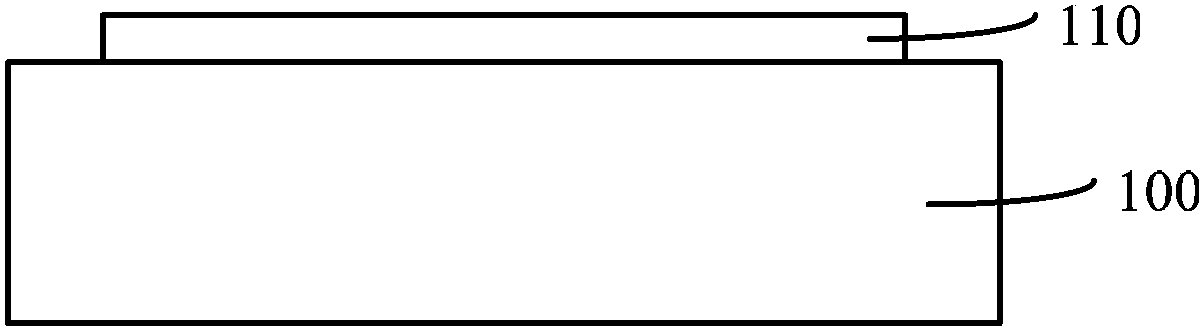

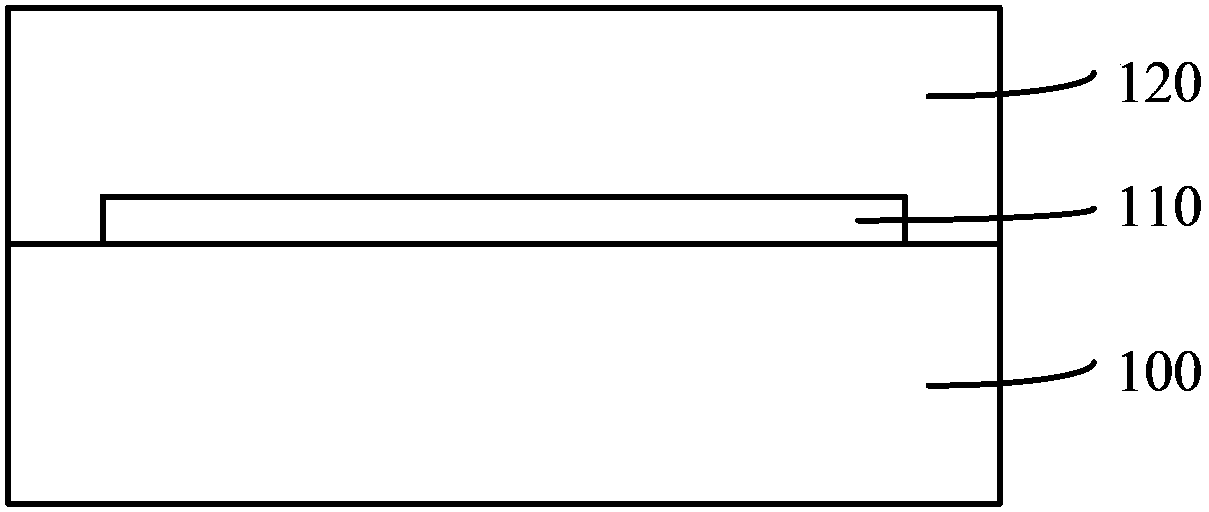

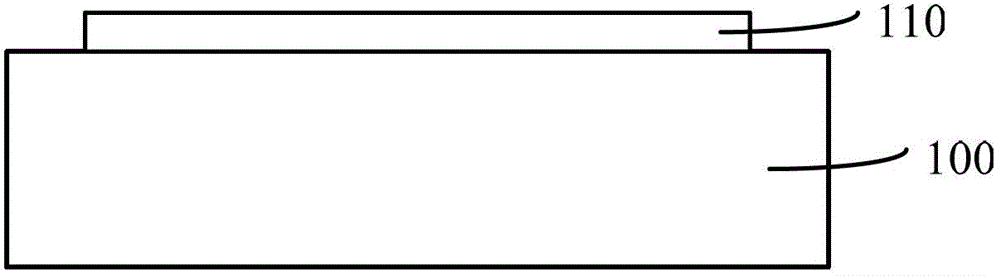

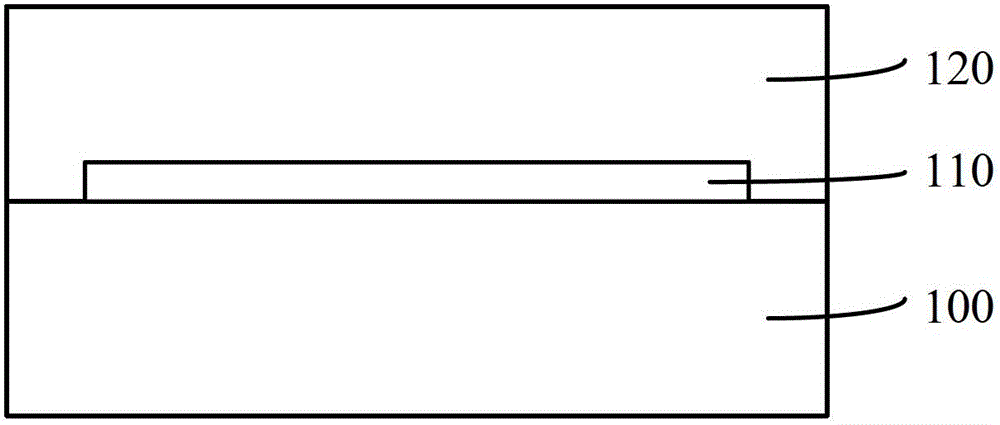

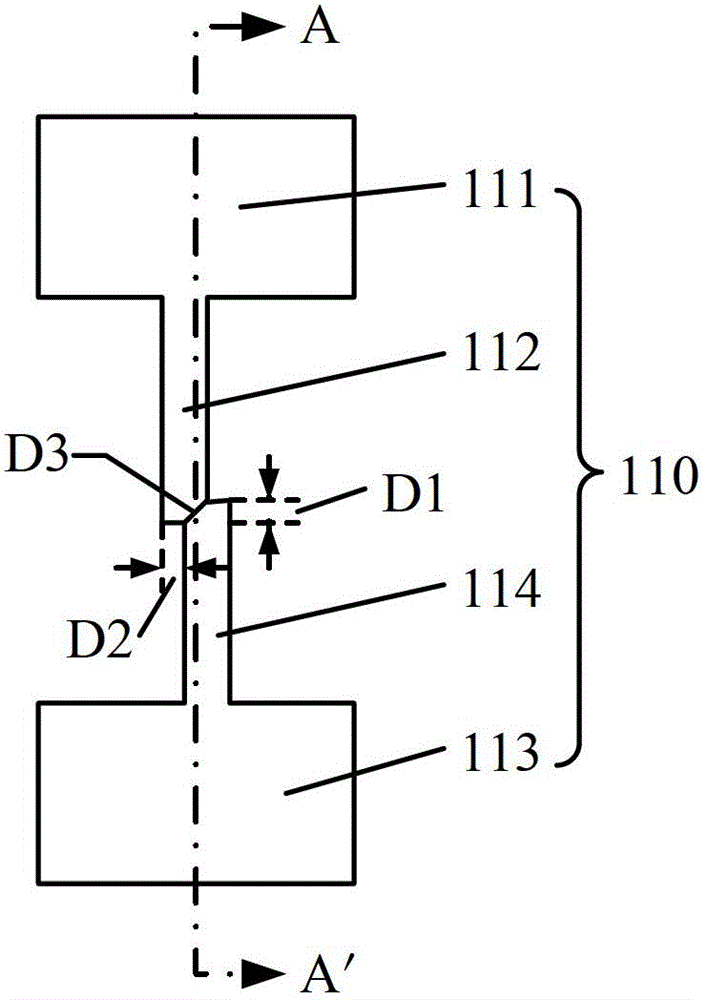

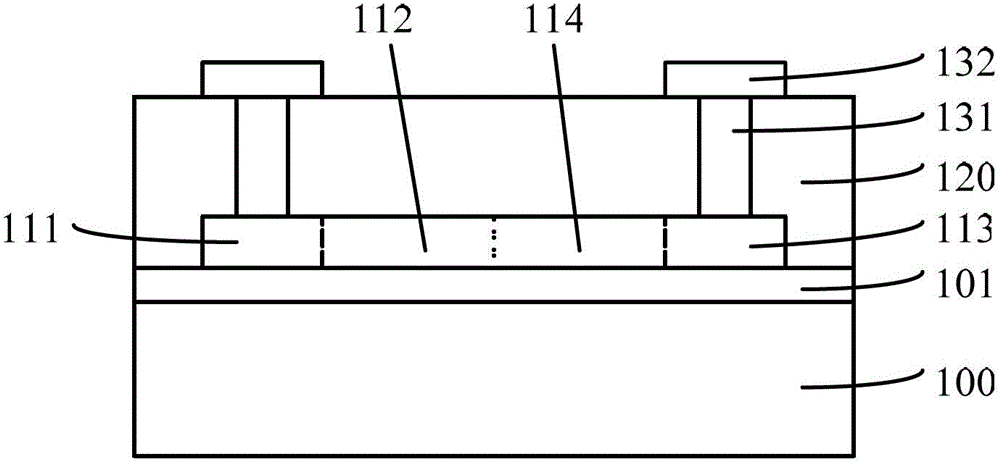

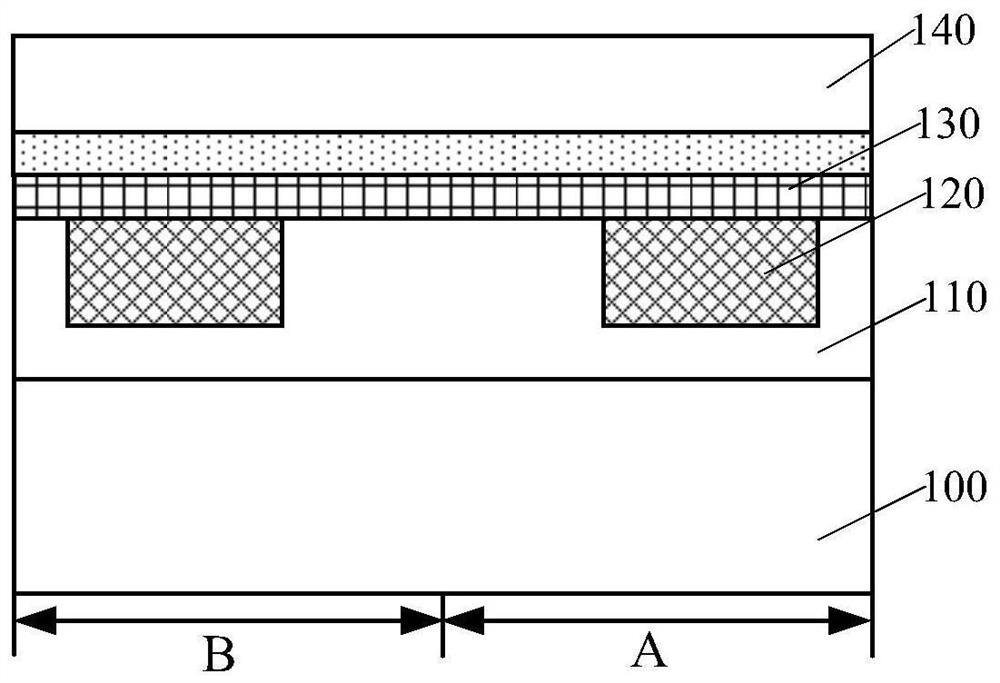

Electric fuse structure and formation method thereof

ActiveCN104103623AConducive to controlling the fusing timeImprove stabilitySemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductanceElectric fuses

Provided is an electric fuse structure and a formation method thereof. The electric fuse structure comprises a substrate, a first conductive layer which is arranged on the surface of the substrate, a layer-to-layer dielectric layer which covers the first conductive layer and the substrate, a first conductive plug which is arranged on the surface of the first conductive layer and penetrates through the layer-to-layer dielectric layer, and a second conductive layer which is arranged on the surfaces of the first conductive plug and the layer-to-layer dielectric layer. The surfaces of the bottom parts of the first conductive layer and the first conductive plug are partially contacted, or the surfaces of the top parts of the second conductive layer and the first conductive plug are partially contacted. The first conductive plug is partially contacted with the first conductive layer and the second conductive layer, and the partially contacted positions are higher in resistance, higher in electric field intensity and higher in electro-migration rate so that the partially contacted positions are more liable to be fused, fusing time is shortened and control is easier.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Composition for high-property heat-resisting corrosion-resisting glass fiber

ActiveCN102276153BSolve difficulties such as high manufacturing costsIncrease production capacityGlass fiberResin-Based Composite

The invention provides a composition for high-property heat-resisting corrosion-resisting glass fiber. The composition comprises the following components: 55-63wt% of SiO2, 18-23wt% of Al2O3, 8-16wt% of MgO, 7-13wt% of CaO, 0-1wt% of CeO2, 0-0.5wt% of Li2O, 0-0.4wt% of Fe2O3, 0-2wt% of TiO2, 0-0.5wt% of WO3 and 0-1.5wt% of Bi2O3, wherein the total content of SiO2, Al2O3, MgO and CaO is 94-98wt%; and CeO2, Li2O, Fe2O3, TiO2, WO3 and Bi2O3 are modifiers, the content of a single modifier is 0 at different times, and the total content of the modifiers is 2-6wt%. According to the invention, raw materials are adopted to produce the high-property heat-resisting corrosion-resisting glass fiber, thus the production difficulty is low, and the cost is low; and the produced glass fiber can be used as a reinforcing material and a heat-resisting heat-insulating material of a resin-based composite material and has the characteristics of high strength, corrosion resistance, high temperature resistance and light mass.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Crack source brittle bead surfacing welding wire for marine titanium alloy and preparation method thereof

ActiveCN108284287BFix production issuesEasy to crackWelding/cutting media/materialsSoldering mediaDrop weightTitanium

The invention relates to the field of boat titanium alloy toughness investigation test materials applied to a boat titanium alloy application research and evaluation system, and particularly relates to a brittle weld bead surfacing welding wire for a crack source of titanium alloy applied to a boat and a preparation method of the brittle weld bead surfacing welding wire. The welding wire is prepared from the following elements and components in percentage by mass: 2.0-1.0 percent of aluminum, 3.0-6.0 percent of molybdenum, 5.0-10.0 percent of vanadium, 2.0-5.0 percent of chromium, 1.0-5.0 percent of tin and the balance of titanium. The welding wire provided by the invention can solve the problem about natural sharp cracks generated in a boat titanium alloy toughness investigation application process of a drop-weight test, an explosion test and the like, and thus the drop-weight test and explosion test methods for the titanium alloy applied to the boat can be improved, and the boat titanium alloy application research and evaluation system is more complete.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Steel-making cooling cold material-remelted steel and preparation method thereof

The invention relates to a steel-making cooling material and a preparation method thereof, belonging to the metallurgical industry. The technical solution is: chemical composition mass percentage: C: ≤1.2%, Mn: ≤1.4%, S: ≤0.045%, P: ≤0.045%, Si: ≤0.7%, Fe: ≥92%, others are unavoidable Impurities, apparent density: ≥5.0t / m3. The production process is that steel slag is used as raw material after magnetic separation and screening, pre-firing temperature is 200-300oC, heat preservation is 8-15 minutes, heating temperature is 800-1100oC, molding temperature is 700-1000oC, molding pressure is 950-1100t. The invention has the beneficial effects of being beneficial to energy saving, emission reduction, environmental protection and resource recovery, shortening the smelting cycle, increasing the metal yield, reducing the cost of steelmaking, and alleviating the serious shortage of scrap steel. The invention has the advantages of simple process, low production cost and low energy consumption.

Owner:山西省黎城县通鑫再生资源回收利用有限公司

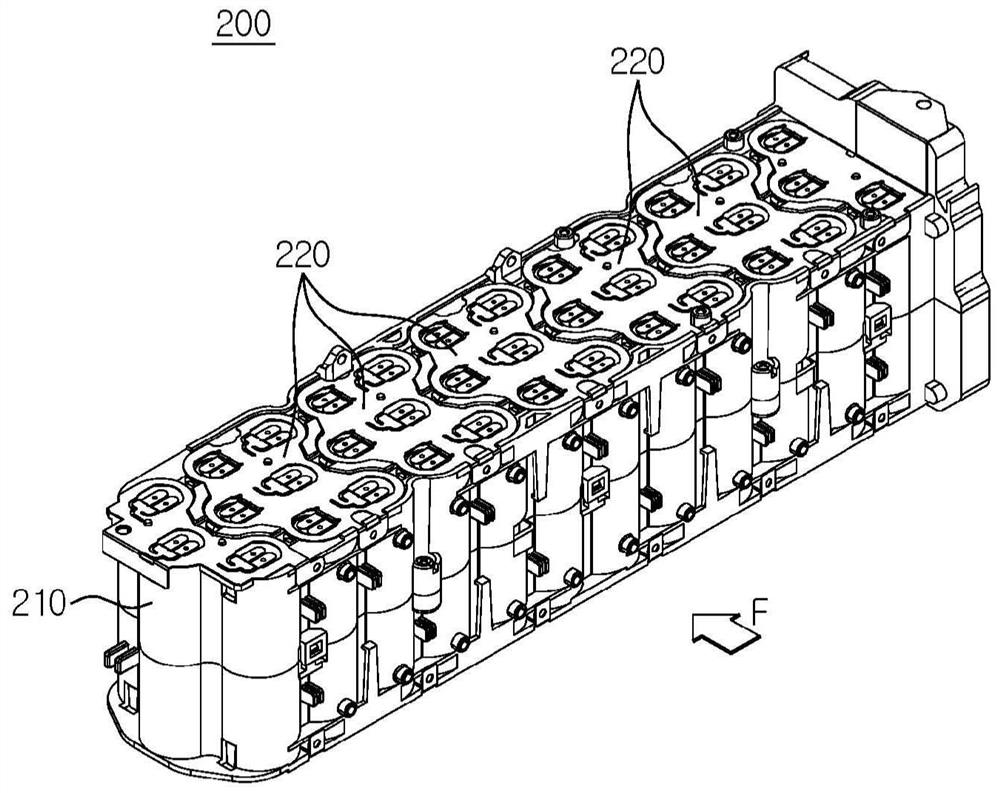

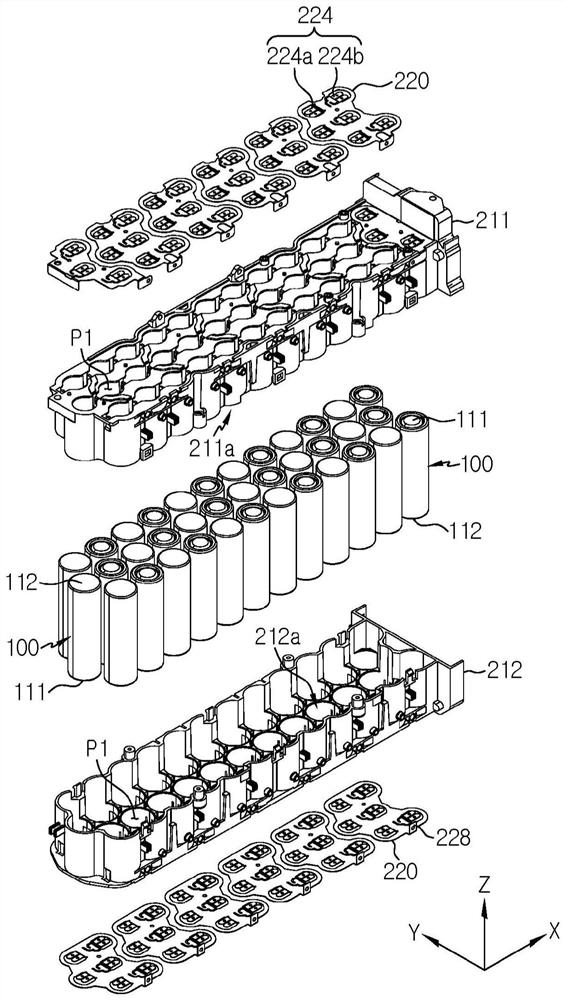

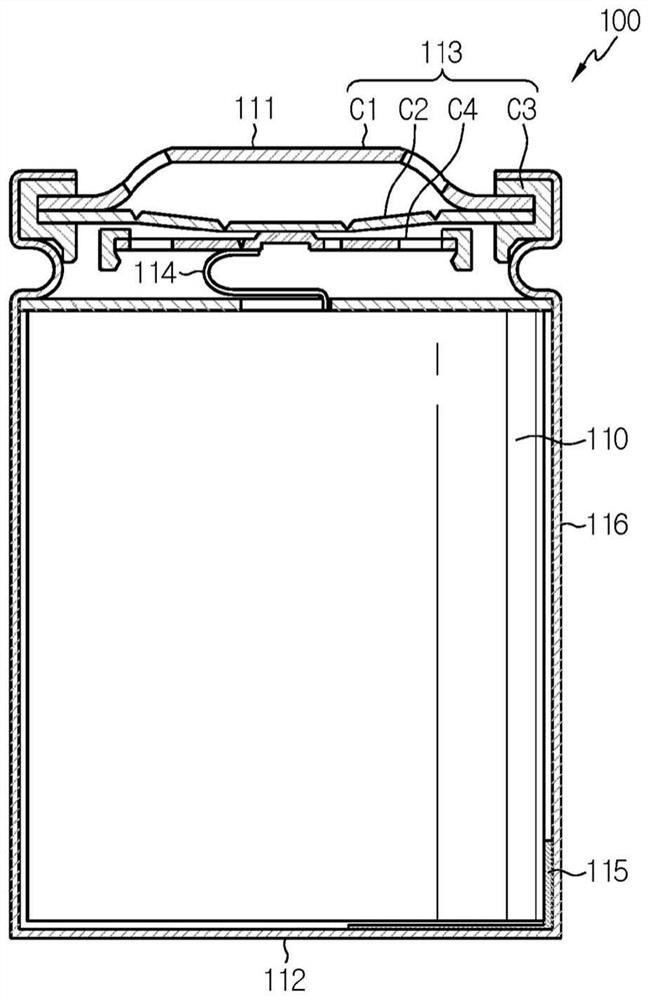

Battery module comprising bus bar plate, battery pack comprising same, and electronic device

PendingCN113939953AAvoid fireImprove securityCurrent conducting connectionsVent arrangementsElectrical batteryElectrical connection

A battery module according to the present invention comprises: a plurality of cylindrical battery cells each including a gas vent unit configured to discharge internal gas; and a bus bar plate including a negative electrode connection terminal which protrudes and extends from a boundary of a connection opening such that the protruding and extending part is in contact with the negative electrode terminal and electrically connects the plurality of cylindrical battery cells. Between the positive electrode connection terminal and the negative electrode connection terminal, a connection terminal which is in contact with a positive electrode terminal or a negative electrode terminal that is not opened by the gas vent unit includes a fuse unit which is configured to be disconnected, when an electric current of a certain level or greater flows from the cylindrical battery cell, and which has a bent structure that is bent at least once in a horizontal direction.

Owner:LG ENERGY SOLUTION LTD

Metamorphic process of hypo eutectic casting aluminum-silicon alloy

The invention discloses a metamorphic process of a hypo eutectic casting aluminum-silicon alloy, which comprises the steps of: 1) dosing according to components of the hypo eutectic casting aluminum-silicon alloy; 2) cleaning, drying and placing the alloy and an intermediate alloy into a crucible resistance furnace which is 5KW in power, heating till completely being melted, and controlling the temperature of the melt at 700+ / -5 DEG C; 3) pressing pure Mg weighed in the step 1) into a melt obtained from the step 2) to stand for 3-5 minutes by a graphite bell jar with preheating temperature of 300 DEG C; 4) heating the melt obtained from the step 3) to be at 740-760 DEG C, adding weighed AlSc4 intermediate alloy till the intermediate alloy is completed melted, refining for 15 minutes by rotatably jetting high purity argon and drossing after standing for 10-20 minutes; 5) cooling the melt obtained from the step 4) to be at 680-700 DEG C and pouring into sand moulds, then cooling along with the mould to be at room temperature to obtain an as-cast structure containing fiberous and short-rod-shaped eutectic Si; and 6) performing heat treatment for cast obtained from the step 5) according to a T6 heat treatment process to obtain a particle eutectic silicon structure with good mechanical properties.

Owner:ZHONGBEI UNIV

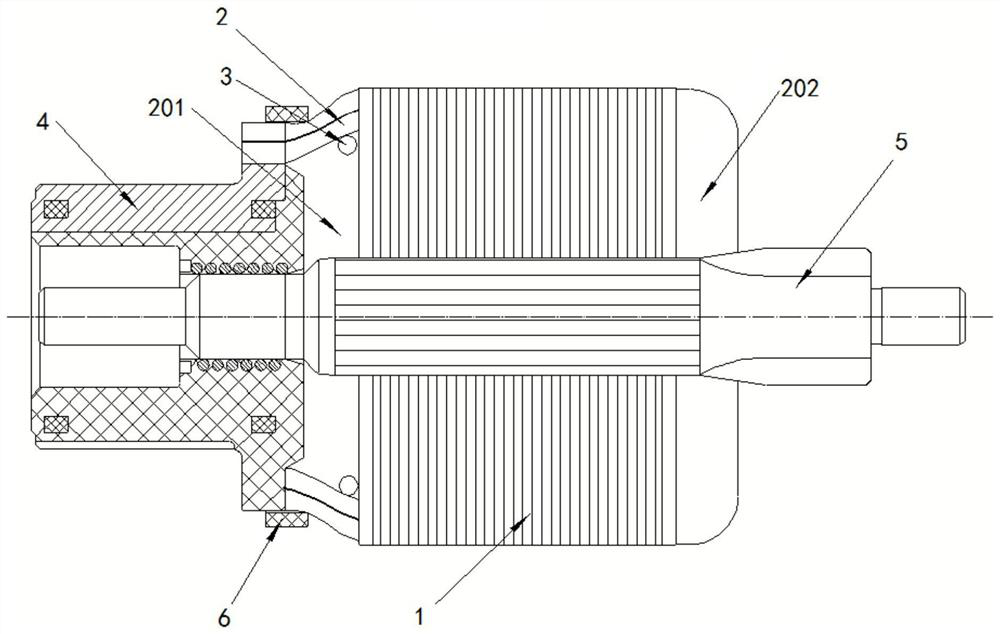

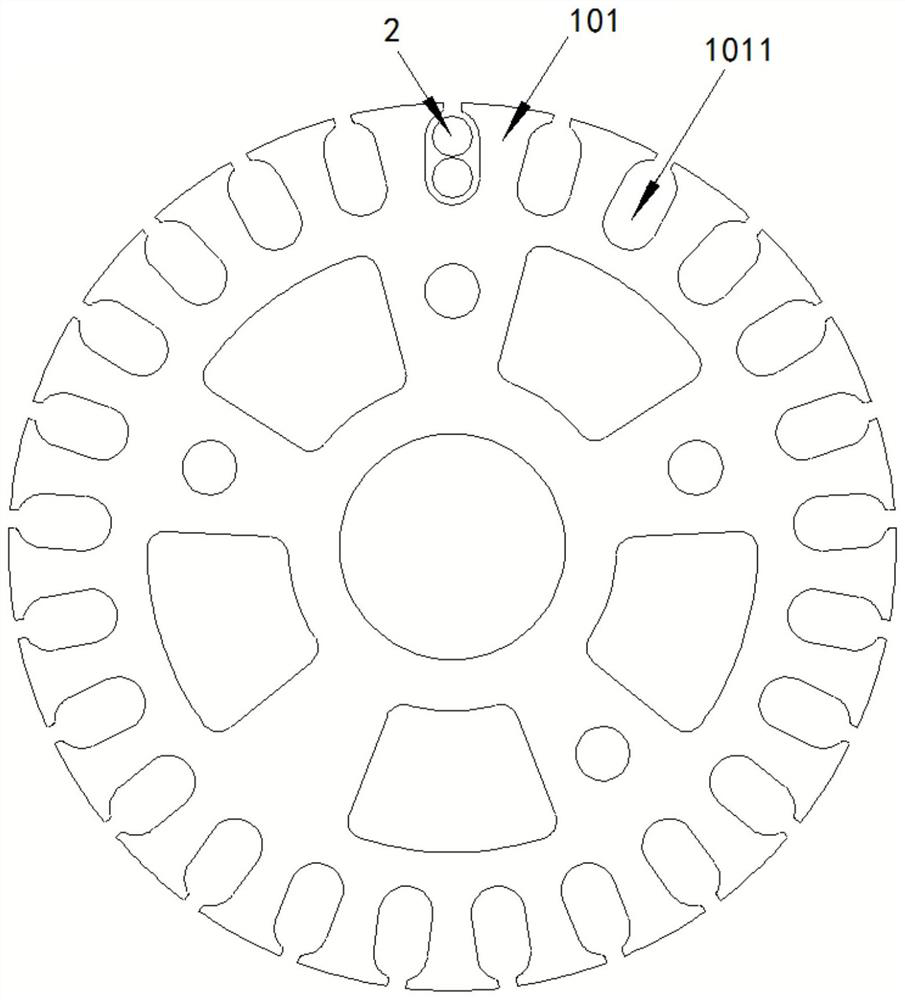

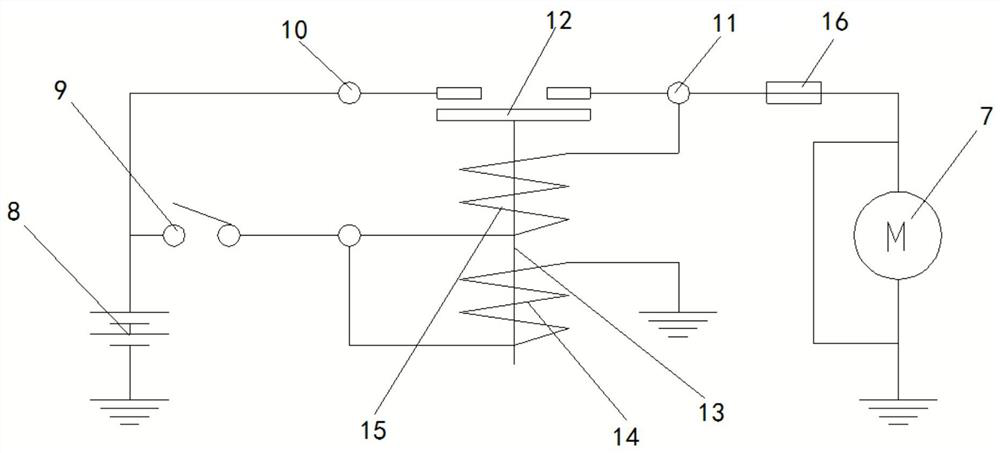

Armature assembly and starter

PendingCN114759707AIncrease pressureClose contactEmergency protective circuit arrangementsWindings conductor shape/form/constructionEngineeringElectrical and Electronics engineering

The invention provides an armature assembly and a starter, relates to the technical field of starter overload protection, and aims to optimize the structure of the armature assembly to a certain extent and ensure the consistency of overload failure modes of the starter. The invention provides an armature assembly which comprises an iron core, an armature winding and an abutting piece. The armature winding is wound on the iron core, a first containing space and a second containing space are defined at the two ends of the iron core respectively, and the abutting piece is arranged in the first containing space and / or the second containing space and abuts against the armature winding.

Owner:JINZHOU HALLA ELECTRICAL EQUIP

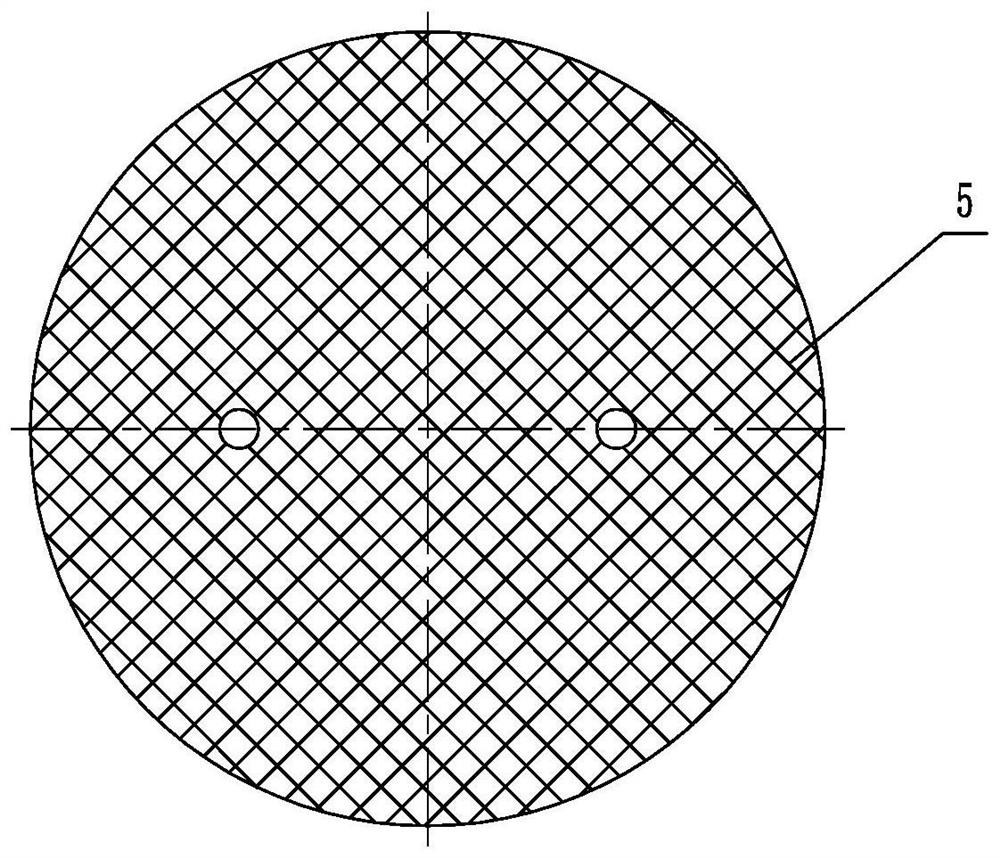

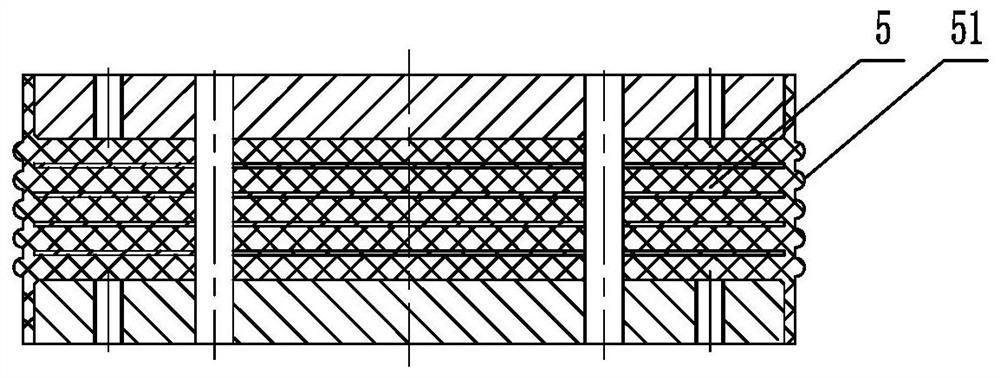

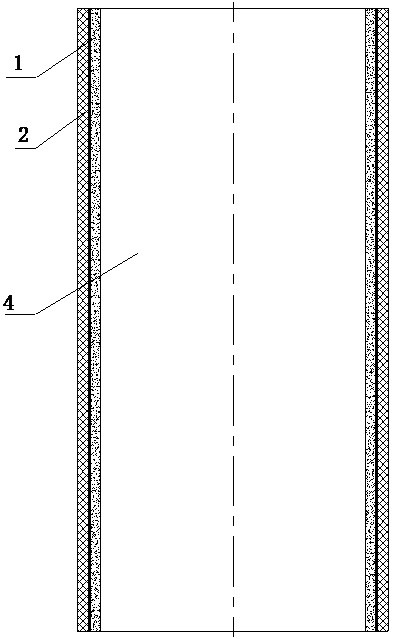

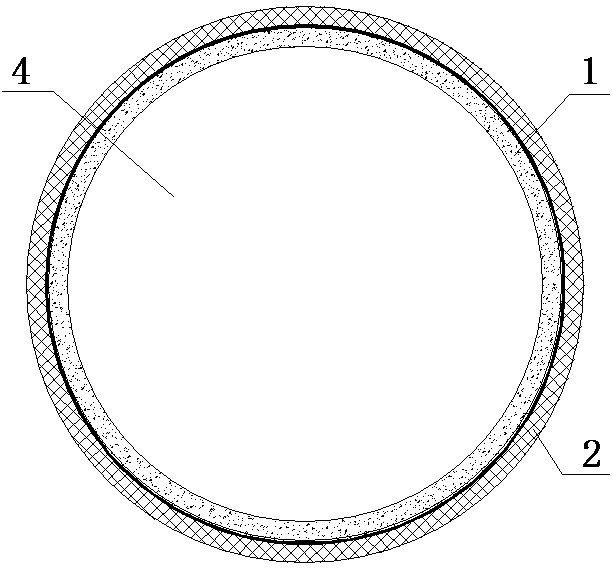

Polytetrafluoroethylene and basalt composite fiber hollow ultrafiltration membrane

The invention discloses a polytetrafluoroethylene and basalt composite fiber hollow ultrafiltration membrane, and belongs to hollow ultrafiltration membranes for sewage treatment. A basalt fiber layer of the hollow ultrafiltration membrane is cylindrical, and a polytetrafluoroethylene layer is coated outside the basalt fiber layer; micropores are densely distributed on the cylinder wall of the basalt fiber woven layer, and the combined surfaces of the polytetrafluoroethylene layer and the basalt fiber layer are compounded at high temperature to form the hollow ultrafiltration membrane with membrane center hole composite fibers; the basalt fiber layer is formed by interweaving, laminating and weaving basalt fibers into a cylinder shape through a weaving machine, and a central hole of the cylinder is a membrane central hole; microorganisms, colloids and other turbid substances in water can be isolated; and the polytetrafluoroethylene layer is made of polytetrafluoroethylene fibers which are interwoven, laminated, woven and coated outside the basalt fiber layer through a weaving machine. The polytetrafluoroethylene and basalt composite fiber hollow ultrafiltration membrane has the advantages of high cost performance, low price, no toxicity and environmental protection; and basalt and polytetrafluoroethylene are similar in melting point, high-temperature compounding is achieved, breaking strength is high, flame retardance is good, modulus is high, and high-temperature poisonous gas and dust can be efficiently filtered.

Owner:徐州洁诚环保科技有限公司

Industrialized method for producing fuel oil by using waste plastics

InactiveCN101117585BIncrease heat absorption areaReduce the temperatureLiquid hydrocarbon mixture productionDistillationHeat conducting

The present invention relates to an oil refining technology by utilizing waste plastic, in particular to an industrialized fuel oil producing method by utilizing the waste plastic. The present invention solves the shortcoming existed in the prior art that the effect for using the waste plastic to produce the fuel oil is bad. The steps includes: dehydrated mineral oil is used as the medium of liquidized waste plastic to be put into a reactor, the mineral oil being used for liquidizing the waste plastic is preheated in the reactor, the waste plastic is put into the reactor, the waste plastic inthe reactor is stably heated and time-lapsed cracked, gaseous hydrocarbon produced from the reaction is fed into a flash distillation column, light distillated oil produced from the flash distillation column is distilled in the normal atmosphere. The present invention adopts molten salt as the heat-conducting medium, so as to enable the plastic being heated evenly, the operation temperature is controlled at 500 DEG C, the liquid liquidoid temperature inside the reactor is controlled at 370 DEG C for delaying the cracking operation and stabilizing the cracking temperature, the liquid inside the reactor is cracked under the stable condition, so as to overcome disadvantages in the prior art that using the coal fire to burn directly, the stability of the oil product is bad and the yield of the liquid is low.

Owner:党德润

Electric fuse structure and method of forming the same

ActiveCN104103623BReduce areaMiniaturizationSemiconductor/solid-state device detailsSolid-state devicesContact positionDielectric layer

Owner:SEMICON MFG INT (SHANGHAI) CORP

Electric fuse structure

ActiveCN104347588BIncrease the lengthFusibleSemiconductor/solid-state device detailsSolid-state devicesElectricityMetal interconnect

The invention discloses an electric fuse structure, comprising: an electric fuse, the electric fuse includes at least three sections of end-to-end sub-fuses, and the angle between the end-to-end sub-fuses is greater than 0 degrees and less than 180 degrees; An anode and a cathode respectively located at both ends of the electric fuse and connected to the electric fuse. The distance between the anode and the cathode can be reduced under the premise of ensuring that the electric fuse has a relatively long length so that the electric fuse structure is more likely to be blown, thereby reducing the area occupied by the electric fuse structure on the integrated circuit chip. When synchronously forming the electric fuse structure and the metal interconnection on the integrated circuit chip, the layout design of the metal interconnection in the integrated circuit chip has more choices.

Owner:SEMICON MFG INT (SHANGHAI) CORP

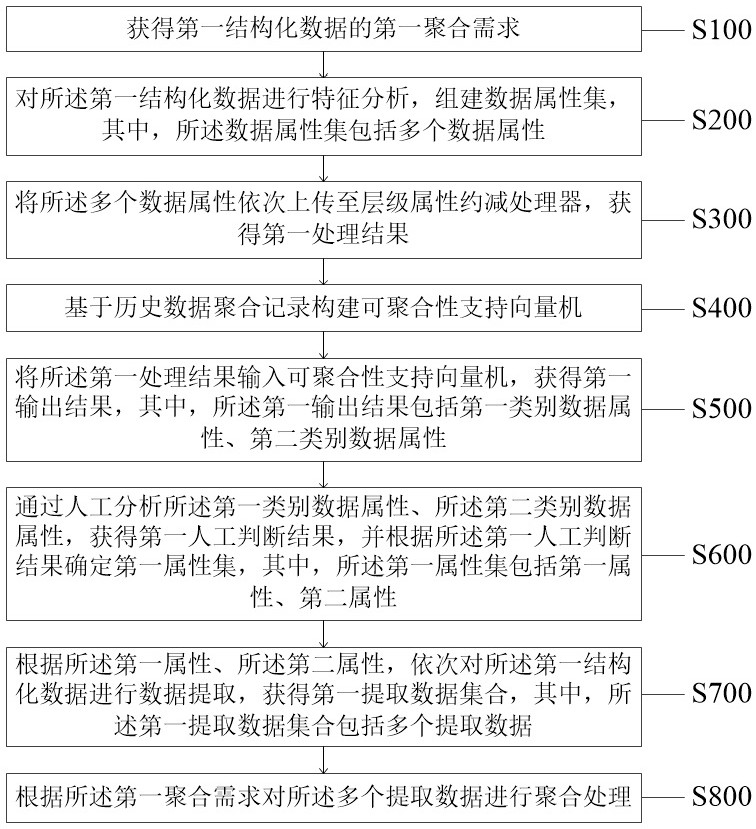

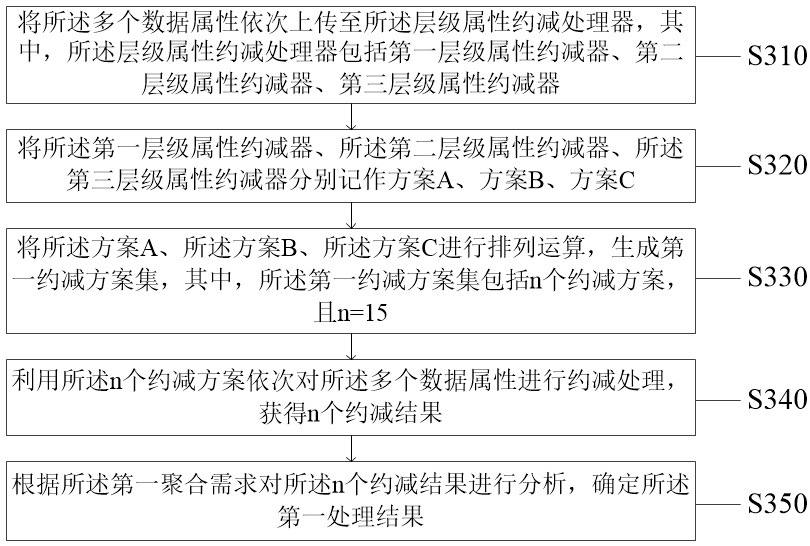

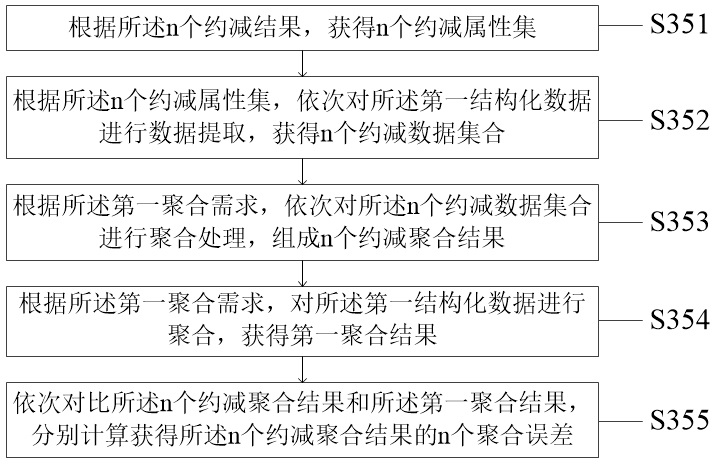

Self-adaptive aggregation method and system for mass structured data and electronic equipment

ActiveCN114510518AGuaranteed aggregation accuracyReduce the amount of data aggregated and processedDigital data information retrievalCharacter and pattern recognitionData aggregatorData mining

The invention discloses an adaptive aggregation method and system for mass structured data and electronic equipment, and relates to the field of artificial intelligence, in particular to a reduction aggregation method and system for mass structured data and electronic equipment. The method comprises the following steps: obtaining a first processing result by utilizing a hierarchical attribute reduction processor through a first aggregation demand and a data attribute set; constructing an aggregability support vector machine to obtain a first output result; a first attribute set is determined through manual judgment; sequentially extracting to obtain a plurality of extraction data; and aggregating the plurality of extracted data according to the first aggregation demand. The technical problems that in the prior art, during data aggregation, the processing data volume is large, the aggregation efficiency is low, and aggregation after data screening is unstable in precision and low in aggregation reliability are solved. Through reasonable and effective data attribute reduction, the technical effects of effectively reducing the aggregation processing data volume and improving the aggregation reliability, pertinence and aggregation efficiency on the basis of ensuring the aggregation precision are achieved.

Owner:北京快立方科技有限公司

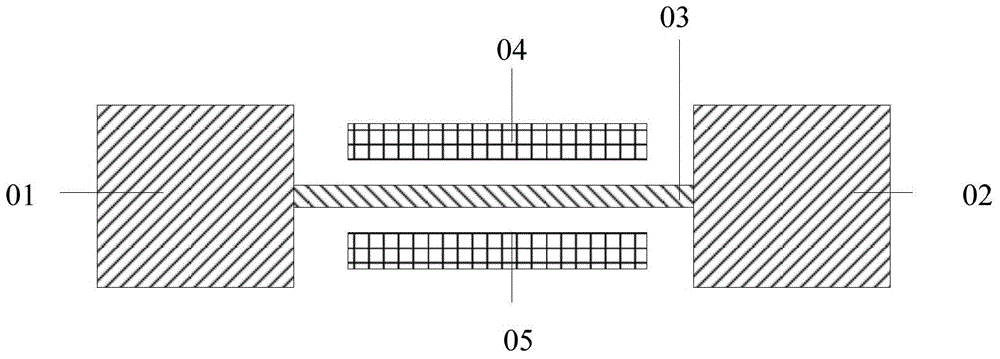

Electric fuse structure and method of forming the same

ActiveCN104051417BReduce areaIncrease resistanceSemiconductor/solid-state device detailsSolid-state devicesElectricityOffset distance

An electric fuse structure and a forming method thereof, the electric fuse structure comprising: a substrate, an insulating layer positioned on the surface of the substrate; an electric fuse positioned on the surface of the insulating layer, the electric fuse including a first electrode , a strip-shaped first fuse connected to the first electrode, a second electrode and a strip-shaped second fuse connected to the second electrode, the first fuse and the second fuse are connected and connected There is a dislocation at the position, and the distance between the two intersections of the edge of the first fuse and the edge of the second fuse at the dislocation is less than or equal to the width of the first fuse and less than or equal to the width of the second fuse; A metal interconnection structure on the surface of the first electrode and the second electrode. Since the distance between the two intersection points at the dislocation is the smallest, the resistance of the electric fuse at the dislocation becomes larger, so that more heat is generated at the dislocation, and it is easier to fuse, so that the fusing current does not need to be too large, and the length of the electric fuse It does not need to be too long, thereby saving the chip area.

Owner:SEMICON MFG INT (SHANGHAI) CORP

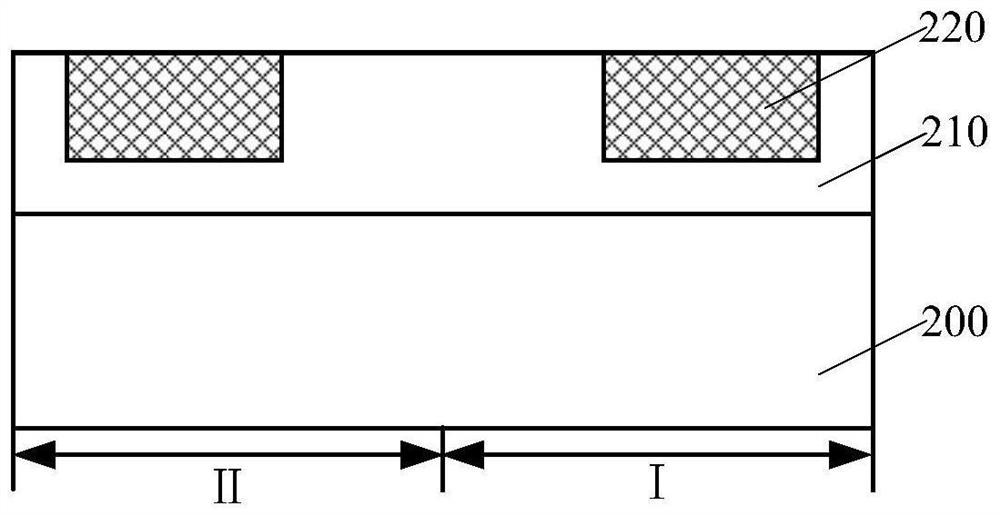

Fuse structure circuit and its forming method

ActiveCN108666262BImprove performanceFusibleSemiconductor/solid-state device detailsSolid-state devicesBinding energyFuse (electrical)

A fuse structure circuit and its forming method, wherein the method includes: providing a base, the base includes a fuse area and a control area; respectively forming a metal layer on the base fuse area and the control area, and the metal layer of the control area is used to be electrically connected to the metal layer of the fuse area; a first cover layer is formed on the top surface of the metal layer of the fuse area, and the material of the first cover layer and the material of the metal layer of the fuse area have a first bonding energy; The top surface of the metal layer in the control area forms a second covering layer, the material of the second covering layer and the material of the metal layer in the control area have a second binding energy, and the first binding energy is smaller than the second binding energy. The method results in improved performance of the fuse structure circuit.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com