Metamorphic process of hypo eutectic casting aluminum-silicon alloy

A technology for casting aluminum-silicon alloys and aluminum-silicon master alloys, which is applied in the field of hypoeutectic casting aluminum-silicon alloy modification technology, and can solve problems such as single function, complicated processing technology, and easy volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

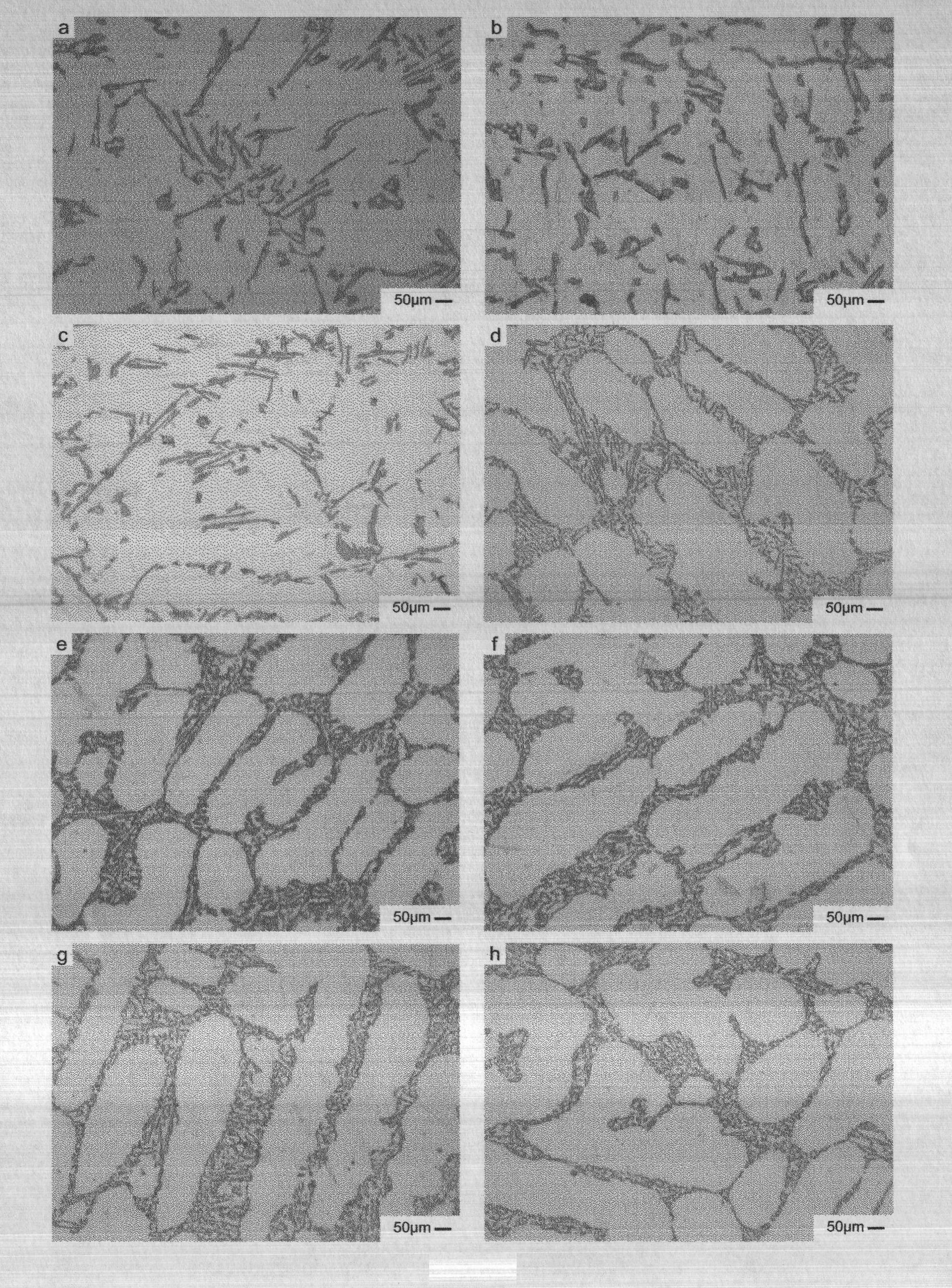

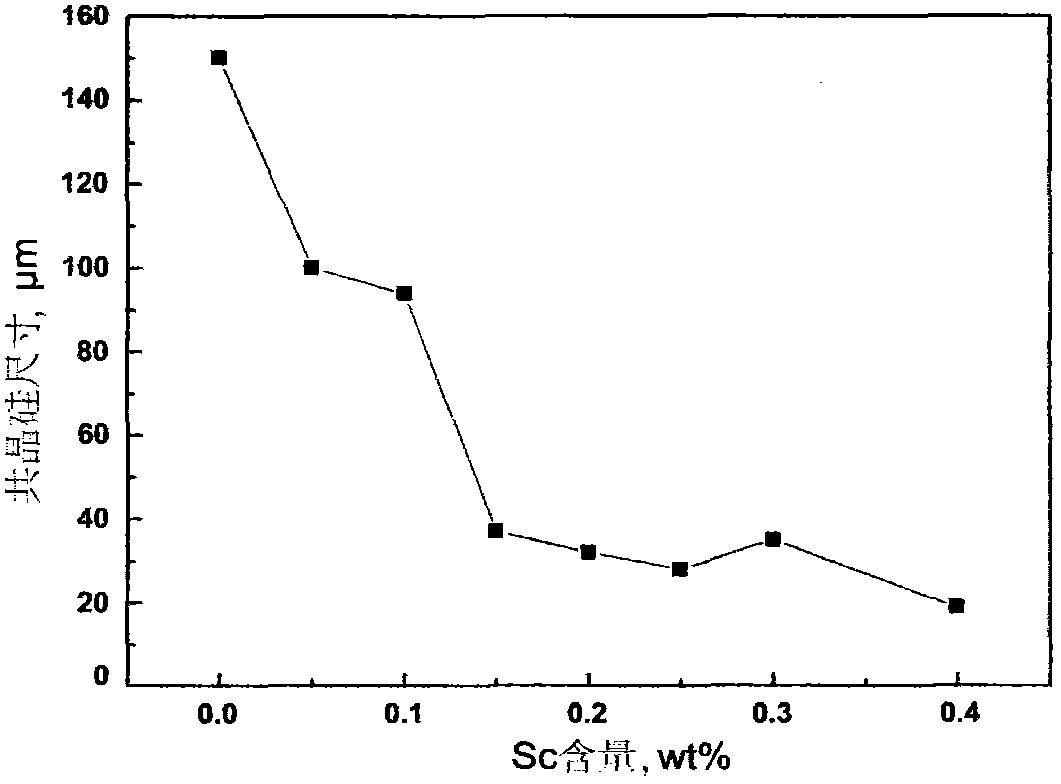

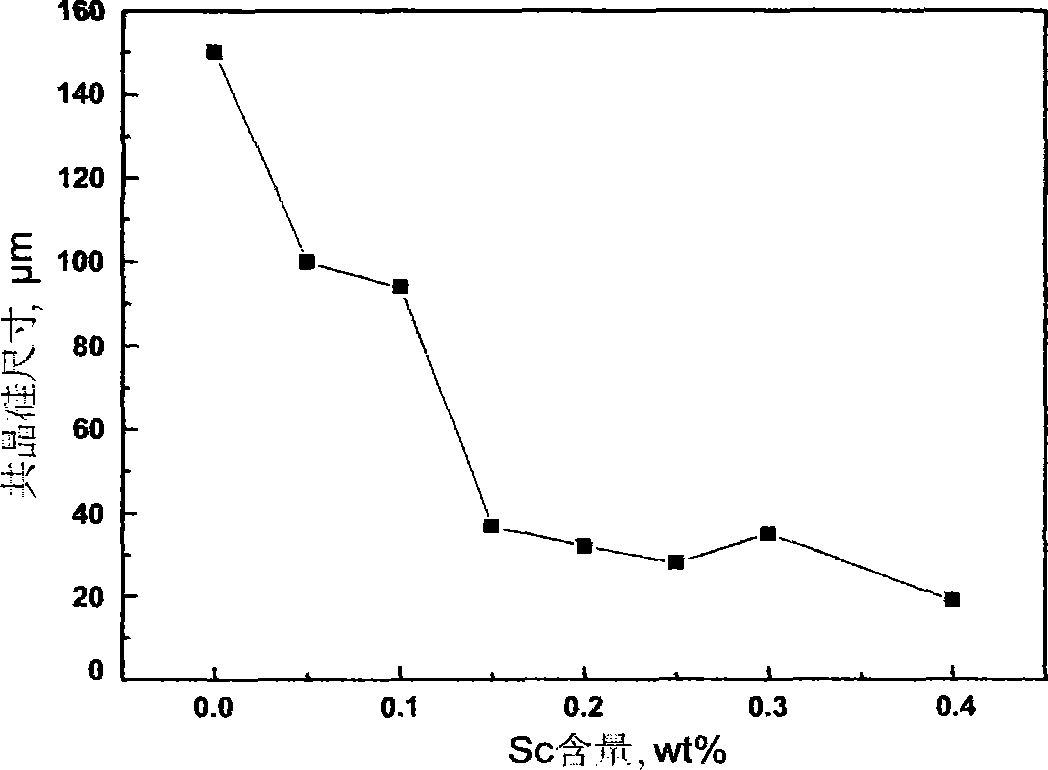

Image

Examples

Embodiment 1

[0020] Embodiment 1: The method for modifying Zl114 alloy by rare earth Sc in this embodiment is realized through the following steps:

[0021] 1) Ingredients according to Z1114 alloy composition: Si: 6.5-7.5, Mg: 0.45-0.60, Ti: 0.10-0.20, Be: 0.04-0.07, Fe (sand casting): ≤0.2, Mn: ≤0.1, Al: balance , The sum of impurities: (sand casting) ≤ 0.75.

[0022] 2) After cleaning and drying the pure aluminum, aluminum-silicon master alloy, aluminum-manganese master alloy, aluminum-titanium master alloy prepared in step 1), put them into a graphite clay crucible resistance furnace with a power of 5KW, and heat and melt them completely.

[0023] 3) Press the pure Mg weighed in step 1) into the melt obtained in step 2) in a graphite bell jar with a preheating temperature of 300°C at 700°C, and let it stand for 5 minutes;

[0024] 4) Heat up the melt obtained in step 3) to 740°C, add the weighed AlSc 4 The amount of the intermediate alloy (Sc) accounts for 0.15wt% of the total amount ...

Embodiment 2

[0027] Embodiment 2: The method for modifying Zl107 alloy by rare earth Sc in this embodiment is realized through the following steps:

[0028] 1) According to the composition of Zl107 alloy: Si: 6.5~7.4, Cu: 3.5~4.5, Zn: 0.8~1.2, Mg: 0.1~0.2, Cd: 0.1~0.2, Fe≤0.12, Ti: 0.1~0.2, Al: margin.

[0029] 2) After cleaning and drying the pure aluminum, aluminum-silicon master alloy, aluminum-copper master alloy, aluminum-manganese master alloy, aluminum-titanium master alloy prepared in step 1), put them into a graphite clay crucible resistance furnace with a power of 5KW, and heat them completely melt.

[0030] 3) Press the pure Mg weighed in step 1 into the melt obtained in step 2) in a graphite bell jar with a preheating temperature of 300°C at 700°C, and let it stand for 3 minutes;

[0031] 4) Heat up the melt obtained in step 3) to 760°C, add the weighed AlSc4 master alloy (the amount of Sc added accounts for 0.18wt% of the total amount of the alloy), and after the melting is ...

Embodiment 3

[0034] Embodiment 3: The method for modifying Zl702 alloy by rare earth Sc in this embodiment is realized through the following steps:

[0035] 1) According to the composition of Zl702 alloy: Si: 6.0-7.0, Cu: 1.5, Mg: 0.35, Ti: 0.1-0.2, Mn: 0.1-0.2, Fe≤0.2, Al: balance.

[0036] 2) After cleaning and drying the pure aluminum, aluminum-silicon master alloy, aluminum-copper master alloy, aluminum-manganese master alloy, aluminum-titanium master alloy prepared in step 1), put them into a graphite clay crucible resistance furnace with a power of 5KW, and heat them completely melt.

[0037] 3) Press the pure Mg weighed in step 1) into the melt obtained in step 2) in a graphite bell jar with a preheating temperature of 300°C at 700°C, and let it stand for 3 minutes;

[0038] 4) Heat up the melt obtained in step 3) to 750°C, add the weighed AlSc4 master alloy (the amount of Sc added accounts for 0.2wt% of the total amount of the alloy), and after the melting is completed, use the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com