Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Flexible heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

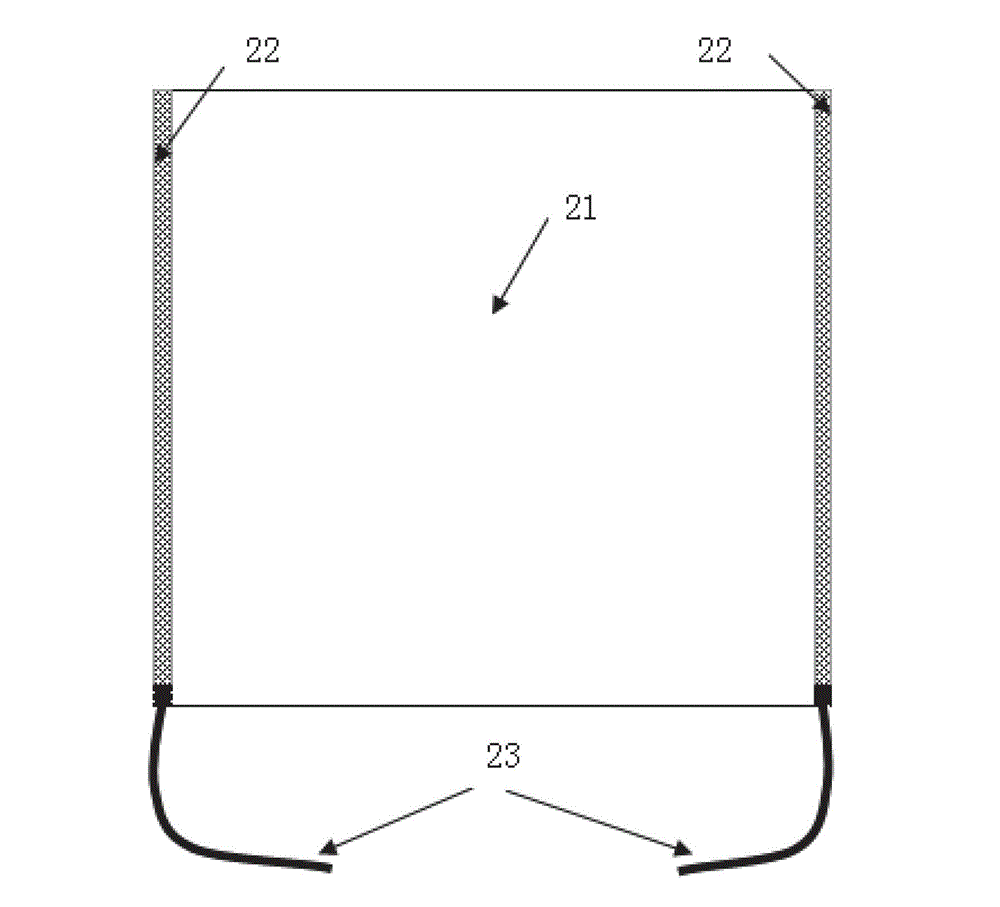

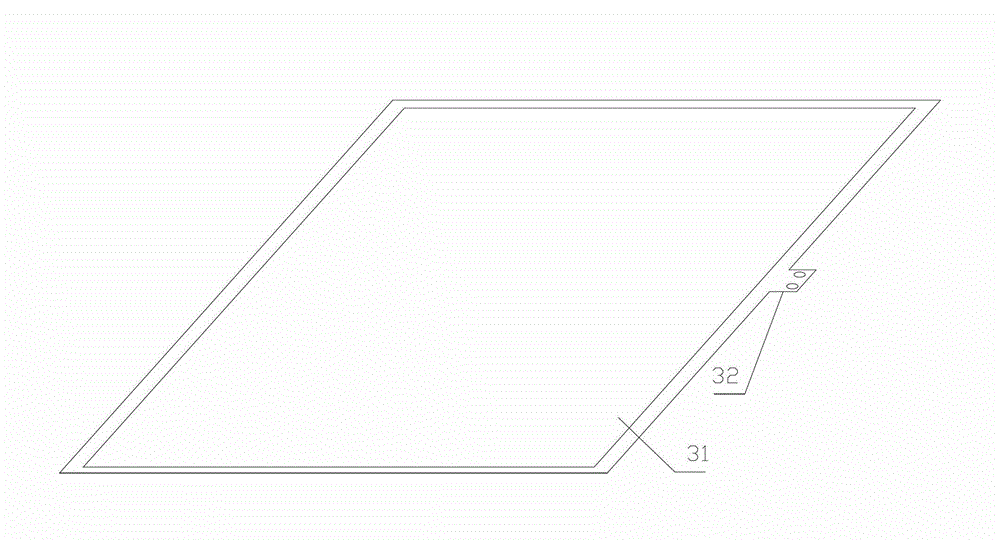

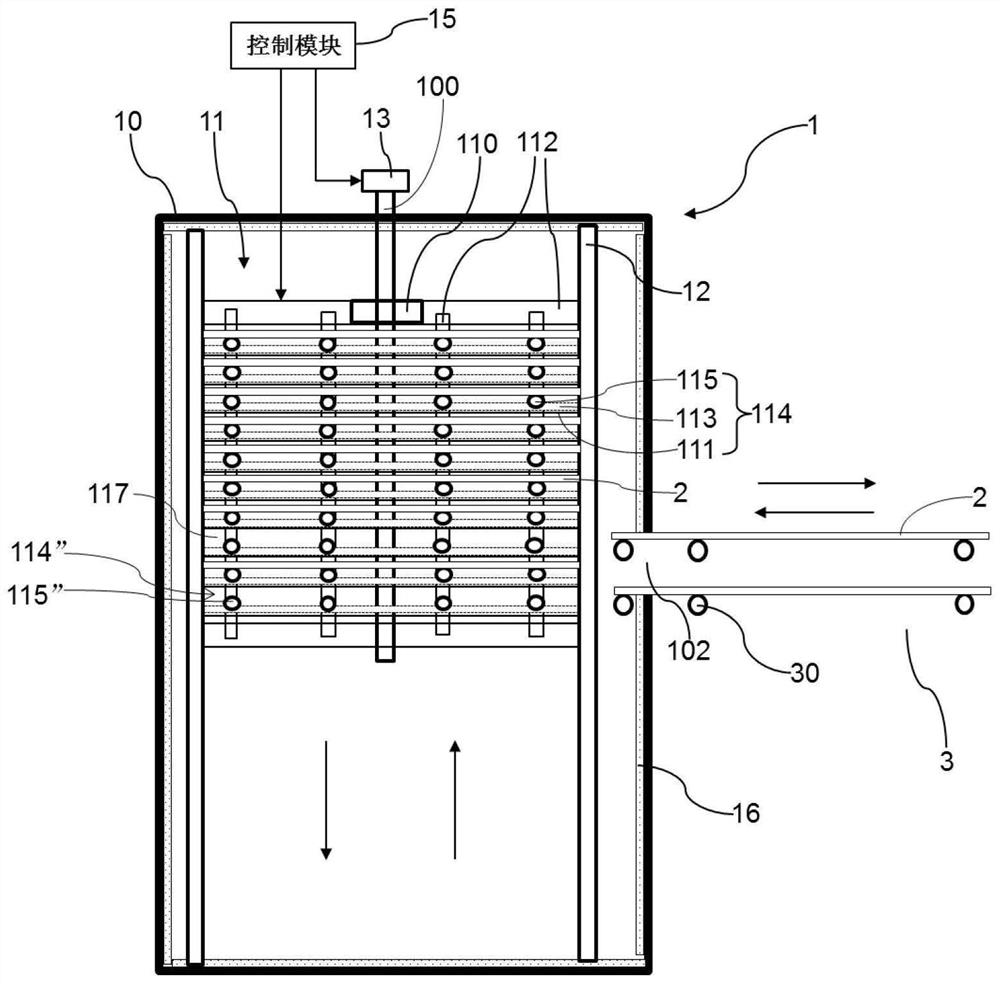

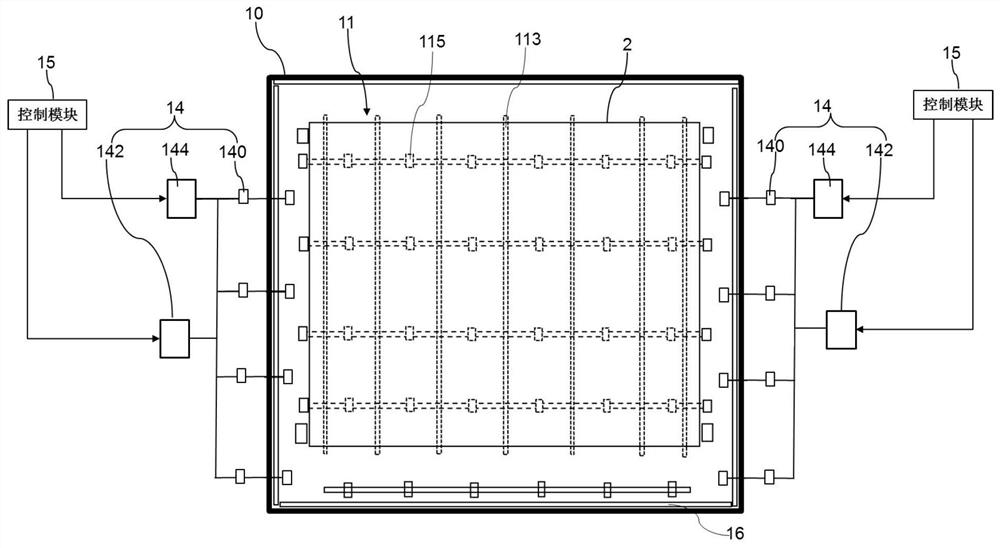

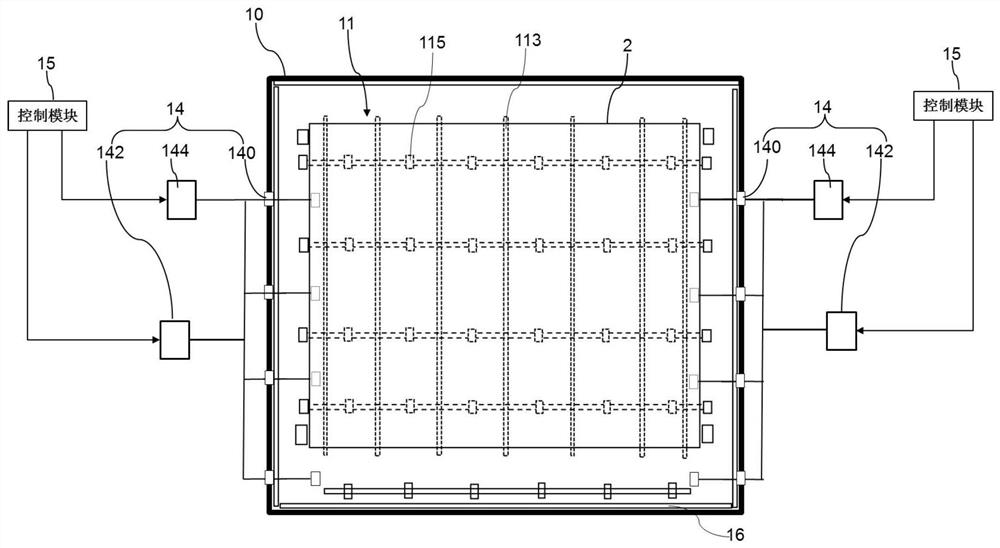

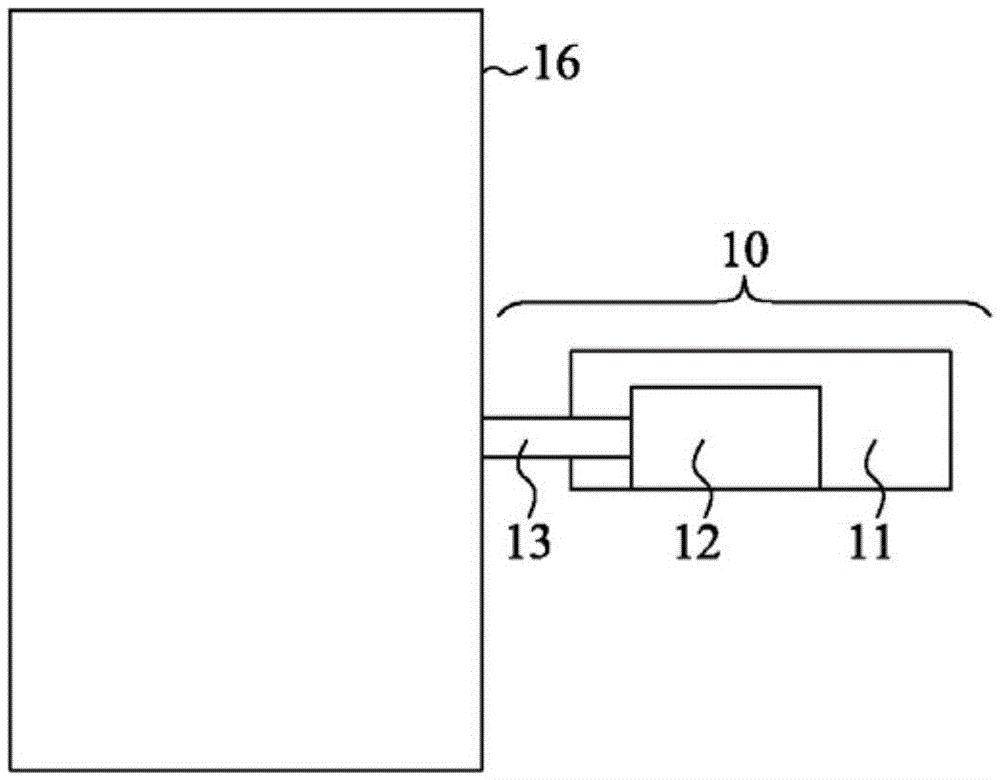

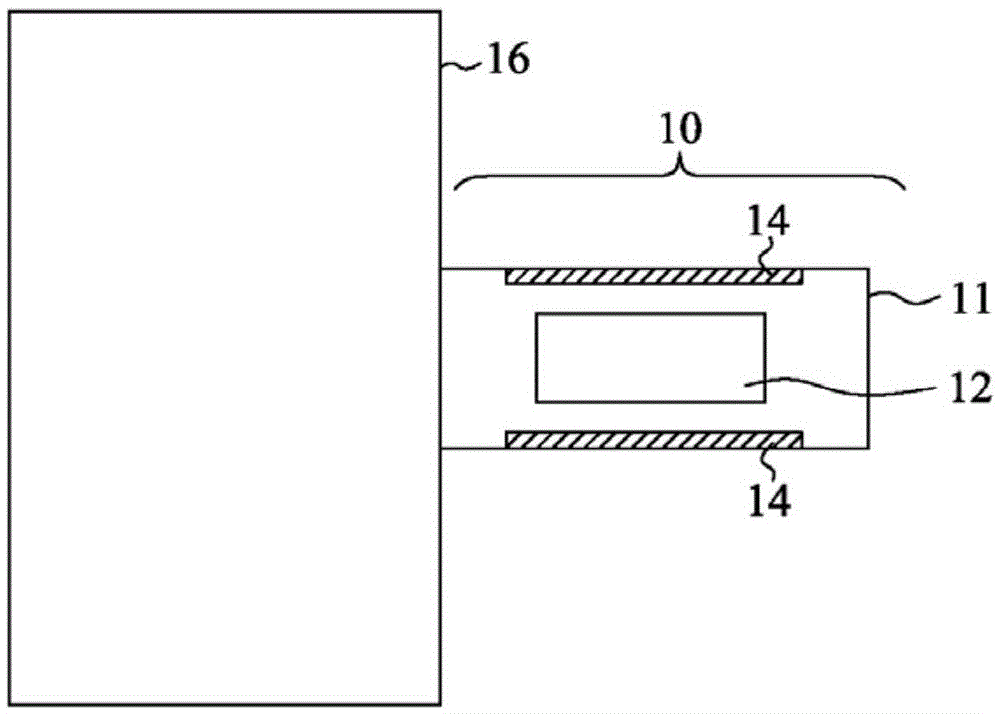

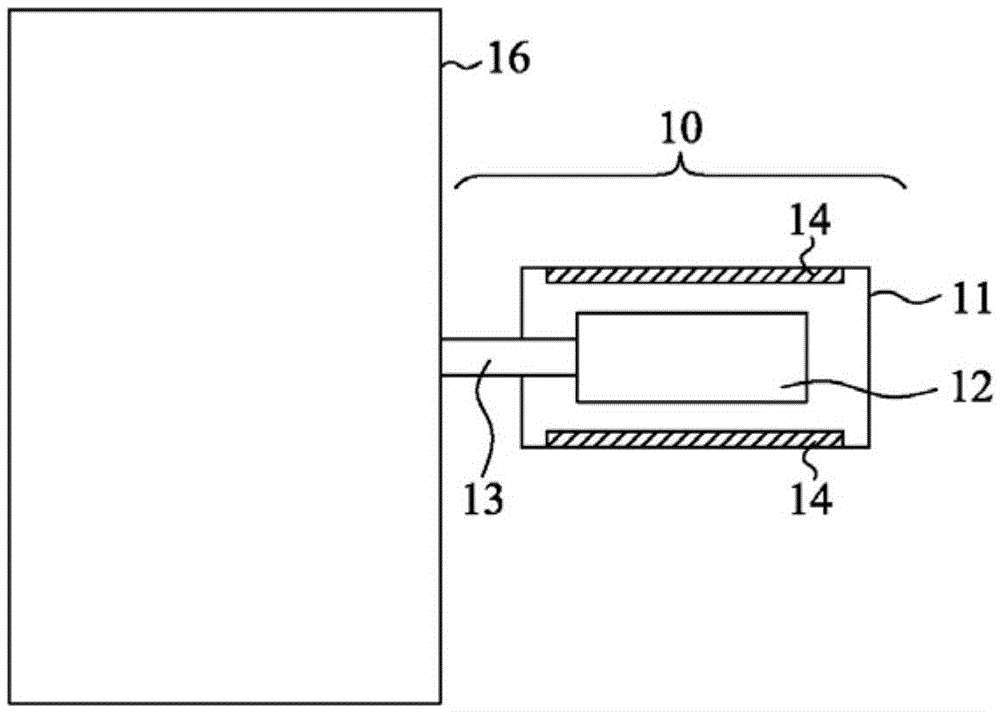

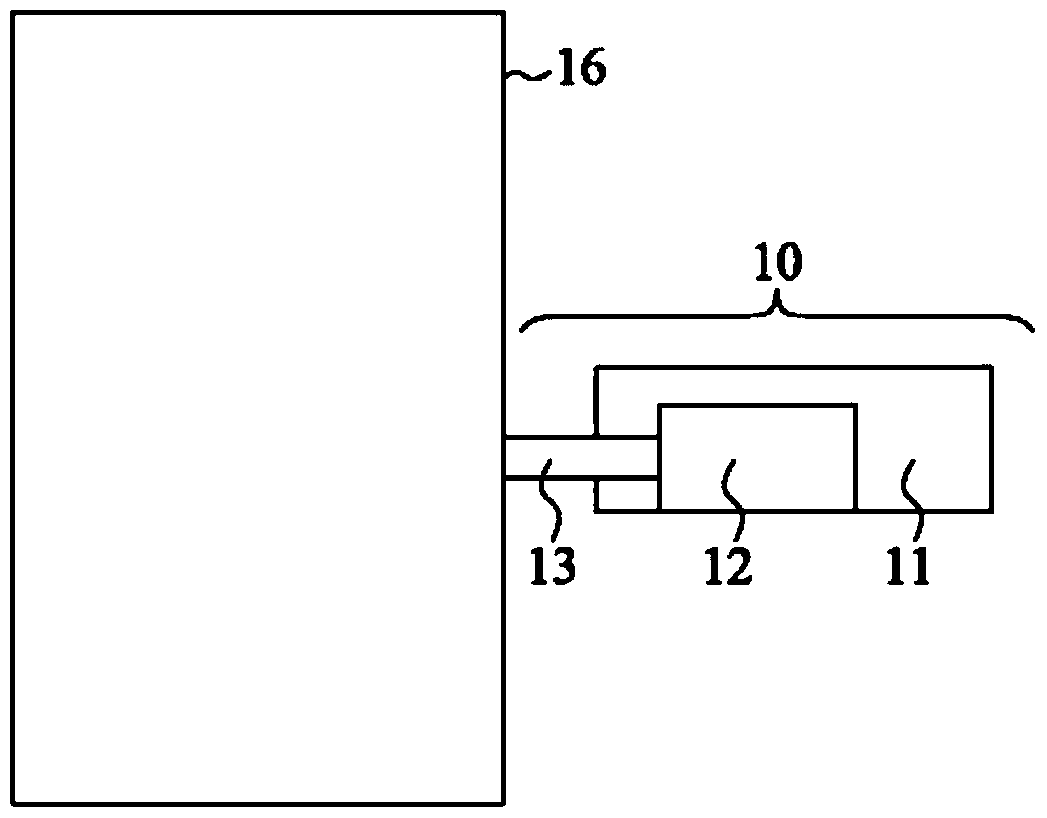

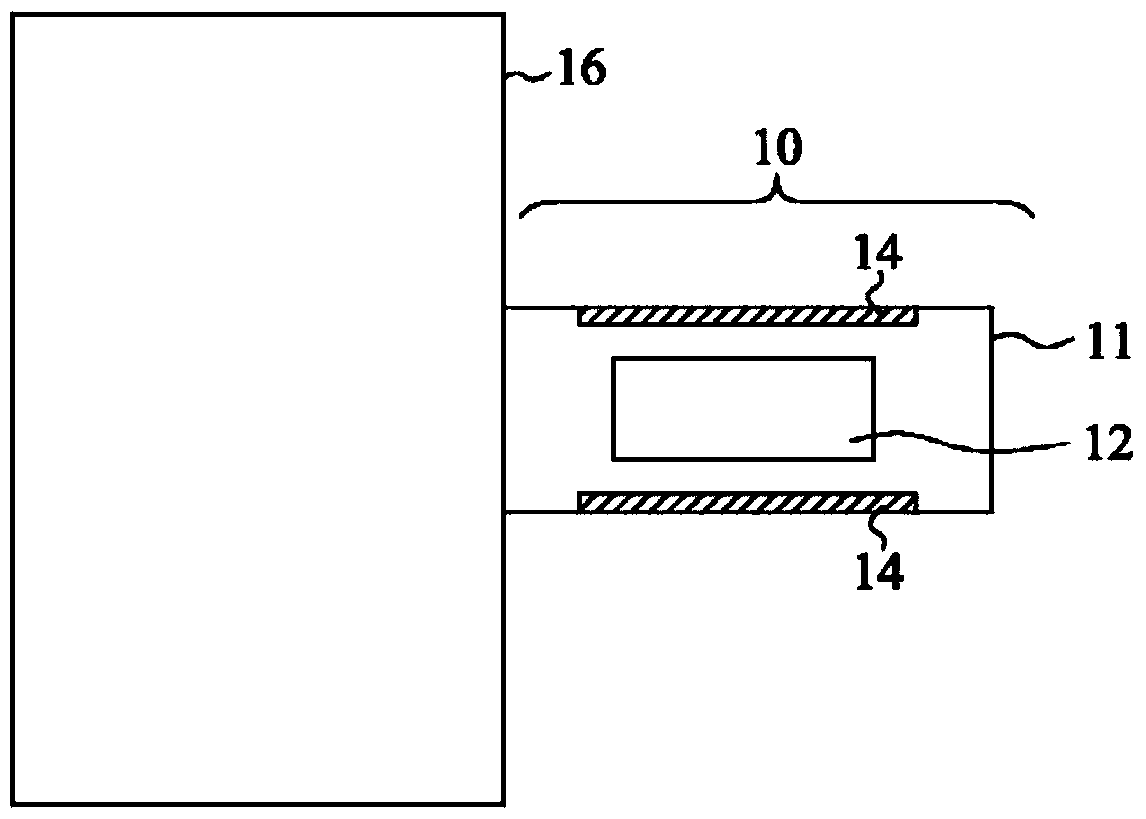

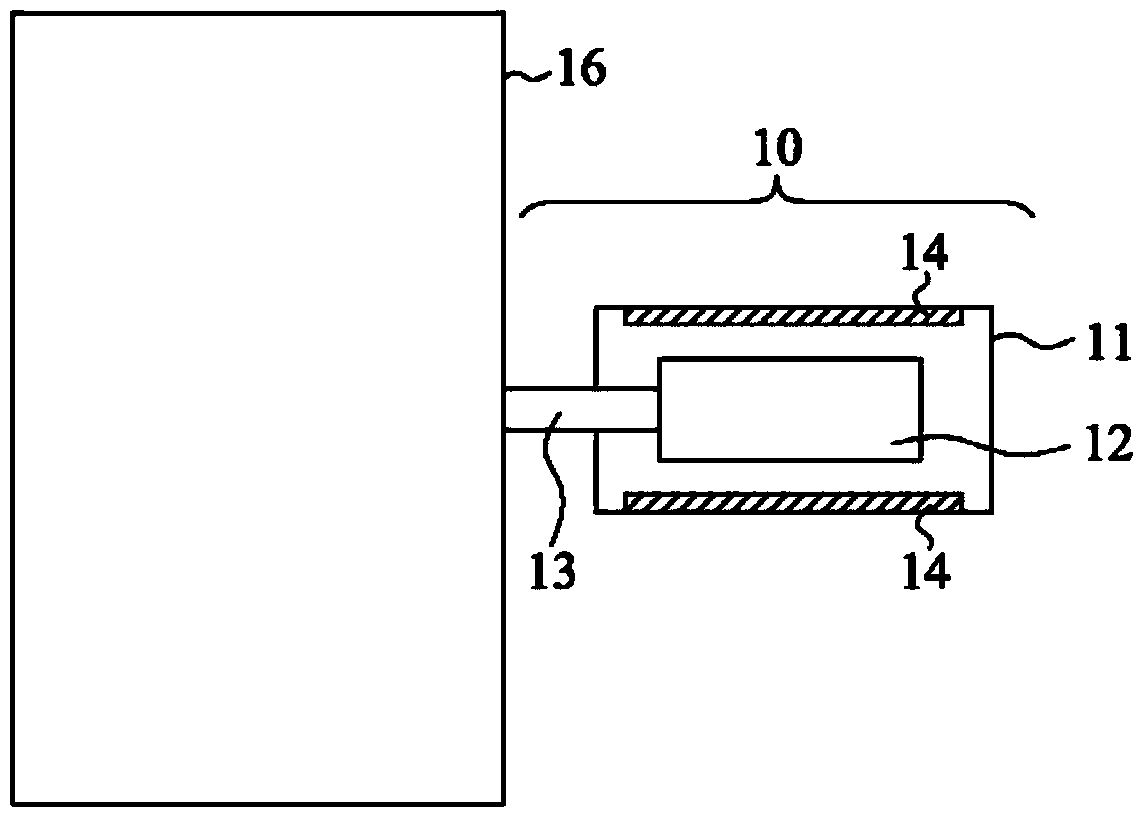

Uniform heating device applied to liquid crystal display and liquid crystal display

InactiveCN102879936AAchieve normal workEliminate display defectsOhmic-resistance heatingNon-linear opticsLiquid-crystal displayIndium tin oxide

The invention discloses a uniform heating device applied to a liquid crystal display and the liquid crystal display. The uniform heating device comprises a first heating unit and a second heating unit. The first heating unit is fixed in a display area of a liquid crystal screen of the liquid crystal display. The second heating unit is fixed on the back surface of the liquid crystal screen. The heating surfaces of the first and second heating units face the liquid crystal screen. The first heating unit is a flexible resistive film which is shaped along the outer edge of the display area of the display screen. The second heating unit adopts indium tin oxide (ITO) transparent conductive glass for heating. The uniform heating device and the liquid crystal display have the advantages that a rational heating design is adopted, so that the shortcomings of display of the liquid crystal screen at low temperature can be overcome, the 6-minute overall performance display of the liquid crystal screen at -45 DEG C can be realized, and the requirements of the liquid crystal display in most environments can be met.

Owner:中航华东光电有限公司

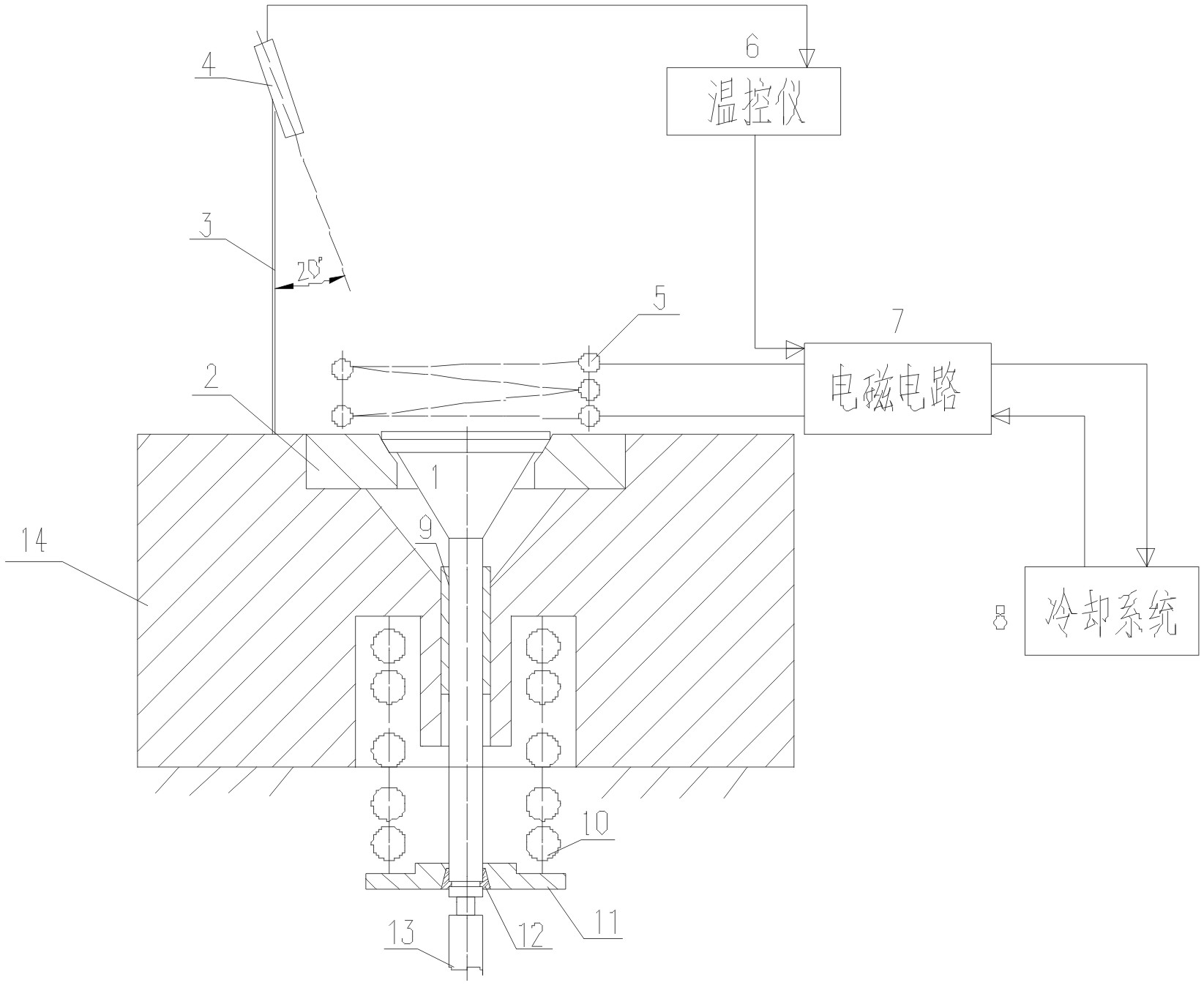

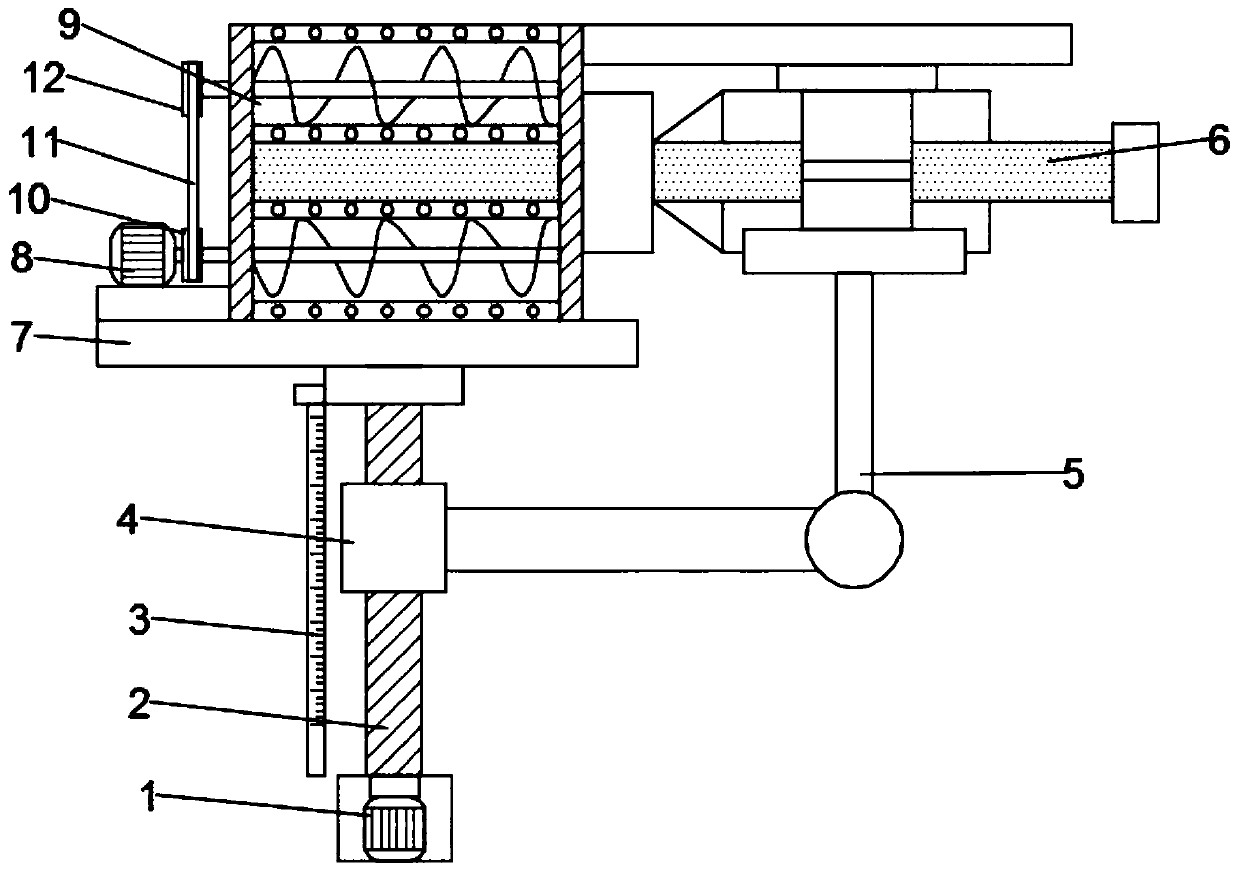

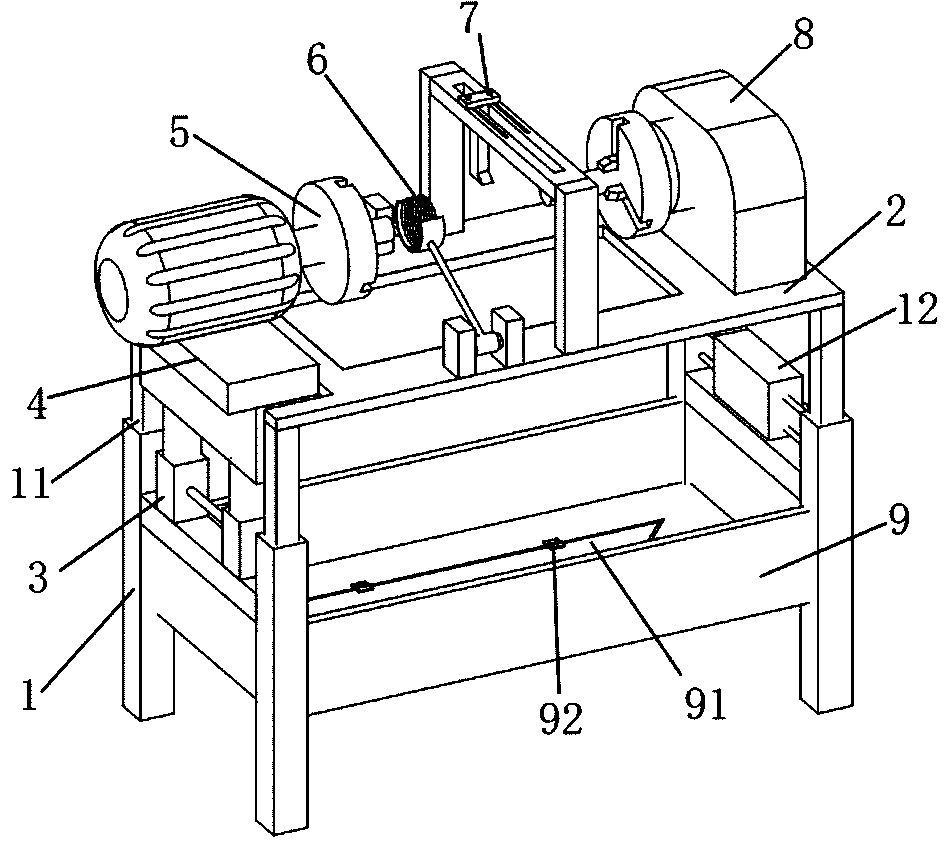

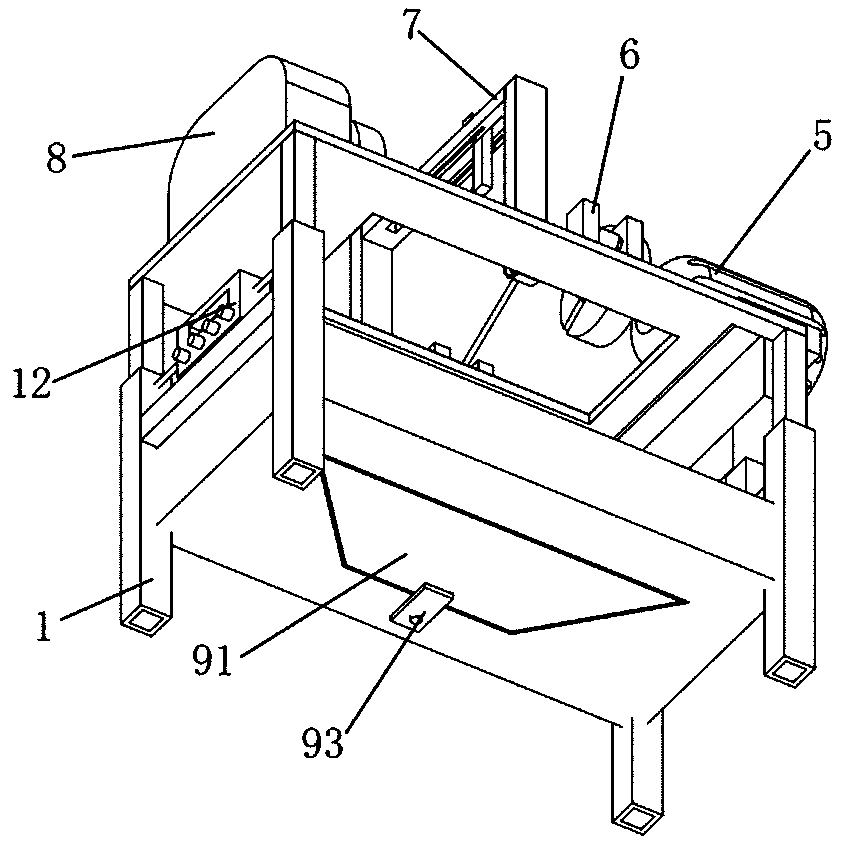

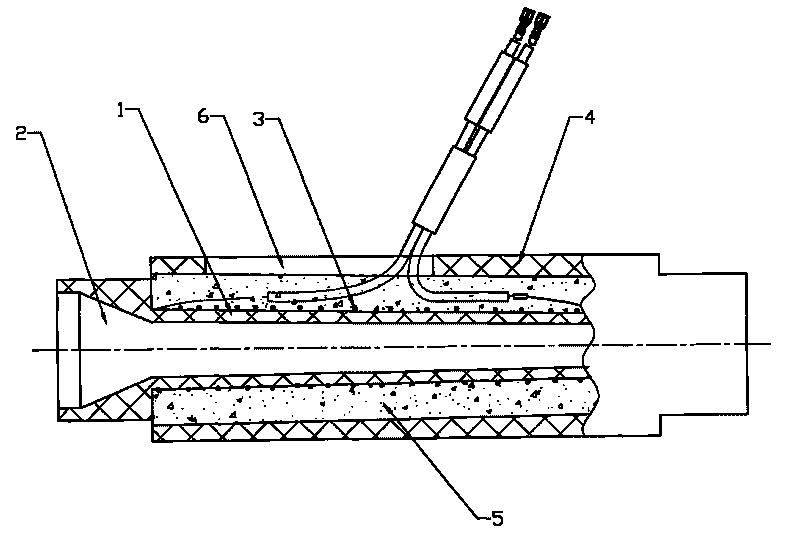

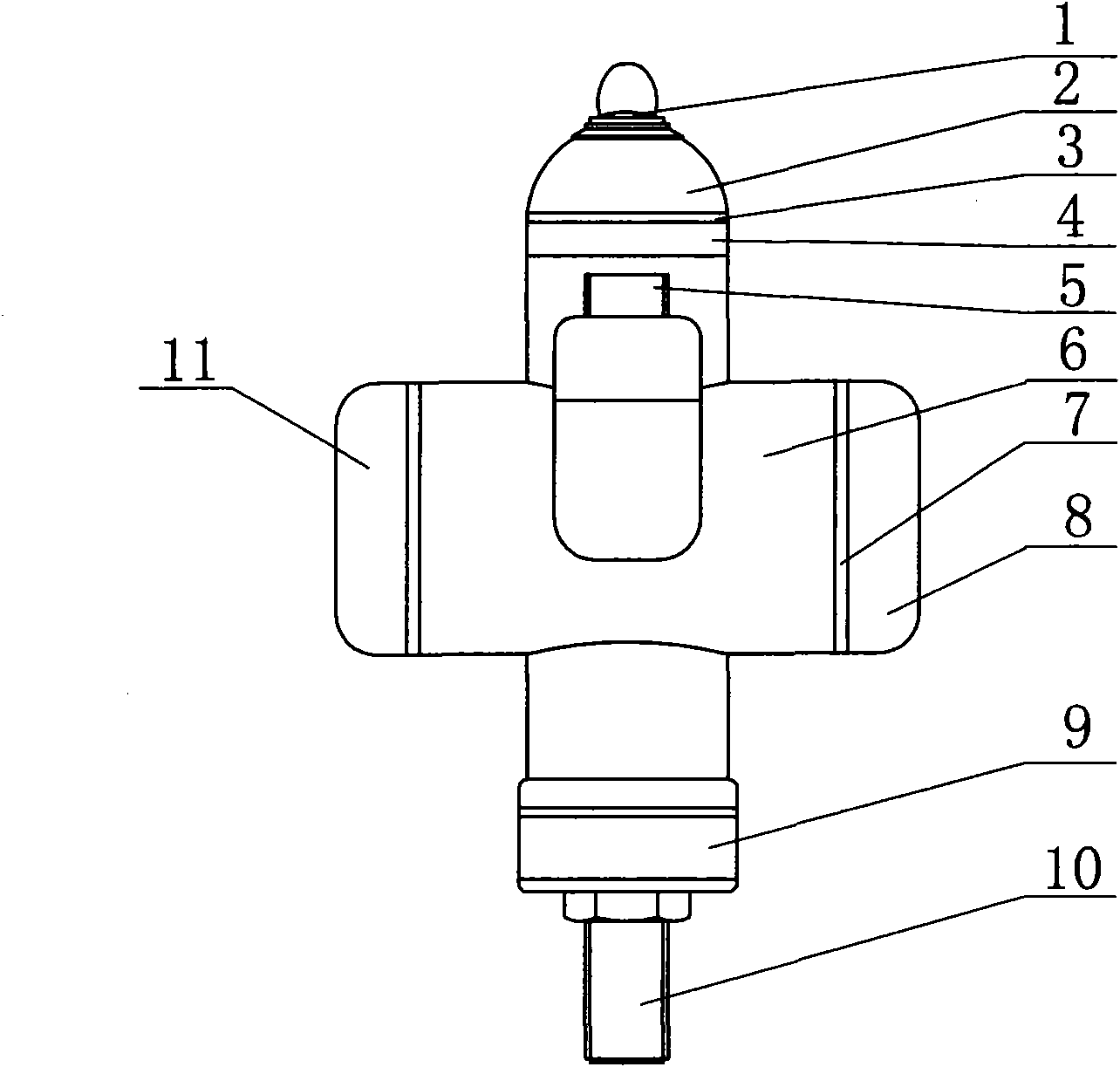

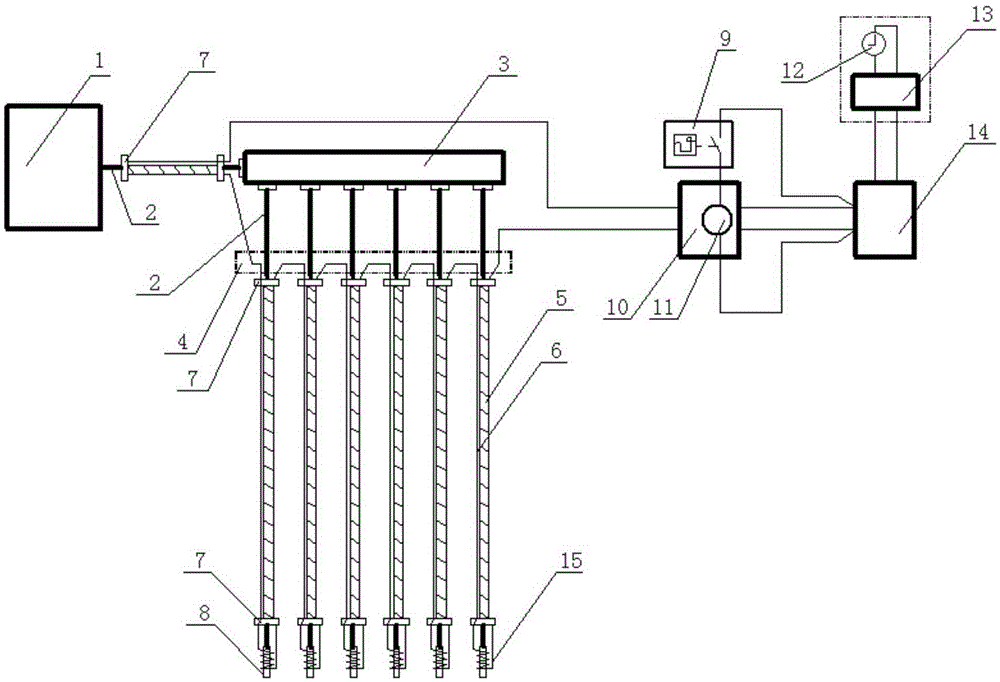

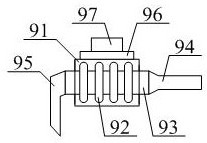

Electromagnetic induction temperature field simulating device for abrasion test table of engine valve and housing

InactiveCN102410964ATargetedReduce heat loadInvestigating abrasion/wear resistanceEm inductionEngineering

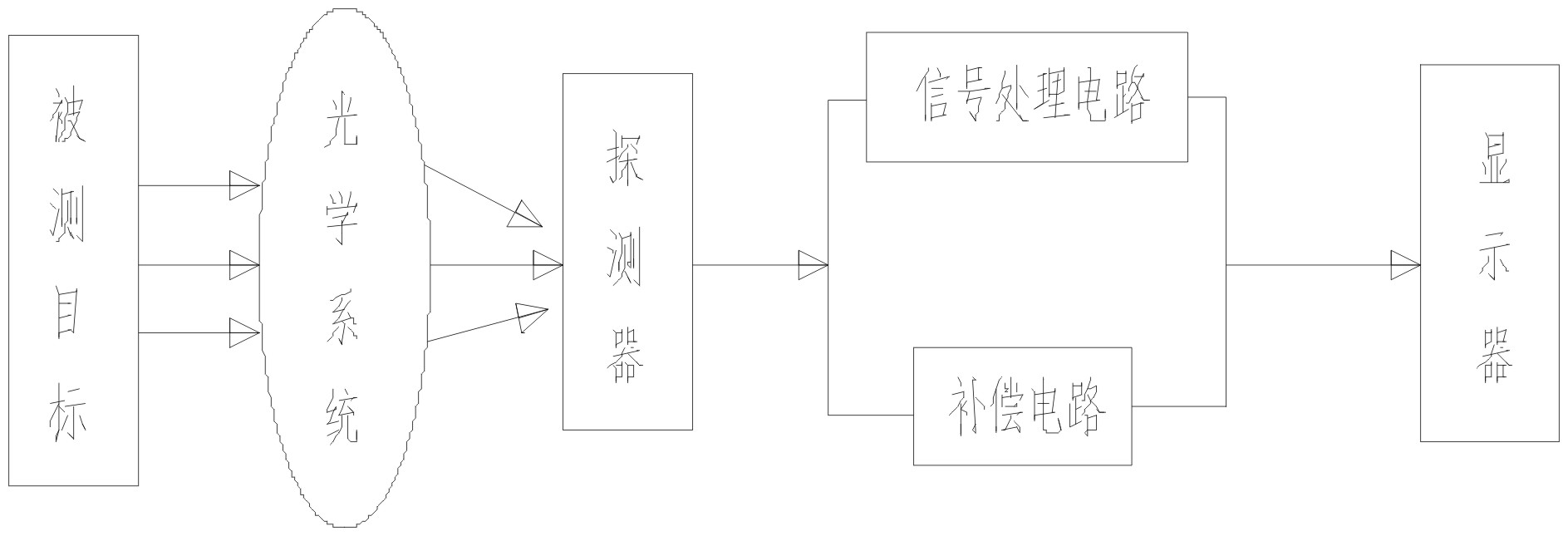

The invention relates to an electromagnetic induction temperature field simulating device for abrasion test table of engine valve and housing. A valve (1) is arranged on a test table frame (9); the washer (2) is arranged out of the valve (1); a copper tube sensor (5) and the washer (2) are coaxially arranged and the bottom surface of the copper tube sensor is 5 mm higher than the washer (2); the copper tube sensor (5) is connected with an electromagnetic circuit device (7); an infrared sensor (4) is arranged on the test table frame (9) by a bracket (3); the infrared sensor (4) is connected with a temperature controller (6); the temperature controller (6) is connected with the electromagnetic circuit device (7); and the electromagnetic circuit device (7) is connected with a cooling device (8). The electromagnetic induction temperature field simulating device provided by the invention has features of small volume, long service life, good appearance, capability of realizing non-contact temperature measuring control, good heating stability, uniform heating, high heating pertinence, lower thermal load and capability of reducing pollution on laboratories.

Owner:CHINA NORTH IND GRP NO 70 RES INST

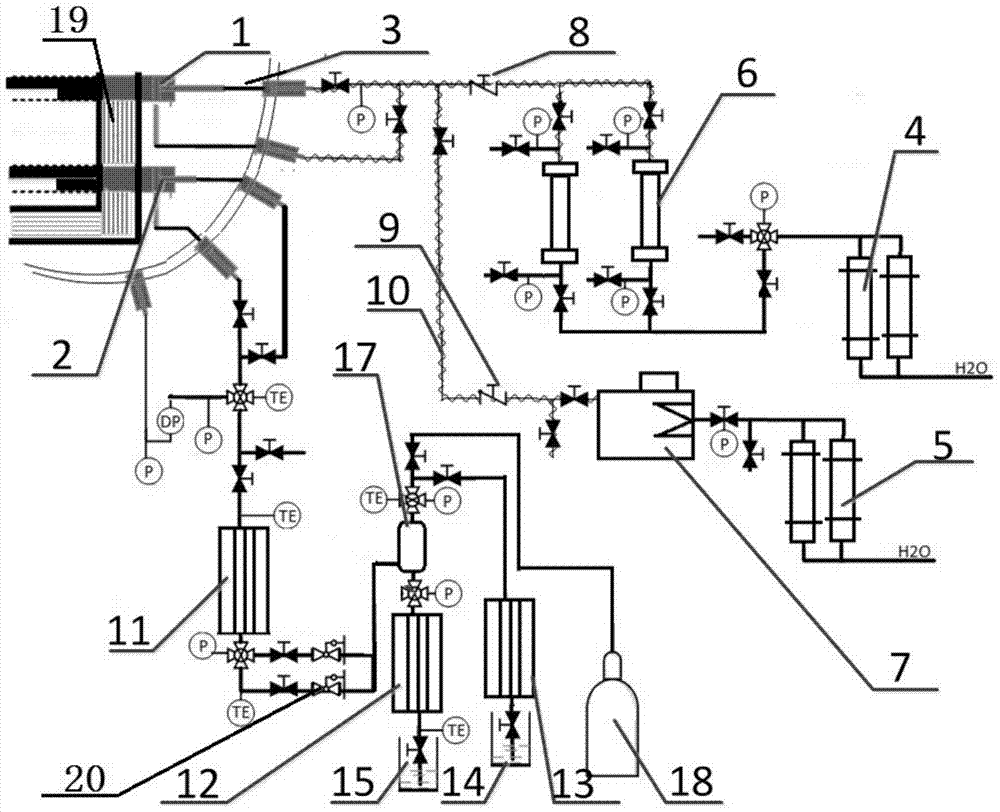

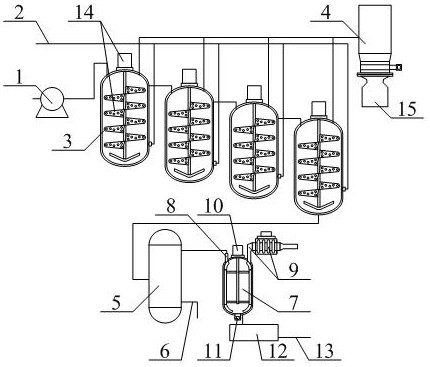

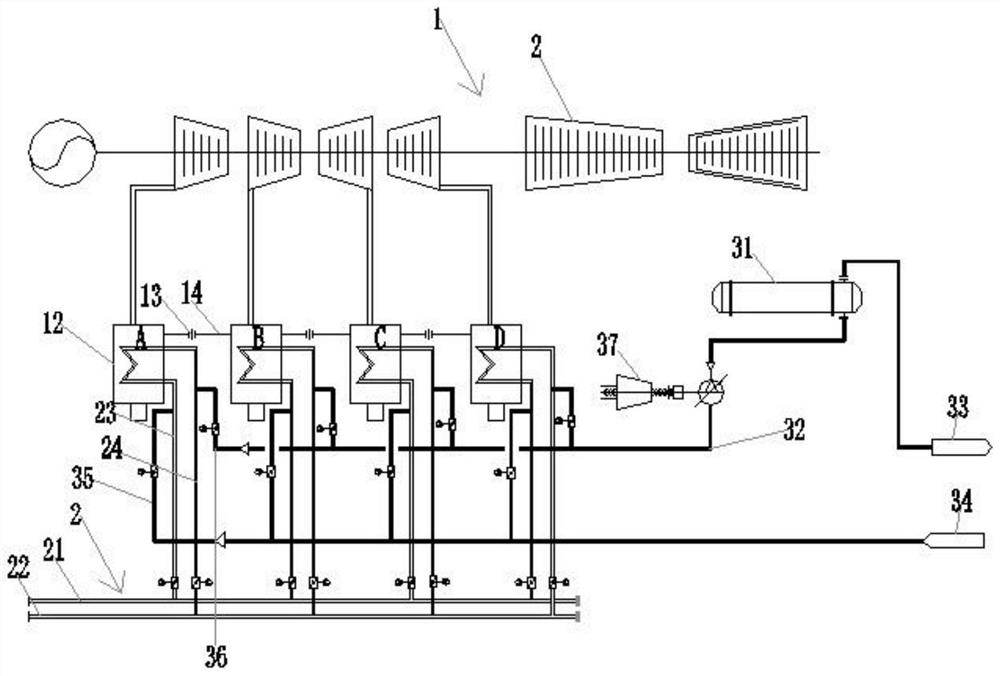

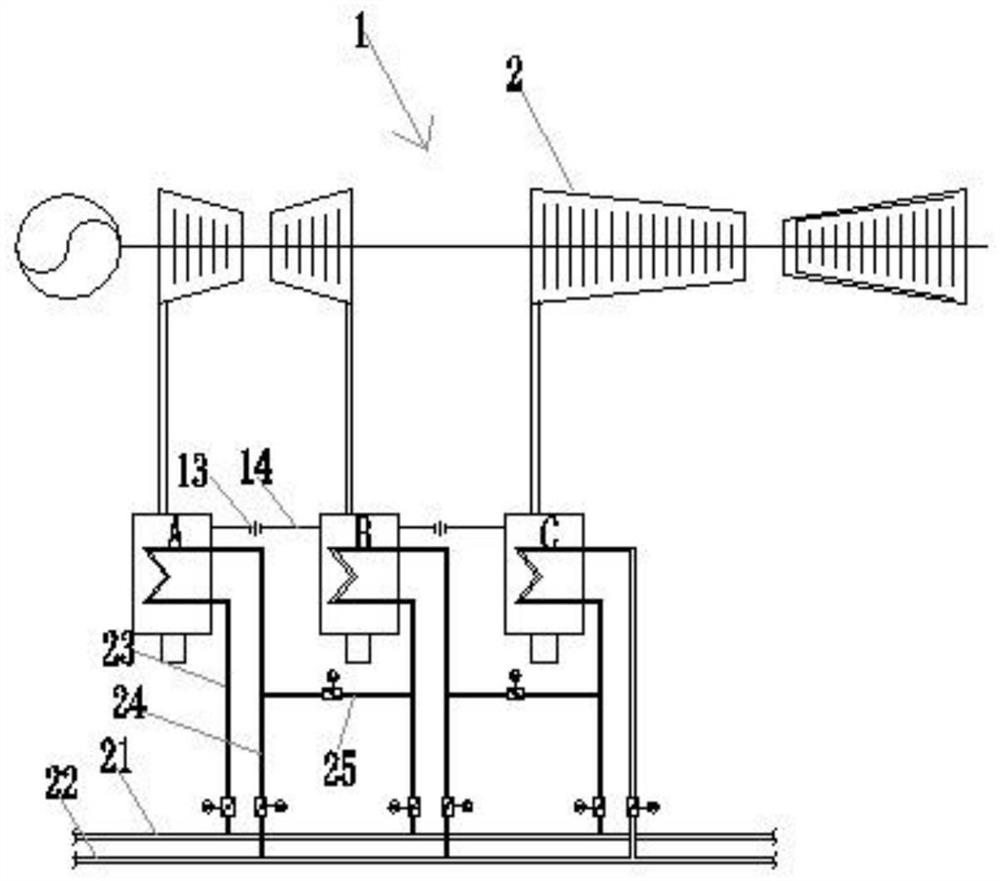

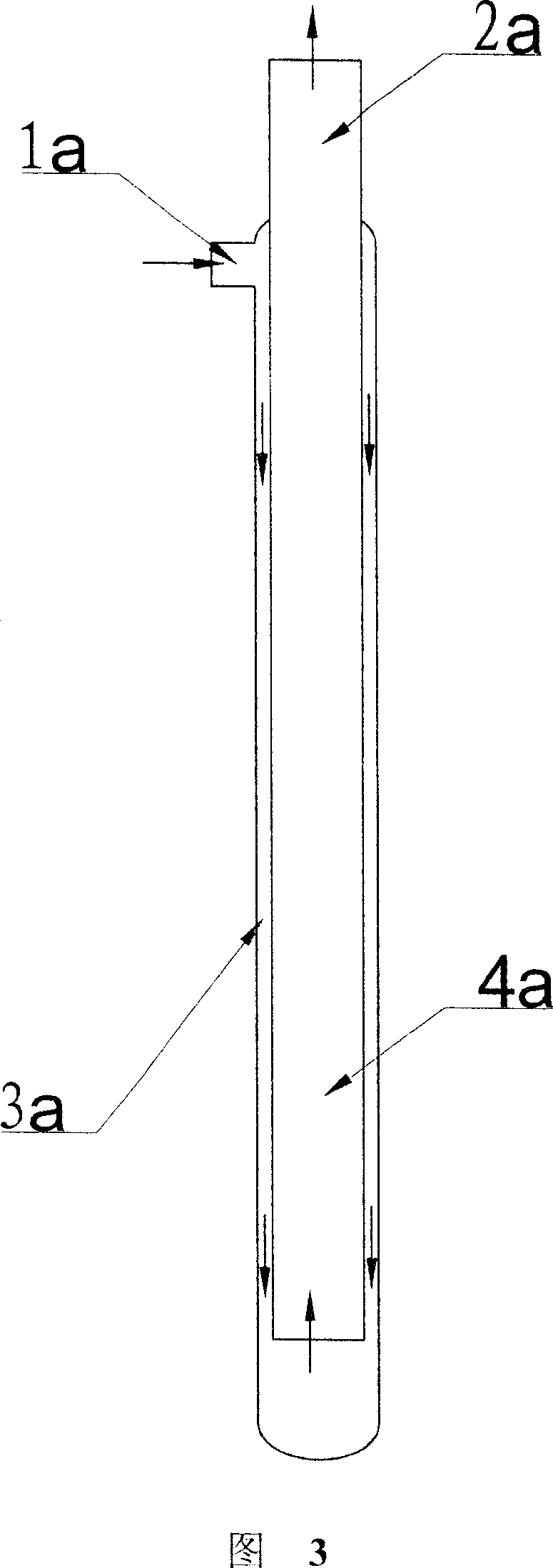

Solvent-assisted SAGD three-dimensional physical simulation experiment method and device

ActiveCN104948153ASteady injectionStable pressureFluid removalVapor–liquid separatorProcess engineering

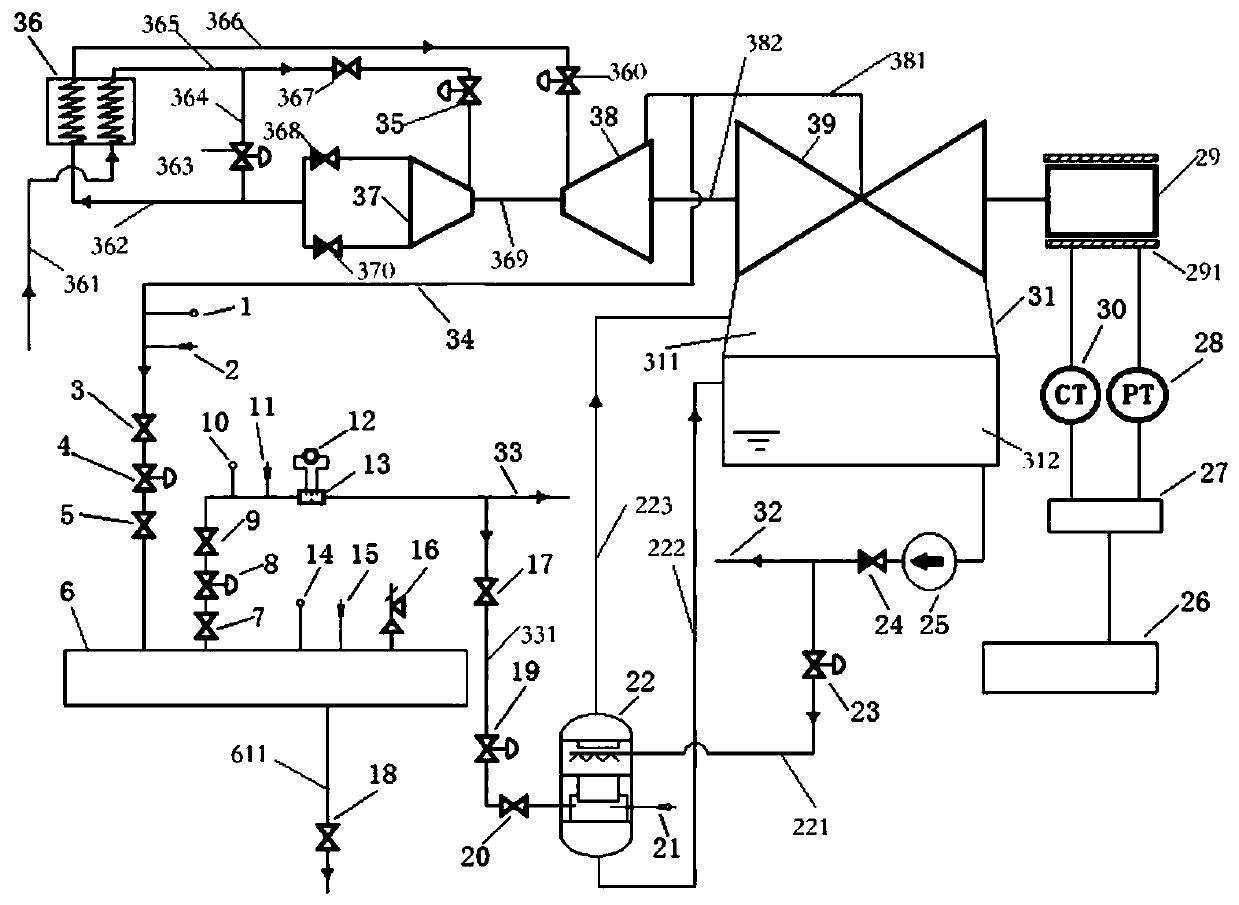

The invention provides a solvent-assisted SAGD three-dimensional physical simulation experiment method and device. The device comprises an injection device, a simulated oil reservoir model and a recycling device, a first pump unit in the injection device is communicated with a piston container unit, a second pump unit is communicated with a steam generator, the piston container unit and the steam generator are communicated with a gas injection well of the simulated oil reservoir model respectively, one end of a first condenser of the recycling device is communicated with a production well of the simulated oil reservoir model while the other end of the same is communicated with a feeding port of a gas-liquid separator, a second condenser is communicated with a liquid outlet of the gas-liquid separator, a third condenser is communicated with a gas outlet of the gas-liquid separator, a raw oil and water collection container is connected with the second condenser, and a solvent recycling container is connected with the third condenser. By the method and the device, mining conditions of solvent-assisted SAGD technology can be simulated, and mechanism of solvent in the process of SAGD can be studied so as to optimize and improve existing solvent-assisted SAGD technology according to oil reservoir conditions.

Owner:PETROCHINA CO LTD

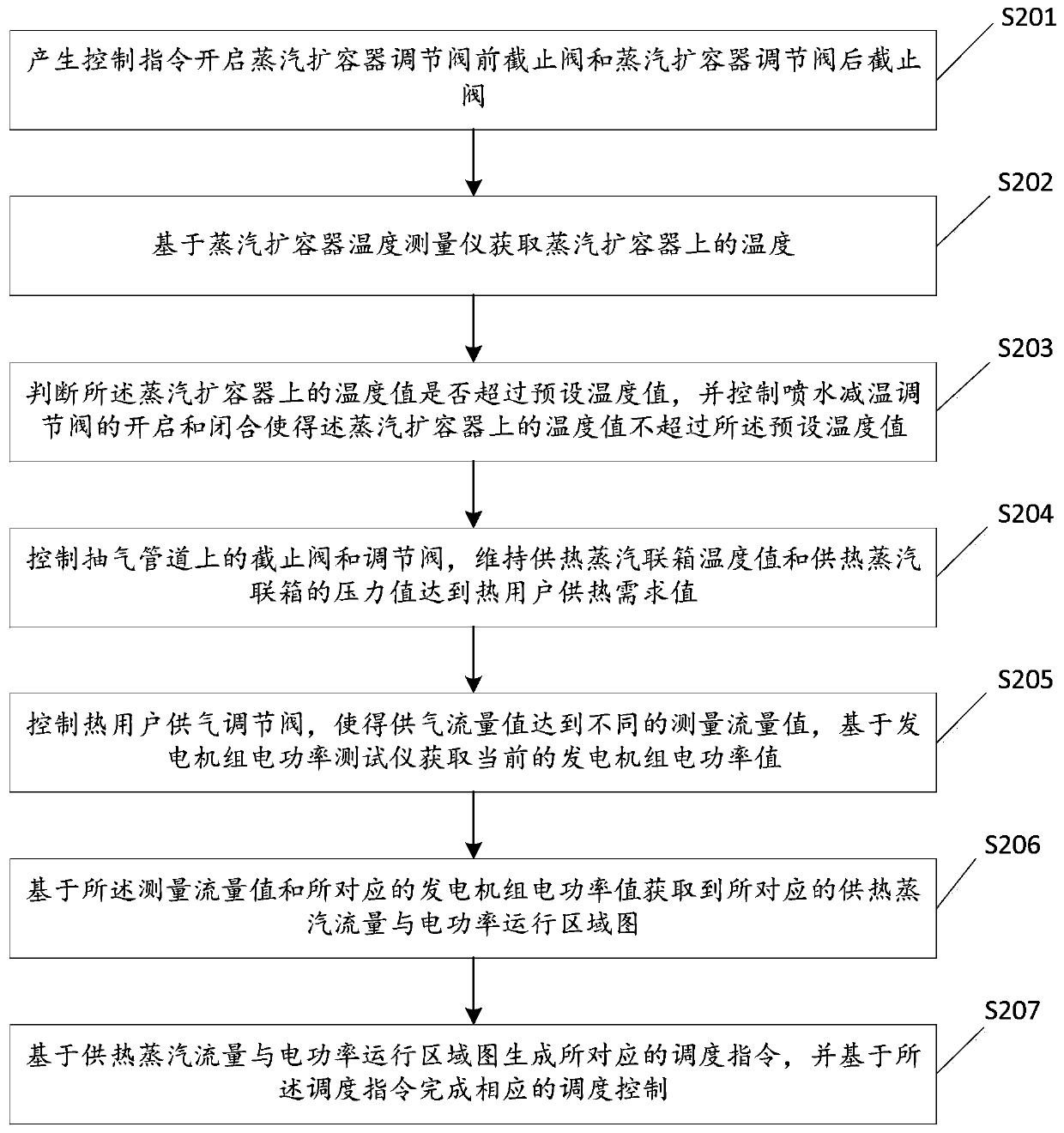

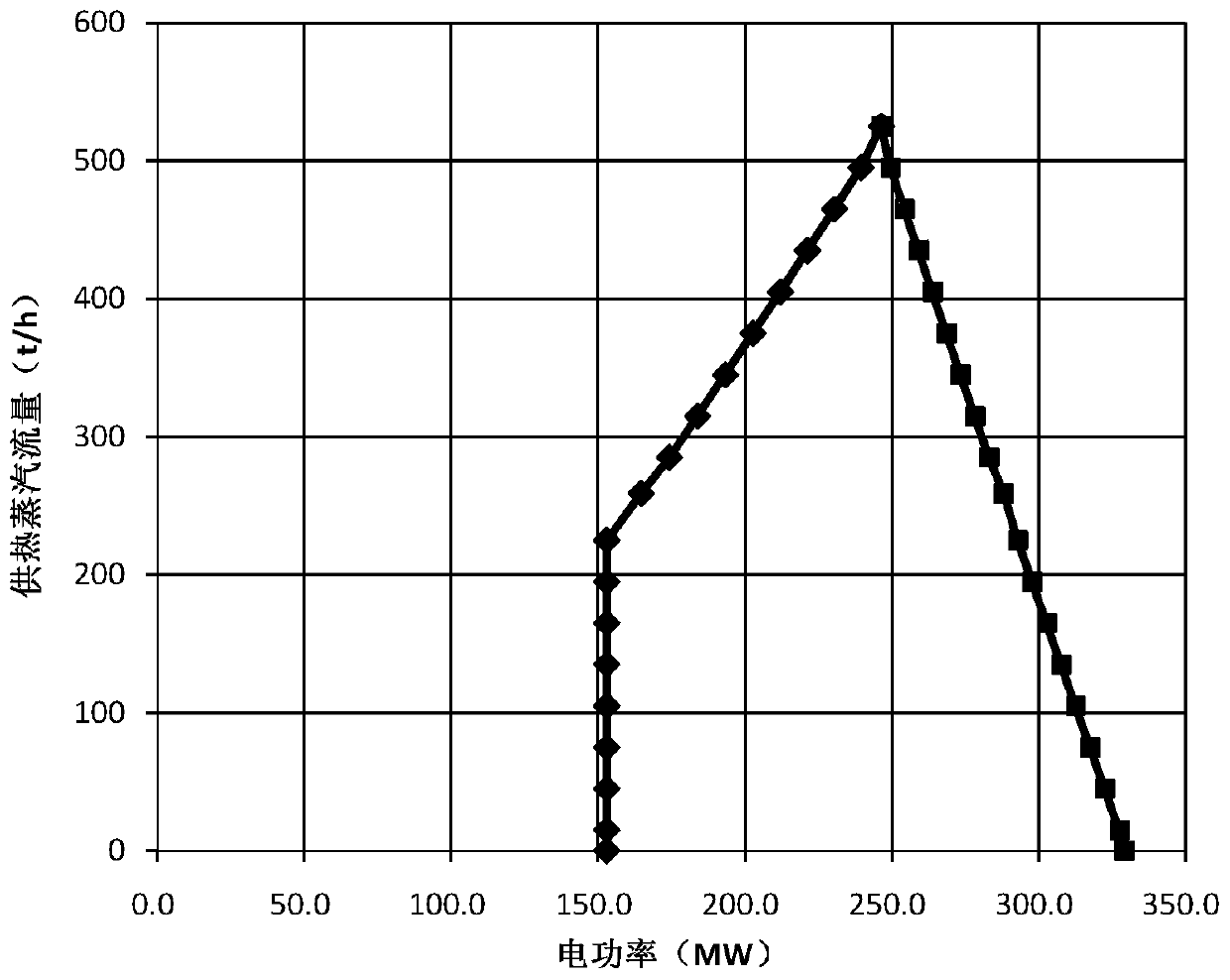

Testing method and system of combined heat and power generation unit running area

ActiveCN111561360AMeet normal productionNormal production does not affectBoiler indication operationsBoiler cleaning apparatusTemperature controlTester device

The invention discloses a testing method and system of a combined heat and power generation unit running area. The method includes the following steps that a control command is generated to open a steam expanding vessel adjusting valve front stop valve and a steam expanding vessel adjusting valve back stop valve; the temperature of a steam expanding vessel is acquired on the basis of a steam expanding vessel temperature measurement instrument; a stop valve and an adjusting valve on an exhaust pipeline are controlled, the temperature value and the pressure value of a heating steam header are maintained to reach the heat user heating requirement values; a heat user gas supply adjusting valve is controlled, so that the gas supply flow value reaches different measured flow values, and the current power generation unit electric power value is acquired on the basis of a power generation unit electric power testing instrument; and the corresponding heating steam flow and electric power running area chart is acquired on the basis of the measured flow value and the corresponding power generation unit electric power value. According to the method and the system, the unit heating requirementis guaranteed, meanwhile, the unit electric power peak adjustment capacity is fully exerted, and the heating and electric power real-time adjustment flexibility of the transformed power generation unit is enhanced.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD

Pediatric clinical breathing device with flow rate regulation function

The invention discloses a pediatric clinical breathing device with a flow rate regulation function, and belongs to the technical field of pediatric nursing equipment. The problem that when an existingbreathing device provides oxygen to a patient, oxygen flow control is inconvenient, and consequently normal breathing of children is affected is solved. The pediatric clinical breathing device is technically characterized in that the pediatric clinical breathing device comprises a flow regulation mechanism, and further comprises a second working motor, a heating box and spiral mixing propellers;and the heating box is fixedly welded to the upper surface of a partition plate, the second working motor is arranged at the bottom of the left side of the heating box, two heat conducing cavities areformed in the heating box in the mode of being symmetrical with respect to an oxygen flow guiding pipe, rotating shafts are mounted in the middles of the heat conducting cavities, and the spiral mixing propellers are fixedly welded to the rotating shafts. According to the pediatric clinical breathing device, the oxygen flow can be flexibly controlled, the oxygen flow with different flow demands in pediatric nursing is met, rehabilitation of children is facilitated, meanwhile, the oxygen can also be evenly heated, and the situation of stimulation to the bodies of the children due to uneven oxygen heating is avoided.

Owner:泗水县人民医院

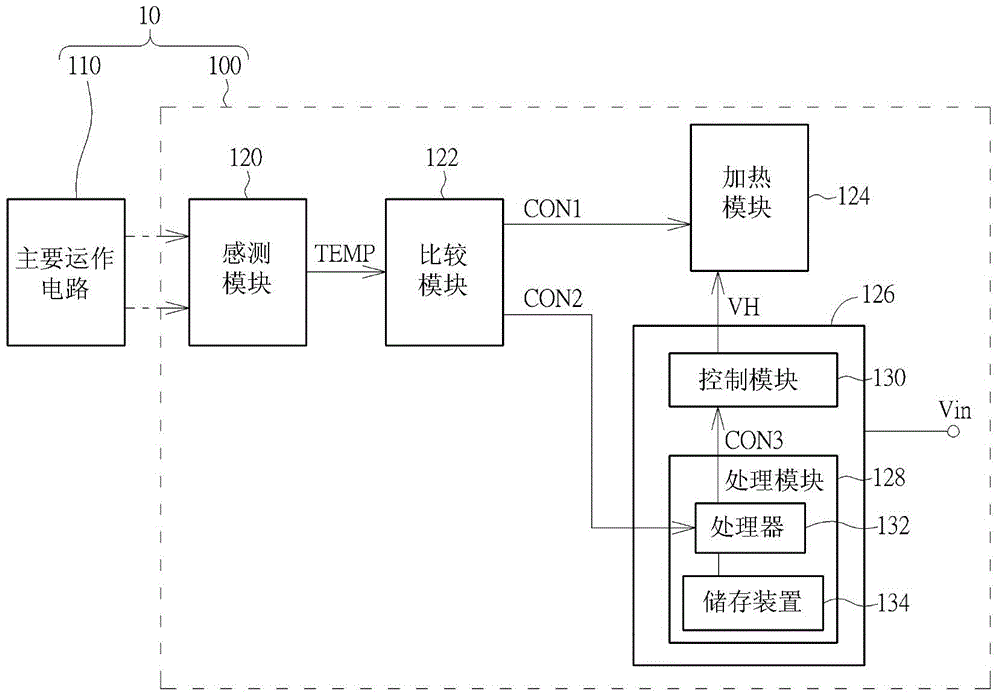

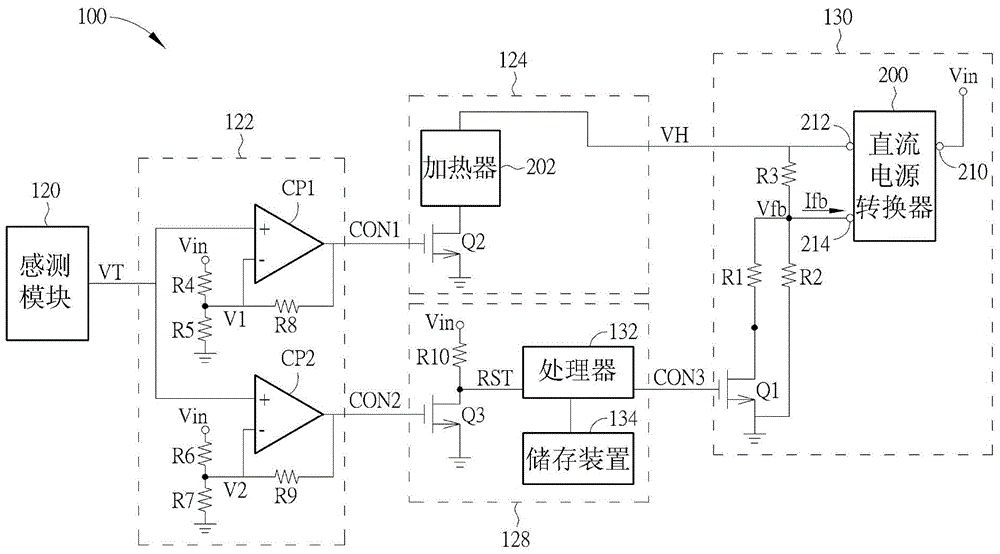

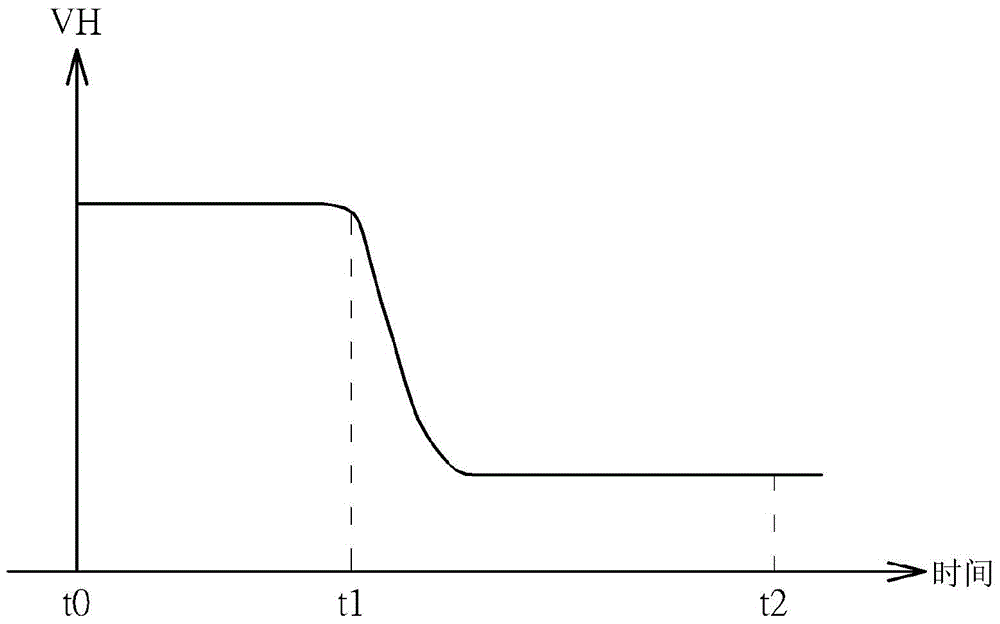

Heating system used for electronic device

ActiveCN104703302AFlexible heatingIncrease the ambient temperatureElectric heatingControl signalComputer module

The invention discloses a heating system used for an electronic device. The heating system is used for increasing environment temperature inside the electronic device and comprises a sensing module, a comparing module, an operating module and a heating module, the sensing module is used for sensing the environment temperature to generate an environment temperature value, the comparing module is coupled to the sensing module and used for generating a first control signal and a second control signal according to the environment temperature value, the operating module is coupled to the comparing module and used for converting power source voltage to output heating voltage and adjusting the output heating voltage according to the second control signal, and the heating module is coupled to the comparing module and the operating module and used for deciding whether the heating voltage is used for heating or not to increase the environment temperature. By the heating system, the electronic device can flexibly execute heating to increase the environment temperature inside the electronic device without exceeding required power consumption.

Owner:WISTRON NEWEB +1

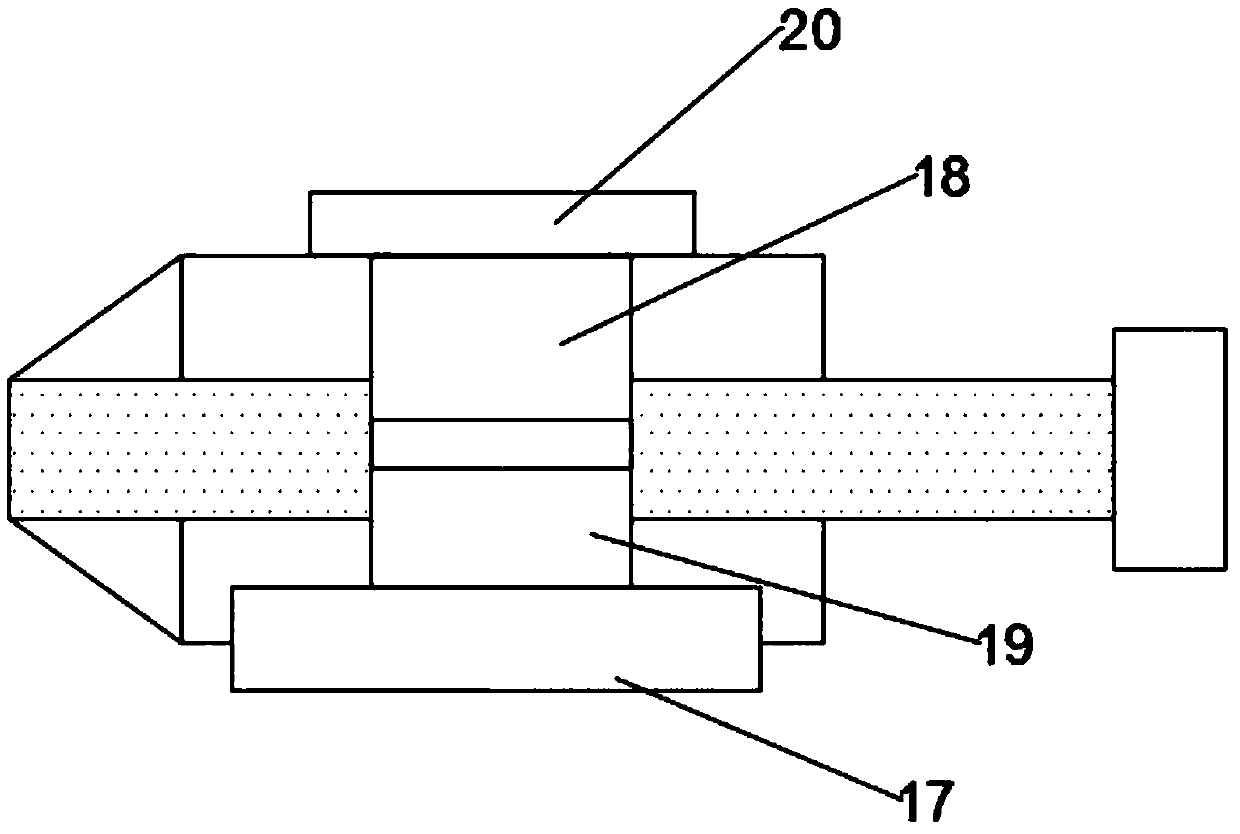

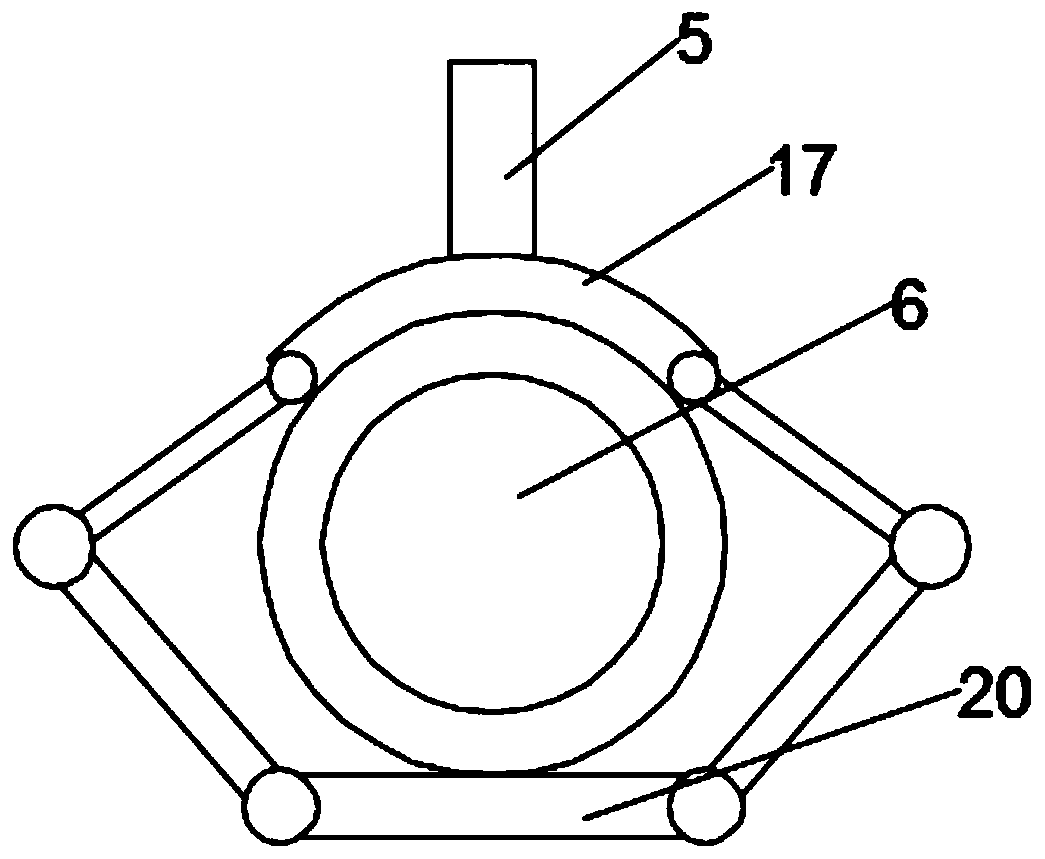

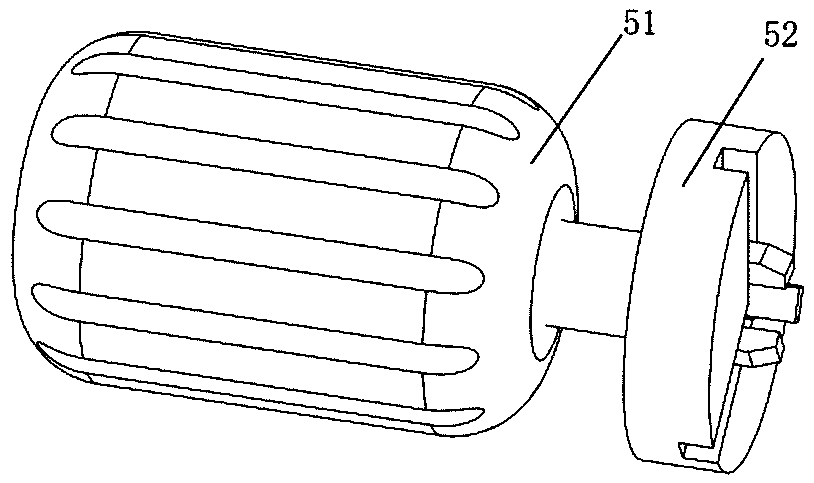

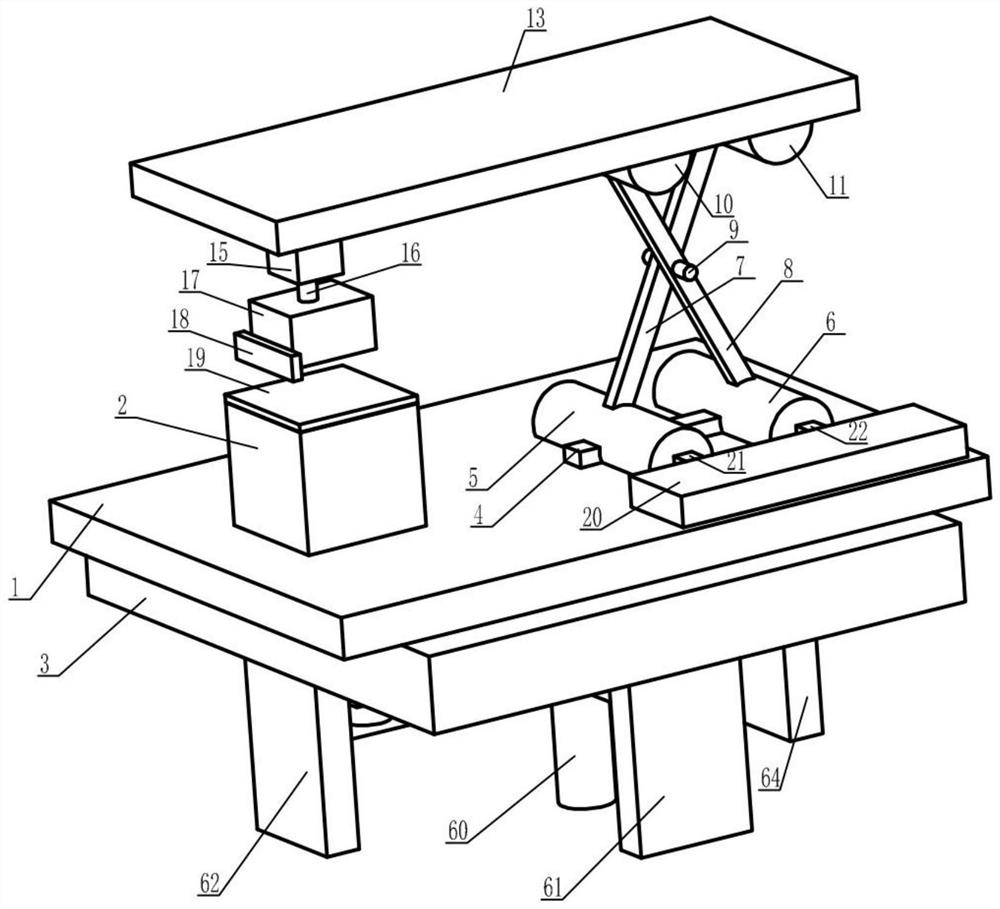

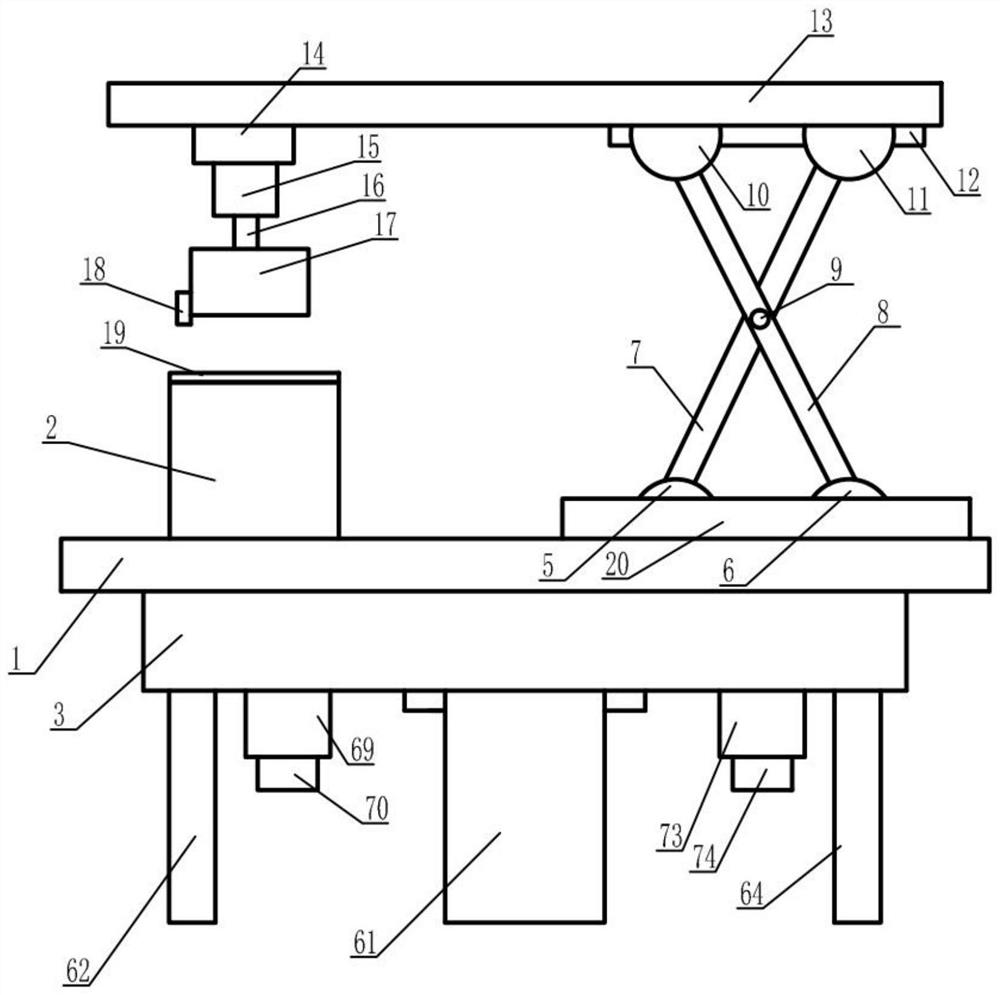

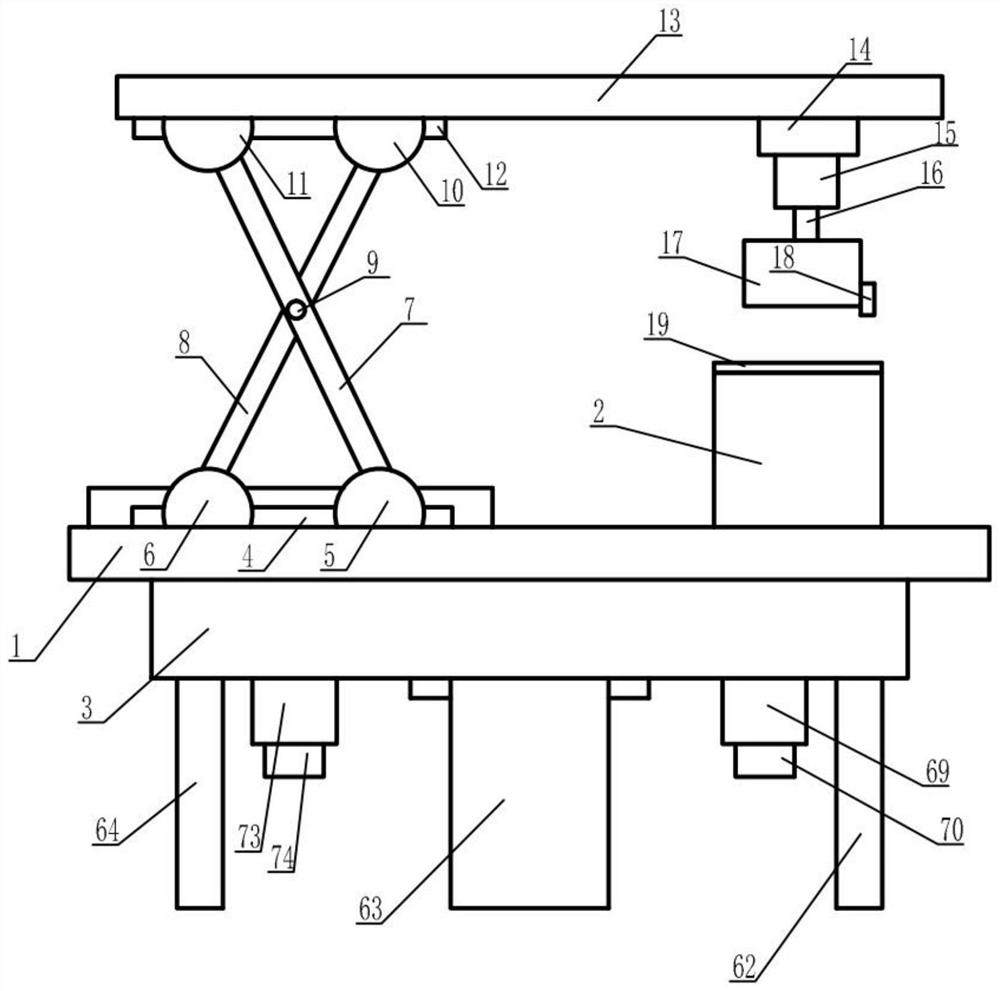

Friction welding device capable of removing outer flashings through forward pushing type turning and use method thereof

PendingCN110842569AHigh positioning accuracyAccelerateOther manufacturing equipments/toolsNon-electric welding apparatusPhysicsElectric machinery

The invention relates to the frication welding technology field, in particular to a friction welding device capable of removing outer flashings through forward pushing type turning and a use method thereof. The friction welding device comprises two H-shaped support frames and an object placing plate, wherein the object placing plate is fixed above the H-shaped support frames, a hydraulic lifting pillar is fixed on a cross beam on the H-shaped support frame on one side, a lifting board is fixed at the top of the hydraulic lifting pillar, a notch adaptive to the lifting board is formed in the object placing plate and used for enabling the lifting board to pass, a friction device is fixed on the lifting board, the friction device comprises a friction welding motor and a three-jaw workpiece fixer I, the three-jaw workpiece fixer I is fixed on a motor shaft of the friction welding motor, an induction heating device, a turning device and a pushing device are further sequentially fixed on theobject placing plate and in the direction of the motor shaft of the friction welding motor, the pushing device comprises a pushing hydraulic pump and a three-jaw workpiece fixer II installed on the pushing hydraulic pump, and the three-jaw workpiece fixer I and the three-jaw workpiece fixer II are oppositely arranged.

Owner:SHANXI SHENZHOU AEROSPACE SCI & TECH CO LTD

Medical electric heater

InactiveCN101742743ASave electricityLow costHeating element materialsHeatBiomedical engineeringEnergy consumption

The invention relates to a medical electric heater which is used for heating or sterilizing a medical appliance or a medical reagent. The medical electric heater comprises a hollow heating element made from a mullite ceramic material; one end of the heating element is provided with an inserted hole used for the medical appliance or the medical reagent to insert; a resistance wire is wound on the outer wall of the heating element; a shell is covered at the periphery of the heating element; and a temperature preservation and insulation material is filled between the shell and the heating element. The medical electric heater has the advantages of simple structure, convenient manufacture and installation, rapid temperature rise, capability of heating and sterilizing a single medical appliance and a single reagent rapidly, and low energy consumption.

Owner:ZHENJIANG DONGFANG ELECTRIC HEATING TECH

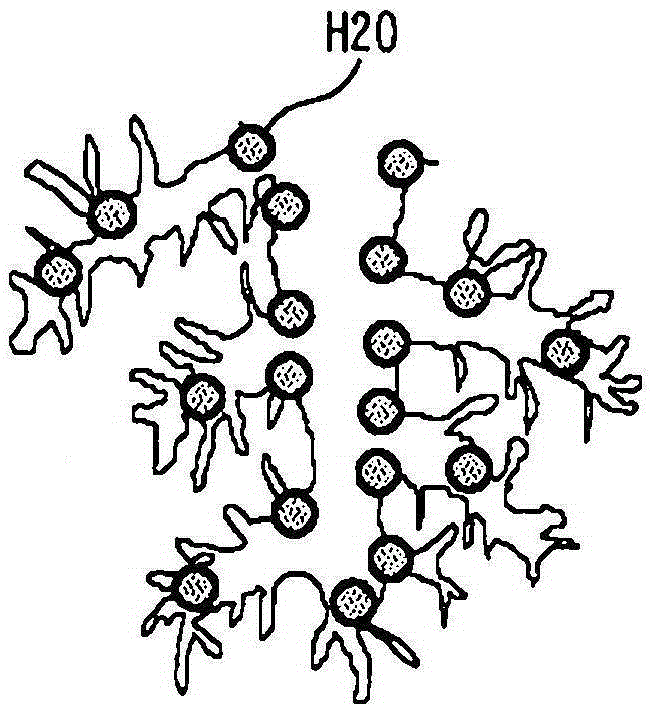

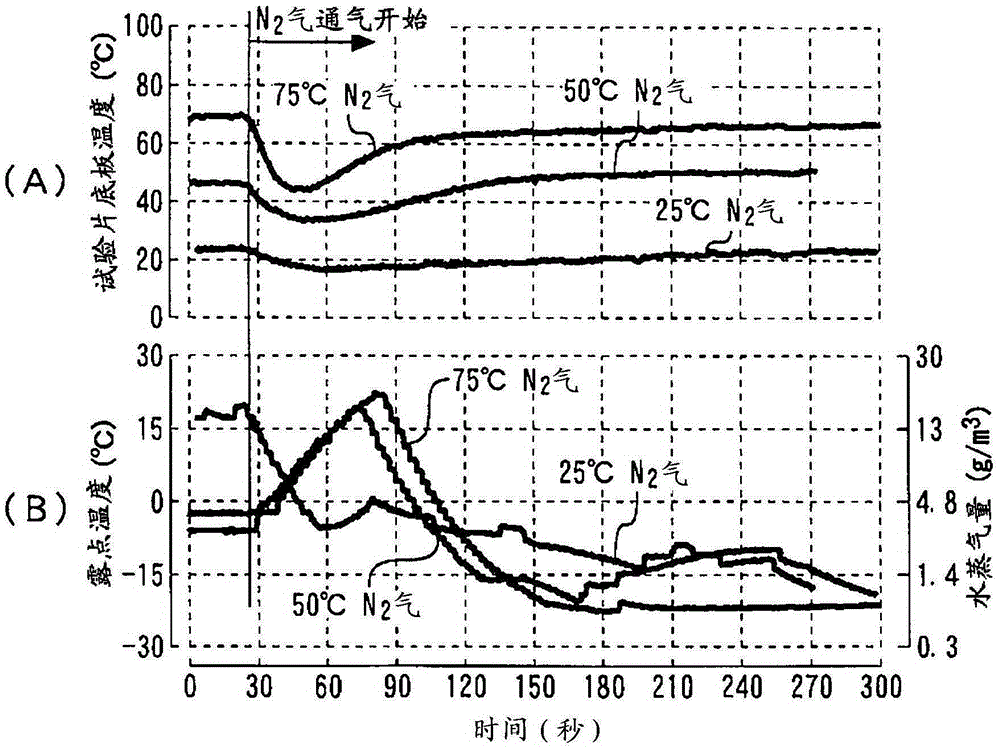

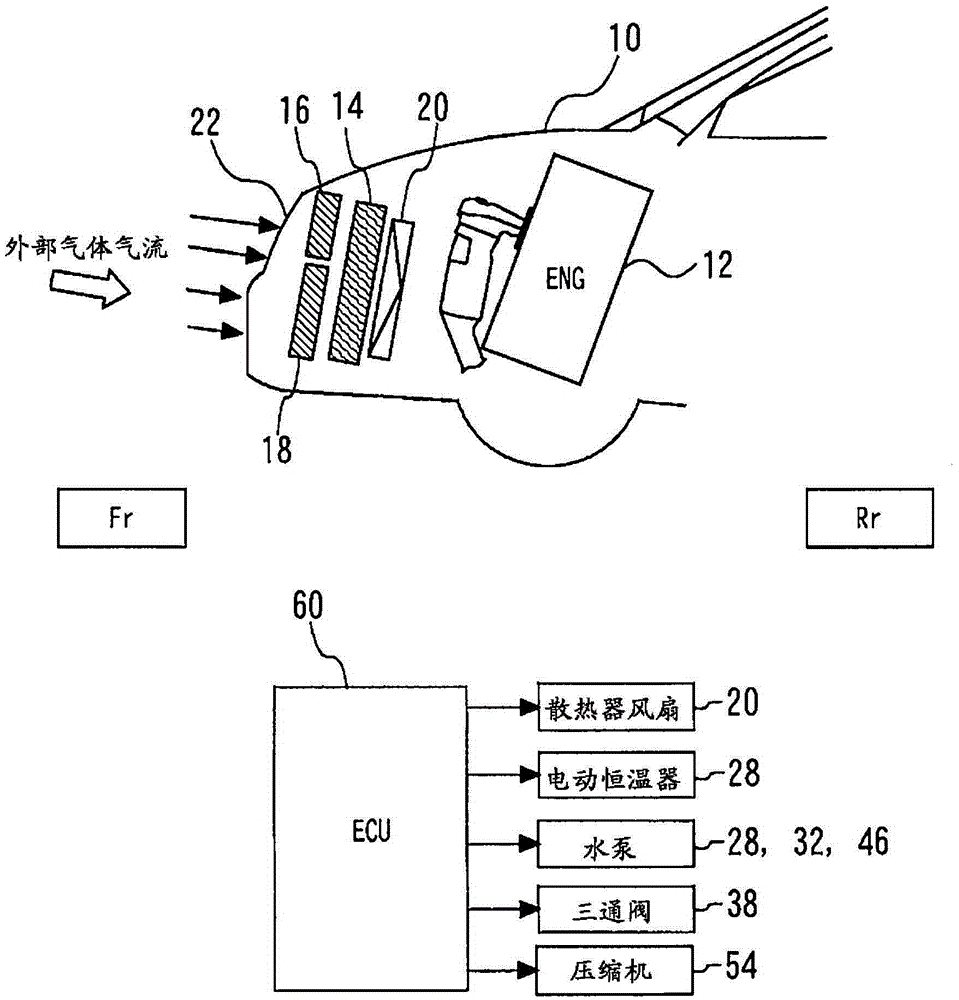

Vehicle atmosphere purifying apparatus

ActiveCN103906638AReduced ozone purification performanceOzone purification performance recoveryGas treatmentAir-treating devicesActivated carbonHeat spreader

The present invention relates to a vehicle atmosphere purifying apparatus aiming to provide a direct ozone reduction (DOR) system such that a decrease in ozone purifying performance due to water attachment can be suppressed and ozone purifying performance can be recovered. According to the present invention, a core portion of each of radiators (14, 16) and a capacitor (18) is coated with activated charcoal as an ozone purifier. As shown in FIG. 5, when water is attached to activated charcoal pores or their surrounding areas, it becomes difficult for ozone to enter mesopores or micropores. Even if ozone could enter, it becomes difficult for electron donation to occur from the activated charcoal to ozone. Thus, the ozone purifying performance of the activated charcoal is decreased as long as there is the attached water. Thus, when the amount of water attached to the activated charcoal is not less than a predetermined amount, a water elimination control is performed to eliminate water by compulsorily heating the activated charcoal.

Owner:TOYOTA JIDOSHA KK

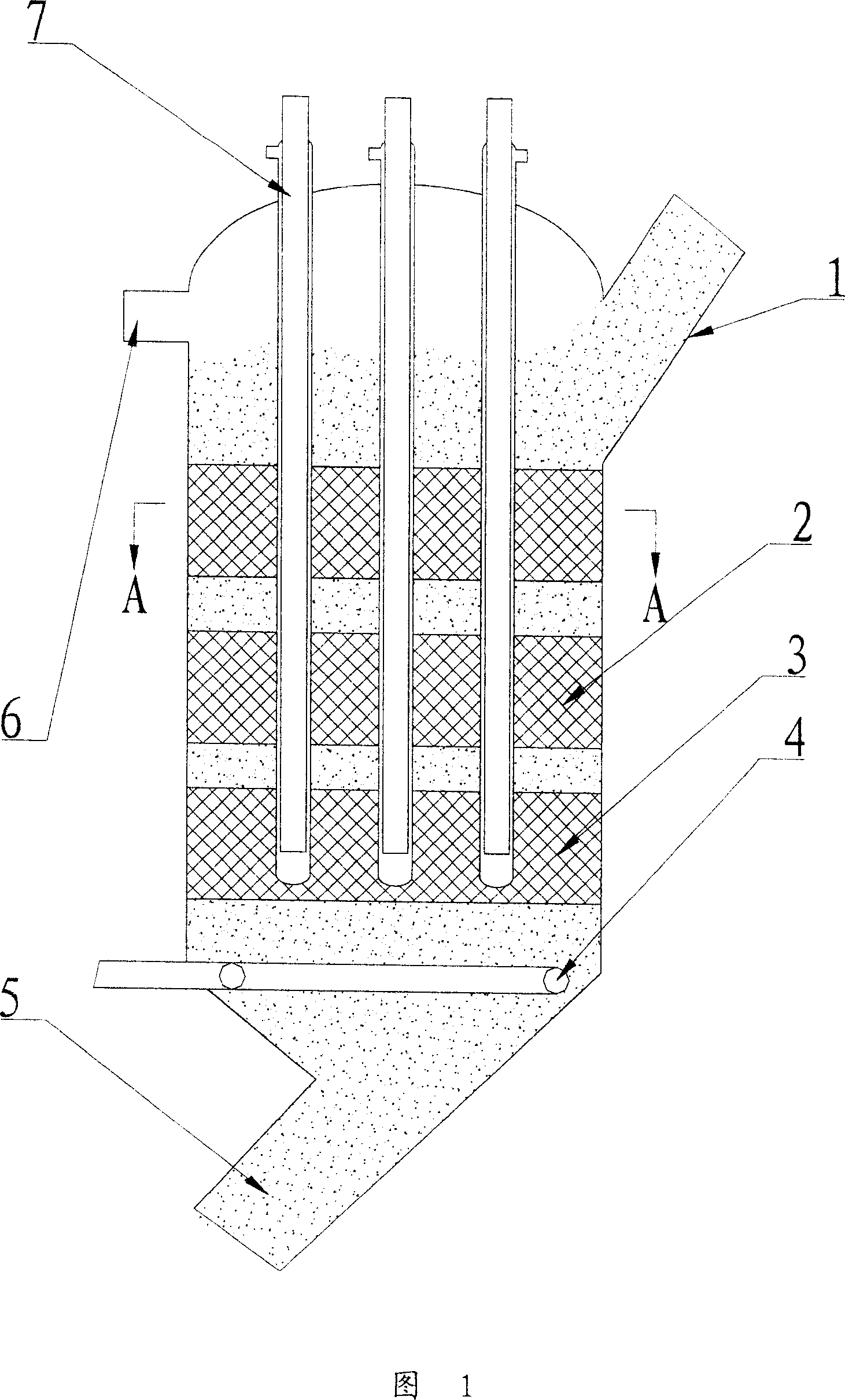

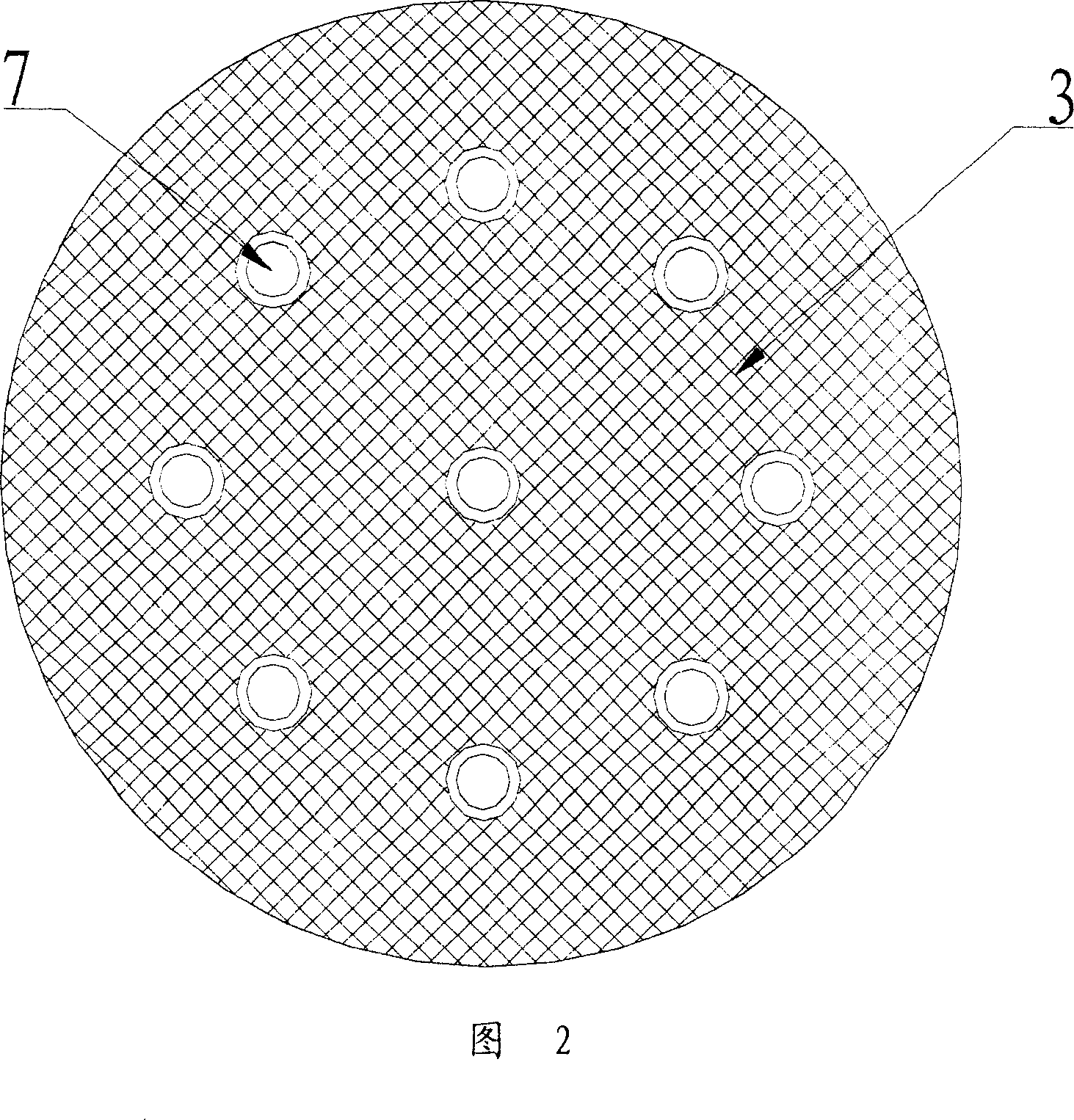

Method for directly reducing iron through electric reduction furnace

The invention discloses a method for directly reducing an iron through an electric reduction furnace. The method is characterized by comprising steps as follows: mixing a desulfurizing agent, a dephosphorizing agent and a reducing agent; drying until materials contain less than 3% of water; crushing dried materials until reaching granularity less than 1.5mm, so as to obtain a reducing additive; crushing an iron ore, then drying until the materials contain less than 3% of the water; heating the reducing additive and the iron ore in the electric reduction furnace, wherein iron oxide is reduced to obtain the iron; cooling the materials in the electric reduction furnace; crushing; and magnetically separating to obtain reduced iron. By adopting the method, the iron ore with any quality and any shape and proper carbon are mixed as reducing agents, which are directly reduced to obtain a sponge iron in a form of solid by the electric reduction furnace; and a metal ratio can reach over 96%.

Owner:贵州绿水青山环保科技有限公司

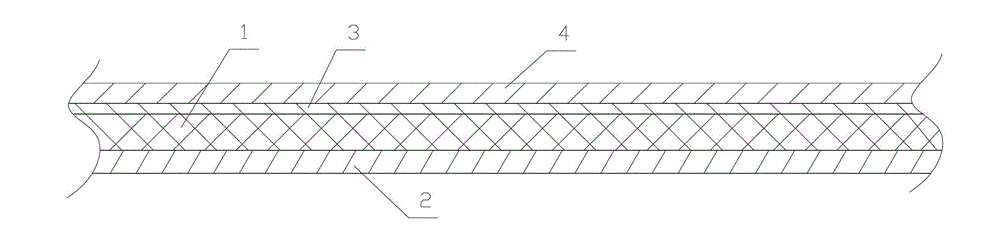

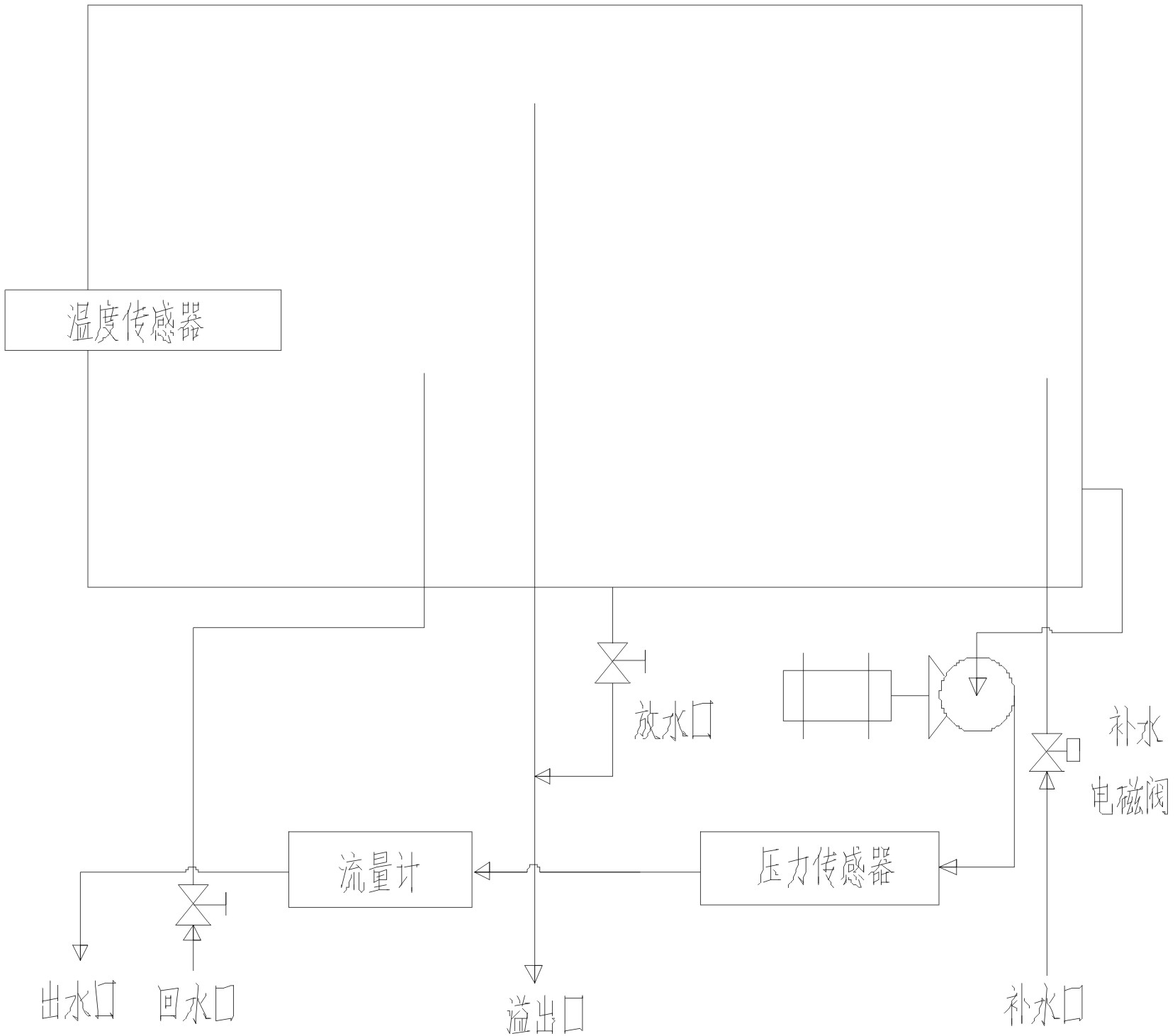

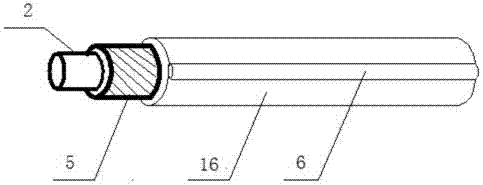

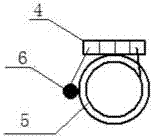

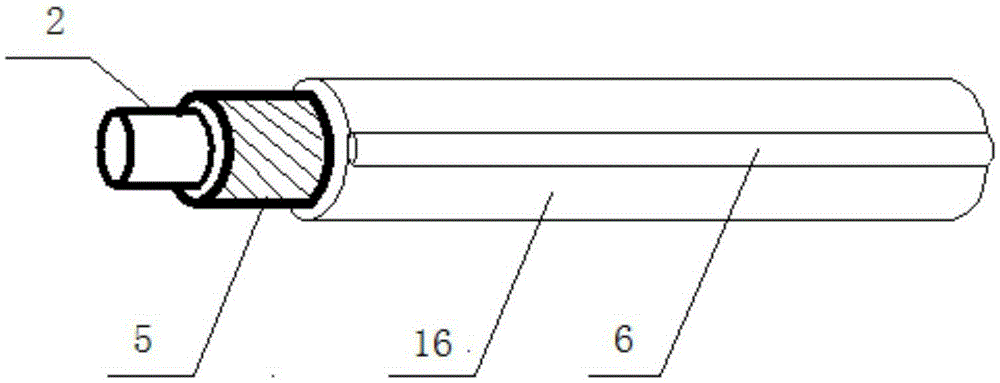

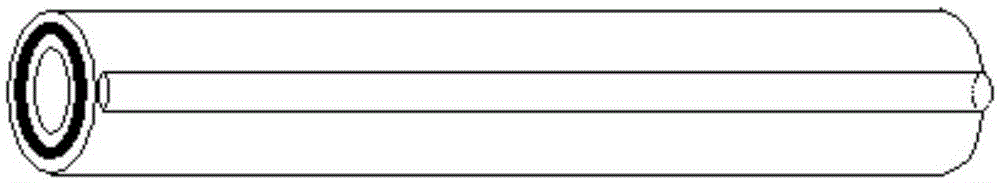

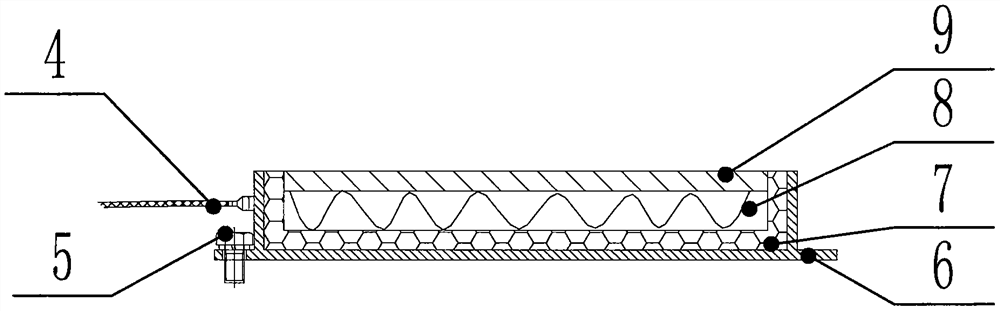

Heating system for centralized lubrication pipeline and usage method

ActiveCN103807591AFlexible heatingUniform heating effectLubrication elementsTemperature controlElectricity

The invention discloses a heating system for a centralized lubrication pipeline and a usage method. The system comprises a terminal strip, electric heating nets, return lines, connecting rings, external heating wires, a temperature control switch, a contactor, a timer, a heating power supply and a circuit breaker, wherein the electric heating nets of all oil pipelines are connected in series sequentially through the terminal strip; the electric heating nets are arranged inside the oil pipelines; the return lines are parallel with and insulated from the electric heating nets; the connecting rings are arranged at two ends of each oil pipeline; the temperature control switch is used for controlling connection of the power supply; the contactor is controlled to be connected with the power supply; the timer is responsible for setting of cycles and time; and the circuit breaker plays a role in protection. The electric heating nets, with which the pipelines are sleeved, are electrically connected in series, and the power supply is switched on under the control of the temperature control switch so as to heat the whole pipeline. The method is even and synchronous in pipeline heating effect, one power supply can drive heating of all the branch pipelines, the heating efficiency is high, and the cost is low; and the heating power supply can be adjusted according to specific conditions of the pipelines after laying, so that the method can meet requirements under different conditions more flexibly as well as meet requirements of pipeline transformation in the future.

Owner:CRRC WIND POWER(SHANDONG) CO LTD

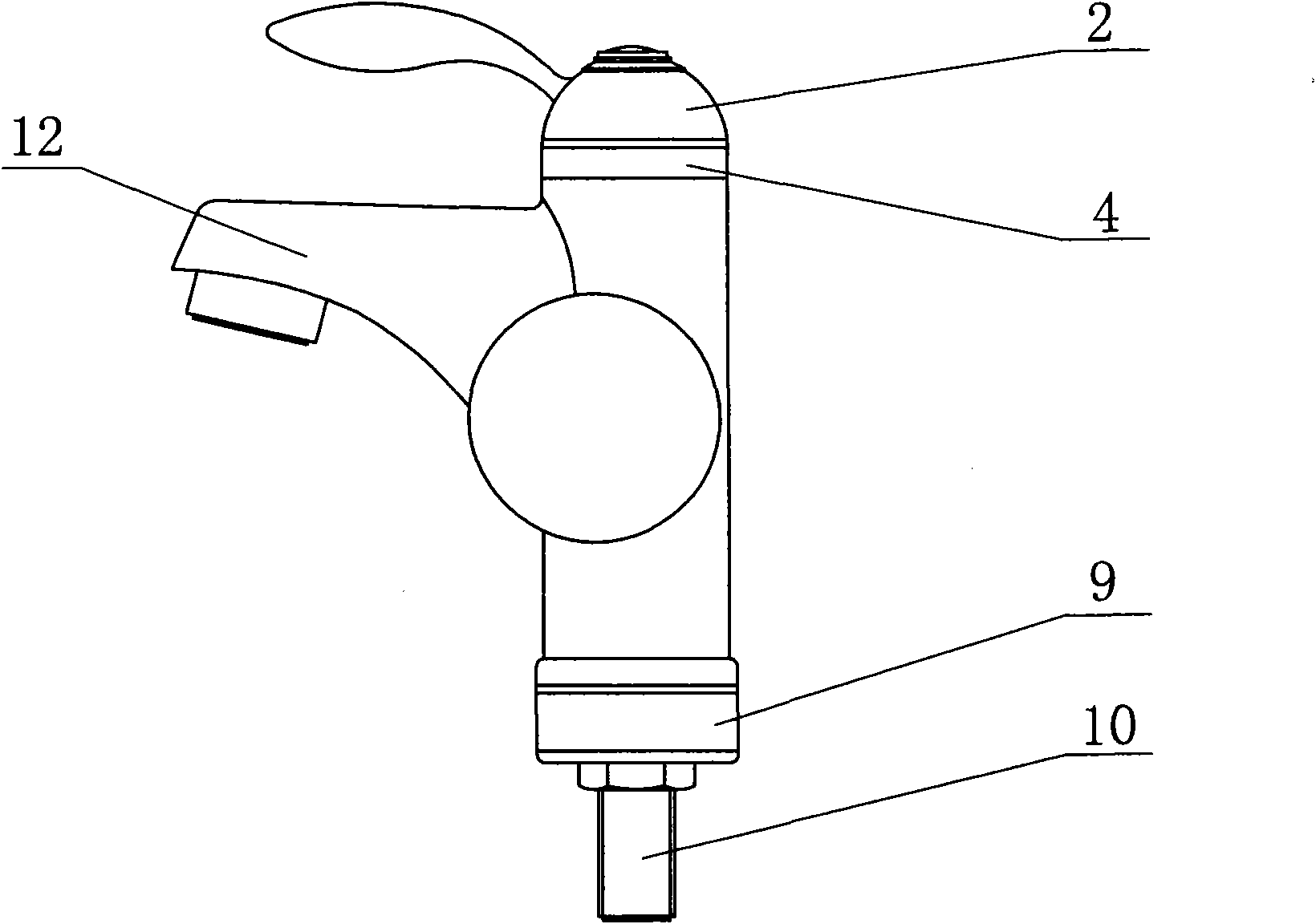

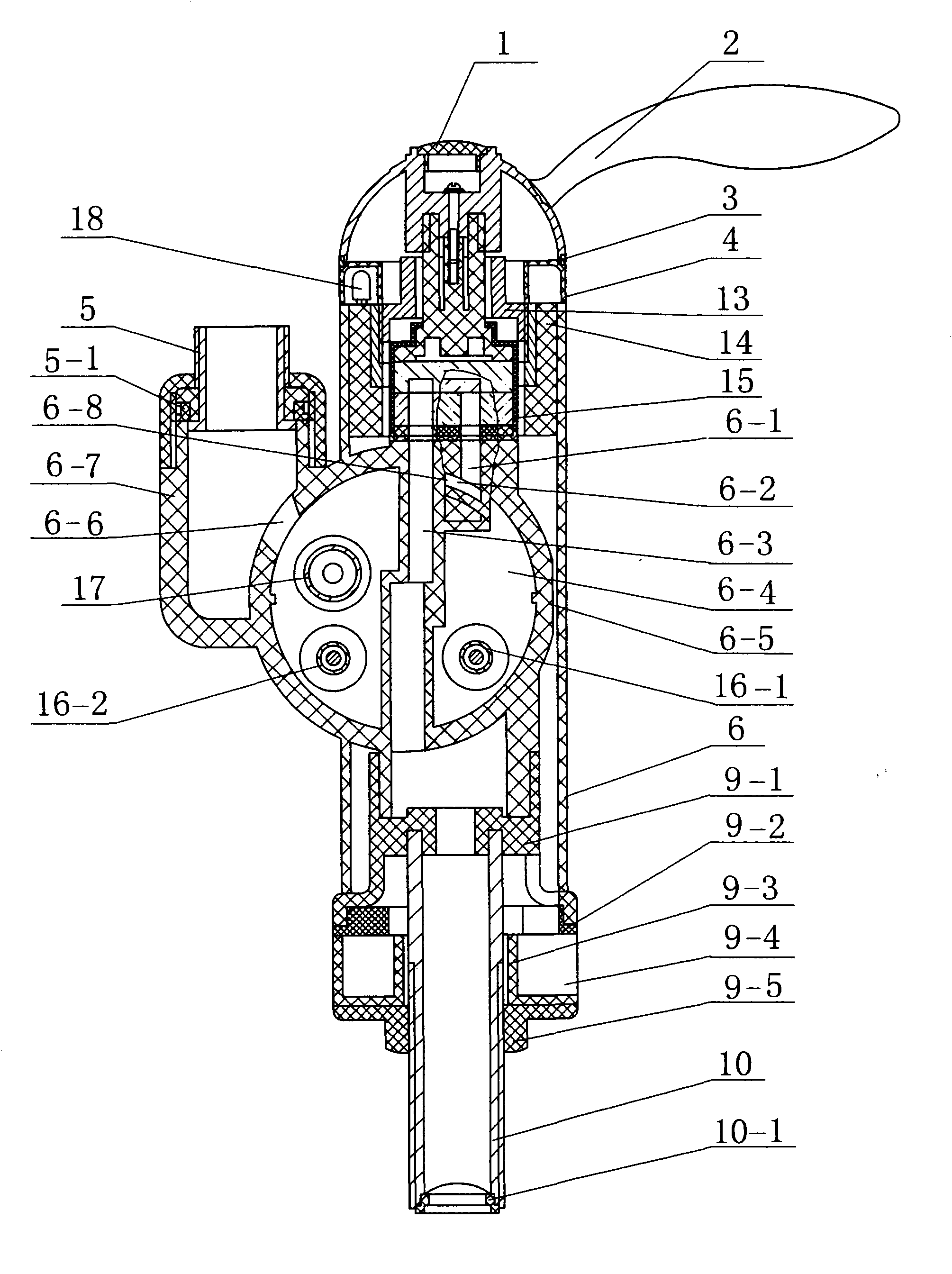

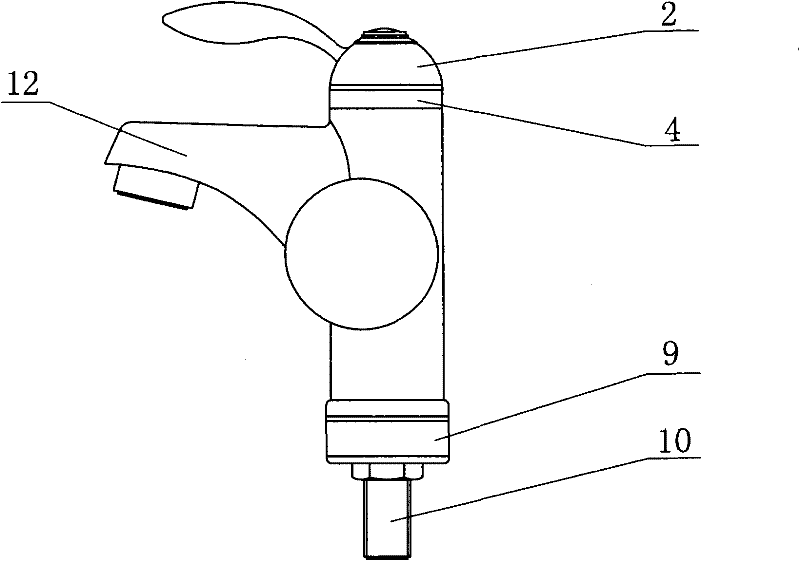

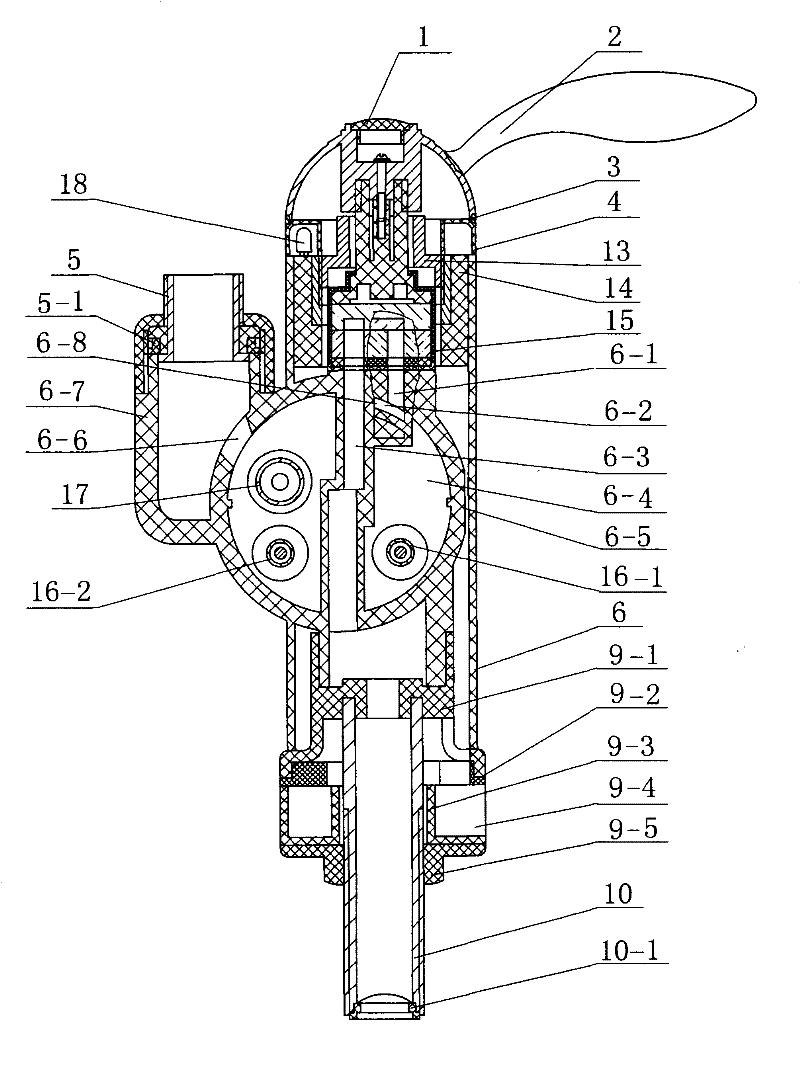

Energy-saving water heater

The invention relates to an energy-saving water heater. The shell is injection-molded into an integral body and separated into a left control chamber and a right heating chamber by a partition, wherein a wiring board in the control chambers is connected with an electrothermal tube switch which is composed of upper and lower contact spring tabs and a hydraulic pressure switch; the hydraulic pressure switch is formed by inserting an elastic cup, which is provided with an expansion link and installed on the partition, into a cover with a through hole in the middle; the inner wall of the heating chamber is provided with a transverse water inlet duct; the side wall of the transverse water inlet duct is provided with a cold water outlet which is tangential to the inner wall of the heating chamber; a ceramic valve core and a handle are connected to constitute a rotatable integral body; and the ceramic valve core is formed by connecting movable and fixed chips in a sleeve, a bottom plate, a seal ring and a rotary handle. The invention has the advantages of simple and compact structure, small size, easy assembly and maintenance, and convenient and flexible operation. The electric heater is automatically connected by using the hydraulic pressure switch, only one water inlet tube is required, the user can use the water heat without adding accessories, and cold water can become hot water within 3 seconds; no bubbles are produced in the heating chamber; and thus, the invention greatly enhances the thermal efficiency and the effluent rate and prolongs the service life of the electrothermal tube.

Owner:钟国芳

Electric heating method for liquid metal

PendingCN114295666AExtended service lifeReduce shockThermometer detailsMaterial thermal conductivityThermodynamicsLiquid state

The invention discloses an electric heating method of liquid metal, the liquid metal flows through a test pipeline and test equipment, the method comprises the following steps: S1, dividing the field test pipeline and test equipment into regions to obtain a plurality of sub-regions, S2, calculating the thermal load of the liquid metal in the test pipeline or test equipment corresponding to each sub-region; s3, arranging a plurality of heating wires for heating liquid metal in the test pipeline or the test equipment outside the test pipeline or the test equipment in each sub-region, wherein the plurality of heating wires are connected in parallel; and S4, each sub-region is provided with a junction box, and the heating wire of the sub-region is connected with the junction box of the sub-region. And S5, the solid-state relay conducts or cuts off the heating wire, and the liquid temperature is made to be within the set range. According to the invention, a plurality of low-power heating loops are used for heating, the heating is uniform, the power is adjustable, non-stop maintenance and replacement can be conveniently realized when a fault occurs on site, and the device is suitable for the condition of narrow or irregular site space.

Owner:湖南汉华京电清洁能源科技有限公司

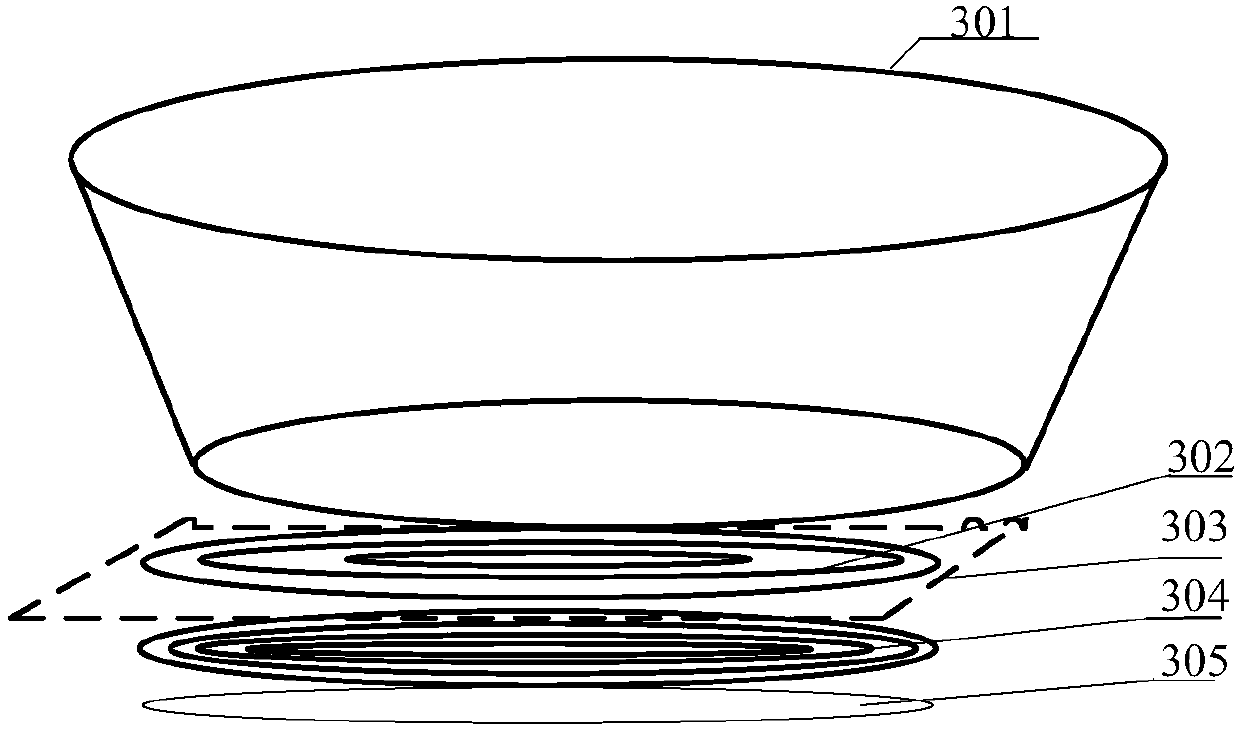

Tray preheating cavity and corresponding PECVD equipment

PendingCN111850518AShort stayIncrease production capacityFinal product manufactureChemical vapor deposition coatingAmorphous siliconThin membrane

The invention provides a tray preheating cavity and corresponding PECVD equipment. The PECVD equipment comprises a loading module used for placing silicon wafers in trays, a tray transfer module usedfor sending the trays conveyed by the loading module to the tray preheating cavity and receiving the preheated trays, the tray reheating cavity for receiving and preheating the trays to a preset preheating temperature and sending the trays back to the tray transfer module, a loading cavity configured to receive the preheated trays conveyed by the tray transfer module, a PECVD process cavity for receiving the trays conveyed by the loading cavity, an unloading cavity for receiving the trays conveyed by the PECVD process cavity and an unloading module for receiving the trays conveyed by the unloading cavity and unloading the silicon wafers from the trays, wherein the I / N or I / P type amorphous silicon thin films are deposited on the sides, borne with the silicon wafers, of the trays through anintrinsic and doped PECVD process. According to the tray preheating cavity and the corresponding PECVD equipment, the equipment productivity, preheating flexibility and preheating efficiency can be effectively improved, and the equipment cost can be effectively lowered.

Owner:IDEAL ENERGY (SHANGHAI) SUNFLOWER THIN FILM EQUIPMENT LTD

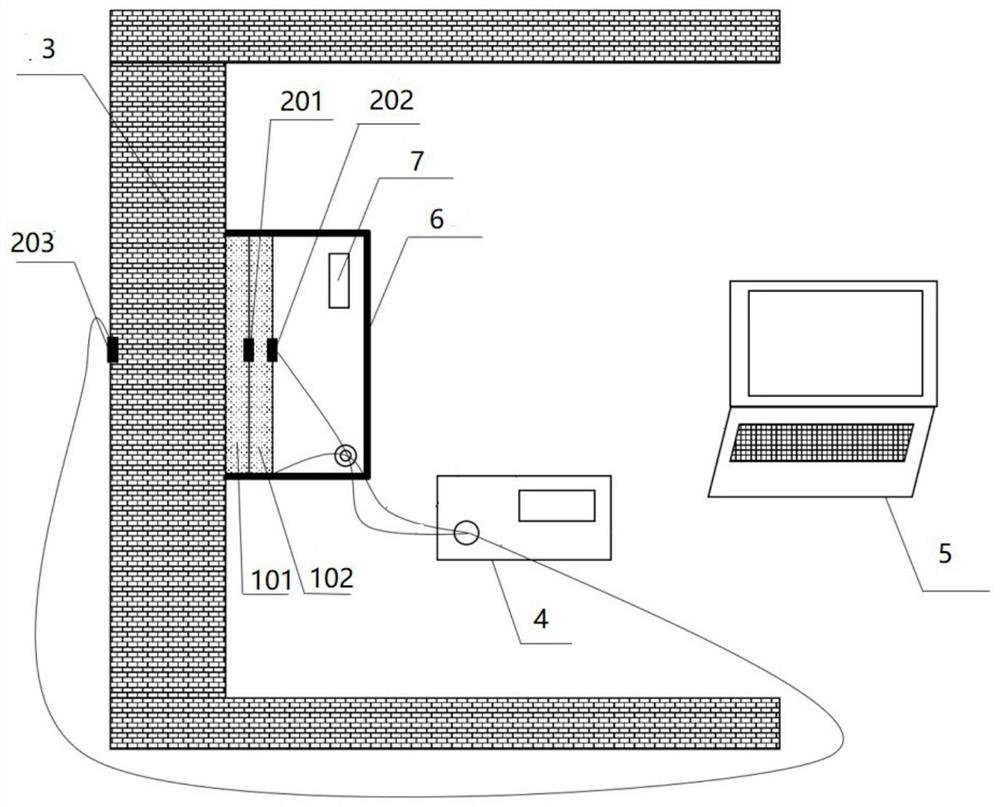

Field testing equipment and method for heat transfer coefficient of building envelope

ActiveCN111551580BChoose flexibleFlexible heatingMaterial thermal conductivityMaterial heat developmentData acquisitionEngineering

The invention discloses an on-site testing device for the heat transfer coefficient of a building enclosure structure, which includes a main part of the device and a data acquisition and processing part; the main part of the device includes: a first auxiliary test material board, a second auxiliary test material board, and a first temperature sensor , a second temperature sensor and a third temperature sensor; the data acquisition and processing part includes: data acquisition equipment and a computer, based on the one-dimensional heat conduction differential equation inside the multi-layer material, the analytical solution to the heat transfer coefficient is realized. Also disclosed is a field testing method for the heat transfer coefficient of the building enclosure structure. The equipment is simple in structure, easy to carry and easy to install. The test site can be flexibly selected according to the needs. The comprehensive heat transfer coefficient of the test enclosure structure can be measured more accurately in a short period of time, and the test site can be flexibly heated. The test results are not affected by the external temperature; secondly, the calculation program of this test method is based on the basic heat conduction equation, which has small programming difficulty and small calculation error.

Owner:SOUTHEAST UNIV

Solvent-assisted sagd three-dimensional physical simulation experiment method and experimental device

The invention provides a solvent-assisted SAGD three-dimensional physical simulation experiment method and an experiment device. The device includes an injection device, a simulated reservoir model and a recovery device. In the injection device, the first pump unit communicates with the piston container unit, the second pump unit communicates with the steam generator, and the piston container unit and the steam generator communicate with the simulated reservoir model respectively. The steam injection well is connected; one end of the first condenser in the recovery device is connected with the production well of the simulated reservoir model, the other end of the first condenser is connected with the feed port of the gas-liquid separator, and the second condenser is connected with the gas-liquid separator. The liquid outlet of the separator is connected, the third condenser is connected with the gas outlet of the gas-liquid separator, the crude oil and water collection container is connected with the second condenser, and the solvent recovery container is connected with the third condenser. The experimental method and experimental device of the present invention can simulate the mining conditions of the solvent-assisted SAGD technology, study the mechanism of the solvent in the SAGD process, and optimize and improve the existing solvent-assisted SAGD technology according to the reservoir conditions.

Owner:PETROCHINA CO LTD

Precise punching die for parts

InactiveCN112091051AFirmly connectedEasy inspection and maintenanceShaping toolsMetal-working feeding devicesStampingEngineering

The invention provides a precise punching die for parts. The precise punching die comprises a base plate, wherein an intelligent bottom box and a lower guide rail are arranged at the top of the base plate; a supporting box is arranged at the bottom of the base plate, and the top surface of the lower guide rail makes contact with the bottom surface of a left lower rotating half shaft and the bottomsurface of a right lower rotating half shaft from left to right correspondingly; the top of the left lower rotating half shaft and the top of the right lower rotating half shaft are fixedly connectedwith the bottom of a first inclined arm and the bottom of a second inclined arm correspondingly, the middle part of the first inclined arm and the middle part of the second inclined arm are hinged through a center shaft, and the top of the first inclined arm and the top of the second inclined arm are fixedly connected with the bottom of a right upper rotating half shaft and the bottom of a left upper rotating half shaft correspondingly; and an upper guide rail is fixed to the right portion of the lower surface of a long strip plate through welding. According to the technical scheme, the technical problems that in the prior art, the integrated stamping and cutting capacity with the adjustable operation height is not achieved, the angle of a placement plate cannot be flexibly adjusted, andthe cold and hot conditions of machining cannot be flexibly switched are effectively solved, and application and popularization are facilitated.

Owner:彭清莲

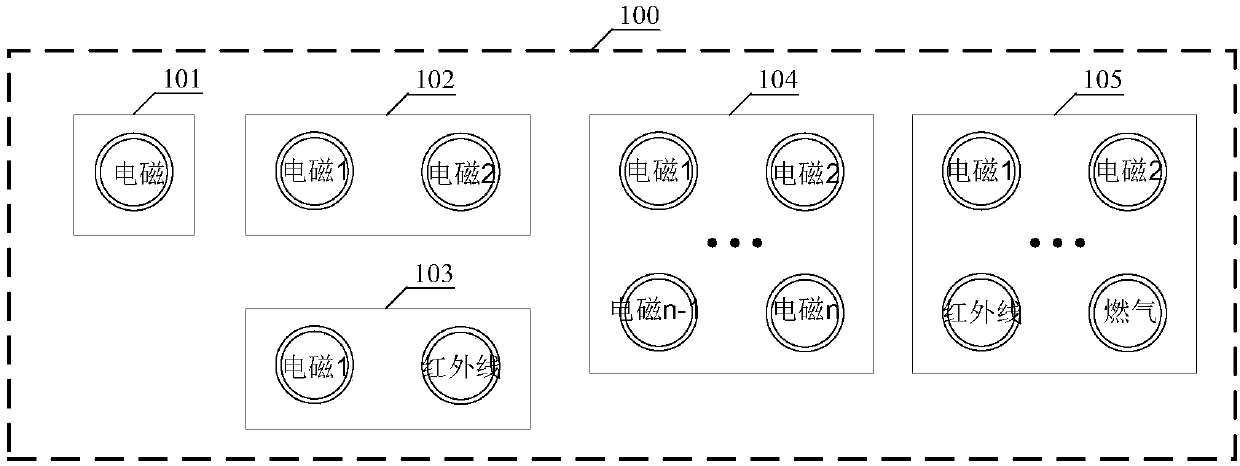

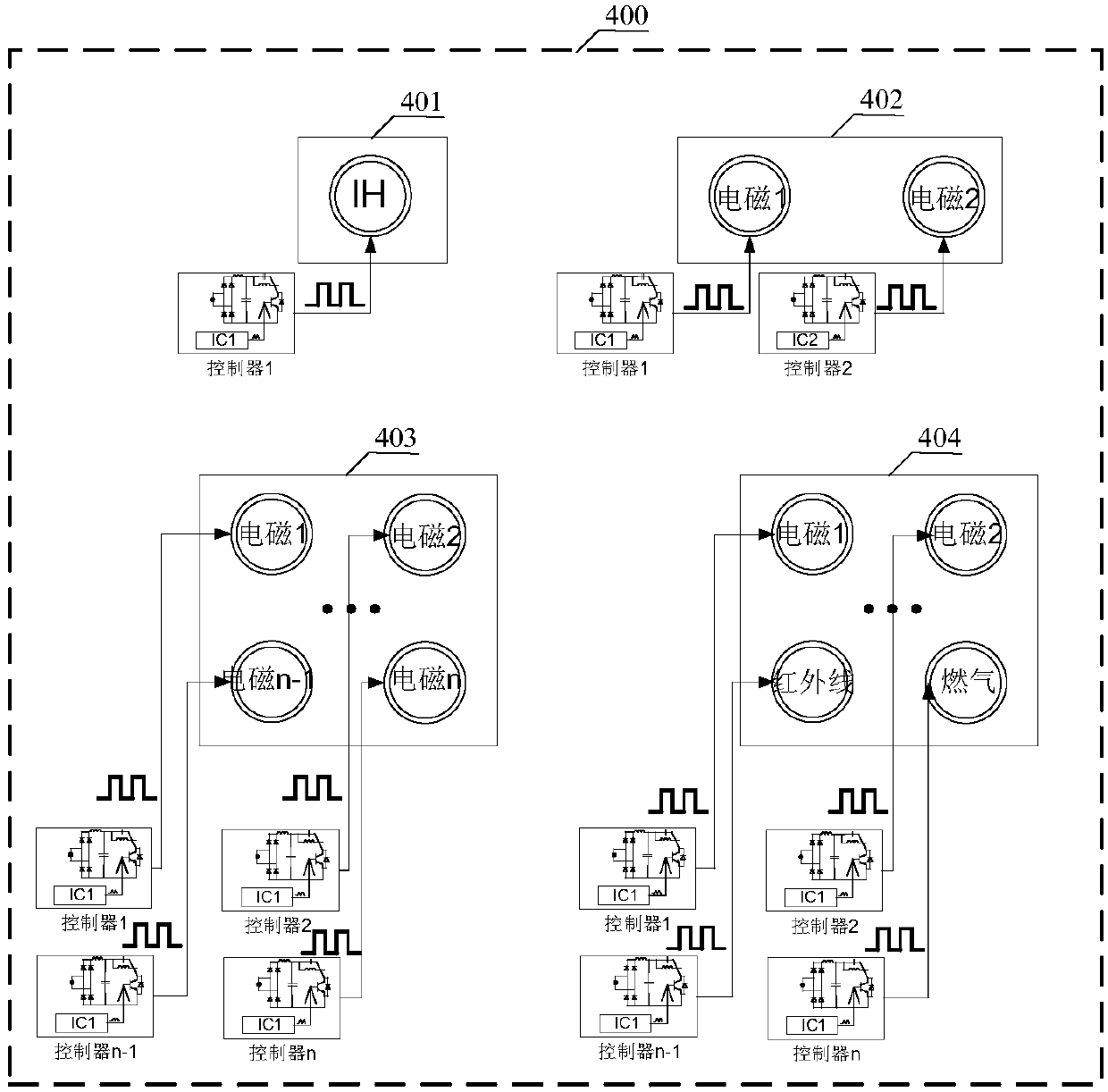

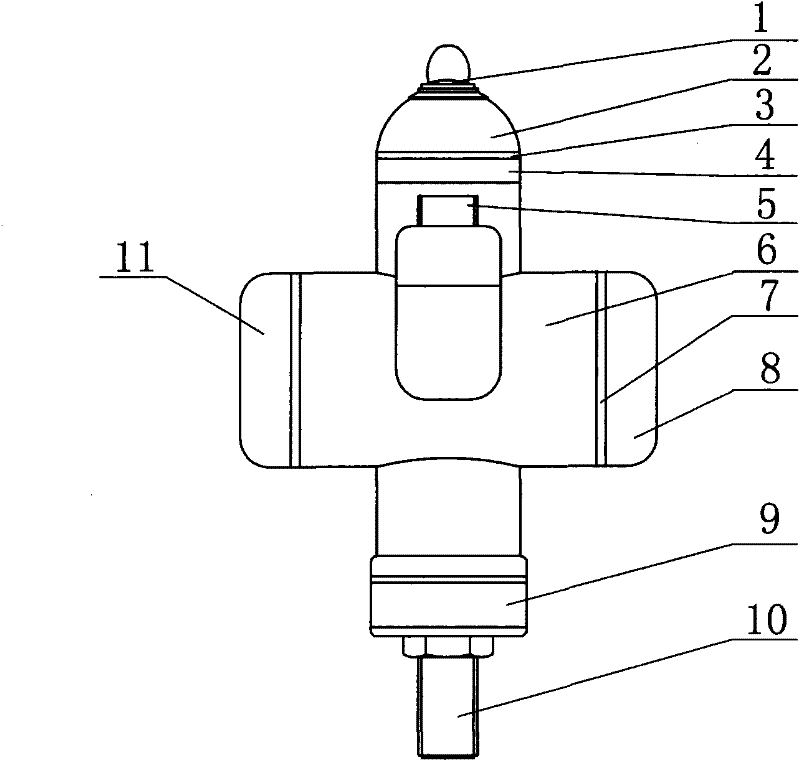

Induction cooker burner and induction cooker

InactiveCN110118369AImprove heating efficiencyIncrease power levelDomestic stoves or rangesLighting and heating apparatusInfraredInduction motor

The invention provides an induction cooker burner and an induction cooker. The induction cooker burner includes a supporting rack, an electromagnetic coil and an infrared coil; the electromagnetic coil is arranged on the supporting rack and used for generating a magnetic field after being connected to an external power supply, and cooking utensils can be heated by utilizing the magnetic field to generate heat; and the infrared coil is arranged above the electromagnetic coil and used for generating infrared rays after being connected to the external power supply, and the cooking utensils can beheated by utilizing the infrared rays to generate heat. Through the above technical schemes, the heating of a plurality of the cooking utensils can be flexibly realized according to user demands andcooking utensil types, so that hardware costs can be reduced, and heating efficiency can be enhanced.

Owner:LG ELECTRONICS CHINA RANDD CENT SHANGHAI CO LTD

A heating system for centralized lubrication pipeline and its application method

ActiveCN103807591BFlexible heatingUniform heating effectLubrication elementsTemperature controlElectricity

The invention discloses a heating system for a centralized lubrication pipeline and a usage method. The system comprises a terminal strip, electric heating nets, return lines, connecting rings, external heating wires, a temperature control switch, a contactor, a timer, a heating power supply and a circuit breaker, wherein the electric heating nets of all oil pipelines are connected in series sequentially through the terminal strip; the electric heating nets are arranged inside the oil pipelines; the return lines are parallel with and insulated from the electric heating nets; the connecting rings are arranged at two ends of each oil pipeline; the temperature control switch is used for controlling connection of the power supply; the contactor is controlled to be connected with the power supply; the timer is responsible for setting of cycles and time; and the circuit breaker plays a role in protection. The electric heating nets, with which the pipelines are sleeved, are electrically connected in series, and the power supply is switched on under the control of the temperature control switch so as to heat the whole pipeline. The method is even and synchronous in pipeline heating effect, one power supply can drive heating of all the branch pipelines, the heating efficiency is high, and the cost is low; and the heating power supply can be adjusted according to specific conditions of the pipelines after laying, so that the method can meet requirements under different conditions more flexibly as well as meet requirements of pipeline transformation in the future.

Owner:CRRC WIND POWER(SHANDONG) CO LTD

Maintainable methylsulfonylbenzene synthesis device

InactiveCN112250605AEasy to cleanEasy dischargeOrganic chemistryOrganic compound preparationStructural engineeringMethyl palmoxirate

The invention provides a maintainable methylsulfonylbenzene synthesis device which comprises a delivery pump, a chloromethane guide pipe, methylation kettles, a heat accumulating type incinerator, a flow dividing tower, a saline water guide pipe, a washing tower, a feeding pipe, a controllable water inlet frame structure, a rotary cleaning frame structure, a discharge valve, a centrifugal machine,a methylsulfonylbenzene guide pipe, a mixing and stirring device and a waste collecting frame structure. The delivery pump is communicated with the left upper side of the methylation kettle through apipeline; the chloromethane guide pipes are respectively communicated with the right lower side of the methylation kettle; the number of the methylation kettles is four, and the methylation kettles are sequentially arranged downwards from left to right. The side scraping plate screws are installed at the ends, away from the transmission rod, of the transverse rods and make contact with the innerwall of the washing tower at the same time, the cleaning motor can conveniently drive the side scraping plates to rotate through the transverse rods by means of the transmission rod during use, and therefore the inner wall of the washing tower can be conveniently cleaned.

Owner:山东斯瑞药业有限公司

Energy-saving water heater

The invention relates to an energy-saving water heater. The shell is injection-molded into an integral body and separated into a left control chamber and a right heating chamber by a partition, wherein a wiring board in the control chambers is connected with an electrothermal tube switch which is composed of upper and lower contact spring tabs and a hydraulic pressure switch; the hydraulic pressure switch is formed by inserting an elastic cup, which is provided with an expansion link and installed on the partition, into a cover with a through hole in the middle; the inner wall of the heating chamber is provided with a transverse water inlet duct; the side wall of the transverse water inlet duct is provided with a cold water outlet which is tangential to the inner wall of the heating chamber; a ceramic valve core and a handle are connected to constitute a rotatable integral body; and the ceramic valve core is formed by connecting movable and fixed chips in a sleeve, a bottom plate, a seal ring and a rotary handle. The invention has the advantages of simple and compact structure, small size, easy assembly and maintenance, and convenient and flexible operation. The electric heater isautomatically connected by using the hydraulic pressure switch, only one water inlet tube is required, the user can use the water heat without adding accessories, and cold water can become hot water within 3 seconds; no bubbles are produced in the heating chamber; and thus, the invention greatly enhances the thermal efficiency and the effluent rate and prolongs the service life of the electrothermal tube.

Owner:钟国芳

Ion source with evaporator

ActiveCN105862006AReduce lossIncrease evaporation rateVacuum evaporation coatingSputtering coatingEvaporatorElectric arc

The invention relates to an ion source with an evaporator; the ion source may have the evaporator, and uses the following one or more modes to reduce temperature difference in the evaporator; firstly, at least one heat insulator is arranged by partial a container and far away from a special heat source, wherein the container of the evaporator is heated by the special heat source; secondly, at least one heat insulator is arranged around the heater, wherein the container is arranged in the evaporator and heated by the heater; thirdly, at least one radiation shield is arranged so as to allow heat energy the pass the housing and a channel unit, wherein an arc chamber is connected with the housing through the channel unit in a machinery manner. The heat insulator can reduce heat energy loss, and the temperature difference in the evaporator is reduced; in addition, a hollow diffuser with a plurality of open pores is used for adding conductivity and reducing evaporated material condensation.

Owner:ADVANCED ION BEAM TECHNOLOGY INC

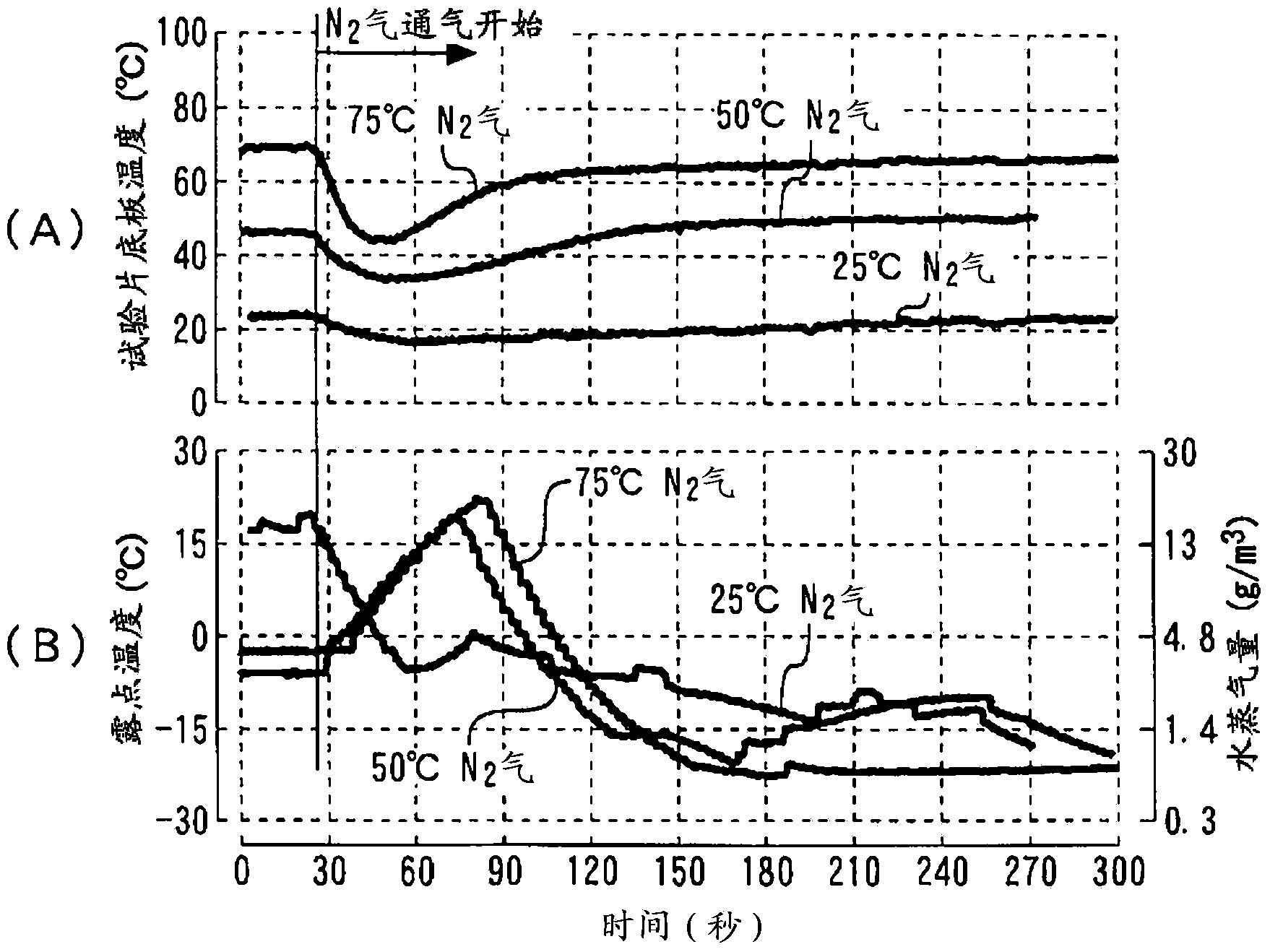

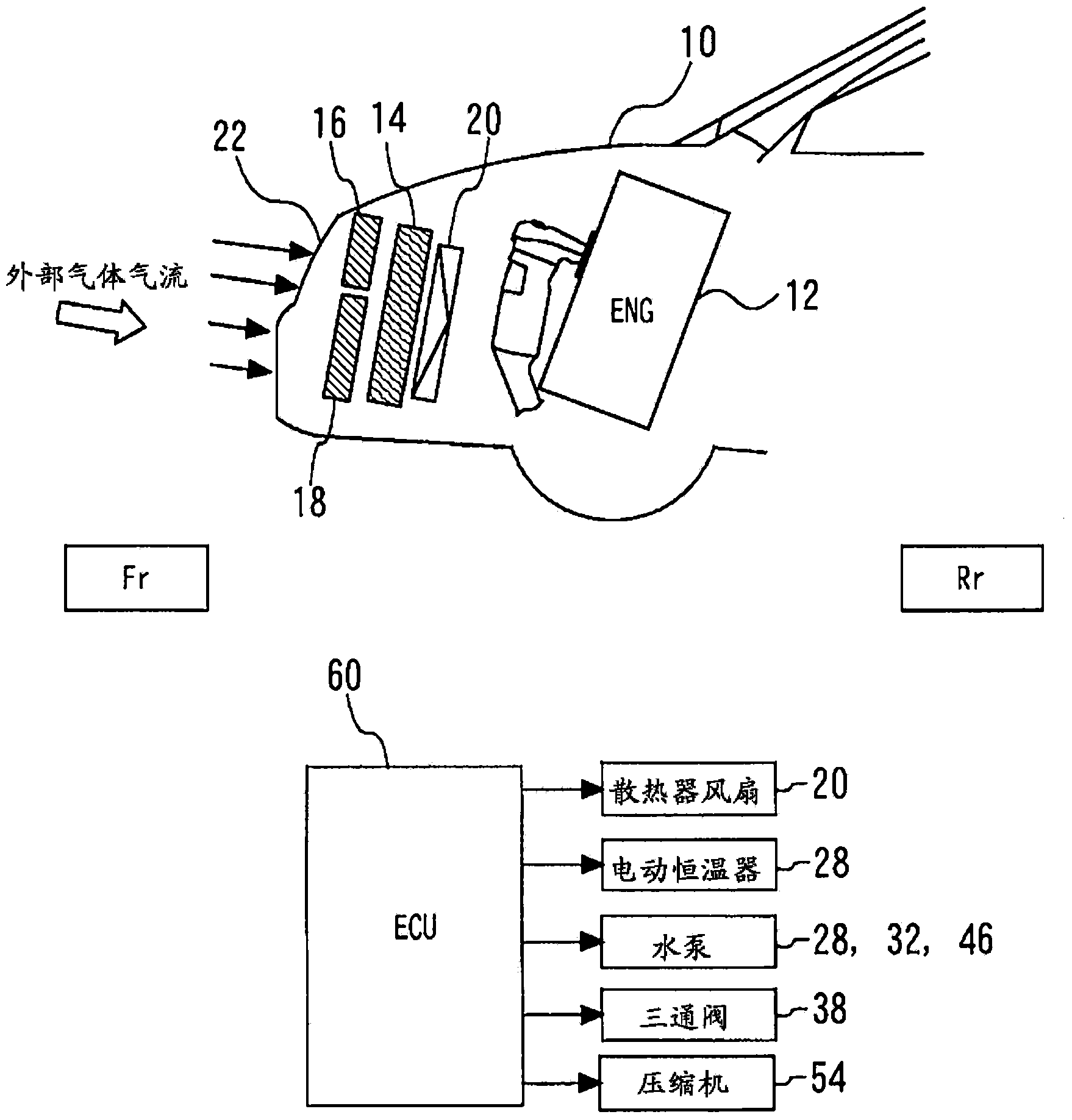

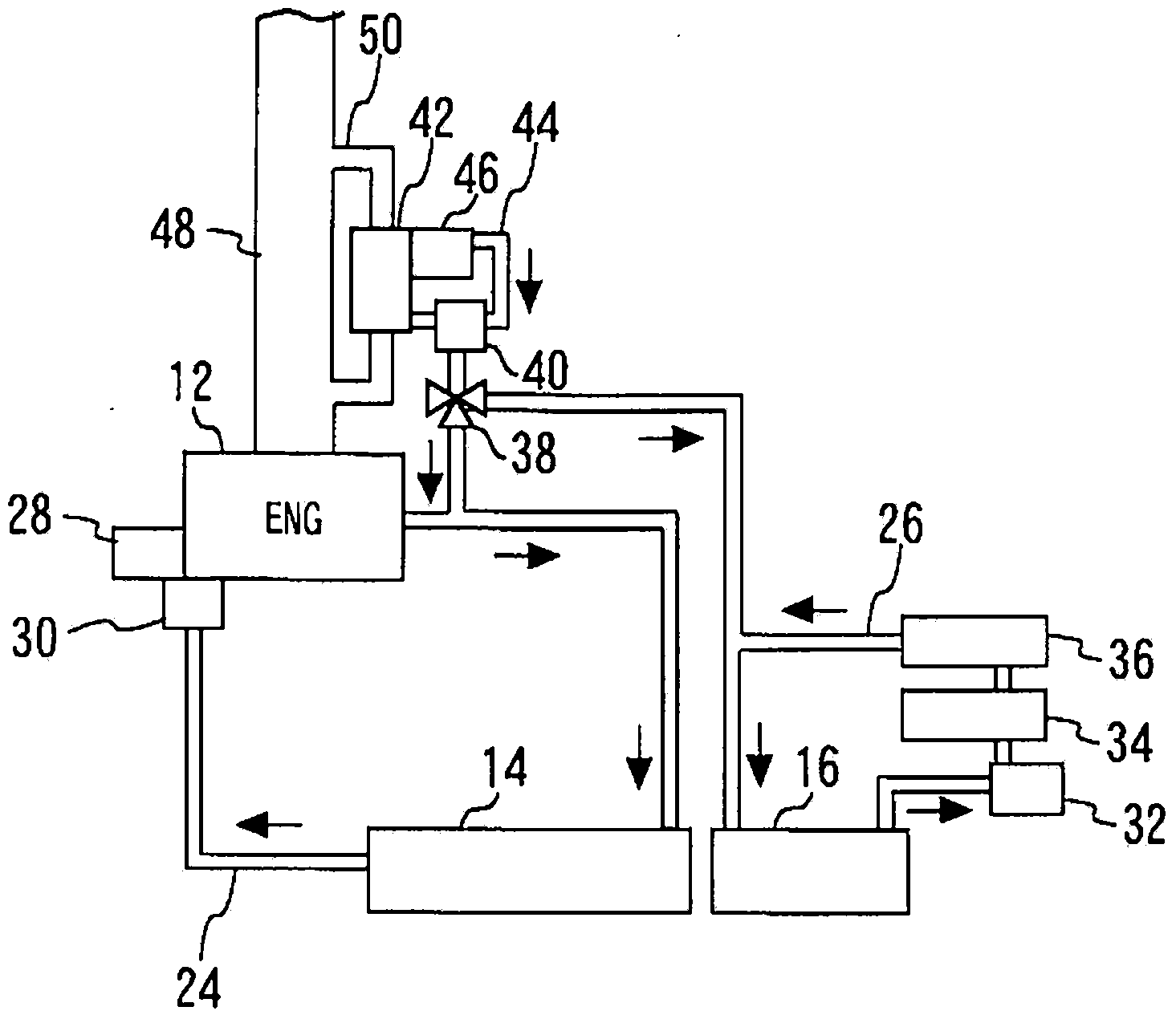

Air purification device for vehicles

ActiveCN103906638BReduced ozone purification performanceOzone purification performance recoveryGas treatmentAir-treating devicesActivated carbonEnvironmental engineering

The present invention relates to an air purification device for vehicles, and its object is to provide a DOR (Direct? Ozone? Reduction: direct reduction of ozone) system capable of suppressing the reduction of ozone purification performance due to water adhesion and recovering Ozone purification performance. In the present invention, activated carbon as an ozone purifier is applied to the respective corners of the radiators (14, 16) and the condenser (18). As shown in Figure 5, when water adheres to the fine pores of activated carbon and its surroundings, it is difficult for ozone to enter the mesopores and micropores. In addition, even if ozone enters, it is difficult to donate electrons to ozone from activated carbon. Thus, during water attachment, the ozone purification performance of the activated carbon will be reduced. Therefore, when the amount of moisture adhered to the activated carbon becomes more than a predetermined amount, the moisture release control is performed by forcibly increasing the temperature of the activated carbon to release the moisture.

Owner:TOYOTA JIDOSHA KK

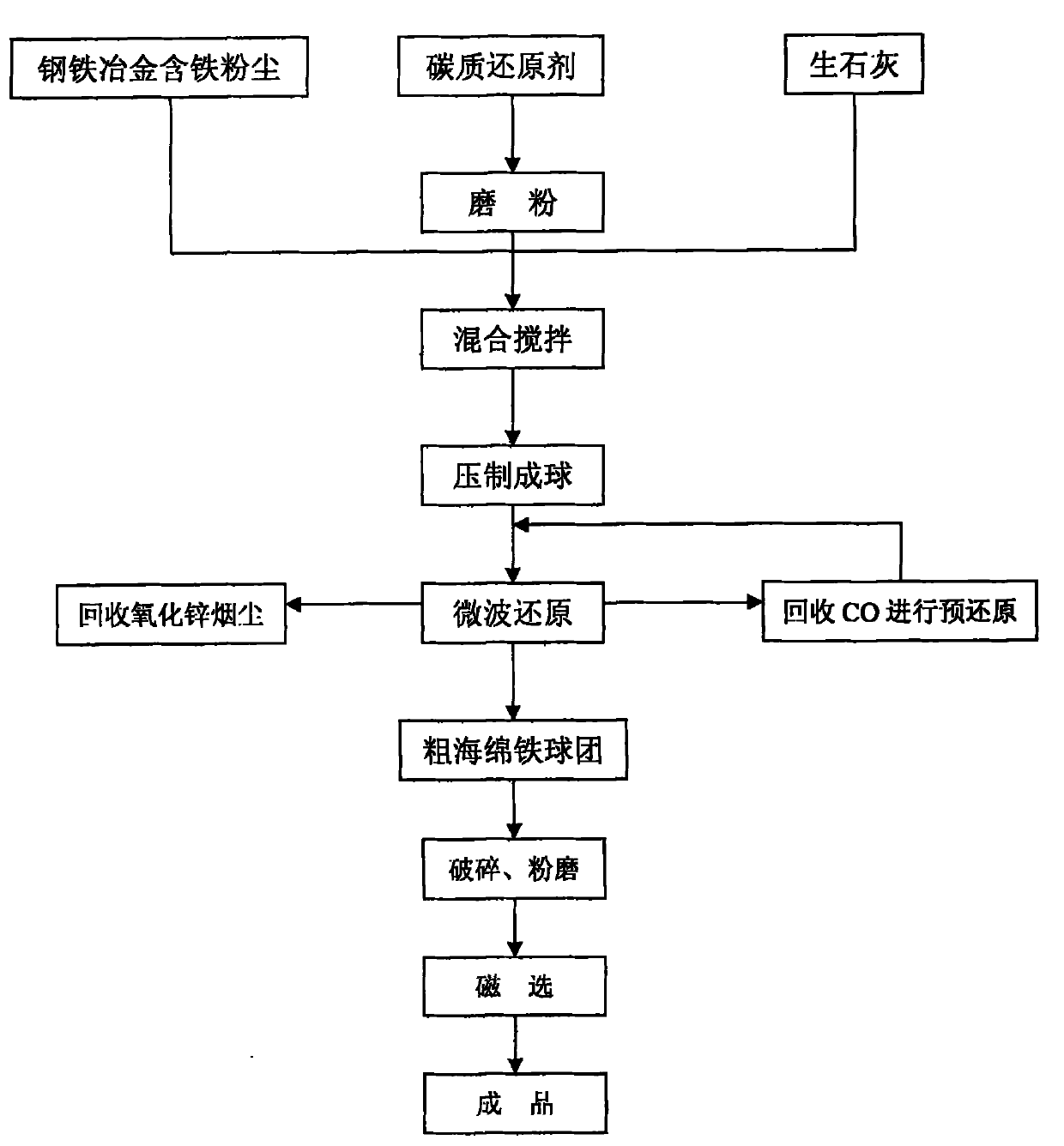

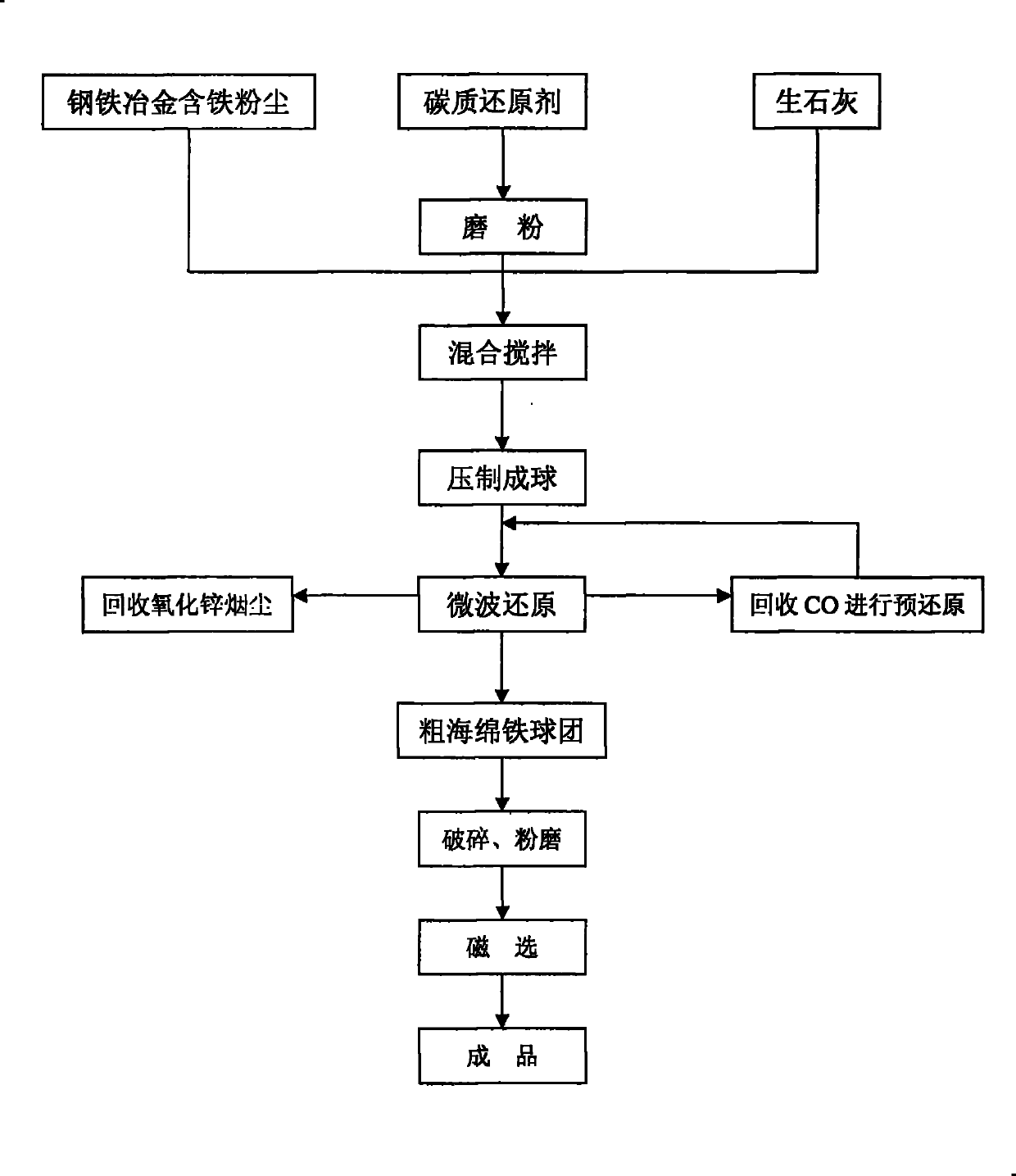

Process for directly producing sponge iron by microwave carbothermal reduction steel metallurgical iron-bearing dust

InactiveCN101457269BProduces fast and uniformReduce consumptionFluidised-bed furnacesChemical reactionMicrowave

The invention discloses a process for directly producing sponge iron by microwave carbothermal reduction of ferrous metallurgical iron-containing dust. Anthracite coal is added to the ferrous metallurgical iron-containing dust, the weight of the ferrous metallurgical iron-containing dust accounts for 20-80% of the total weight, that of the anthracite coal accounts for 10-60%, and 1-20% of calciumlime is added to be taken as an additive; an obtained mixture is pressed into a 2mm-100mm ball after mixing and drying treatment, the heating temperature is between 800 DEG C to 1300 DEG C by adopting a microwave heating mode, the mixture reacts in a microwave reducing furnace to obtain a semi-finished raw sponge ball; and the ball is crushed and ground into fine powder less than 80 meshes, and finally a sponge iron product consistent with the requirement is obtained by a magnetic separation process. The process has the advantages of having selective heating characteristic, being capable of directly heating fine materials, having rapid temperature rise, having even heating, reducing energy consumption, lowering chemical reaction activation energy, and being capable of causing atoms and molecules of the materials to generate high-speed rotation. The process does not produce any pollution, which is beneficial to the environmental protection.

Owner:重庆科健冶金材料有限公司

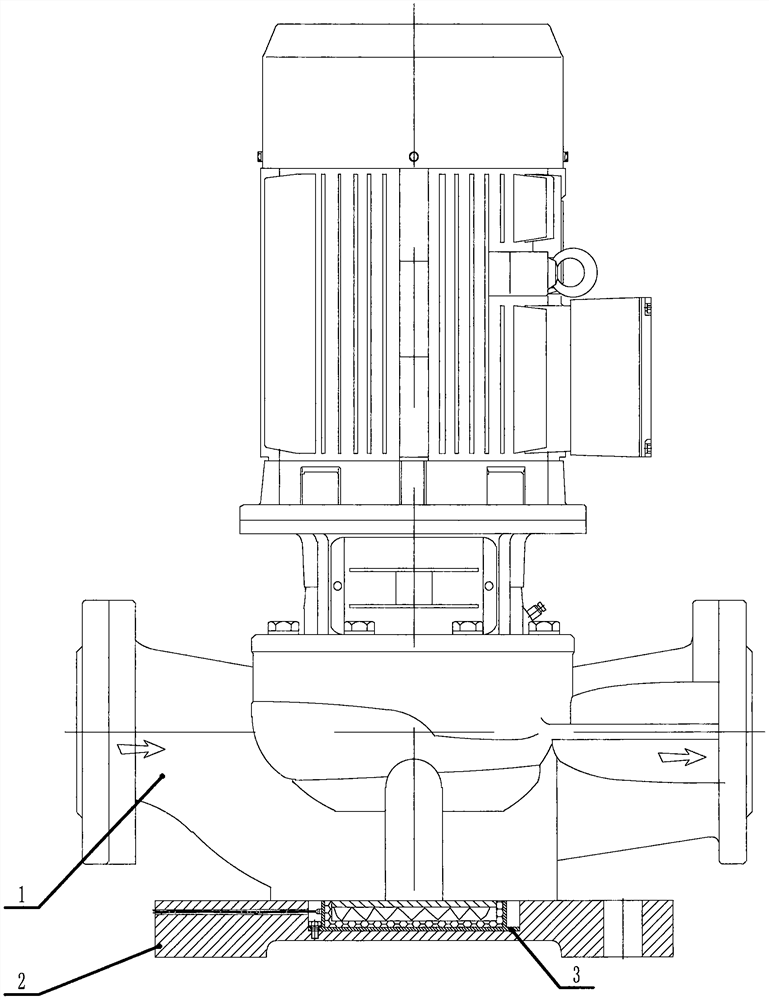

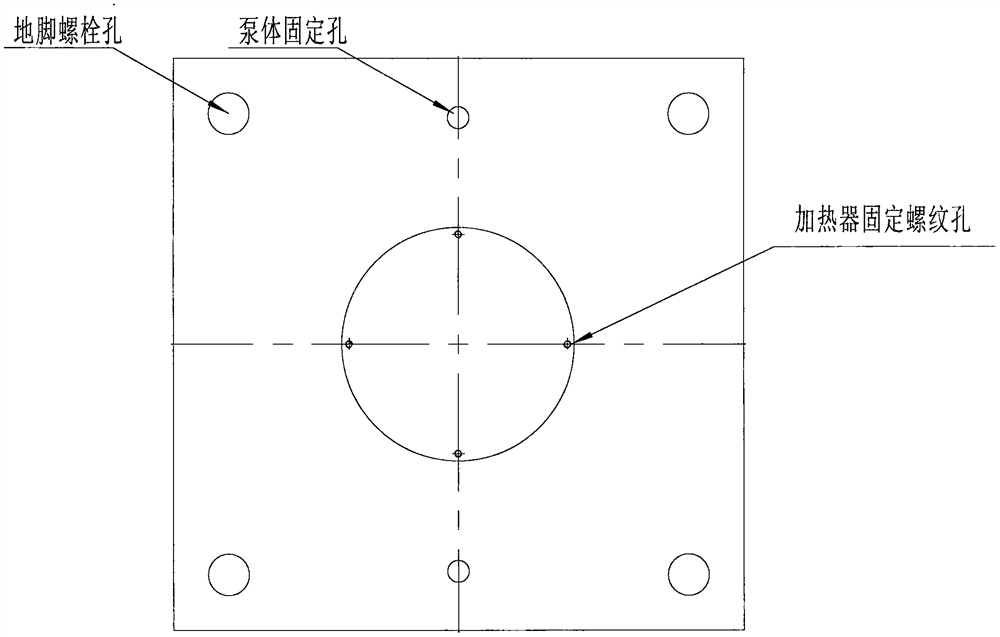

Centrifugal pump with detachable heating bottom plate

InactiveCN112443516APrevent proliferationFlexible heatingPump componentsPumpsEngineeringMechanical engineering

The invention relates to a centrifugal pump with a detachable heating bottom plate. According to the centrifugal pump with the detachable heating bottom plate provided by the invention, a pump body and the bottom plate are detachable, a heater is installed in the bottom plate, the pump body and water in the pump body can be heated, and the water in the pump body can be prevented from being condensed into ice to damage the water pump at low temperature in winter.

Owner:江苏安立泰流体装备科技有限公司

Technology for extracting iron from steel-making and ironmaking fly ash by micro-wave heating

ActiveCN103205519BHigh recovery rateImprove protectionFluidised-bed furnacesMicrowavePassive heating

The invention discloses a technology for extracting iron from steel-making and ironmaking fly ash by micro-wave heating. The technology comprises procedures of evenly distributing the fly ash into mobile bed of a microwave reduction furnace, heating and cooling the fly ash; the heating procedure is orderly divided into a baking temperature zone, a preheating temperature zone, a baking temperature zone and a sintering temperature zone; the temperature is gradually improved to heat; the temperature of the baking temperature zone is 80-120 DEG C; the temperature of the preheating temperature zone is 200-600 DEG C; the temperature of the baking temperature zone is 700-1100 DEG C; the temperature of the sintering temperature zone is 1300-1550 DEG C; and the delivery speed of the mobile bed is controlled at 0.8-1.2m / m. The microwave belongs a body heating mode, is fast to heat, even to heat, and low in energy consumption; the fly ash contains carbon; the reducing agents such as carbon do not need to be added; and ferric oxide can be directly restored, so as to play the roles of saving energy sources and reducing the production cost. The microwave is a clean energy source, does not generate any pollution, and benefits for environmental protection.

Owner:石家庄市宏晟环保科技有限公司

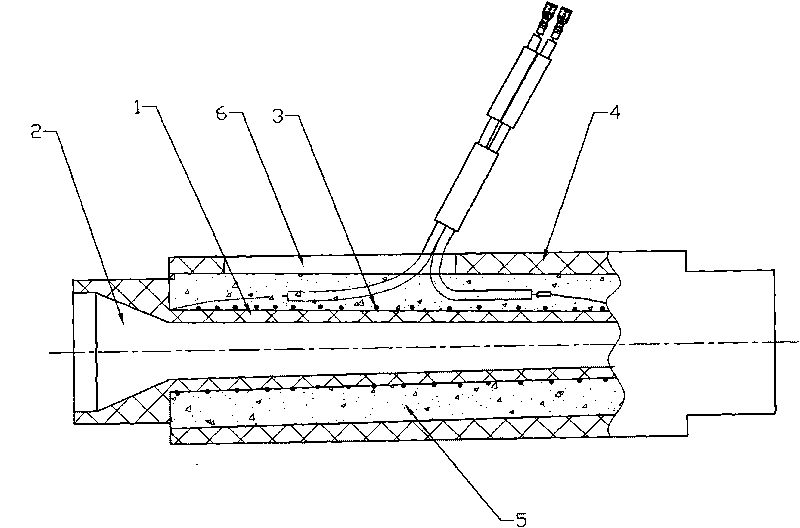

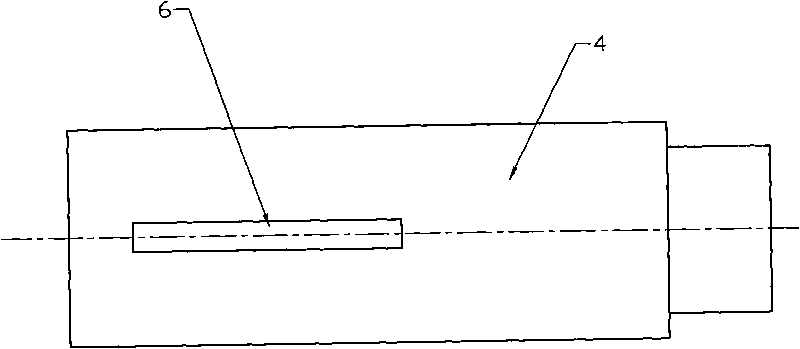

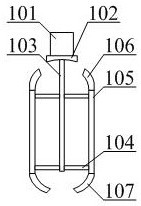

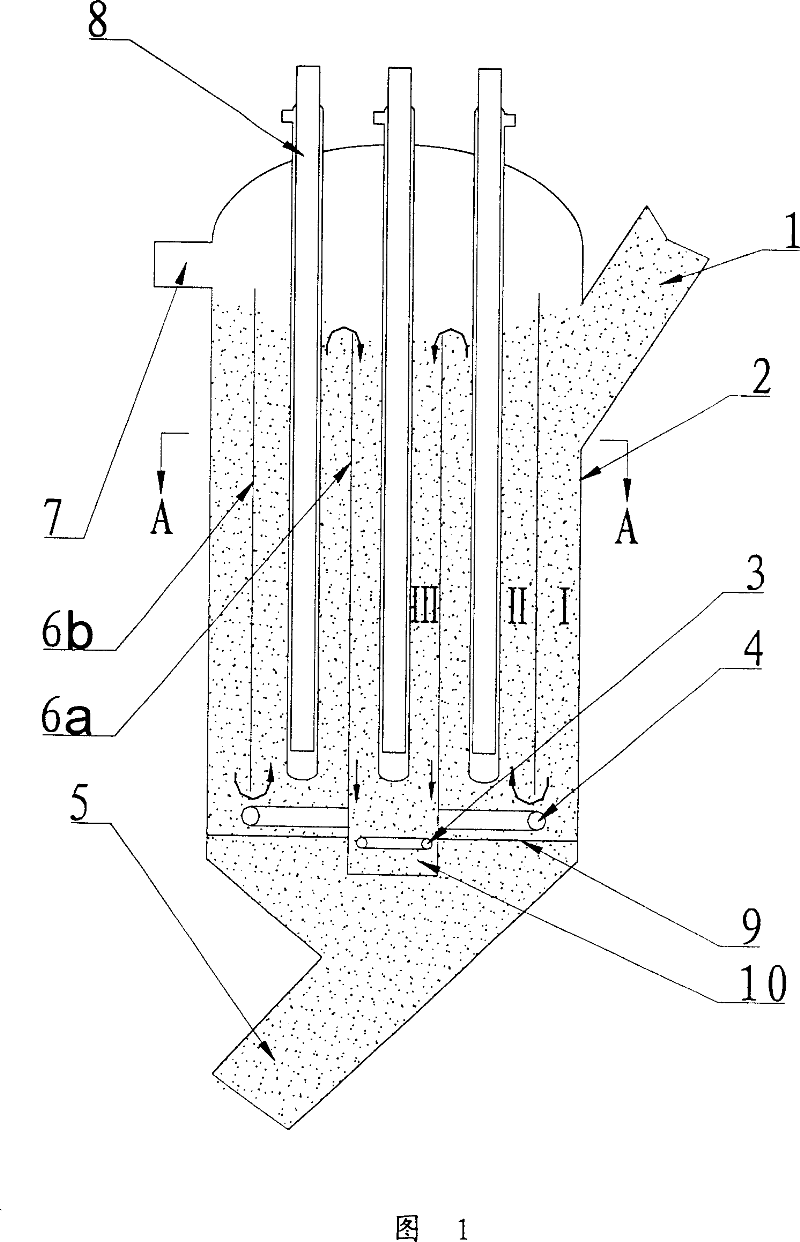

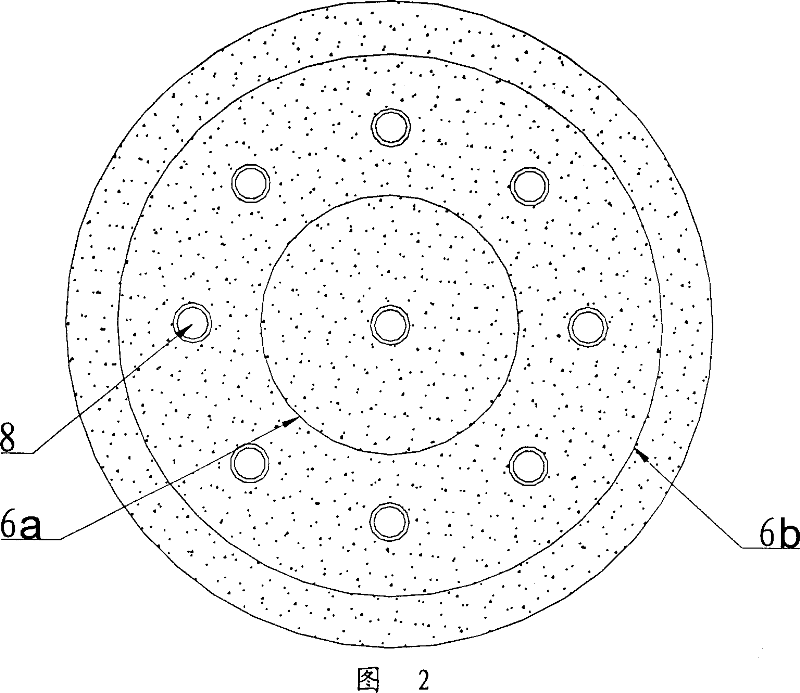

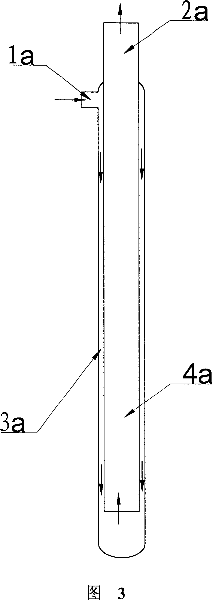

Regenerated catalyst steam-stripping device of flue gas

ActiveCN100337735CSolve the problem of entrained smokeReduce heat loadCatalyst regeneration/reactivationFlue gasEngineering

he regenerated catalyst gas stripper comprises: arranging regenerated catalyst lead-in tube (1) and stripping medium lead-off tube (7) on top of the stripper and regenerated inclined tube (5) on bottom of the stripper; fixing and connecting the bottom separation plate (9) with medium distributor (4) on top and stripper cylinder and catalyst outlet pipe (10); arranging the inner sleeve (6b) on top of distributor (4) with the top end of inner sleeve (6a) in inner sleeve (6b) lower than inner sleeve (6b) and the bottom end passing distributor (4) and separation plate (9) to form outlet pipe (10); arranging stripping medium distributor (3) in catalyst outlet pipe (10 under the heat tube (8) with lead-in and lead-out ends for heat medium outside the stripper and other part in stripper. This product has dual-function both for stripping and cooling.

Owner:CHINA PETROLEUM & CHEM CORP

Cooling system and method for multi-pressure condenser

PendingCN111878180AImprove heat exchange efficiencyReduce work lossCentral heating with accumulated heatCombination enginesPhysicsEngineering

The invention relates to a cooling system and method for a multi-pressure condenser. The cooling system comprises a steam condensing assembly, a cooling assembly and a heating assembly. The steam condensing assembly comprises a multi-cylinder multi-exhaust-steam turbine unit, condensers and rotary blocking plates, the condensers are connected to all cylinders of the multi-cylinder multi-exhaust-steam turbine unit, and the adjacent condensers are connected through the rotary blocking plates; the cooling assembly comprises a circulating water inlet pipeline and a circulating water return pipeline, a first water inlet pipeline of each condenser is communicated with the circulating water inlet pipeline, each condenser is connected with a first water return pipeline, and the first water returnpipelines are connected with the circulating water return pipeline; and the heating assembly comprises a heat supply network heater, a water supply connecting pipeline, a heat supply network water supply pipeline and a heat supply network water return pipeline, the first water inlet pipelines are connected with second water inlet pipelines, the second water inlet pipelines are connected with the heat supply network water return pipeline, the first water return pipelines are connected with second water return pipelines, and the second water return pipelines communicate with the water supply connecting pipeline; and the heat supply network heater is connected between the water supply connecting pipeline and the heat supply network water supply pipeline.

Owner:CHINA ENERGY CONSTR GRP SHAANXI ELECTRIC POWER DESIGN INST CO LTD

Ion source with evaporator

ActiveCN105862006BReduce lossIncrease evaporation rateVacuum evaporation coatingSputtering coatingEngineeringTemperature difference

The invention relates to an ion source with an evaporator; the ion source may have the evaporator, and uses the following one or more modes to reduce temperature difference in the evaporator; firstly, at least one heat insulator is arranged by partial a container and far away from a special heat source, wherein the container of the evaporator is heated by the special heat source; secondly, at least one heat insulator is arranged around the heater, wherein the container is arranged in the evaporator and heated by the heater; thirdly, at least one radiation shield is arranged so as to allow heat energy the pass the housing and a channel unit, wherein an arc chamber is connected with the housing through the channel unit in a machinery manner. The heat insulator can reduce heat energy loss, and the temperature difference in the evaporator is reduced; in addition, a hollow diffuser with a plurality of open pores is used for adding conductivity and reducing evaporated material condensation.

Owner:ADVANCED ION BEAM TECHNOLOGY INC

Flue gas stripping device

ActiveCN100351017CSolve the problem of entrained smokeReduce heat loadCatalytic crackingCatalyst regeneration/reactivationFlue gasFilling materials

This invention relates to smoke stripper, which comprises the following parts: regeneration catalyze agent conductive tube, smoke stripper cylinder, stripper filling materials, stripper medium distributor, regeneration inclined tube, stripper medium output tube, heat fetching tube, wherein, the conductive tube and the stripper medium output tube are located on the stripper and the inclined tube is located on the bottom of the stripper with more than one layers of materials on the stripper; the striper medium distributor is located below the filling materials; the heat fetching tube medium conductive end and output end are located outside the smoke stripper with rest inside. The stripper has regeneration agent to remove smoke and lower double functions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com