Fast repairing method for asphalt concrete pavement

A technology of asphalt concrete and repair method, which is applied in road repair, cohesive pavement paved on site, road, etc. It can solve the problems of no bonding effect, low pavement strength, and late pavement opening, and achieve short maintenance time, The effect of low traffic impact and simple mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

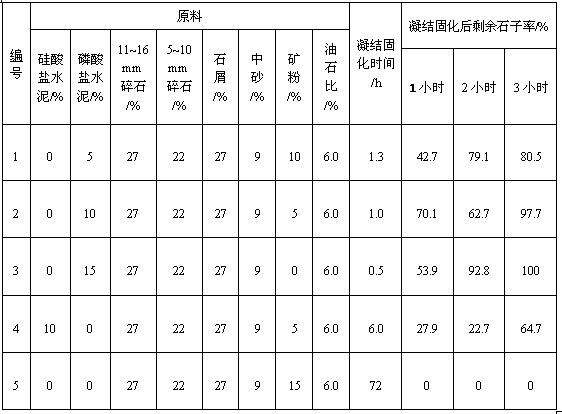

Embodiment 1

[0014] Embodiment 1: A quick repair method for asphalt concrete pavement adopts the following mass proportions: gravel with a particle size of 5-10mm: 22 parts; crushed stone with a particle size of 11-16mm: 27 parts; Stone chips: 27 parts; medium sand: 9 parts; mineral powder: 10 parts; magnesium phosphate cement: 5 parts; emulsified asphalt is added according to the oil-stone ratio of 6% (the oil content of emulsified asphalt is 60%); the magnesium phosphate cement is made of Ammonium dihydrogen phosphate, magnesium oxide (with a specific surface area of 300m 2 / kg of magnesia), borax in a mass ratio of 1:2:0.15; when repairing the pavement, first mix the above-mentioned mass parts of gravel, stone chips, medium sand, mineral powder and emulsified asphalt, and then add magnesium phosphate Continue to stir the cement. After stirring evenly, pour the mixture onto the cleaned and damaged road surface. After paving and compacting, it can be cured for 3 hours.

[0015] The spe...

Embodiment 2

[0016] Embodiment 2, this specific embodiment and specific embodiment 1 are only different in proportion of the following materials, and the rest are the same. In this specific embodiment, the proportion of materials used is: gravel with a particle size of 5-10mm: 22 parts; crushed stone with a particle size of 11-16mm: 27 parts; stone chips with a particle size less than 5mm: 27 parts; : 9 parts; mineral powder: 5 parts; magnesium phosphate cement: 10 parts; emulsified asphalt is added according to the oil-stone ratio of 6%. When this specific embodiment is implemented, the road surface can be opened to traffic after 2 hours of maintenance.

Embodiment 3

[0017] Embodiment 3, this specific embodiment and specific embodiment 1 are only different in proportion of the following materials, and the rest are the same. In this specific embodiment, the proportion of materials used is: gravel with a particle size of 5-10mm: 22 parts; crushed stone with a particle size of 11-16mm: 27 parts; stone chips with a particle size less than 5mm: 27 parts; : 9 parts; mineral powder: 0 parts; magnesium phosphate cement: 15 parts; emulsified asphalt is added according to the oil-stone ratio of 6%. When this specific embodiment is implemented, the road surface can be opened to traffic after 1.5 hours of maintenance.

[0018] In order to further verify the effect of the present invention, the applicant used the material of the present invention to mix and stir evenly with the above-mentioned different proportions, and then directly poured it into a mold to test its solidification and hardening time and its bonding strength. At the same time, the set...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com