Connection pore forming method

A connection hole and process technology, which is applied in the field of connection hole formation, can solve problems such as incomplete removal of the organic glass layer 212, affecting the conductivity of semiconductor devices, and the connection hole is not opened.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

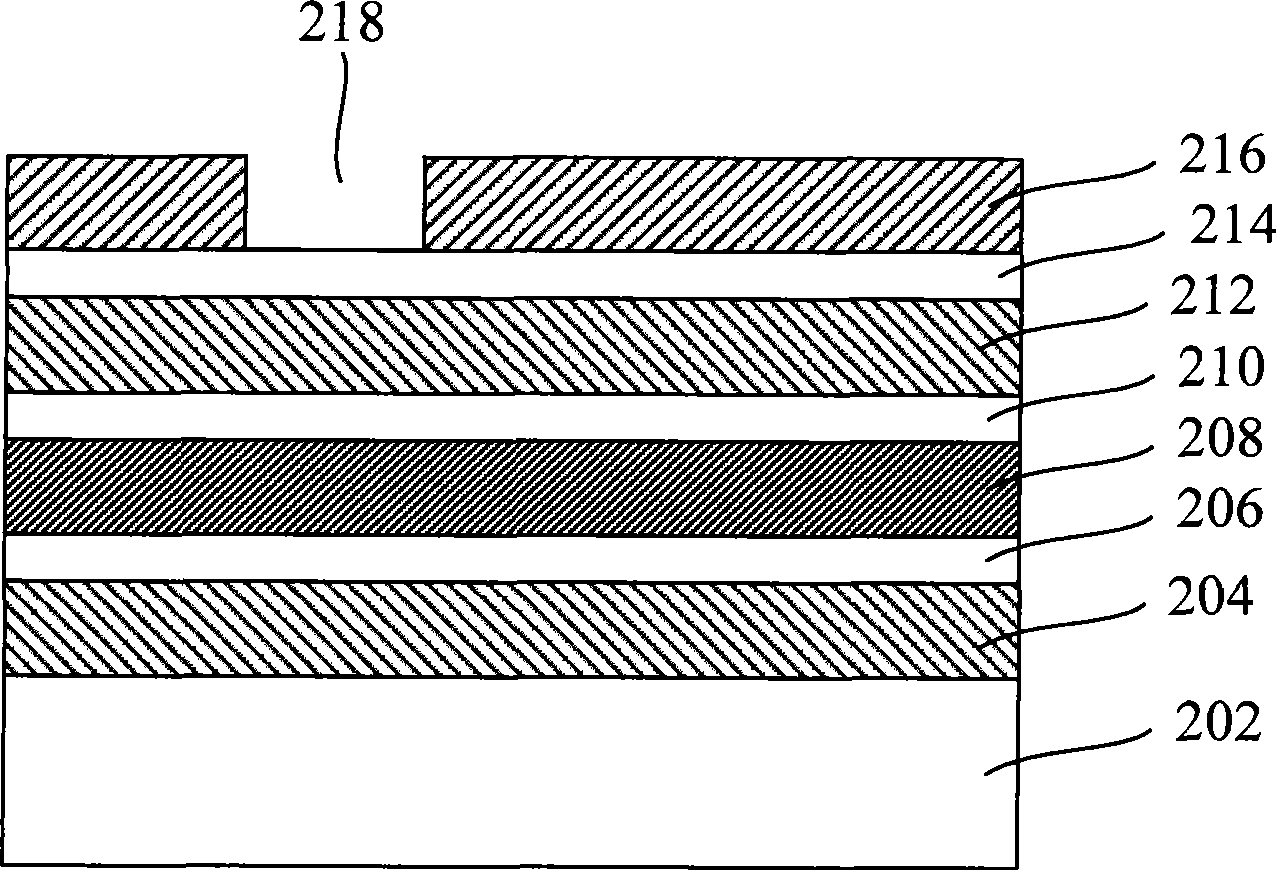

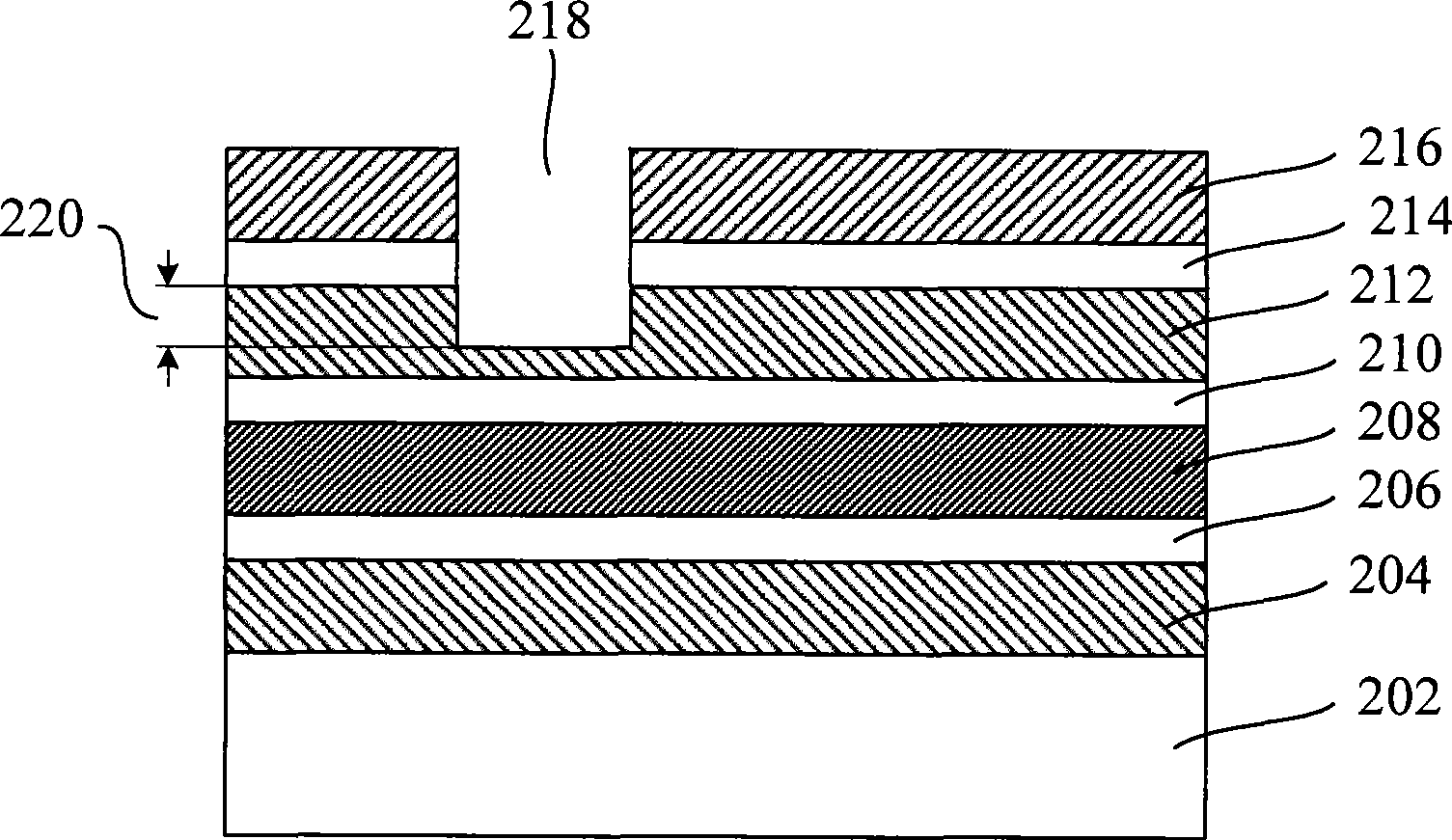

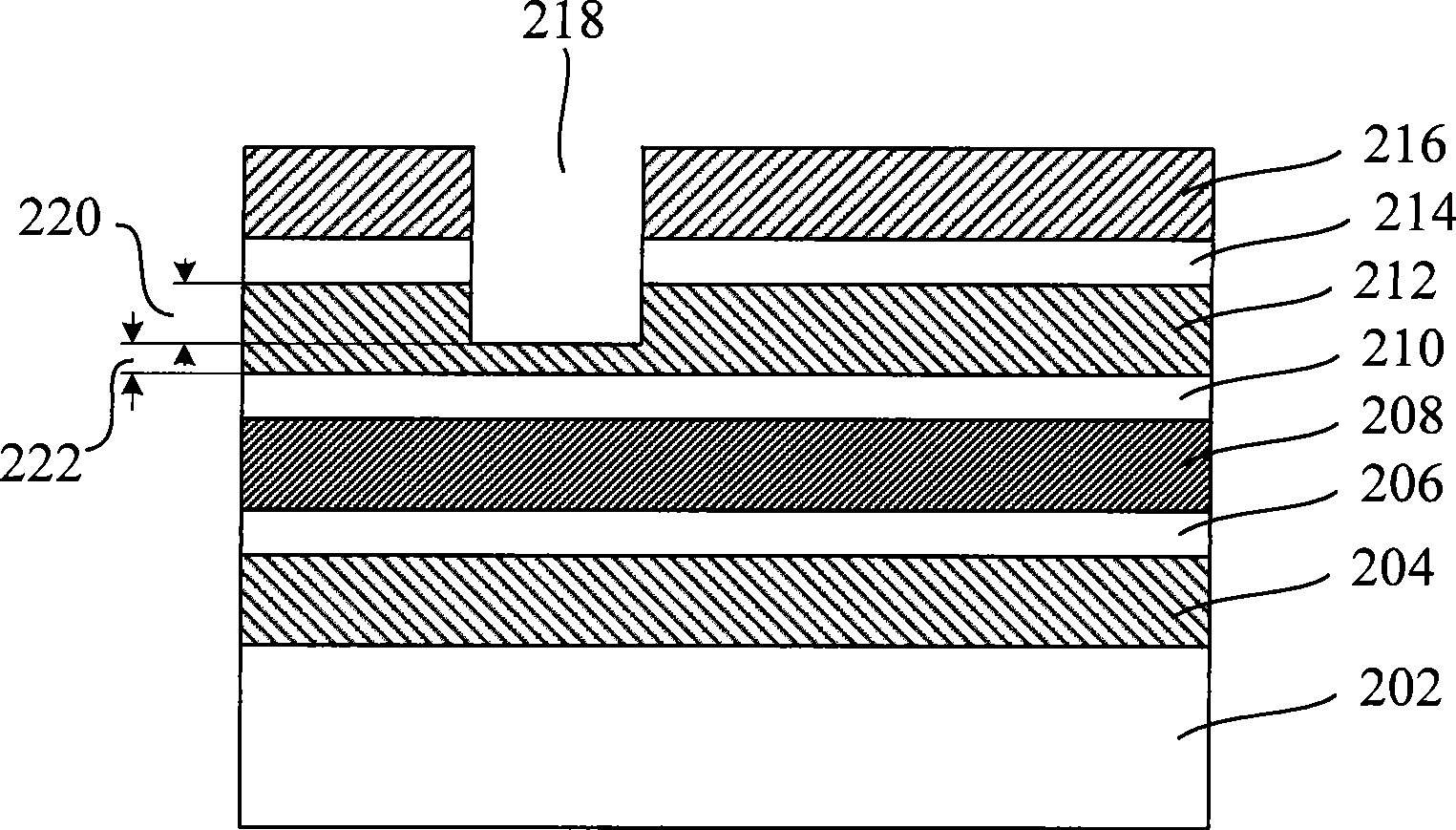

[0060] In the manufacturing process of the dual damascene structure, the connection hole (Via First) can be formed in the intermetal dielectric layer first, and then the trench can be formed; the trench (Trench First) can also be formed first, and then the connection hole can be formed; The holes and trenches are filled with metal material, forming a dual damascene structure.

[0061] The invention provides a method for manufacturing connection holes, which can be applied to the manufacture of connection holes in the manufacturing process of forming connection holes first and then forming grooves in the dual damascene structure, and is also suitable for forming grooves first and then forming connection holes. Fabrication of connection holes in the manufacturing process of the hole dual damascene structure.

[0062] Figure 4 It is a flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com