Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Dirt resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

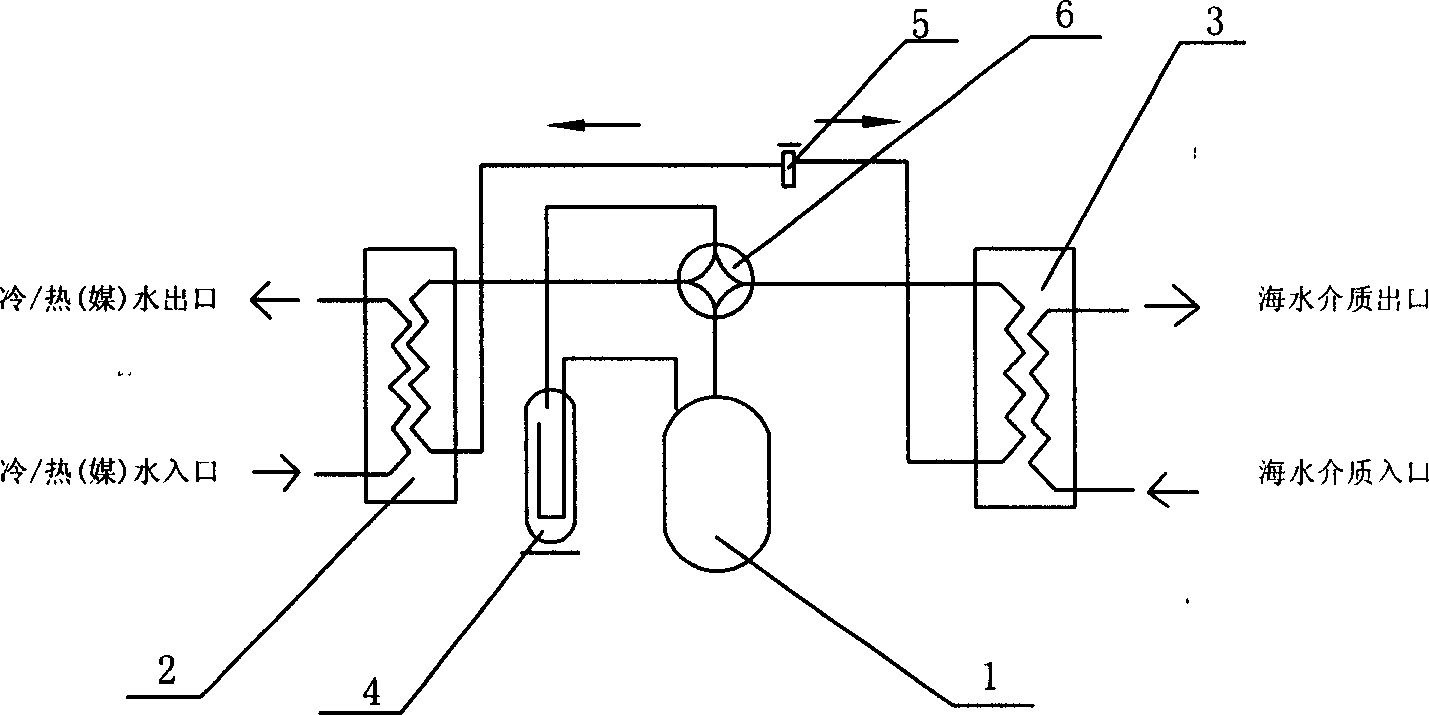

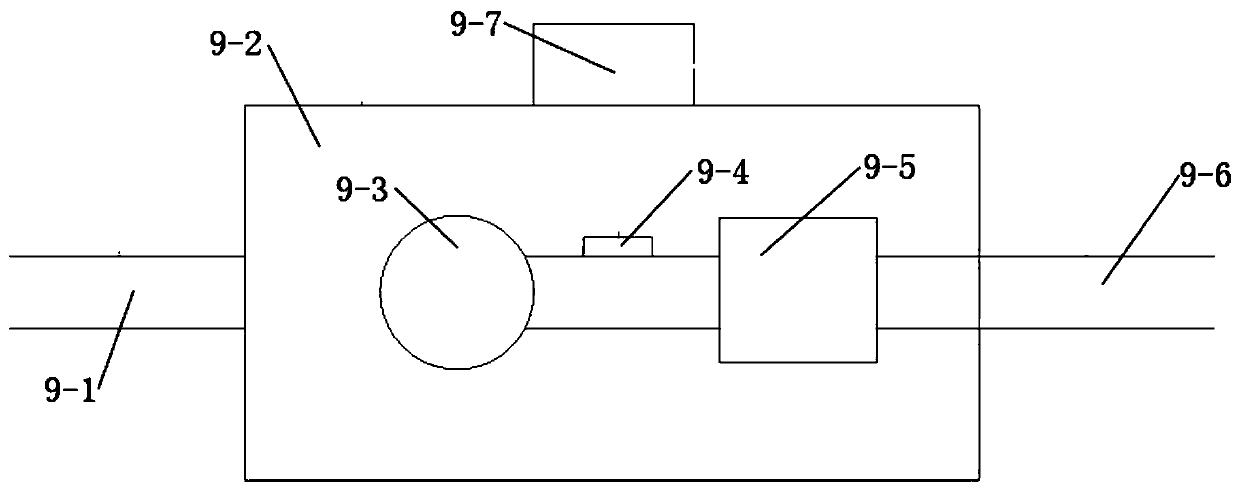

Sea-water heat-pump apparatus

InactiveCN1710357AGood for flow washingHigh thermal efficiencyHeating and refrigeration combinationsSeawaterRefrigerant

A heat pump of sea water consists of compressor , exchanger of cold / hot media water ( ECHMW ) , exchanger of sea water ( ESW ) , gas / liquid separator , refrigeration pipeline and computer control unit . It is prepared by setting four - way valve on pipeline between compressor and ECHMW as well as ESW, setting through valve on pipeline between ECHMW and ESW and having media passing through pipe set in ESW . The prepared heat pump can utilize energy resource of sea water adequately.

Owner:JIUYUAN AIR CONDITIONER REFRIGERATION APP QINGDAO

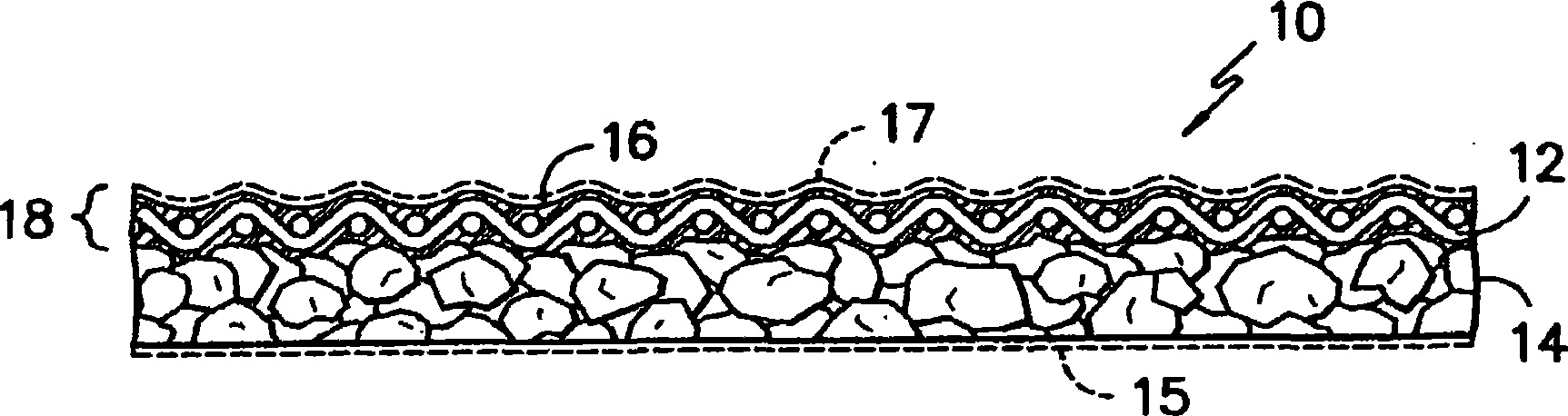

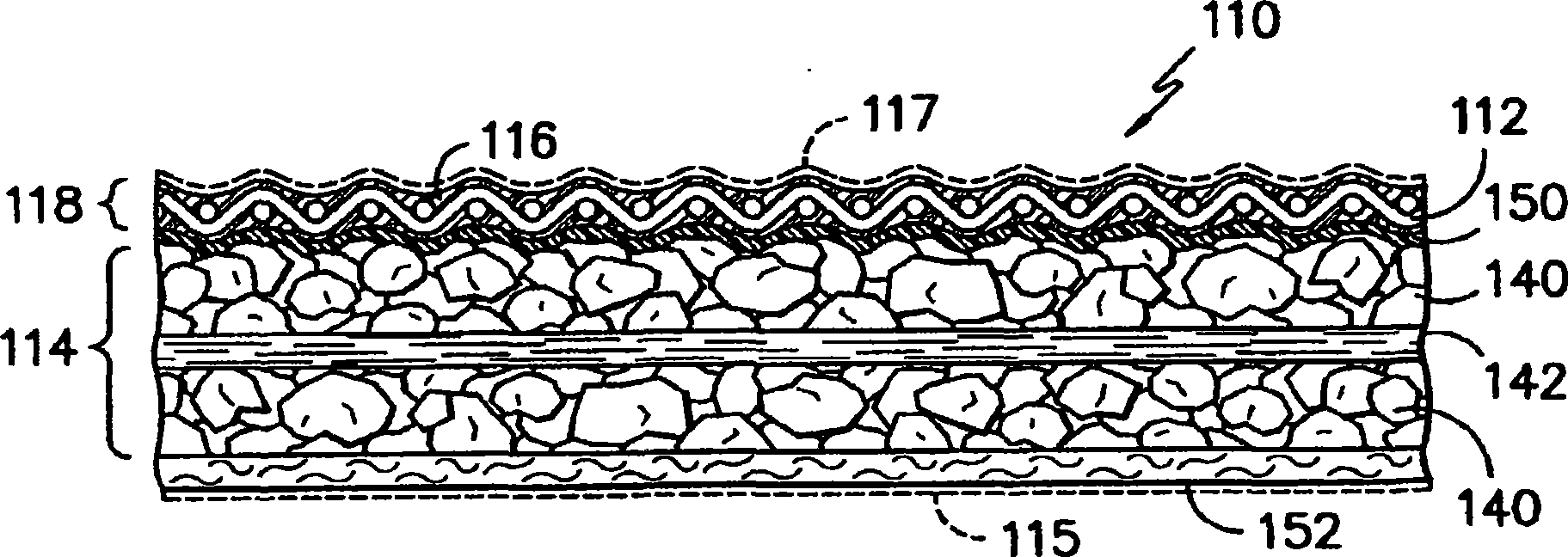

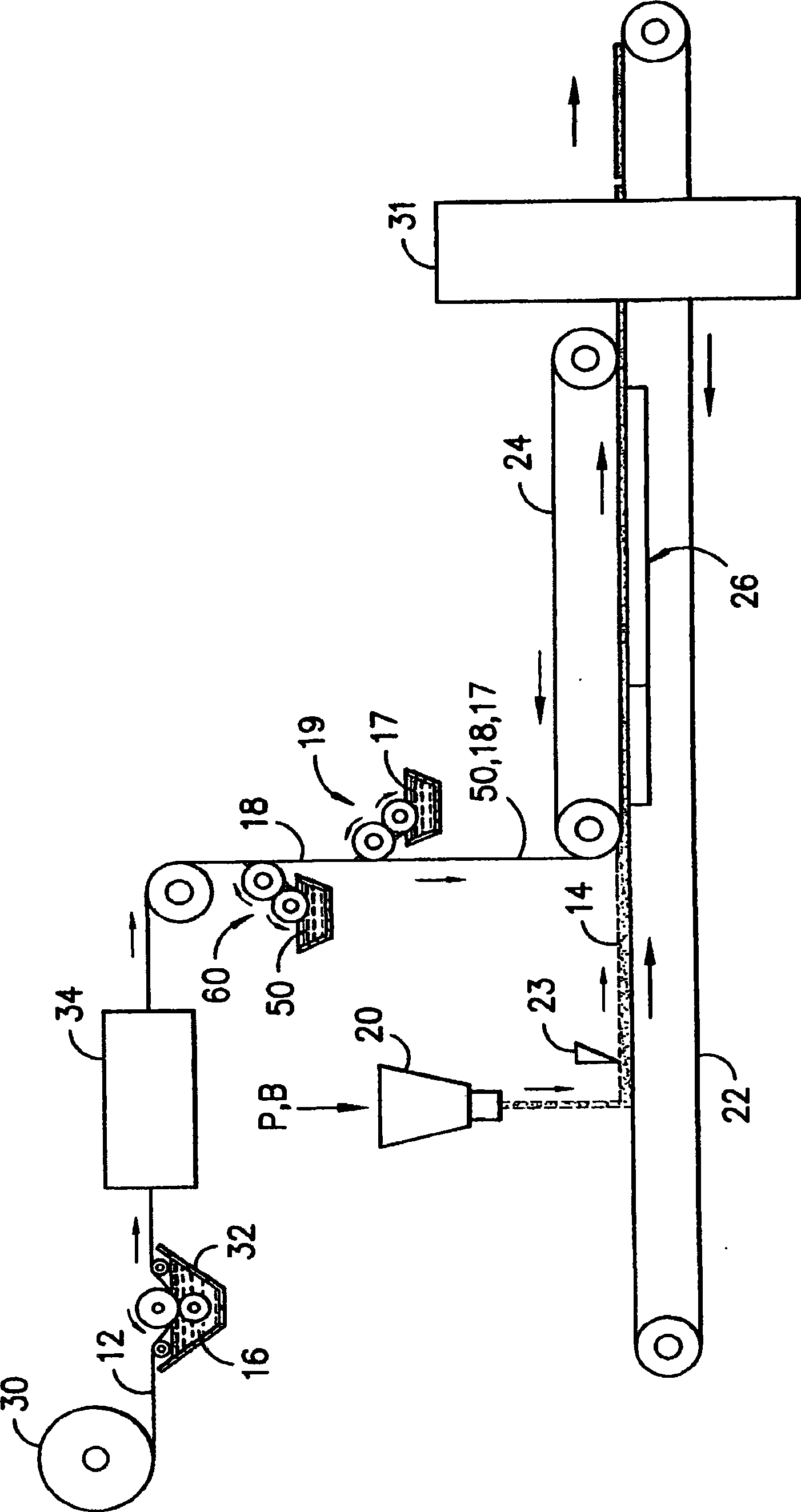

Surface coverings and methods

InactiveCN101501271AWear-resistantDirt-resistantLayered productsTextiles and paperTectorial membraneEngineering

A surface covering comprises a show surface, decorative layer, or face and an optional backing layer. The show surface, decorative layer, or face can comprise a decorative textile or fabric layer that is optionally saturated, covered, and / or coated with a protective film or film-forming composition. The backing can optionally comprise an agglomerated mass of particles, a foam, foam and particles, a felt, or a combination thereof. Methods for producing such surface coverings are also disclosed.

Owner:MILLIKEN & CO

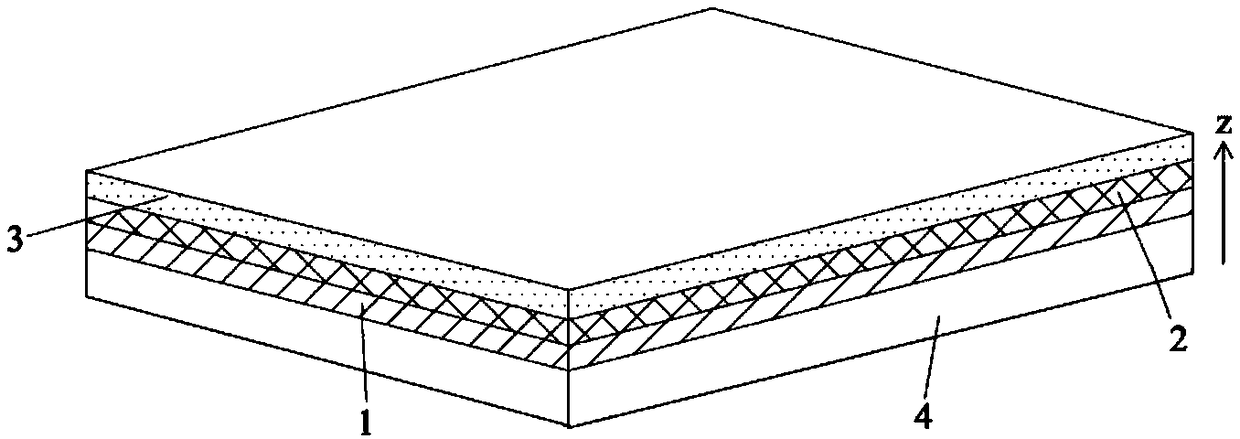

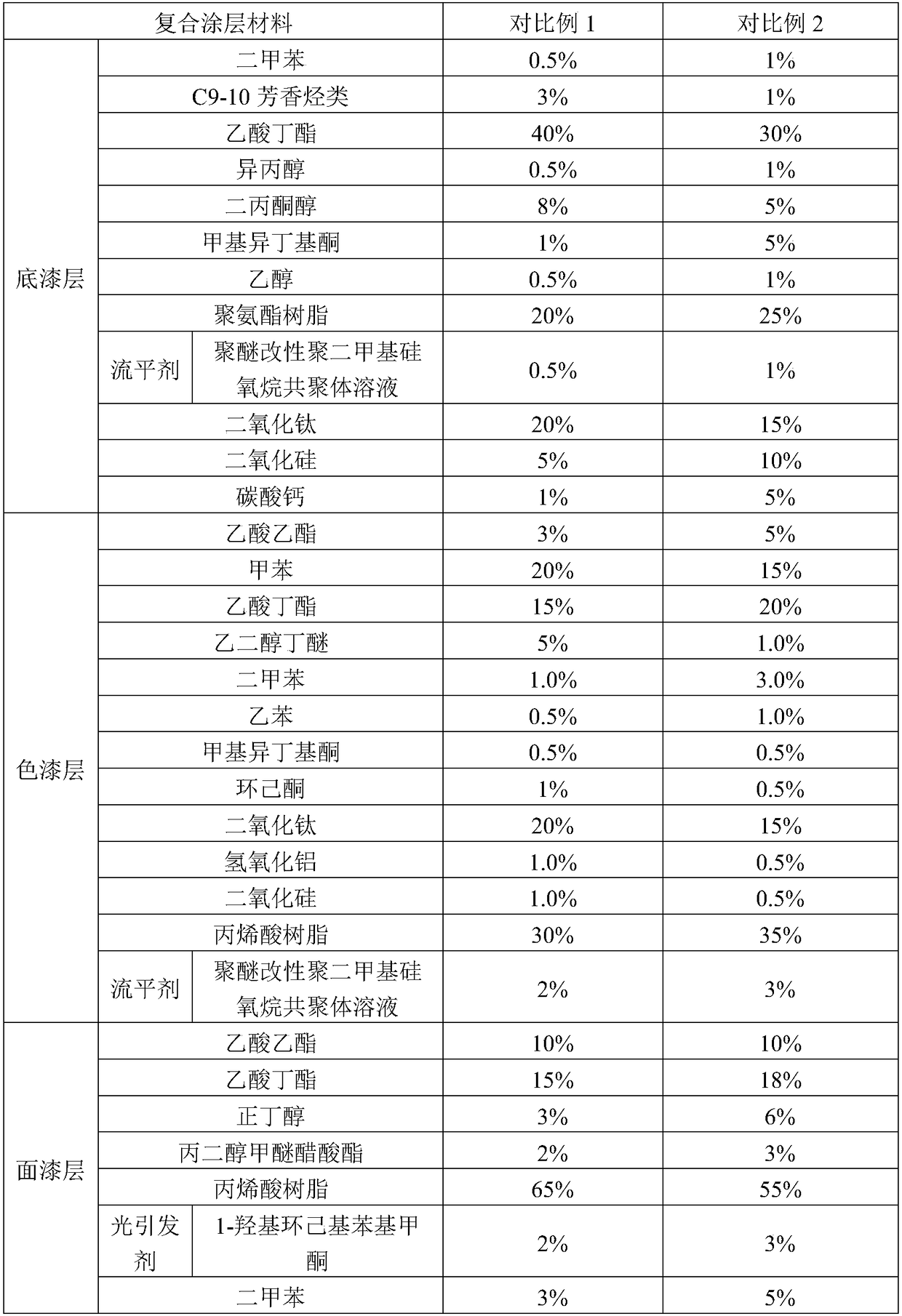

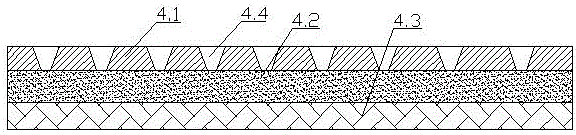

Composite coating material as well as a preparation method and application thereof

ActiveCN108977053AImprove the problem of aging and discolorationImprove discoloration and agingAntifouling/underwater paintsPaints with biocidesLacquerAge problems

The disclosure relates to a composite coating material as well as a preparation method and application thereof. The composite coating material is prepared from a base material, a primer layer formed on the surface of the base material, a paint layer which contacts the primer layer, and a topcoat layer formed on one side of the paint layer opposite to the primer layer, wherein the primer layer is prepared from polyurethane acrylate, epoxy acrylate oligomer, a resin monomer and additives. The composite coating material disclosed in the disclosure can improve the aging and discoloration problems.Even if a composite coating of a light color system (e.g. white, light green, light pink, etc.) is used, the discoloration and aging problems can also be improved.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

Fabric for airplane interior trimming

InactiveCN105506973AImprove use comfort performanceEasy to useCarbon fibresHeat resistant fibresYarnJet aeroplane

The invention discloses a fabric for airplane interior trimming, and relates to the technical field of fabrics for airplane interior trimming. The fabric for airplane interior trimming is prepared from PET, graphite, carbon fibers, glass fibers, a lubricating agent, anti-cracking pigment, terry yarn, a corrosion inhibitor, spinning oil, POY, wool and the like through processing production. According to the fabric for airplane interior trimming, the higher anti-static capacity is achieved, the fabric can be kept safe and sanitary due to the fact that sterilizing factors are contained, cleaning is convenient, the aid-sleeping function is achieved, and the wear-resisting function, the soiling-resisting function and the heat preservation function are achieved; the using comfort degree and the health maintenance effect of the fabric are improved, and the fabric is durable in use and has various beneficial functions.

Owner:安徽博朗凯德织物有限公司

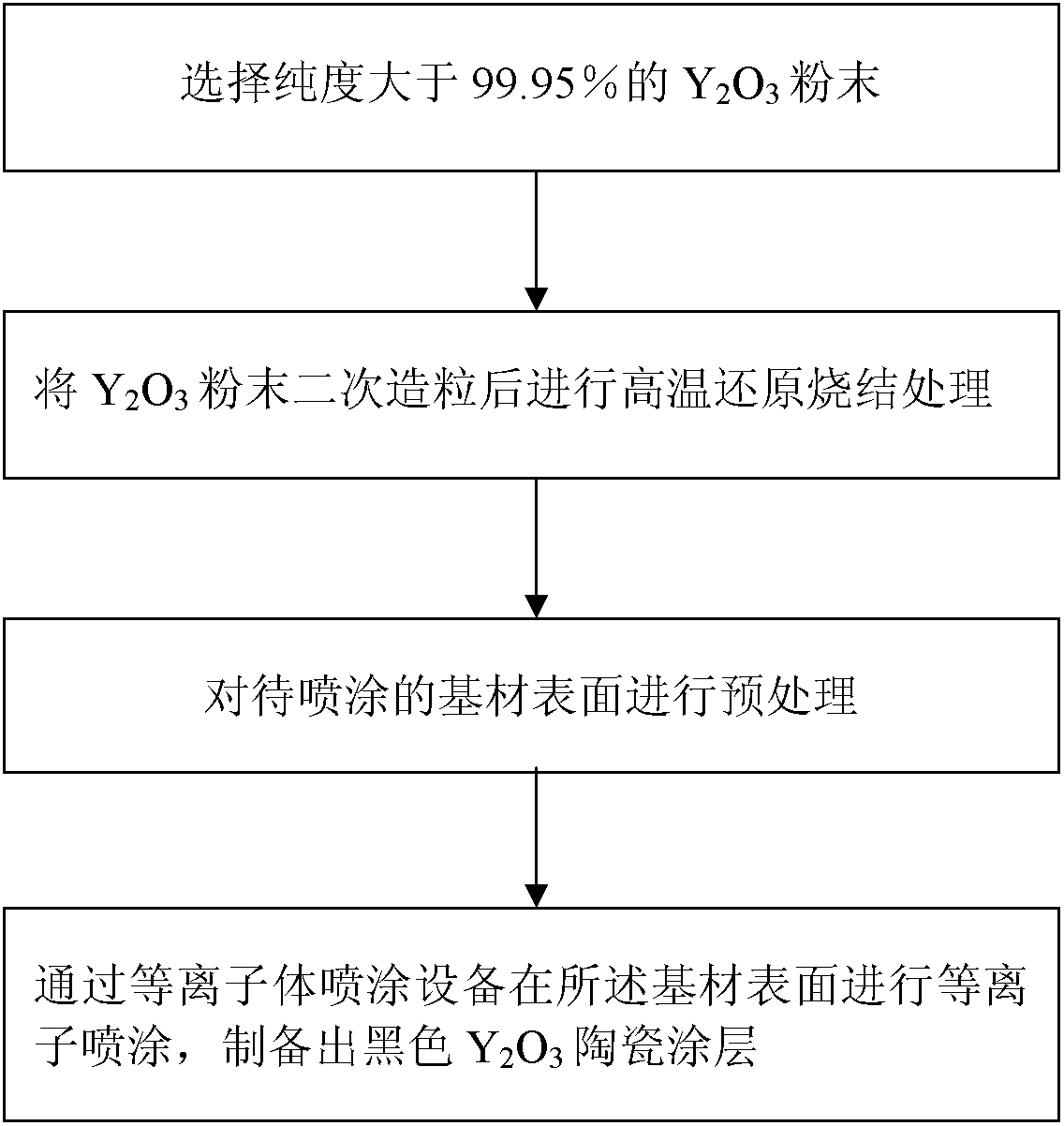

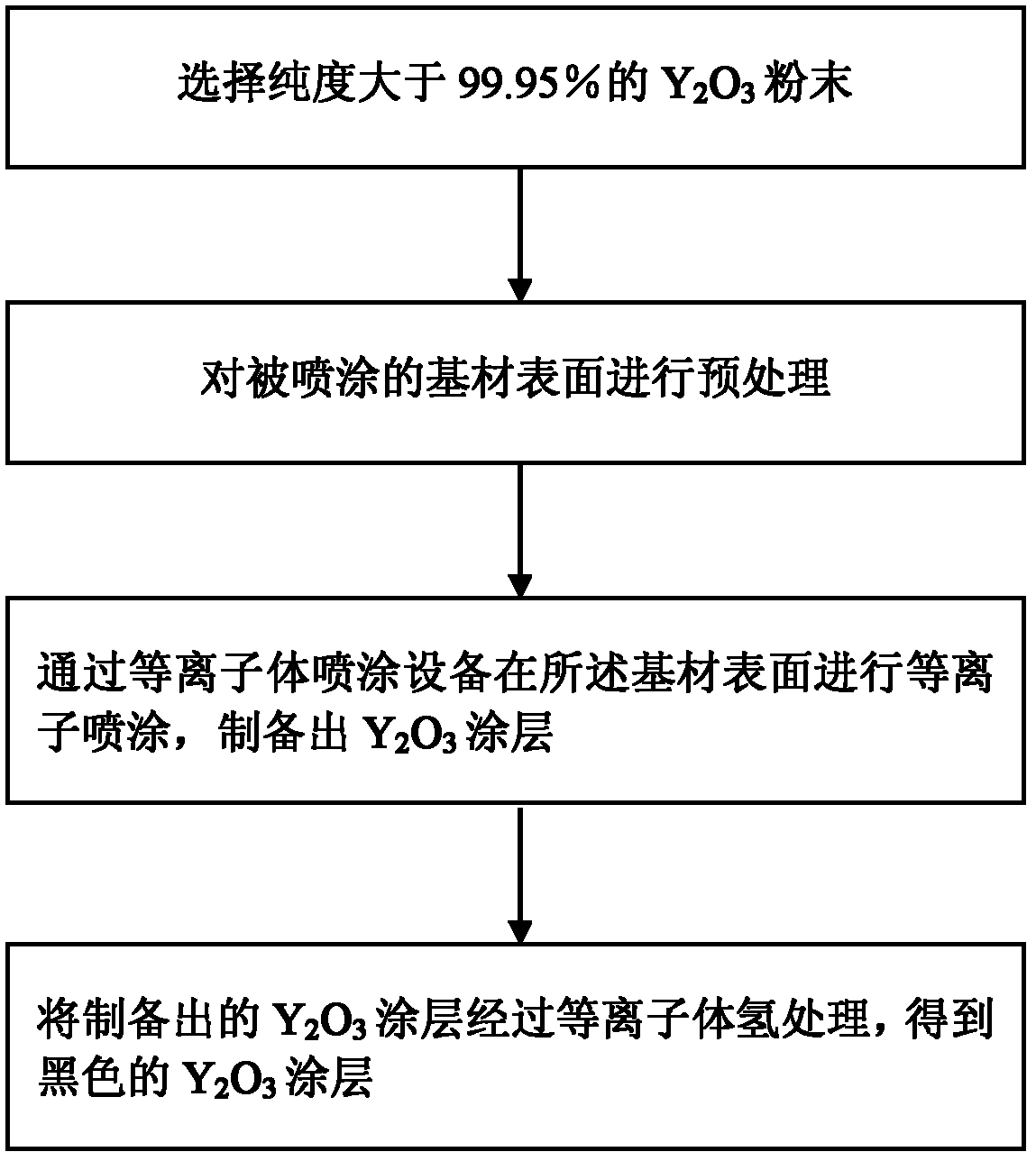

Preparation method of black yttrium oxide (Y2O3) ceramic coating

The invention relates to the technical field of yttrium oxide (Y2O3) ceramic coatings, in particular to a preparation method of a black Y2O3 ceramic coating. The preparation method comprises the following steps: (1) selecting Y2O3 powder larger than 99.95% in purity; (2) conducting secondary granulation on the Y2O3 powder, and conducting high-temperature reduction sintering treatment; (3) pre-processing the surface of a substrate to be coated; (4) conducting plasma spraying on the surface of the substrate through plasma spraying equipment, and preparing the black Y2O3 coating. The preparation method restores original Y2O3 powder into black through deuterium (H2) in the secondary granulation process, sprays the Y2O3 powder to the substrate through the plasma spraying, and then prepares the black Y2O3 ceramic coating. The black Y2O3 ceramic coating prepared through the preparation method has corrosion resistance and dirty resistance, and is low in manufacture cost.

Owner:SOI MICRO CO LTD

Combed composite quilt and manufacturing process thereof

InactiveCN105361556ASoft and comfortableAdds elasticity and warmthBlanketFibre mixingPolypropyleneCombing

The invention discloses a combed composite quilt and a manufacturing process thereof. The combed composite quilt is manufactured by wrapping a comforter inner with a quilt cover. The comforter inner comprises an outer wrapping layer and an inner core layer, and the weight ratio of the outer wrapping layer to the inner core layer is 1:3. The outer wrapping layer comprises raw cotton, polyacrylonitrile fibers, polynosic, bamboo carbon fibers, bast fibers, polypropylene melt sprayed yarn and spandex fibers. The inner core layer comprises raw cotton, polyvinyl alcohol fibers and polyvinyl chloride fibers. The combed composite quilt is good in warm keeping performance, softness and comfortableness, free of static, damp-proof, dustproof, resistant to dirt, breathable and antibacterial.

Owner:SHANDONG JINCHENG IND & TRADE

Method of processing and preparing black Y203 ceramic coating with hydrogen plasma

The invention relates to the technical field of manufacture of Y203 ceramic coatings, in particular to a method of processing and preparing a Y203 ceramic coating. The method comprises the following steps: choosing Y203 powder with purity higher than 99.95%, carrying out pre-processing on base materials to be sprayed, carrying out plasma spraying on the base materials through plasma spraying equipment to prepare the Y202 coating, and carrying out hydrogen plasma processing on the prepared Y203 coating in the last step to obtain a black Y203 coating. The black Y203 coating prepared through a hydrogen plasma reduction method is etching resisting and dirty resisting, and low in cost.

Owner:锐立平芯微电子(广州)有限责任公司

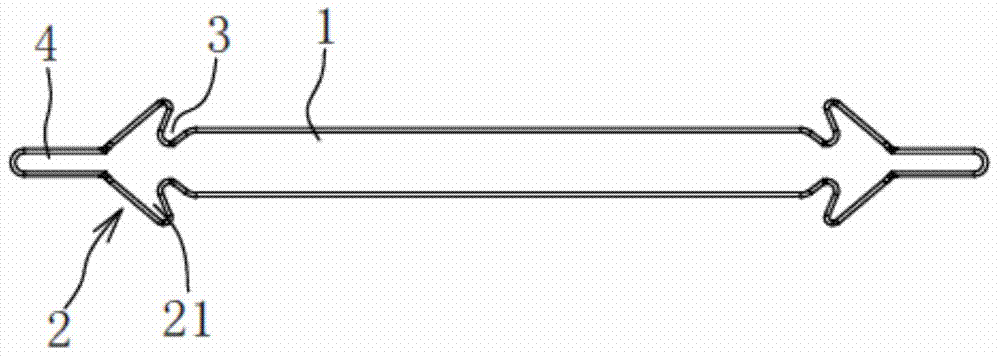

Silica-gel tying-free shoelace

InactiveCN103783733AEasy to pass throughPrevent reverse prolapseShoe lace fasteningsEngineeringSilica gel

Owner:FOSHAN JIASHI ELECTRONICS

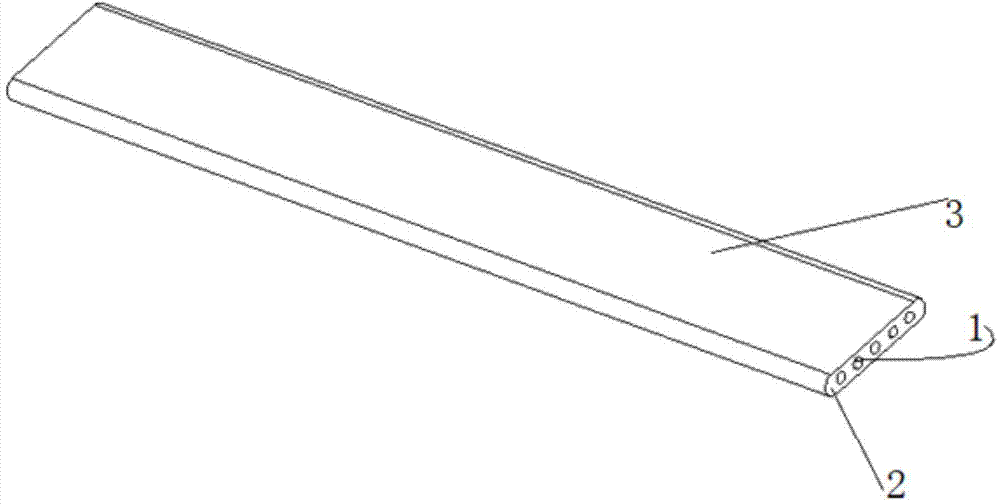

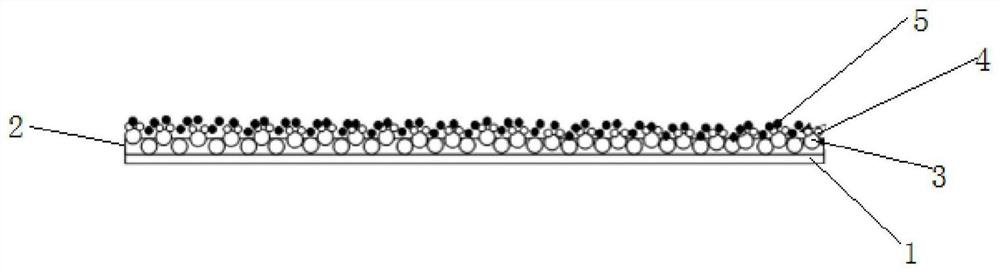

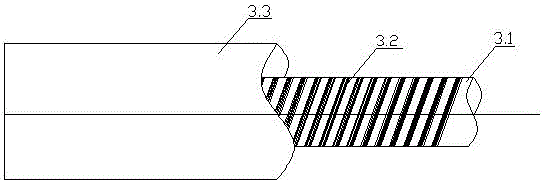

Preparation method of nanometer coated earphone line and product thereof

ActiveCN104505171AEasy to identifyEasy to distinguishPlastic/resin/waxes insulatorsCable/conductor manufacturePlasticizerPlasticulture

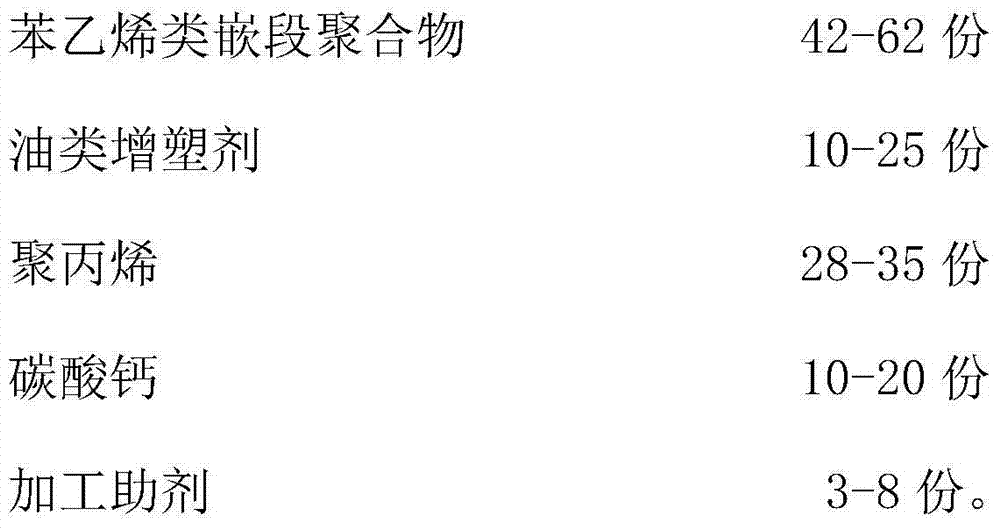

The invention discloses a preparation method of a nanometer coated earphone line. The preparation method comprises the following steps: preparing single lines, preparing an insulating jacket, preparing a nanometer coating film and the like. The invention also discloses a nanometer coated earphone line product prepared by using the method. The product comprises a plurality of strands of single lines and the insulating jacket layer which wraps the single lines, wherein the surface of the insulating jacket layer is provided with the nanometer coating layer; more than four strands of single lines are arranged side by side; the insulating jacket layer is flat; the thickness of the nanometer coating layer is 50-100 nm and is deposited on the surface of the insulating jacket layer by using the principle of vapor deposition; the insulating jacket is formed of styrene block polymer, an oil type plasticizer, polypropylene, calcium carbonate and a processing aid through extrusion plasticizing. The unique flat appearance facilitates the recognition, and the unique nanometer coating layer guarantees that the product has the superior performances such as water resistance, oxidation resistance, dirt resistance, scratch resistance and ultraviolet protection.

Owner:DONGGUAN YINGTONG WIRE +1

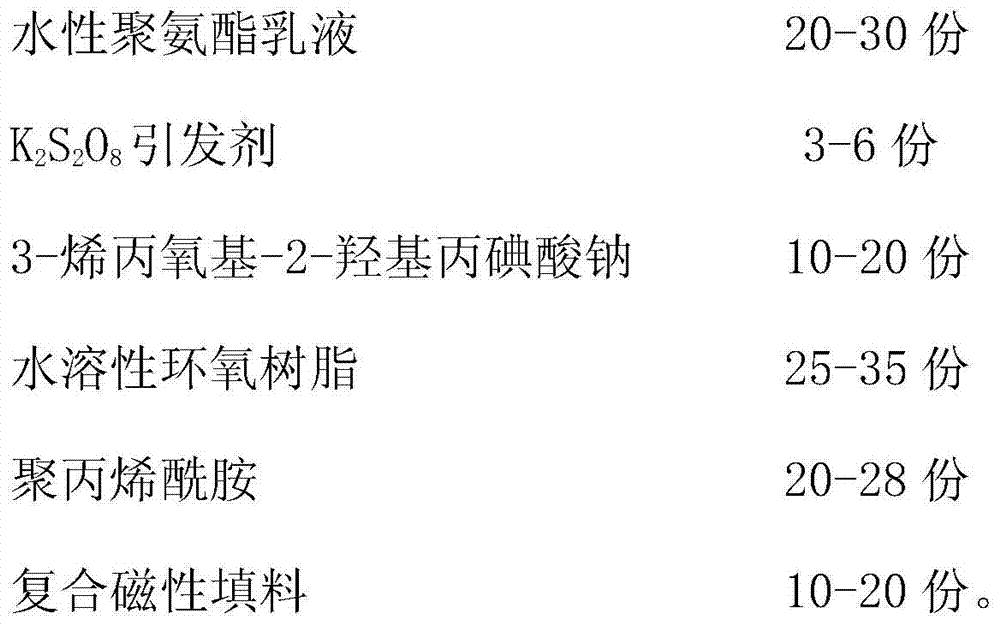

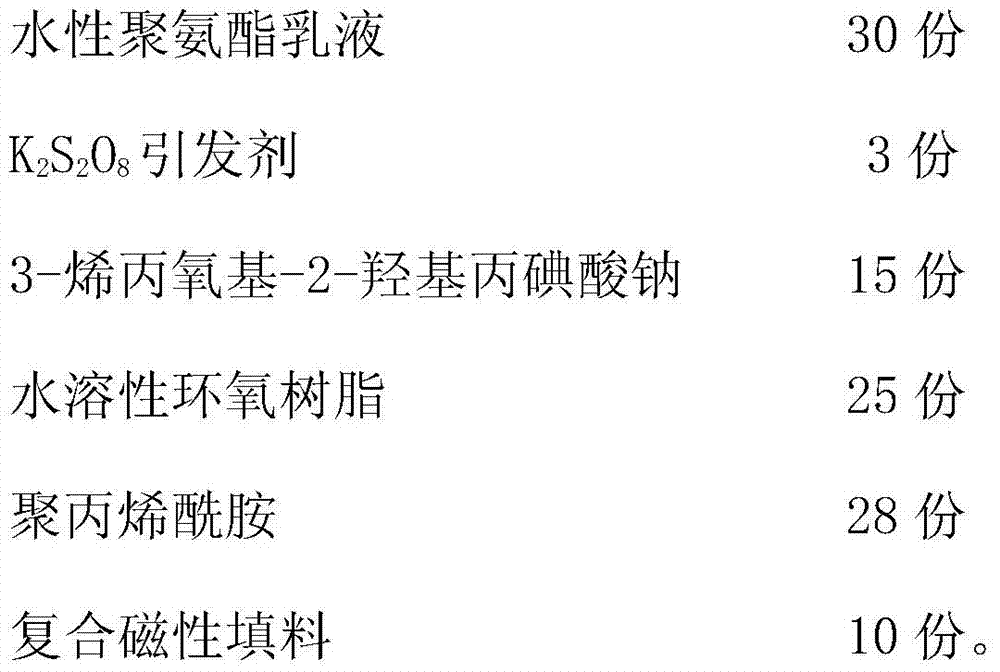

Modified polyurethane soap-free emulsion for leather finish and preparation method of modified polyurethane soap-free emulsion

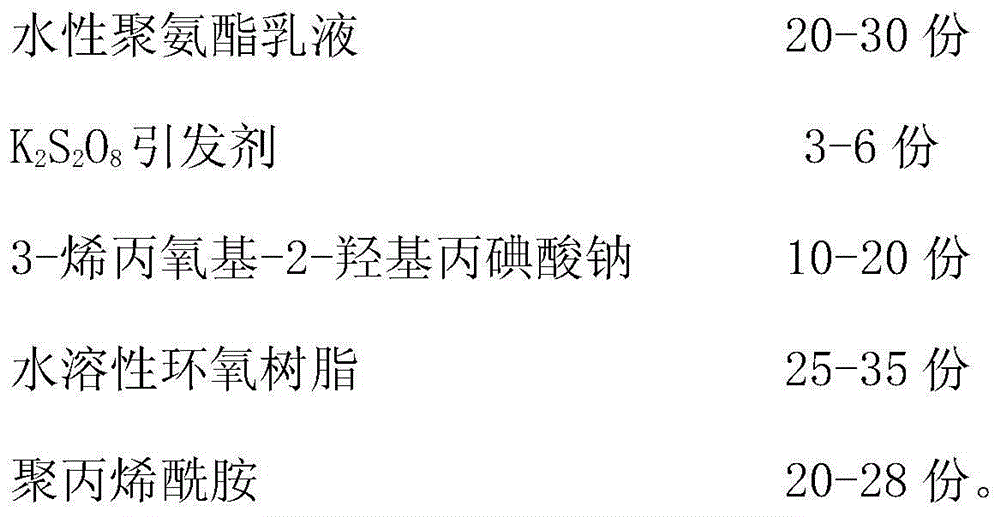

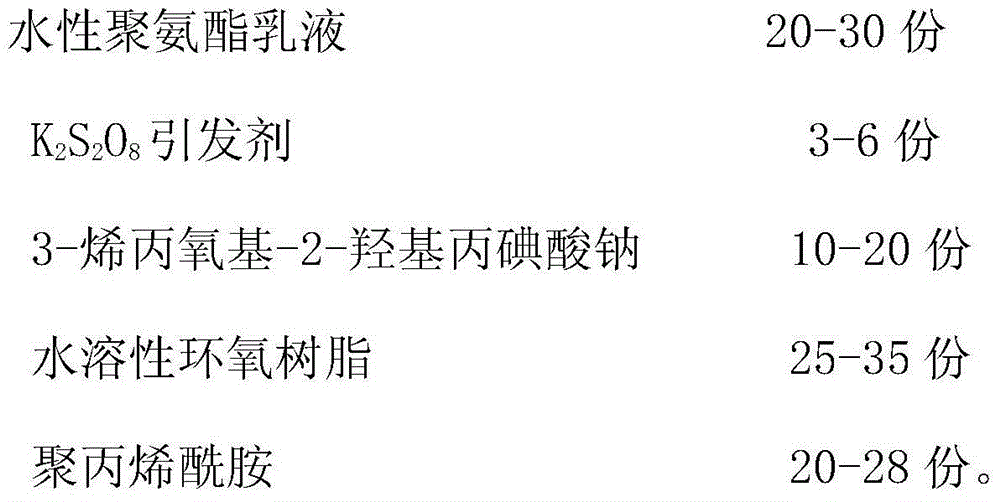

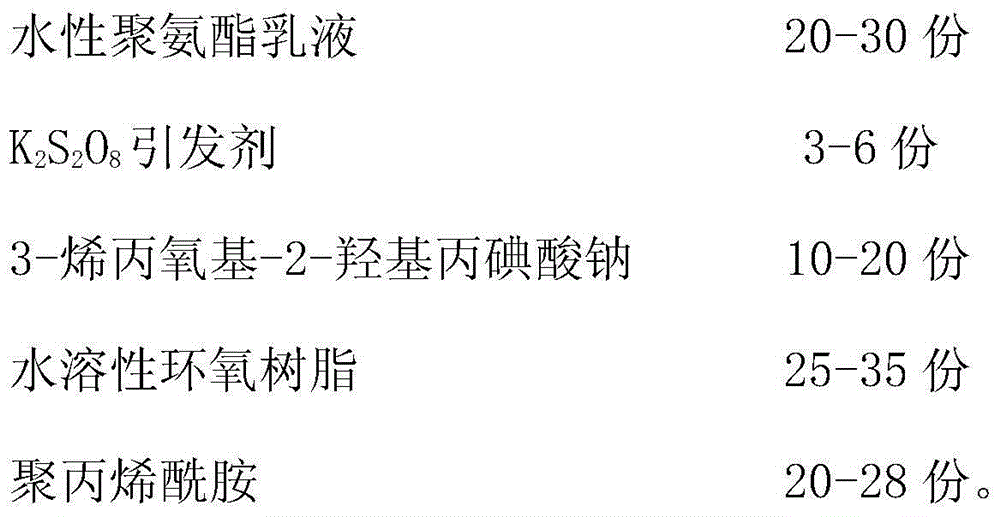

The invention discloses a modified polyurethane soap-free emulsion for leather finish. The modified polyurethane soap-free emulsion comprises components as follows: 20-30 parts of a waterborne polyurethane emulsion, 3-6 parts of a K2S208 initiator, 10-20 parts of 3-allyloxy-2-hydroxypropyl sodium iodate, 25-35 parts of water soluble epoxy resin and 20-28 parts of polyacrylamide, wherein the waterborne polyurethane emulsion is prepared with an ultrasonic dispersion method. The invention further discloses a preparation method of the modified polyurethane soap-free emulsion for leather finish. The preparation method comprises steps as follows: (1), preparation of the waterborne polyurethane emulsion; (2), preparation of the modified polyurethane soap-free emulsion. The product provided by the invention is environment-friendly, has high solid content, good film forming property, excellent coating compactness and wear resistance and high emulsion stability, and is suitable for a leather finishing agent, the preparation method of the modified polyurethane soap-free emulsion has low cost, the process is reasonable, and large-scale production can be facilitated.

Owner:派兔信息技术(广州)有限公司

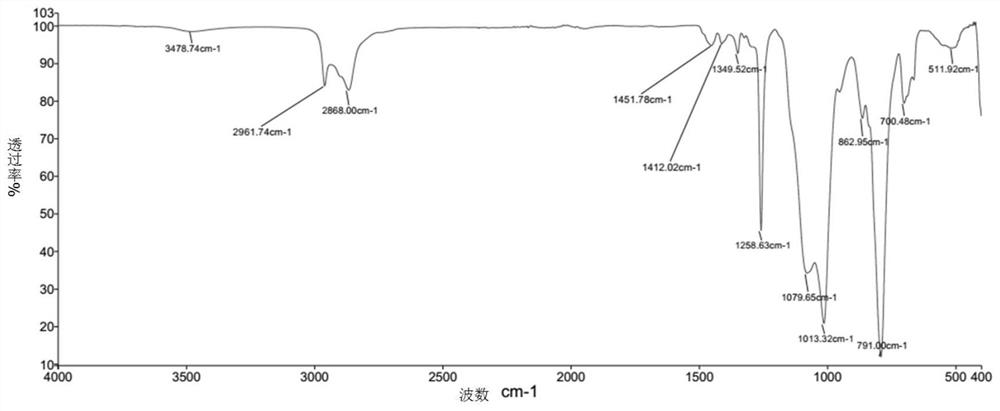

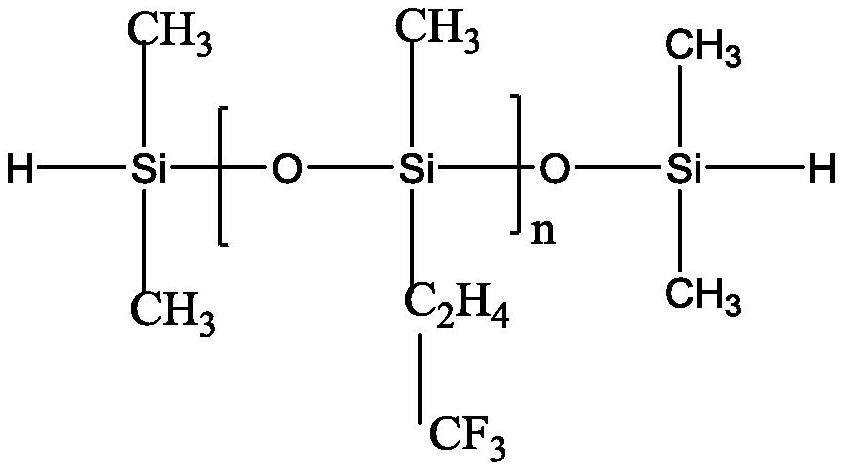

A kind of preparation method of fluorine-containing polyether modified organosilicon polyol

The invention belongs to the technical field of polymer material intermediates, and the matrix relates to a preparation method of a fluorine-containing polyether modified silicone polyol. The invention mainly uses a monoallyl polyether and a terminal hydrogen-containing fluorosilicone to perform hydrosilicon addition reaction to prepare fluorine-containing polyether modified silicone polyol. The fluorine-containing polyether modified silicone polyol prepared by this method can combine the excellent properties of silicone materials and organic fluorine materials, such as heat resistance, hydrolysis resistance, and dirt resistance, etc. At the same time, the terminal ether hydroxyl group has good reactivity and can be widely used The method is applied in the field of chemical modification of polyurethane, epoxy resin, etc., and the reaction process of the method of the present invention does not involve solvent, the process is simple, efficient and easy to control, green and environmentally friendly, and conducive to large-scale industrial production.

Owner:MIRACLL CHEM

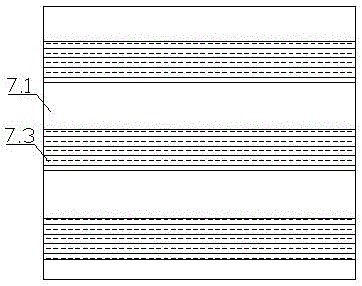

Dust-free fabric

The invention discloses a dust-free fabric, which comprises a dustproof layer and a fabric layer. A scarf joint layer is arranged between the dustproof layer and the fabric layer. A plurality of fine air vents are arranged on the upper surface of the fabric layer. The dustproof layer is formed by fibrous materials and nano materials in a weaving way by mixing. By adopting the method, the dust-free fabric can bring about unique comfort in the world of dresses, can be used in special working environments, has the advantages of no dust, dirty resistance, air permeability and the like, and fills the blank of the market in the aspect. Besides, the cost is low, the practicability is high, the energy is saved, the environment is protected and the popularization and the use are facilitated.

Owner:CHANGSHU YALAN GARMENTS

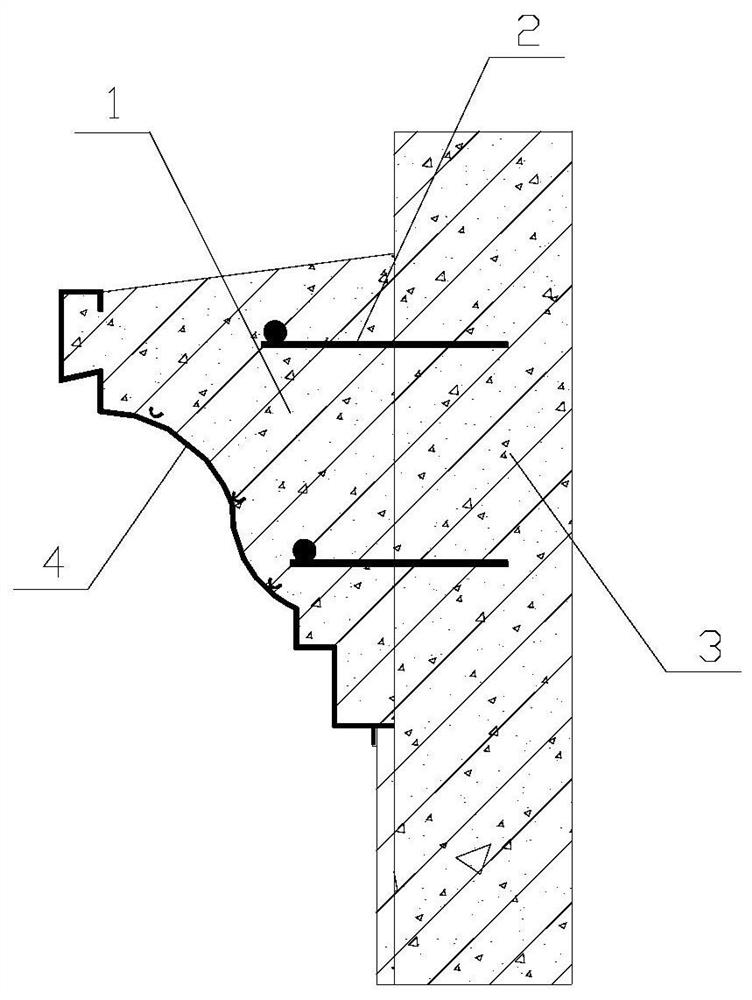

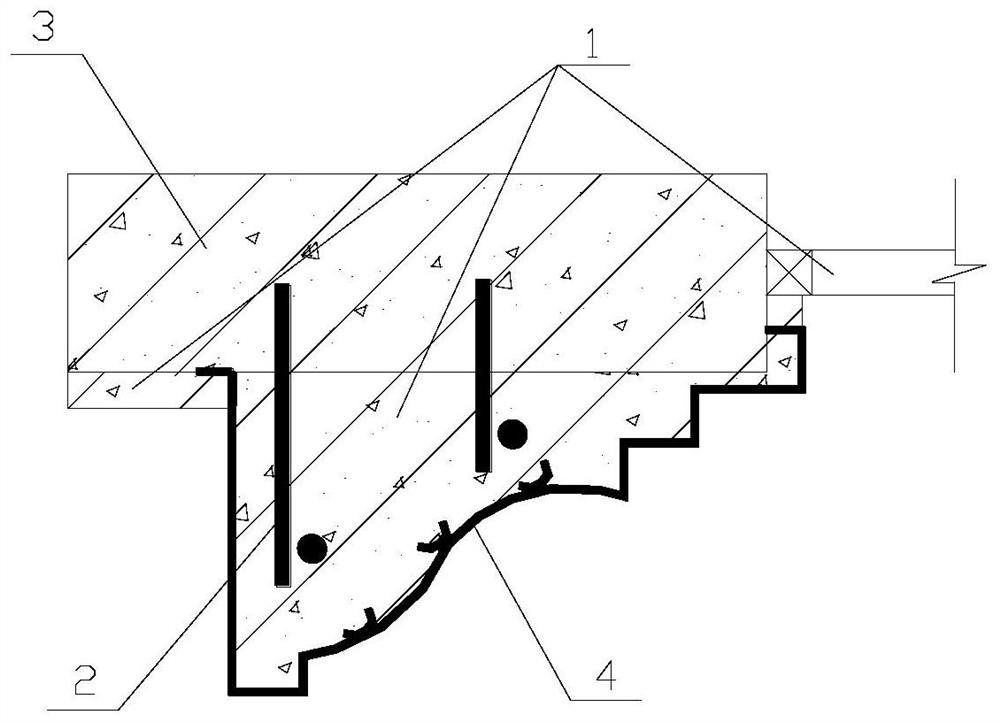

Stone-like concrete and aluminum rust stone decorative structure manufactured from same

InactiveCN111993833AEasy constructionThe effect is three-dimensional and fullSpecial ornamental structuresAdhesive glueChemistry

The invention provides stone-like concrete and an aluminum rust stone decorative structure manufactured from the same, and belongs to the technical field of decorative materials. The stone-like concrete comprises white cement, granite particles, glue and water, and the weight ratio of the white cement to the granite particles to the glue to water is 1:(1.5-2):0.05:(0.3-0.4). According to the design, construction is convenient, and the effect is stereoscopic, full, rich and diversified; the stone-like concrete has the advantages of being resistant to dirt, easy to clean, waterproof and long inservice life and can replace granite for decoration, and damage to nature due to mining is reduced; the problem about manufacturing of line string courses and window and door frame molds is solved; industrialized production of outer aluminum molds is achieved, and the molds are convenient to install and do not deform, and edges and corners are clear; through cast-in-place, the service life can beprolonged to a hundred years, mold removal is not needed, and time, labor and cost are saved; after pouring is completed, other visual surfaces except aluminum mold surfaces are processed into a stone-like effect through chiseling, chopping and the like; and an aluminum profile color processing technology is mature and stable, so that building decoration lines can be rich in color and colorful.

Owner:肖云南 +1

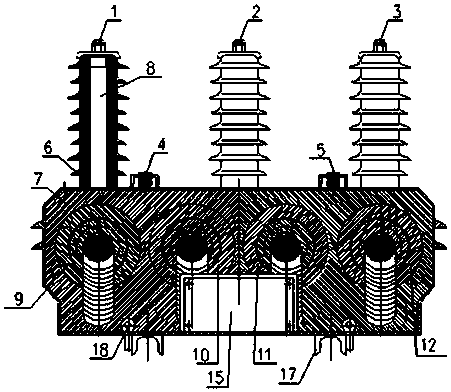

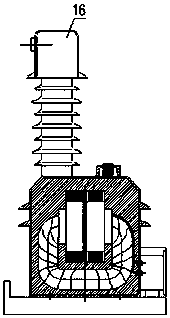

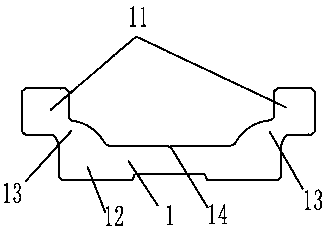

Miniature resonant-resistant three-phase outdoor composite insulation combination voltage transformer

InactiveCN108389708AArc resistantUV resistantTransformersTransformers/inductances casingsTransformerEngineering

The invention discloses a miniature resonant-resistant three-phase outdoor composite insulation combination voltage transformer. Three voltage mutual inductors and a harmonic-elimination mutual inductors are arranged in the miniature resonant-resistant three-phase outdoor composite insulation combination voltage transformer, voltage mutual inductor primary winding coils are arranged on the voltagemutual inductors, a terminal of the primary winding coils of the three voltage mutual inductors is electrically connected with a primary terminal of the voltage transformer via a high-voltage fuse, the other end of the primary winding coils of the three voltage mutual inductors are connected in series to a coil terminal O of the harmonic-elimination mutual inductor, the other coil terminal N of the harmonic-elimination mutual inductor is connected to the primary terminal of the voltage transformer and is electrically and directly connected with ground for use, tail ends of secondary winding coils of the voltage mutual inductors are connected in series to a terminal o of the harmonic-elimination mutual inductor, protection winding coils of the voltage mutual inductors are sequentially connected in series in end-to-end way to form an opening triangle and a harmonic-elimination resistor is connected in series among openings of the opening triangle. By the miniature resonant-resistant three-phase outdoor composite insulation combination voltage transformer, the safety and the insulativity are greatly improved, three-phase unbalance and harmonic burnt-out phenomena are prevented, and miniature is achieved.

Owner:DALIAN ZHONGGUANG INSTR TRANSFORMER

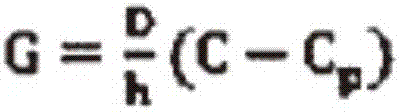

Composite air bubble film

InactiveCN104527146ATear-resistantDirt-resistantSynthetic resin layered productsHigh resistanceShock resistance

The invention belongs to the technical field of packaging materials and relates to a composite packaging material, in particular to a composite air bubble film. The composite air bubble film comprises a weaving layer, an air bubble layer and a PE foaming layer, wherein the weaving layer, the air bubble layer and the PE foaming layer are sequentially co-extruded to form the composite air bubble film. The composite air bubble film has the advantages of being high in strength and tear-preventing, has good buffering, abrasion-preventing, rainproof, damping, impact-resisting and heat seal performance, and the PE foaming layer has a function of protecting the surface of a packaged workpiece. The composite air bubble film integrates three purposes in one, and practical performance is greatly improved. The composite air bubble film has the advantages of being high in cleanliness, soft, light in weight, high in strength, tear-resistant, dirt-resistant and the like, has high shock resistance and elongation at break and is wide in application range.

Owner:QINGDAO CHIJIAN SPORTS EQUIP

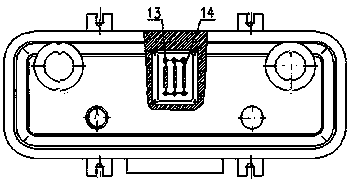

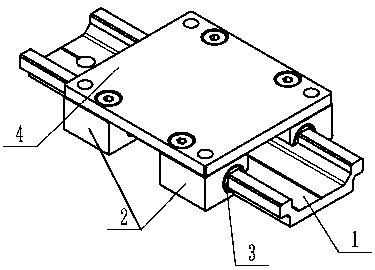

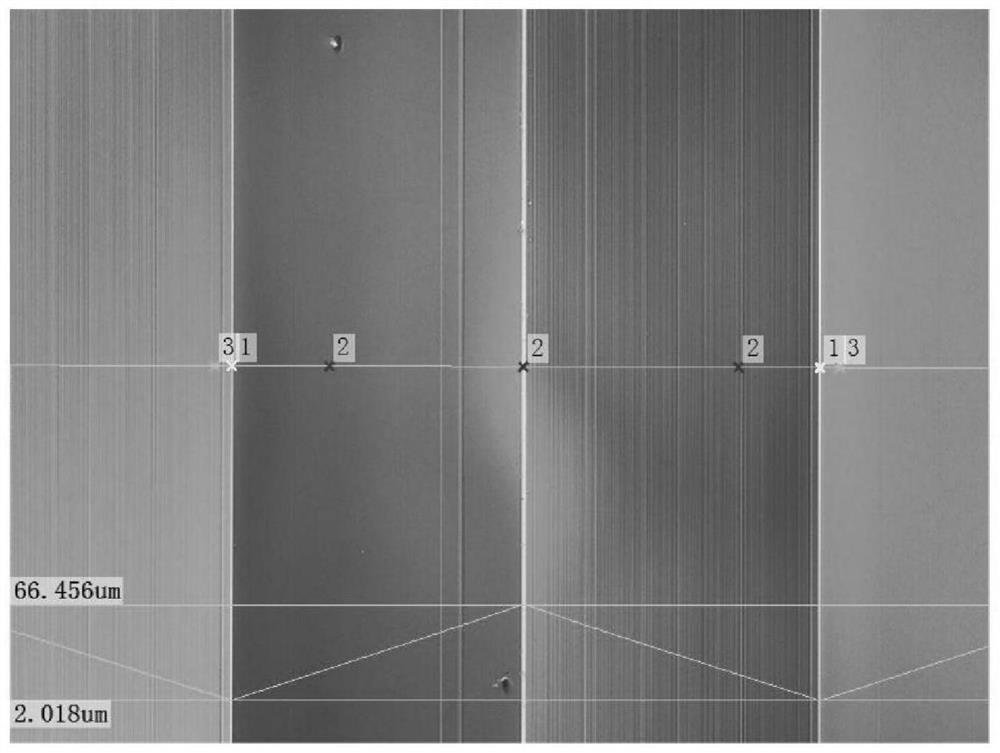

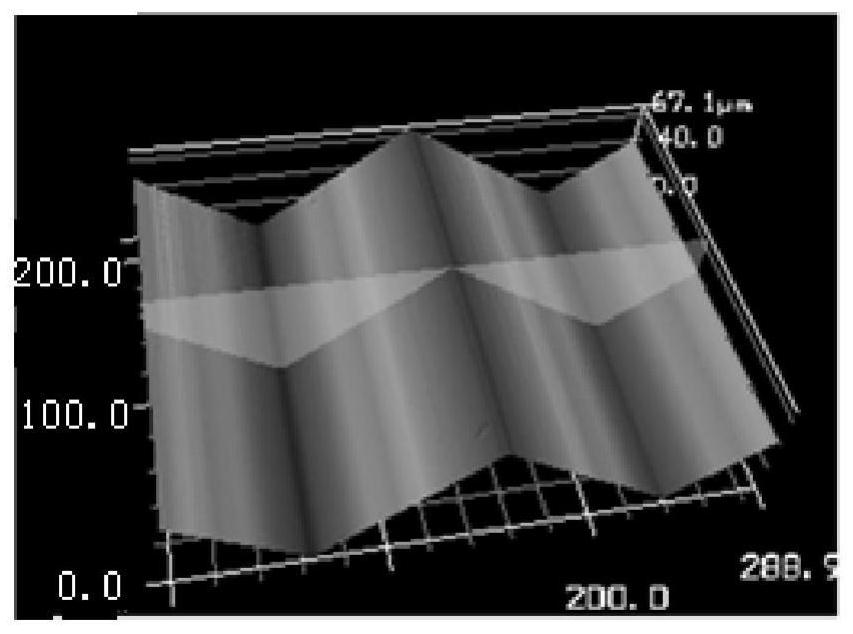

Modular sliding device and use method thereof

The invention relates to the technical field of automated matching equipment, in particular to a modular sliding device and a use method thereof. The modular sliding device comprises a guide rail provided with tracks and sliding blocks installed in the tracks. Sliding sheets used for reducing friction are arranged on the contact surfaces of the sliding blocks and the tracks. In use, the sliding sheets are embedded and installed between the guide rail and the sliding blocks, the sliding sheets and the sliding blocks form an assembled integrated structure, the sliding blocks are supported by thesliding sheets and slide on the guide rail stably in a mode of sliding friction, frequent cleaning and maintaining of the guide rail are avoided, and thus the production efficiency is improved; besides, direct contact of the sliding blocks and the guide rail is avoided through the sliding sheets, abrasion is reduced, and the service life of the equipment is prolonged; and meanwhile the modular sliding device has high carrying capacity.

Owner:成都金士力科技有限公司

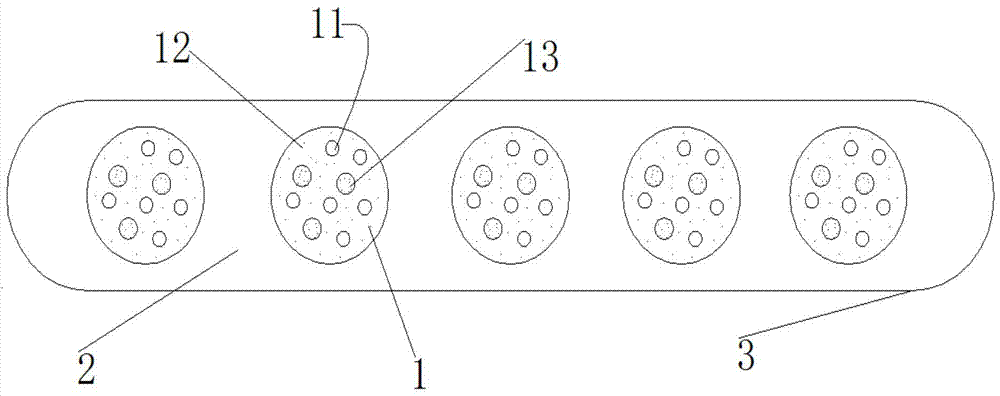

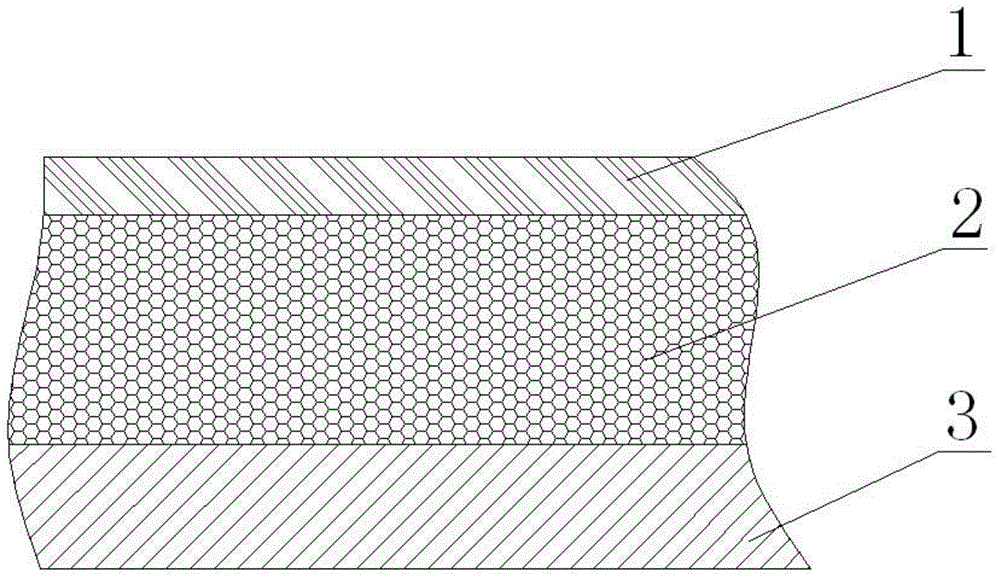

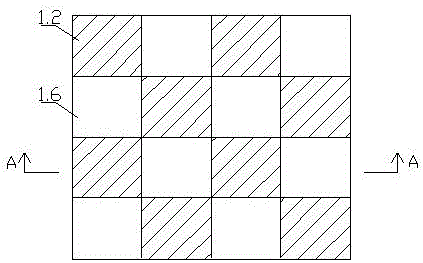

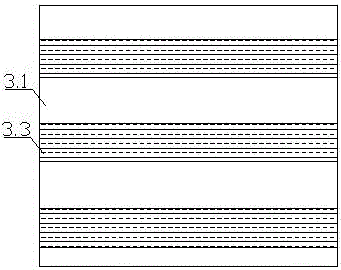

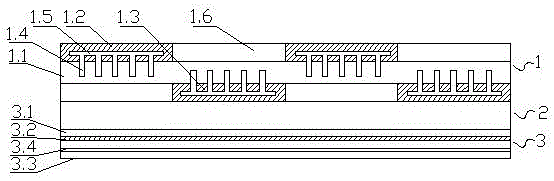

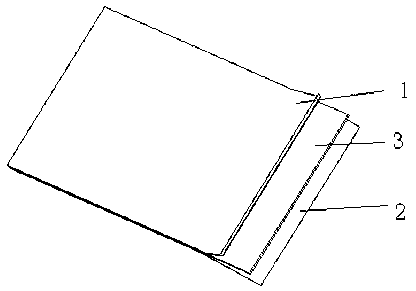

Antibacterial fabric with abundant colors and good resilience

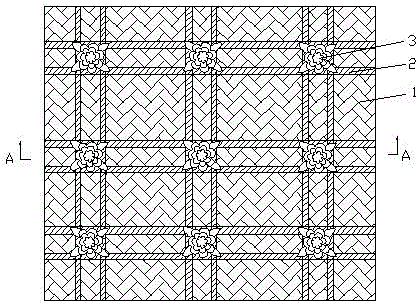

The invention relates to an antibacterial fabric with abundant colors and good resilience. The fabric sequentially comprises an antibacterial fabric layer (1), a fireproof fabric layer (2) and a waterproof fabric layer (3) from top to bottom. The antibacterial fabric layer (1) comprises a middle antibacterial fabric (1.1). Upper decoration matrix blocks (1.2) arranged in a staggered mode are arranged on the upper surface of the middle antibacterial fabric (1.1). Lower decoration matrix blocks (1.3) arranged in a staggered mode are arranged on the lower surface of the middle antibacterial fabric (1.1). A lining layer is composited on the back face of the waterproof fabric layer. The lining layer is formed by bi-color weft and warp composed of bi-color yarn and mono-color yarn. The antibacterial fabric has various functions, has the functions of resisting bacteria and resisting fire and water and has abundant colors and good resilience.

Owner:JIANGYIN HULIAN DYEING & FINISHING

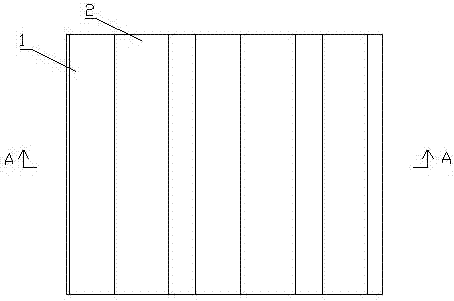

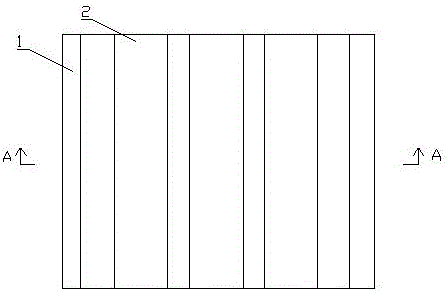

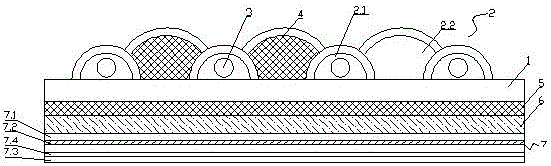

Crease-resistant fabric with rich colors and good elastic resilience

The invention relates to a wrinkle-resistant fabric with rich color and good resilience, comprising a fabric body (1), the upper surface of the fabric body (1) is provided with a vertically arranged hollow jacquard layer (2), and the lower surface of the fabric body (1) is An antistatic layer (5), a fireproof layer (6) and a waterproof layer (7) are sequentially arranged on the surface downward. The lower surface of the waterproof layer is provided with a lining layer, and the lining layer is formed by interweaving warp yarns composed of two-color threads and single-color threads and two-color weft yarns. The invention is antibacterial, anti-radiation, fireproof, waterproof, antistatic, anti-wrinkle, delicate, soft and has a drape feeling.

Owner:WUXI HUALIAN PLASTIC PROD CO LTD

A kind of photocuring coating, ultraviolet light curing hydrophobic anti-adhesion film surface and preparation method thereof

ActiveCN109181521BImprove hydrophobicityThe water contact angle does not decreaseAntifouling/underwater paintsPaints with biocidesPhotoinitiatorMicrostructure

The invention provides a light-cured coating, an ultraviolet light-cured hydrophobic anti-adhesion film surface and a preparation method thereof. The light-cured coating comprises the following components in parts by weight: 15-30 parts of polyurethane acrylate, 10-30 parts of nano Particles, 2-4 parts of photoinitiator, 1-15 parts of perfluoropolyether, 5-15 parts of perfluoro-modified long-chain alkylsilane and 30-50 parts of solvent. The invention uses polyurethane acrylate, perfluoropolyether and perfluoromodified long-chain alkyl silane to compound nanoparticles, so that the photocurable coating is crosslinked through photocuring reaction to form a tight coating, which has wear resistance and forms a cured coating. The super-hydrophobic microstructure of the substance enhances its hydrophobicity. Through the microstructure formation and ultraviolet curing methods, a concave-convex microstructure is produced on the surface of the prepared film, which produces a lotus leaf effect, enhances hydrophobicity, and achieves superhydrophobicity. Production Afterwards, it can be rolled directly without the need for a protective film, saving costs.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

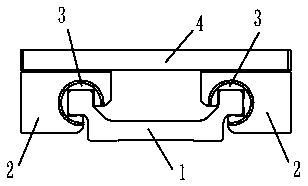

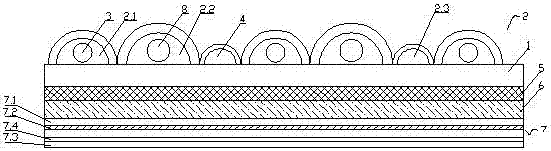

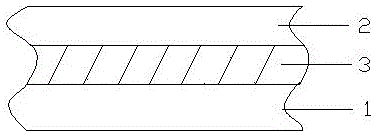

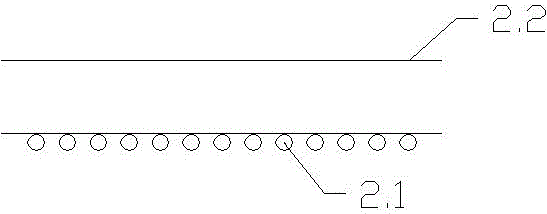

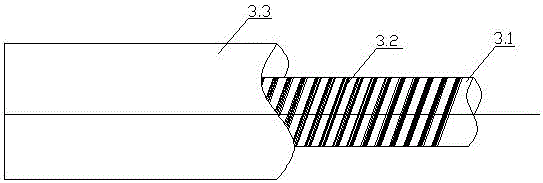

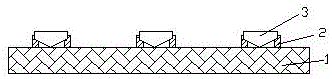

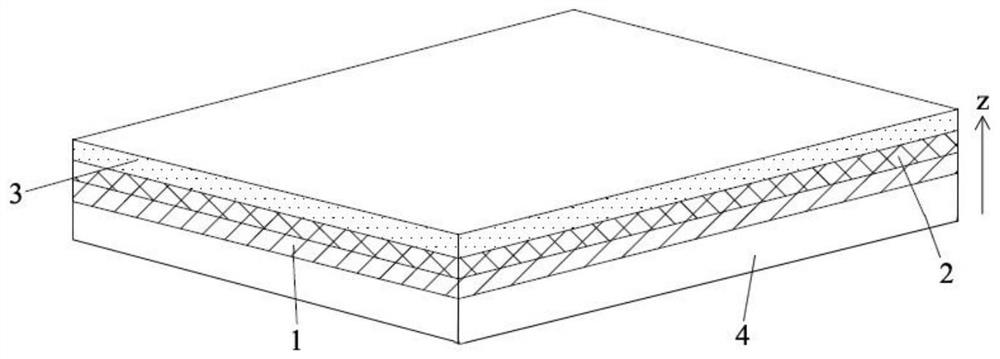

Down feather synthetic leather with rich color and luster, good resilience and repellency against mosquitoes

InactiveCN105951463AImprove fullnessGood flexibilityLayered productsWoven fabricsPolymer scienceEngineering

The invention relates to down feather synthetic leather with rich color and luster, good resilience and repellency against mosquitoes. The down feather synthetic leather comprises a base layer (1) and a surface layer (2), wherein an interlayer (3) is arranged between the base layer (1) and the surface layer (2), and comprises down feathers, the down feathers are flatly and uniformly arranged between the base layer (1) and the surface layer (2), the plastic surface layer (2) comprises a small fish scale-shaped knitted layer (2.1) at the inner layer and a mosquito repellent protective layer (2.2) at the outer layer. A lining layer is compounded on the back surface of the base layer, and formed by interweaving warp yarns which comprise double-color lines and single-color lines with double-color weft yarns. The down feather synthetic leather disclosed by the invention is rich in color and luster, good in resilience and mosquito-repellent.

Owner:JIANGYIN LONGSHENG PLASTIC

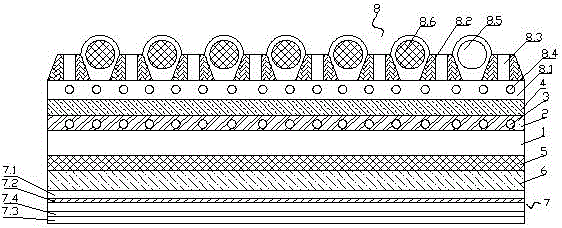

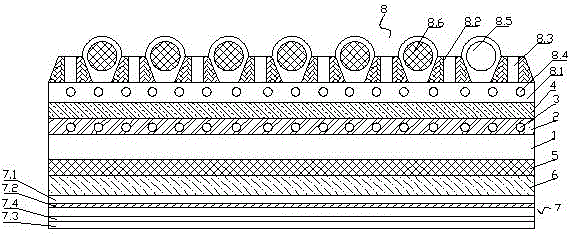

Abrasion-resistant and flame-retardant home textile fabric with abundant colors and high color fastness

InactiveCN105965972AFlame retardantThree-dimensionalSynthetic resin layered productsWoven fabricsColour fastnessYarn

The invention relates to an abrasion-resistant and flame-retardant home textile fabric with abundant colors and high color fastness. The abrasion-resistant and flame-retardant home textile fabric comprises a fabric body (1). A radiation-proof layer (2), an antistatic layer (4) and an upper waterproof layer (8) are sequentially arranged on the upper surface of the fabric body, and an antibacterial layer (5), a flame-retardant layer (6) and a lower waterproof layer (7) are sequentially arranged on the lower surface of the fabric body (1). Lining layers are arranged on the lower surfaces of the lower waterproof layer, warps and double-color wefts are interwoven to form the lining layers, and the warps comprise double-color yarns and single-color yarns. The abrasion-resistant and flame-retardant home textile fabric has the advantages of abundant colors, abrasion resistance, high color fastness and flame-retardant, radiation-proof, waterproof and antistatic properties.

Owner:JIANGYIN TOPWAY TEXTILE

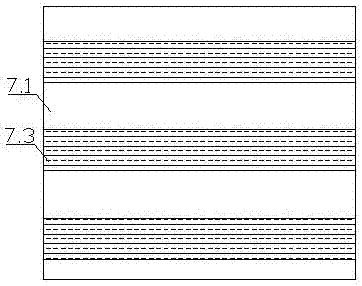

Environment-friendly fabric with abundant colors and good resilience

InactiveCN106079648AThree-dimensionalAntibacterialSynthetic resin layered productsCellulosic plastic layered productsEngineeringWeft yarn

The invention relates to an environment-friendly fabric with abundant colors and good resilience. The environment-friendly fabric comprises an environment-friendly fabric body (1). A hollow-out jacquard layer (2) is longitudinally arranged on the upper surface of the environment-friendly fabric body (1), and an antistatic layer (5), a fireproof layer (6) and a waterproof layer (7) are downwardly sequentially arranged on the lower surface of the environment-friendly fabric body (1). Lining layers are compounded on the lower surface of the waterproof layer and comprise warp yarns and double-color weft yarns which are interwoven with one another, and the warp yarns and the double-color weft yarns comprise double-color threads and single-color threads. The environment-friendly fabric has the advantages of abundant colors and good resilience.

Owner:JIANGYIN JIAYI GIFT

Weather-proof protecting film

InactiveCN103129065AAvoid manual contactUse cost compression or controlSynthetic resin layered productsTectorial membraneEngineering

Owner:KUNSHAN HANBAO TAPE TECH

Production method of digital functional printing seamless wall cloth

InactiveCN107385954AEasy dischargeYield effectFabric breaking/softeningLaminationEngineeringMethods of production

Owner:HANGZHOU ZUNSHANGBI DECORATION MATERIAL CO LTD

Waterproof fabric with rich color and good resilience

The invention relates to a waterproof fabric with rich color and good resilience. The waterproof fabric comprises a fabric body (1), wherein an anti-radiation layer (2) is arranged on the upper surface of the fabric body; a reinforcing layer (4) and an upper waterproof layer (8) are sequentially arranged on the upper surface of the anti-radiation layer (2); an antibacterial layer (5), a fireproof layer (6) and a lower waterproof layer (7) are sequentially arranged on the lower surface of the fabric body; a lining layer is arranged on the lower surface of the lower waterproof layer and is formed by interweaving of warp yarns and bi-color weft yarns, and the warp yarns consist of bi-color threads and unicolor threads. The waterproof fabric provided by the invention is strong in stereoscopic impression, resistant to bacteria, radiation, fire and water, rich in color and good in resilience.

Owner:JIANGSU YUNFU FASHION CO LTD

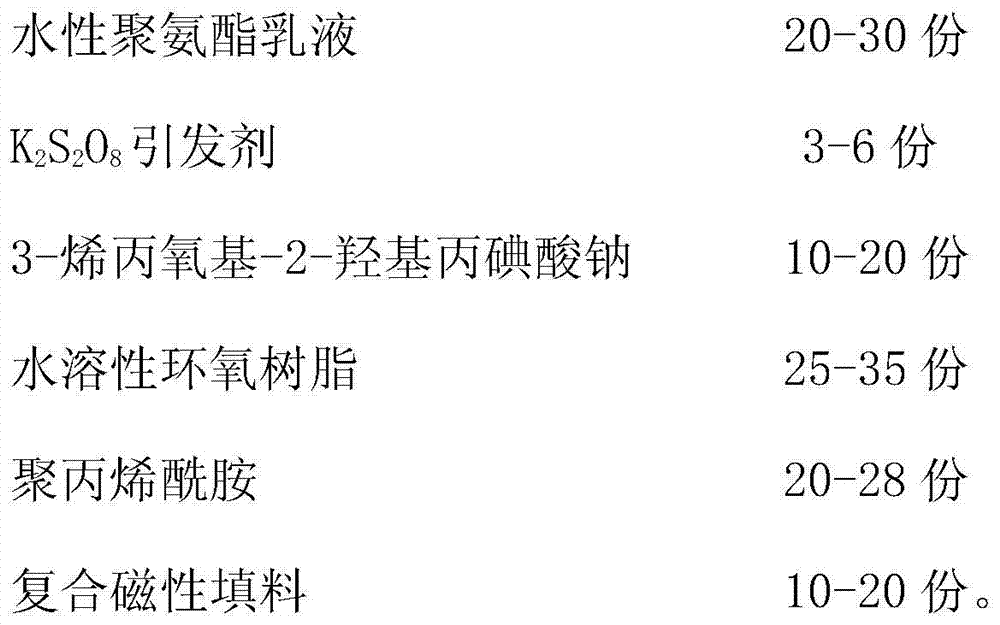

Magnetic polyurethane soap-free emulsion for coating and preparation method thereof

The invention discloses magnetic polyurethane soap-free emulsion for coating. The magnetic polyurethane soap-free emulsion comprises the following components in parts by weight: 20-30 parts of waterborne polyurethane emulsion, 3-6 parts of a K2S2O8 initiator, 10-20 parts of 3-allyloxy-2-hydroxypropyl sodium iodate, 25-35 parts of water-soluble epoxy resin, 20-28 parts of polyacrylamide and 10-20 parts of composite magnetic packing, wherein the waterborne polyurethane emulsion is prepared through an ultrasonic dispersion method. The invention further discloses a preparation method of magnetic polyurethane soap-free emulsion for leather coating; the method comprises the following steps: (1) preparing the composite magnetic packing; (2) preparing the waterborne polyurethane emulsion; (3) preparing the modified polyurethane soap-free emulsion. The magnetic polyurethane soap-free emulsion provided by the invention is environment-friendly, high in solid content, good in film-forming property, excellent in coating compactness and abrasive resistance, high in emulsion stability and suitable for a leather coating agent. The preparation method is low in cost, reasonable in process and suitable for large-scale production.

Owner:广东再设计创意文化有限公司

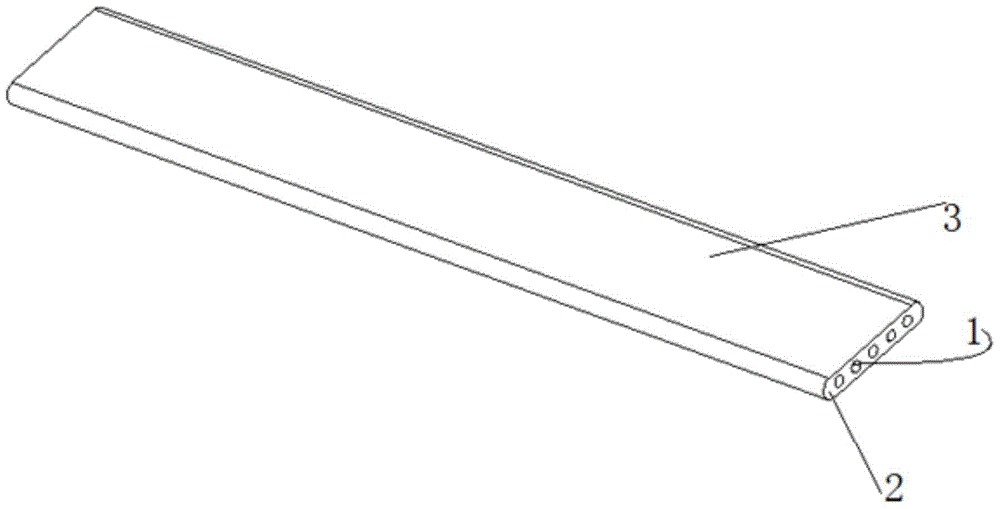

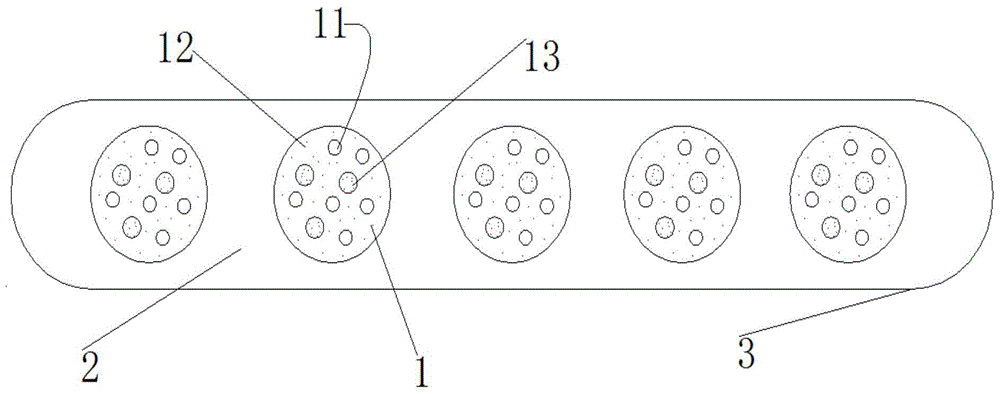

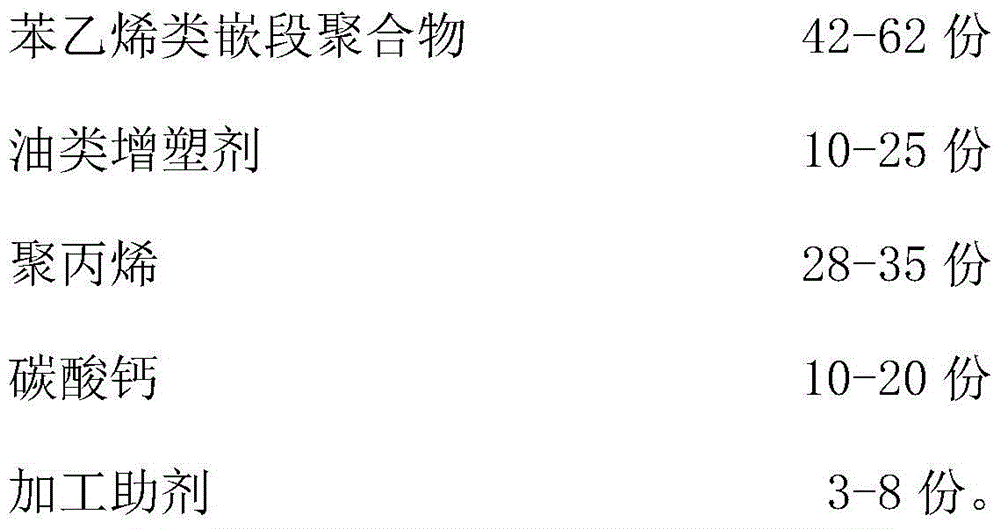

Preparation method and product of nano-coated earphone wire

ActiveCN104505171BEasy to identifyEasy to distinguishPlastic/resin/waxes insulatorsCable/conductor manufacturePlasticizerUltraviolet protection

The invention discloses a preparation method of a nanometer coated earphone line. The preparation method comprises the following steps: preparing single lines, preparing an insulating jacket, preparing a nanometer coating film and the like. The invention also discloses a nanometer coated earphone line product prepared by using the method. The product comprises a plurality of strands of single lines and the insulating jacket layer which wraps the single lines, wherein the surface of the insulating jacket layer is provided with the nanometer coating layer; more than four strands of single lines are arranged side by side; the insulating jacket layer is flat; the thickness of the nanometer coating layer is 50-100 nm and is deposited on the surface of the insulating jacket layer by using the principle of vapor deposition; the insulating jacket is formed of styrene block polymer, an oil type plasticizer, polypropylene, calcium carbonate and a processing aid through extrusion plasticizing. The unique flat appearance facilitates the recognition, and the unique nanometer coating layer guarantees that the product has the superior performances such as water resistance, oxidation resistance, dirt resistance, scratch resistance and ultraviolet protection.

Owner:DONGGUAN YINGTONG WIRE +1

#-shaped tweed with abundant color and luster and good rebound resilience

The invention relates to #-shaped tweed with abundant color and luster and good rebound resilience. The #-shaped tweed comprises a fabric body (1); a plurality of bulges (2) are arranged on the outer surface of the fabric body; the bulges (2) are strip-shaped; two transverse bulges (2) and two vertical bulges (2) are crossed to form a # shape and extend toward the four sides to form a plurality of # shapes; flowers (3) with green leaves are arranged at the centers of the # shapes. A lining layer is arranged on the inner surface of the fabric body; the lining layer is formed through interweaving warp yarns composed of double-colored threads and single-colored threads and double-colored weft yarns. Compared with a flat structure and a tedious feeling of a woolen fabric, the #-shaped tweed with abundant color and luster and good rebound resilience has great stereoscopic sensation. The #-shaped tweed has abundant color and luster and good rebound resilience.

Owner:JIANGYIN YIFAN IND & TRADE

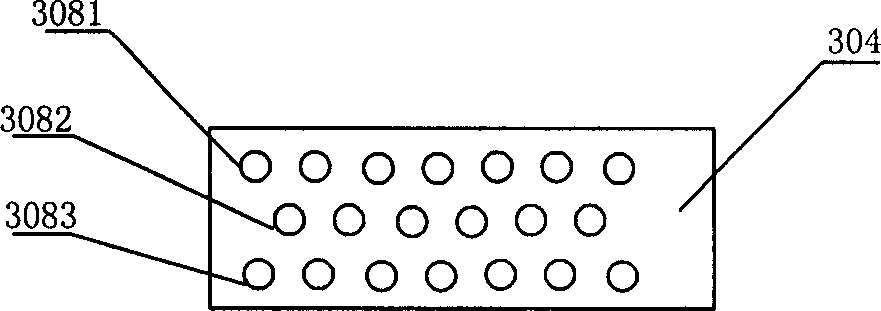

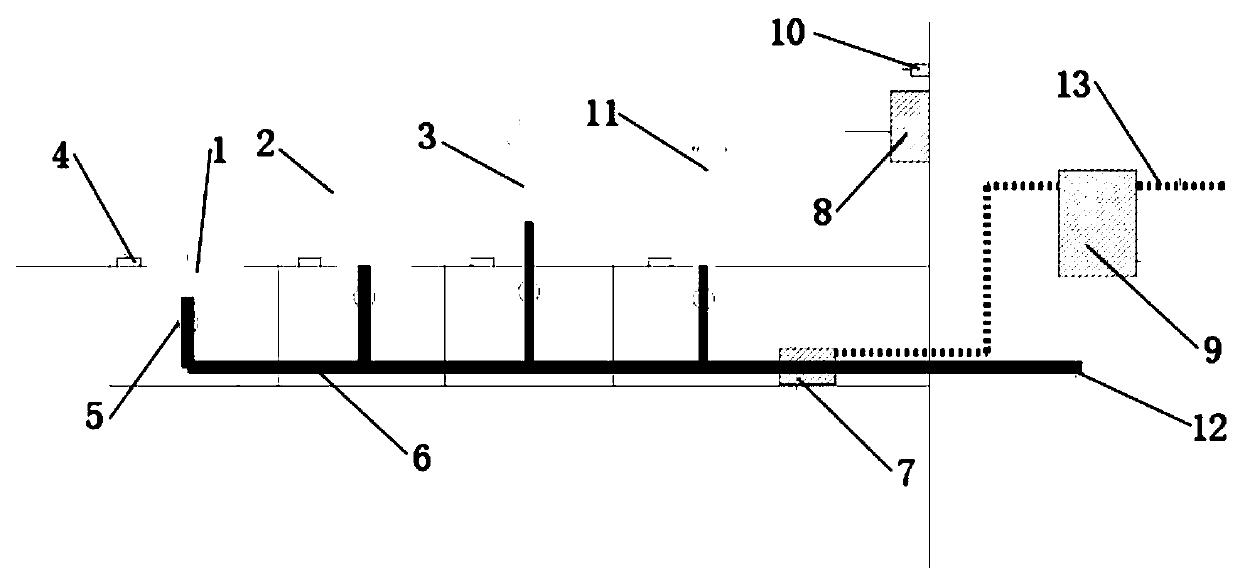

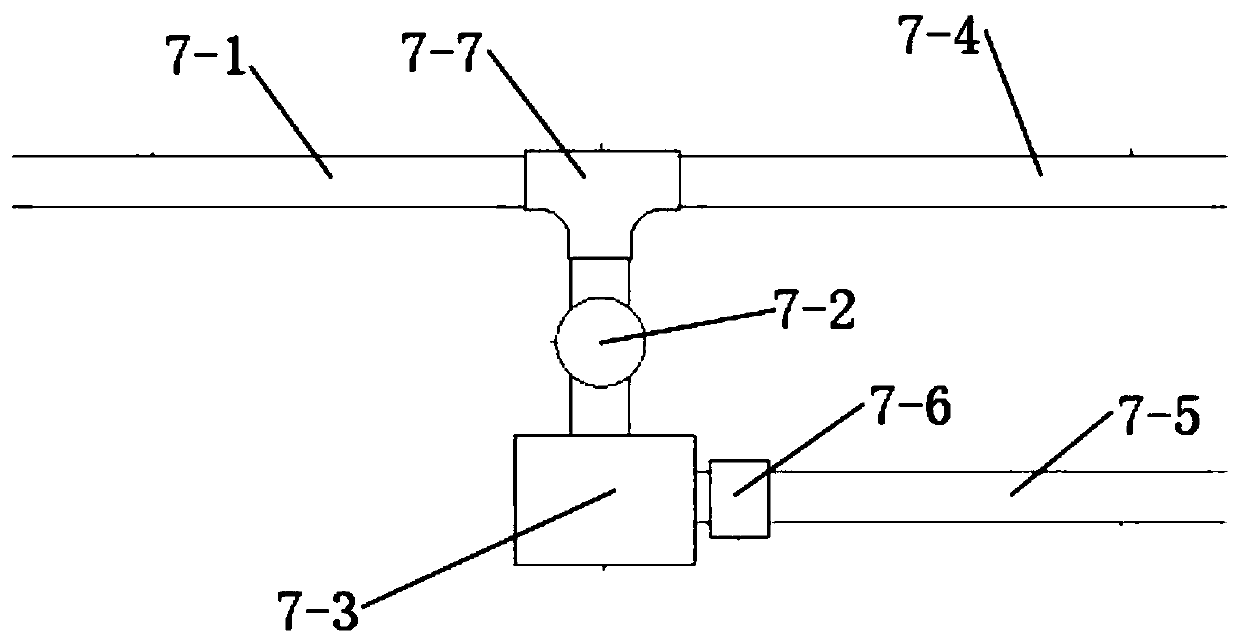

Source separation negative-pressure toilet deodorization system

PendingCN111411671ACorrosion resistantNon-absorbentGas treatmentSewerage structuresWater vaporMechanical engineering

The invention discloses a source separation negative-pressure toilet deodorization system. The system comprises a ground row type source separation collection port, a water-vapor separator, PLC control equipment and a negative-pressure collection and purification host. The source separation negative-pressure toilet deodorization system has the beneficial effects that the PTFE coating treatment isadopted, so that the system has the characteristics of corrosion resistance, no water absorption, dirt resistance and good electrical insulating property; a micro aerodynamic principle and a principlethat a fluid zero-pressure area is generated by ground suction and lower exhaust air are adopted, so that peculiar smell is eliminated from the source; the porous dense wind energy evaporation dehumidification function is achieved; collecting equipment adopts a porous dense design principle, when the equipment is attached to the ground for deodorization, the wind energy can evaporate water on theground, water vapor is continuously taken away under the action of the wind energy, the water vapor is treated by the water-vapor separator at the rear end, and the water is independently collected and discharged. The equipment can achieve the purpose of dehumidifying the ground of the toilet while deodorizing.

Owner:嘉兴森绿环保科技有限公司

Composite coating material and its preparation method and application

ActiveCN108977053BImprove the problem of aging and discolorationImprove the problem of discoloration and agingAntifouling/underwater paintsPaints with biocidesPolymer scienceColored white

The present disclosure relates to a composite coating material and its preparation method and application. The composite coating material includes: a substrate; a primer layer formed on the surface of the substrate; a color paint layer in contact with the primer layer; and a topcoat layer formed on the color The side of the paint layer opposite to the primer layer; wherein, the material of the primer layer includes: polyurethane acrylate, epoxy acrylate oligomer, resin monomer and additives. The composite coating material of the present disclosure can improve the problem of aging and discoloration, even if a composite coating of light color (eg white, light green, light pink, etc.) is used, the problem of discoloration and aging can also be improved.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com