Etching liquid composition and etching method

A technology of composition and etching solution, applied in the direction of surface etching composition, chemical instruments and methods, etc., can solve the problem of not simultaneously etching transparent conductive film and copper or copper alloy film, devices that cannot be applied to crystallized ITO film, etc. problems to achieve significant results

Inactive Publication Date: 2013-04-17

KANTO CHEM CO INC

View PDF9 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0014] However, in the same document, it is pointed out that the ITO film is also aimed at amorphous, and cannot be applied to a device using a crystallized ITO film.

[0015] As mentioned above, there is no sufficient research on the simultaneous etching of transparent conductive films and copper or copper alloy films.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0081] Hereinafter, although an Example and a comparative example are given and the content of this invention is demonstrated in more detail, this invention is not limited to these Examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a display device of a flat panel display (FPD) and an etching liquid composition for the transparent conductive film used for the electrodes of a solar cell or a touch control panel, and provides an etching liquid composition for etching transparent conductive films such as copper and / or copper alloy film and indium tin oxide simultaneously, which includes hydrochloric acid, ferric chloride or copper chloride and water, wherein the concentration of hydrochloric acid is from 15.0 to 36.0 weight%, and the concentration of ferric chloride or copper chloride is from 0.05 to 2.00 weight%.

Description

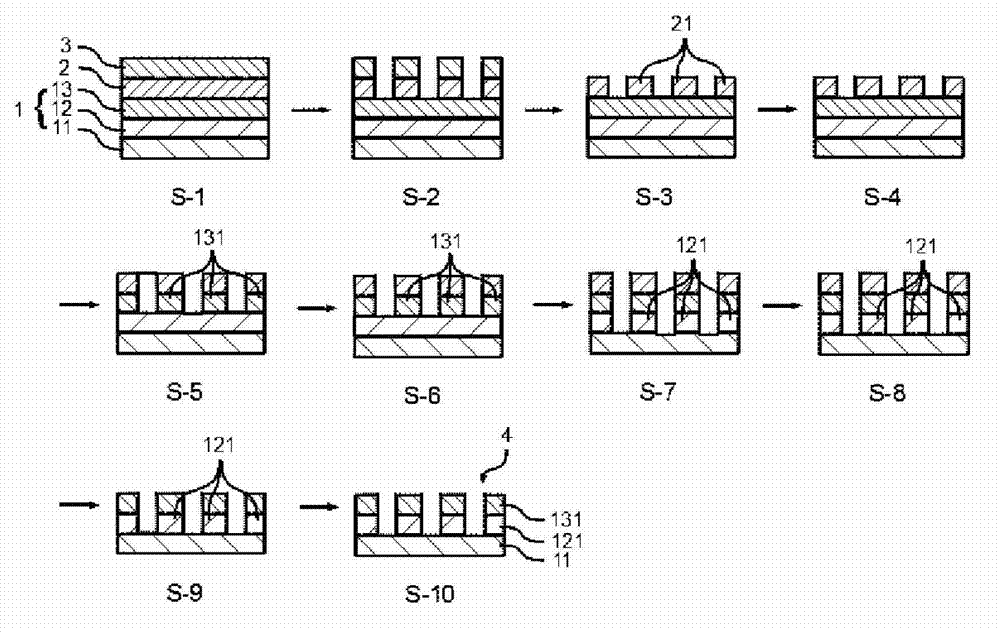

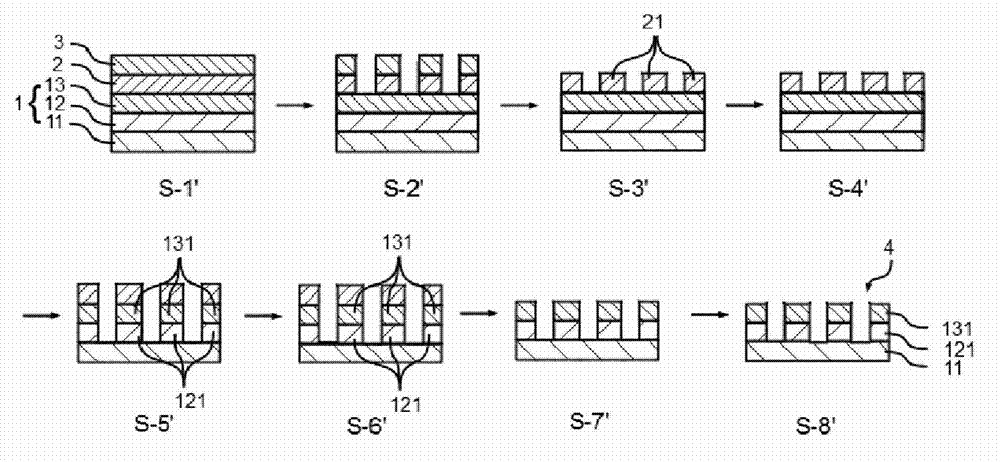

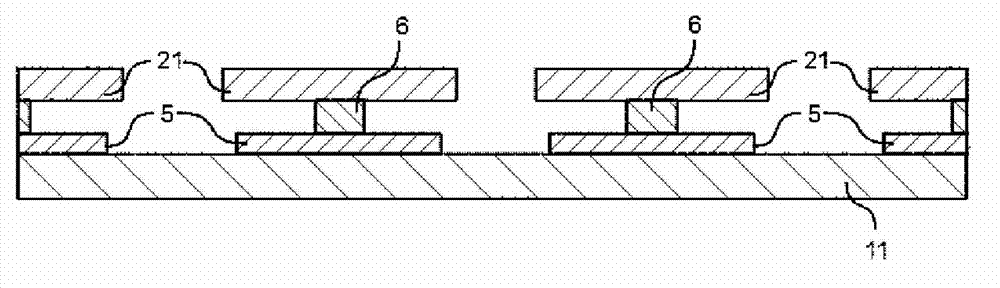

technical field [0001] The present invention relates to simultaneous etching of transparent conductive films used in FPD (Flat Panel Display) display devices, solar cells, electrodes in touch panel sensors, etc., and copper and / or copper alloy films used in wiring, etc. Etching liquid composition, and the etching method using this etching liquid composition. Background technique [0002] Transparent conductive films are light-transmitting conductive materials used in flat-panel displays such as LCDs (liquid crystal displays) and ELDs (electroluminescent displays), solar cells, and touch panels. These transparent conductive films are made of, for example, indium tin oxide, indium oxide, tin oxide, or zinc oxide, among which indium tin oxide (hereinafter also referred to as ITO) is widely used. [0003] In order to use a transparent conductive film as an electrode of an FPD display, a solar cell, a touch panel, etc., it is necessary to form the transparent conductive film wit...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23F1/16C23F1/18

CPCC09K13/00C23F1/18

Inventor 山口隆雄石川典夫

Owner KANTO CHEM CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com