Magnetic polyurethane soap-free emulsion for coating and preparation method thereof

A soap-free emulsion and water-based polyurethane technology, applied in the field of polymers, can solve the problems of product patterns, designs and colors not unique enough, individuality, wear resistance is not outstanding, decoration limitations, etc., to achieve excellent wear resistance, low cost, emulsion Highly stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

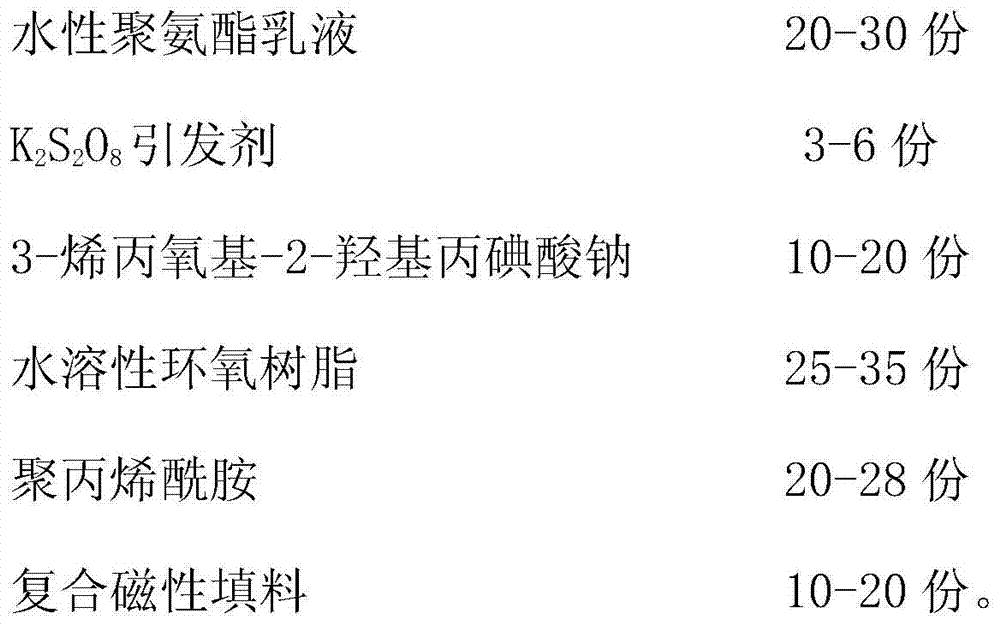

[0034] Embodiment 1 This embodiment provides a magnetic polyurethane soap-free emulsion for finishing products such as leather, which is made of the following components in parts by weight:

[0035]

[0036] The water-based polyurethane emulsion is prepared by ultrasonic dispersion from the following parts by weight: 30-35 parts of polyester diol, 10-20 parts of HDI, 0.5-2 parts of organotin catalyst, 5 parts of DMPA -8 parts, NMP 18-22 parts, methylol propane 5-7 parts, acetone 20-30 parts, modified polyurethane soap-free emulsion chitosan nanoparticles 3-9 parts, ethylenediamine aqueous solution 15-20 parts.

[0037] The polyester diol is polycarbonate diol with a relative molecular weight of 2000; the mass fraction of the ethylenediamine aqueous solution is 10-12%; the modified polyurethane soap-free emulsion chitosan nanoparticles The particle size is 18-24nm.

[0038] The water-soluble epoxy resin is one of 681 water-soluble epoxy resin and 682 water-soluble epoxy res...

Embodiment 2

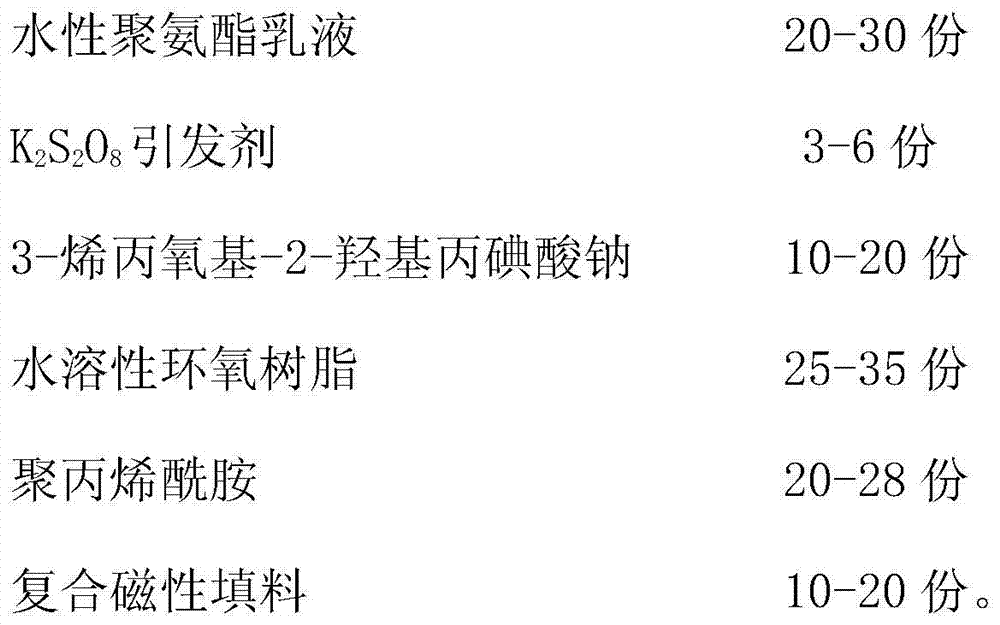

[0054] The magnetic polyurethane soap-free emulsion for finishing provided in this embodiment and its preparation method are basically the same as in Example 1, except that: the magnetic polyurethane soap-free emulsion for finishing is made of the following components in parts by weight:

[0055]

[0056] The water-based polyurethane emulsion is prepared from the following parts by weight by ultrasonic dispersion: 30 parts of polyester diol, 10 parts of HDI, 0.5 parts of organotin catalyst, 8 parts of DMPA, 18 parts of NMP, 7 parts of methylol propane, 20 parts of acetone, 6 parts of modified polyurethane soap-free emulsion chitosan nanoparticles, 20 parts of ethylenediamine aqueous solution.

[0057] Described polyester diol is the polycarbonate diol that relative molecular weight is 2000; The mass fraction of described ethylenediamine aqueous solution is 10%; The particle size of described modified polyurethane soap-free emulsion chitosan nano-particle The diameter is 24n...

Embodiment 3

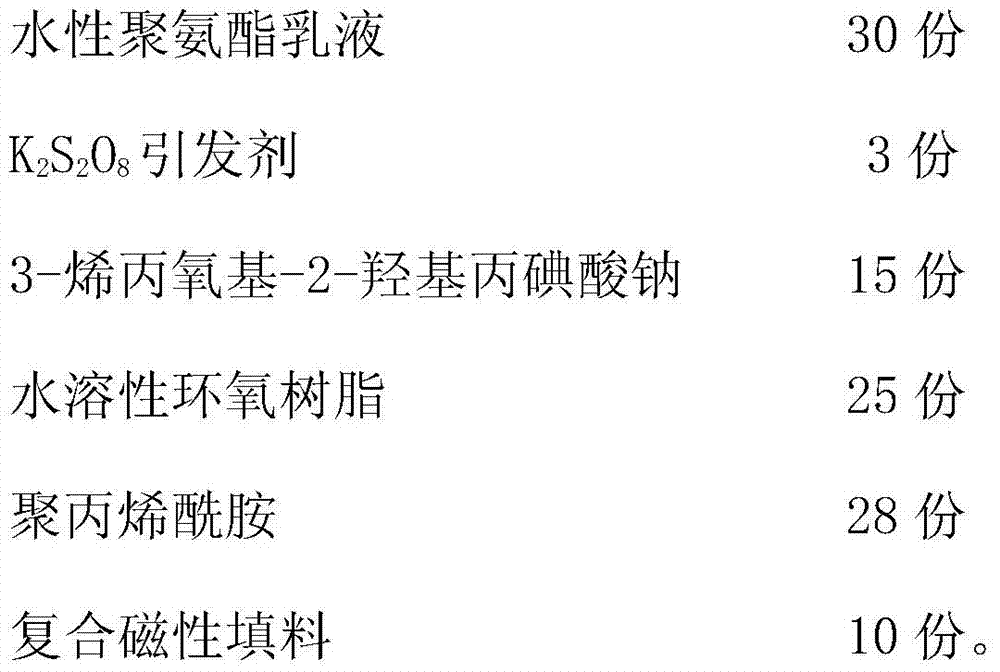

[0073] The magnetic polyurethane soap-free emulsion for finishing leather and other products provided by this embodiment and its preparation method are basically the same as those in Examples 1 and 2, except that the magnetic polyurethane soap-free emulsion for finishing consists of the following parts by weight Components made:

[0074]

[0075] The water-based polyurethane emulsion is prepared from the following parts by weight by ultrasonic dispersion: 32 parts of polyester diol, 18 parts of HDI, 1.5 parts of organotin catalyst, 6 parts of DMPA, 20 parts of NMP, 6 parts of methylol propane, 25 parts of acetone, 3 parts of modified polyurethane soap-free emulsion chitosan nanoparticles, and 18 parts of ethylenediamine aqueous solution.

[0076] Described polyester diol is the polycarbonate diol that relative molecular weight is 2000; The mass fraction of described ethylenediamine aqueous solution is 11%; The particle size of described modified polyurethane soap-free emuls...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com