Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70results about How to "Fast demulsification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

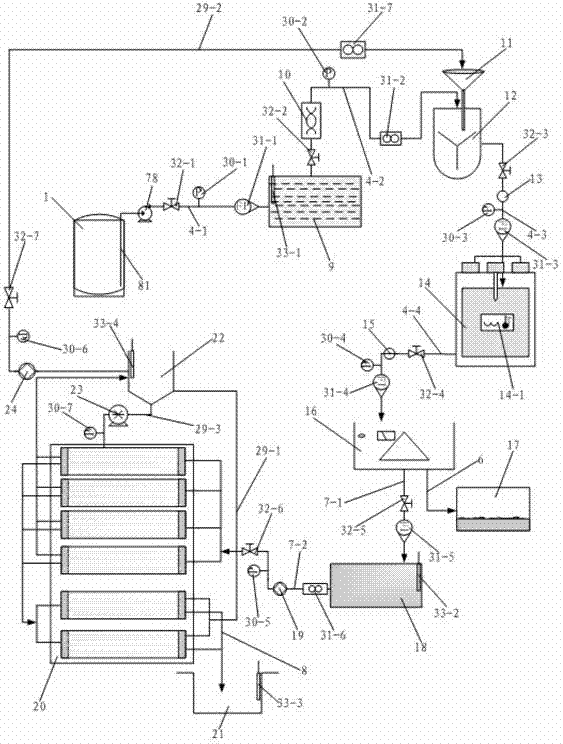

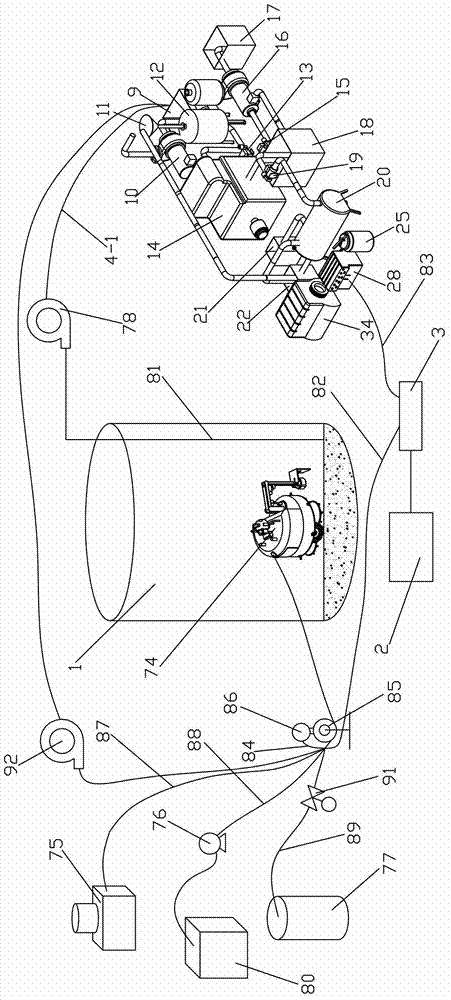

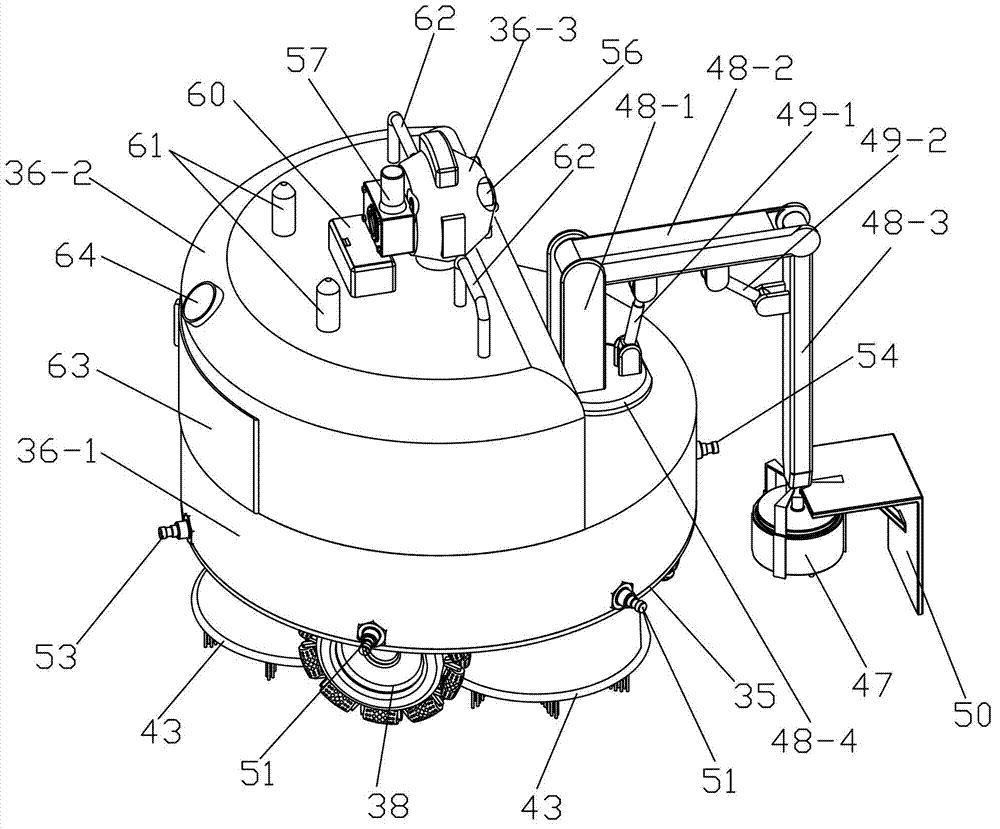

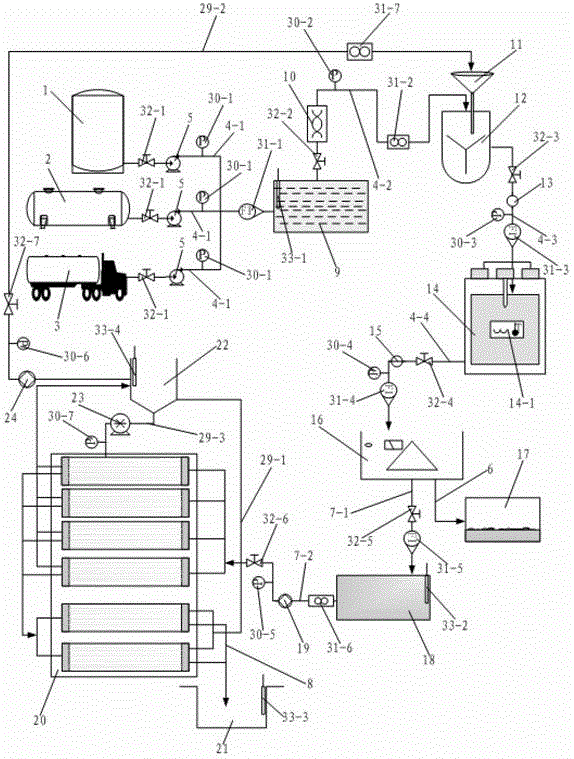

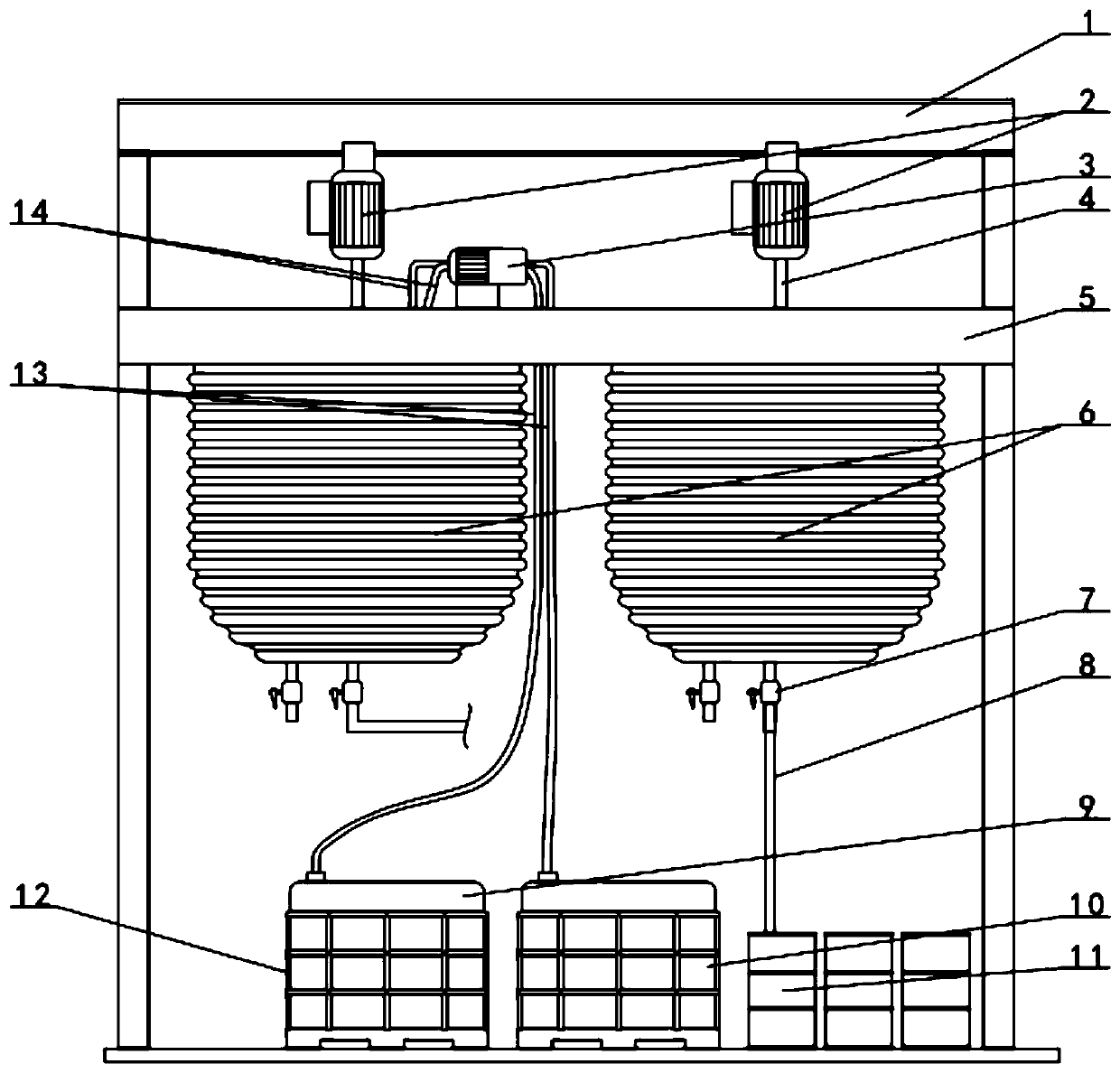

Oil sludge cleaning and processing system for oil tank

InactiveCN102825040ARealize all-round cleaningCompact structureSludge treatmentHollow article cleaningUltrafiltrationResource utilization

The invention discloses an oil sludge cleaning and processing system for an oil tank. The oil sludge cleaning and processing system comprises a cleaning system, an oil sludge processing system and an integrated control system, wherein the cleaning system comprises a cleaning robot, an electric hydraulic pump, a water pump, an inert gas storage tank and a screw pump; the cleaning robot comprises a machine body, a traveling unit, a cleaning unit, a robot cleaning control unit, a sensing and communication unit and a robot power supply unit; the oil sludge processing system comprises an oil sludge processing device, an oil sludge processing control system and an oil sludge processing power supply device; the oil sludge processing device comprises a stirring machine, an ultrasonic emulsion breaking device, a centrifuge and an ultrafiltration system, as well as an oil sludge storage pool, a sludge pool, a centrifugal liquid storage tank, a concentration tank and a filtrate pool; a funnel is arranged on the stirring machine; and the integrated control system comprises an integrated control computer and a communication circuit module. The oil sludge cleaning and processing system disclosed by the invention has the advantages of reasonable design and high degree of intelligentization, and can realize comprehensive cleaning of the oil tank, good safety, fast oil sludge processing speed and resource utilization of oil sludge, and further reduce environmental pollution and waste of resources.

Owner:周利坤

Bitumen compositions and preparation method thereof

InactiveCN101100553AImprove high temperature stabilityHigh high temperature stabilityBuilding insulationsEmulsionPetroleum

An asphalt composite and its production are disclosed. The composite consists of modified asphalt 63-70 wt% and soap liquid 30-37 wt%; the modified asphalt contains petroleum asphalt 84-92 wt%, polymer 3.5-5 wt%, stabilizer 0.05-0.2 wt%, compatible agent 4-10 wt% and filler 0-3 wt%; the soap liquid contains 0.8-1.5 wt% emulsifier, 0.1-0.2 wt% emulsion stabilizer, thickening agent 0.03-0.06 wt% and water 100%. The pH value is adjusted to 1.5-2.5 by concentrated sulfuric acid. The process is carried out by: preparing modified asphalt, preparing soap liquid, and emulsifying. The evaporating residue content is 63-70 wt%, demulsifying rate is less than 40% and evaporating residue softening point is equal to or greater than 60 deg. C.

Owner:中咨公路养护检测技术有限公司

Fast emulsion breaking method

InactiveCN101121898AImprove dehydration rateImprove demulsification efficiencyHydrocarbon oil dewatering/demulsificationNon-miscible liquid separationMass ratioRadiation frequency

The invention relates to a rapid emulsion breaking method, including microwave radiation. Emulsion breaker is added according to the water content of the rolly oil (calculated by weight percent), the mass ratio of the water and emulsion breaker is 1:0.5*10-4 to 5*10-4, and microwave is adopted for emulsion breaking. The emulsion breaker is one or more than two types of mixtures of polyamine polyoxy-propylene polyoxyethylene ether, resin polyoxy-propylene polyoxyethylene ether, higher-alcohol initiator emulsion breaker or propylene glvcol emulsion breaker. The microwave radiation and microwave radiation frequency are 2450MHz or 915MHz. Under the synergistic reaction, water-in-oil emulsion liquid is broken within a relatively short period, a bigger anhydration rate is achieved, and the emulsion-breaking efficiency is improved. In the circumstance of a little emulsion breaker, microwave radiation breaking method can be adopted, and the emulsion breaking speed is increased by 1-2 orders of magnitude compared with the traditional emulsion breaking by heating. The method is easy to implement, energy efficient, rapid in emulsion breaking, and the emulsion breaking effect is good.

Owner:LIAONING UNIVERSITY

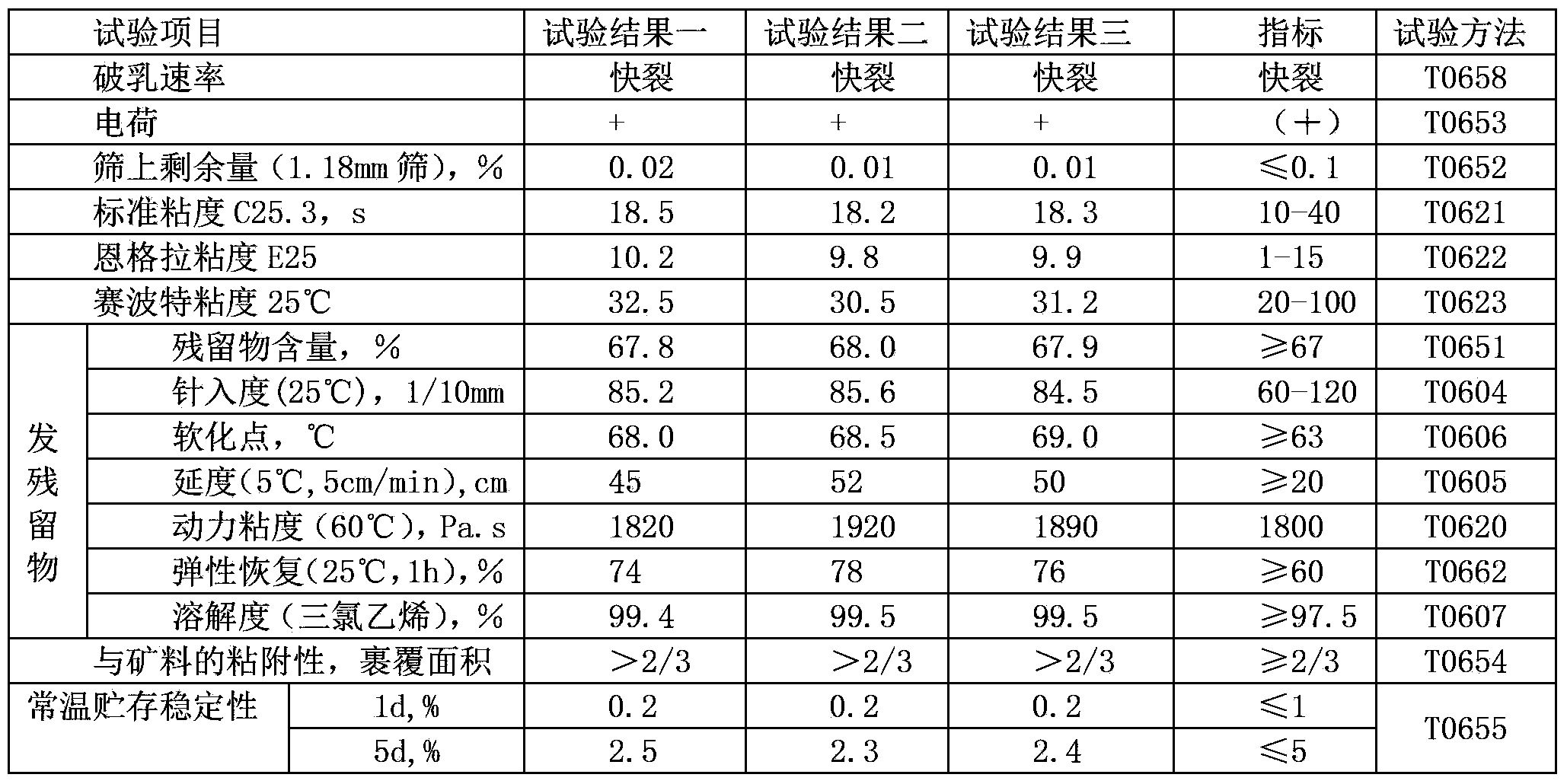

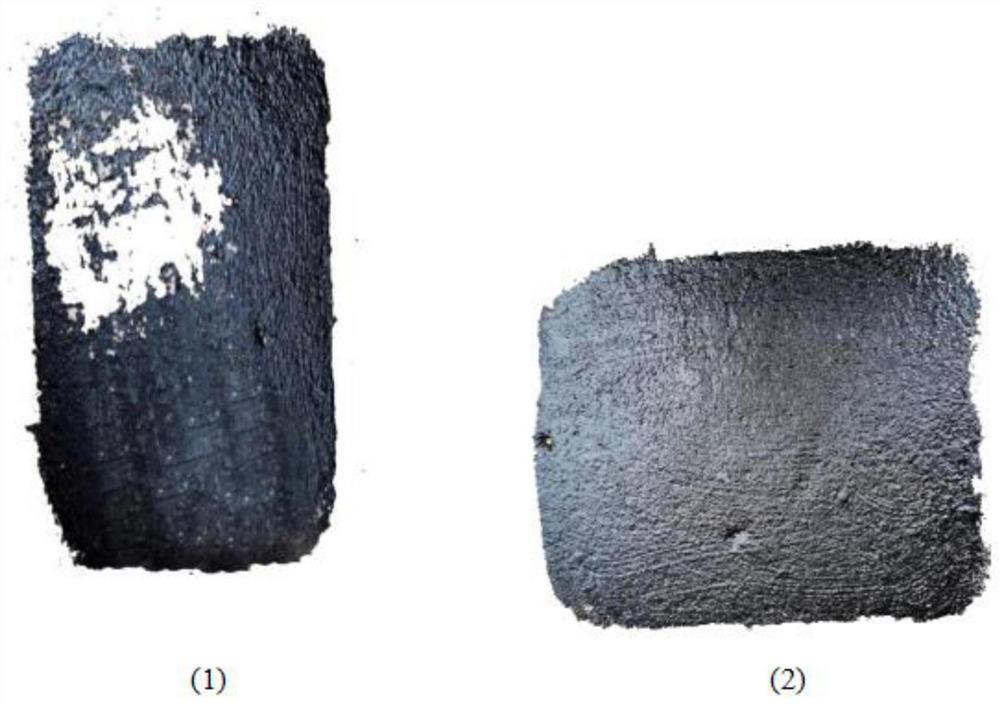

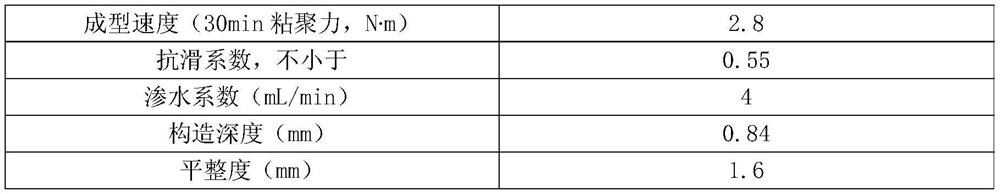

Adhesive layer emulsified asphalt and preparation method thereof

ActiveCN104403335AGood emulsifiabilityFast demulsificationIn situ pavingsBuilding insulationsPolymer scienceBitumen emulsion

The invention relates to an adhesive layer emulsified asphalt and a preparation method thereof. The emulsified asphalt comprises the following components in percentage by weight: 40%-60% of low mark number asphalt, 0-3% of an emulsification promoting additive, 0-3% of a modifier, 0.2%-2% of an asphalt emulsifier, 0.2%-2% of an acid-base modifier and the balance of water. The preparation method comprises the following steps: firstly preparing two intermediate materials, namely easily emulsified and modified low mark number asphalt and liquid soap, and then performing high-speed grinding on the intermediate materials to form unsteady emulsified asphalt; finally performing constant-temperature stirring on the unsteady emulsified asphalt to obtain the adhesive layer emulsified asphalt. The adhesive layer emulsified asphalt has the benefits of high demulsification speed and quick forming, and thus the construction efficiency is greatly improved; the adhesive layer emulsified asphalt is of a non-sticking characteristic, the damage of construction equipment and transport vehicles to an adhesive layer material is avoided, the adhesive efficiency and adhesive strength are improved, and thus the durability of road surfaces is improved; the asphalt is high in high temperature performance; meanwhile, the technology is simple and practical, and is beneficial to popularization and application.

Owner:南京交科瑞路技术有限公司

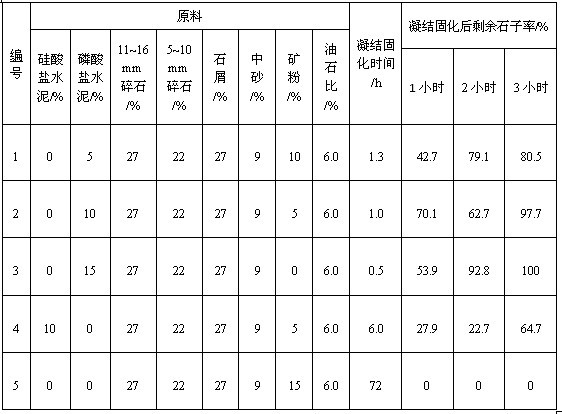

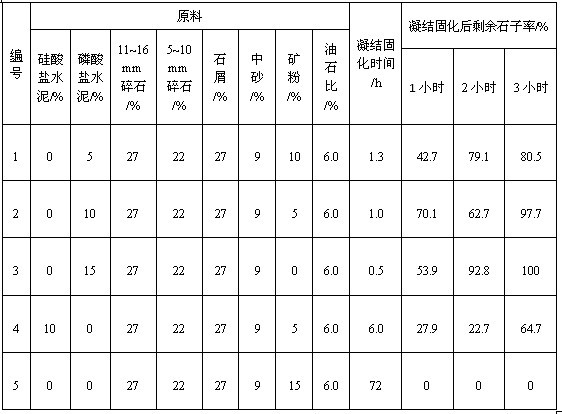

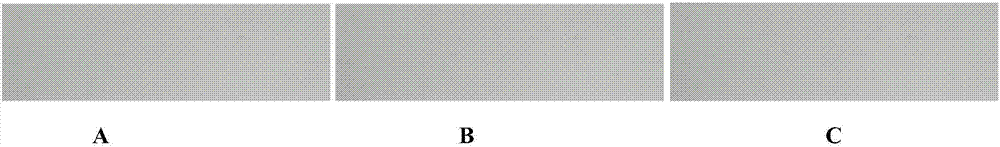

Fast repairing method for asphalt concrete pavement

InactiveCN102505601ASimple demulsification speedFast demulsificationIn situ pavingsRoads maintainenceChipsealMagnesium phosphate

The invention discloses a fast repairing method for an asphalt concrete pavement. The method adopts the following materials by weight part: 1 to 40 parts of magnesium phosphate cement; 10 to 30 parts of rubble with particle sizes ranging from 5 to 10 mm; 20 to 40 parts of rubble with particle sizes ranging from 11 to 16 mm; 20 to 50 parts of stone chips with particle sizes smaller than 5 mm; 5 to 15 parts of medium sand; 0 to 10 parts of mineral powder; and emulsified asphalt added according to 4 to 10 percent of bitumen-aggregate ratio. After being stirred uniformly, all the materials are poured to the damaged pavement which is cleaned; and when the materials are tamped and flattened, the damaged pavement is only maintained for about 3 hours. As the method adopts the pouring forming method in the practical application, and no stirring equipment and no construction equipment are required during the application process, the method has the advantages that the construction is convenient; the maintenance time is short; the impact on transportation is low; and application requirements on both mechanical property and lasting quality can be met. The method is particularly suitable for the fast repairing of the asphalt concrete pavement, and also can be used in small-area of asphalt concrete engineering requiring cold construction.

Owner:CHONGQING UNIV

Preparation method of modified emulsified asphalt for ultra-thin wearing layer

InactiveCN104341603AImprove adhesionImprove low temperature resistanceBuilding insulationsEmulsionSolid content

The invention discloses a preparation method of modified emulsified asphalt for an ultra-thin wearing layer. The preparation method comprises the following steps: (1) preparing materials of asphalt, a modifying agent, a cationic quick-cracking type emulsifying agent and water according to the following matching ratio: 45.0-68.0% of asphalt, 3.0-4.0% of modifying agent, 0.25-0.45% of cationic quick-cracking type emulsifying agent, 0.5-2.0% of stabilizing agent, 1-5% of auxiliary agent and the balance of water; (2) rising the temperature of the asphalt to 160-189 DEG C, adding the modifying agent, stirring uniformly, grinding by a grinding machine, and controlling the particle size of the modifying agent to be less than 5mum, thereby preparing the modified asphalt; (3) adding the emulsifying agent and the stabilizing agent into water with the temperature of 40-60 DEG C, and adjusting the pH value to be 1.5-3 by using the auxiliary agent, thereby preparing soap liquid; and (4) preparing the modified asphalt obtained in the step (2) and the soap liquid in proportion by an emulsifying device. By virtue of the scheme, the obtained modified emulsified asphalt for the ultra-thin wearing layer has the advantages of strong adhesive property, high solid content and fast emulsion-breaking speed.

Owner:JIANGSU COING SPECIAL ASPHALT

High-pour-point crude oil demulsifier

InactiveCN103980932AIncrease viscosityRaise the ratioDewatering/demulsification with chemical meansToluene diisocyanatePotassium hydroxide

The invention provides a high-pour-point crude oil demulsifier. The high-pour-point crude oil demulsifier is prepared from the following components by weight: 20 to 50 parts of epoxypropane, 30 to 60 parts of oxirane, 10 to 15 parts of polyethylene polyamine or alkyl phenolic resin, 2.5 to 5 parts of toluene diisocyanate, 20 to 25 parts of a solvent and 1 to 15 parts of potassium hydroxide. The demulsifier provided by the invention is applicable to demulsification and dehydration of oil field crude oil and dehydration of oil refinery or other oil-water emulsions and has the characteristics of a fast demulsification speed, high dehydration efficiency and the like on asphalt-based crude oil with high viscosity, high gravity and high water content. In use, the demulsifier is injected into end points of a main oil transportation pipeline or into the dehydration pipeline of a combination station.

Owner:盘锦富隆化工有限公司

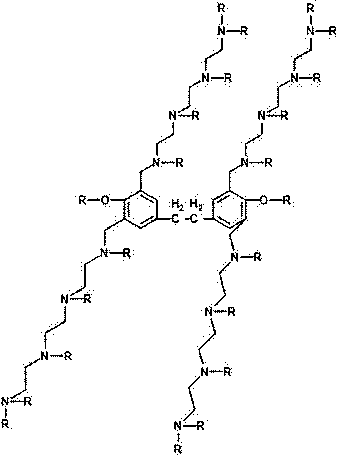

Fast demulsification flocculant for well cleanout truck of oil field

InactiveCN104724801AFast demulsificationGood demulsification effectWaste water treatment from quariesWater/sewage treatment by flocculation/precipitationSewageTruck

The invention discloses a fast demulsification flocculant for a well cleanout truck of an oil field. The flocculant consists of a dendritic nonionic demulsification agent, a polymeric flocculant and a macromolecular ion settling agent in a weight ratio of 1: (1-5): (0.1-1). During use, the dosage is 50ppm, the dehydrating temperature is 30 DEG C, the dehydrating rate after 1 hour is greater than 99%, the discharge sewage is clear in color, the suspended solids are less than or equal to 3mg / L, and the median particle diameter is less than or equal to 1.5 microns. The oil content is less than or equal to 5mg / L, and the flocculant has the advantages of being few in medicament dosage, fast in settling speed and low in using temperature. Compared with a field compound flocculant, the performances of a flushing fluid settled for 1 hour cannot satisfy the requirement of field reinjection water.

Owner:NORTHEAST GASOLINEEUM UNIV

Easily-prepared anti-adhesive emulsified asphalt achieving normal-temperature rapid demulsification and preparation method thereof

InactiveCN106928732AHigh softening pointHigh bonding strengthBuilding insulationsPolymer sciencePolymer adhesive

The invention relates to easily-prepared anti-adhesive emulsified asphalt achieving normal-temperature rapid demulsification and a preparation method thereof, and belongs to the technical field of road engineering materials. The anti-adhesive emulsified asphalt is prepared from heavy traffic road asphalt, deoiled asphalt, an asphalt interface modifier, polymer latex, an auxiliary, an emulsifier, an acidifying or alkalizing agent and water; the preparation method comprises the steps that the emulsifier, the polymer latex and an auxiliary-aqueous solution are added into water, the PH value is adjusted, liquid soap is prepared, the heavy traffic road asphalt, the deoiled asphalt and the asphalt interface modifier are stirred to be uniform at a high temperature and heated to reach a proper temperature, the mixture and the liquid soap are subjected to colloid mill high-speed shear preparation, and the anti-adhesive emulsified asphalt is obtained. The anti-adhesive emulsified asphalt has the advantages that the emulsifying temperature of the asphalt is low, emulsification is easy, and the emulsification technology is simple and easy to operate; demulsification can be conducted rapidly at a normal temperature, and the construction efficiency is improved; the anti-adhesive emulsified asphalt has the advantage of being resistant to wheel adhesion when serving as a road adhesion layer, the phenomenon that due to damage of a construction vehicle to the adhesion layer, the adhesion layer loses efficacy is avoided, and the service life of a road is prolonged.

Owner:BEIJING MUNICIPAL ROAD & BRIDGE BUILDING MATERIALGRP +1

Emulsified asphalt for non-stick wheel, and preparation method thereof

InactiveCN110878174AFast demulsificationFast film formationBuilding insulationsBitumen emulsionProcess engineering

The invention relates to emulsified asphalt for a non-stick wheel, and a preparation method thereof, and belongs to the technical field of emulsified asphalt modification. The emulsified asphalt for the non-stick wheel is prepared from the following raw materials in parts by weight: 50-65 parts of petroleum asphalt, 3-8 parts of sulfur, 1-3 parts of a cationic emulsifier, 0.3-2 parts of a stabilizer, 0.5-3 parts of a pH regulator, 2-5 parts of polymer emulsion and 40-50 parts of water, wherein the petroleum asphalt comprises 10-30 parts of low-grade asphalt and 30-55 parts of high-grade asphalt. The prepared emulsified asphalt for the non-stick wheel has advantages of high demulsification speed, high film forming speed and high film forming strength, does not have the phenomenon of sticking to the tire of a construction vehicle, does not have the phenomenon of stripping of a lower layer, and has good adhesion inhibition effect on the tire; and the preparation method of the emulsified asphalt for the non-stick wheel is simple, practical and convenient to operate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fast repairing method for asphalt concrete pavement

InactiveCN102505601BSimple demulsification speedFast demulsificationIn situ pavingsRoads maintainenceChipsealMagnesium phosphate

The invention discloses a fast repairing method for an asphalt concrete pavement. The method adopts the following materials by weight part: 1 to 40 parts of magnesium phosphate cement; 10 to 30 parts of rubble with particle sizes ranging from 5 to 10 mm; 20 to 40 parts of rubble with particle sizes ranging from 11 to 16 mm; 20 to 50 parts of stone chips with particle sizes smaller than 5 mm; 5 to 15 parts of medium sand; 0 to 10 parts of mineral powder; and emulsified asphalt added according to 4 to 10 percent of bitumen-aggregate ratio. After being stirred uniformly, all the materials are poured to the damaged pavement which is cleaned; and when the materials are tamped and flattened, the damaged pavement is only maintained for about 3 hours. As the method adopts the pouring forming method in the practical application, and no stirring equipment and no construction equipment are required during the application process, the method has the advantages that the construction is convenient; the maintenance time is short; the impact on transportation is low; and application requirements on both mechanical property and lasting quality can be met. The method is particularly suitable for the fast repairing of the asphalt concrete pavement, and also can be used in small-area of asphalt concrete engineering requiring cold construction.

Owner:CHONGQING UNIV

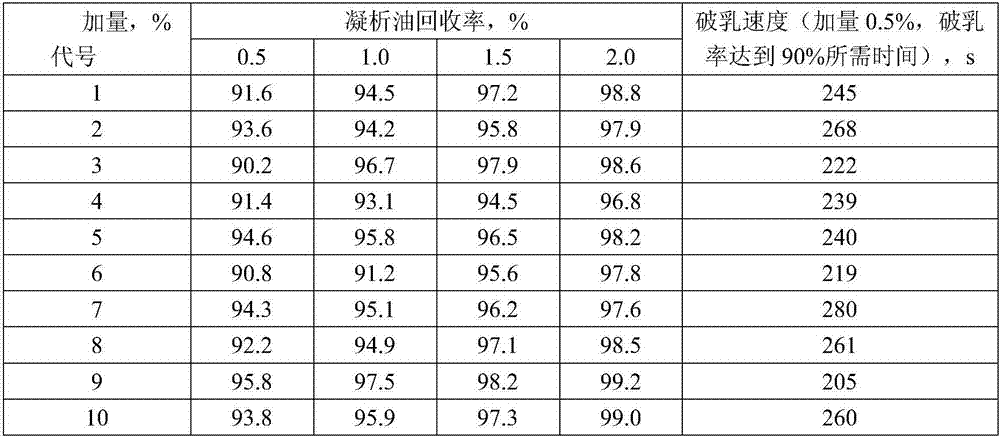

Oil-soluble condensate oil emulsion breaker and preparation method thereof

ActiveCN104498080ALow recovery rateFast demulsificationDewatering/demulsification with chemical meansHydrocarbon oils treatmentBetaineOil emulsion

The invention discloses an oil-soluble condensate oil emulsion breaker and a preparation method thereof. The oil-soluble condensate oil emulsion breaker is a compound formed by adding a cross-linking type block polyether emulsion breaker, a comb-type polysiloxane emulsion breaker and a glycine betaine type fluorocarbon surfactant to a solvent, and the compound comprises the following components in percentage by weight: 10%-25% of the cross-linking type block polyether emulsion breaker, 5%-15% of the comb-type polysiloxane emulsion breaker, 0.05%-0.2% of the glycine betaine type fluorocarbon surfactant and the balance of the solvent. The oil-soluble condensate oil emulsion breaker disclosed by the invention is suitable for the recovery of condensate oil contained in a produced fluid of a natural gas well foaming drainage gas recovery process, can achieve an ideal emulsion breaking effect of an condensate oil emulsion formed from different foaming drainage agents, has the characteristics of high emulsion breaking speed and high emulsion breaking efficiency at normal temperature, and can ensure the high-efficiency recovery of the condensate oil of a gas field.

Owner:成都华阳兴华化工有限公司

Bio-based non-viscous wheel tack coat and preparation method thereof

ActiveCN107083232AReduce consumptionReduce high temperature viscosityNon-macromolecular adhesive additivesBituminous material adhesivesEpoxyDisease

The invention belongs to the technical field of emulsified asphalt and relates to a bio-based non-viscous wheel tack coat and a preparation method thereof. The method comprises the preparation steps of mixing hard asphalt with biomass heavy oil under the shear conditions of 120-130 DEG C and 3,000-5,000r / min according to ratio for 20-30min to obtain biological asphalt; shearing the biological asphalt, epoxy resin and nano silicon dioxide at 110-120 DEG C evenly to obtain modified biological asphalt; and preparing the bio-based non-viscous wheel tack coat from the modified biological asphalt at 130-140 DEG C and an emulsifier solution at 50-60 DEG C through a colloid mill according to the ratio. Compared with the prior art, the tack coat prepared through the method is high in emulsifying speed, non-viscous to a wheel, and not easy to fall off, enough interlayer bonding strength can be provided, the interlayer disease generated by interlayer shear force of an asphalt pavement is effectively improved, and the bio-based non-viscous wheel tack coat is low in cost and has important application value and economic benefit.

Owner:SHANXI PROVINCIAL RES INST OF COMM

Broad-spectrum aged oil demulsifier and preparation method thereof

ActiveCN107418616AReduce intensityReduce interfacial tensionDewatering/demulsification with chemical meansHydrocarbon oils treatmentDemulsifierEther

The invention discloses a broad-spectrum aged oil demulsifier. The broad-spectrum aged oil demulsifier is prepared from the components in percentage by weight: 3 percent to 15 percent of a super-high molecular weight crude oil demulsifier, 21 percent to 35 percent of ternary copolymerized ether, 16 percent to 30 percent of an auxiliary agent and 20 percent to 60 percent of a mixed solvent; the invention further discloses a preparation method. The demulsifier has a reasonable molecular structure, proper molecular weight and strong cooperativity, has the characteristics of deep dehydration on aged oil, rapid demulsifying speed, clear and smooth oil-water interface, wetting, penetration and water clearing and the like, and has broad-spectrum performance.

Owner:盘锦富隆化工有限公司

Cosmetic composition with cool and refreshing use feeling, and preparation method thereof

InactiveCN107753314AMild and non-irritating to the eyesCoolCosmetic preparationsToilet preparationsChemistrySkin temperature

The invention discloses a cosmetic composition with cool and refreshing use feeling. The cosmetic composition is characterized by comprising the following components in parts by weight: 5 to 25 partsof volatile oil, 0.1 to 1.5 parts of acrylic acid (ester) copolymer sodium and 0.1 to 0.5 part of lecithin. The cosmetic composition, which is prepared by adding the volatile oil with specific contentand specific variety into the formula of the cosmetic composition, has high demulsification speed during coating on the basis of guaranteeing the emulsification stability of the product, takes away part of skin temperature through volatilization of the water and the volatile oil, enables the skin to have certain cool feeling, does not influence the odor of the product and is mild and non-irritantto skin, particularly eyes, during use.

Owner:HUAANTANG BIOTECH GRP CO LTD

Emulsified asphalt and preparation method thereof

PendingCN111621035AAvoid destructionHigh bonding strengthBuilding insulationsCellulosePolymer science

The invention relates to emulsified asphalt and a preparation method thereof. The emulsified asphalt comprises the following components in percentage by mass: 45%-65% of asphalt, 1%-12% of a modifier,0.4%-3.5% of an emulsifier, 0.1%-0.5% of a separant, 0-4% of hydrochloric acid or phosphoric acid, 0-1% of a stabilizer and the balance of water. The preparation method comprises the following steps:adding the separant, the cellulose and the emulsifier into water to prepare liquid soap, heating the liquid soap and the asphalt, adding the modifier, and carrying out high-speed shearing and grinding on the liquid soap and the asphalt through a colloid mill after the modifier is completely dissolved to obtain the emulsified asphalt. The material has the advantages that the construction efficiency is improved, the integrity of an adhesive layer material is guaranteed, the pavement performance is improved, the storage stability is excellent, special equipment does not need to be purchased additionally, and popularization is easy.

Owner:江苏高速新材料科技有限公司

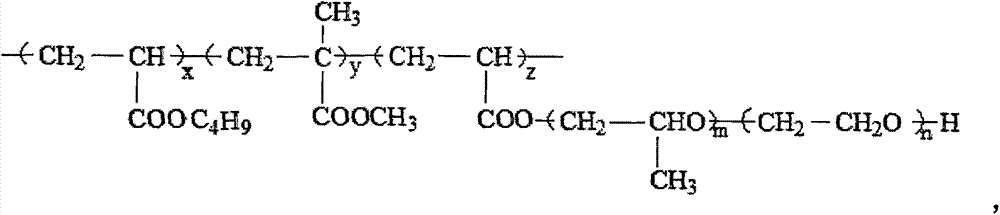

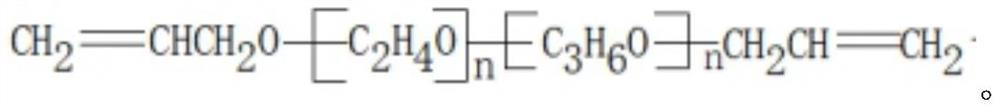

Amphiphilic allyl polymer for sewage treatment demulsifier and preparation method thereof

InactiveCN111675811AHigh active ingredientIncreased double bond contentFatty/oily/floating substances removal devicesNon-miscible liquid separationDemulsifierPolymer science

The invention relates to an amphiphilic allyl polymer for a sewage treatment demulsifier and a preparation method thereof, and belongs to the technical field of polymer synthesis industrial sewage treatment. The amphiphilic allyl polymer is obtained by carrying out a polymerization reaction on diallyl-terminated polyether and one or more of low-hydrogen silicone oil, acrylamide (AM), acrylic acid(AA) and chloropropene. The amphiphilic allyl polymer for a sewage treatment demulsifier has the characteristics of strong demulsifying capacity, high demulsifying speed, low dosage, low demulsifyingtemperature and particular suitability for thick oil emulsion; and meanwhile, the invention provides a simple and convenient preparation method.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

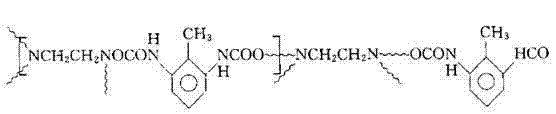

Preparation method of ASP flooding crude oil demulsifier

InactiveCN111778065AImprove surface activityImprove efficiencyDewatering/demulsification with chemical meansTert butyl phenolPtru catalyst

The invention discloses a preparation method of an ASP flooding crude oil demulsifier, which comprises the following steps: (1) mixing tert-butyl phenol and triethylene tetramine, heating until complete dissolution, and dropwisely adding a formaldehyde solution to generate an initiator A; (2) putting the initiator A and a catalyst into a reaction kettle, sealing, vacuumizing, introducing epoxypropane, heating, and controlling the pressure to obtain an intermediate product B; (3) putting the intermediate product B and a catalyst into a reaction kettle, sealing, vacuumizing, introducing epoxypropane, heating, and controlling the pressure to obtain polyether C; and (4) adding polyether C into the reaction container, dissolving polyether C, adding choline chloride, stirring, heating to 50-75 DEG C, completely dissolving, dropwise adding TDI, and finishing dropwise adding when the wire drawing length is 3-4cm, thereby obtaining the ASP flooding crude oil demulsifier. The demulsifier obtained by the process has good lipophilicity, can significantly improve the use efficiency of a chemical agent, and has high surface activity, high demulsification speed and good demulsification effect.

Owner:BINZHOU UNIV

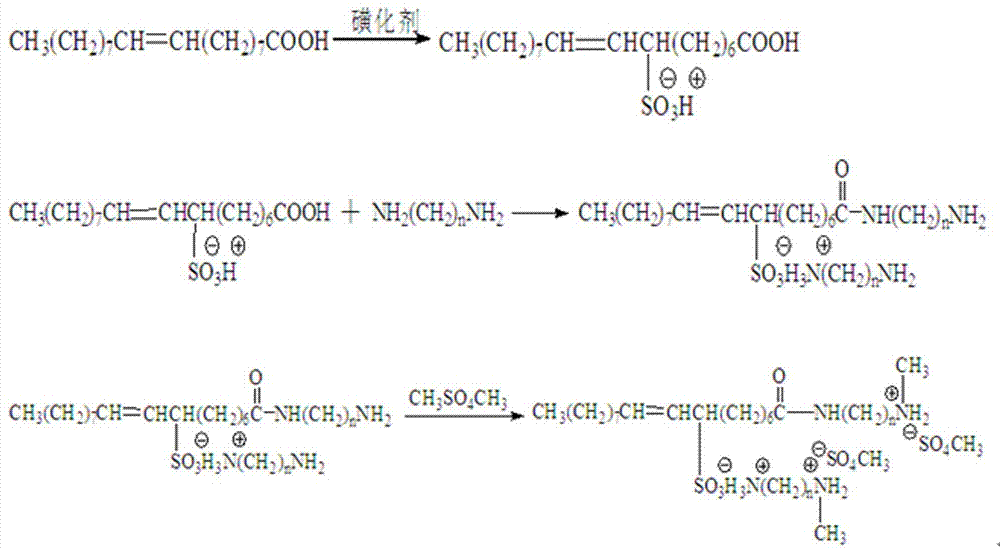

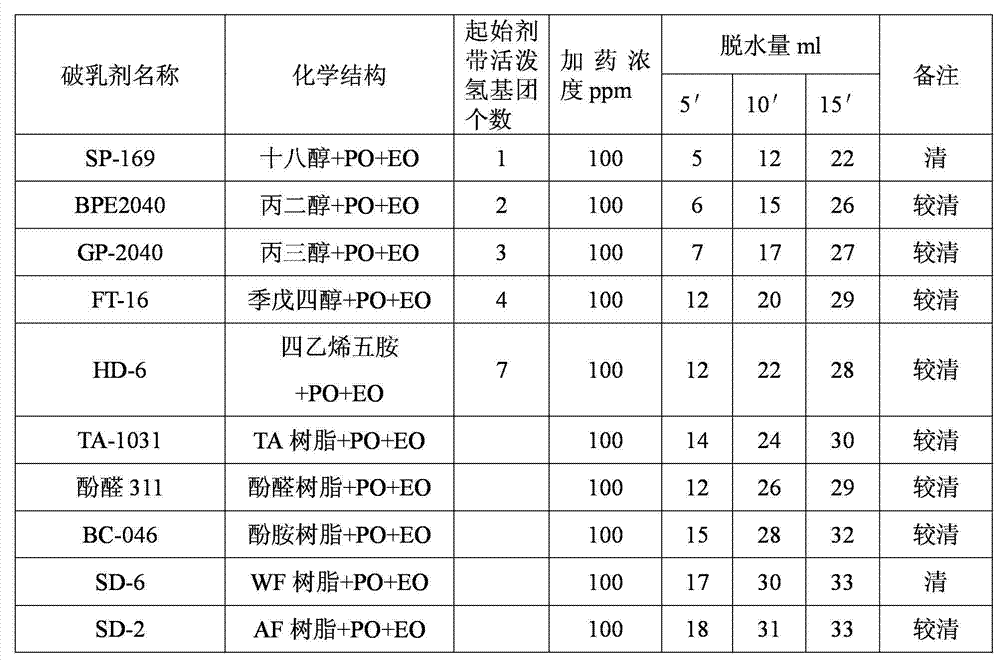

Method for synthesizing crude oil demulsifying agent initiator

InactiveCN103113545AFast demulsificationImprove dehydration rateDewatering/demulsification with chemical meansChemical reactionPhenol

The invention relates to a method for synthesizing a crude oil demulsifying agent initiator. The initiator is novel thermoplastic resin and is synthesized by chemical reaction from organic phenol, organic amine and formaldehyde which are used as starting materials, wherein the molar ratio of the organic phenol to the organic amine to the formaldehyde is 1:(2-4):(2-6). By adopting the initiator, a demulsifying agent which is high in demulsifying speed and dehydration rate and has a good use effect at a low temperature can be synthesized, a lot of heating energy sources of an oil field can be saved, the crude oil demulsifying dehydration cost is reduced, and the pollution to the environment is reduced, so that the initiator has important practical significance for crude oil production, gathering and transportation.

Owner:BINZHOU UNIV

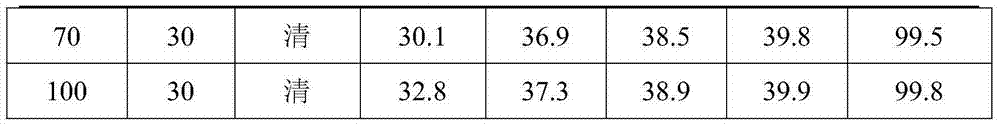

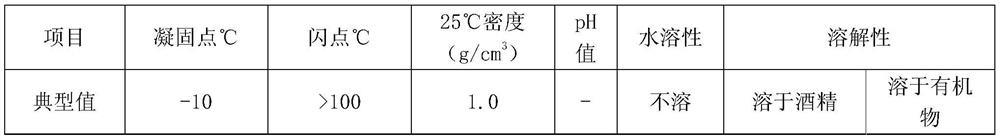

Micro-surfacing emulsified asphalt suitable for low-temperature construction at night as well as preparation method and application thereof

InactiveCN111849179ASeal the water wellImprove adhesionBuilding insulationsHigh humidityBitumen emulsion

The invention provides micro-surfacing emulsified asphalt suitable for low-temperature construction at night as well as a preparation method and application thereof. The micro-surfacing emulsified asphalt suitable for low-temperature construction at night is prepared from the following raw materials in parts by weight: 50-65 parts of petroleum asphalt, 0.5-10 parts of an emulsifier, 2-6 parts of awarm mixing agent, 35-50 parts of water, 2-10 parts of modified latex and 2-10 parts of an additive. The emulsified asphalt and the mixture prepared by the invention are especially suitable for roadnight construction application, the technical problems that the micro-surfacing demulsification speed is low and the maintenance time is long due to low temperature and high humidity at night and it is difficult to adapt to night construction of expressways in Beijing areas are effectively solved, the pavement has good water seepage resistance, wear resistance and skid resistance, the driving useperformance is good, and the service life of the pavement can be prolonged to a great extent.

Owner:BEIJING SHOUFA HIGHWAY MAINTENANCE & CONSTR +1

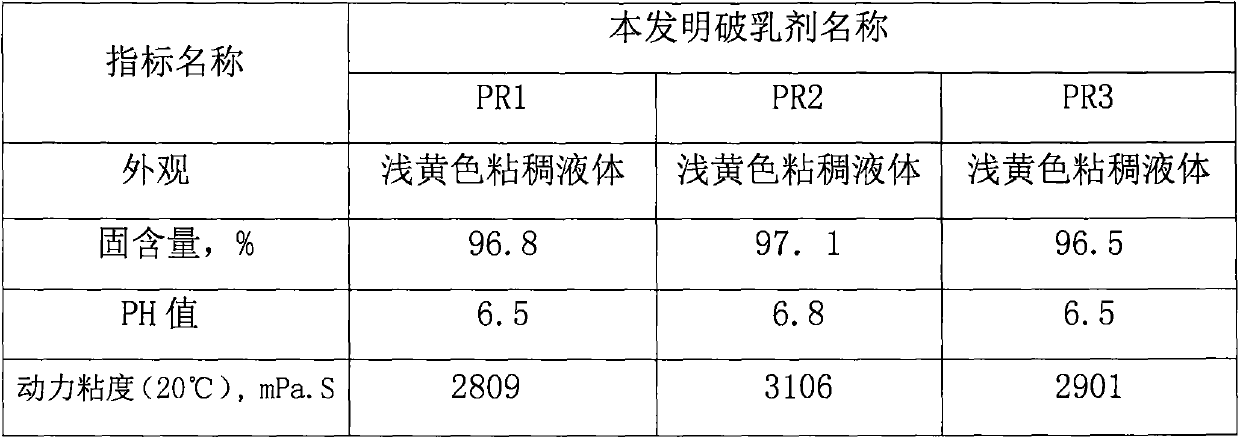

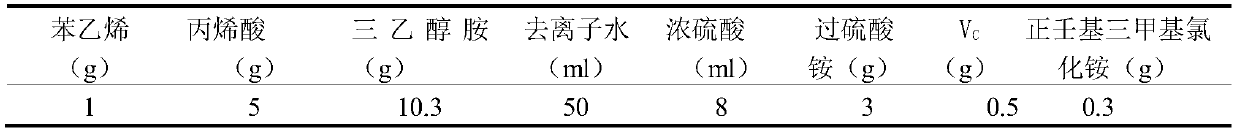

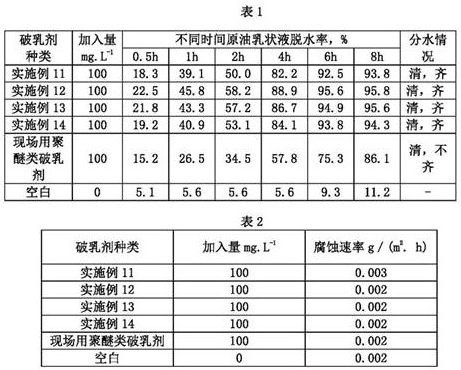

Polymer flooding crude oil low temperature fast demulsifier and preparation method thereof

ActiveCN110387256AExcellent compatibility and synergyFast demulsificationDewatering/demulsification with chemical meansUreaPolymer flooding

The invention discloses a polymer flooding crude oil low temperature fast demulsifier and a preparation method thereof. The polymer flooding crude oil low temperature fast demulsifier is prepared fromthe following components in percentage by mass: 35-70% of a DR-type crude oil demulsifier, 15-60% of a conventional TA1031 crude oil demulsifier, 0.5-2% of vitamin C and3-7% of urea by the preparation method. The DR type crude oil demulsifier, the conventional demulsifier TA1031, the vitamin C and the urea are uniformly mixed by mass percentage, and the polymer flooding crude oil low temperaturefast demulsifier PR is obtained. According to the polymer flooding crude oil low temperature fast demulsifier, Daqing polymer flooding crude oil can be effectively demulsified, and the polymer flooding crude oil low temperature fast demulsifier has the characteristics of high low-temperature demulsification speed, high demulsification efficiency, clear oil-water interface, and low oil content in dehydrated water.

Owner:盘锦富隆化工有限公司

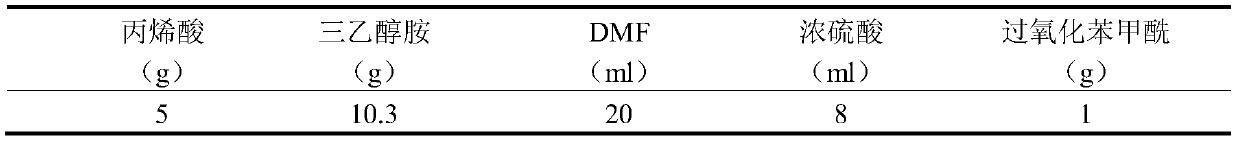

Preparation method of coal tar wastewater demulsifier

InactiveCN110240225AGood demulsification effectFast demulsificationFatty/oily/floating substances removal devicesNon-miscible liquid separationEnvironmentally friendlyTriethanolamine

The invention relates to the technical field of preparation of demulsifiers, in particular to a preparation method of a coal tar wastewater demulsifier. The preparation method of the coal tar wastewater demulsifier comprises the following steps of sequentially adding agents into a three-necked flask while stirring an obtained mixture, and after reflux condensation and heating are conducted, cooling the obtained mixture to room temperature to obtain the coal tar wastewater demulsifier, wherein the agents at least comprise acyclic acid, triethanolamine and concentrated sulfuric acid. The coal tar wastewater demulsifier prepared by means of the preparation method has a better demulsification effect than those of existing demulsifiers on the market, and is high in demulsification speed, little in usage and environmentally friendly. The preparation method of the demulsifier is simple, preparation is convenient, and the demulsifier is fast, efficient and low in cost, and has small toxic and side effects.

Owner:LULIANG UNIV

Demulsifier for treating heavy oil and preparation method thereof

ActiveCN109609178BFast demulsificationImprove water qualityDewatering/demulsification with chemical meansAlkaneDemulsifier

The invention relates to the technical field of petroleum demulsifiers and their preparation, and relates to a demulsifier for treating heavy oil and a preparation method thereof. The raw materials of the former include polyoxyethylene polyoxypropylene block copolymers, ketoacids, acetylenic alcohols and water. The oxyethylene polyoxypropylene block copolymer is mixed and dissolved with keto acid, acetylenic alcohol and water after being heated in a reactor to obtain a demulsifier for treating heavy oil. The demulsifier for treating heavy oil of the present invention has the characteristics of fast demulsification speed and good water quality after separation, especially can solve the corrosion problem of equipment containing acid demulsifier products, and has better antirust and anticorrosion effects. The preparation process of the present invention is simple, convenient for large-scale production, and the demulsifier for treating heavy oil has excellent demulsification effect and dehydration performance. At the same time, the raw materials do not contain sulfur, phosphorus, aromatic rings, chlorine and other substances harmful to human body and environment, which meet the requirements of The concept of safe and environmentally friendly production.

Owner:克拉玛依新科澳石油天然气技术股份有限公司

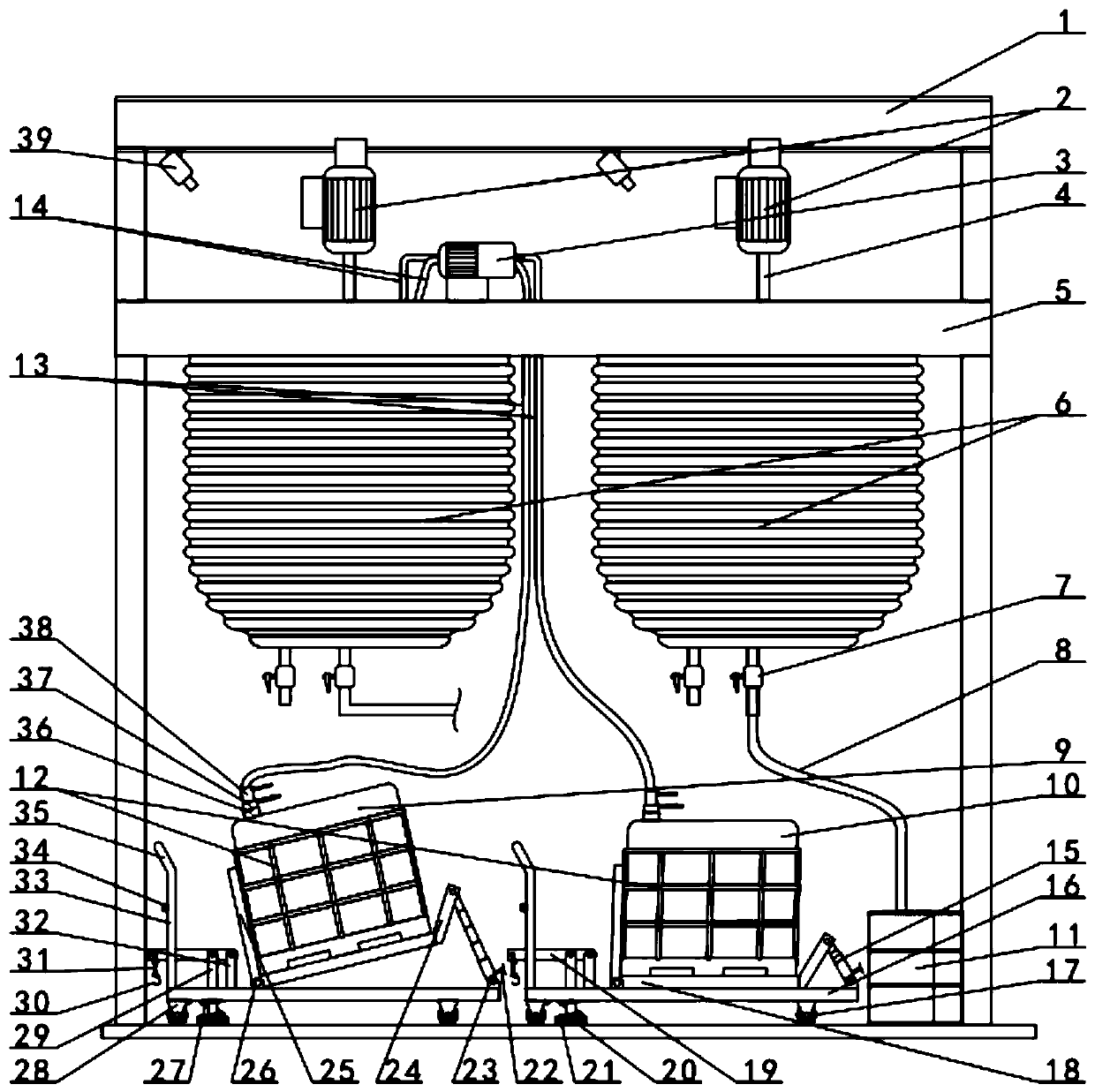

Oily sludge treatment process and device

InactiveCN102757162BEasy to separateThe treatment process is simple and effectiveSludge treatmentAutomatic controlResource utilization

The invention discloses an oily sludge treatment process and a device. The oily sludge treatment process includes the steps of watering and stirring for dilution, ultrasonic wave demulsification, solid-liquid separation and oil-water separation. The device comprises an oily sludge treatment system, an automatic control system and a power supply device, wherein the oily sludge treatment system comprises a stirrer, an ultrasonic wave demulsification device, a centrifugal machine, a ultra-filtration system, an oily sludge storage tank, a sludge tank, a centrifugation liquid storage tank, a concentration tank and a filtrate tank, the stirrer is used for adding water into oily sludge for diluting the oily sludge, the ultrasonic wave demulsification device is used for demulsifying the oily sludge, the centrifugal machine is used for performing solid-liquid separation to the oily sludge, the ultra-filtration system is used for performing oil-water separation to the oily sludge, the oily sludge storage tank is used for storing the oily sludge, the sludge tank is used for storing the sludge, the centrifugation liquid storage tank is used for storing oily sewage, the concentration tank is used for storing oil, and the filtrate tank is used for storing water. According to the oily sludge treatment process and the device, the design is novel and reasonable, achievement costs are low, the treatment speeds are fast, the separation of the oil, the sludge and the water is thorough, the resource utilization of the oily sludge is achieved, and environmental pollution and resource waste are reduced.

Owner:周利坤

Oil-soluble condensate oil demulsifier and preparation method thereof

InactiveCN106947517ANo smellImprove compatibilityDewatering/demulsification with chemical meansOrganic acidDemulsifier

The invention discloses an oil-soluble condensate oil demulsifier, which is prepared through reacting an SP-type demulsifier, an AP-type demulsifier, an AE-type demulsifier, an AR-type demulsifier and an organic acid and adjusting the pH to be 7-10. The demulsifier has the characteristics of good compatibility, small dosage, high demulsifying speed, high condensate oil recovery rate and clear oil-water interface after demulsifying. Effective separation of oil and water can be quickly achieved through condensate oil after demulsifying at a room temperature, efficient recovery of the condensate oil is ensured and the water treatment technology is simplified. The invention further provides a preparation method of the oil-soluble condensate oil demulsifier. The method is simple in step and convenient to operate.

Owner:广汉泰能特新材料科技有限公司

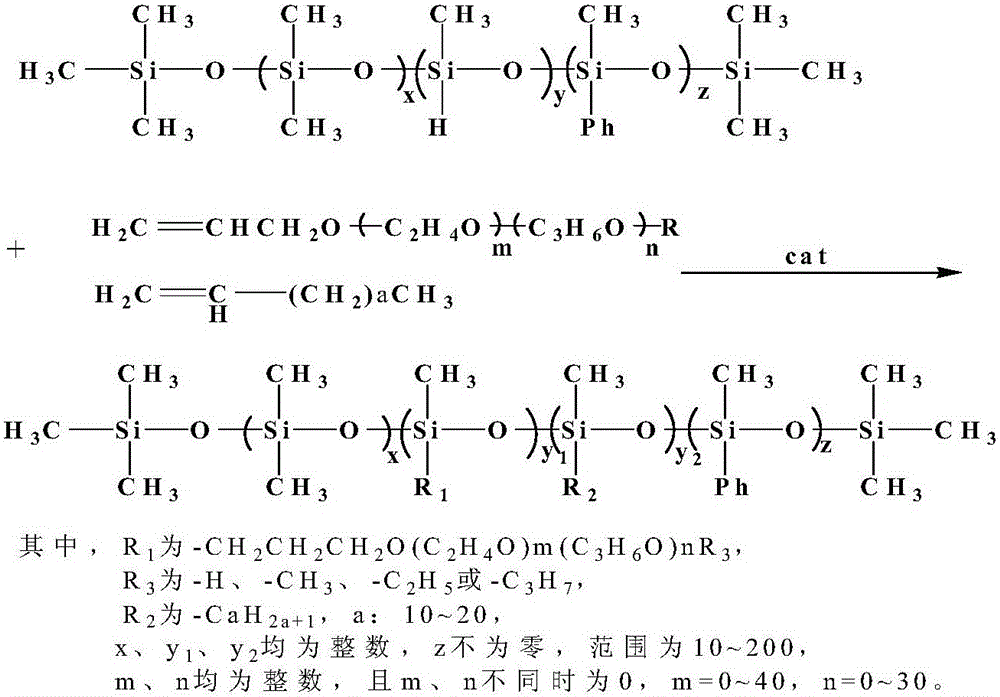

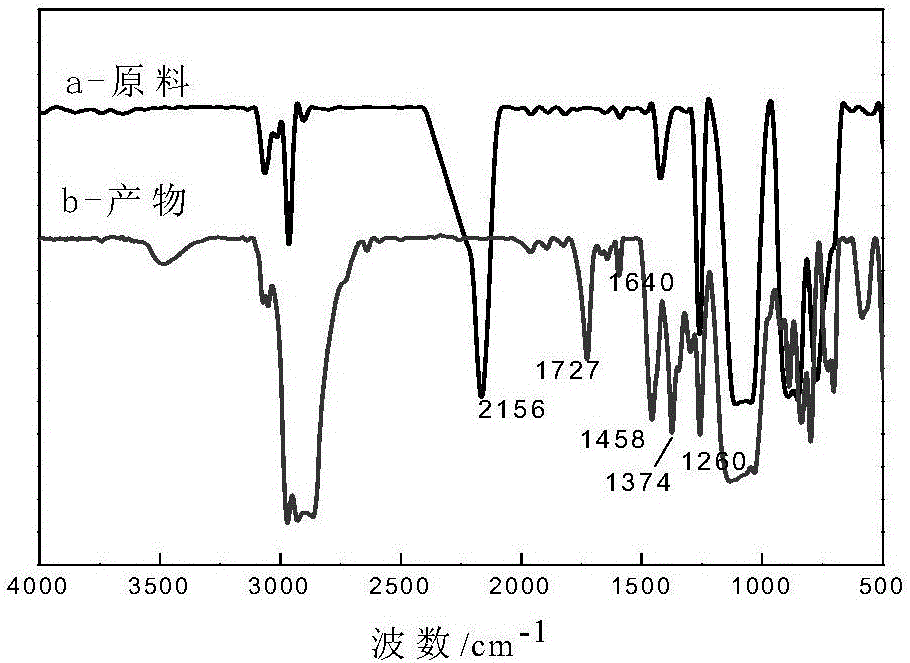

Oil-soluble demulsifier and preparation method thereof

InactiveCN105778107AGood solubility and diffusionAchieve separationDewatering/demulsification with chemical meansDemulsifierHydrogen

The invention discloses an oil-soluble demulsifier and a preparation method thereof. The preparation method comprises the following steps: adding phenyl hydrogen-containing silicone oil and an organic solvent into a reaction kettle; heating to 70 to 75 DEG C with stirring; adding a suitable amount of catalyst at the temperature; then heating to 80 to 130 DEG C; dropwise adding a mixture of long-chain carbon olefins and polyether; after the mixture is dropwise added, reacting for 5 to 10 hours at the temperature; distilling under a reduced pressure to remove low-boiling-point substances and unreacted raw materials to obtain the novel oil-soluble demulsifier, wherein the molar ratio of the phenyl hydrogen-containing silicone oil to the mixture of polyether and long-chain alkyl is 1:(1-1.3); the molar ratio of polyether to long-chain carbon olefins is 1:(1-4). The novel oil-soluble demulsifier provided by the invention can prolong action time in demulsification application, and moreover, has the advantages of high-efficiency demulsifying effect, wide application range, small using amount and low toxicity.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of block polyether type ageing oil demulsifier

InactiveCN111205449AGood demulsification effectFast demulsificationDewatering/demulsification with chemical meansXylylenePtru catalyst

The invention discloses a preparation method of a block polyether type ageing oil demulsifier. The preparation method comprises the following steps: adding a certain amount of phenol and ethylene glycol into a quartered bottle, adding hydrogen chloride and a methanol solution, heating to 75-85 DEG C, reacting for 2.5 hours, and distilling at 45 DEG C to obtain an intermediate product A; putting the intermediate product A and triethylene tetramine into a quartered bottle, heating to dissolve, slowly dropwise adding a formaldehyde solution at the temperature of 40-55 DEG C, carrying out heat preservation reaction, adding xylene, carrying out reflux dehydration, and distilling off xylene to generate an initiator B; putting the initiator B and catalyst potassium hydroxide into a high-temperature and high-pressure reaction kettle, sealing, introducing propylene oxide, and carrying out a heating reaction to obtain an intermediate product 1; and adding potassium hydroxide into the intermediate product 1, introducing ethylene oxide, and carrying out a heating reaction to obtain the block polyether type aging oil demulsifier. The block polyether type aging oil demulsifier prepared by the method has more branched chain structures, and can better destroy the interfacial film on the oil-water surface of the aging oil, thereby achieving the goals of demulsification and dehydration.

Owner:NORTHEAST GASOLINEEUM UNIV

Quick-setting wheel-sticking-free adhesive layer emulsified asphalt for adhesive layer as well as preparation method and use method of quick-setting wheel-sticking-free adhesive layer emulsified asphalt

InactiveCN112662190AImprove efficiencyImprove construction efficiencyBuilding insulationsBitumen emulsionMechanical engineering

The invention discloses quick-setting wheel-sticking-free adhesive layer emulsified asphalt for an adhesive layer as well as a preparation method and a use method of the quick-setting wheel-sticking-free adhesive layer emulsified asphalt, and the quick-setting wheel-sticking-free adhesive layer emulsified asphalt is prepared from the following components in percentage by weight: 40-60% of matrix asphalt; 0.1%-2% of water-based resin; 10%-15% of an asphalt blending agent; 1%-3% of an asphalt emulsifier; 1-3% of hydrochloric acid; 0.1%-0.3% of an emulsified asphalt stabilizer; 3-5% of an SBS aqueous emulsion; remaining amount of water. The invention has the advantages of high demulsification speed and high forming speed, overcomes the fragility of hard asphalt, has certain flexibility, greatly enhances the pavement performance and construction efficiency of the adhesive layer, has the characteristic of no wheel sticking, avoids the damage of construction equipment and transport vehicles to the adhesive layer material, enhances the integrity of the adhesive layer, and paves the non-stick equipment; the paving is convenient, and the application prospect is good.

Owner:南通福伦利新材料有限公司

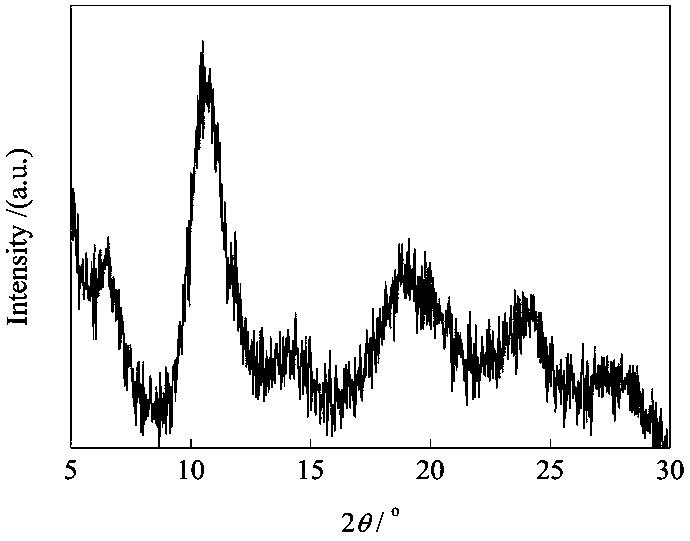

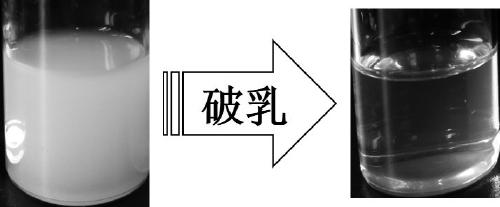

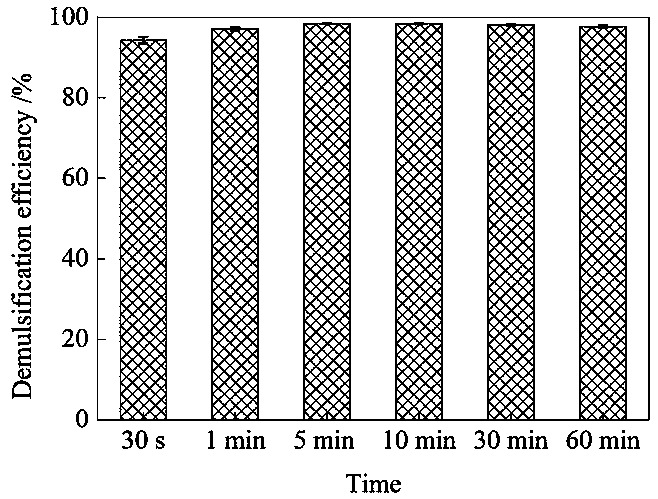

Preparation method of MIL-100 (Fe) composite material capable of circularly and quickly demulsifying

ActiveCN111392813ASuper fast demulsification speedStable cycle demulsification abilityFatty/oily/floating substances removal devicesWater contaminantsEnvironmental chemistryTrimesic acid

The invention provides a preparation method of an MIL-100 (Fe) composite material capable of circularly and quickly demulsifying. The preparation method comprises the following steps: at room temperature, mixing an ionic liquid and a Fe (III) metal salt solution, and encapsulating the ionic liquid in pores of MIL-100 (Fe) through self-assembly of Fe < 3 + > and trimesic acid, thereby preparing theMIL-100 (Fe) composite material anchored by taking the ionic liquid as a positive charge carrier. The MIL-100 (FE) composite material prepared by the preparation method disclosed by the invention canbe used for quickly demulsifying within 30 seconds, so that large-flux treatment of emulsified oily wastewater can be realized; the MIL-100 (Fe) composite material still maintains higher demulsification capacity after being used for multiple times, can be repeatedly utilized, and is beneficial to reducing the operation cost of emulsified oily wastewater pollution remediation and demulsification application in the petroleum industry. Therefore, the method has important potential application value in the fields of environmental pollution remediation, petroleum industry and the like.

Owner:SOUTHWEST PETROLEUM UNIV

De-emulsifiers for oil and gas gathering and transferring and production device thereof

ActiveCN109971506AFast demulsificationImprove dehydration rateDewatering/demulsification with chemical meansTransportation and packagingComputerized systemEngineering

The invention discloses de-emulsifiers for oil and gas gathering and transferring and a production device thereof, and relates to a de-emulsifier. In a processing workshop, a glass house provided withan independent ventilation system is arranged; and the production process is controlled by a computer system server and a control switch. Through a hydraulic jack (15), raw materials in a raw material barrel A (9) and a raw material barrel B (10) can be maximally utilized. Due to an opening locker, the damage to the health of a worker who holds a suction pipe (13) is avoided. The provided I typede-emulsifier and II type de-emulsifier have the advantages of quick demulsifying speed, high dehydration rate, and little using amount, can maximally reduce the interfacial tension of water-oil emulsion, and separate water and oil. The glass house is used to barrier harmful gas. A controllable plate trailer and the opening locker are used to replace manual operation. An intelligent control systemformed by the computer system server is used to monitor raw materials.

Owner:盘锦辽河油田辽海集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com