Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Fine graphics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

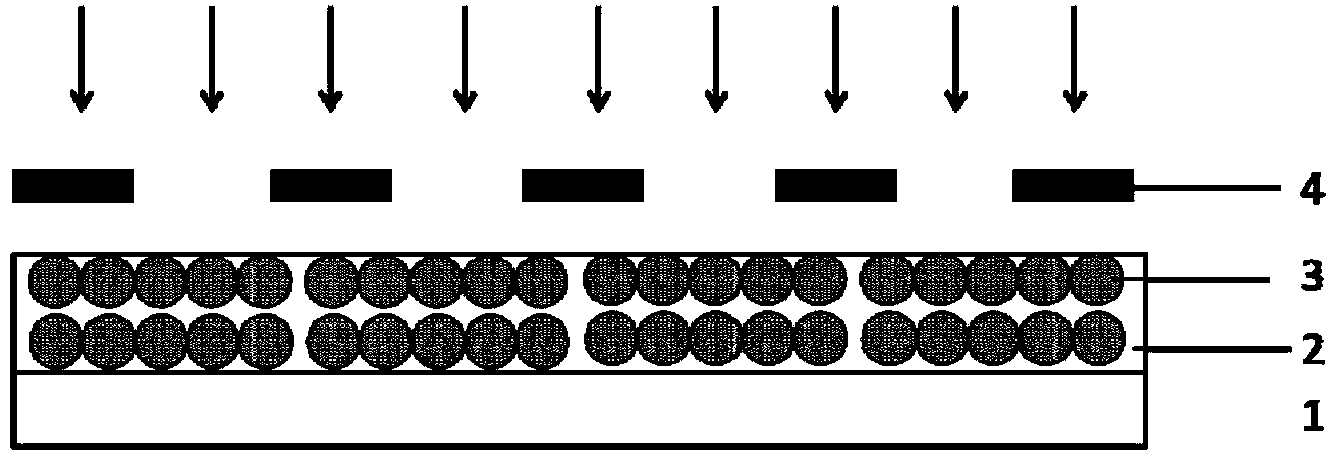

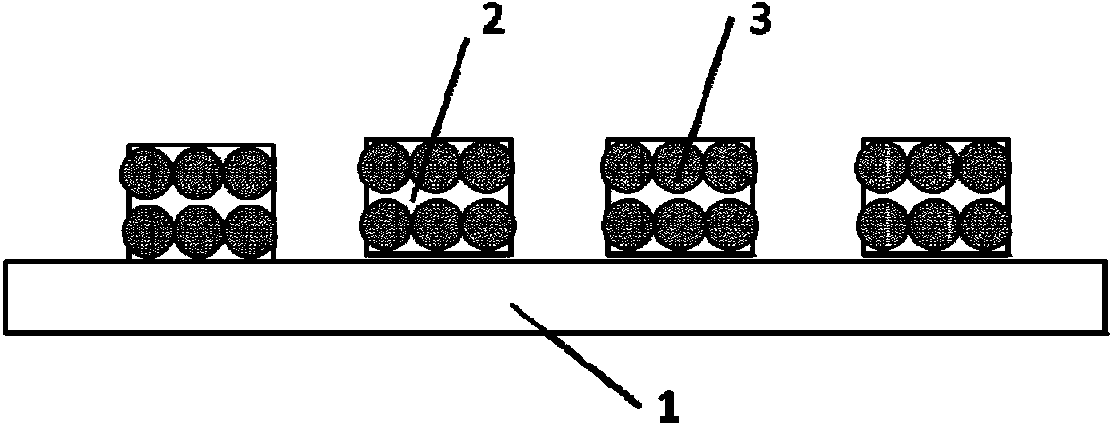

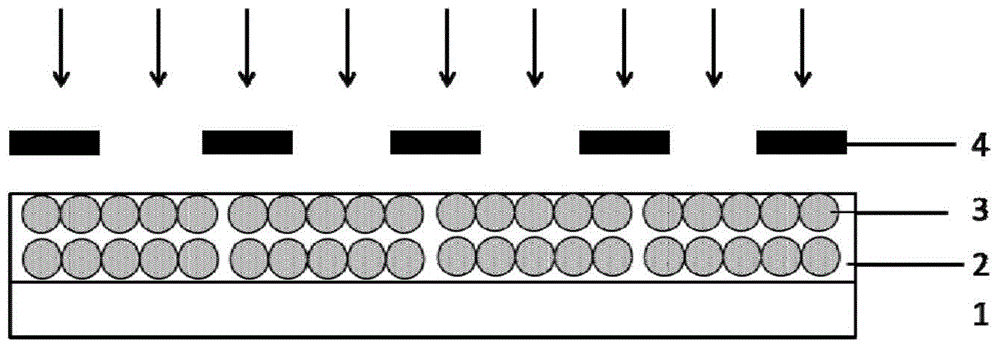

Photosensitive resin combination and method of preparing quantum dot pattern from photosensitive resin combination

ActiveCN103728837ASimple preparation processFine graphicsPhotomechanical exposure apparatusPhotosensitive material processingPhotoresistQuantum dot

The invention discloses a photosensitive resin combination and a method of preparing a quantum dot pattern from the photosensitive resin combination. The photosensitive resin combination is prepared from quantum dots which are dispersed in the photosensitive resin combination and are respectively provided with a modified layer. The method of preparing the quantum dot pattern from the photosensitive resin combination comprises the steps: with the photosensitive resin combination as a photoresist, carrying out coating, exposure and development to obtain the quantum dot pattern. The method of preparing the quantum dot pattern from the photosensitive resin combination has the advantage of being simple, the fine graph, the boding stability of the combination and a substrate, the difficulty in abscission, the high resolution and the like can be achieved. In addition, with the adoption of the method, based on existing equipment, the mass production of the quantum dot pattern can be realized, and the application potential of the quantum dots is greatly improved.

Owner:BOE TECH GRP CO LTD

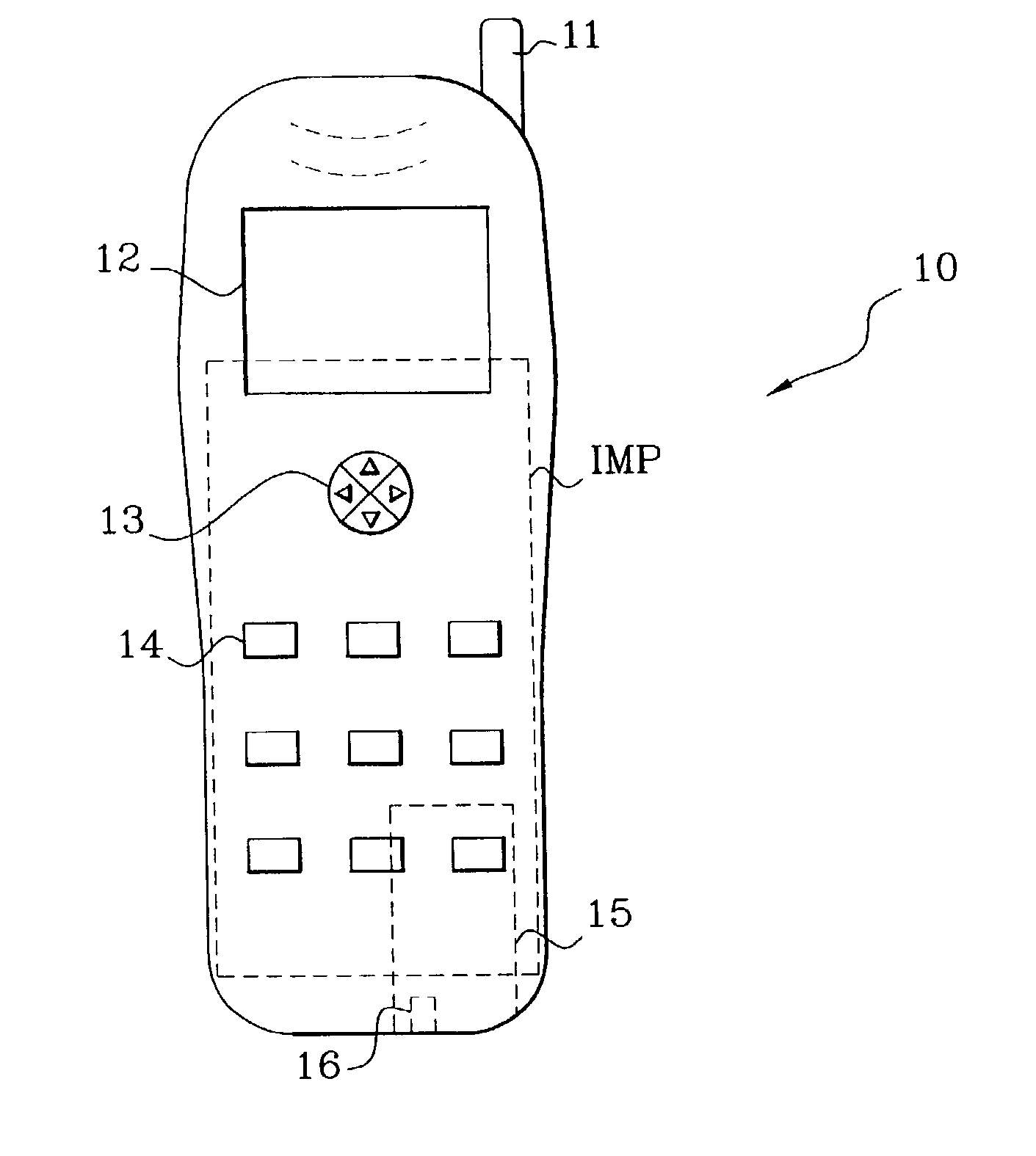

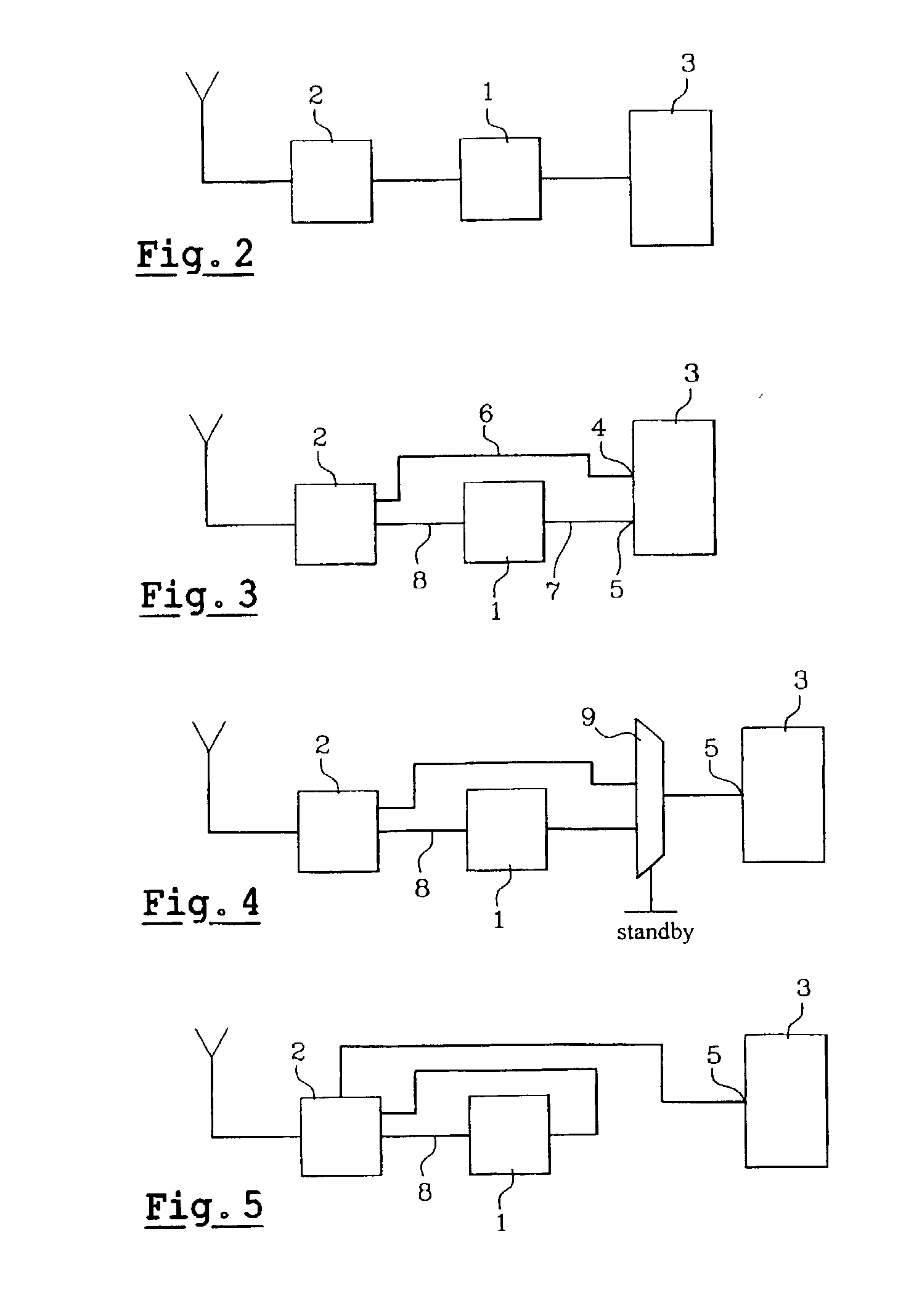

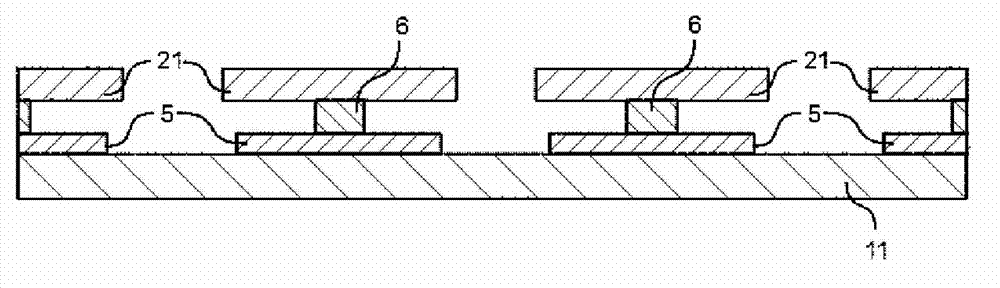

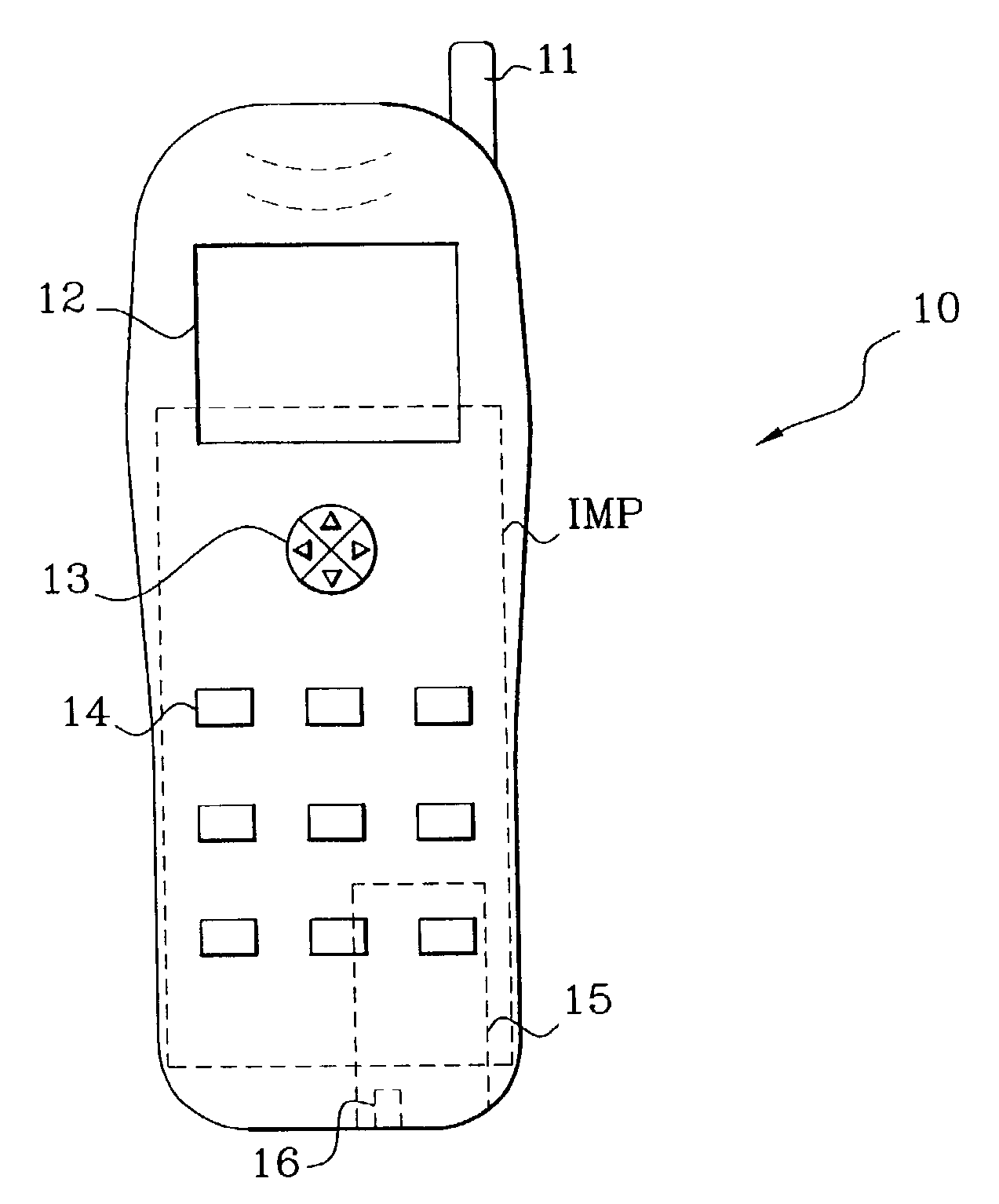

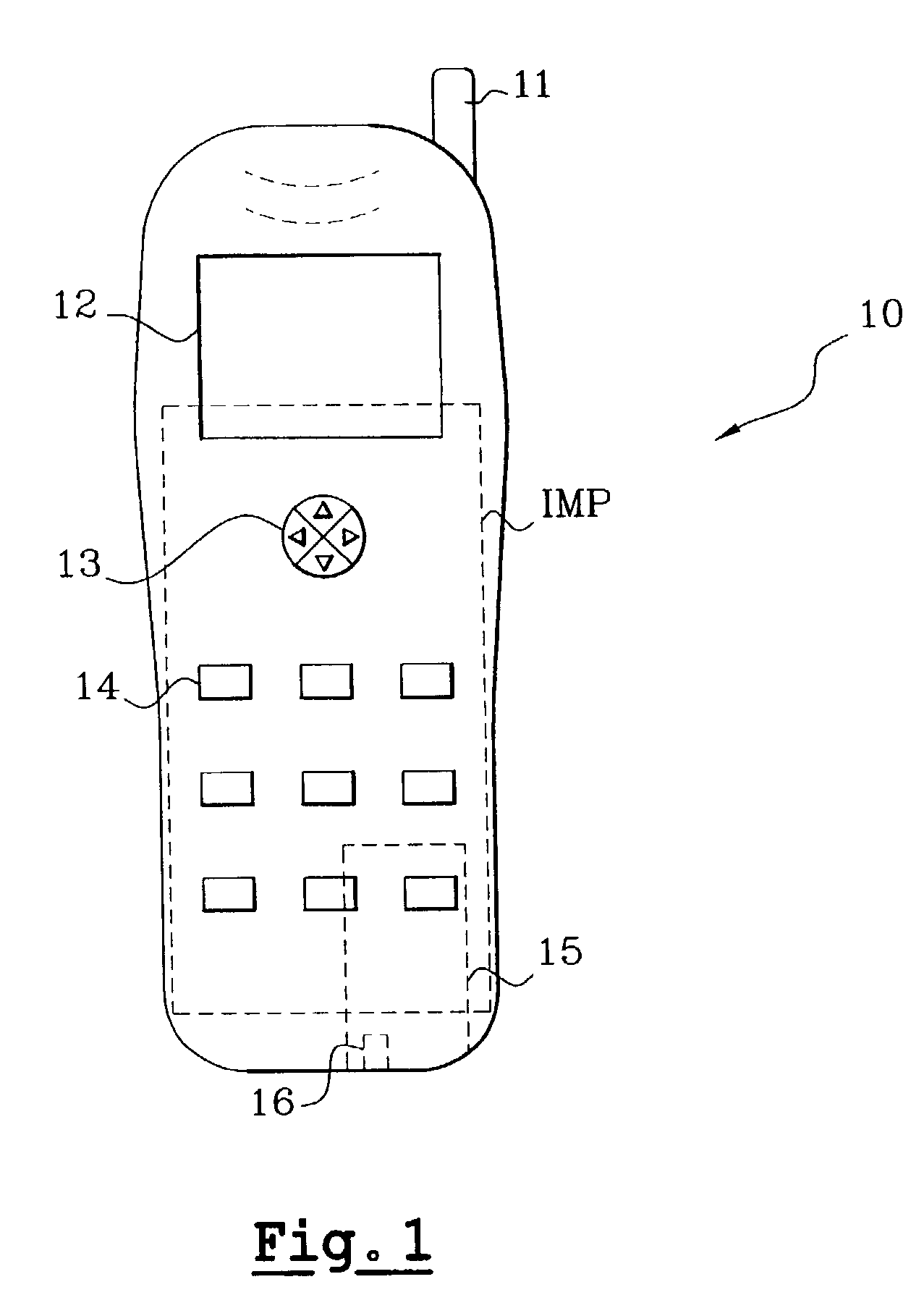

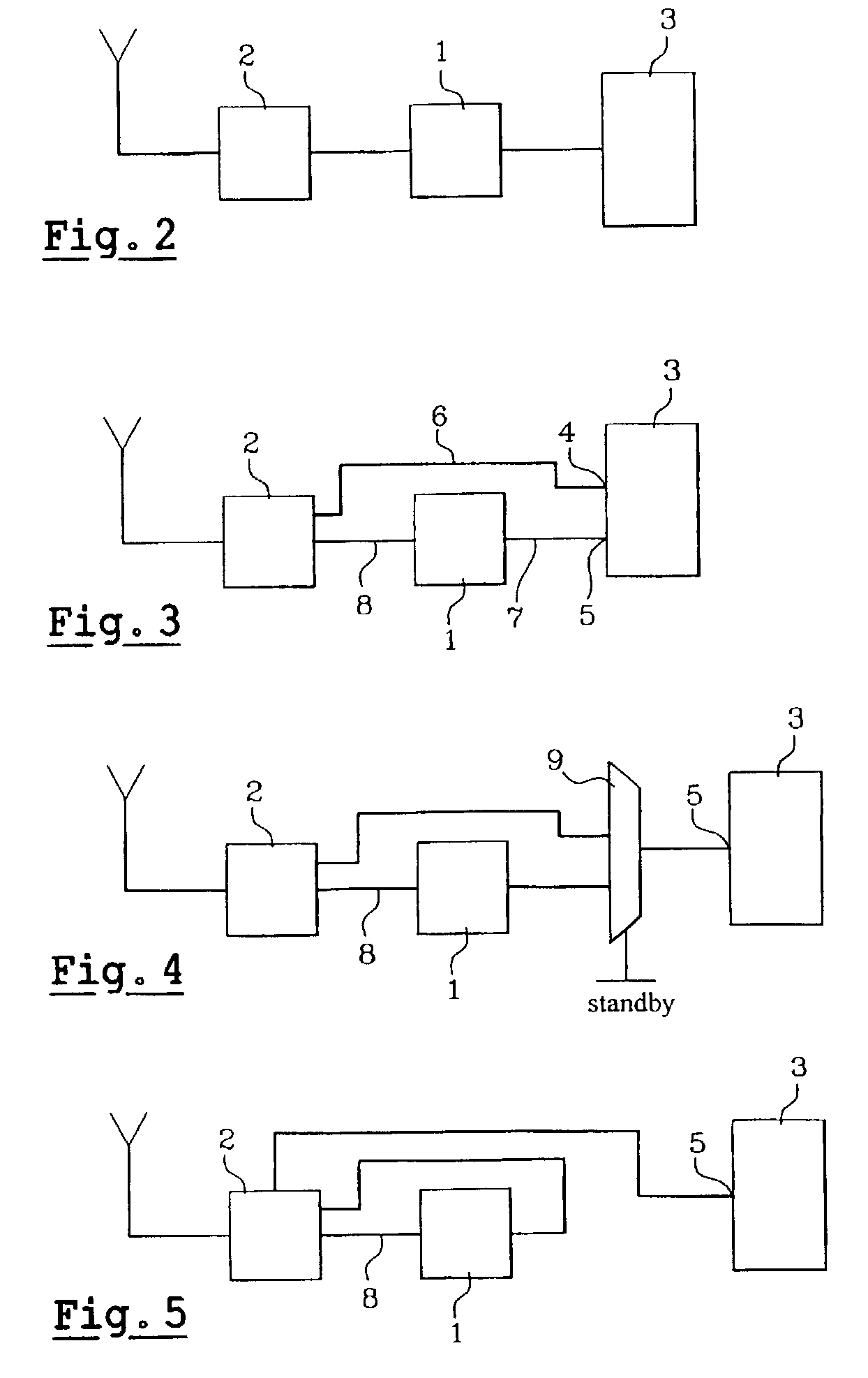

Optimizing the consumption of a multimedia companion chip in a mobile radio communications terminal

ActiveUS20030109287A1Mitigate such drawbackFine graphicsPower managementCurrent supply arrangementsGraphicsMobile radio

The present invention relates to a radio communications terminal (10) comprising a screen (12) controlled by a control module (3) and also at least two different types of microprocessor (1, 2), said first type of microprocessor (1) improving the graphics capabilities of said terminal (10) and driving said control module (3) of the screen (12), said second type of microprocessor (2) handling the other functions of said terminal (10), the terminal being characterized in that in standby mode said first type of microprocessor (1) is deactivated while second type of microprocessor (2) drives said control module (3) of the screen (12).

Owner:DRNC HLDG INC

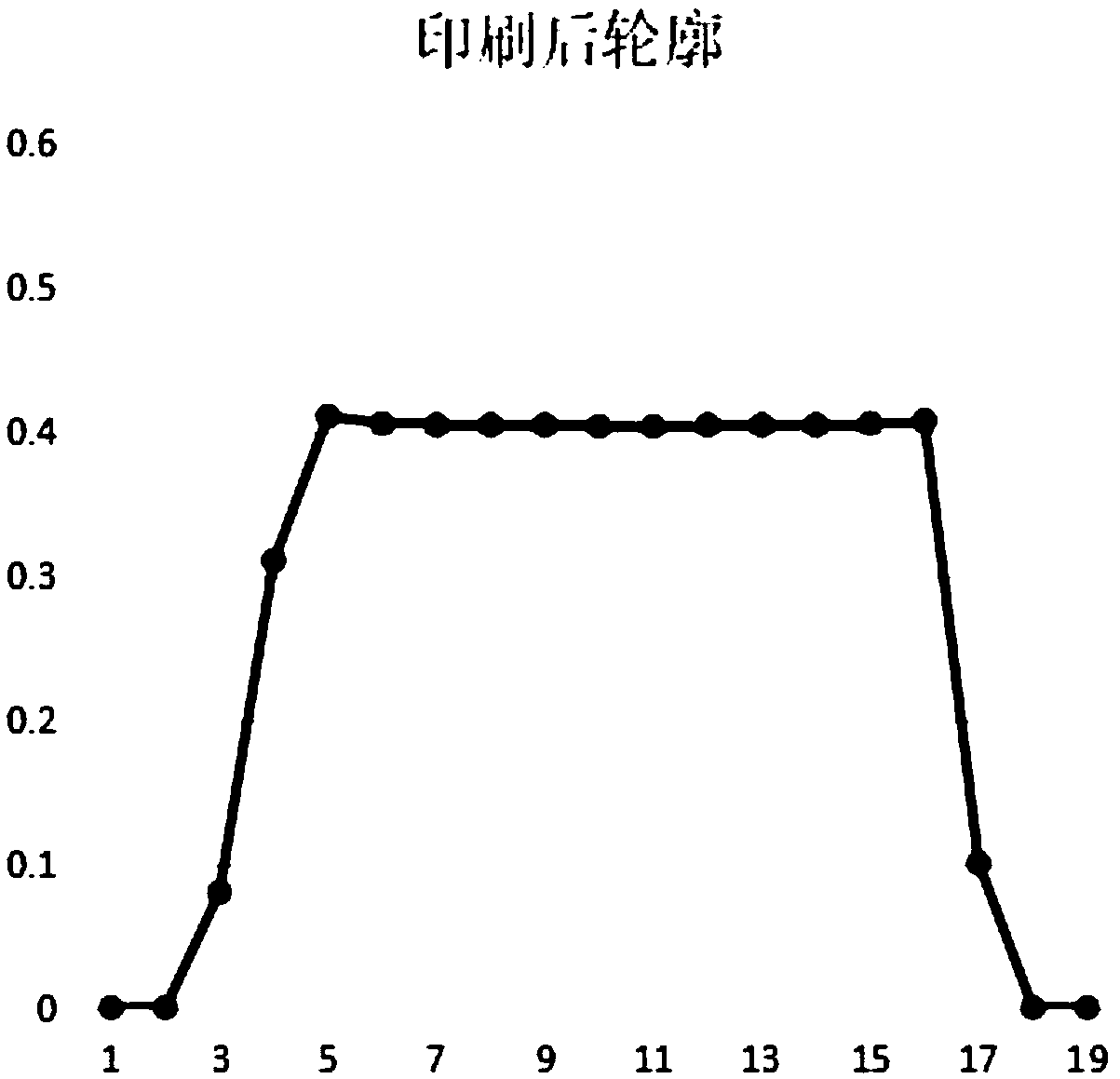

Nickel paste for multilayer ceramic capacitor based on gravure coating printing and application of nickel paste

ActiveCN109616321AQuality improvementImprove rheologyFixed capacitor dielectricStacked capacitorsConductive pasteOrganic solvent

The invention discloses nickel paste for a multilayer ceramic capacitor based on gravure coating printing and an application of the nickel paste; the nickel paste for the multilayer ceramic capacitorbased on gravure coating printing is characterized by comprising the following raw materials in parts by mass: 40-50 parts of nickel powder, 5-12 parts of ceramic powder, 0.1-2 parts of dispersing agent, 0.1-5 parts of plasticizer and 22.1-43 parts of glue, wherein the glue comprises the following substances of an organic solvent, resin and a thixotropic agent at the mass ratio of 80-98:2-4:0.1-0.2. The nickel paste has high rheological property and thixotropy, the requirements of the market are met, high-quality conductive paste can be obtained, and the pattern is good after being printed, and the nickel paste is free of burrs and the like; and after sintering, the continuity is high, and the yield is high, so that the production efficiency is improved, and the production cost is lowered.

Owner:大连海外华昇电子科技有限公司

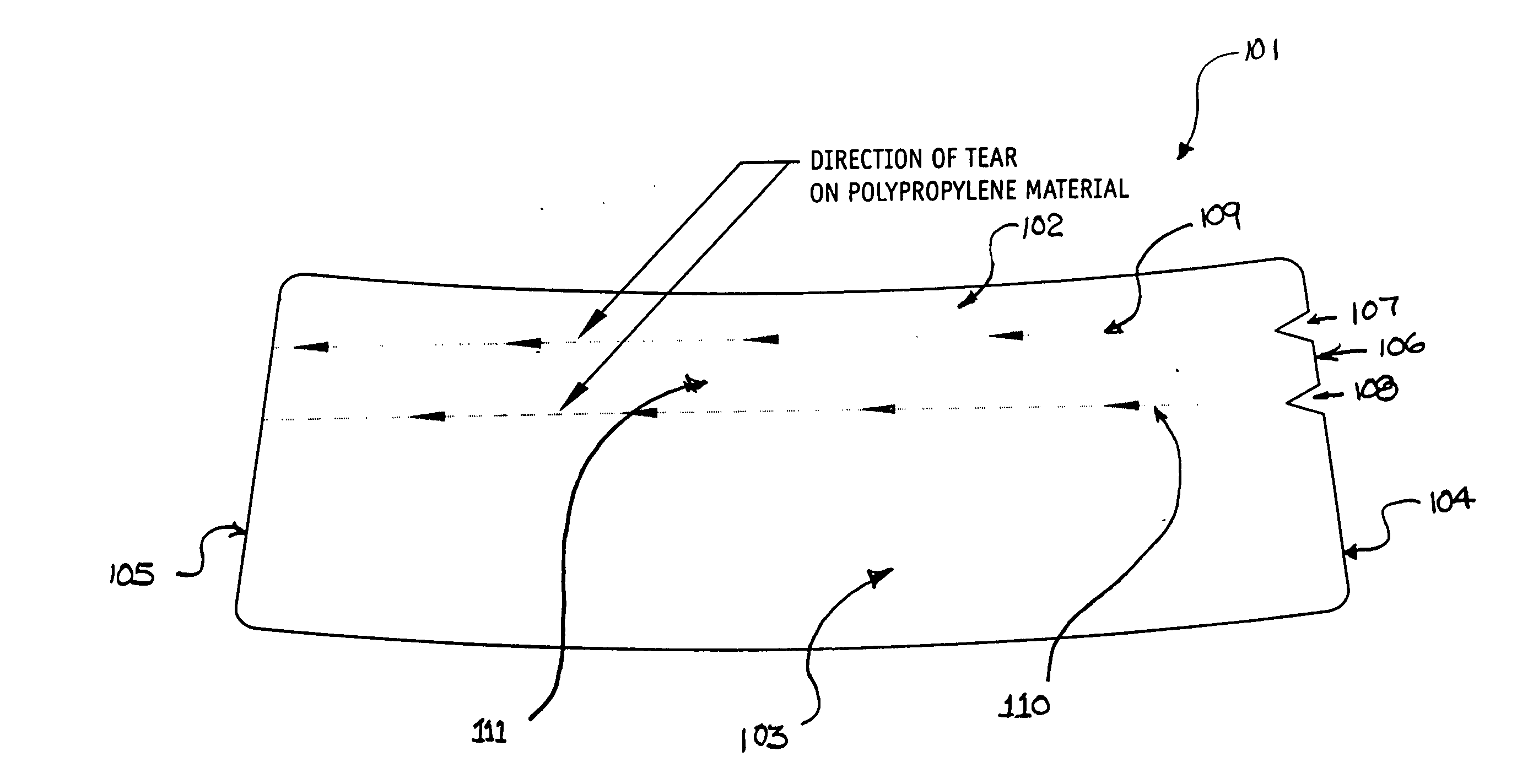

Neck band using straight-tear film

An improved neck band is provided for a container having a neck and removable closure at the end. The neck band is prepared from a straight-tear film, preferably a polypropylene film that has been oriented in a single direction. The neck band is provided with a tab and is attached to the neck and removable closure so that when the tab is pulled, the polymer material separates along a line around the circumference of the neck adjacent the skirt of the removable closure.

Owner:RENAISSANCE MARK

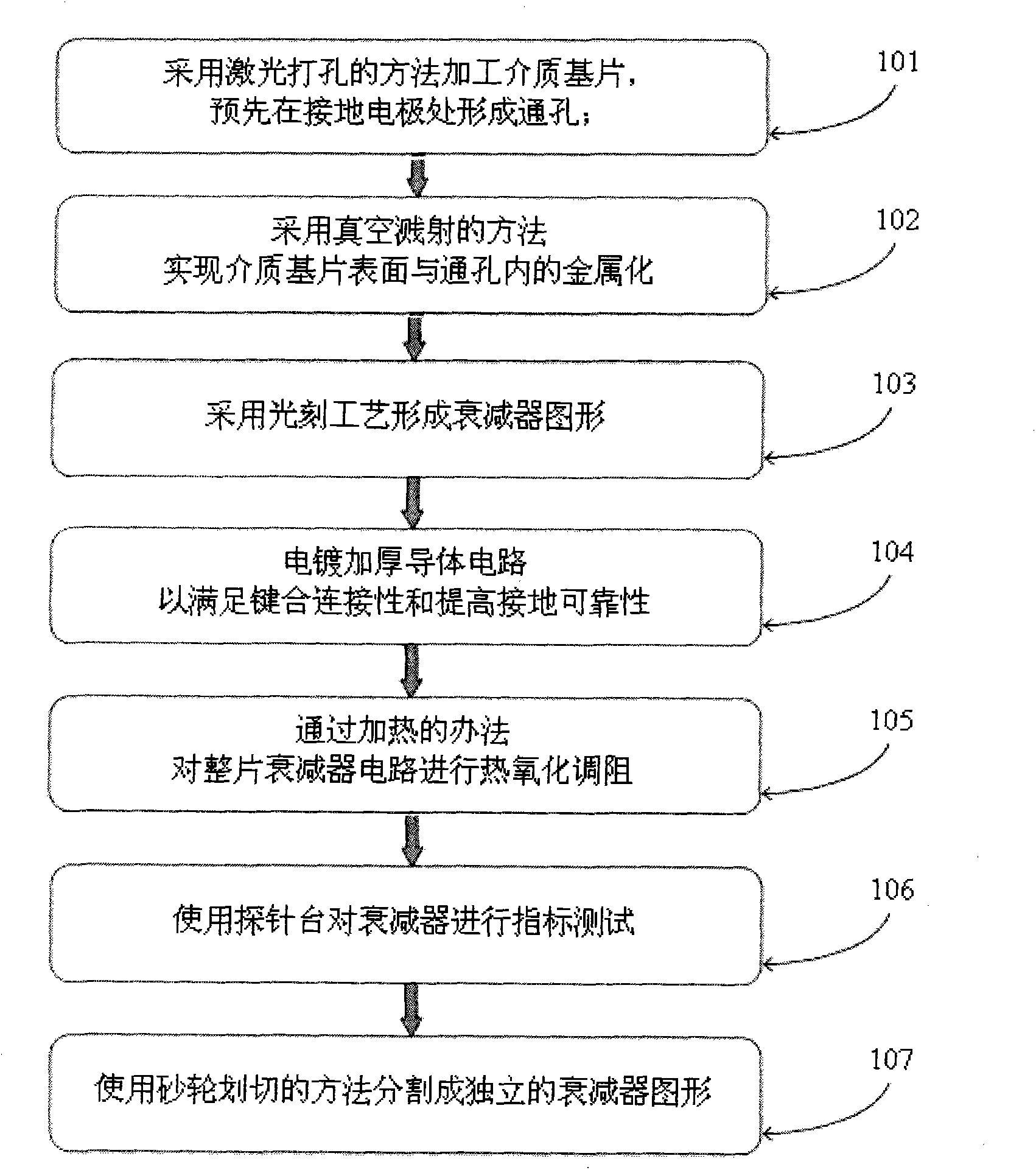

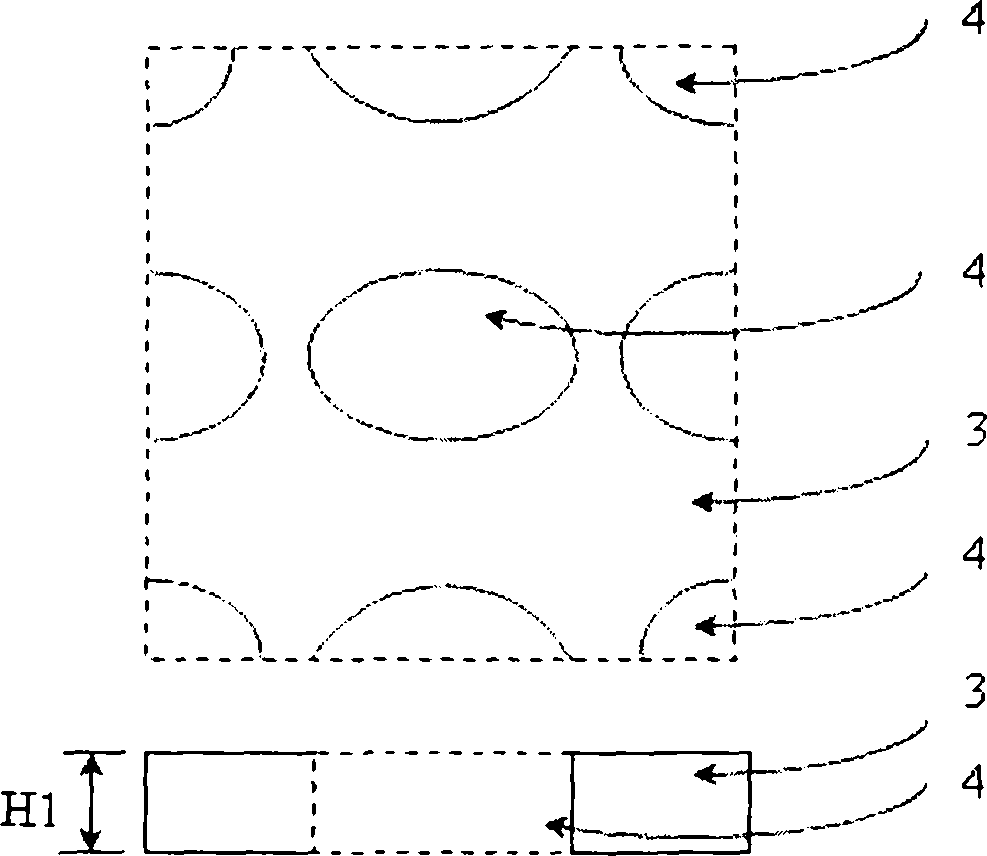

Method for manufacturing microwave thin film attenuator

InactiveCN103545590AFine graphicsMiniaturizationWaveguide type devicesSputteringElectrical conductor

The invention belongs to the technical field of attenuators and relates to a method for manufacturing a microwave thin film attenuator. The method comprises the steps that a medium substrate is processed through a laser cutting method, and a through hole is formed in the position of a grounding electrode; metallization of the surface of the medium substrate and the inside of through hole is achieved through a vacuum sputtering method, and a metallized film layer structure is formed; a attenuator diagram is formed through the photolithography technique; a conductor circuit is thickened through electroplating; thermal oxidation resistance adjustment is conducted on the whole piece of attenuator through a heating method, a probe station is utilized to conduct index testing on the attenuator; independent attenuator diagrams are formed in a cutting method, and the lateral metallization effect is presented on the four corners of the attenuator. The method for manufacturing the microwave thin film attenuator can achieve the fine circuit diagrams, is favorable for being minimized, meets the requirements for the occasions of high frequency application, avoids single sheet manual edge wrapping and grounding, improves production efficiency, and is favorable for volume production.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

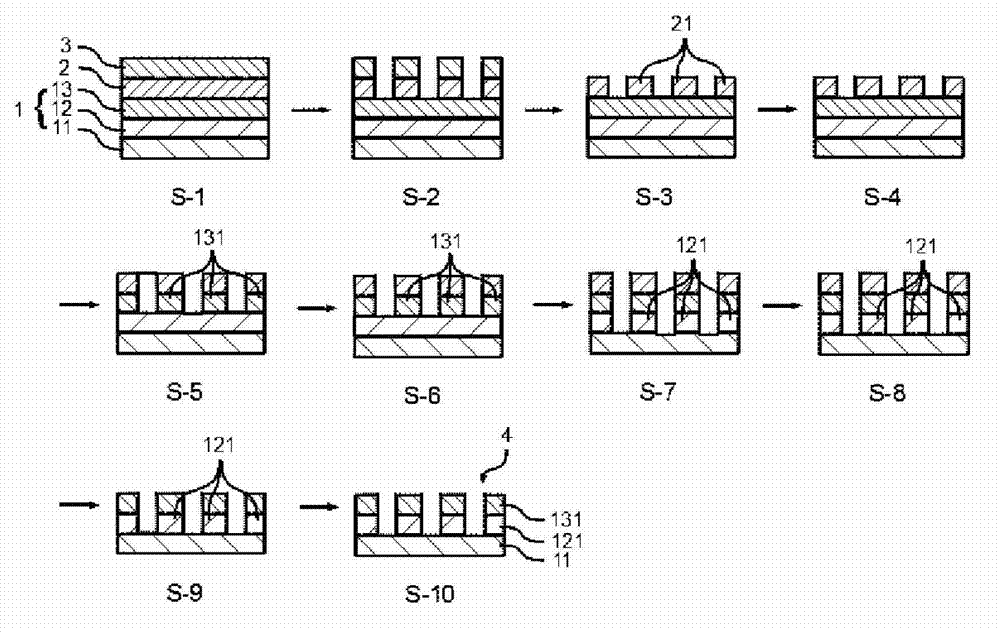

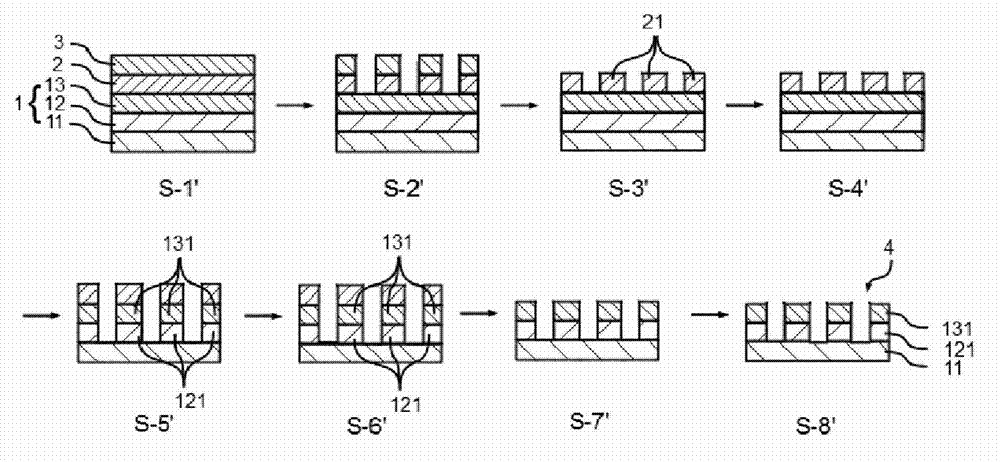

Dual graphing method

ActiveCN102478764AHigh precisionReduce line widthPhotomechanical apparatusSemiconductor/solid-state device manufacturingGraphicsPhotoresist

The invention relates to a dual graphing method. The method comprises the following steps: 1, respectively providing a substrate and a stamping die, wherein a hard mask layer is formed on the substrate, the stamping die has a first graph, and the material of the hard mask is a metal or a metal compound; 2, stamping the hard mask layer by the stamping die to transfer the first graph to the hard mask layer; 3, forming a photoresist layer to cover the stamped hard mask layer; 4, graphing the photoresist layer to define a second graph; and 5, etching the hard mask layer with the graphed photoresist layer as a mask layer to transfer the second graph to the hard mask layer. The method is in favor of improving the graphing precision, reducing the graph line width and improving the device integration level.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

Etching liquid composition and etching method

InactiveCN103046050AReduce etch rateEtching speed is fastSurface treatment compositionsCopper chlorideDisplay device

The invention relates to a display device of a flat panel display (FPD) and an etching liquid composition for the transparent conductive film used for the electrodes of a solar cell or a touch control panel, and provides an etching liquid composition for etching transparent conductive films such as copper and / or copper alloy film and indium tin oxide simultaneously, which includes hydrochloric acid, ferric chloride or copper chloride and water, wherein the concentration of hydrochloric acid is from 15.0 to 36.0 weight%, and the concentration of ferric chloride or copper chloride is from 0.05 to 2.00 weight%.

Owner:KANTO CHEM CO INC

Optimizing the consumption of a multimedia companion chip in a mobile radio communications terminal

ActiveUS7058427B2Mitigate such drawbackFine graphicsPower managementCurrent supply arrangementsGraphicsEngineering

A radio communications terminal (10) having a screen (12) controlled by a control module (3) and also at least two different types of microprocessor (1, 2), the first type of microprocessor (1) improving the graphics capabilities of the terminal (10) and driving the control module (3) of the screen (12), the second type of microprocessor (2) handling the other functions of the terminal (10), the terminal being characterized in that in standby mode the first type of microprocessor (1) is deactivated while the second type of microprocessor (2) drives the control module (3) of the screen (12).

Owner:DRNC HLDG INC

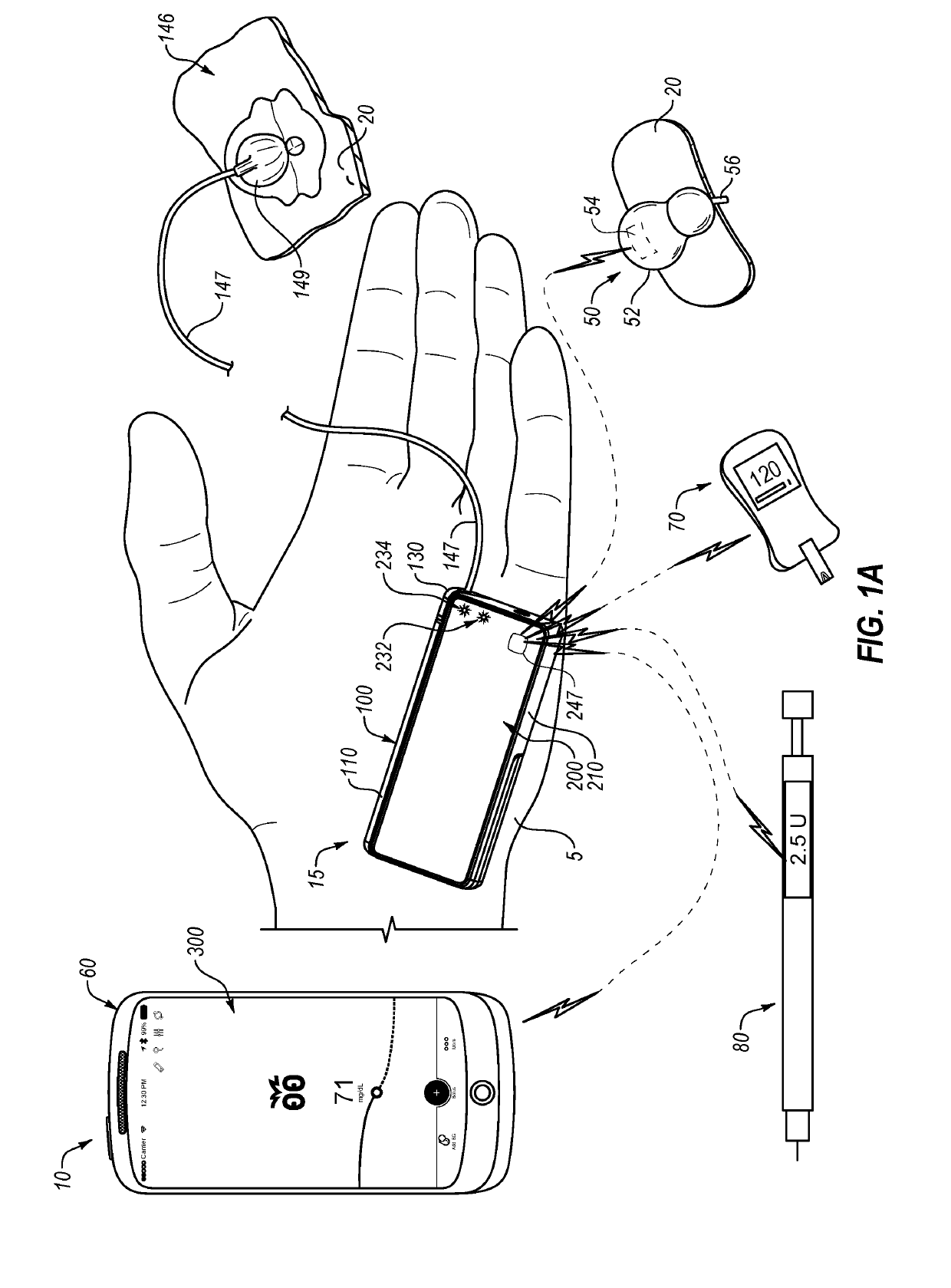

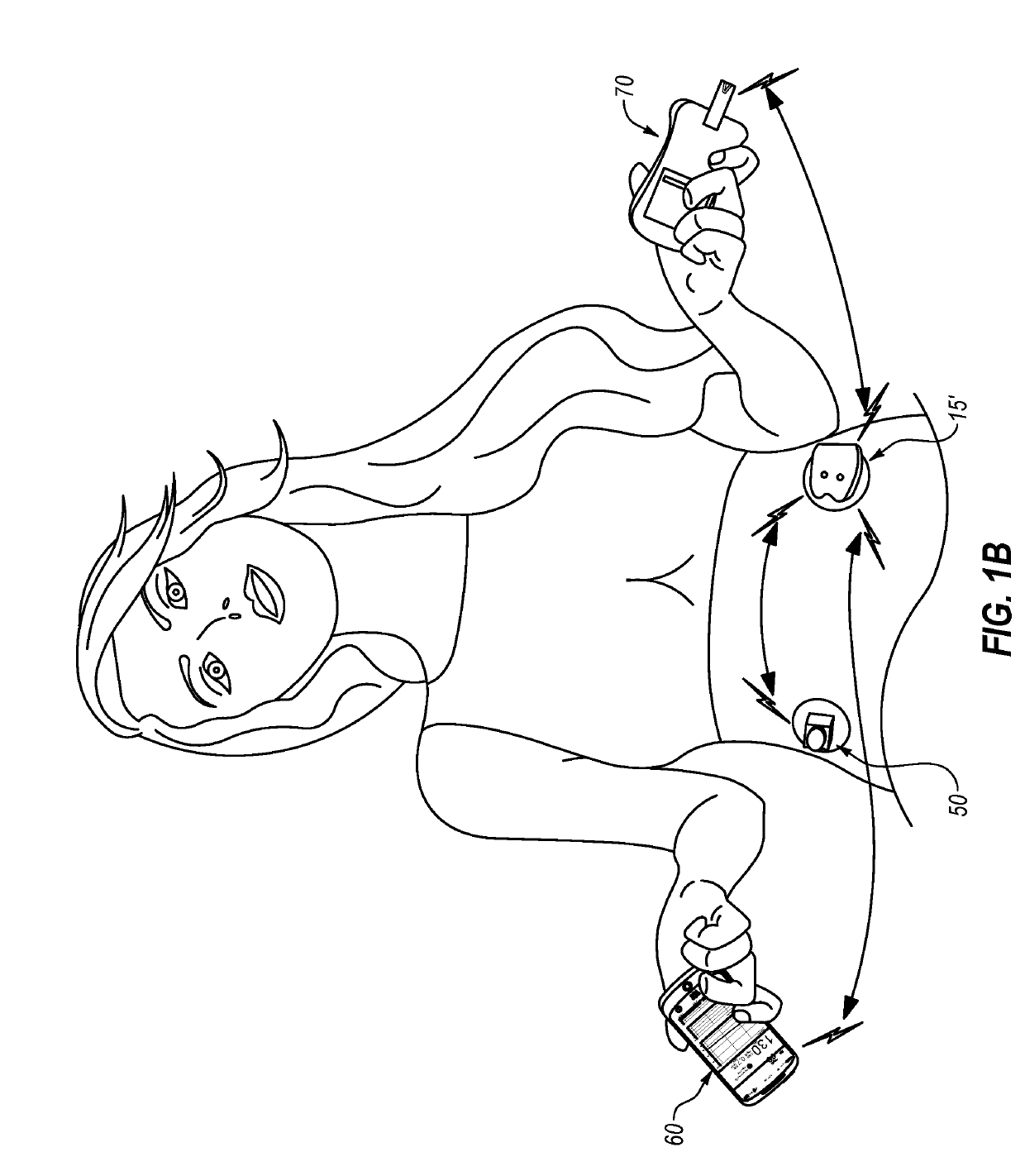

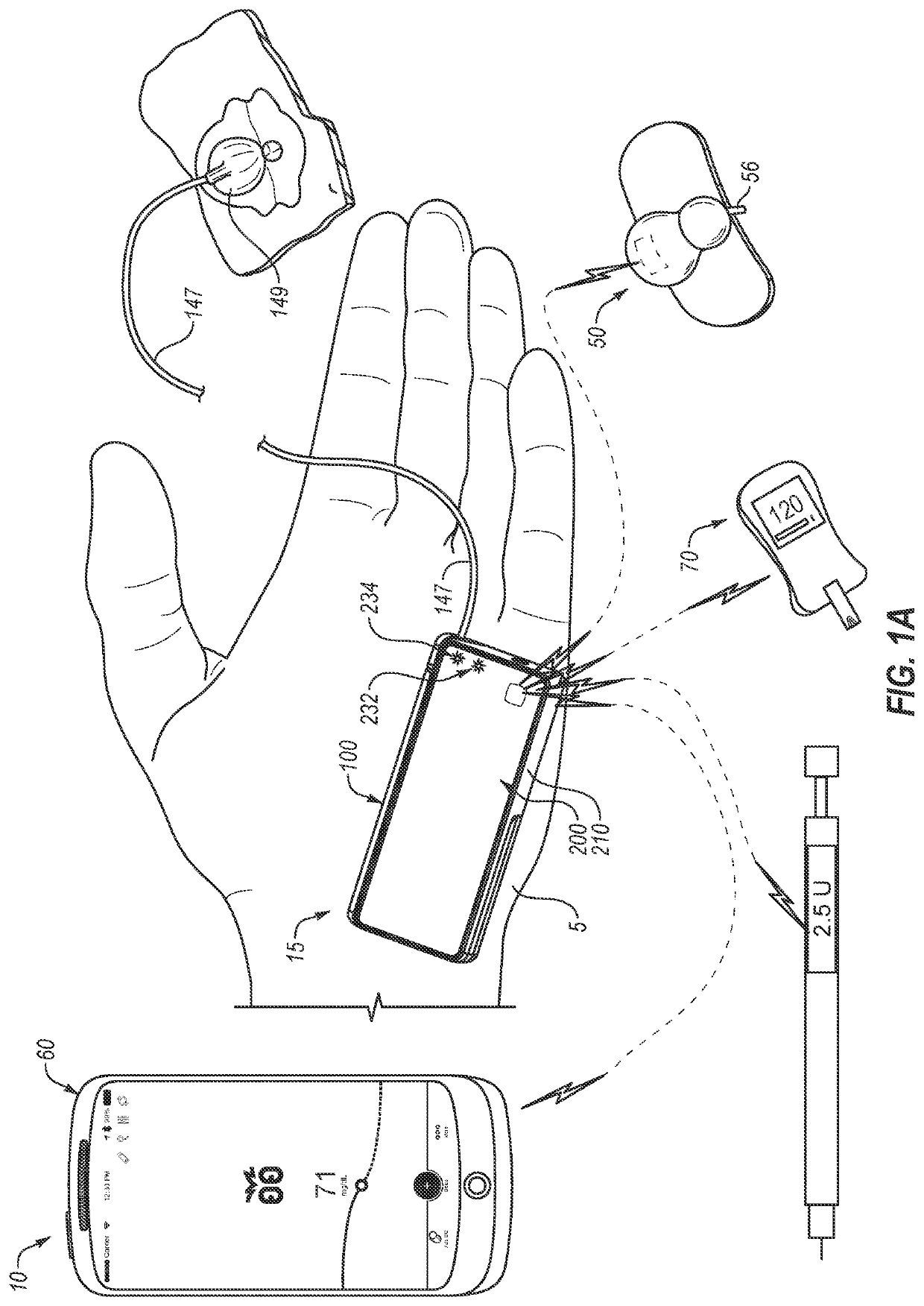

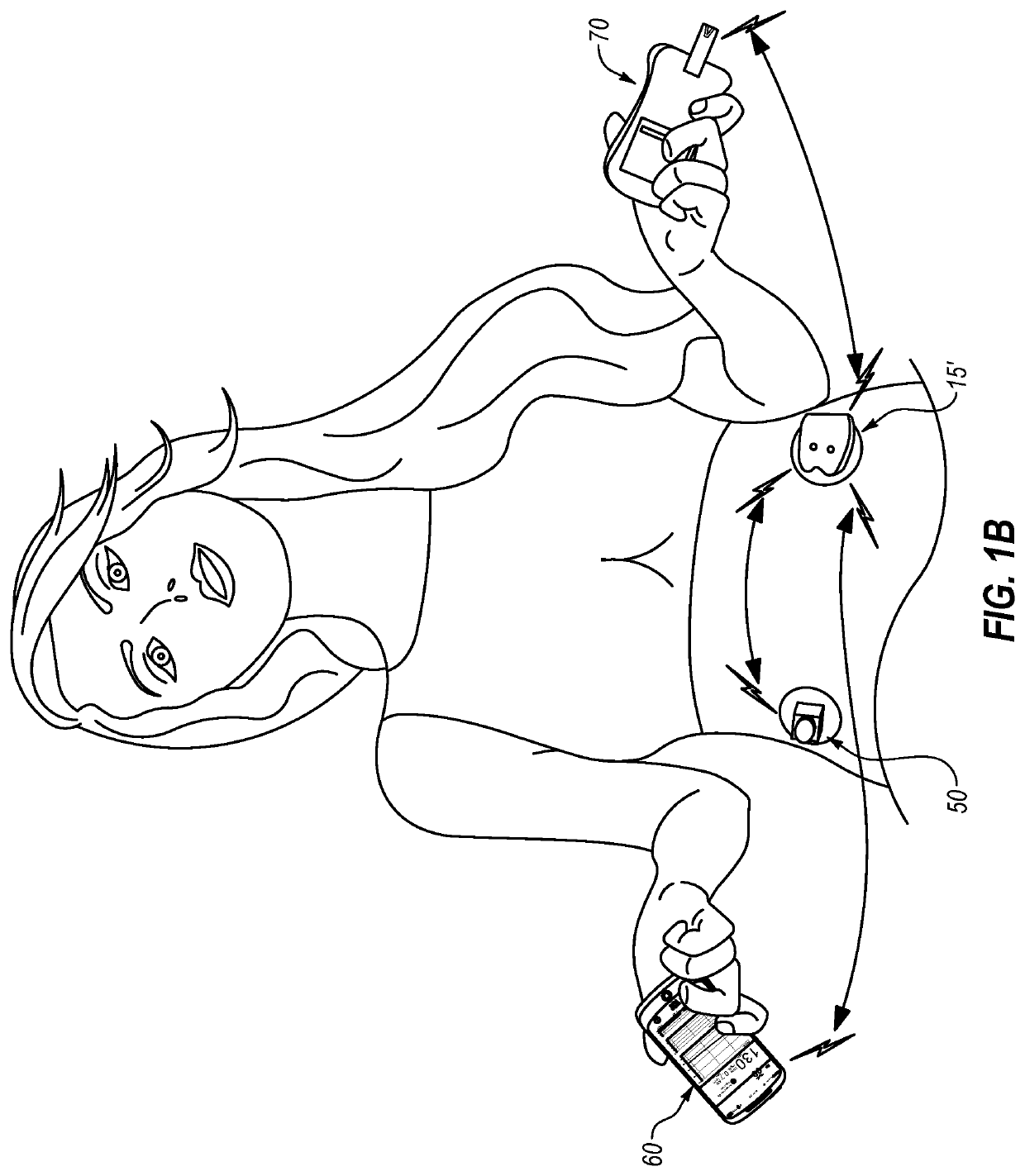

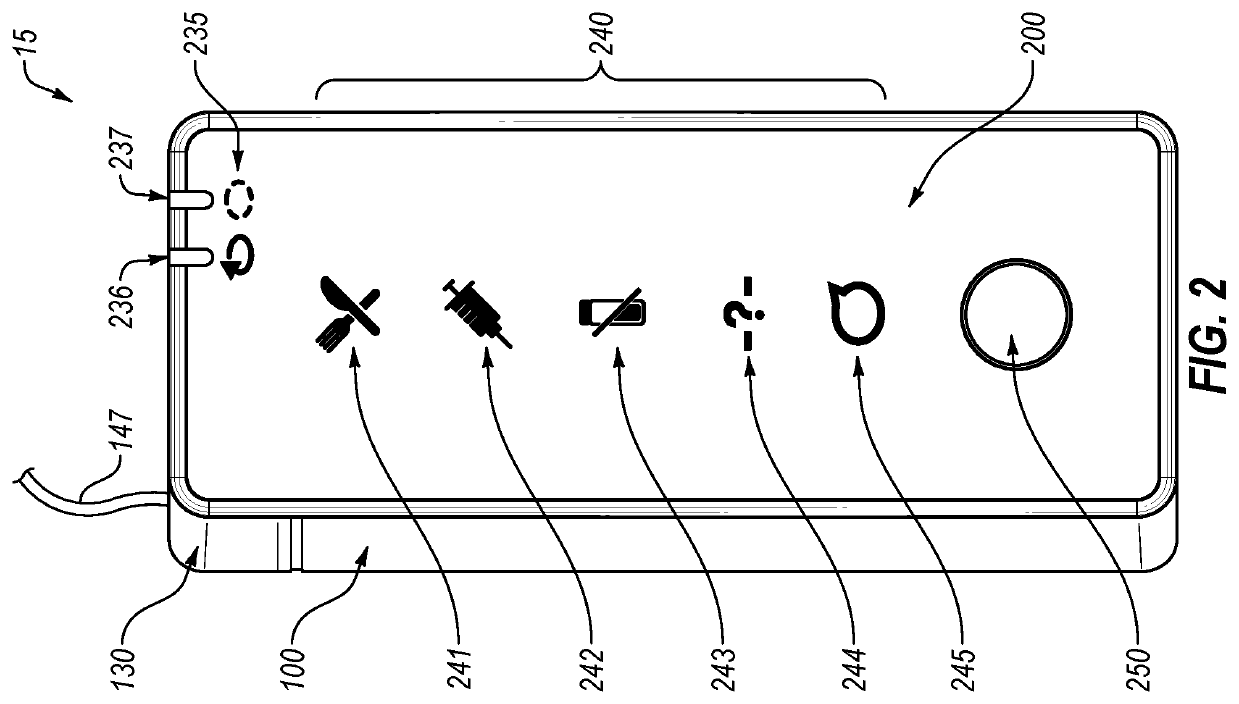

Alarms and alerts for medication delivery devices and systems

ActiveUS20190274624A1Save powerReduce needSensorsBlood characterising devicesGlucose sensorsDiabetes management

Systems, methods, and devices provide alarms and alerts in an on-body networked diabetes management system. Methods may include receiving glucose sensor data from a continuous glucose monitor and determining a dosage of insulin delivery based at least in part on the glucose sensor data. The method may include detecting an alarm or alert condition, and sending a wireless communication regarding the alarm or alert condition to a remote user-interface device. The method may include triggering an audible, visual, or haptic alarm or alert on the insulin delivery device unless an acknowledgement of the alarm or alert condition is received within a predetermined period of time.

Owner:BIGFOOT BIOMEDICAL INC

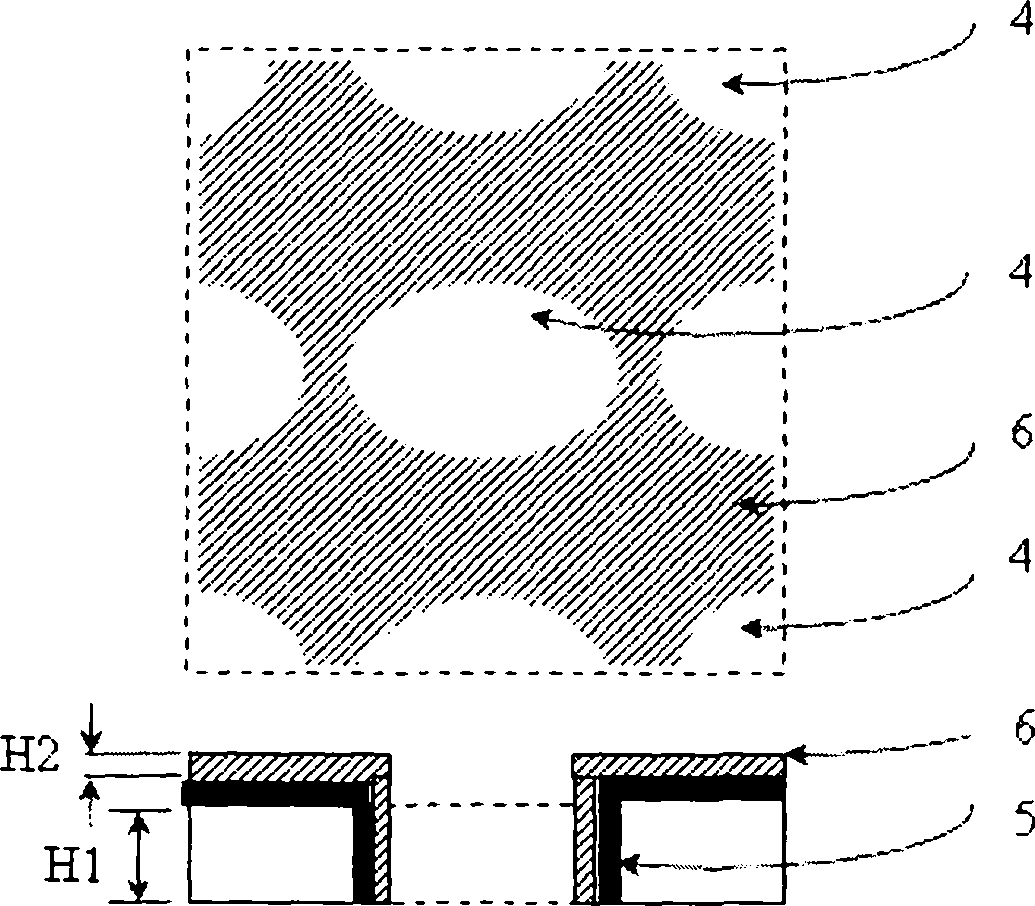

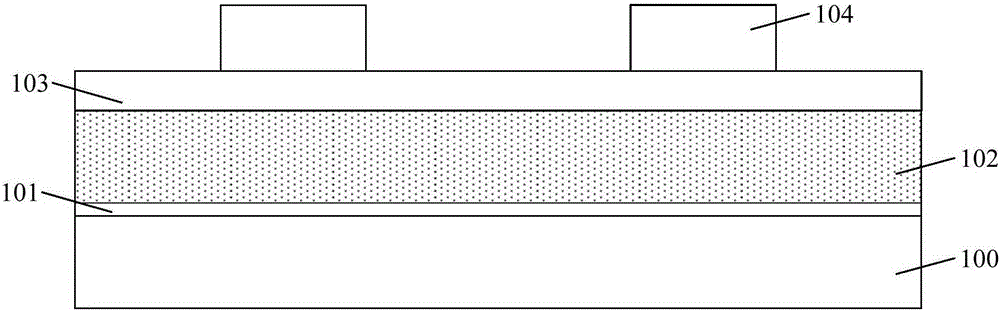

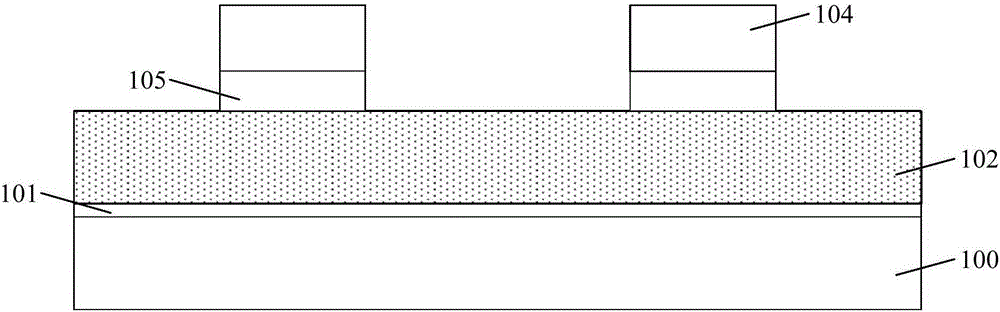

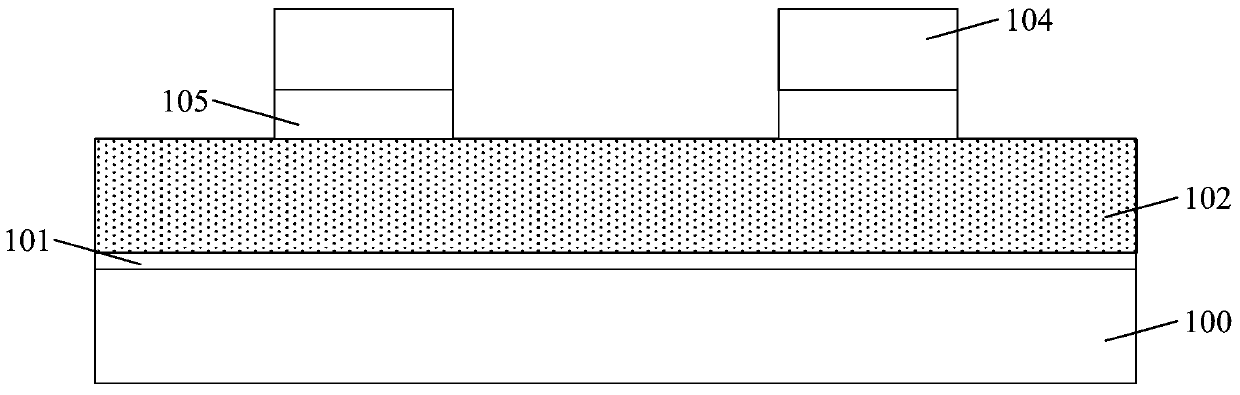

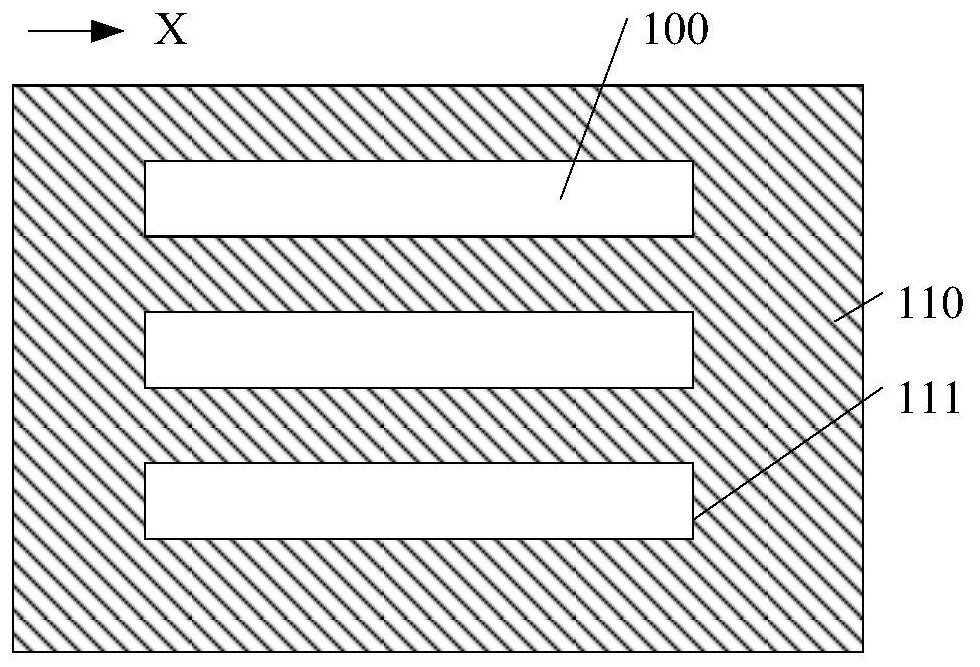

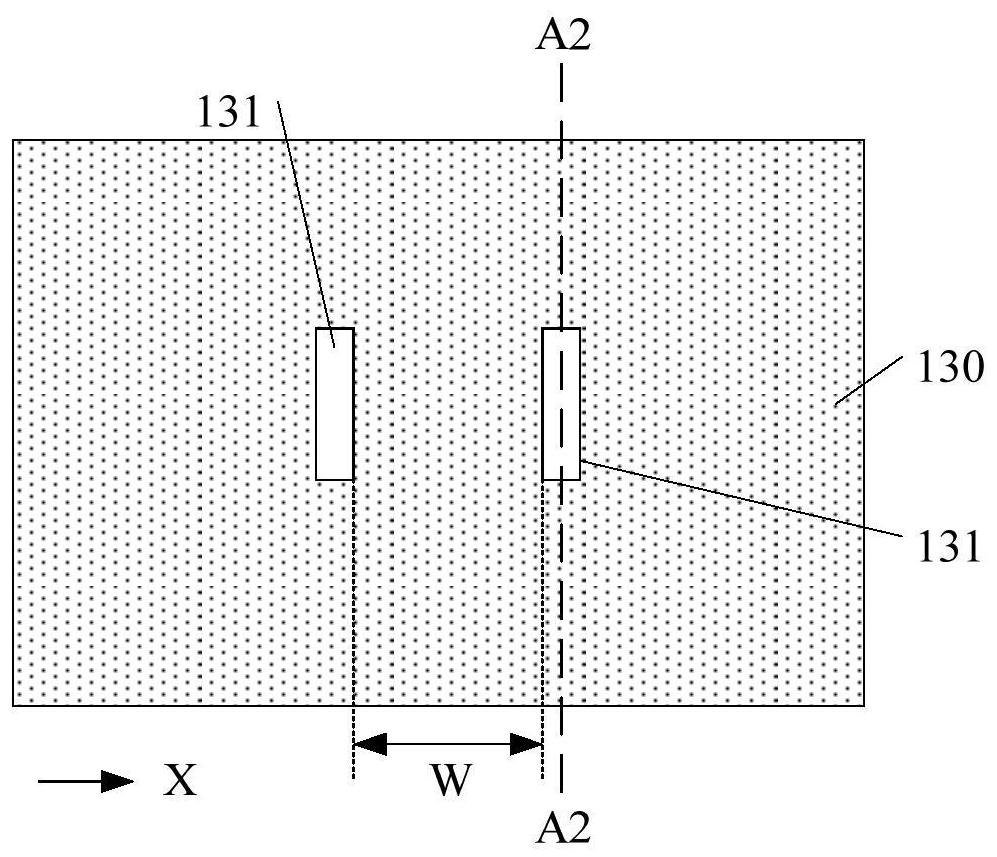

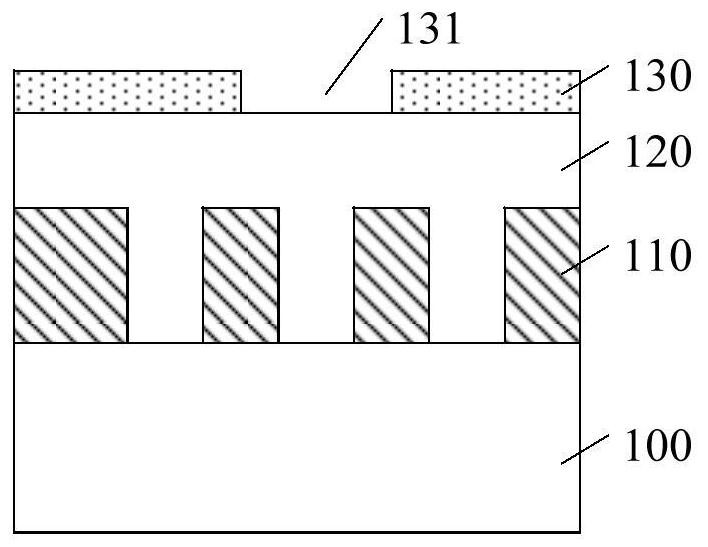

Etching mask group and substrate etching method applying same

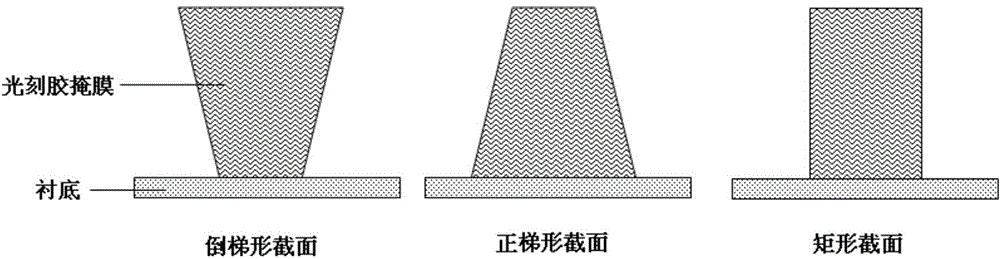

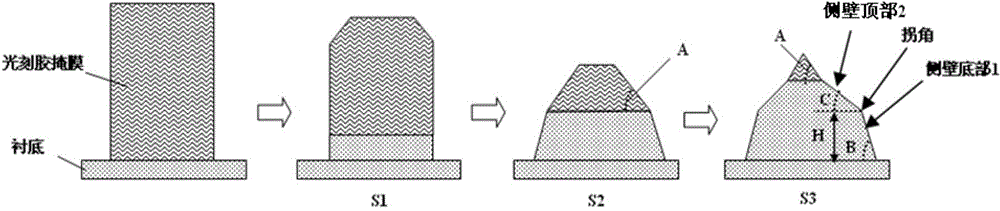

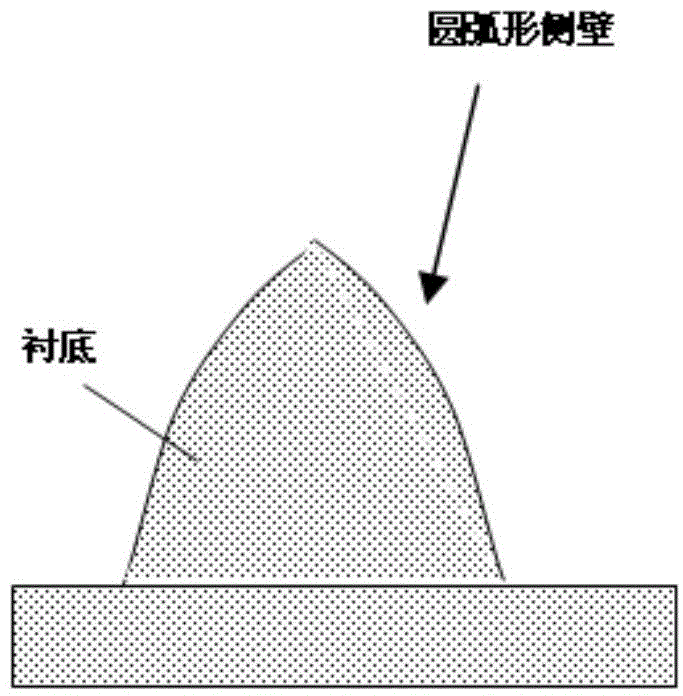

ActiveCN105655231ASlow down lateral shrinkageReduce cornersSemiconductor/solid-state device manufacturingEtching selectivityPhotoresist

The invention provides an etching mask group and a substrate etching method applying the same. The etching mask group comprises a first mask layer made of a photoresist material, and a second mask layer made of a material capable of improving an etching selectivity ratio relative to a substrate, wherein the first mask layer is arranged on the surface of the substrate, the second mask layer is arranged on the first mask layer; and the widths of the bottom portions of respective patterns of first mask layer and the second mask layer are arranged in such a way that the inclination angle of a preset connecting line between the first mask layer and the second mask layer is consistent with a fixed inclination angle of the first mask layer. The etching mask group provided by the invention can realize the purpose of improving the pattern morphology of the substrate.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Preparation method for glass plate with color ink pattern, and glass plate

The invention provides a preparation method for a glass plate with a color ink pattern. The preparation method comprises the following steps: a, cleaning a toughed glass substrate; b, coating the entire surface of the clean glass substrate with a wet-film photoresist and pre-baking the wet-film photoresist, or laminating the clean glass substrate with a dry-film photoresist, and then removing the photoresist located at a position where eventual formation of a first color ink pattern is needed through exposing and developing procedures; c, spraying first color ink on the entire photoresist surface of the glass substrate obtained in the step b, and carrying out baking to immobilize the ink; d, peeling the entire photoresist film layer of the glass substrate obtained in the step c by using a photoresist stripper solution so as to left a pattern formed by the first color ink; and e, spraying bottom-color ink onto the entire pattern surface of the glass obtained in the step d and carrying out baking so as to obtain the glass plate with the color ink pattern. With the method provided by the invention, the elaborate color pattern with straight edges can be obtained on the glass plate.

Owner:LENS TECH CHANGSHA

Sintered type electronic conductive gold paste and preparation method thereof

InactiveCN110322983AGood co-firing matchingImprove compactnessNon-conductive material with dispersed conductive materialCable/conductor manufactureArray data structureIntegrated circuit layout

The invention particularly relates to sintered type electronic conductive gold paste and a preparation method thereof. The gold paste comprises the following components in parts by weight: 70-80% of gold powder, 5-10% of glass powder, 10-20% of an organic carrier and 0.5-3% of an assistant. The raw materials are stirred and mixed uniformly according to a proportion, and a mixture is grinded and filtered to obtain the sintered type electronic conductive gold paste. The cofiring matching between the sintered type electronic conductive gold paste and a ceramic substrate is good; after a film is formed by sintering, the square resistance of a film layer is less than or equal to 5 milliohm / square, and the film layer is high in compactness; the surface is flat and smooth; the stripping adhesiveforce is larger than or equal to 50N / (2*2)mm<2>; and the gold paste does not contain harmful elements such as lead, cadmium and the like, is environment-friendly, simple in preparation process and easy to industrialize, and can be widely applied to a thick-film hybrid integrated circuits (HIC), a large-scale integrated circuit (LSI), a ceramic encapsulated integrated circuit (IC), a thermistor, asemiconductor package, a multilayer wiring circuit, a hybrid integrated circuit and the like.

Owner:TAIYUAN HYPERION NEW MATERIAL CO LTD

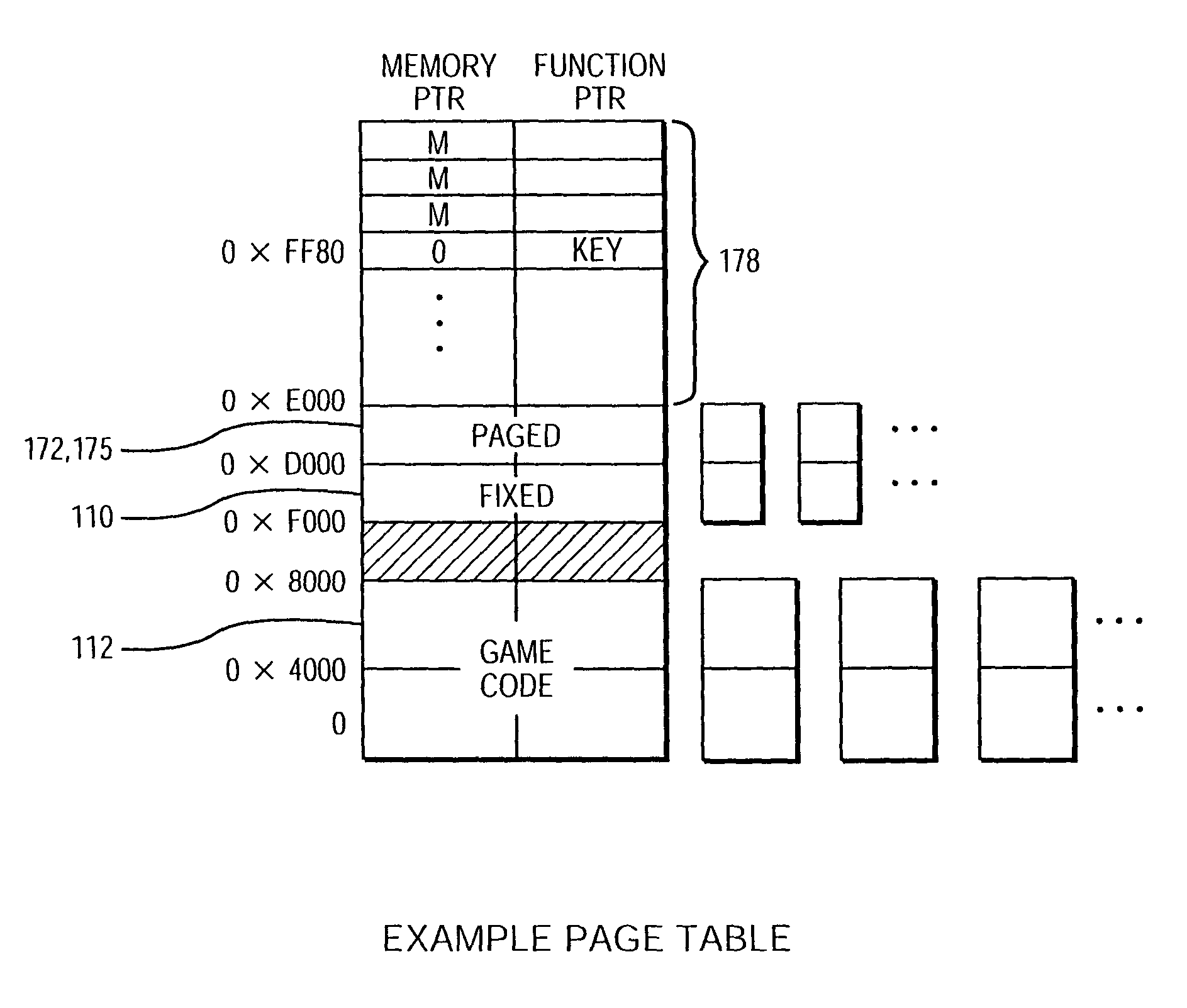

Hand-held video game platform emulation

ActiveUS8157654B2Low costImprove performanceVideo gamesSelective content distributionGraphicsLiquid-crystal display

A software emulator for emulating a handheld video game platform such as GAME BOY®, GAME BOY COLOR® and / or GAME BOY ADVANCE® on a low-capability target platform (e.g., a seat-back display for airline or train use, a personal digital assistant, a cell phone) uses a number of features and optimizations to provide high quality graphics and sound that nearly duplicates the game playing experience on the native platform. Some exemplary features include use of bit BLITing, graphics character reformatting, modeling of a native platform liquid crystal display controller using a sequential state machine, and selective skipping of frame display updates if the game play falls behind what would occur on the native platform.

Owner:NINTENDO CO LTD

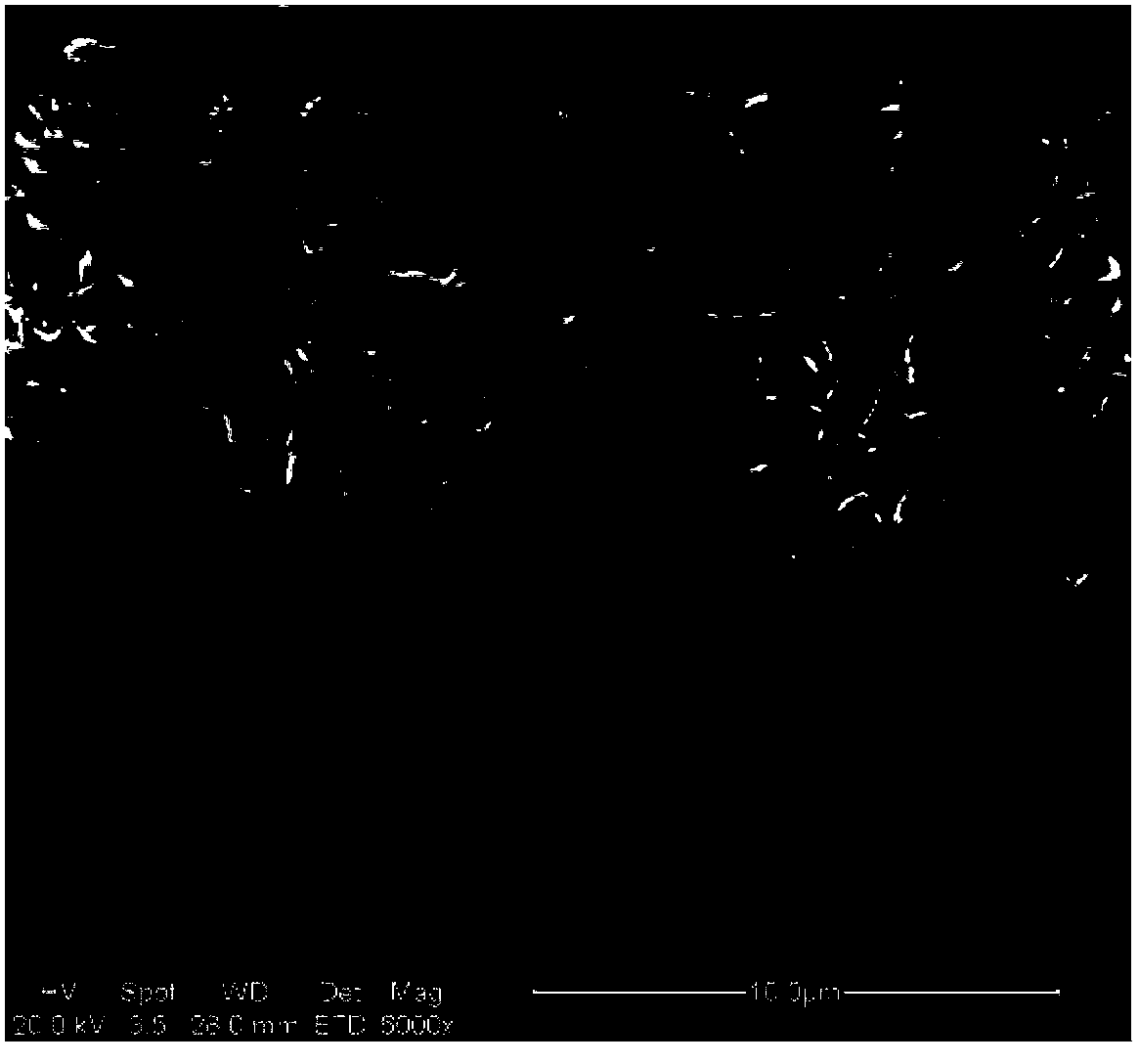

Preparation method of carbon microelectrode array structure

InactiveCN102730628AIncrease surface areaExtended service lifeDecorative surface effectsChemical vapor deposition coatingMicro structureMicro nano

The invention belongs to the technical field of carbon micro electro mechanical system, and provides a preparation method of a carbon microelectrode array structure. The method comprises steps of: (1) photolithography to obtain a carbon micro structure part of the array; (2) metal precipitation: precipitating one or more metal layers on the surface of the obtained carbon micro structure; and (3) pyrolysis: carrying out multiple steps of pyrolysis in an inert gas atmosphere or inert mixed gas atmosphere and at different temperatures. According to the above steps, carbon microelectrode array structure with nano structure integrated on the surface can be grew and obtained. The method of the invention combines thick photoresist lithography, metal precipitation and pyrolysis, so that the obtained micro-nano integrated structure has large specific surface area. The method of the present invention can be used in a micro electro mechanical system, and has the advantages of simple technology, low cost, high controllability, mass growth and good structure. The obtained micro-nano integrated structure has good electrical properties, and can be used as a motor and be widely applied to microcomputer fields, such as the minicell and micro electrochemical sensor, etc.

Owner:HUAZHONG UNIV OF SCI & TECH

Alarms and alerts for medication delivery devices and systems

ActiveUS11096624B2Save powerReduce needSensorsBlood characterising devicesDiabetes mellitusGlucose sensors

Owner:BIGFOOT BIOMEDICAL INC

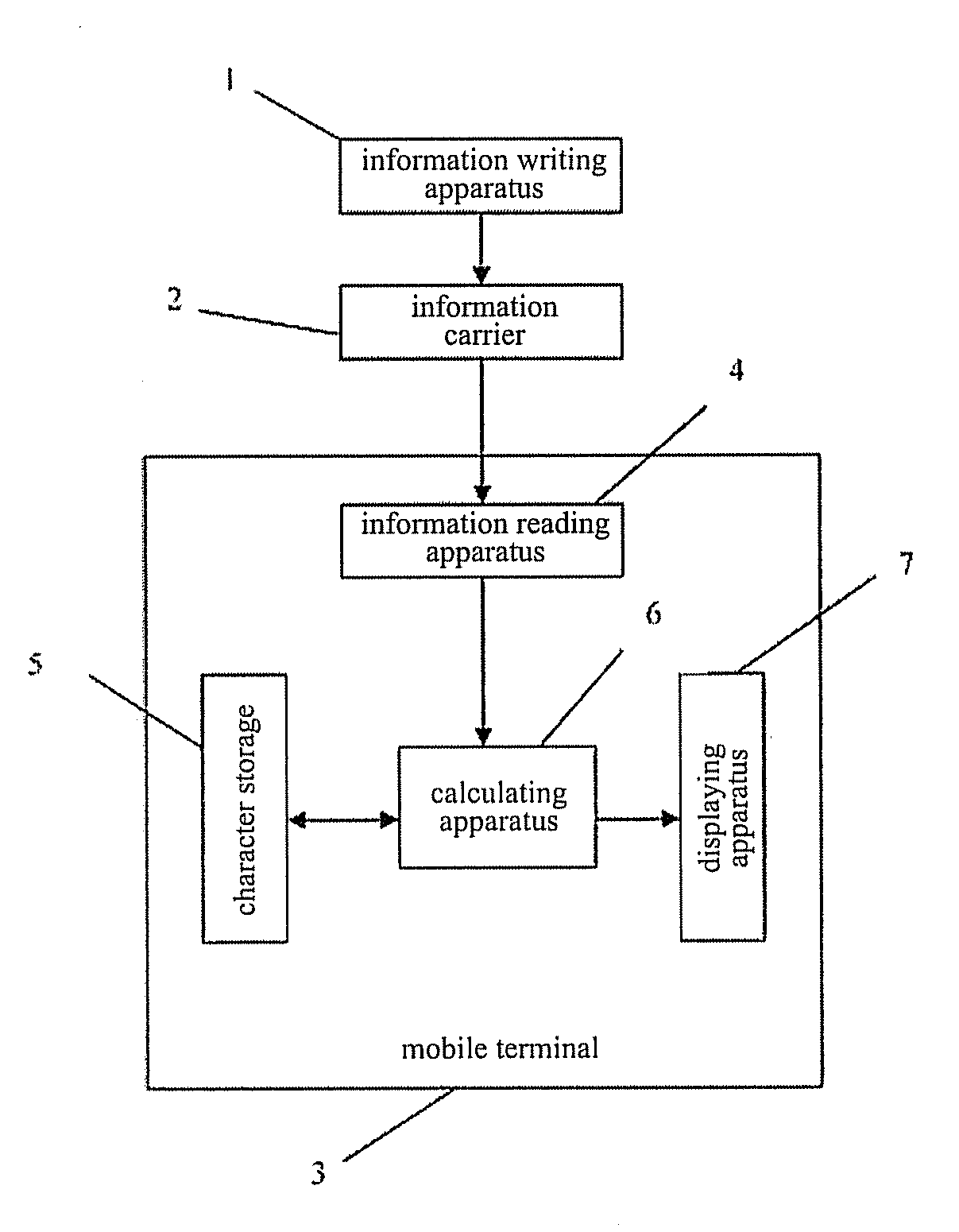

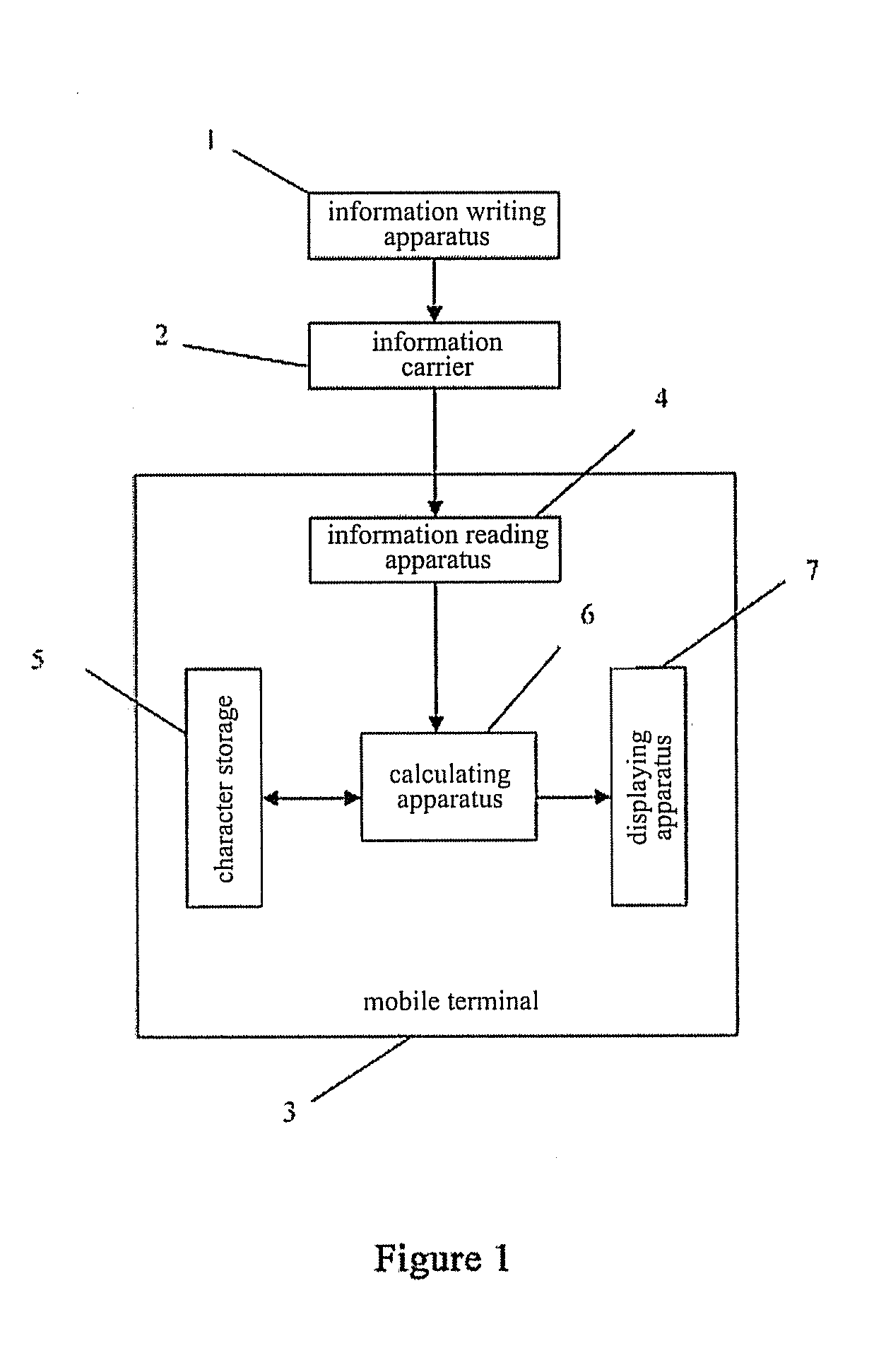

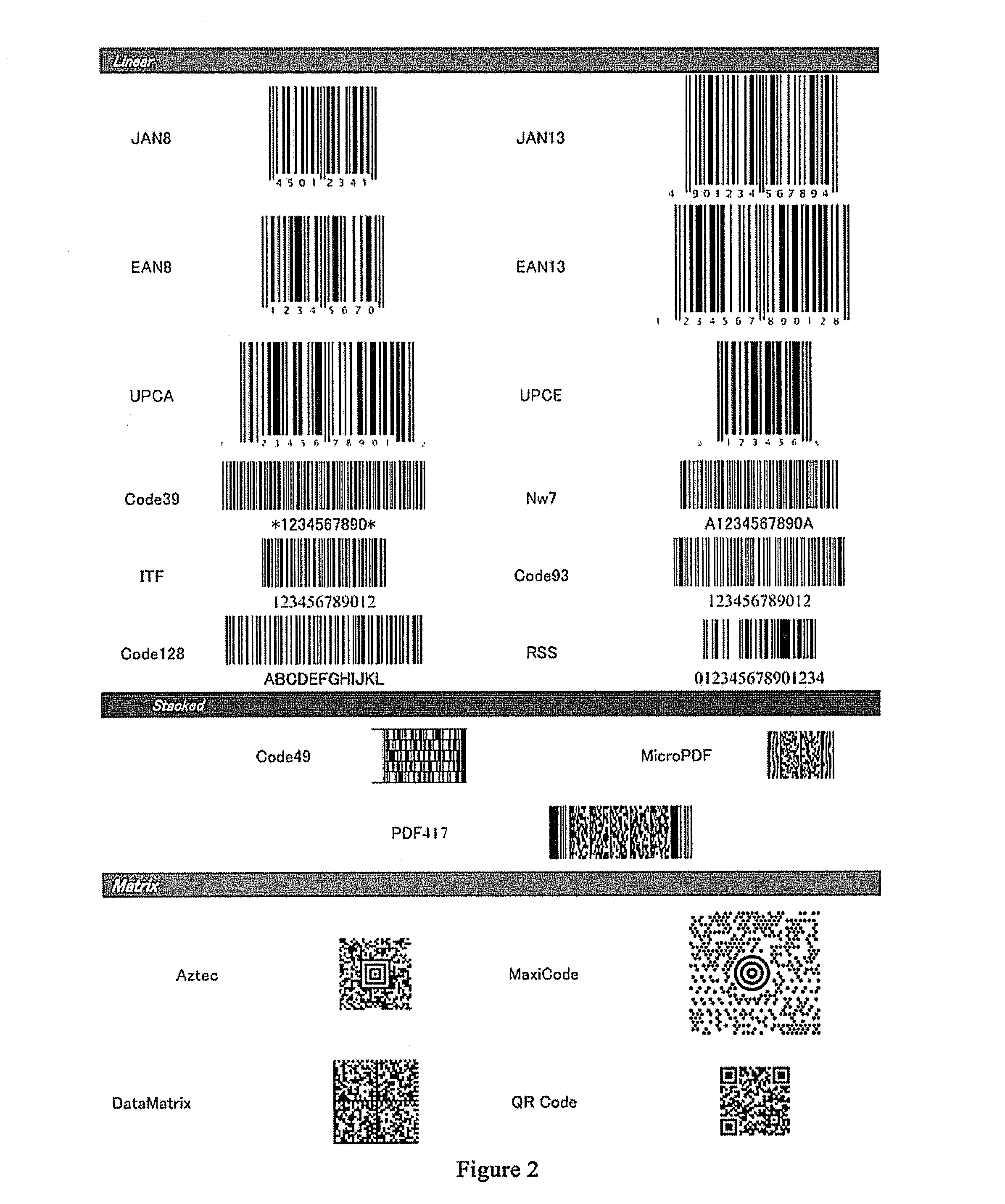

Device for controlling display of mobile terminal and method thereof

InactiveUS20090233648A1Quick in information acquiringFine graphicsCathode-ray tube indicatorsSubstation equipmentGraphicsBarcode

The present invention discloses a device for controlling display of mobile terminal and the method thereof. The device includes: a mobile terminal for receiving, calculating and displaying information; the mobile terminal being configured with an information reading apparatus for reading information on an information carrier; a character storage for storing characters of different types and representing forms; a calculating apparatus for matching the read information with stored information in the character storage, and for generating correspondent character representing information and location information; a displaying apparatus for displaying graphic and text information. This invention can display the contents in the originality of advertisements at once by identifying a barcode with the mobile terminal. The advertisements can be displayed more rapidly and be represented finer, so that users are more attracted to take actions such as reading more advertisements from the network, logging in to take part in activities, placing orders and so on.

Owner:GMEDIA CORP

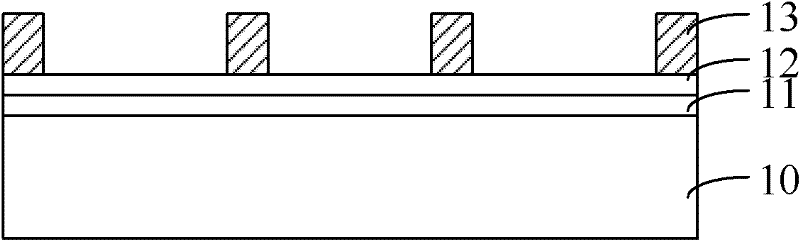

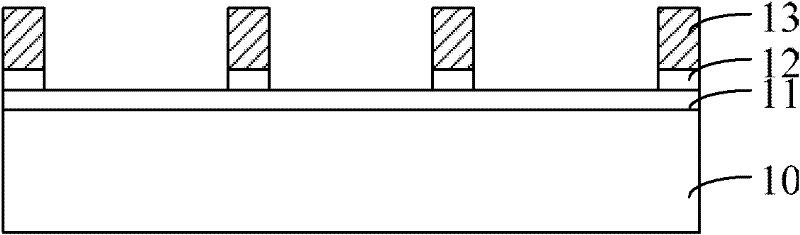

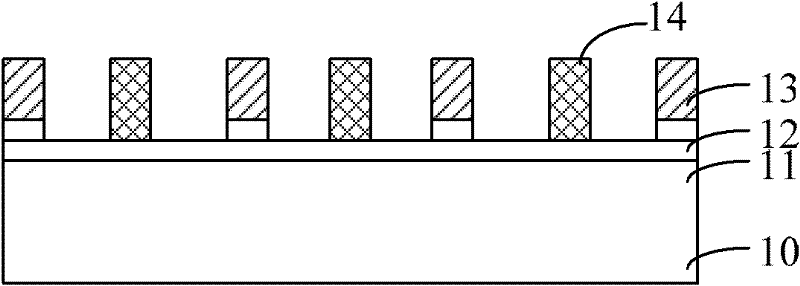

Formation method of semiconductor device

ActiveCN106486365AAvoid damageImprove abilitiesSemiconductor/solid-state device manufacturingSemiconductor devicesPhotoresistSemiconductor

The invention discloses a formation method of a semiconductor device. The formation method comprises steps of: providing a substrate, a grid membrane arranged on the surface of the substrate and an initial mask layer arranged on the surface of the grid membrane; forming a graphical photoresist layer on the initial mask layer; taking the graphical photoresist layer as a mask, and etching the initial mask layer to form multiple separated hard mask layers, wherein polymer impurities are formed on the hard mask layers and the surface of the gate membrane; using the ashing technology to remove the graphical photoresist layer, wherein the ashing technology comprises first ashing technology and second ashing technology which are carries out successively, the first ashing technology is suitable for removing of silicon ions in the polymer impurities and the second ashing technology is suitable for removing carbon ions in the polymer impurities; after the ashing technology is performed, carrying out wet-process cleaning processing on the hard mask layers and the grid membrane; taking the hard mask layers as masks and etching the grid membrane so as to form multiple separated grid electrodes on the substrate; and forming a source region and a drainage region in the substrate on two sides of the grid electrodes. In this way, the quality of the formed grid electrodes is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

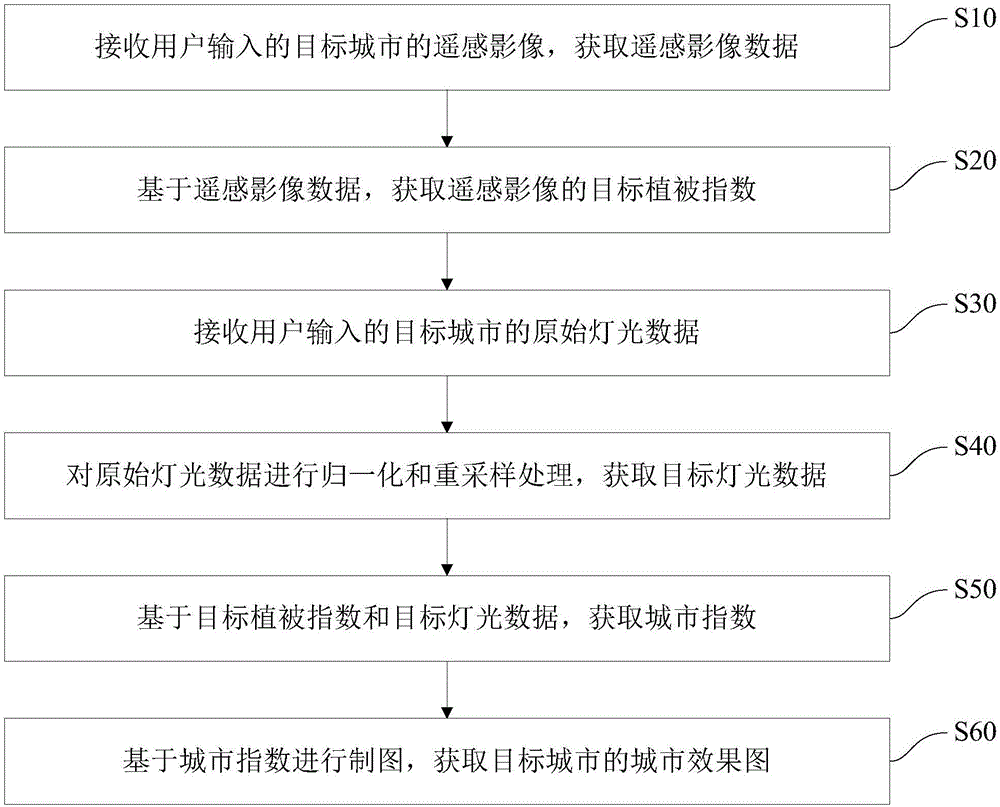

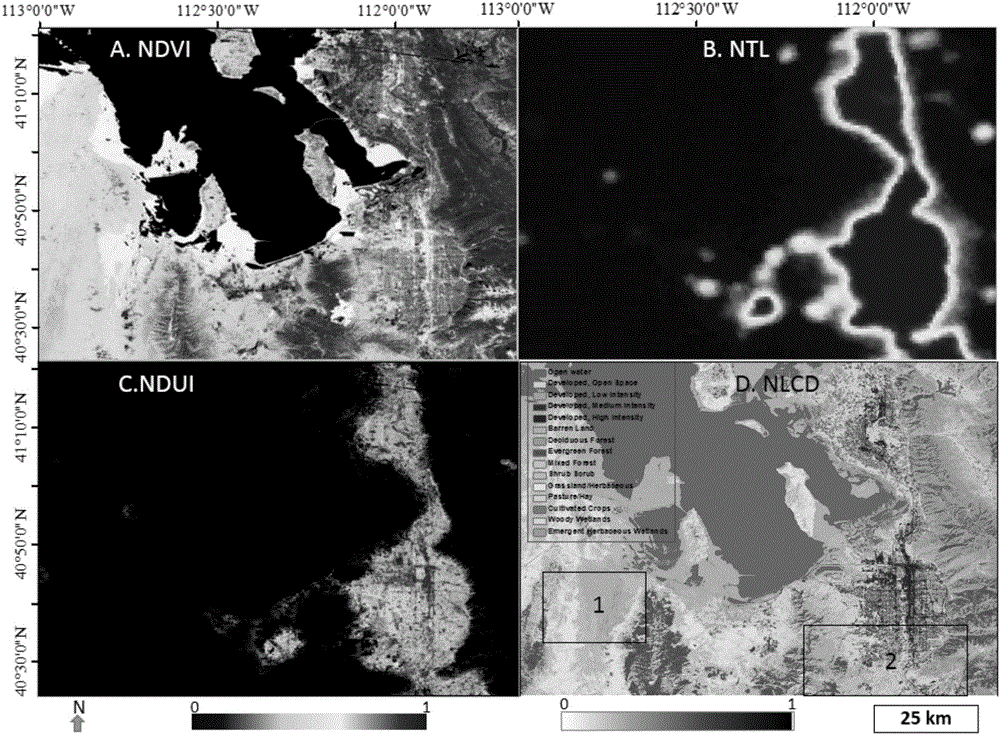

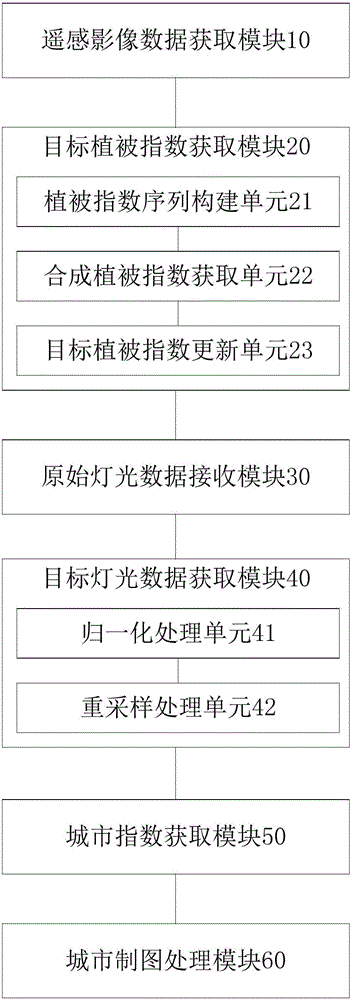

Urban mapping method and device

InactiveCN106650673AEasy to handleHigh degree of automation2D-image generationCharacter and pattern recognitionUrban mappingUser input

The invention discloses an urban mapping method and device. The urban mapping method comprises the following steps of receiving a remote sensing image of a target city input by a user and obtaining remote sensing image data; obtaining a target vegetation index of the remote sensing image based on the remote sensing image data; receiving original light data of the target city input by the user; carrying out normalization and re-sampling processing on the original light data to obtain target light data; obtaining a city index based on the target vegetation index and the target light data; and carrying out mapping based on the city index to obtain a city effect drawing of the target city. The urban mapping method has simple and convenient processing process, high automation degree and high processing efficiency and does not need a complicated preprocessing process; and furthermore, the city index is obtained based on the target vegetation index and the target light data, the city index is utilized to carry out mapping, the mapping effect is good, the precision is high and the method is easy to popularize and apply.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

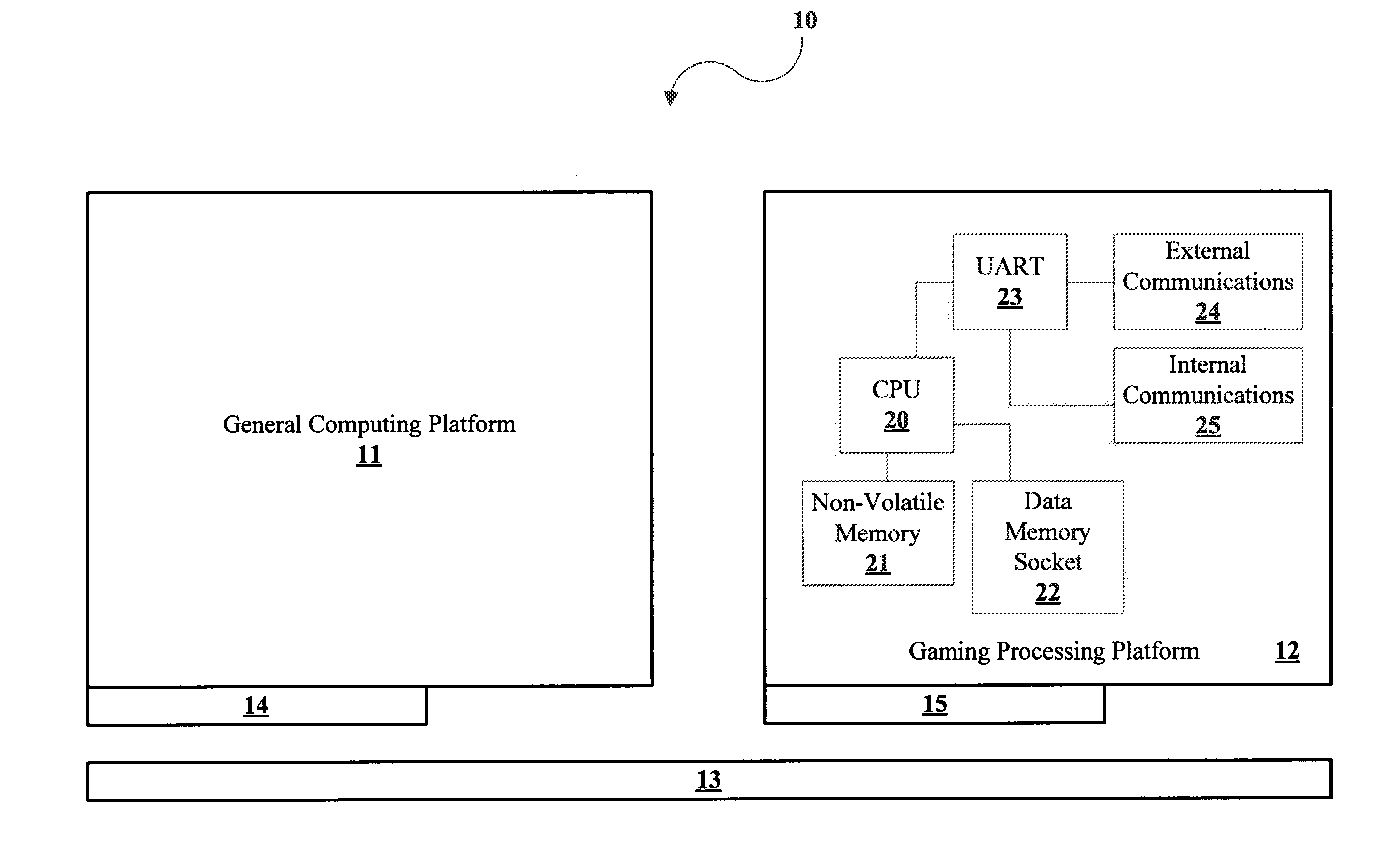

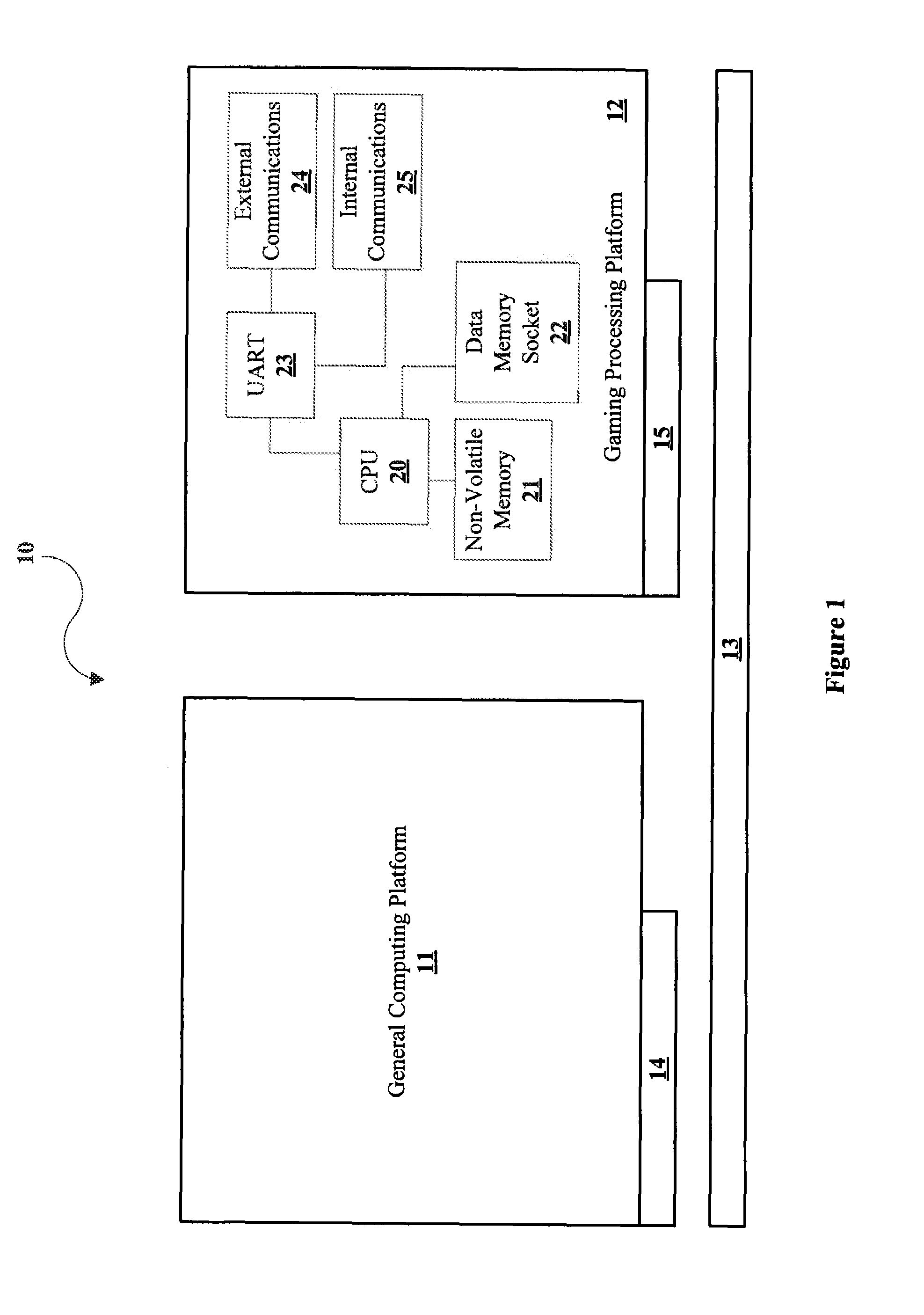

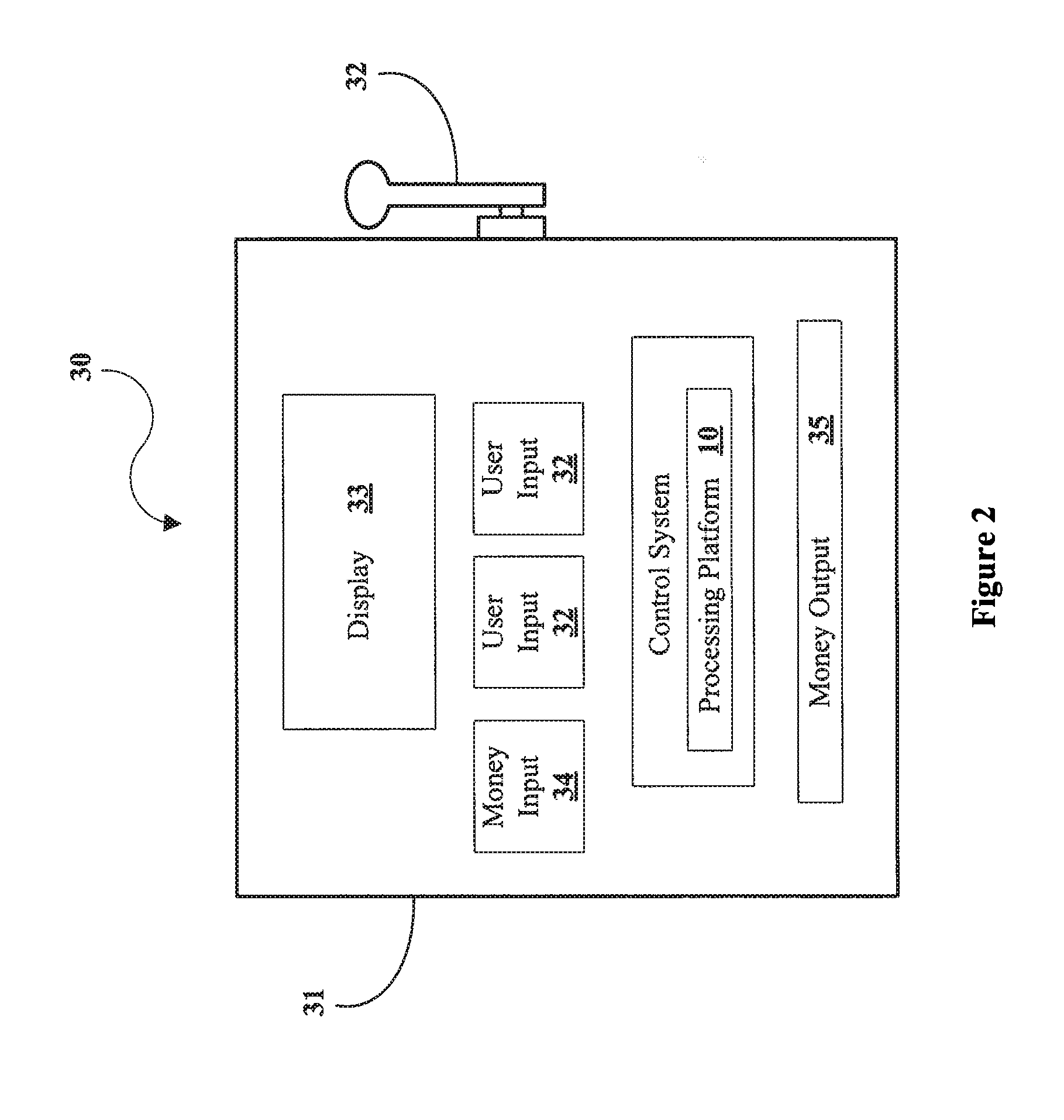

Processing platform for a gaming machine

InactiveUS7637814B2Quick and easy changeReduce needApparatus for meter-controlled dispensingVideo gamesComputer hardwareNon functional

A processing platform for operation of a gaming machine. The processing platform includes a gaming processing subsystem for controlling functional aspects of gaming machine operation and a general computing subsystem for controlling non-functional aspects of gaming machine operation. The gaming processing subsystem and the general computing subsystem are physically separate from one another and are coupled to a bus included within the processing platform.

Owner:IGT

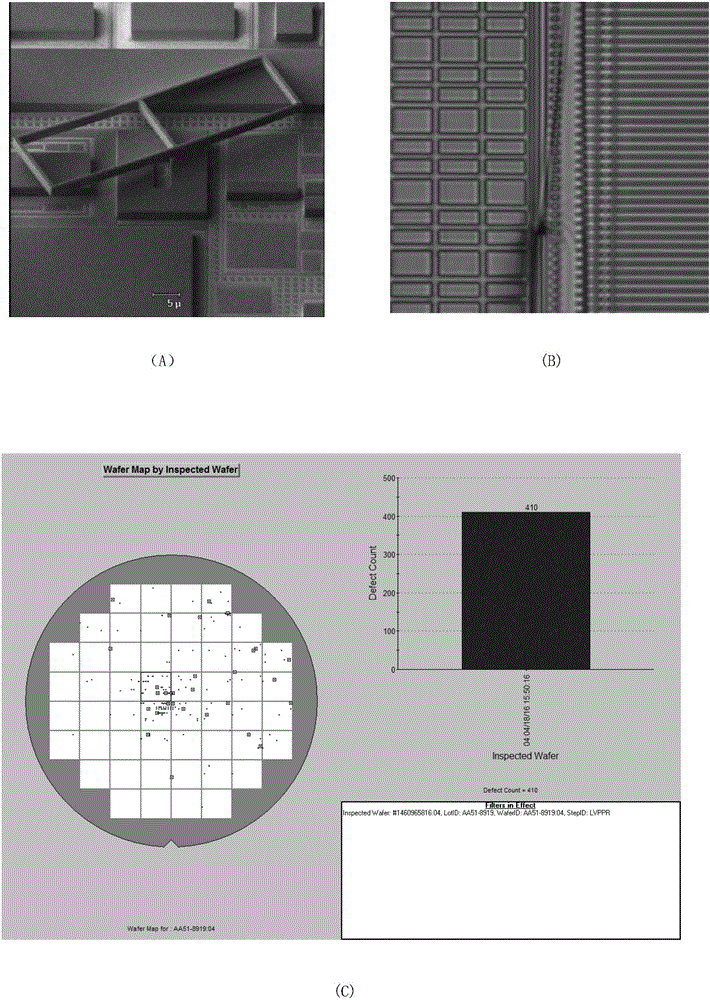

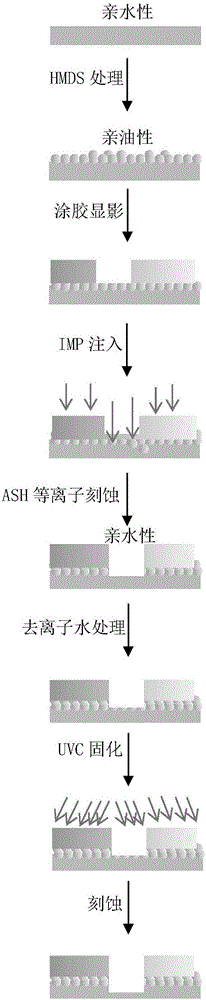

Method for preventing peeling of photoresist

The invention discloses a method for preventing peeling of a photoresist. The method is used after an ion implantation process and before an etching process, and specifically comprises the following steps: 1) carrying out treatment on a silicon substrate surface, so that the silicon substrate surface not coated with the photoresist is changed to be hydrophilic; 2) treating the silicon substrate surface by employing water, so that a silicon substrate not coated with the photoresist absorbs the water and is expanded; and 3) carrying out curing treatment on the photoresist. According to the method disclosed by the invention, after the ion implantation, through firstly treating the silicon substrate surface by employing an ASH plasma so that the exposed silicon substrate surface is changed to be hydrophilic, and then treating the silicon substrate surface by employing the water so that the exposed silicon substrate absorbs the water and is expanded, a stress produced by colloid shrinkage when UVC is cured is offset; and thus, the photoresist, when being etched, is prevented from occurring the peeling with the silicon substrate, and the etching is guaranteed to obtain good graphics.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

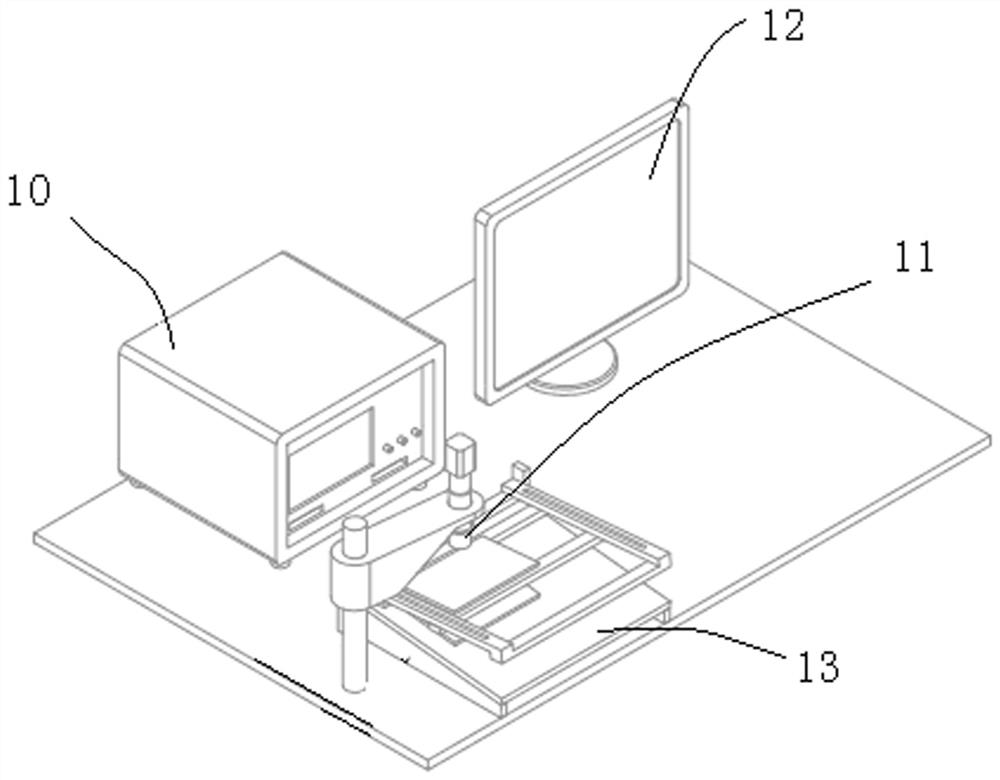

Method for detecting visual angle deviation direction of LCD full-visual-angle VA

PendingCN112612152ABad thickness deformationSolve the problem of inaccurate offset detectionNon-linear opticsGraphicsAutofocus

The invention relates to the technical field of LCD testing, and in particular, relates to a method for detecting the visual angle deviation direction of an LCD full-visual-angle VA. According to the method for detecting the visual angle deviation direction of the LCD full-visual-angle VA, a video magnifier suitable for the product is selected according to the characteristics of the full-visual-angle LCD. The focal length is automatically and finely adjusted through an automatic detection judgment program. When the definition is optimal, a standard pattern at a fixed position is collected; the automatic detection program can automatically detect the nesting deviation direction and the deviation value of an ITO circuit, combined up and down, of the LCD, display the detected deviation value and judge whether the visual angle deviation value of the full-visual-angle product meets the requirement or not. In addition, the program can also clearly detect the defects of LCD graphic font convex-concave badness, graphic font thickness deformation badness, short circuit, missing scratching badness and the like. The full-visual-angle LCD precision detection device is high in detection precision, effectively improves the detection efficiency, and is accurate and effective in detection.

Owner:株洲晶彩电子科技有限公司

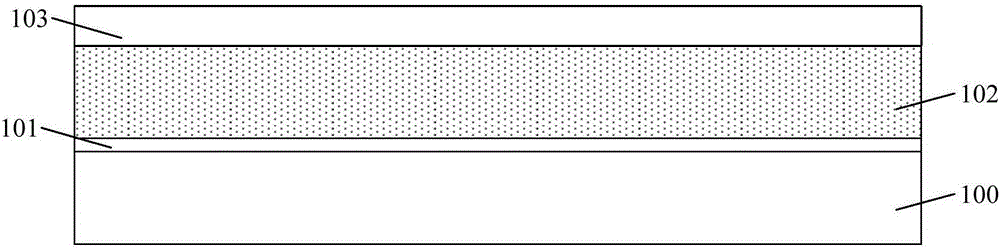

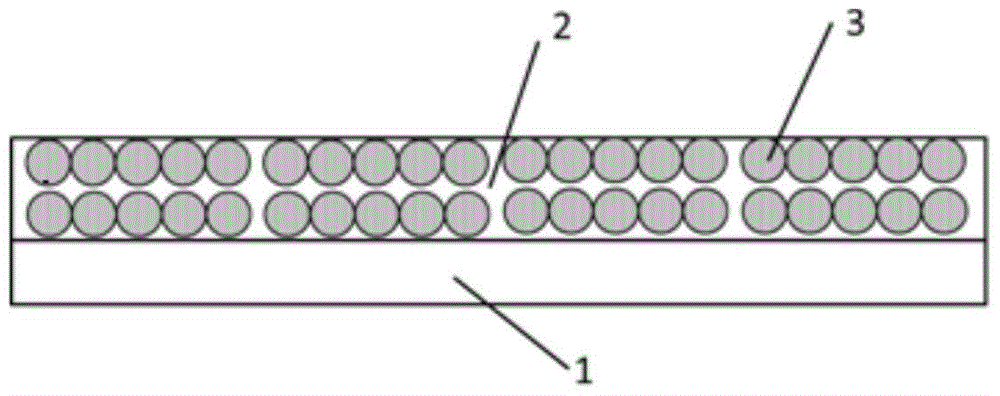

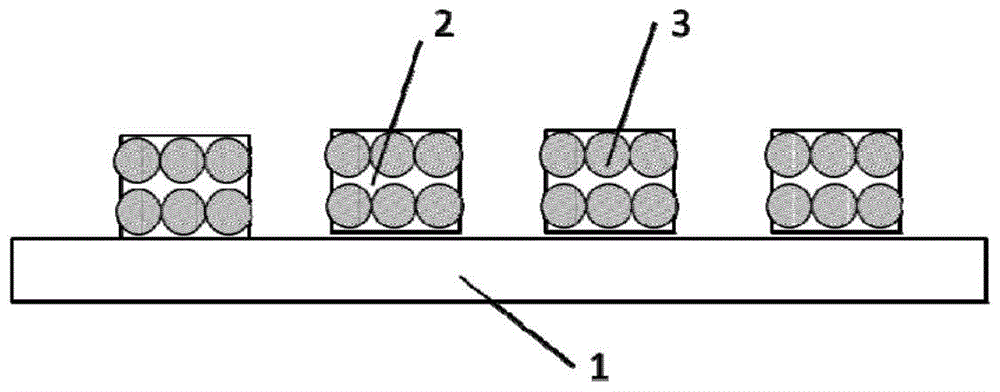

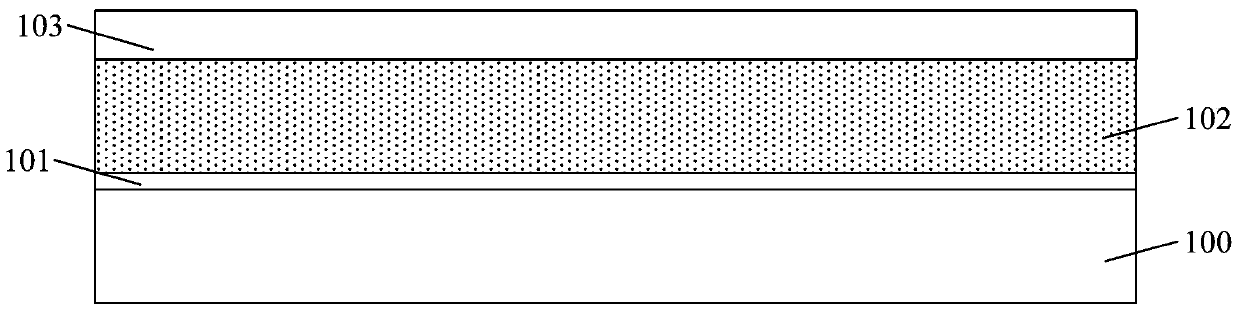

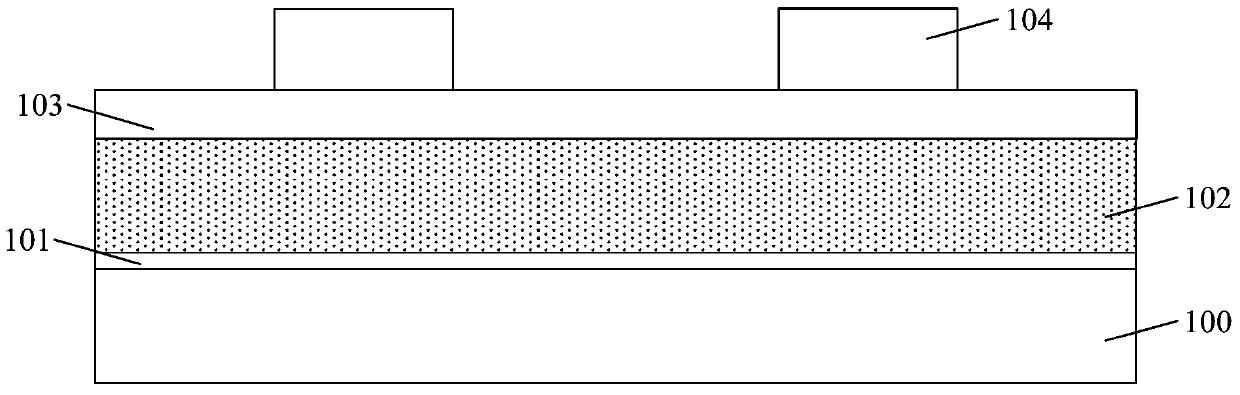

Photosensitive resin composition and method for preparing quantum dot pattern with photosensitive resin composition

ActiveCN103728837BHigh application potentialSimple preparation processPhotomechanical exposure apparatusPhotosensitive material processingQuantum dotPhotoresist

The present disclosure provides a photosensitive resin composition and a method for forming a quantum dot pattern using the same. The photosensitive resin composition includes quantum dots which are dispersed in the photosensitive resin composition and each has a modification layer. The method for forming a quantum dot pattern includes coating, exposing and developing a photoresist to obtain the quantum dot pattern, wherein the photoresist is the above-mentioned photosensitive resin composition.

Owner:BOE TECH GRP CO LTD

Preparation method of carbon microelectrode array structure

InactiveCN102730628BIncrease surface areaExtended service lifeDecorative surface effectsChemical vapor deposition coatingMicro nanoMicro structure

The invention belongs to the technical field of carbon micro electro mechanical system, and provides a preparation method of a carbon microelectrode array structure. The method comprises steps of: (1) photolithography to obtain a carbon micro structure part of the array; (2) metal precipitation: precipitating one or more metal layers on the surface of the obtained carbon micro structure; and (3) pyrolysis: carrying out multiple steps of pyrolysis in an inert gas atmosphere or inert mixed gas atmosphere and at different temperatures. According to the above steps, carbon microelectrode array structure with nano structure integrated on the surface can be grew and obtained. The method of the invention combines thick photoresist lithography, metal precipitation and pyrolysis, so that the obtained micro-nano integrated structure has large specific surface area. The method of the present invention can be used in a micro electro mechanical system, and has the advantages of simple technology, low cost, high controllability, mass growth and good structure. The obtained micro-nano integrated structure has good electrical properties, and can be used as a motor and be widely applied to microcomputer fields, such as the minicell and micro electrochemical sensor, etc.

Owner:HUAZHONG UNIV OF SCI & TECH

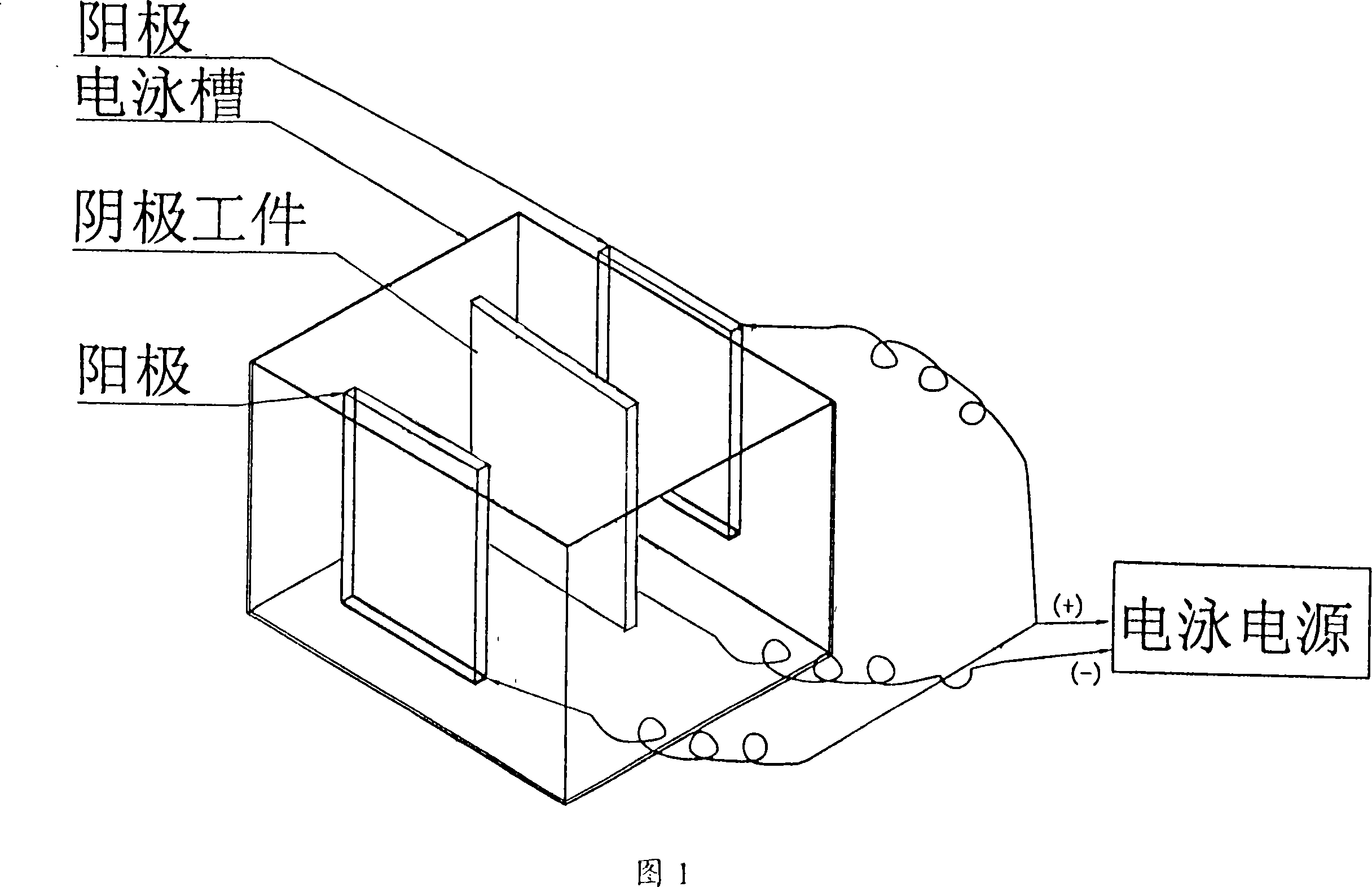

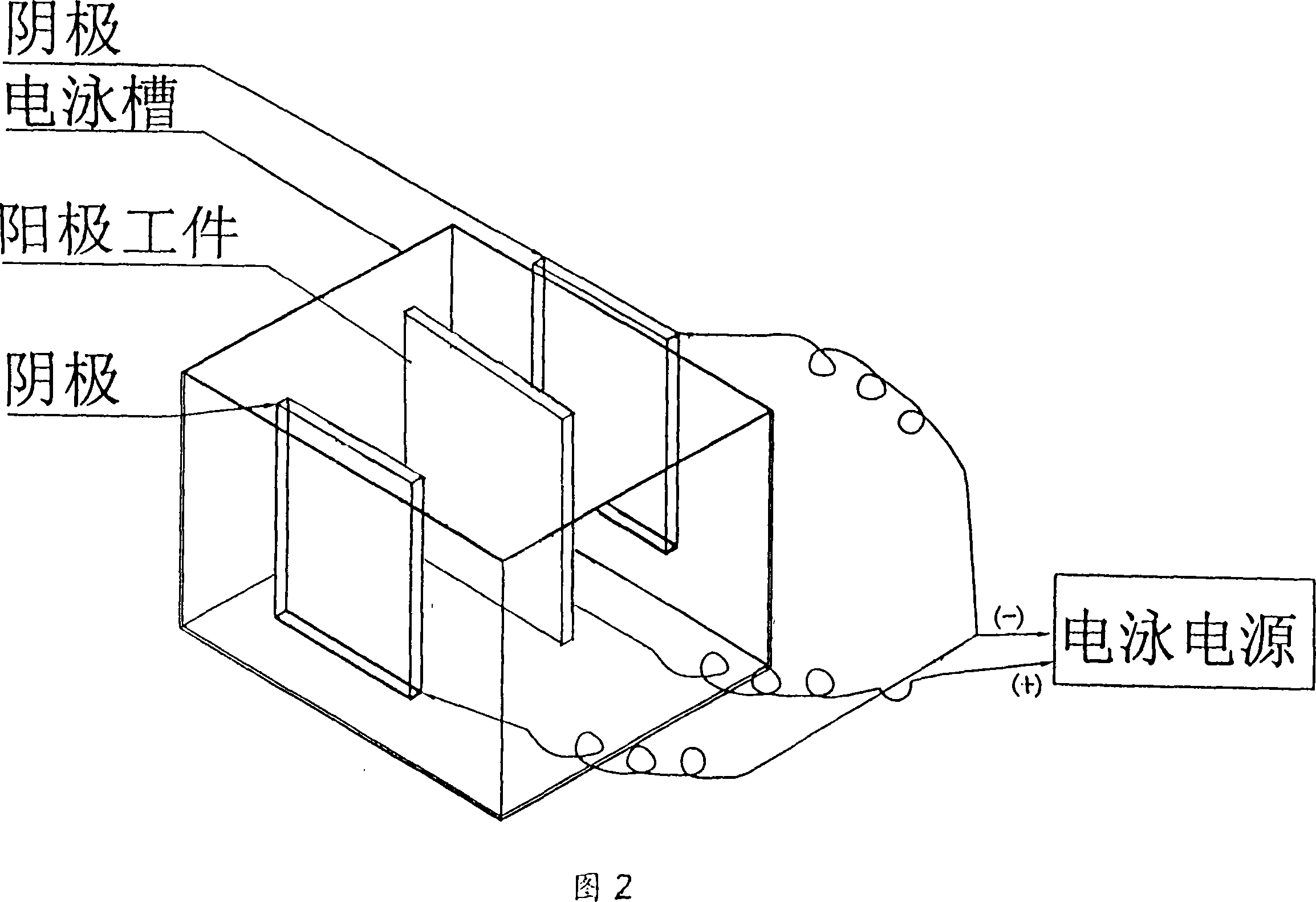

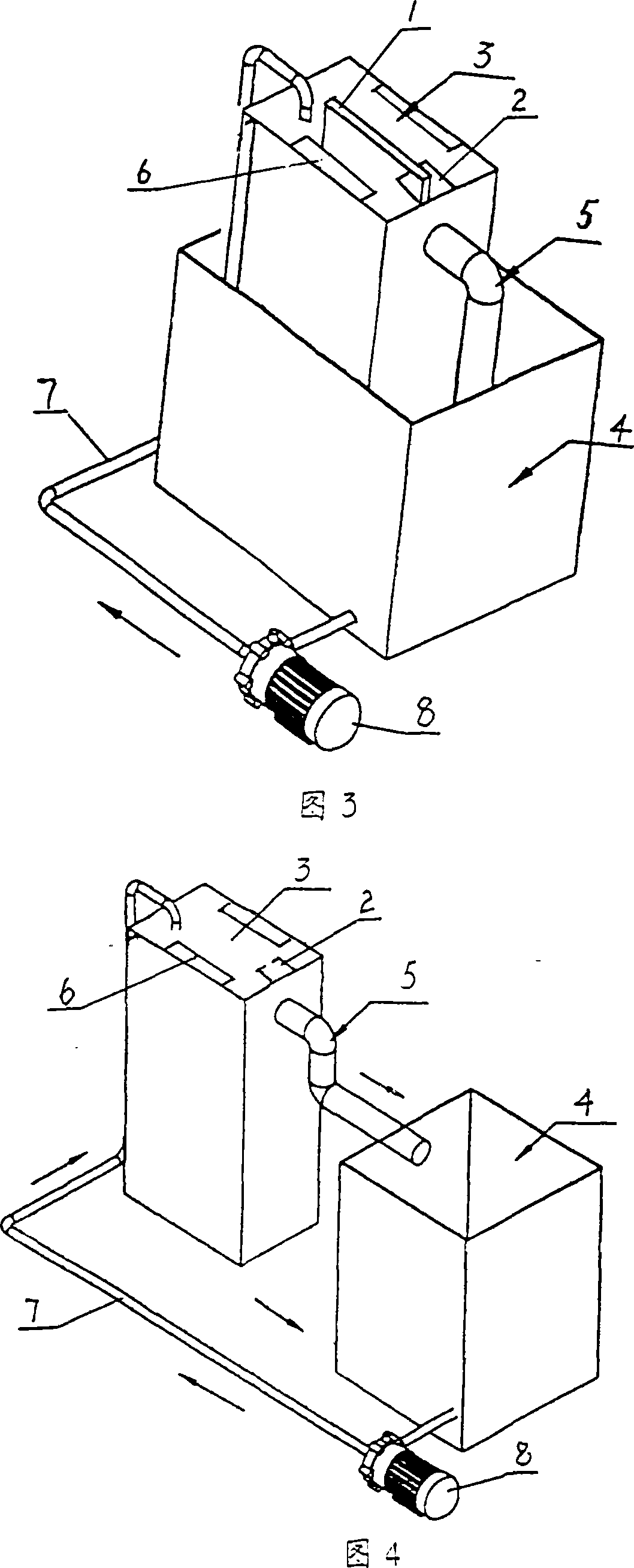

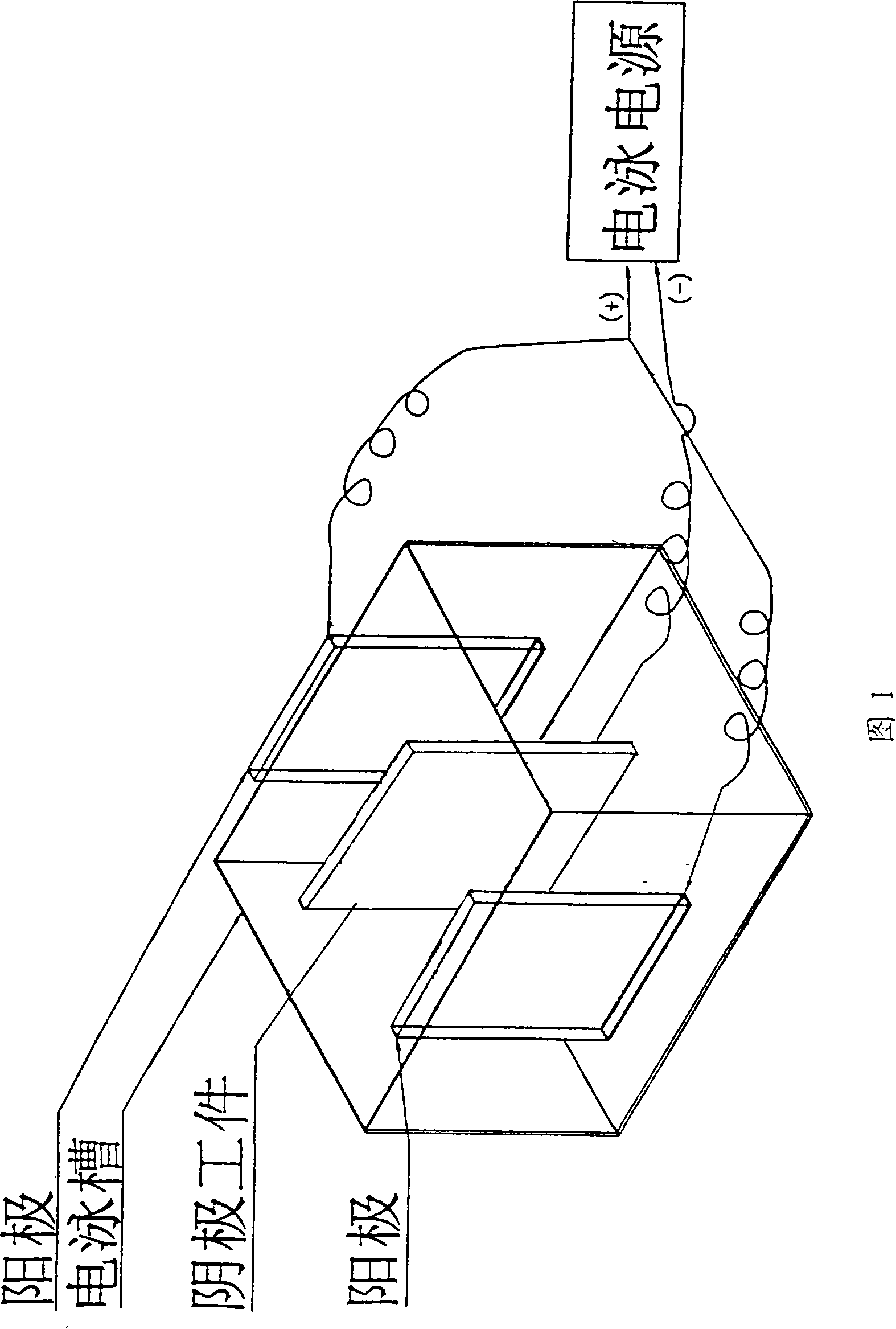

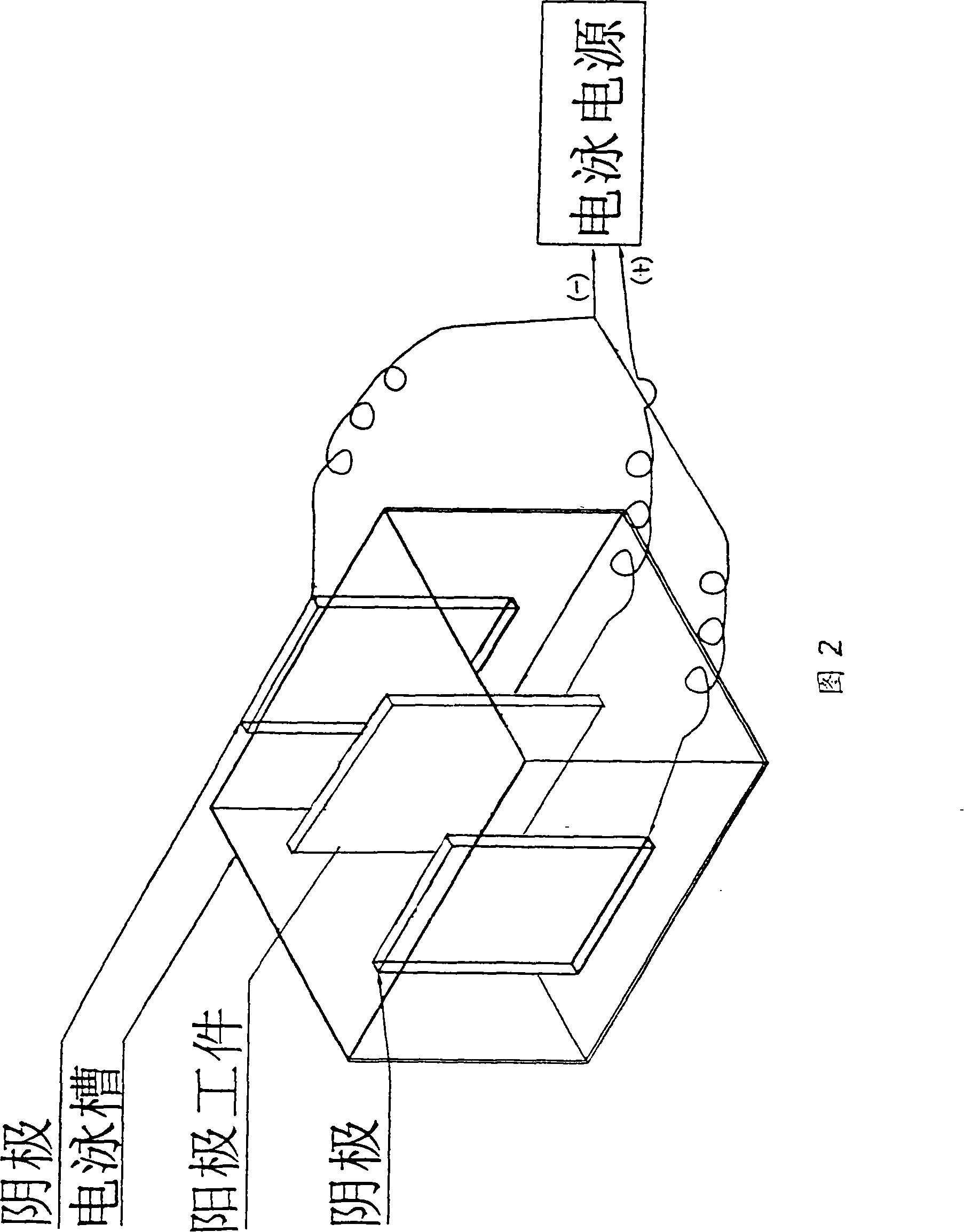

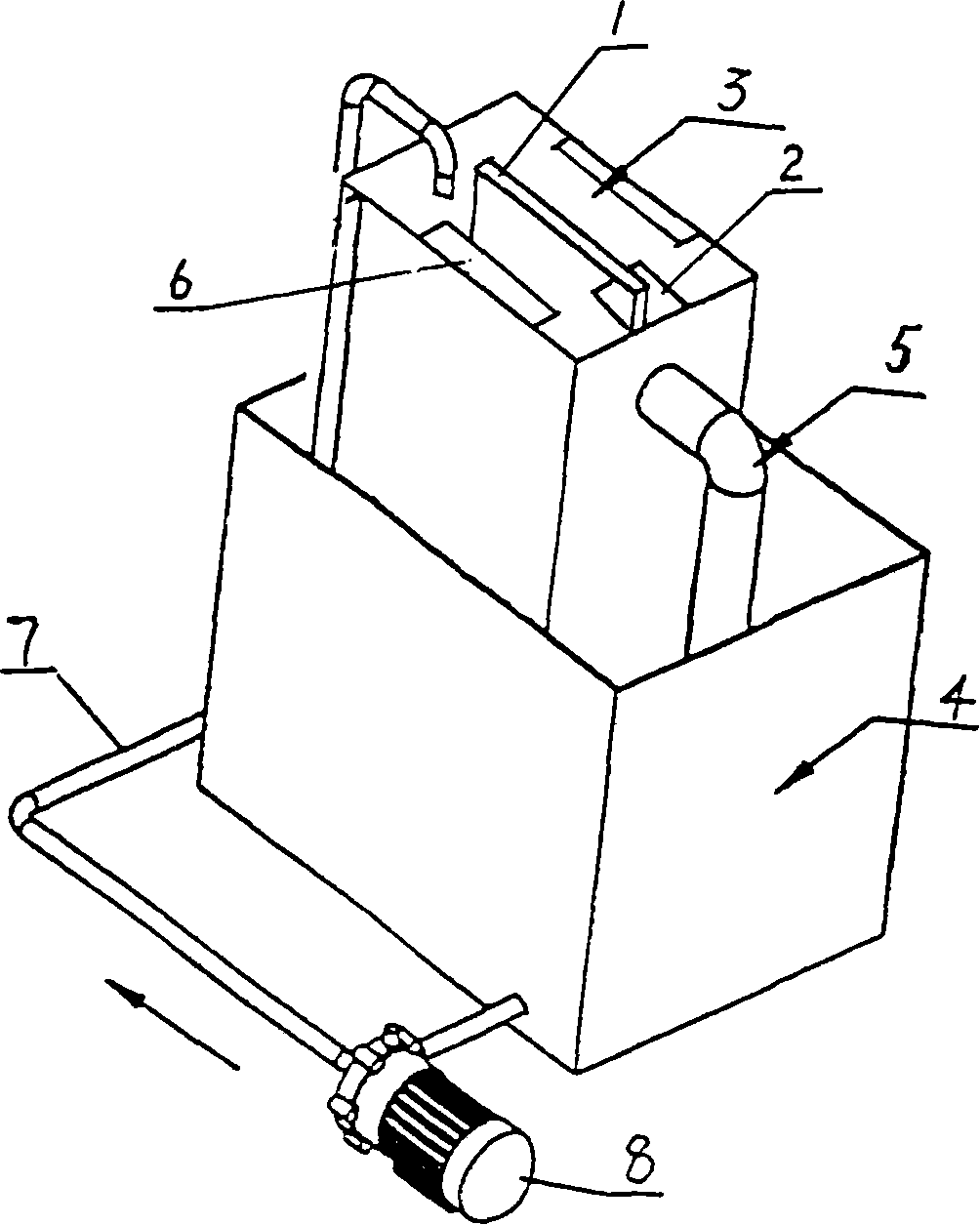

Electrophoresis coating method and whole set apparatus for pattern transfer of positive electrophoresis coating on printing board

InactiveCN101144967ASolve the problem of finer linesMeet the requirements of more miniaturizationElectrophoretic coatingsPhotosensitive composition applicationElectrophoresisMiniaturization

The present invention relates to a positive electrophoresis coating method and a complete set of equipment when a positive electrophoresis coating is used in image transferring of printed boards; the present invention adopts anode and cathode electrophoresis processes, and comprises the concrete steps as follow: (1) an anode or a cathode system can be achieved by connecting a printed board and a conductive device; the conductive device is connected with the anode or cathode of the electrophoresis power; the anode or cathode of the conductive device is connected with the anode or cathode of power to achieve a anode or a cathode system; (2) the printed board is positioned in the electrophoretic tank filled with electrophoretic painting solution to be conducted electrophoresis; (3) having treated by posing, developing and etching, the positive electrophoretic coating film of the electrophoresis can be made out an image of the printed board. The present invention solves the problem further refining the lines in image transferring of the printed circuit board, as well as making the image of the printed circuit board more sophisticated, more accurate, more compact, and thereby electronic products can meet the miniaturized requirement.

Owner:武汉科利尔立胜工业研究院有限公司

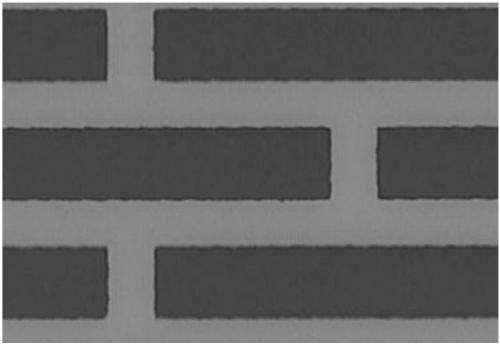

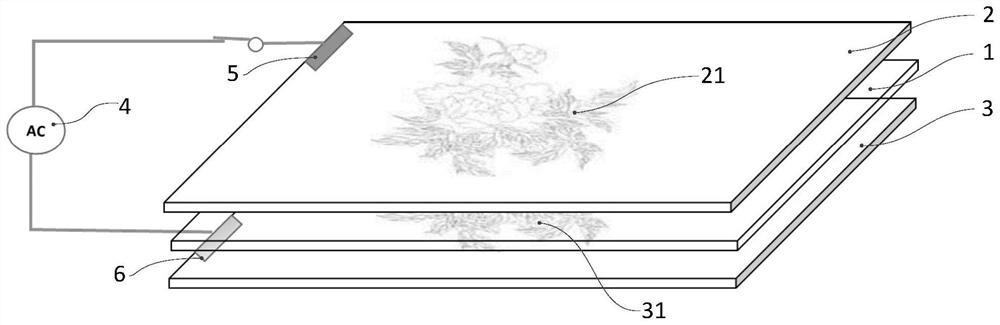

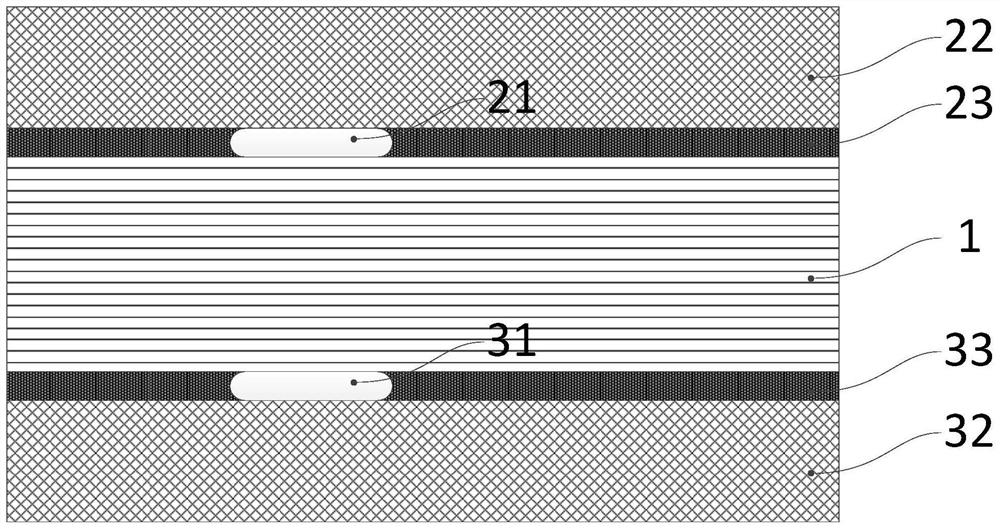

Production method of pattern color mixing film

ActiveCN112269283ASimple structureEasy to manufactureFinal product manufactureNon-linear opticsCoated surfaceElectrical resistance and conductance

The invention relates to a production method of a pattern color mixing film. The production method comprises the following preparation steps: step 1, preparing a conductive solution; step 2, coating atransparent film with the conductive solution by using a reverse plate coating roller, wherein the resistance of the coated surface conductor reaches 40-70 [ohm] / square; 3, respectively fixing the positive electrode pattern conducting layer film and the negative electrode pattern conducting layer film on two sides of a liquid crystal coating machine, wherein the positive electrode conducting region and the negative electrode conducting region are oppositely arranged; coating PDLC liquid crystals between the positive electrode pattern conducting layer thin film and the negative electrode pattern conducting layer thin film; and drying and rolling to obtain the pattern color mixing film. The pattern color mixing film prepared by the invention is simple in structure and easy to manufacture; and different reverse coating rollers can be manufactured according to the requirements of customers to obtain pattern toning films with different patterns, and the pattern contour lines are manufactured by printing, so that the patterns are exquisite and fine, and the display effect is good.

Owner:JIANGYIN TONGLI OPTOELECTRONICS TECH

Method for preparing crystal silicon cell metal electrode

ActiveCN103779431AImprove performanceReduce humidityFinal product manufacturePhotovoltaic energy generationSilver inkScreen printing

Disclosed is a method for preparing a crystal silicon cell metal electrode. The method comprises the following steps: heating a slurry on a slurry conveyer belt below a laser through the laser beam of the laser, enabling the slurry to be transferred to the surface of a crystal silicon cell below the slurry conveyor belt through the meshes of the slurry conveyor belt, and depositing a metal electrode on the surface of the crystal silicon cell. The front surface grid line width of a photovoltaic cell metal electrode prepared by the method can be smaller than 20 [mu]m, the height can be 10 to 15 [mu]m, and the figure high precision can reach 5 [mu]m, which is far higher than the 25 [mu]m figure precision of screen printing. Silver ink is transferred to an emitter electrode through a laser transfer technology so that a finer electrode structure and a superior aspect ratio can be formed by using the method provided by the invention, compared to a conventional screen printing technology. The method provided by the invention has great application potential in the field of commercial high-efficient crystal silicon cell preparation, and represents a mainstream development trend in the technology of making a cell front surface electrode grid line.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

Electrophoresis coating method and whole set apparatus for pattern transfer of positive electrophoresis coating on printing board

InactiveCN101144967BSolve the problem of finer linesMeet the requirements of more miniaturizationElectrophoretic coatingsPhotosensitive composition applicationElectrophoresisMiniaturization

The present invention relates to a positive electrophoresis coating method and a complete set of equipment when a positive electrophoresis coating is used in image transferring of printed boards; the present invention adopts anode and cathode electrophoresis processes, and comprises the concrete steps as follow: (1) an anode or a cathode system can be achieved by connecting a printed board and a conductive device; the conductive device is connected with the anode or cathode of the electrophoresis power; the anode or cathode of the conductive device is connected with the anode or cathode of power to achieve a anode or a cathode system; (2) the printed board is positioned in the electrophoretic tank filled with electrophoretic painting solution to be conducted electrophoresis; (3) having treated by posing, developing and etching, the positive electrophoretic coating film of the electrophoresis can be made out an image of the printed board. The present invention solves the problem further refining the lines in image transferring of the printed circuit board, as well as making the image of the printed circuit board more sophisticated, more accurate, more compact, and thereby electronic products can meet the miniaturized requirement.

Owner:武汉科利尔立胜工业研究院有限公司

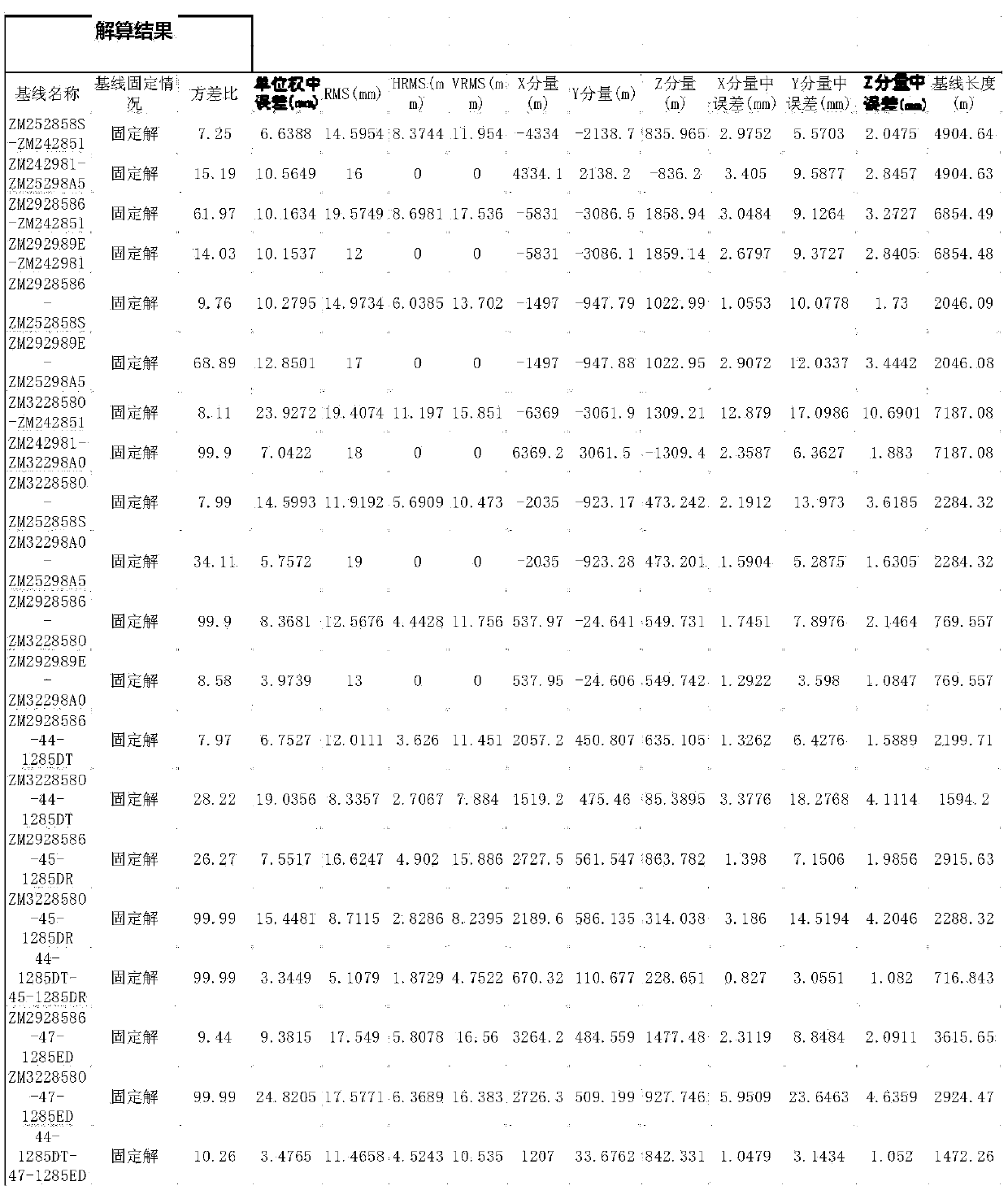

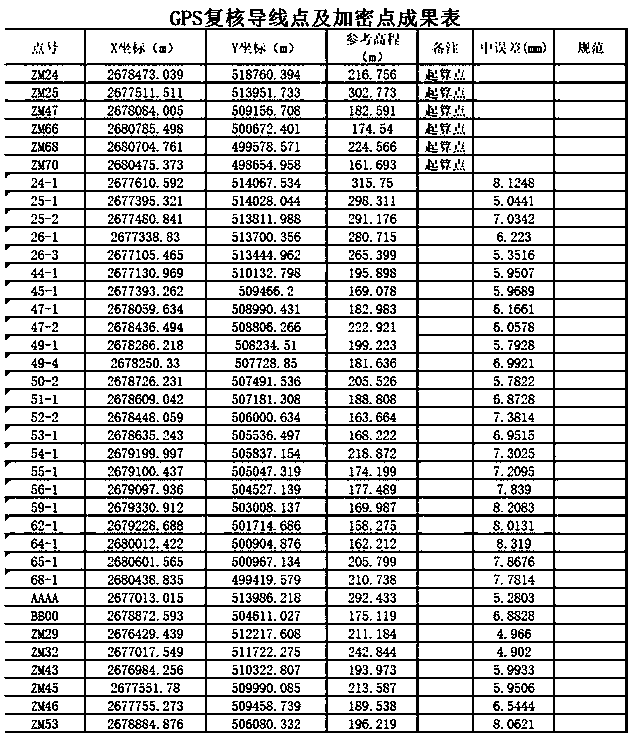

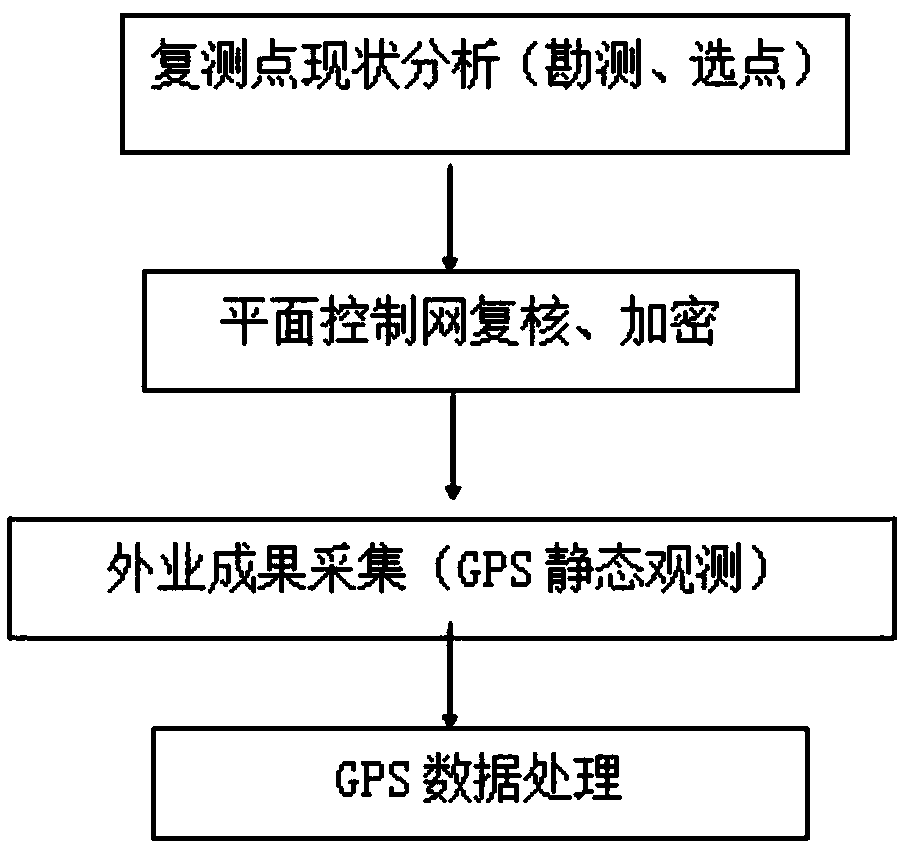

Method for measuring tunneling construction precision at two ends of extra-long tunnel

ActiveCN109520485AFine graphicsFlexible choiceSurveying instrumentsSatellite radio beaconingData acquisitionMeasurement precision

The invention discloses a method for measuring tunneling construction precision at two ends of an extra-long tunnel. The method comprises the following steps: rechecking and encrypting mapping base points arranged in the whole route according to the present coordinate control point and benchmark data; using double-frequency receivers for collecting field data of horizontal control points, and synchronously starting up and collecting satellite signals under the condition of strictly centering and leveling; synchronously observing at different horizontal control points by multiple receivers, moving to other horizontal control points for synchronously observing after finishing the synchronous observation in a period of time, and forming a synchronous pattern while synchronously observing at each time. During the measuring process, different synchronous patterns are generally connected by a plurality of common points; the whole GPS network is formed by the synchronous patterns; measuring points are uniformly distributed in a control network, have a mutual restraining effect to the whole control network and can effectively increase the measuring precision.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

Method for forming semiconductor device

ActiveCN106486365BGood electrical propertiesImprove reliabilitySemiconductor/solid-state device manufacturingSemiconductor devicesPhotoresistImpurity

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Formation method of semiconductor structure

PendingCN114823292AGood exposureGood graphicsSemiconductor/solid-state device manufacturingEngineeringOptics

A method for forming a semiconductor structure comprises the following steps: providing a layer to be etched; a first sacrificial layer is formed on the surface of the to-be-etched layer, a first opening extending in the first direction is formed in the first sacrificial layer, and the first opening exposes the surface of the to-be-etched layer; forming an initial second sacrificial layer on the first sacrificial layer and in the first opening; forming an initial first mask layer on the surface of the initial second sacrificial layer; a plurality of patterning steps are carried out on the initial first mask layer to form a first mask layer, a plurality of partition mask openings distributed in the first direction are formed in the first mask layer, each partition mask opening stretches across the first opening in the second direction, and the second direction is perpendicular to the first direction. Therefore, adjacent patterns with small spacing and good morphology can be transmitted to the to-be-etched layer.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com