Electric fuse structure and method of forming the same

An electric fuse and fuse technology, applied in circuits, electrical components, electric solid devices, etc., can solve the problems of large integrated circuit area and high cost, and achieve the effect of saving chip area, easy to generate heat, and easy to fuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Since the electric fuse requires a large fusing current to blow the electric fuse, the program power supply of the electric fuse needs a programming transistor with a large area to generate a large fusing current, which increases the size and cost of the integrated circuit. And because electromigration causes electric fuse disconnection, it is often because a large amount of metal atoms in the electric fuse accumulate, so that holes are formed in the electric fuse, which leads to the electric fuse disconnection, and when the length of the electric fuse in the prior art is long It is easy to cause a large number of metal atoms to accumulate to form voids. Therefore, the length of the existing electric fuse formed by metal is often longer, and the area and cost of the integrated circuit will also be increased.

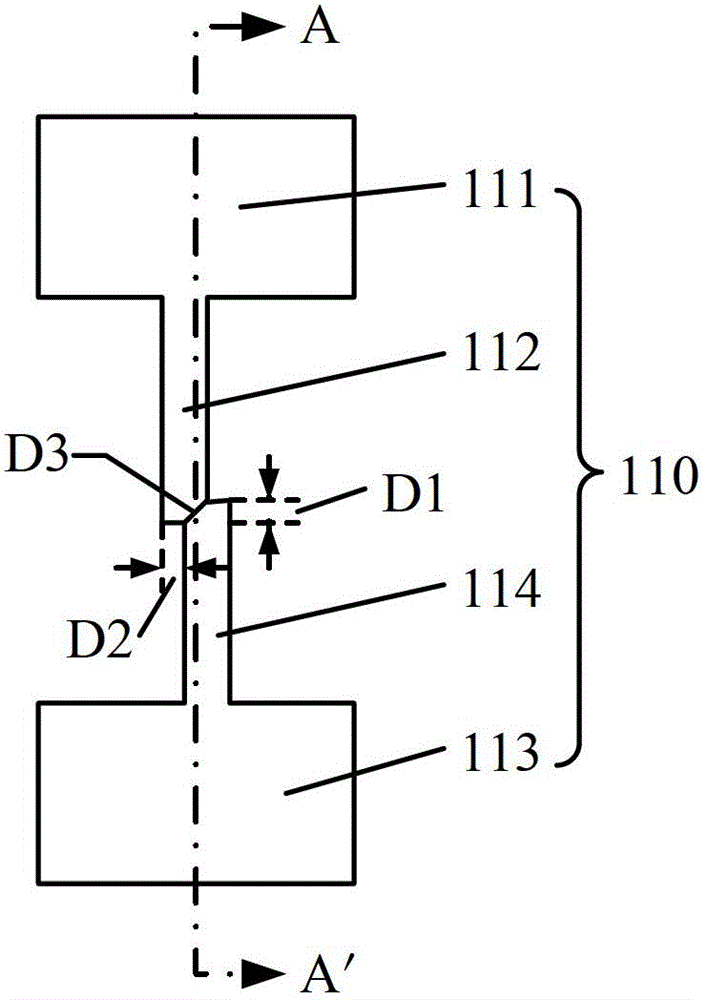

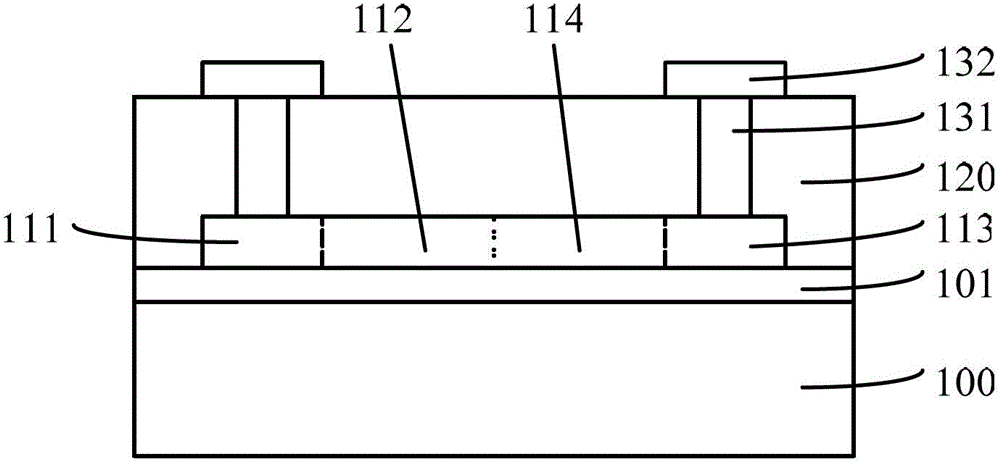

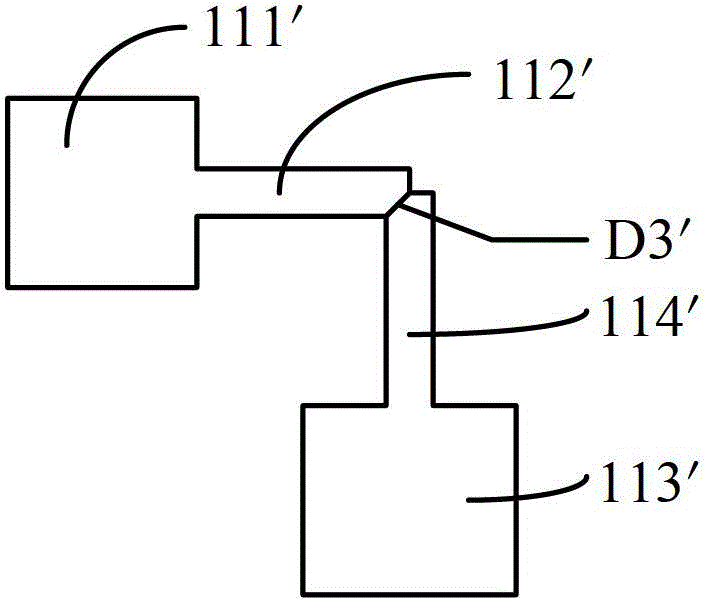

[0034]For this reason, the inventor has proposed an electric fuse structure and a method for forming the same after research. The distance between the two interse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com