Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

268results about How to "Easy to solidify" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

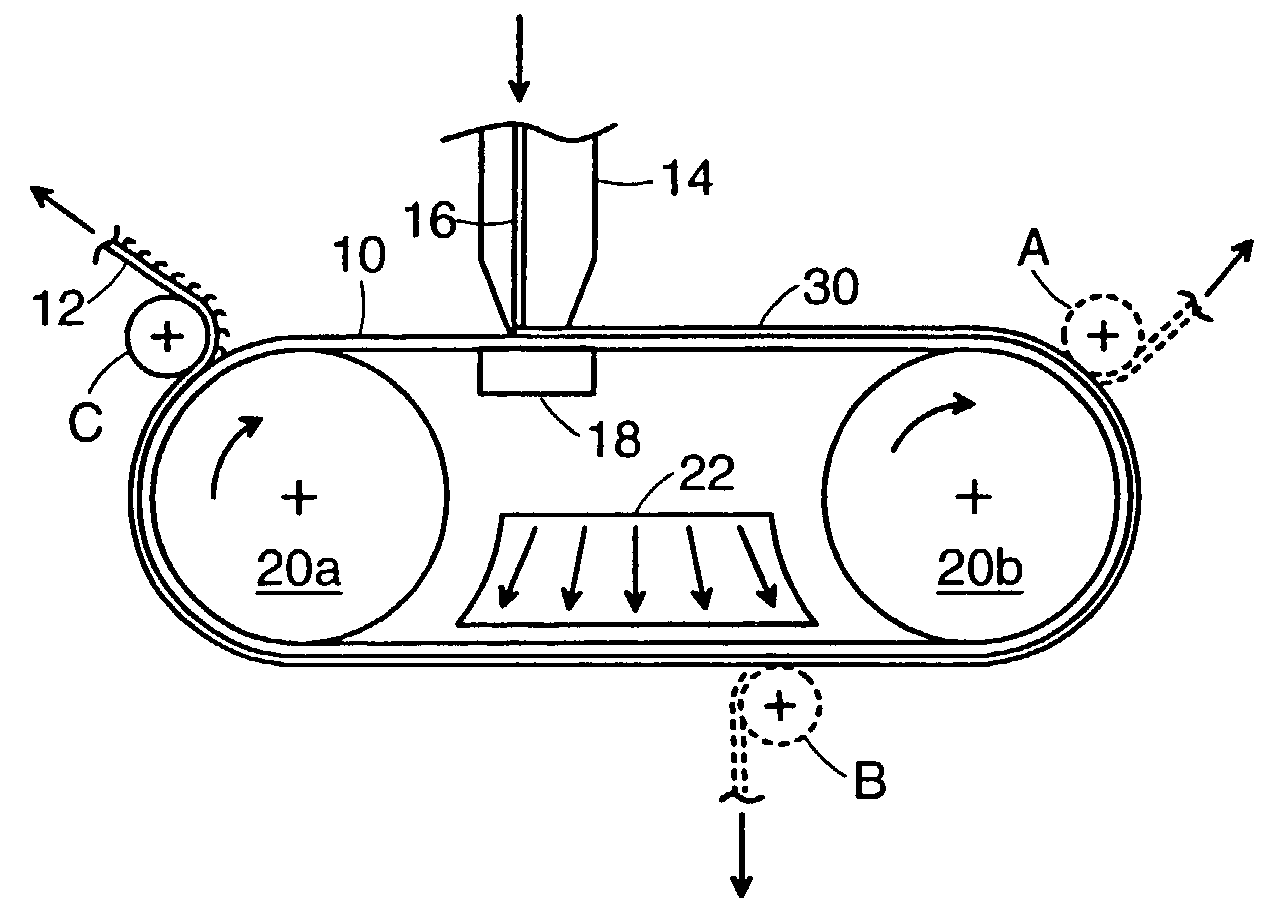

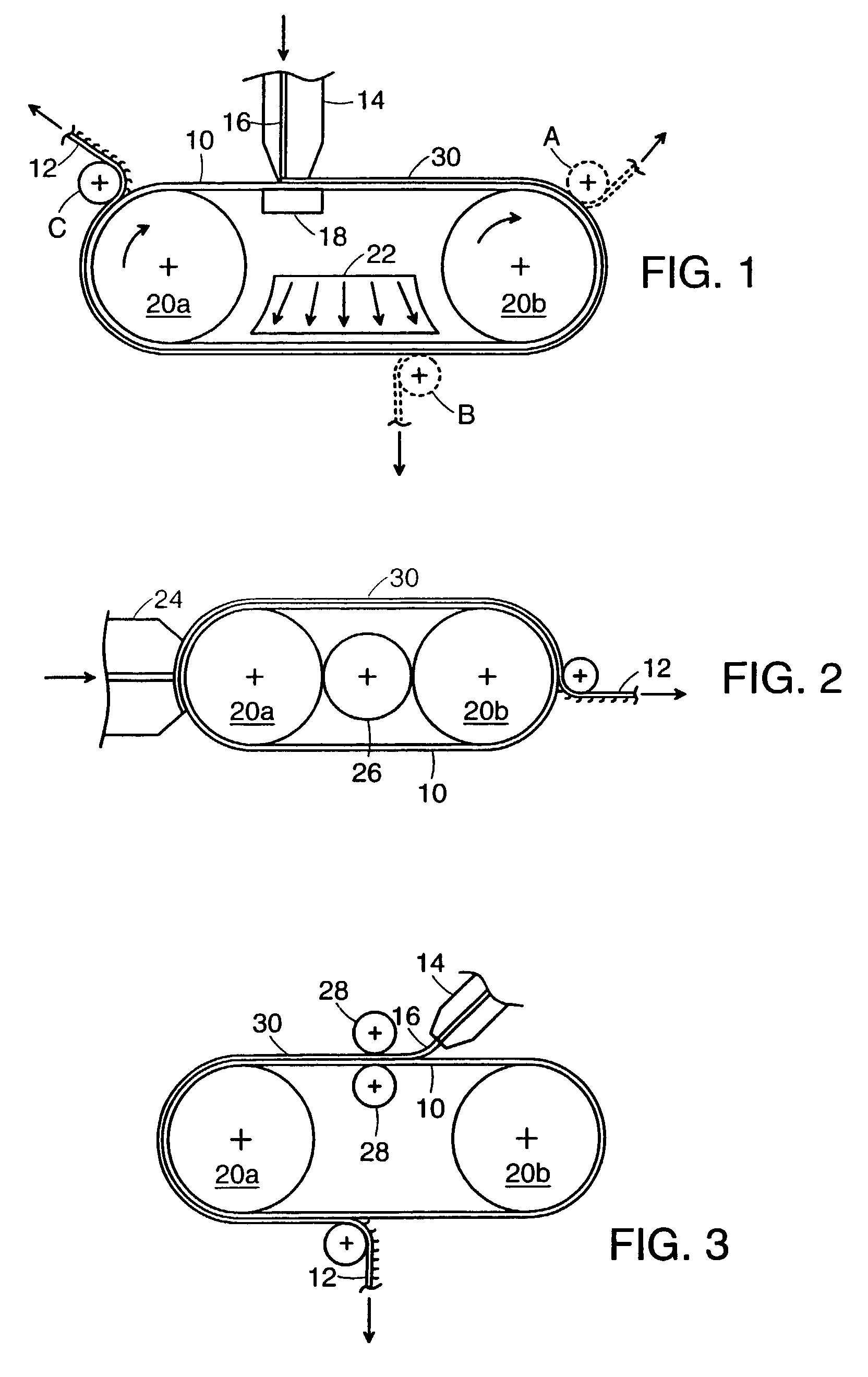

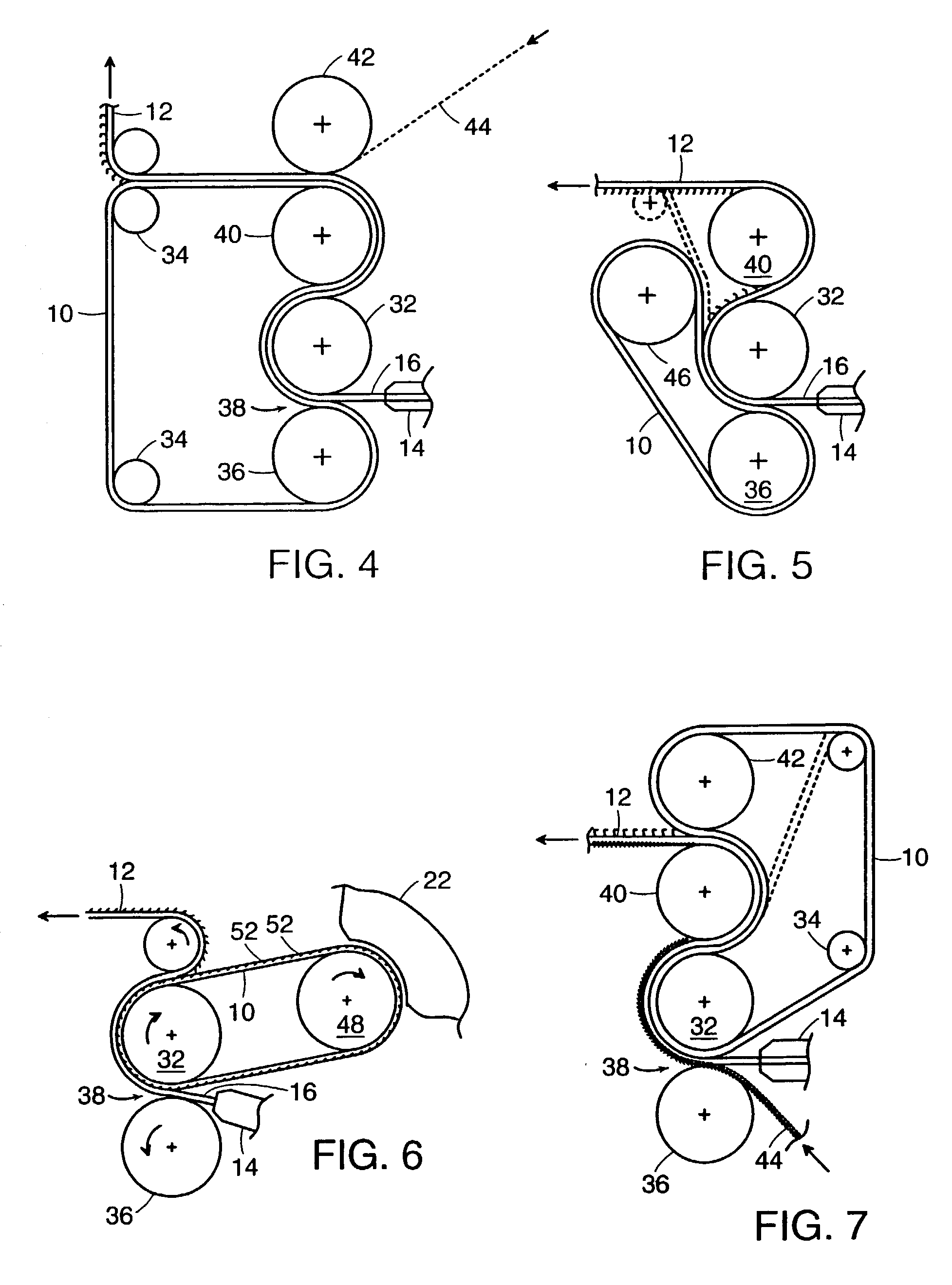

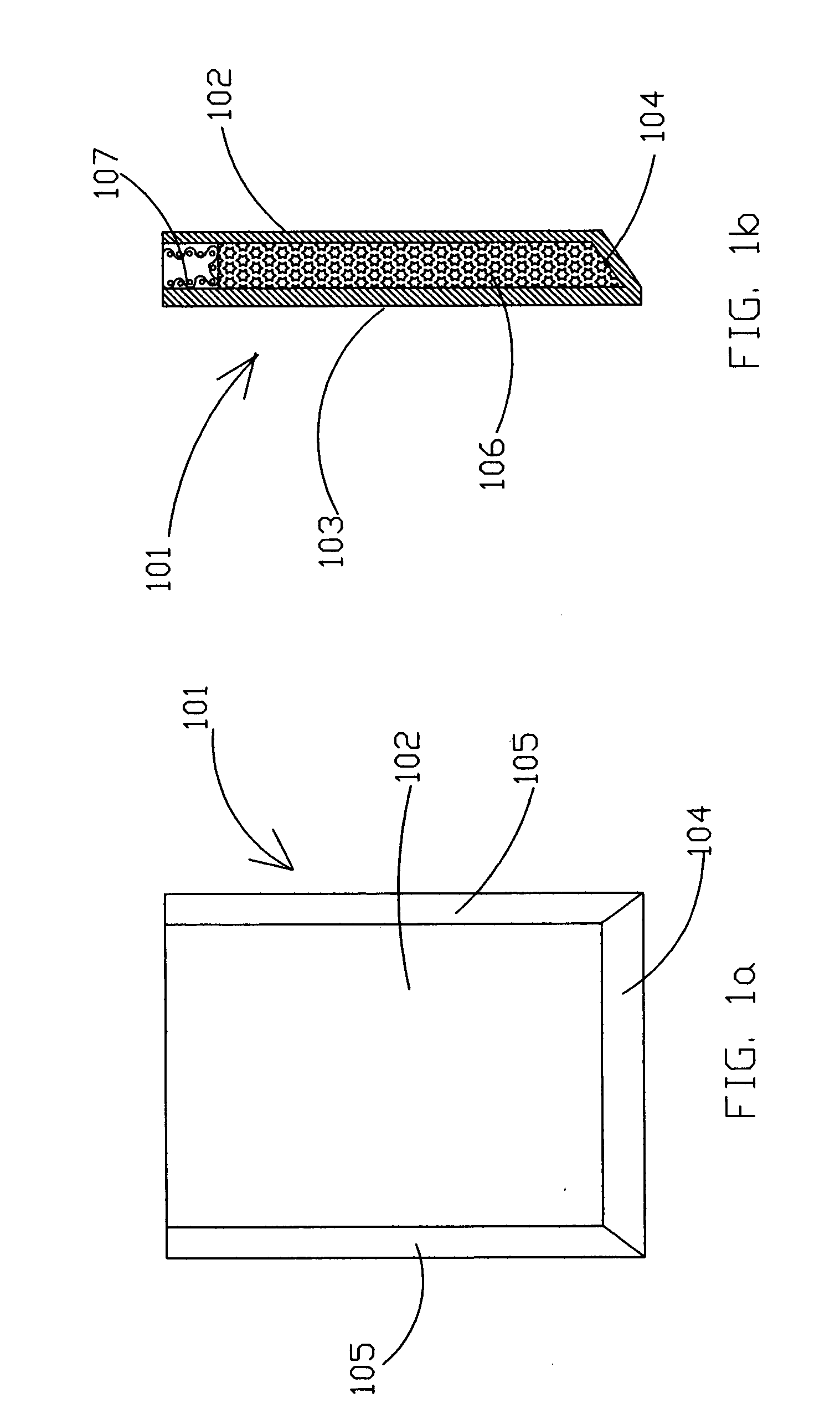

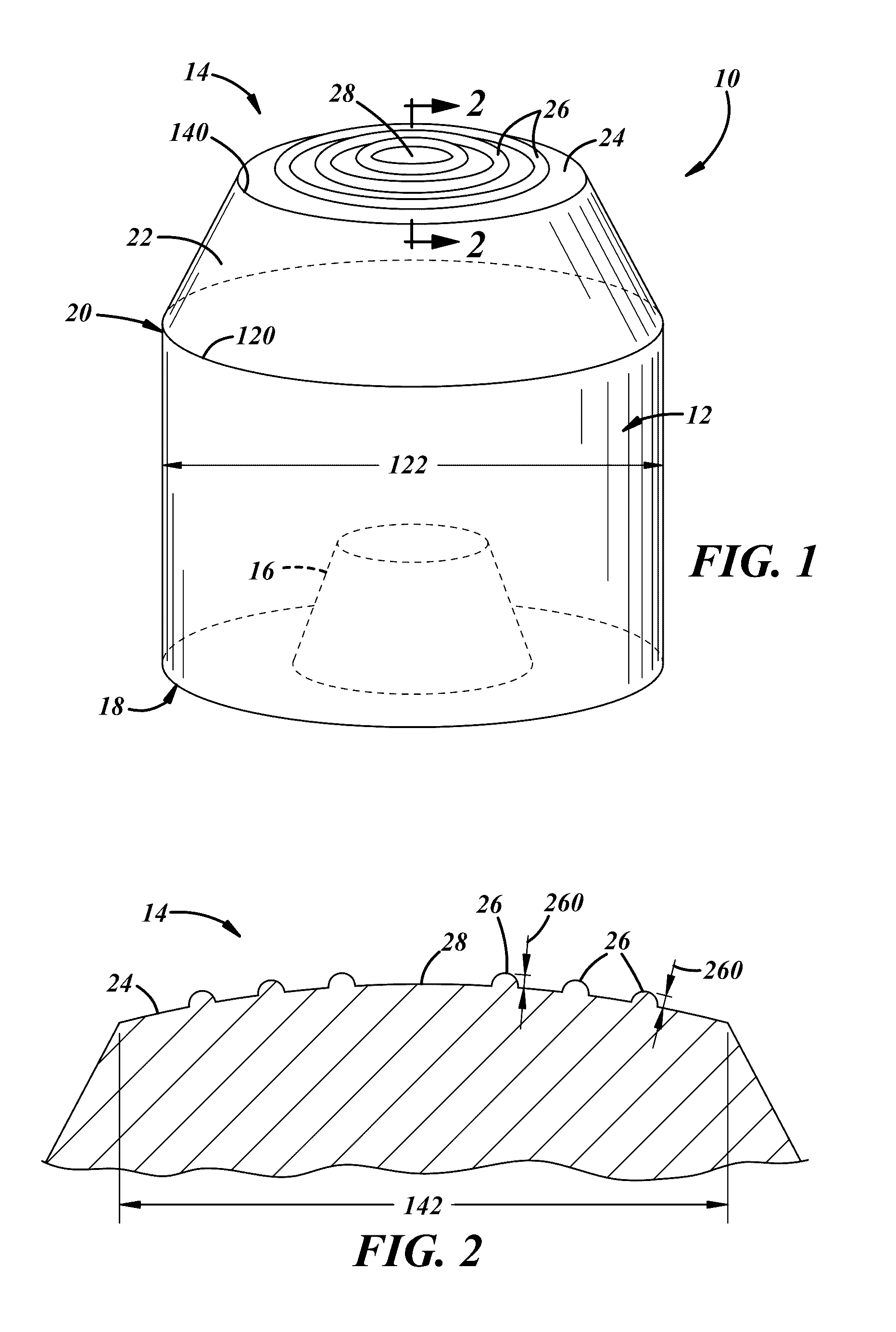

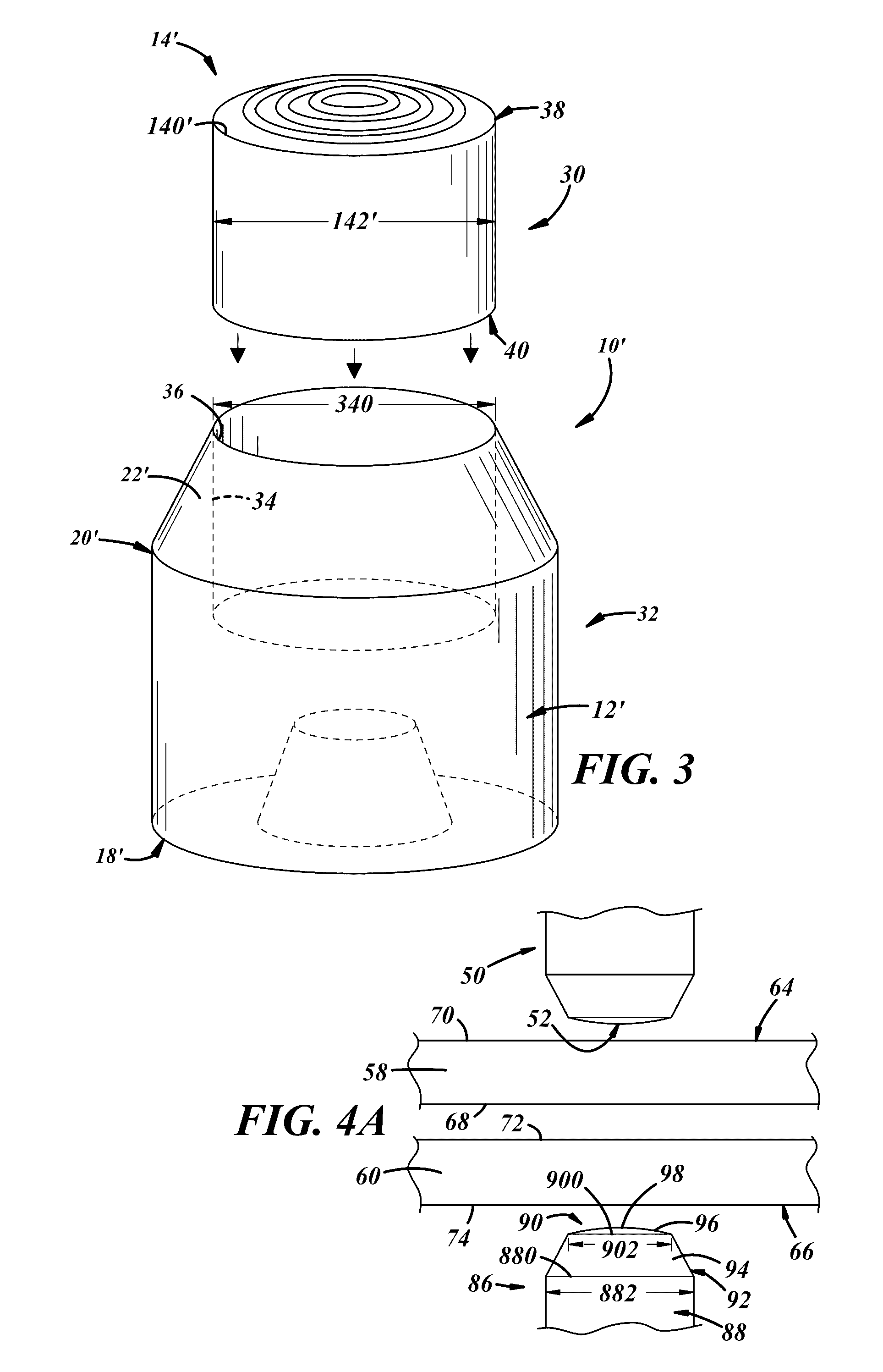

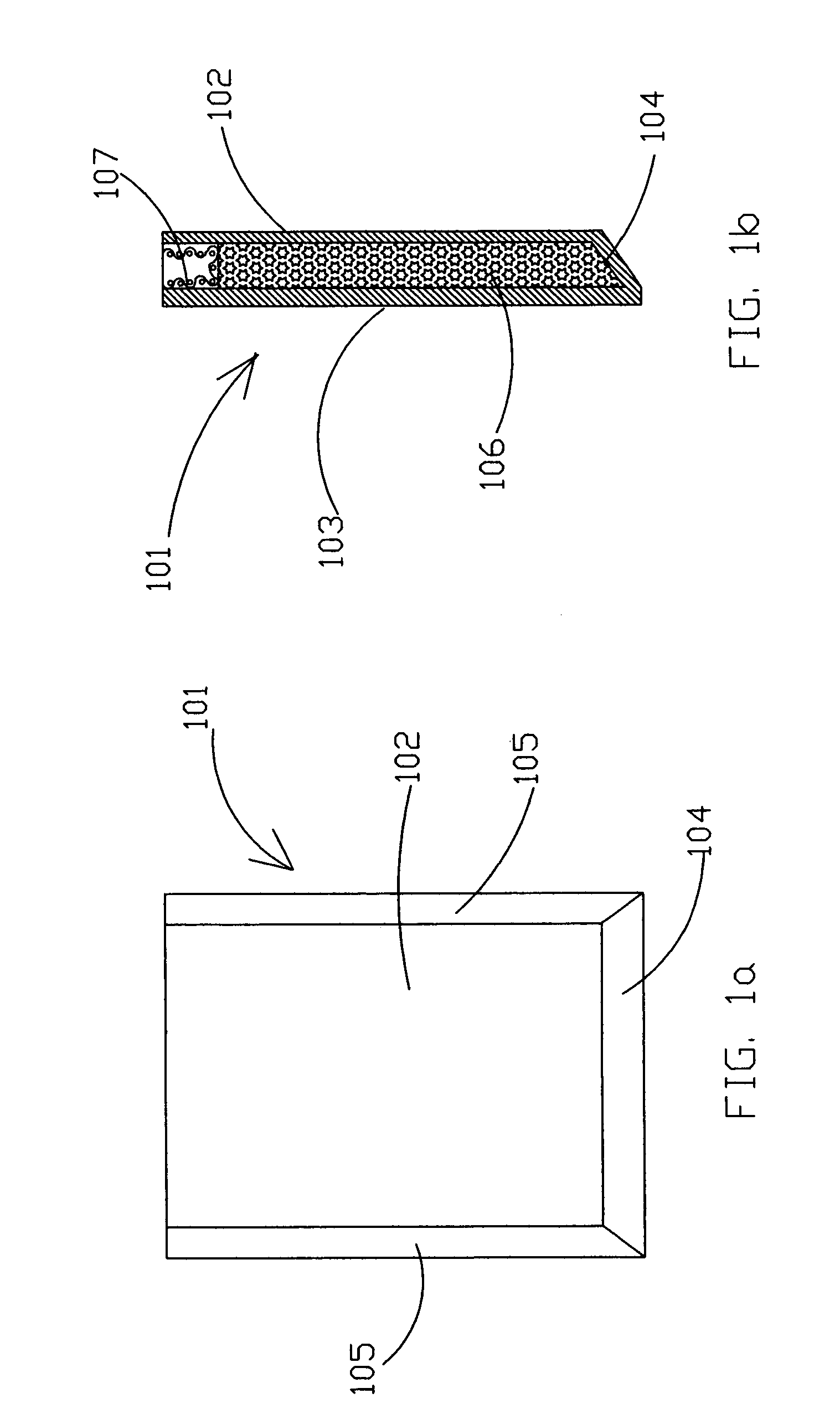

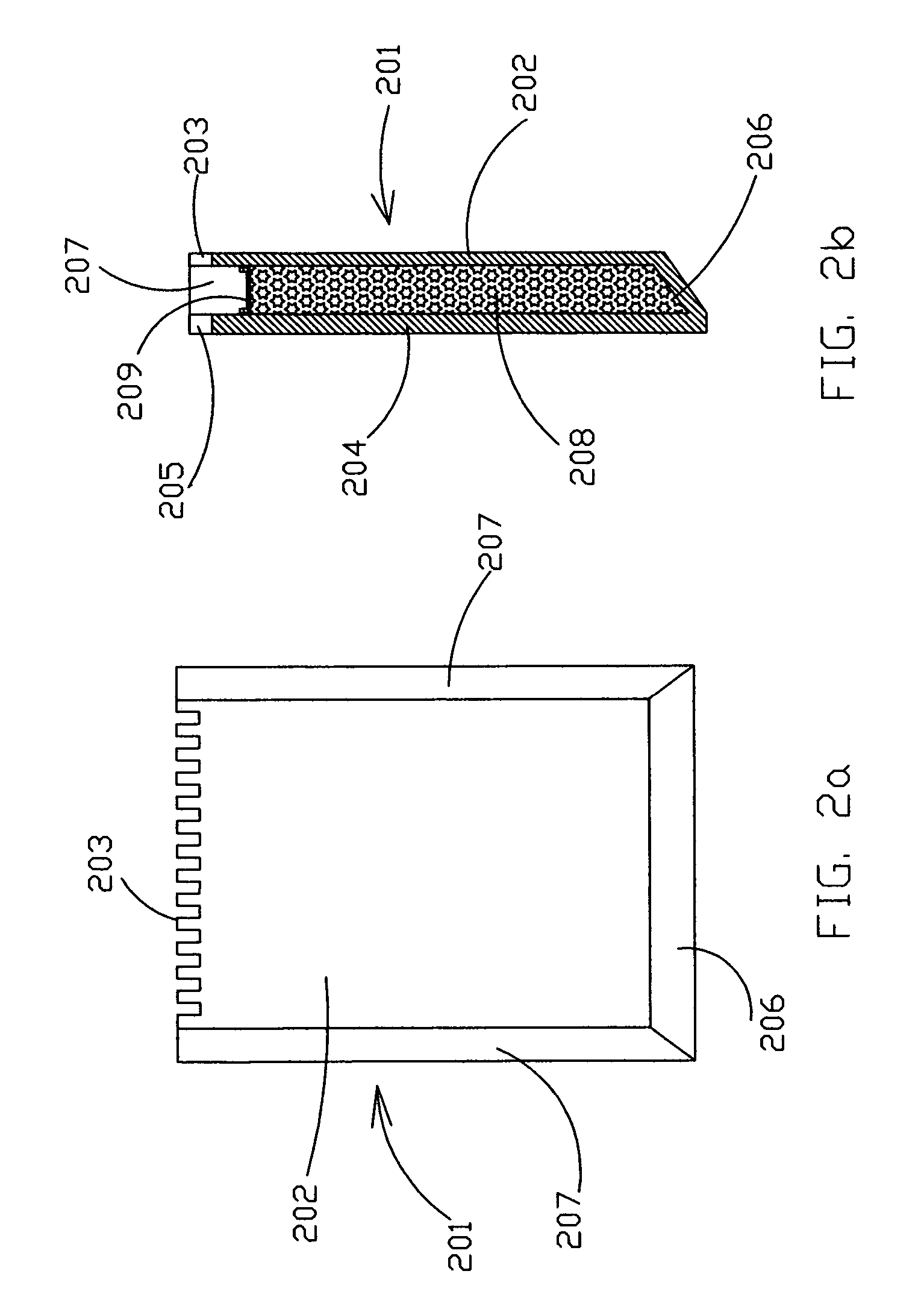

Continuous molding of fastener products

InactiveUS7214334B2Long residence timeReadily removeConfectioneryPress rollersFastenerBiomedical engineering

Several methods and machines for continuously forming a fastener product having an array of fastener elements extending from a continuous, sheet-form base, employing a mold belt on which the sheet-form base of the product is formed and from which it is subsequently stripped. The belt defines an array of cavities extending from its outer surface, for molding either the array of fastener elements or an array of preform stems that are subsequently reformed into the fastener elements. In some cases the cavities are blind, such as for forming hook-type fastener elements; in other cases, the cavities extend through the belt, such as for forming mushroom-type fastener elements. Various belt constructions and fastener element shapes are also disclosed.

Owner:VELCRO IND BV

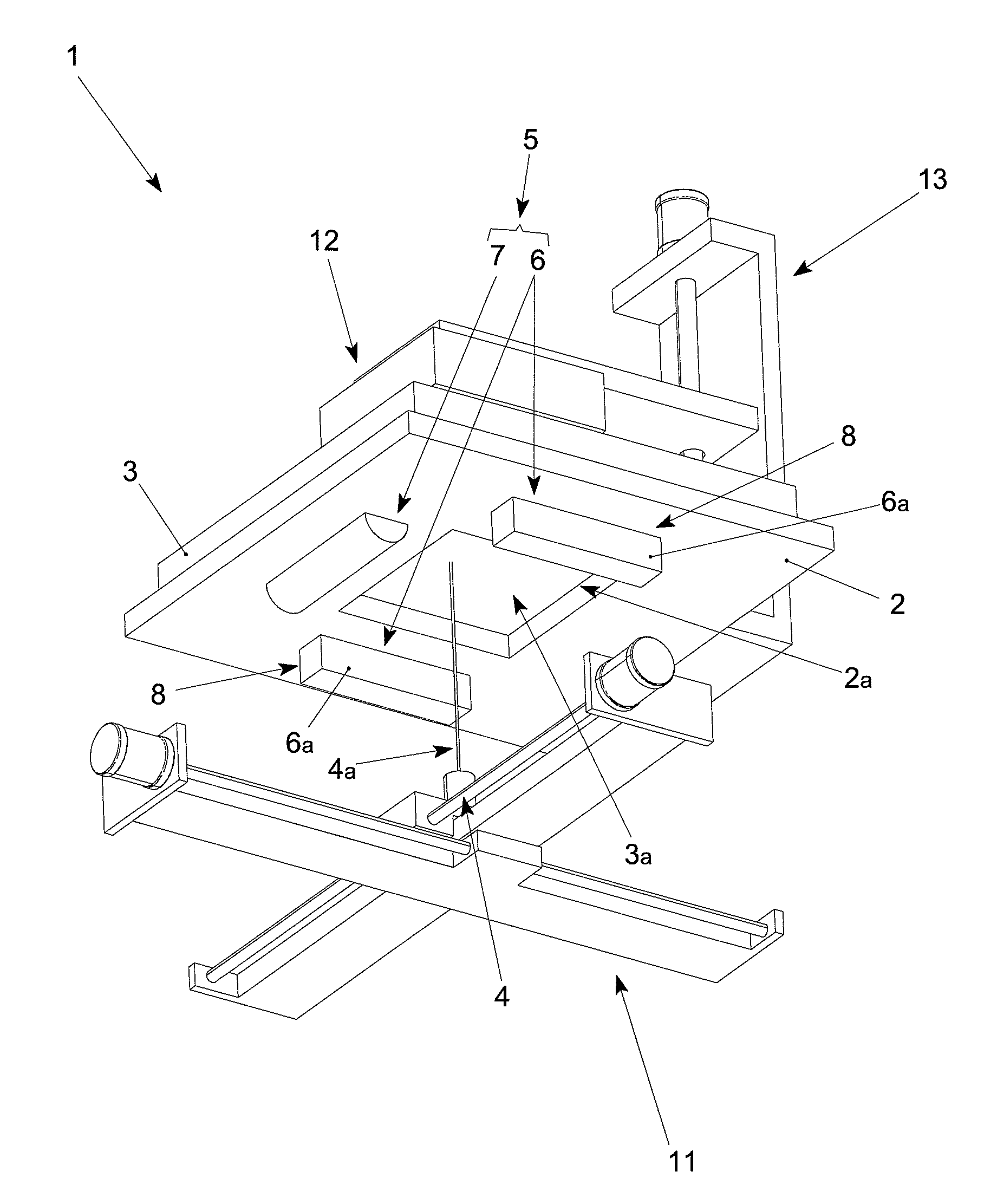

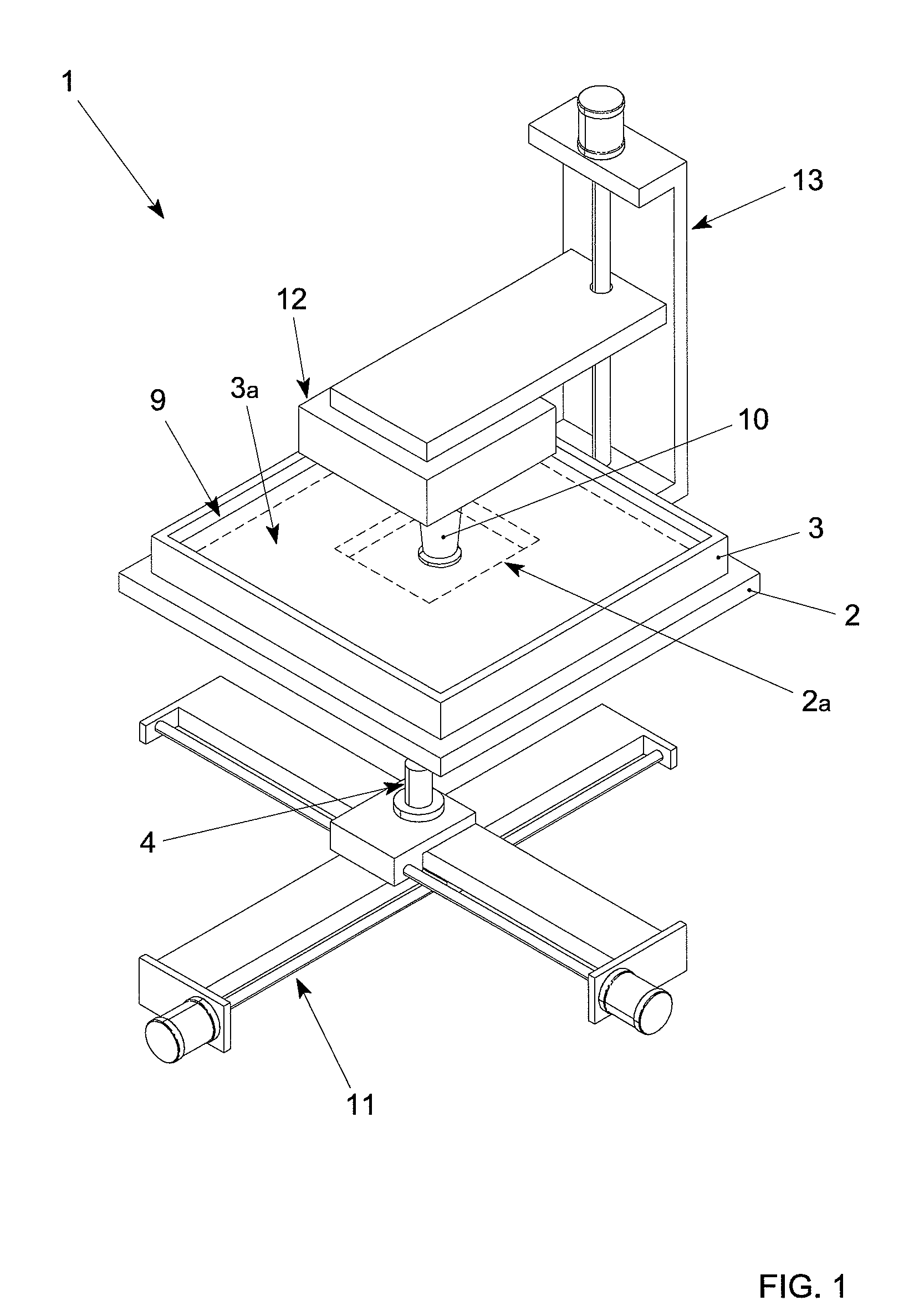

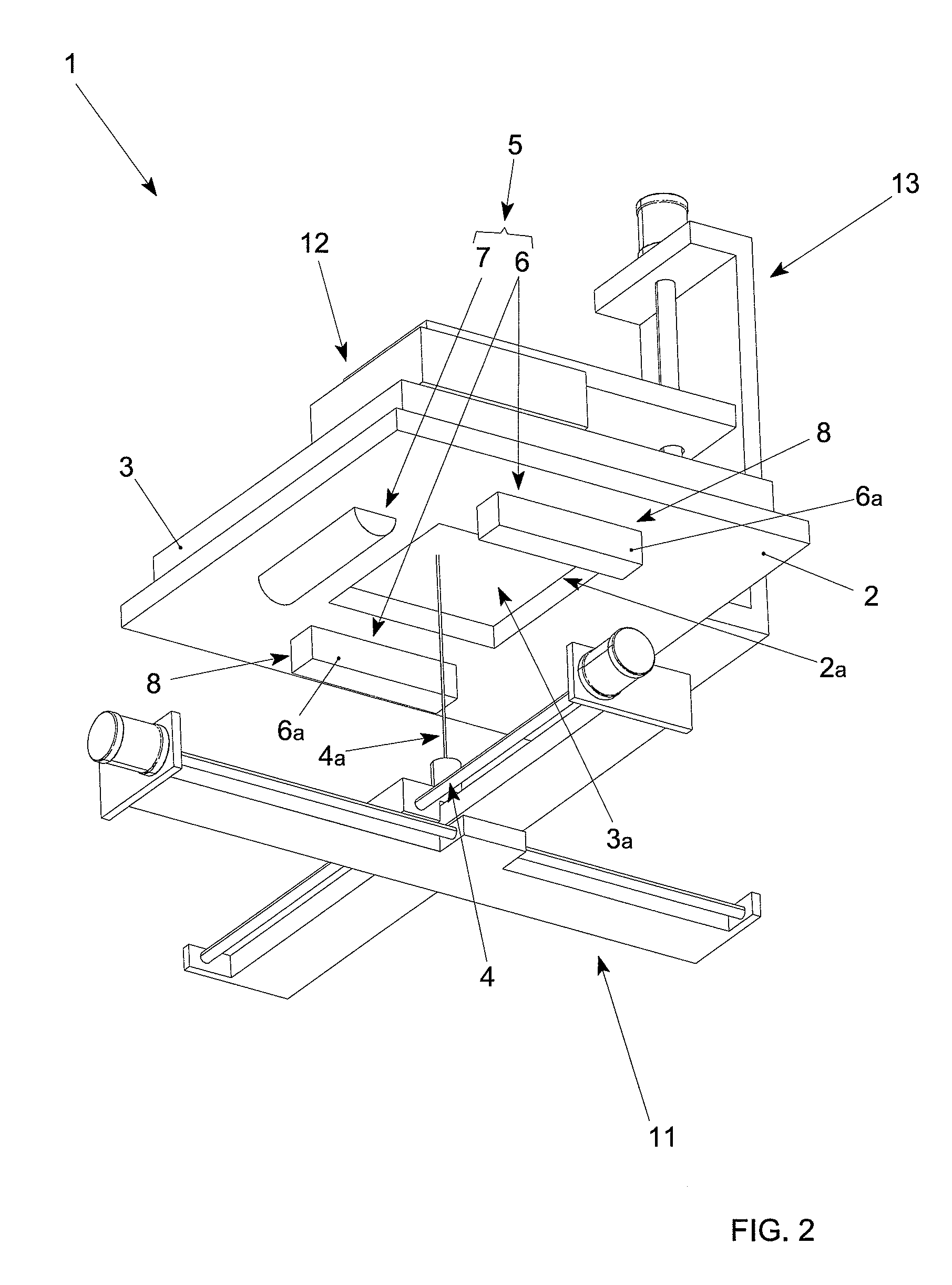

Stereolithography machine

ActiveUS8945456B2Optimal solidification resultEasy to solidifyManufacturing heating elementsAuxillary shaping apparatusTemperature controlEngineering

The invention is a stereolithography machine (1) comprising the following: a support plate (2) provided with a hole (2a); a container (3) associated with the support plate (2) and comprising a transparent bottom (3a); a radiation source (4) arranged below the support plate (2) and suited to convey a radiation beam towards the transparent bottom (3a) through the hole (2a); a temperature control unit (5) suited to maintain the support plate (2) at a predetermined temperature.

Owner:DWS SRL

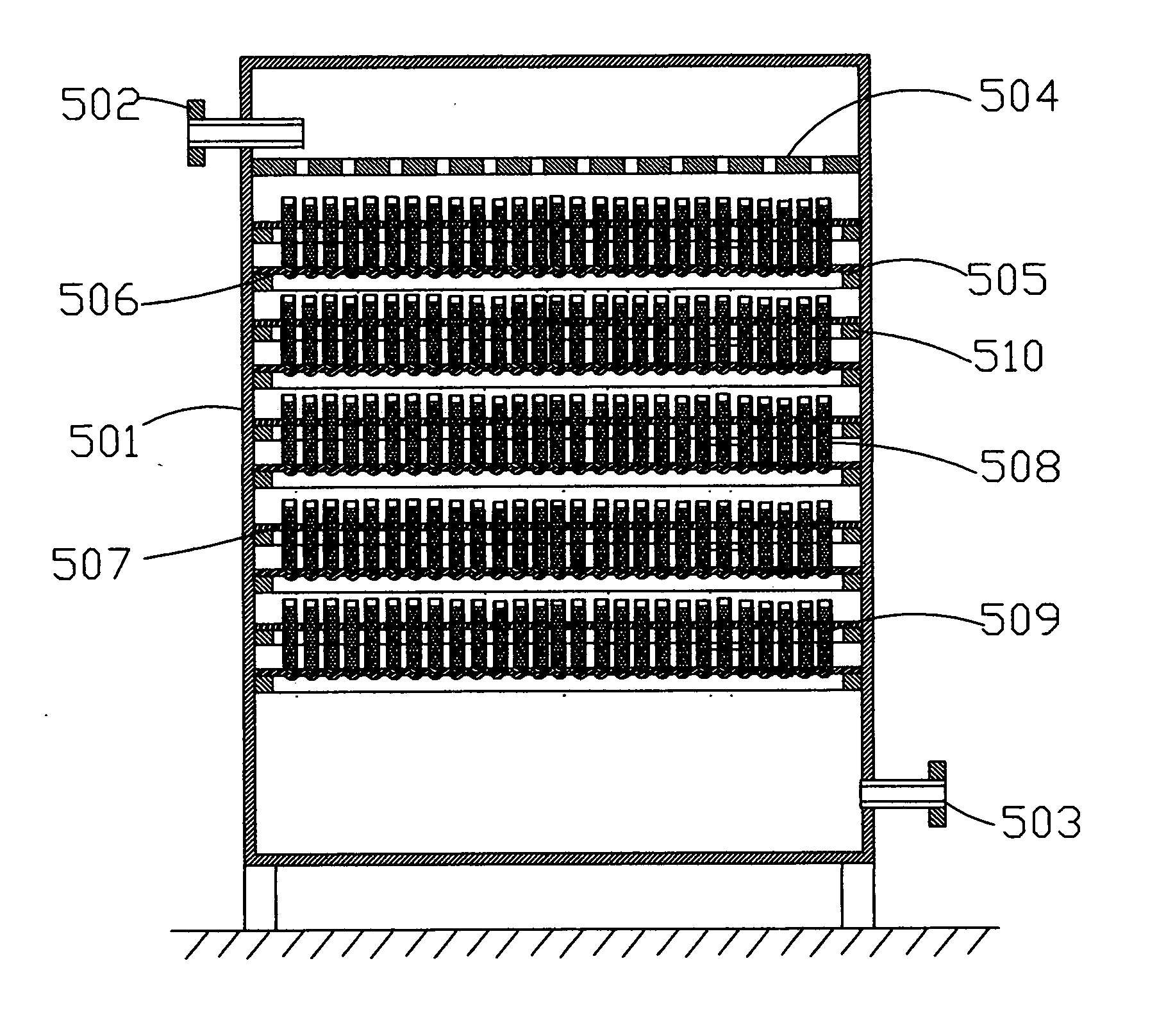

Heat and cold storage multistage tower with application of PCM

InactiveUS20060225863A1Inhibition formationImprove thermal conductivityMilk preservationHeat storage plantsEngineeringThermal management system

This invention relates to the area of heat management systems and, specifically, to the heat management systems, which include application of phase change materials (PCM). Proposed heat or cold storage multistage tower comprises a housing with a multistage system of flat rigid containers; significant fraction of internal space of each container is filled with PCM; these containers are fabricated from ceramics, glass, glass ceramics or sulfur concrete. Another version of the heat or cold storage tower is based on application of multi-channel blocks from ceramics, glass, glass ceramics or sulfur concrete; the parallel internal vertical channels of the blocks are open and sealed at their bottoms alternatively, and the channels with the sealed bottoms are filled partially with PCM. The proposed invention allows to achieve effective heat transfer between a heat transfer fluid (HTF) and PCM in the processes of charging and discharging of the containers with heat or cold.

Owner:LEVIN ALEXANDER

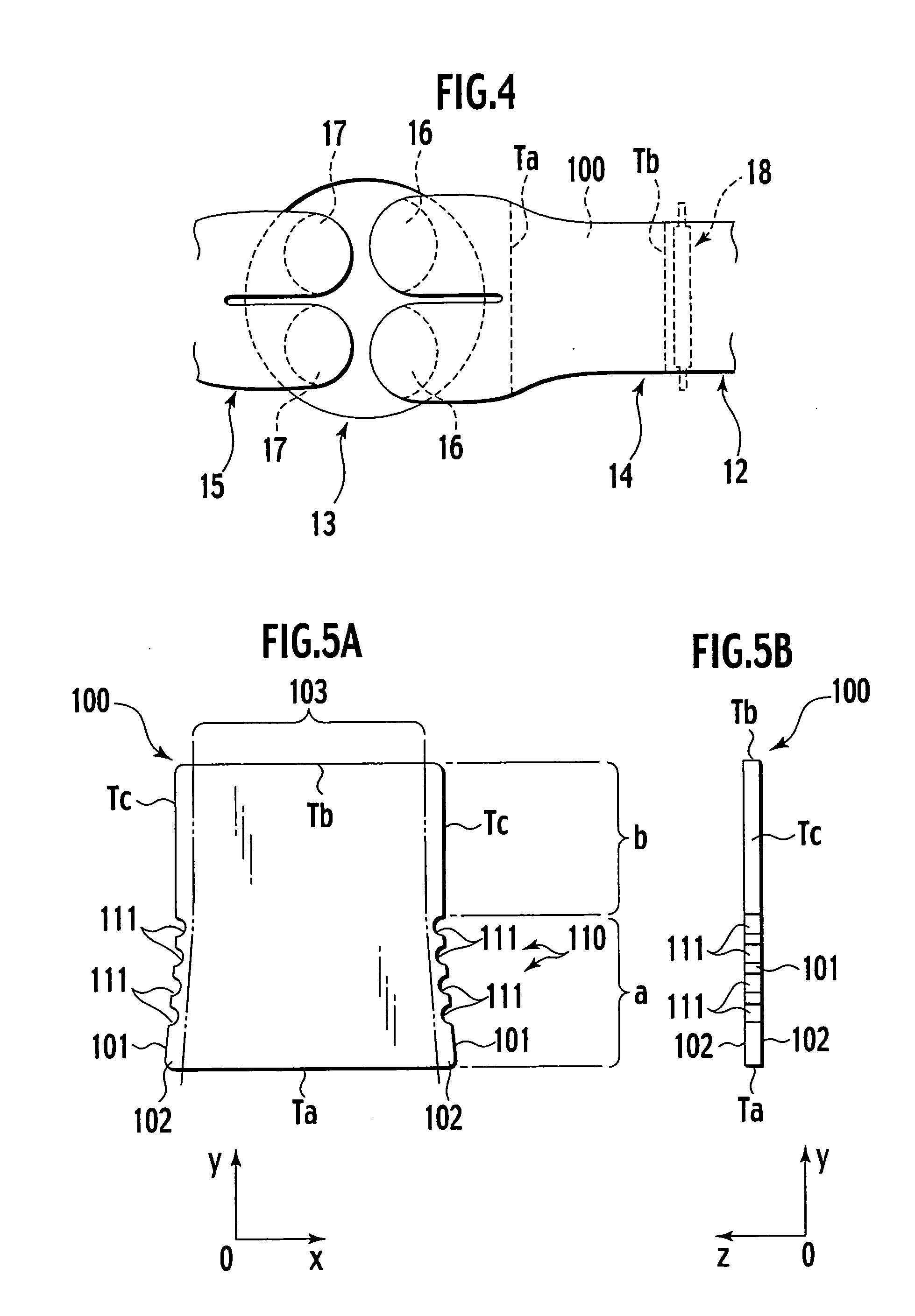

Inkjet printer including discharger with cap

An inkjet printer includes: (a) a head unit having ejecting portions and operable to eject a plurality of kinds of inks through the ejecting portions; (b) a discharger for discharging the inks through the ejecting portions; and (c) a communication controller. The discharger includes: (b-1) a cap selectively placeable in a contact state in which the cap is held in contact with the head unit, and in a separate state in which the cap is separated from the head unit; (b-2) a suction pump; and (b-3) a connector connecting the cap and the suction pump. The cap defines therein ink storage chambers in which the respective kinds of inks are to be stored. The connector includes passage definers defining respective discharge passages each communicating the corresponding ink storage chamber and a chamber of the suction pump. The communication controller allows communication between at least two of the ink storage chambers when the cap is placed in the separate state, and inhibits the communication between the at least two ink storage chambers when the cap is placed in the contact state.

Owner:BROTHER KOGYO KK

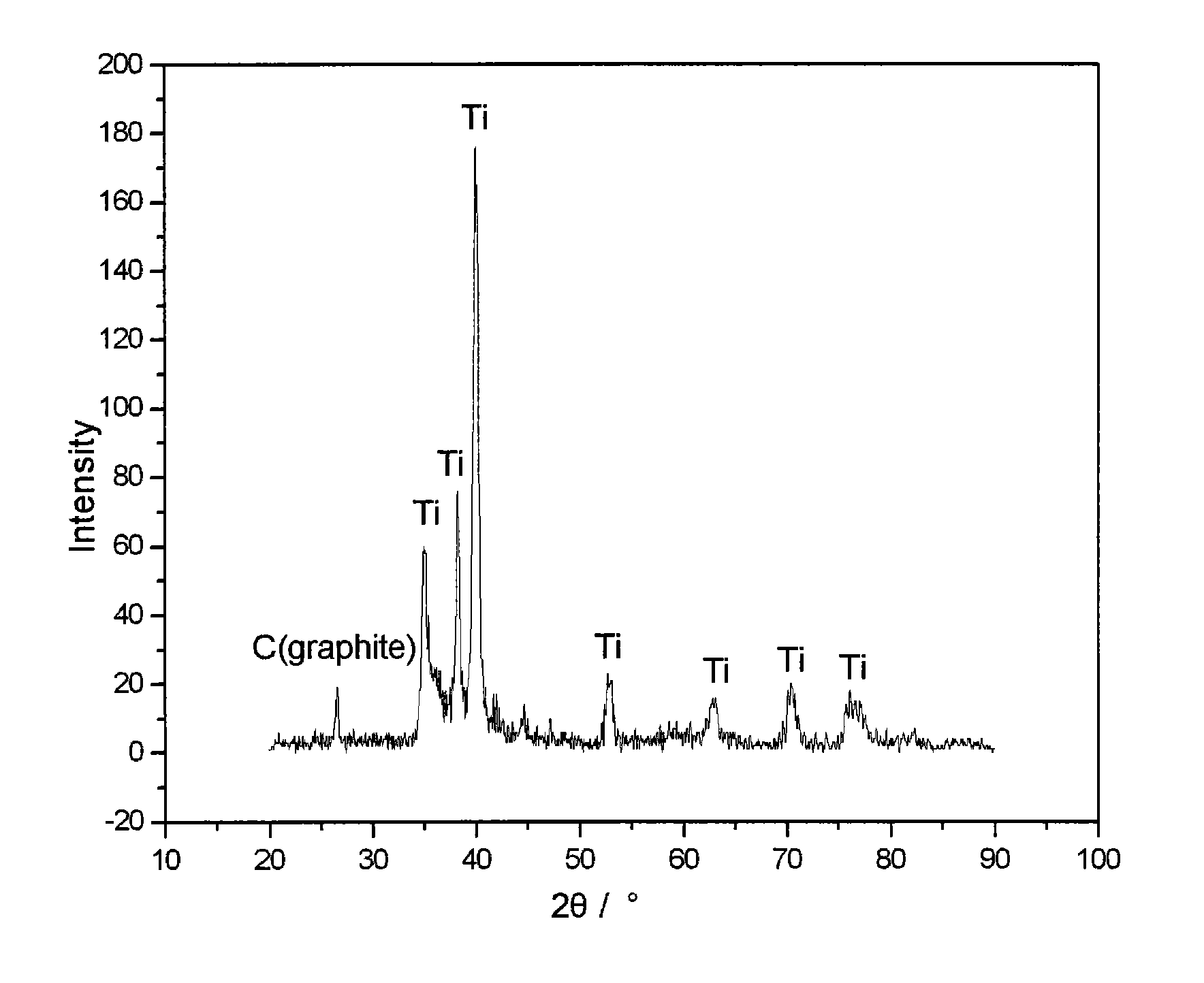

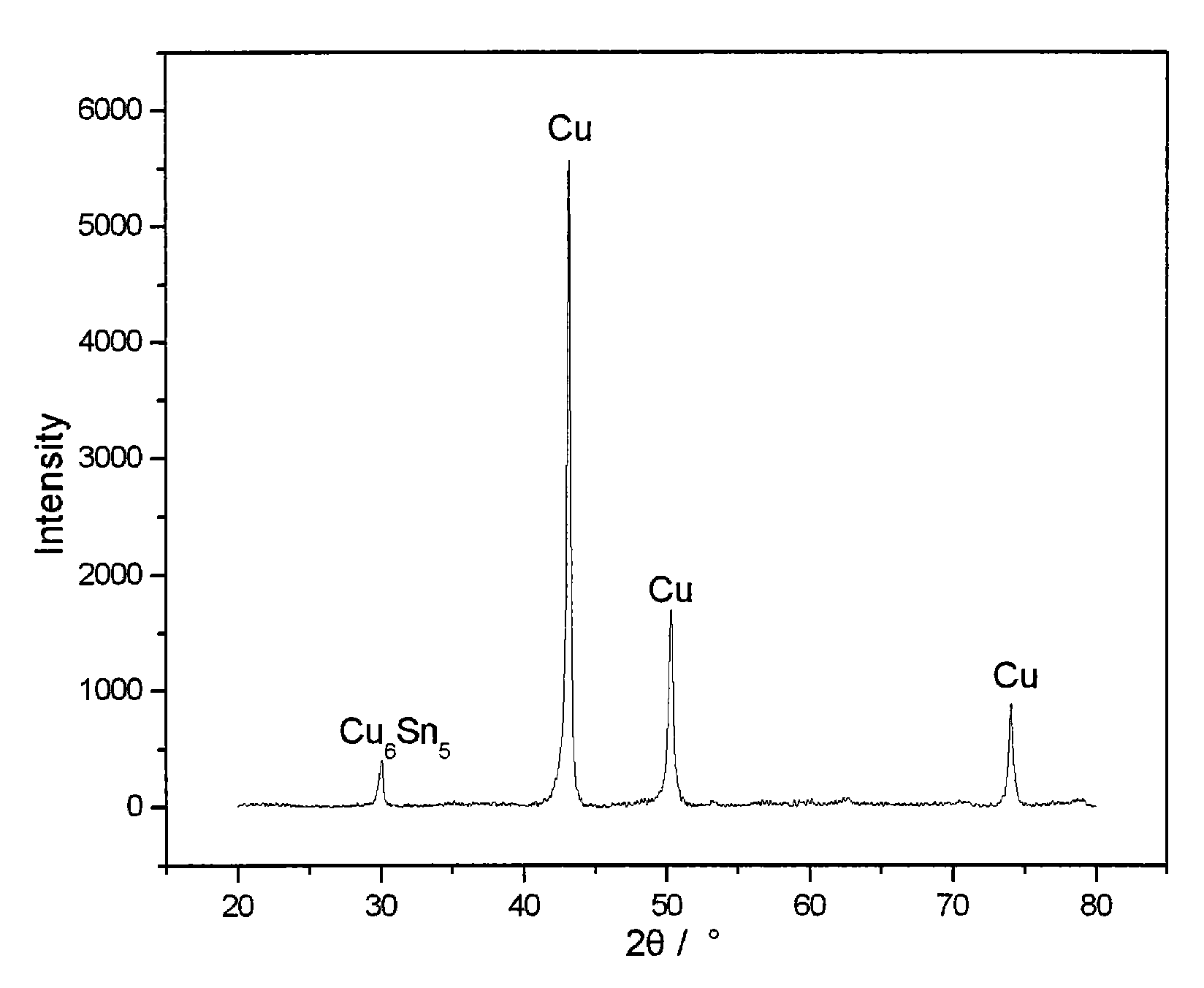

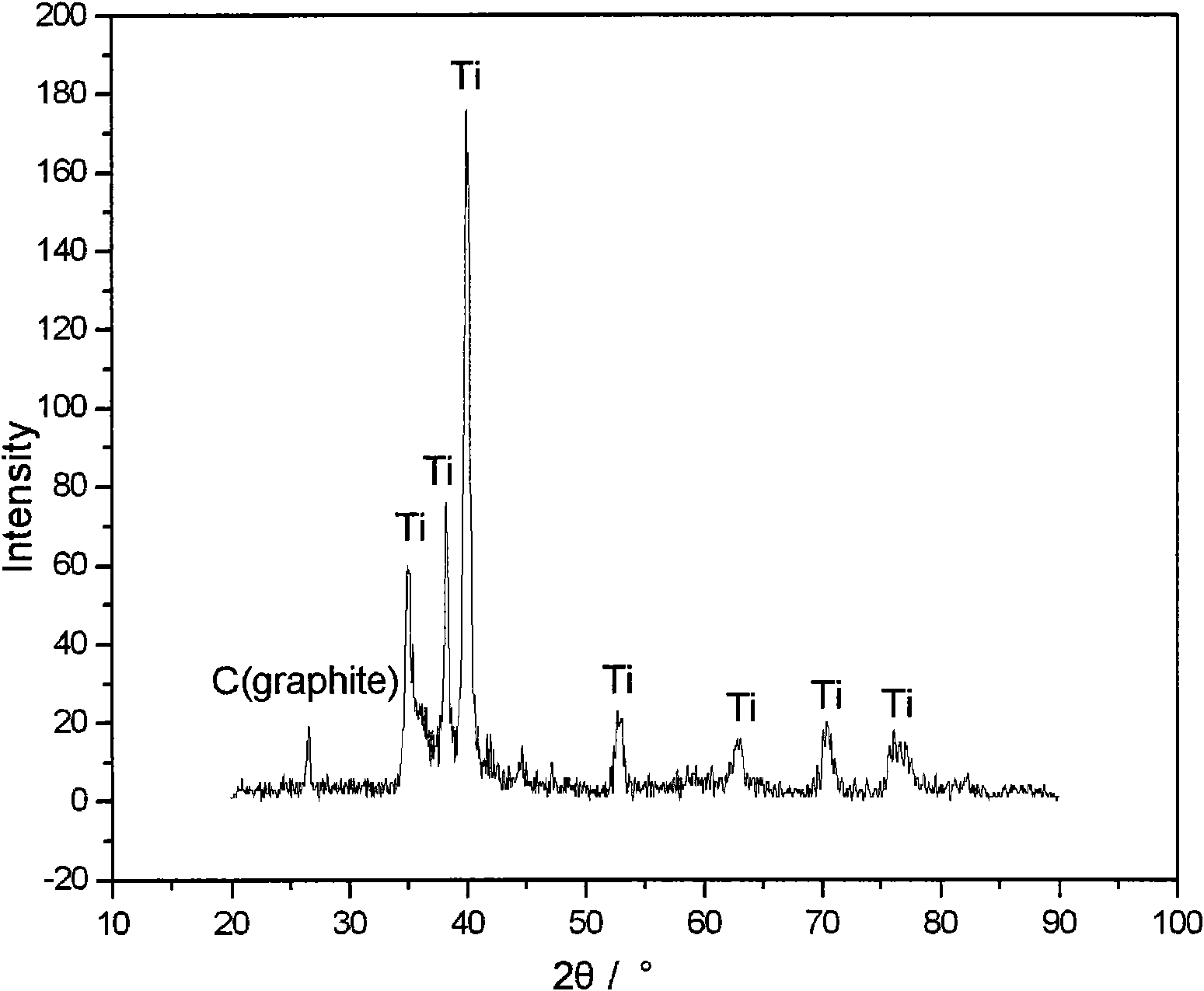

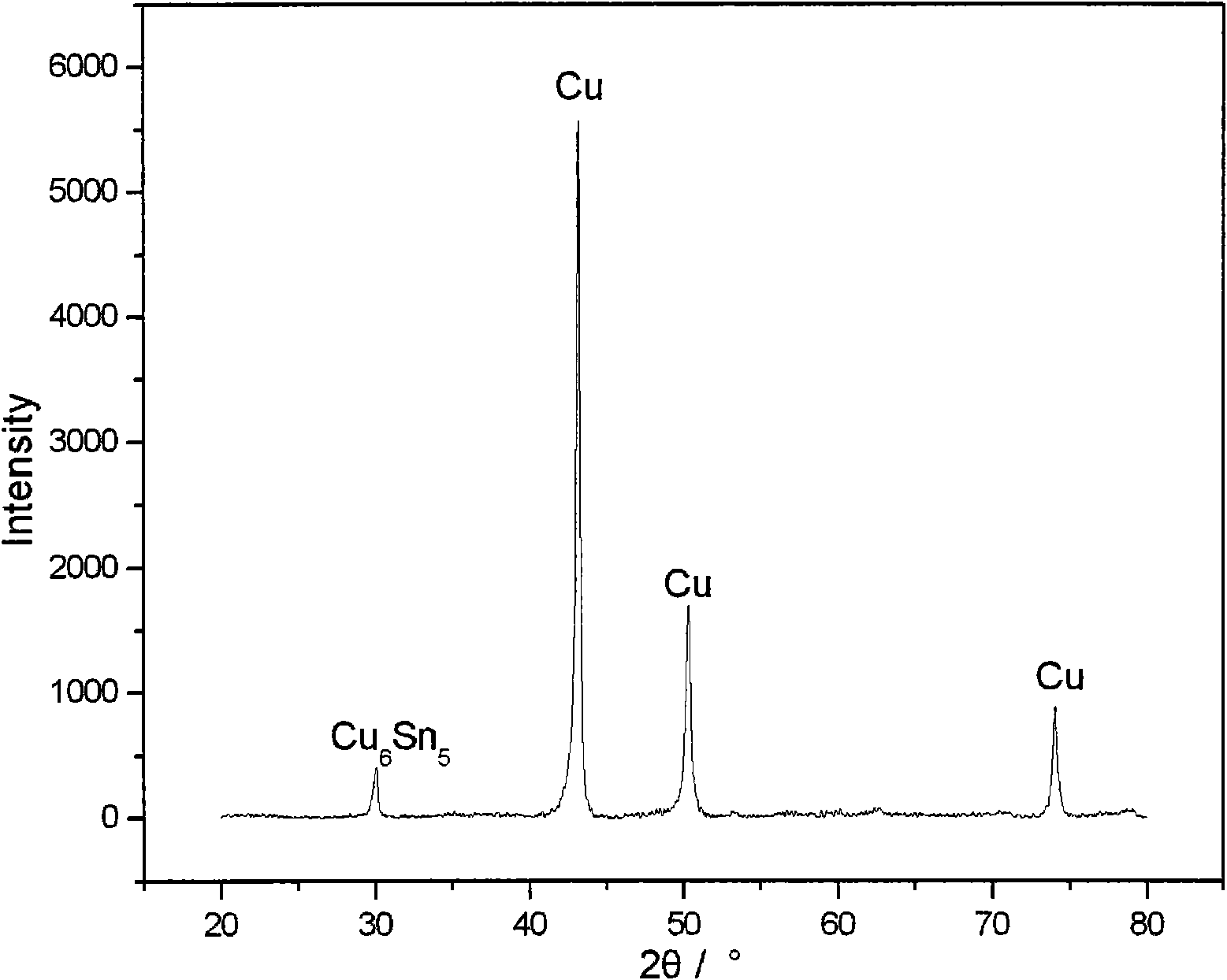

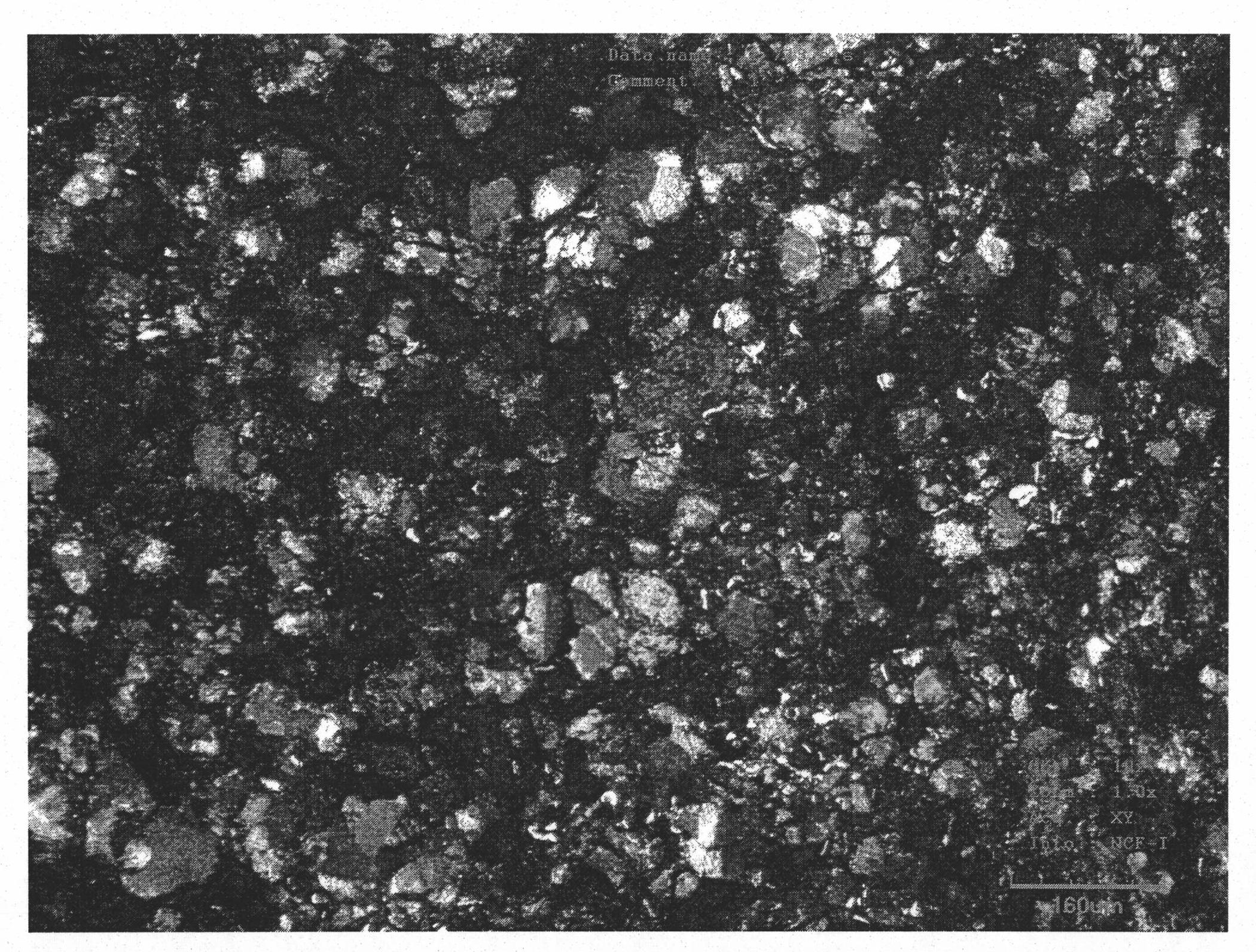

Metal-based powder metallurgy brake lining material and preparation methods thereof

InactiveCN101602105AExcellent material performanceSimple material compositionFriction liningPowder metallurgyCeramic particle

The invention discloses a metal-based powder metallurgy brake lining material and preparation methods thereof. The invention aims to solve the problems that the strength of a material is reduced along with the adding of ceramic particles when the powder metallurgy brake lining material is produced by the prior art and the like. The material comprises the following components in percentage by weight: 10 to 80 percent of Cu-Sn mechanical alloy powder, 1.25 to 15 percent of Ti-C mechanical activated powder, 2 to 65 percent of Fe powder, 0 to 10 percent of Ni powder, 0 to 12 percent of Cr powder, 2 to 8 percent of Al2O3 powder, and 7.75 to 23 percent of graphite, wherein the Cu-Sn mechanical alloy powder is prepared from Sn powder and Cu powder which contains 6 to 10 percent of Sn powder by mechanical alloying beforehand; and the Ti-C mechanical activated powder is prepared from Ti powder and C powder according to the ratio of 2:1-8:1 through mechanical activation beforehand, and forms TiC during the sintering. The invention also provides two preparation methods which combine the mechanical activation and the mechanical alloying with the prior powder metallurgy or discharge plasma sintering method.

Owner:JILIN UNIV

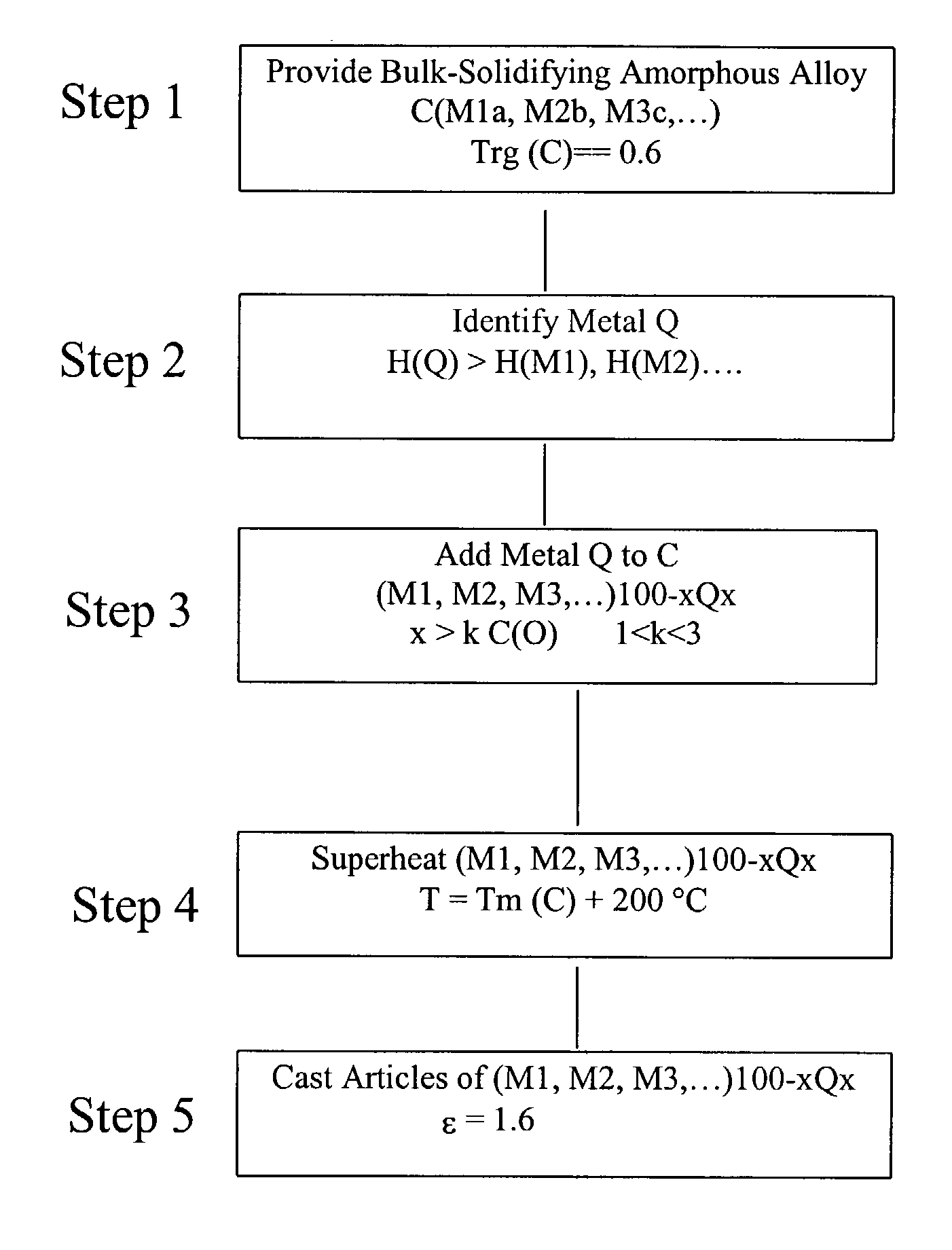

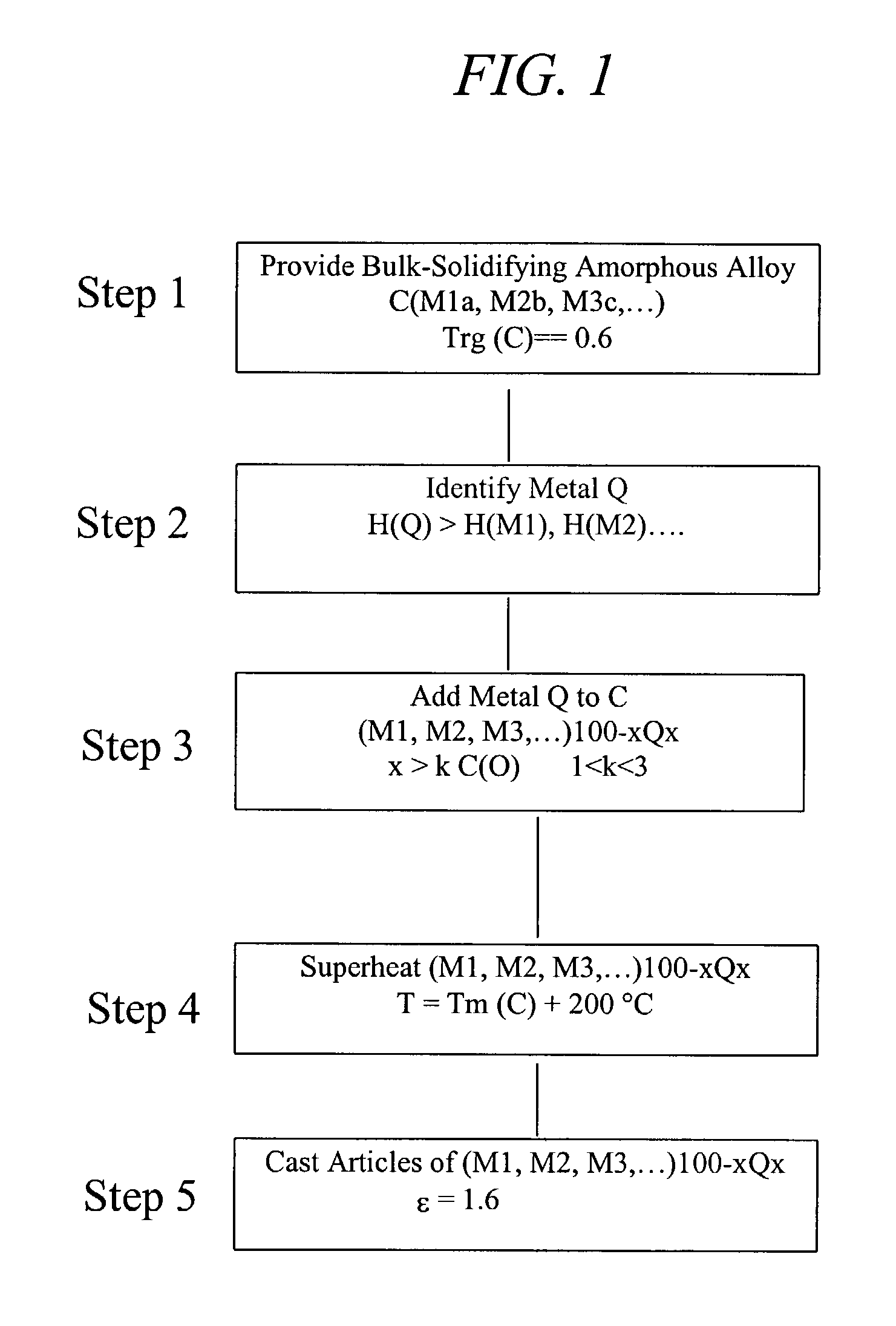

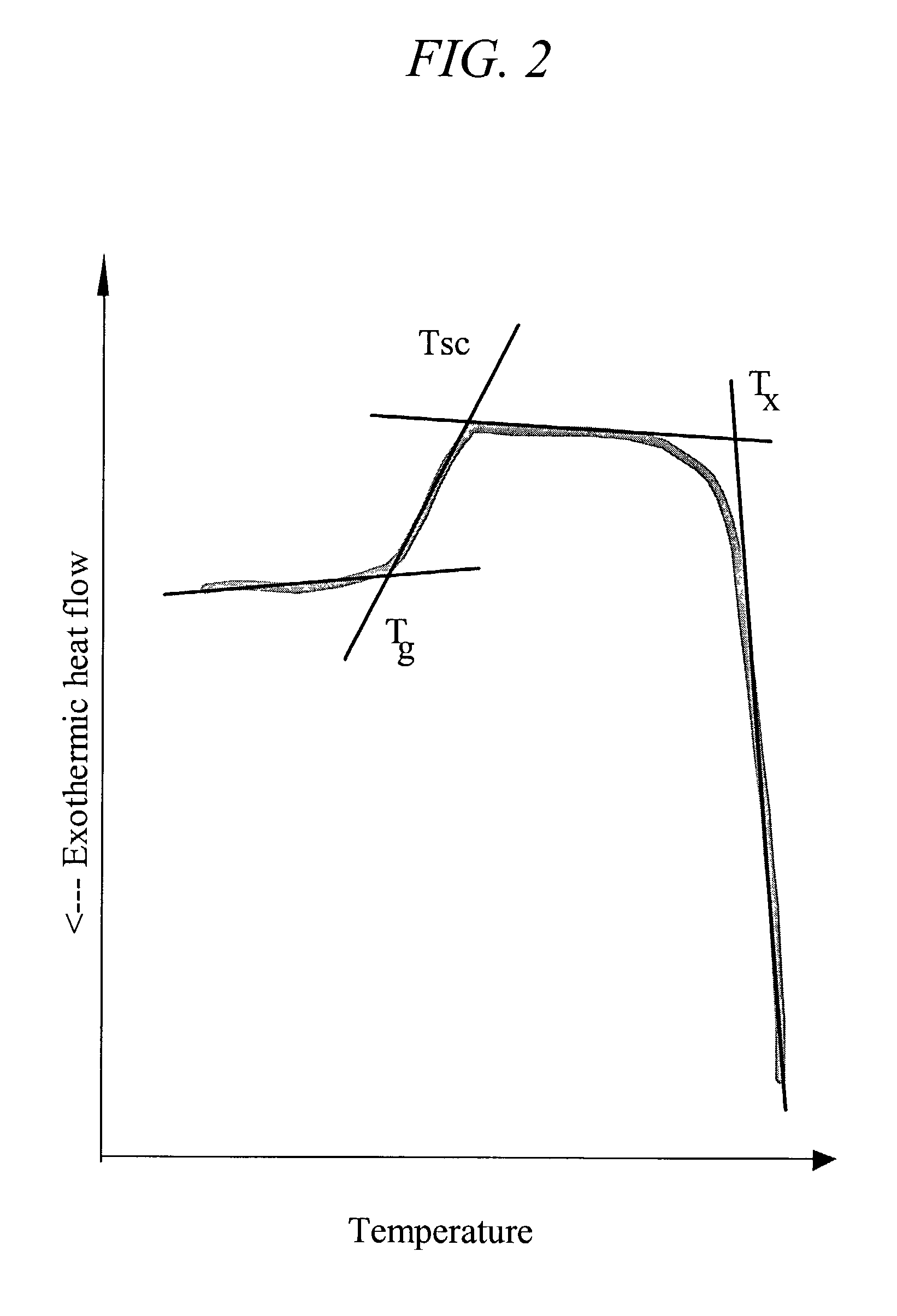

Method of improving bulk-solidifying amorphous alloy compositions and cast articles made of the same

Improved bulk-solidifying amorphous alloy compositions and methods of making and casting such compositions are provided. The improved bulk-solidifying amorphous alloys are preferably subjected to a superheating treatment and subsequently are cast into articles with high elastic limit. The invention allows use of lower purity raw-materials, and as such effectively reduces the overall cost of the final articles. Furthermore, the invention provides for the casting of new alloys into shapes at lower cooling rates then is possible with the conventional bulk-solidifying amorphous alloys.

Owner:CRUCIBLE INTPROP LLC

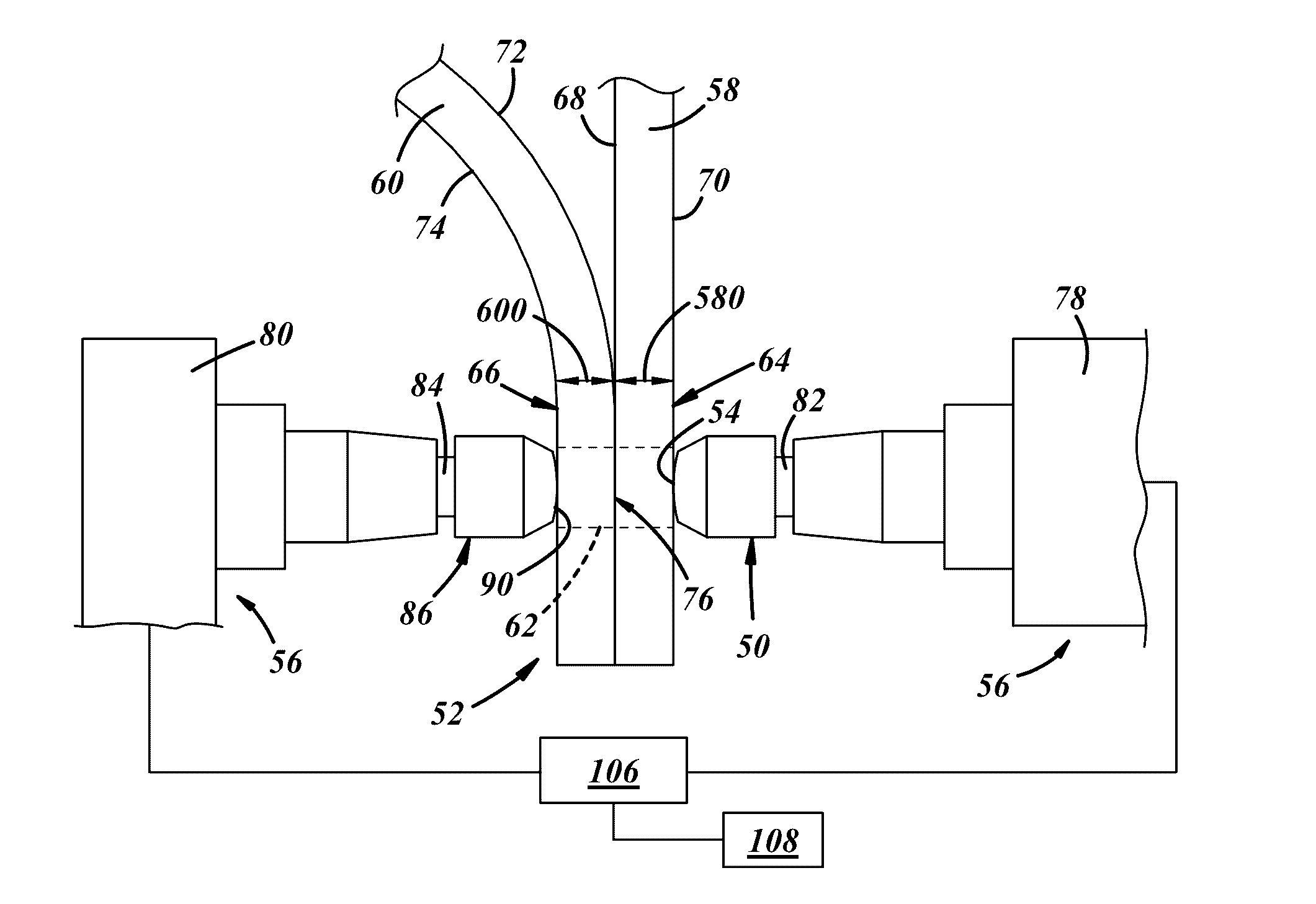

Resistive welding electrode and method for spot welding steel and aluminum alloy workpieces with the resistive welding electrode

ActiveUS20160279732A1Increase contact areaHigh densityWelding/cutting media/materialsPressure electrodesElectrical resistance and conductanceRefractory

A resistive welding electrode includes at least a weld face constructed of a refractory-based material that exhibits an electrical conductivity that is less than or equal to 65% of the electrical conductivity of commercially pure annealed copper as defined by the International Annealed Copper Standard (IACS). A method of using the resistive welding electrode to resistance spot weld a workpiece stack-up that includes an aluminum alloy workpiece and steel workpiece that overlap and contact each other at a faying interface is also disclosed.

Owner:GM GLOBAL TECH OPERATIONS LLC

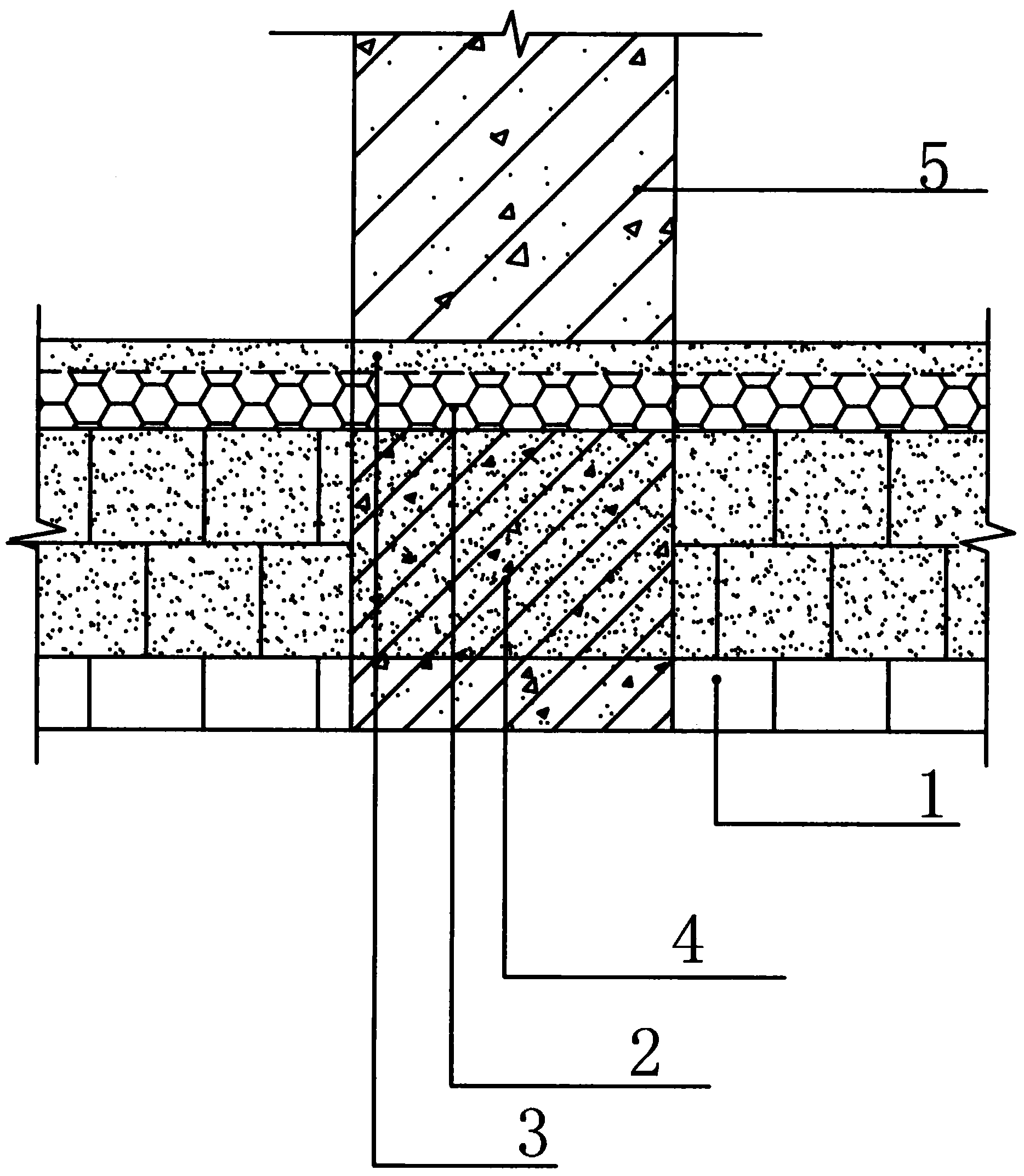

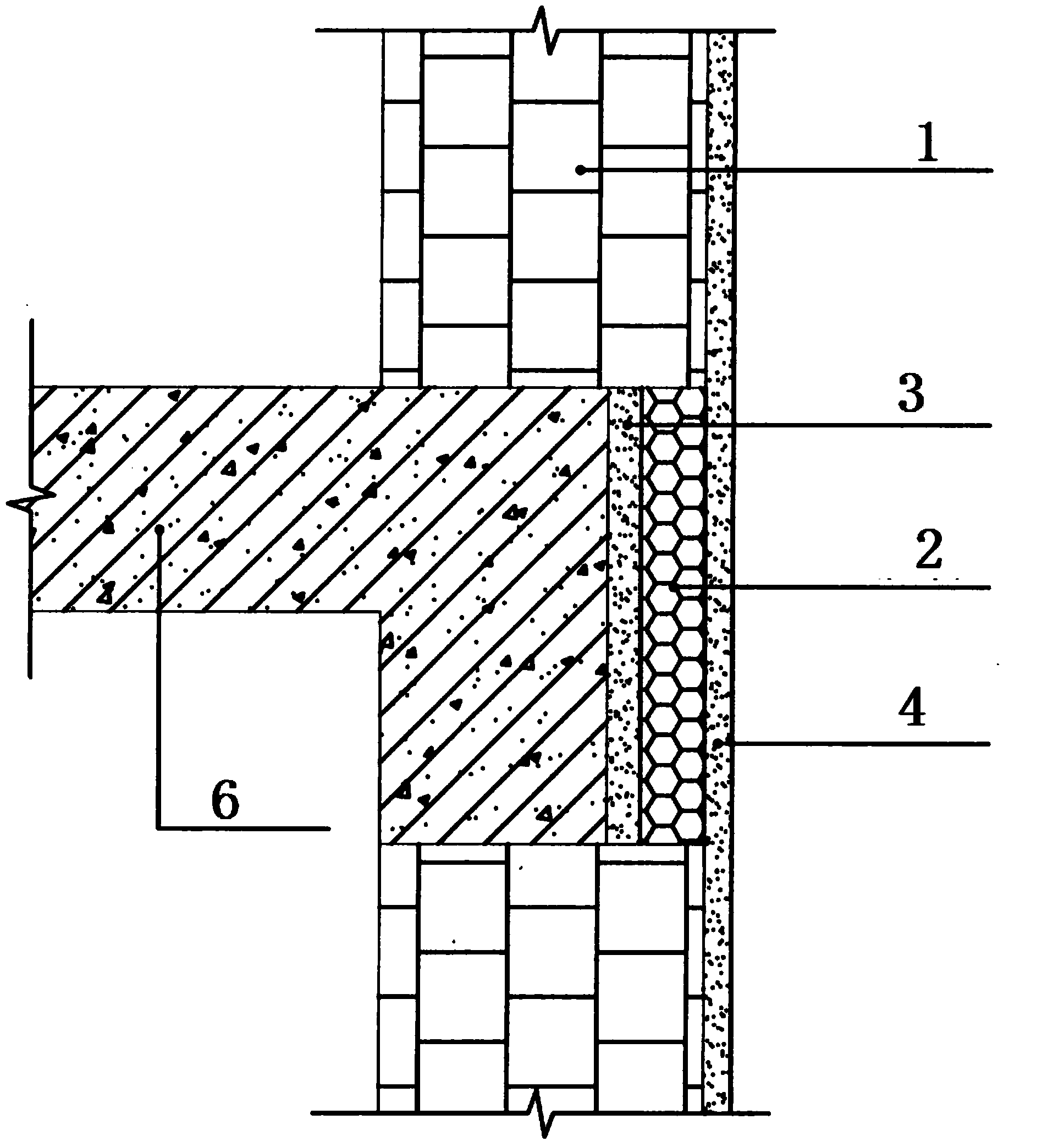

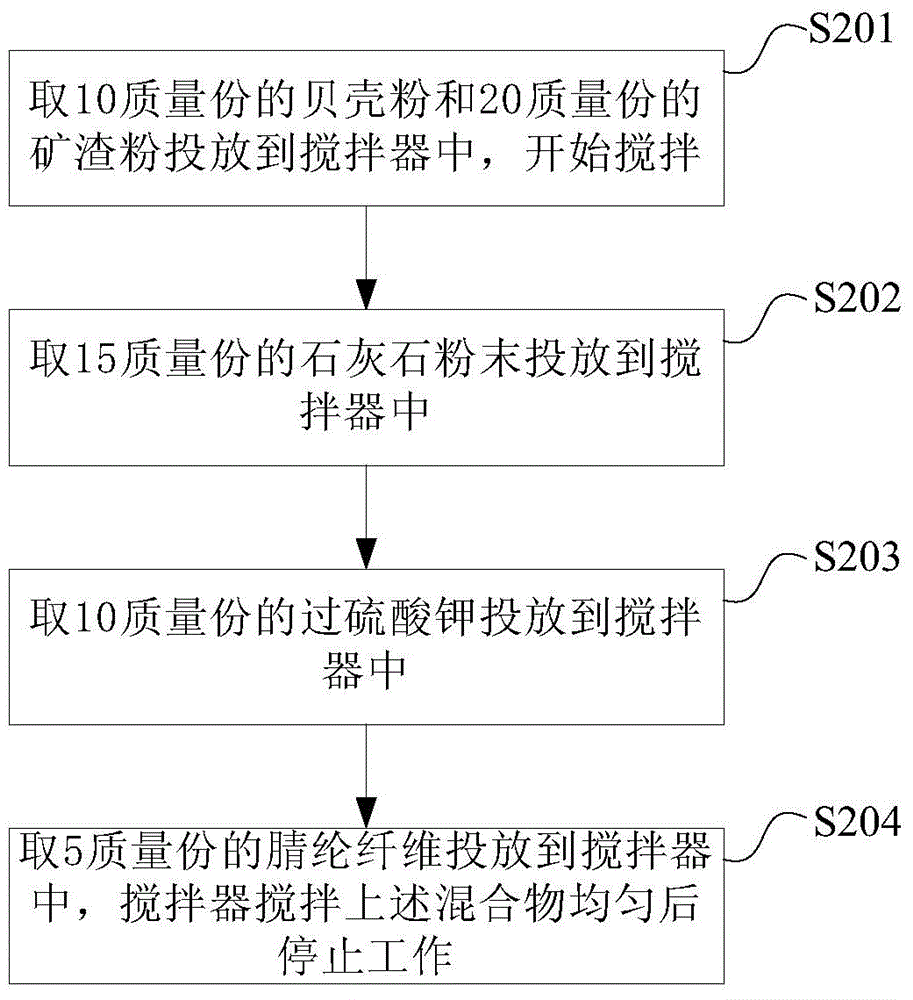

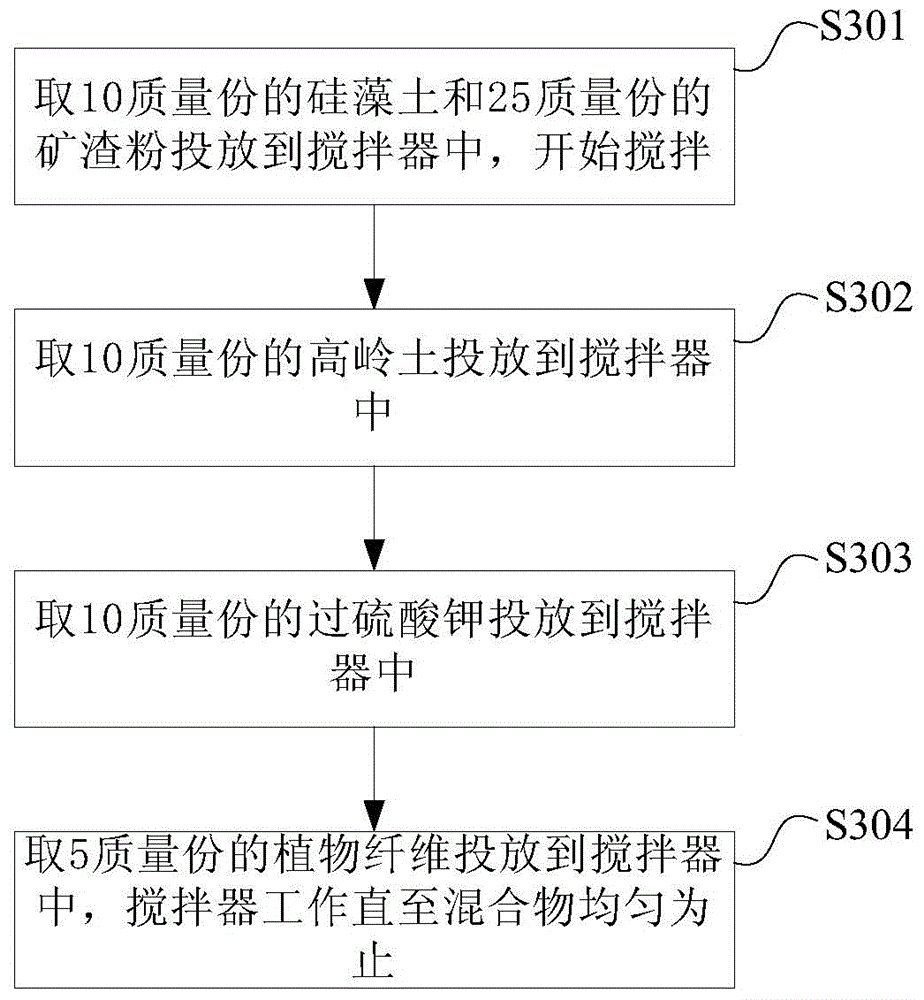

Grade-A fireproof self-heat-insulation wall body and manufacturing method thereof

ActiveCN103755287AEasy to solidifyShorten molding timeSolid waste managementUltimate tensile strengthMaterials science

The invention discloses a grade-A fireproof self-heat-insulation wall body and a manufacturing method thereof. The wall body comprises a grade-A fireproof self-heat-insulation wall body building block, a heat-insulation plate, a plastic rivet bolt, a masonry mortar layer and a heat-insulation anti-crack mortar layer, wherein the heat-insulation plate is adhered to a beam column of a frame structure through the masonry mortar layer; heat-insulation anti-crack mortar wraps each surface of the combination of the heat-insulation plate and the masonry mortar layer; the grade-A fireproof self-heat-insulation wall body building block, the heat-insulation plate, the plastic rivet bolt, the masonry mortar layer and the heat-insulation anti-crack mortar layer adopt an integrated structure; moreover, manufacturing methods for each part are introduced in detail. According to the grade-A fireproof self-heat-insulation wall body and the manufacturing method thereof, the product strength is greatly improved, the volume-weight is reduced on the basis that the product strength meets requirements, and the labor intensity is further reduced; the load of a building is reduced, the weight is light, the strength is high, and the fireproof, waterproof and heat-insulation effects are good; one-time construction is performed, the masonry of a main wall body is completed, the requirement for saving 65 percent of energy is also met, heat-insulation construction is not required to be performed, and the service life of the wall body is the same as that of the building.

Owner:环秀(青岛)建材科技有限公司

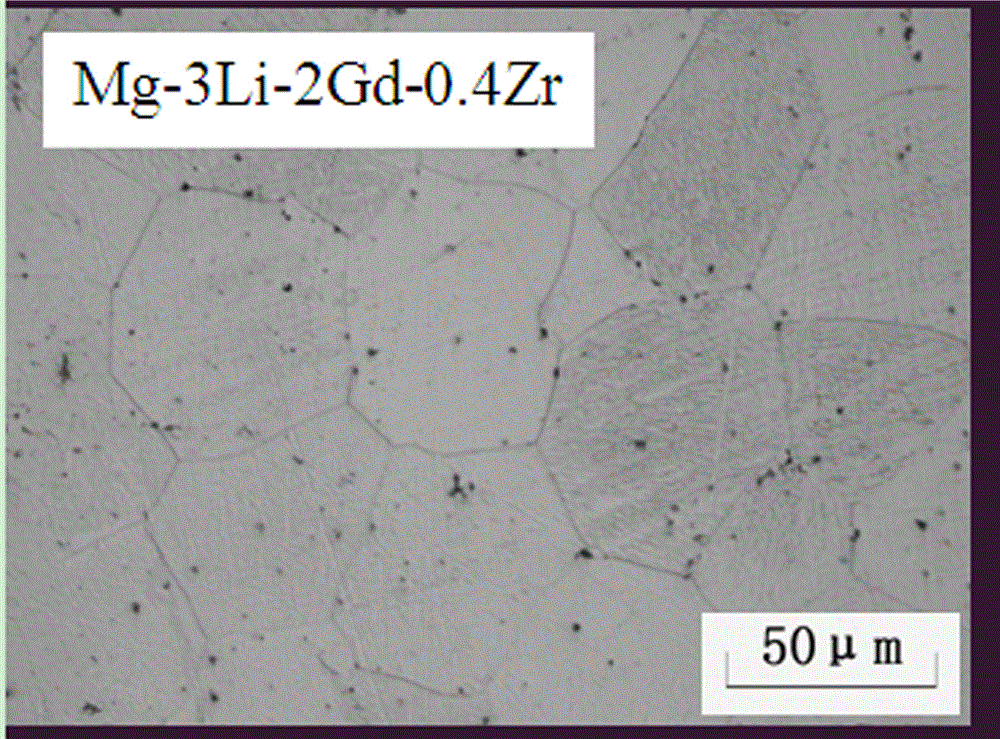

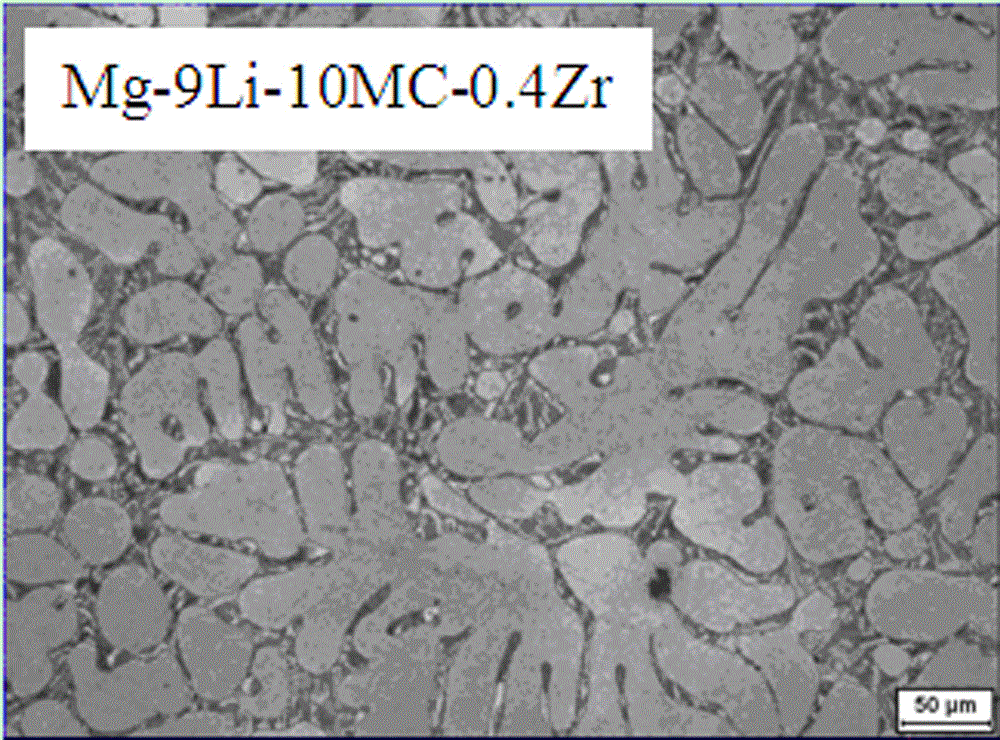

Air-cooled semi-continuous casting system and method of high-activity alloy

The invention relates to an air-cooled semi-continuous casting system and method of a high-activity alloy. The system comprises water-cooled crystallizers, air injection devices, an air-cooling device, an air tank, and a casting device, wherein the water-cooled crystallizers are located above the air injection devices; each air injection device is composed of an air injection ring, an air nozzle, and an air guide plate; the air injection devices are connected with the air cooling device and the air tank in order. The method comprises the following process steps: (1) checking leakproofness and unobstruction of the system, and adjusting angles of the air nozzles; (2) enabling dummy ingots to extend into the water-cooled crystallizers; directing an alloy melt to flow into a cavity, turning on a casting machine, adjusting a casting speed, and controlling a temperature of cooling air and adjusting a flow velocity of the air; and (3) when a length of an ingot blank meets a requirement, stopping melt supply firstly, closing a flow control valve after the melt in the water-cooled crystallizers is gradually cooled and solidified, and after an upper surface of the ingot blank is lowered down to a position below secondary cooling air injection devices, removing the water-cooled crystallizers and the secondary cooling air injection devices, lifting out the metal ingot blank, and then finishing casting.

Owner:NORTHEASTERN UNIV

Additive for inoculation of cast iron and method

InactiveUS20050050992A1Increase nucleation numberUniform structureBlast furnace componentsBlast furnace detailsRare earthMetallic sulfide

An additive for increasing the toughness of thin-wall iron castings is provided. The additive includes amounts of a non-ferrous metal oxide and a metal sulfide in which the non-ferrous metal has an affinity for oxygen less than that of iron, and the metal has an affinity for sulfur less than that of magnesium. The metals contained in the oxides and sulfides are also not alkali, alkali earth or rare earth metals to reduce the incidence of defect formation in the castings. The metal oxide and metal sulfide, when added to a cast iron melt react with magnesium added to the melt as a spheroidizing graphite element to form nucleation sites having a core of magnesium oxide surrounded by magnesium sulfide. These nucleation sites allow for increased nucleation of graphite, whether in vermicular or spheroidal form, such that the cross-section of the thin-wall iron casting is more uniform, thereby decreasing the amount of carbide formed in the casting and increasing the toughness of the casting.

Owner:WISCONSIN ALUMNI RES FOUND

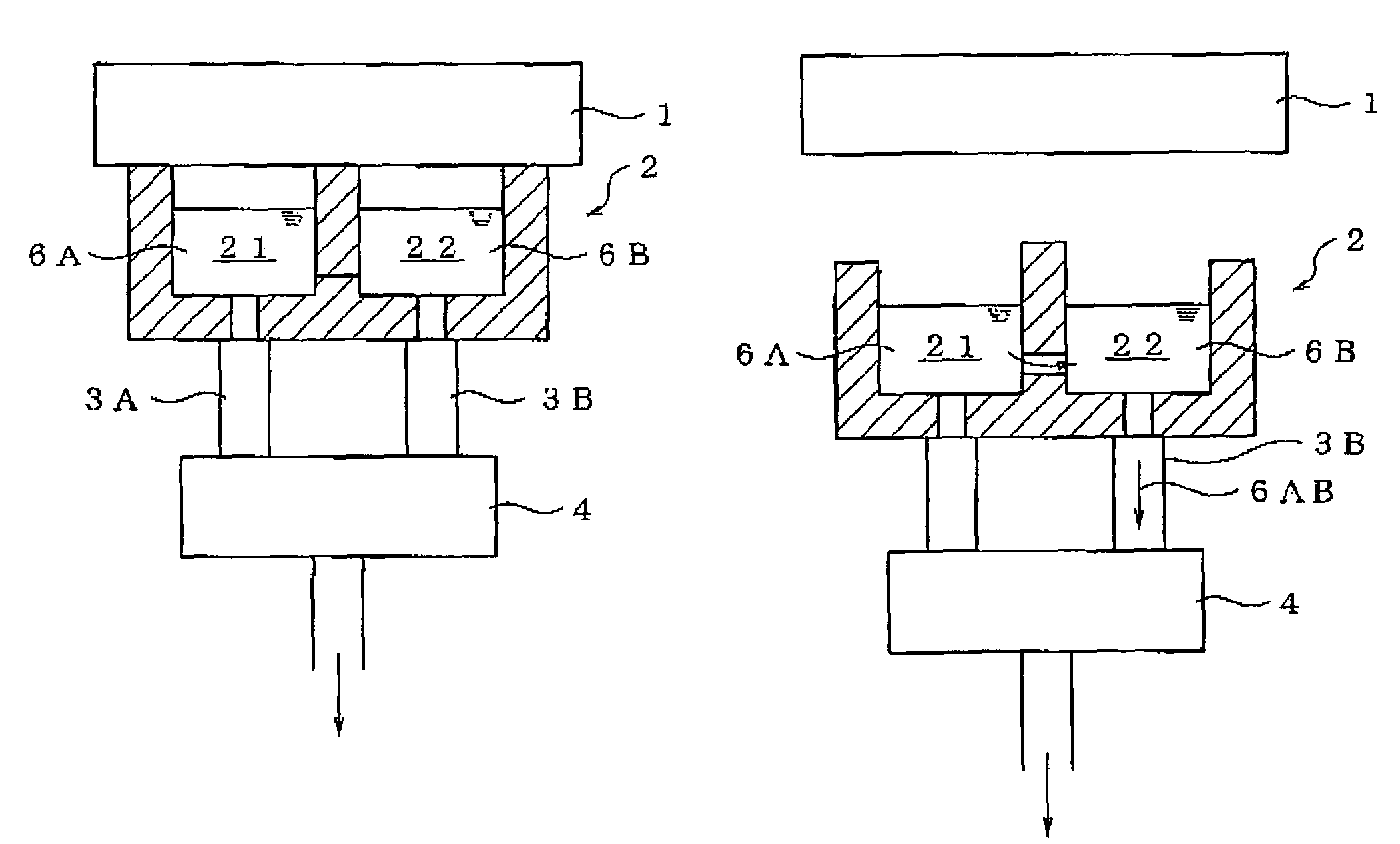

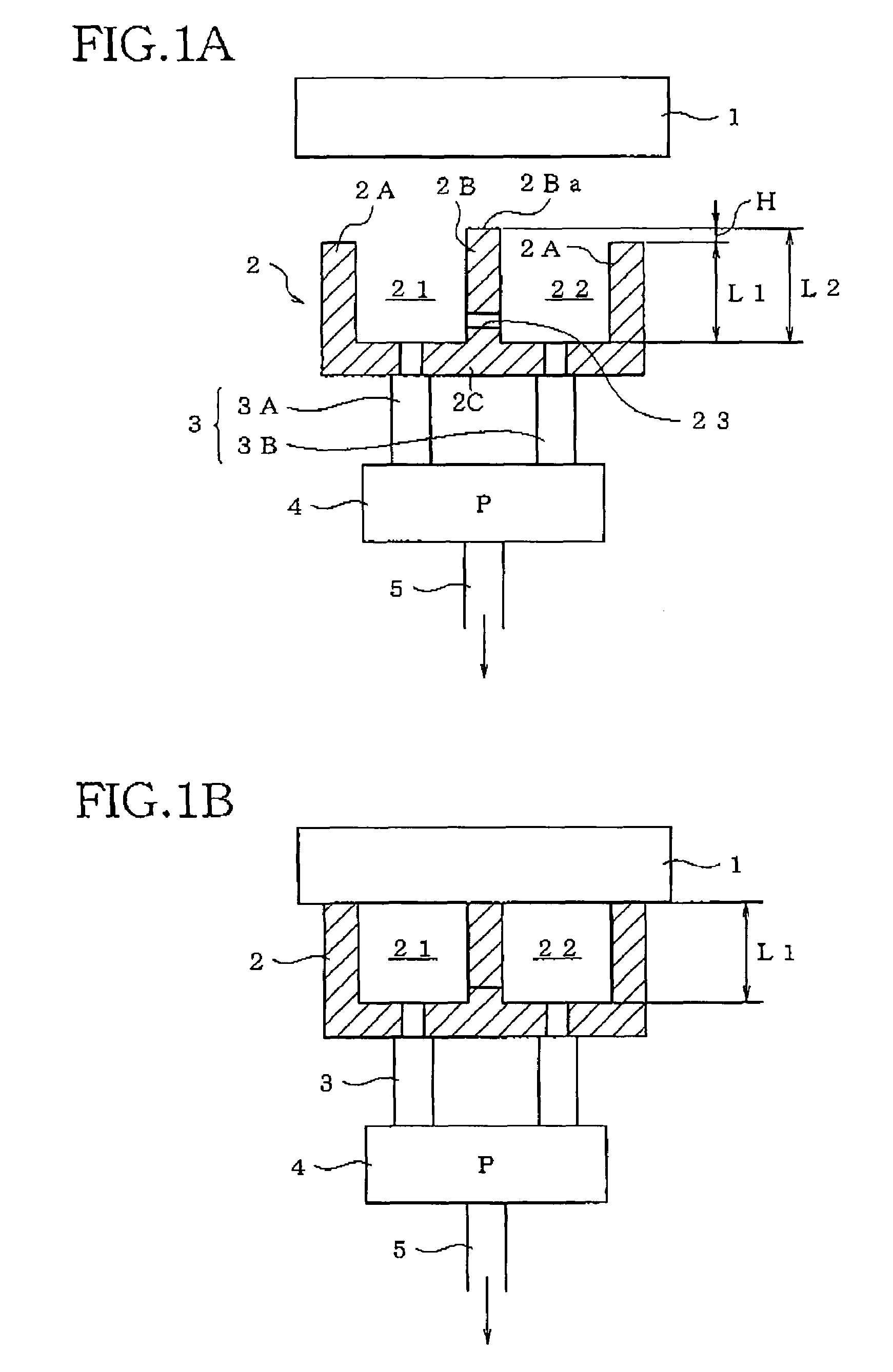

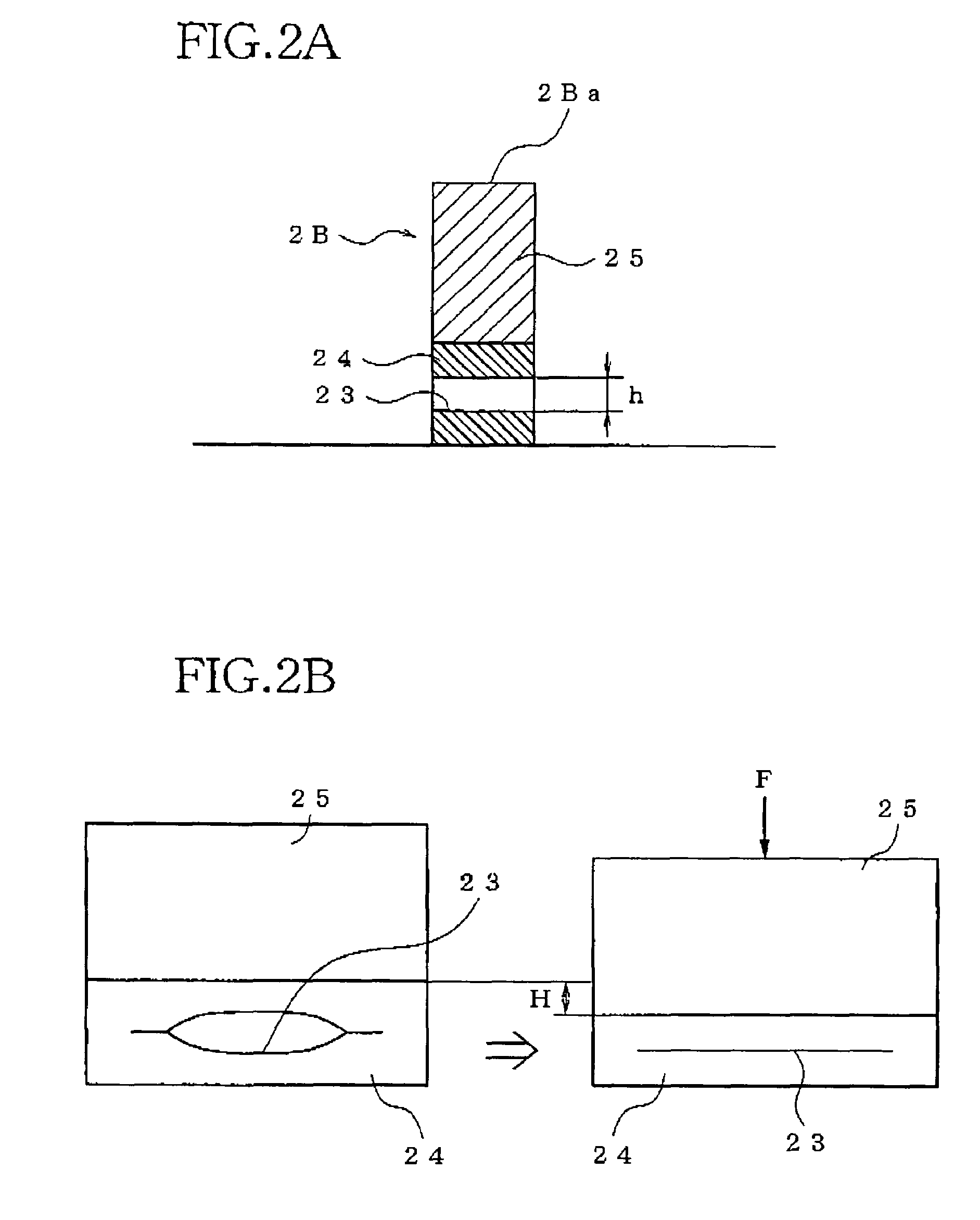

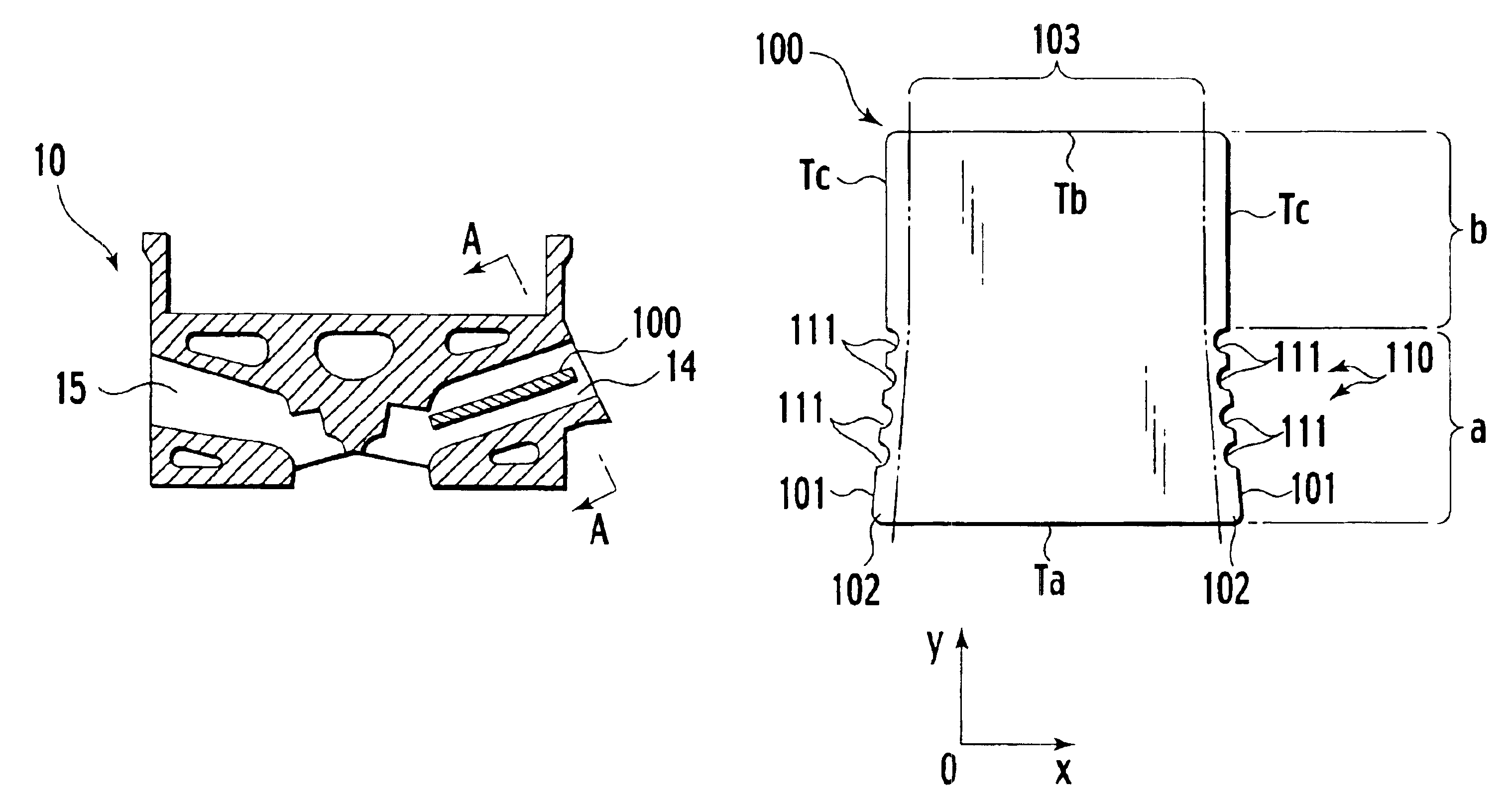

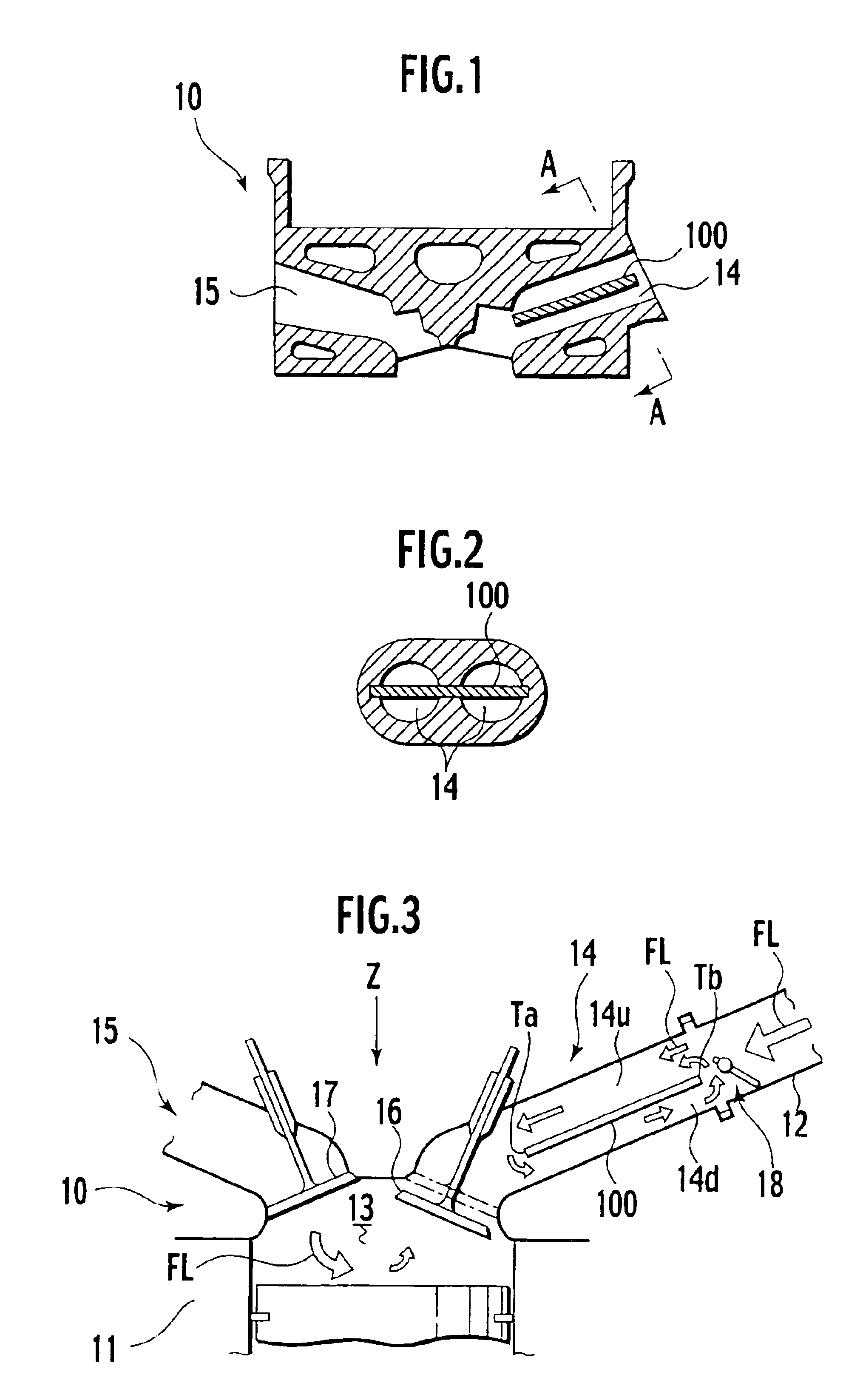

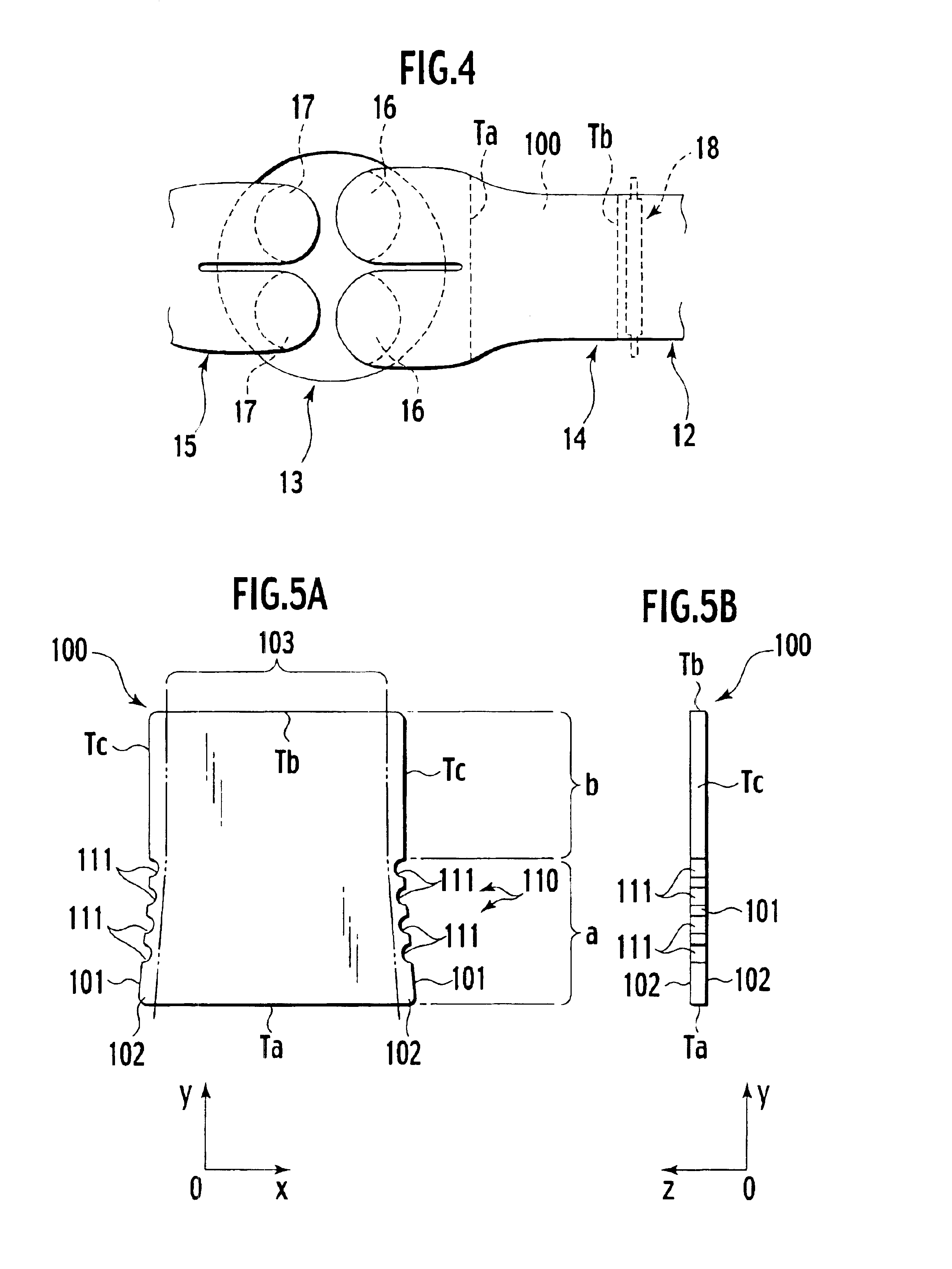

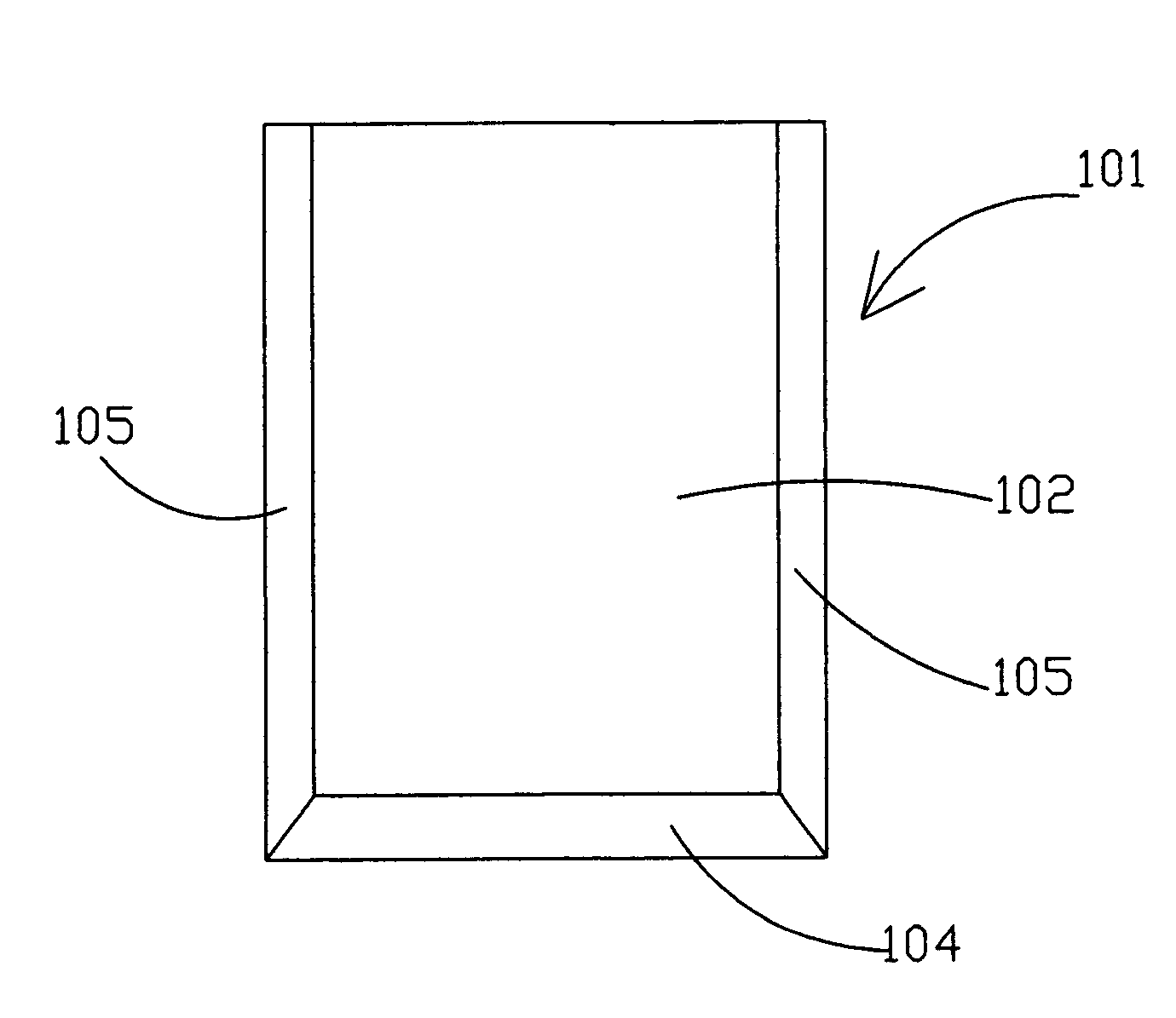

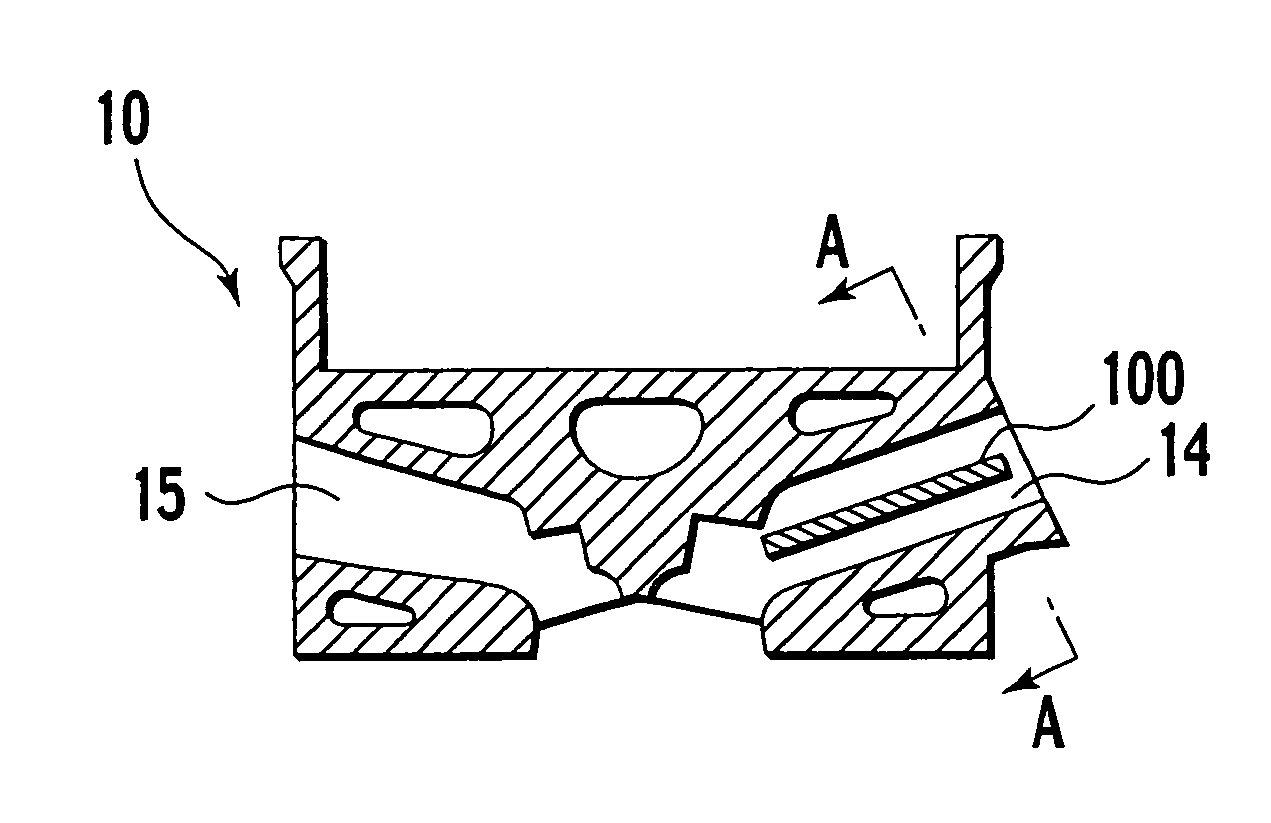

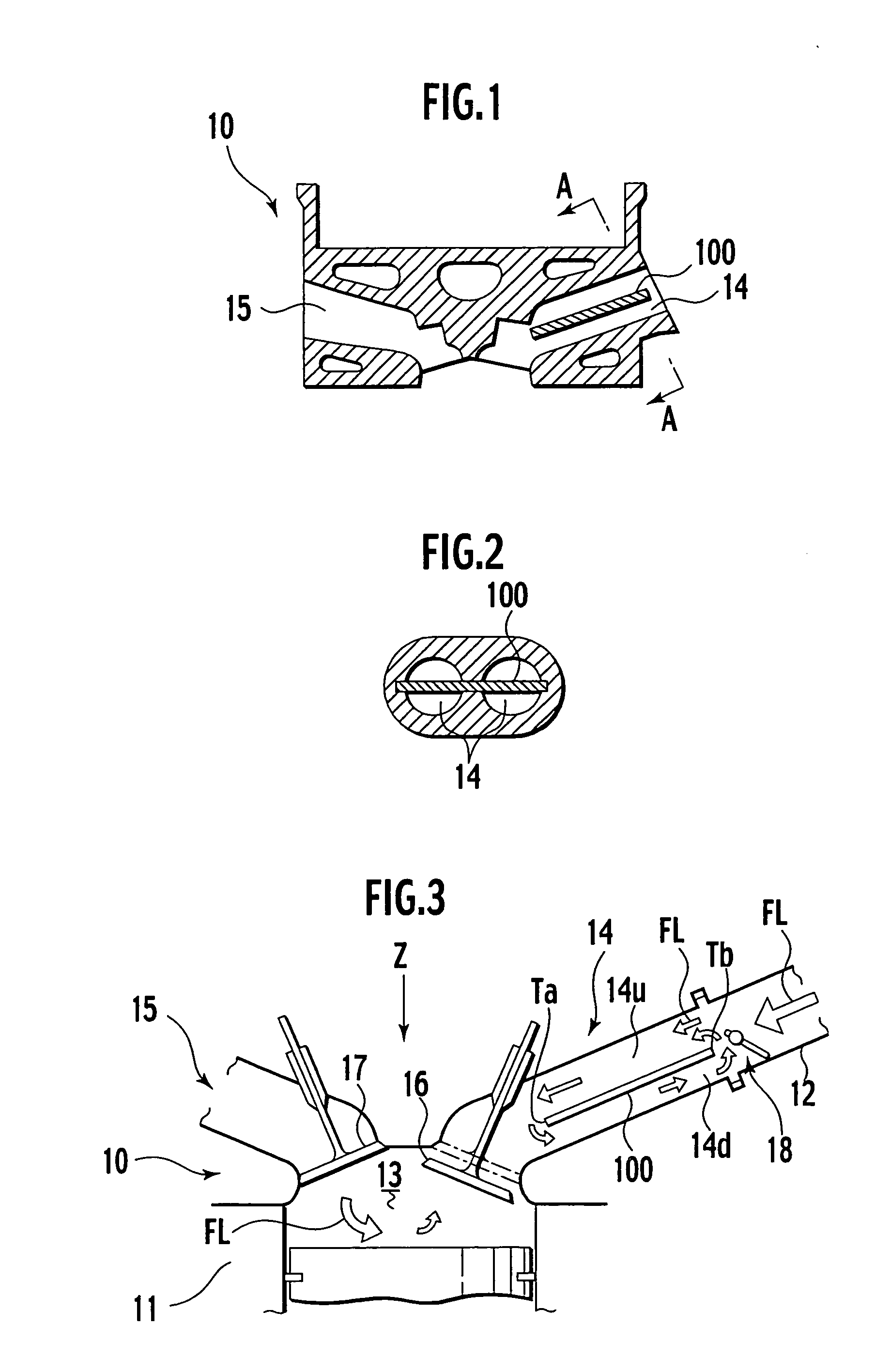

Partition plate for intake port, sand core for forming intake port, and cylinder head

ActiveUS7032560B2Removed positioningIncrease productionInternal combustion piston enginesCylinder headsMetallurgyCylinder head

A partition plate for an intake port of a cylinder head to be manufactured by cast molding is preliminarily set prior to the cast molding in a sand core applied to form the intake port and then cast in by the cast molding to partition the intake port into a plurality of ports. The partition plate is provided with an intake-side distal end, a cylinder-side distal end, a pair of side edges continuous with the intake-side distal end and the cylinder-sided distal end and to be cast in by molten metal during the cast molding. Each of the pair of side edges having end faces facing in a thickness direction and a side end face continuous with the end faces. The partition plate is further provided with a promoter section provided on at least one of the side end face and the end faces of each of the pair of side edges to promote solidification of the molten metal.

Owner:NISSAN MOTOR CO LTD +1

Heat and cold storage multistage tower with application of PCM

InactiveUS7222659B2Inhibition formationImprove thermal conductivityMilk preservationHeat storage plantsThermal management systemHeat transfer fluid

A heat management system include including application of phase change materials (PCM). A heat or cold storage multistage tower has a housing with a multistage system of flat rigid container. A significant fraction of internal space of each container is filled with PCM; these containers are fabricated from ceramics, glass, glass ceramics or sulfur concrete. Another version of the heat or cold storage tower is based on application of multi-channel blocks from ceramics, glass, glass ceramics or sulfur concrete; the parallel internal vertical channels of the blocks are open and sealed at their bottoms alternatively, and the channels with the sealed bottoms are filled partially with PCM. The tower achieves effective heat transfer between a heat transfer fluid (HTF) and PCM in the processes of charging and discharging of the containers with heat or cold.

Owner:LEVIN ALEXANDER

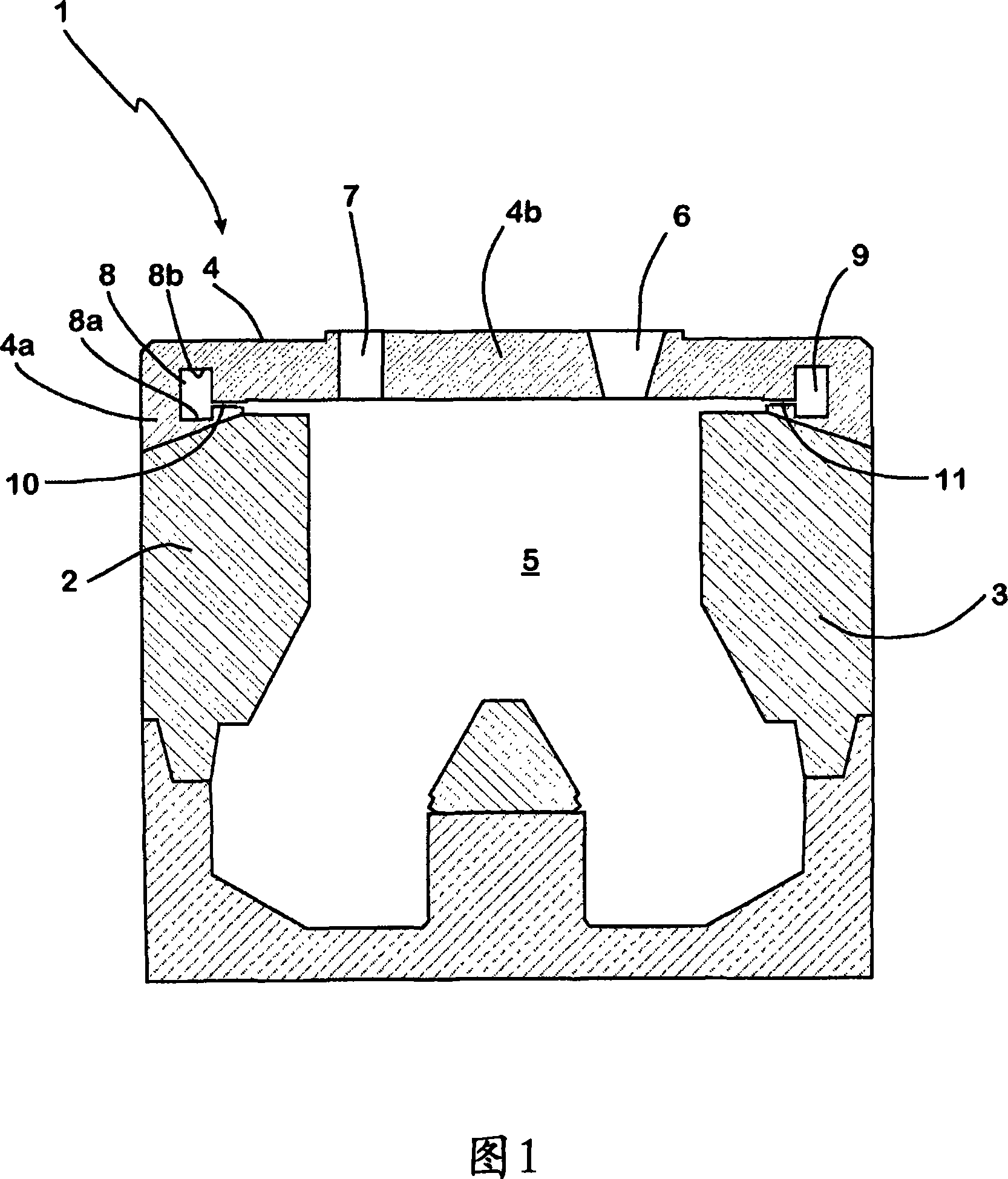

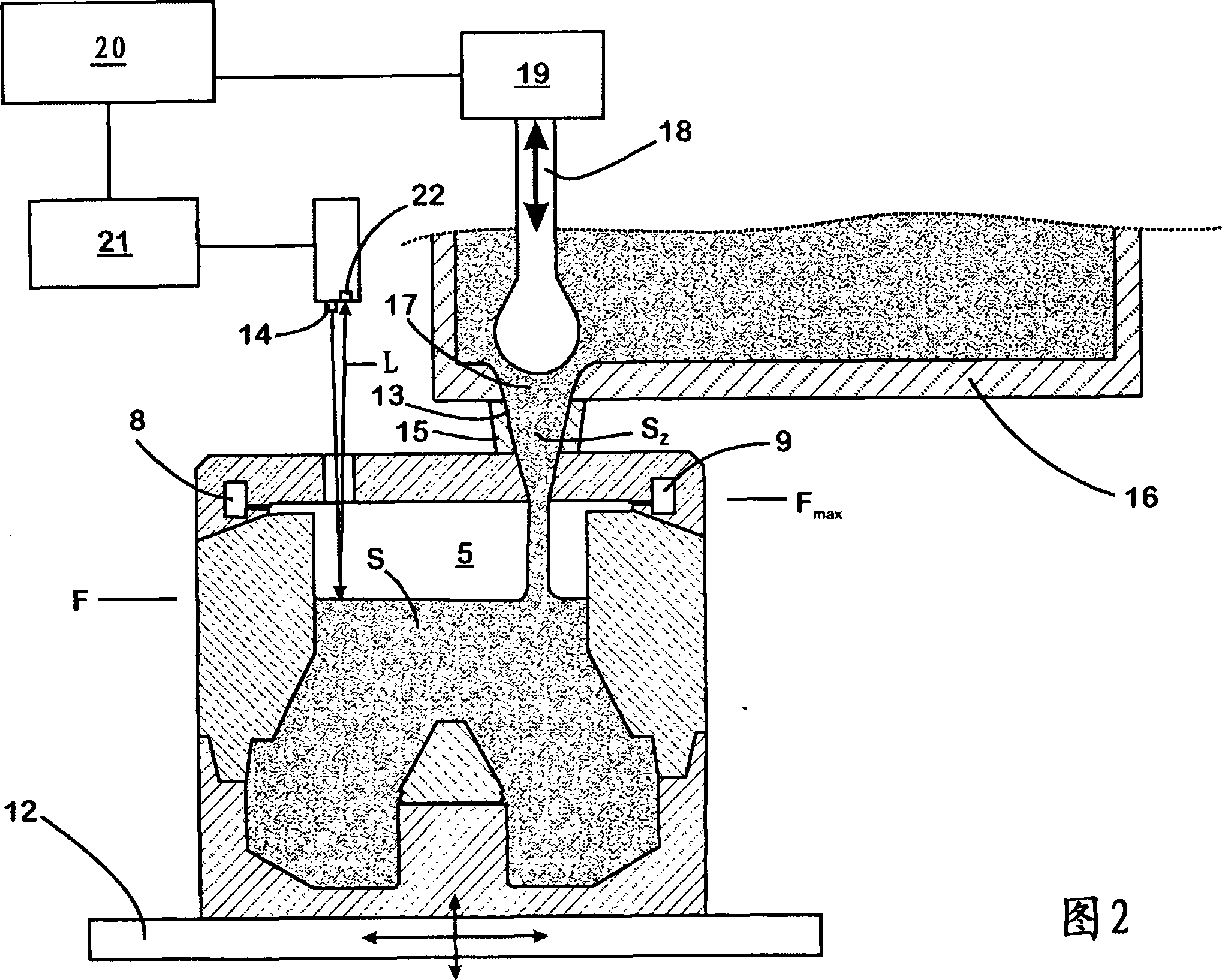

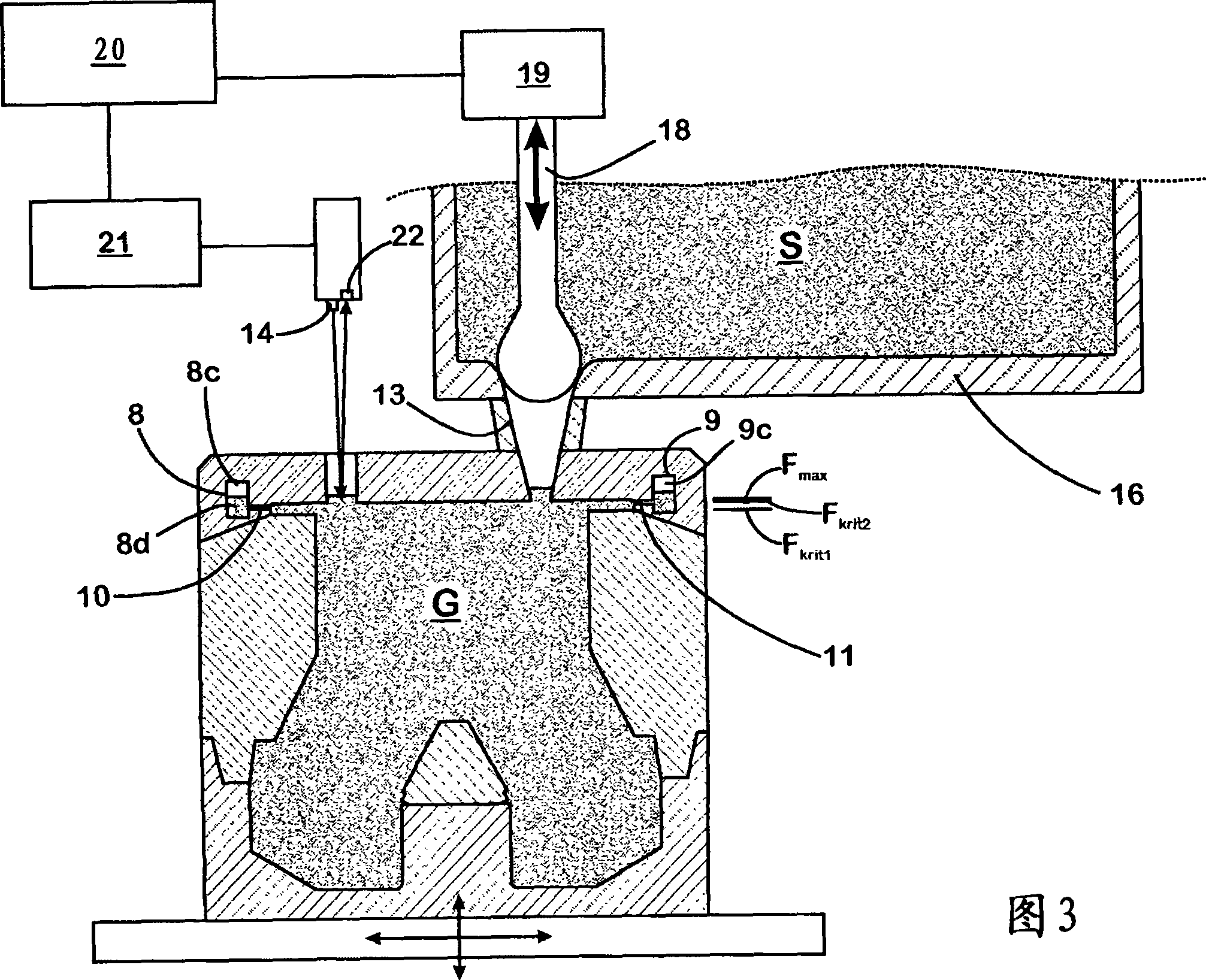

Casting mould, process and device for casting metal melts

ActiveCN101137452AAvoid pressure spikesEasy to separateMolten metal pouring equipmentsMolten metal supplying equipmentsCasting moldMetal

A casting mould is disclosed for manufacturing a casting from a metal melt (S) in a hollow moulding cavity (5) for reproducing a casting, and through an inlet for pouring a metal melt (M) into the hollow moulding cavity (5), as well as a device and a process for casting such metal melts. The disclosed casting mould also makes it possible to achieve a further optimised casting result, even in the hard operation conditions found in casting practice. Moreover, the use of the claimed device and process minimises the risk of jamming because of a pressure build-up during casting. This is achieved in that the casting mould comprises at least one compensation chamber (8, 9) linked to the moulding cavity (5) by a channel (10, 11) and having at least one section (8a, 9a) located above the maximum filling level (Fmax) of the casting mould (1) during the solidification of the metal melt (S).

Owner:HYDRO ALUMINUM ALUCAST

Sand core structure for precasting high-pressure oil channel of engine cylinder cover and precasting method

ActiveCN101817061ASimple structureIncrease annual production capacityFoundry mouldsFoundry coresNormal sequenceQuality control

The invention discloses a sand core structure for precasting a high-pressure oil channel of an engine cylinder cover. In the sand core structure, a through hole is formed on a dead head core; a high-pressure oil channel sand core is arranged in the through hole; the high-pressure oil channel sand core comprises a high-pressure oil channel hole sand core and a push rod hole sand core; the push rod hole sand core is arranged on the high-pressure oil channel hole sand core; a positioning hole is formed on an internal arm of the through hole; the push rod hole sand core is fixed in the positioning hole; the push rod hole sand core is provided with a core head; and a vent hole is formed on the dead head core corresponding to the positioning hole. The precasting method comprises the following steps of: firstly, matching and adhering the high-pressure oil channel sand core with the dead head core; secondly, matching and adhering the dead head core with an oil pool core; thirdly, making a cylinder cover water jacket sand core and an air duct sand core in an external die according to a normal sequence; and finally, placing the assembled sand cores into a metal external die for pouring to obtain the high-pressure oil channel precast cylinder cover after the sand cores are solidified. The sand core structure and the precasting method have the advantages of improving labor productivity, reducing processing cost, reducing rejection rate and improving the quality control effect of cast blanks.

Owner:CHERY AUTOMOBILE CO LTD

Viable-bacteria functional jelly and processing technique thereof

InactiveCN106690199AHigh in juiceAdd flavorFood ingredient functionsOligosaccharide food ingredientsBifidobacteriumFruit juice

The invention relates to a viable-bacteria functional jelly and a processing technique thereof. The viable-bacteria functional jelly comprises a jelly outer layer and a jelly core layer. The jelly core layer comprises the following components in parts by mass: 25-35 parts of fruit flesh, 0.5-10 parts of trehalose, 15-20 parts of white granulated sugar, 1.5-7.5 parts of first jelly glue powder, 0.2-1 part of first acidity regulator, 0.1-0.5 part of calcium lactate, 30-60 parts of water and probiotic powder. The jelly outer layer comprises 30-50 parts of fruit juice, 5-15 parts of white granulated sugar, 0.5-5 parts of galactooligosaccharide, 2-7 parts of second jelly glue powder, 25-65 parts of water, 0.2-2 parts of second acidity regulator and 0.1-0.5 part of calcium lactate. By adding the galactooligosaccharide, the prebiotics can promote the proliferation of Bifidobacterium and other probiotics in the human body, thereby providing sweetness on the premise of not increasing the possibility of diabetes and saprodontia. The higher content of active probiotics fills up the blank of active probiotic jellies in the market.

Owner:LINGBAO BRANCH OF SHAANXI HAISHENG FRESH FRUIT JUICE CO LTD +1

Casting method of spheroidal graphite cast iron valve

ActiveCN108531803AStable productionReduce manufacturing costFoundry mouldsFurnace typesElectricitySlag

The invention discloses a casting method of a spheroidal graphite cast iron valve, and relates to the spheroidal graphite cast iron valve. The method comprises the steps of model making, modeling, smelting, pouring, heat treatment and obtaining of a finished product valve casting. Alloy elements are not added, the spheroidal graphite cast iron valve with the supersize can be stably produced, a dedicated slag blocking device is arranged at the front end of a transverse sprue, when molten iron of the transverse sprue is introduced into the front end, the slag blocking effect is achieved, it is ensured that a mold cavity is rapidly and stably filled with the molten iron, oxide inclusions are reduced, a heat preservation top riser is adopted, and is placed on the top of the valve, and castingfeeding, slag discharging and exhausting are facilitated; a chilling block is arranged at the position, on the large and thick section and the portion with the large wall thickness difference, in thecasting, chromite sand is used around an even core and a shaft head in a shaft hole of the casting, the upper portion of an annular belt is paved with chromite sand, it is ensured that the casting canbe subject to directional sequential solidification, and meanwhile, the casting surface quality is ensured, and the method is particularly suitable for making a spheroidal graphite cast iron water and electricity butterfly valve with the supersize and the large section.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

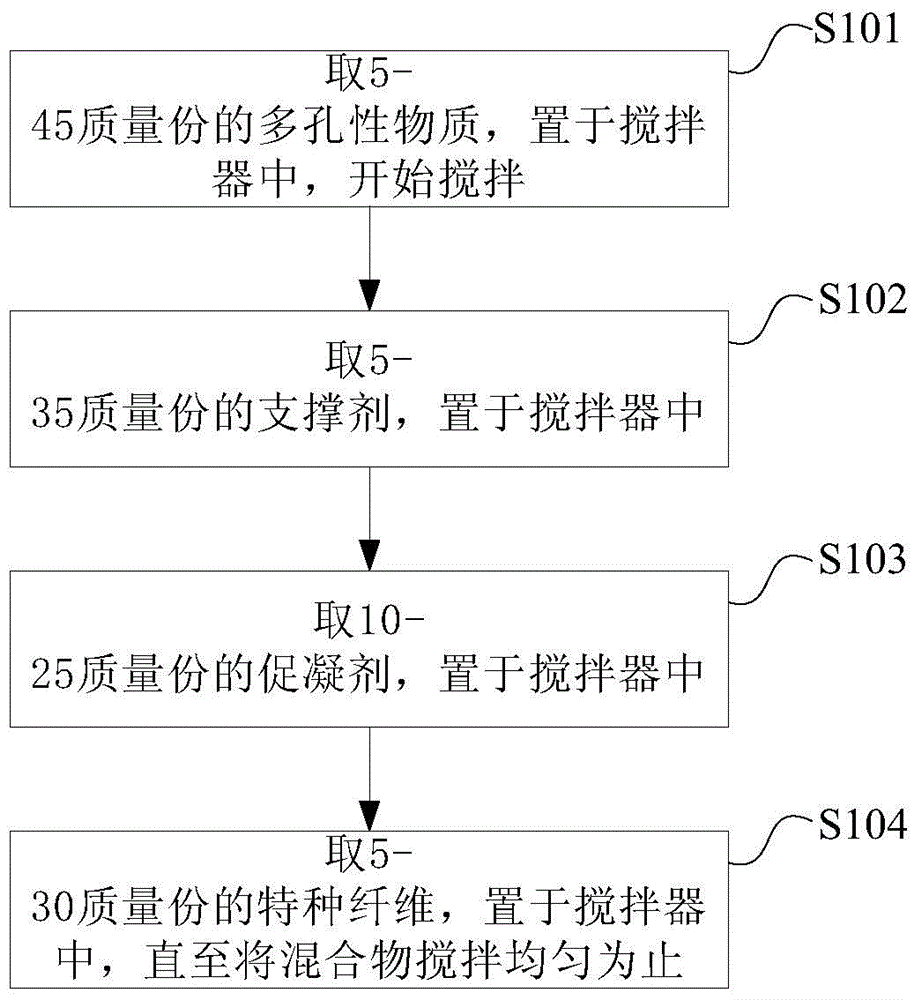

Plugging agent and preparation method thereof

ActiveCN104130759AThe problem of reducing productionEasy to solidifyDrilling compositionFiberBridge type

The invention relates to the technical field of well drilling, and discloses a plugging agent and a preparation method thereof. The plugging agent comprises, by mass, 5-45 parts of a porous substance, 5-35 parts of a proppant, 10-25 parts of a coagulant, and 5-30 parts of special fiber. The plugging agent provided by the invention does not cause permanent damage to a leakage loss section of an oil reservoir. When filter cake formed by the plugging agent is dissolved by using acid, oil and gas pores can be reopened, such that a problem of oil and gas production reduction can be avoided, and further a problem of oil and gas recovery failure caused by completely blocked oil and gas pores can be avoided. Also, under the effect of geotemperature, the filter cake formed by the plugging agent provided by the invention can be gradually solidified. As a result of tests, compared with a bridging type plugging agent, the plugging agent provided by the invention has the advantages of faster solidification, higher pressure bearing capacity, and thus better plugging effect.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Vehicle including power storage unit

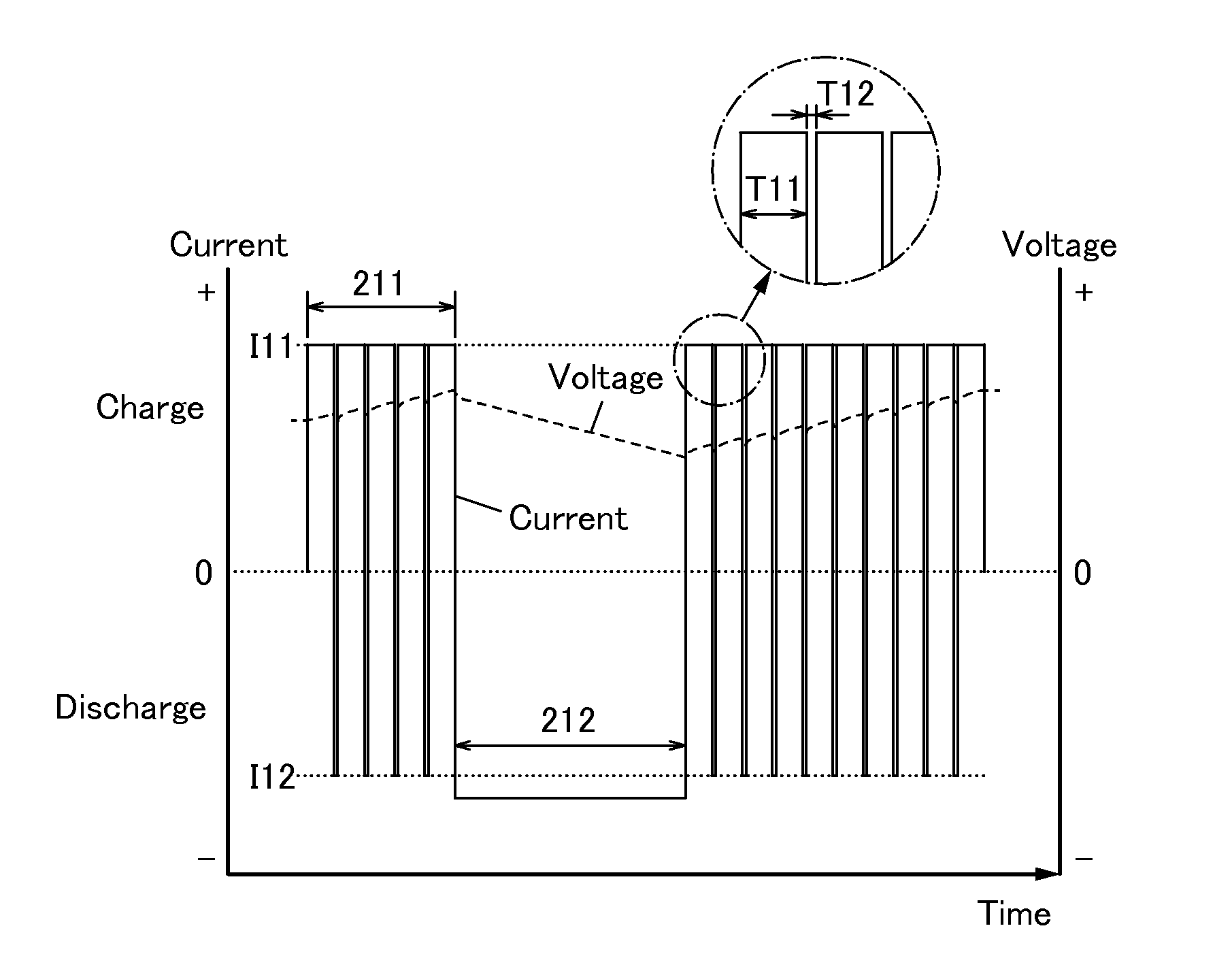

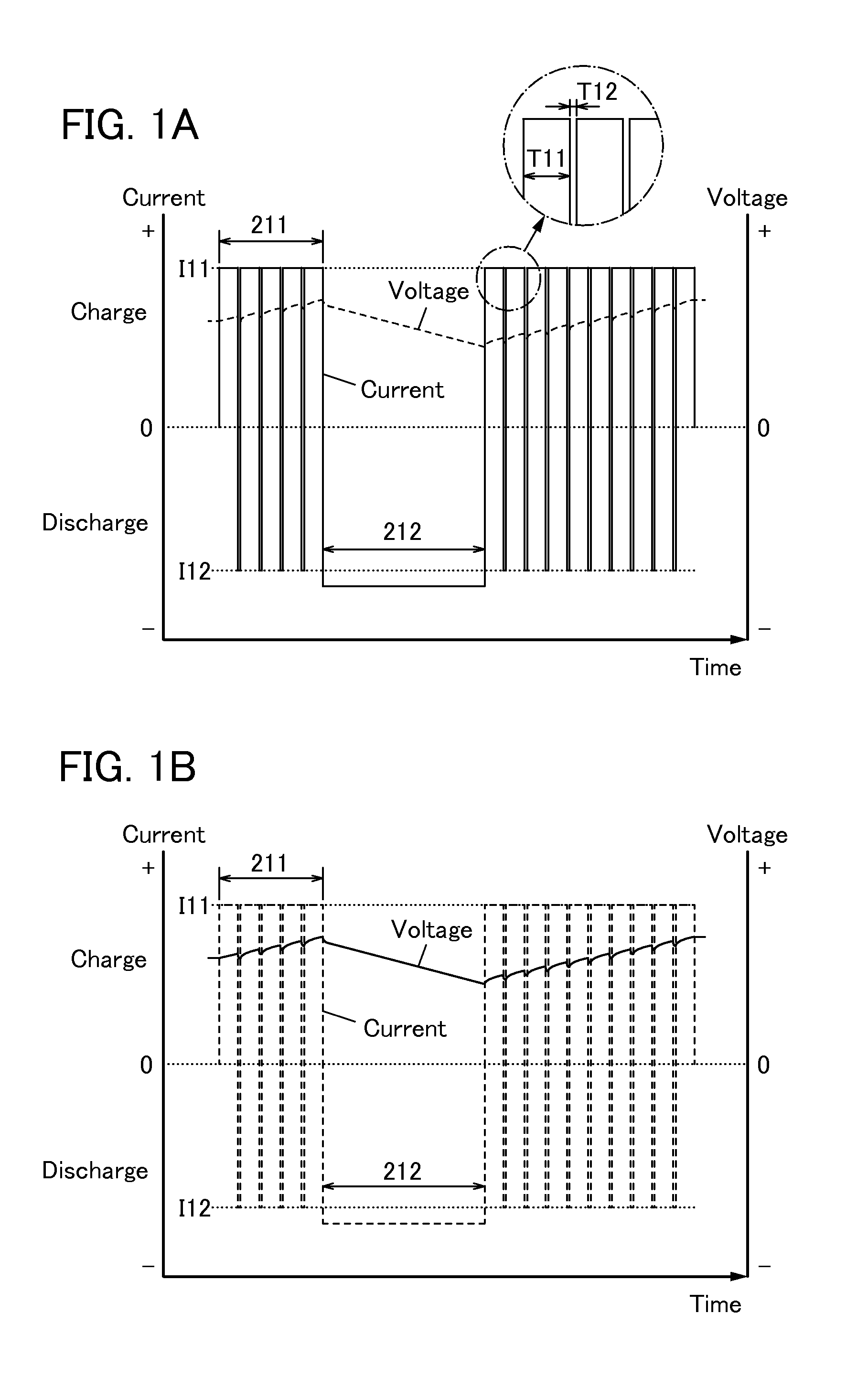

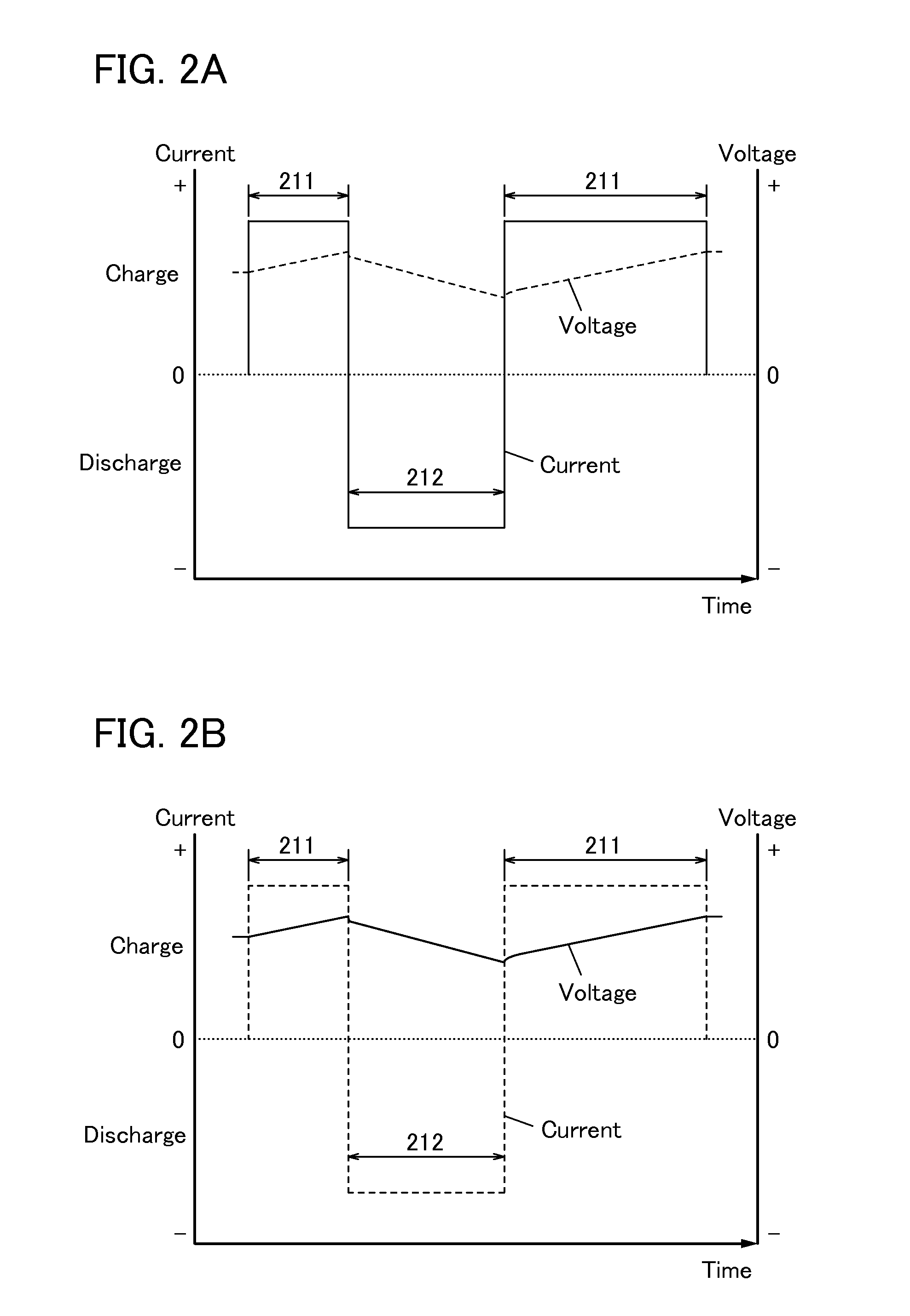

ActiveUS20140203738A1Inhibit deteriorationEasy to solidifyHybrid vehiclesBatteries circuit arrangementsLithiumEngineering

Deterioration of a power storage unit included in a vehicle is prevented or the power storage unit that has deteriorated is repaired, and the charge and discharge performance of the power storage unit is maximized to be maintained for a long time. Attention has focused on a reaction product formed on an electrode surface which causes malfunction or deterioration of a power storage unit such as a lithium-ion secondary battery. In the power storage unit used for a vehicle that runs on the power of an electric motor, rapid discharge occurring in the acceleration of the vehicle or the like tends to promote the solidification of the reaction product. The reaction product is removed by application of an electrical stimulus, specifically, an inversion pulse voltage.

Owner:SEMICON ENERGY LAB CO LTD

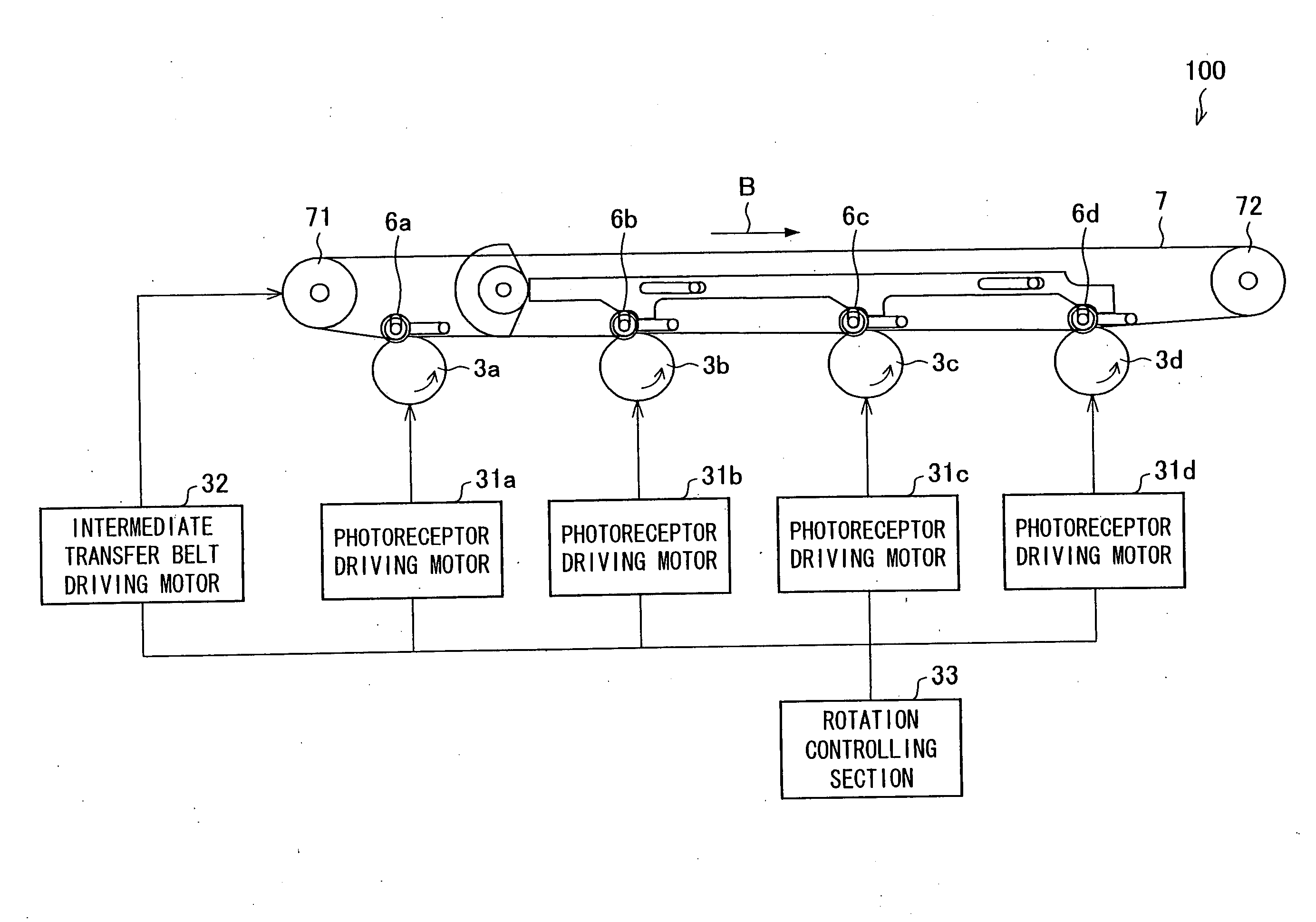

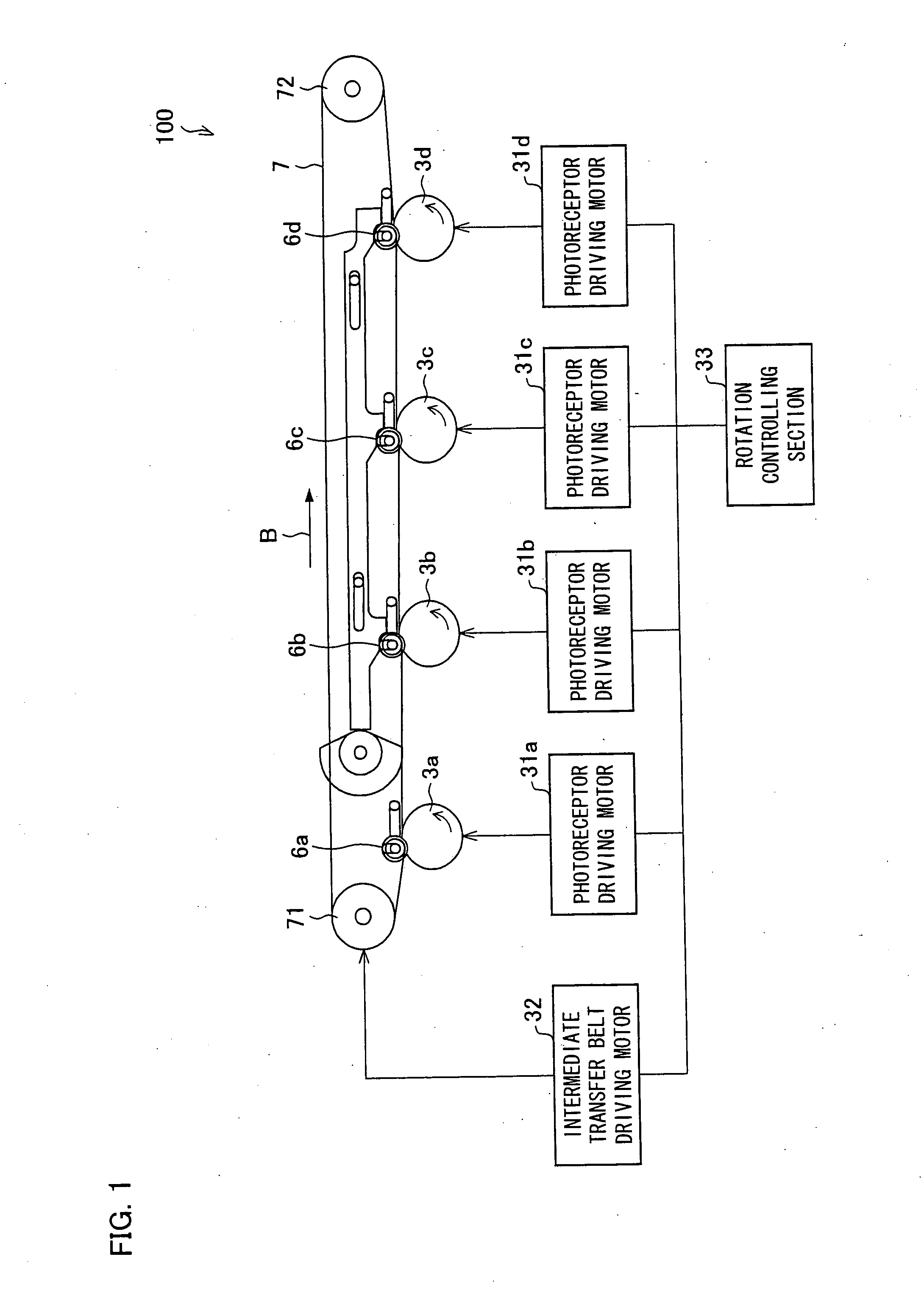

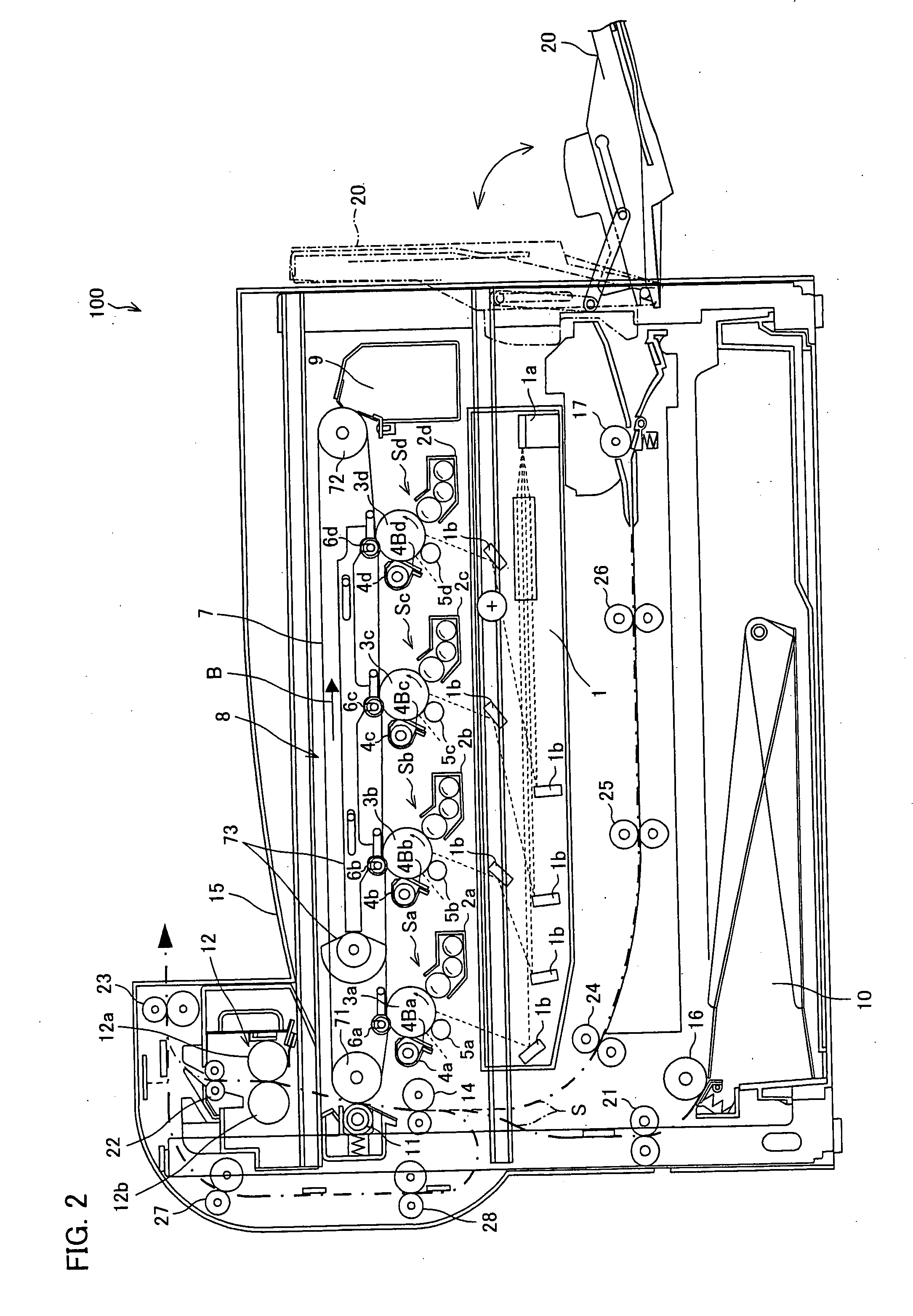

Image forming apparatus

InactiveUS20080145084A1Prevent toner scatteringPrevent gap formationElectrographic process apparatusImage formationContact position

In an image forming apparatus in which a visual image on a photosensitive drum is developed with columnar toner, and the developed toner image is transferred from the photosensitive drum to an intermediate transfer belt, a moving speed of the photosensitive drum and a moving speed of the intermediate transfer belt are different at a contact position (transfer nip section) where the photosensitive drum and the intermediate transfer belt are in contact. With this arrangement, toner scattering, nonuniform image etc. can be reduced in the image forming apparatus, in which the development is carried out with columnar toner.

Owner:SHARP KK

Technique method for improving density of injection molding high-speed steel columnar deposition blank

The invention relates to a technique method used for raising the density of a steel-column shaped sediment blank of a spray-forming high-speed tool and belongs to the technical field of material processing. The invention thoroughly combines the theory idea and the technical advantage of spray-forming and heat-control concretion. In an early phase of the spray sediment process, the advantages of the spray-forming that an equiaxed grain (less than 20Mum) having no segregation but a uniform and thin structure can be manufactured in a short process can be performed, and then the manufactured high-speed steel sediment blank has high strength, better plasticity and easy-forging capability. In a later phase of the sediment process, i.e. after the spray-forming is finished, the structure of a main body of equipment (such as a tundish and an atomizing sprayer, etc.) is adopted to control output and radiation of the heat. The invention enhances solidification of easy-loosening part of the high-speed steel sediment blank, so as to manufacture high quality and high density sediment blank. The technique not only can solve the segregation of the high-speed steel but also further enhance the density of the sediment blank to guarantee a following smooth process of fine-forging, etc.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

Partition plate for intake port, sand core for forming intake port, and cylinder head

ActiveUS20050081821A1Promote solidificationRemoved positioningInternal combustion piston enginesCylinder headsMetallurgyMolten metal

A partition plate for an intake port of a cylinder head to be manufactured by cast molding is preliminarily set prior to the cast molding in a sand core applied to form the intake port and then cast in by the cast molding to partition the intake port into a plurality of ports. The partition plate is provided with an intake-side distal end, a cylinder-side distal end, a pair of side edges continuous with the intake-side distal end and the cylinder-sided distal end and to be cast in by molten metal during the cast molding. Each of the pair of side edges having end faces facing in a thickness direction and a side end face continuous with the end faces. The partition plate is further provided with a promoter section provided on at least one of the side end face and the end faces of each of the pair of side edges to promote solidification of the molten metal.

Owner:NISSAN MOTOR CO LTD +1

Forming method for ceramic hollow balls

InactiveCN106007781ADensity controllableThe size is easy to controlCeramicwarePeristaltic pumpWater baths

A method for forming ceramic hollow spheres. Ceramic micropowder, pore forming agent, sintering aid, dispersant and calcium salt are formulated into a uniform slurry in a certain proportion, and sodium alginate is precisely controlled by a precision peristaltic pump under heating and stirring in a water bath. The solution is added dropwise to solidify the slurry into balls. After all the slurry is formed into balls, it is filtered, dried, and then sintered into ceramic balls. The size of the obtained ceramic balls is controllable, the gap is adjustable, the roundness is good, and the quality is close to isostatic pressing. Technology, less equipment investment, easy operation, low cost, suitable for various ceramic materials into balls.

Owner:SHAANXI UDC MATERIALS TECH CO LTD

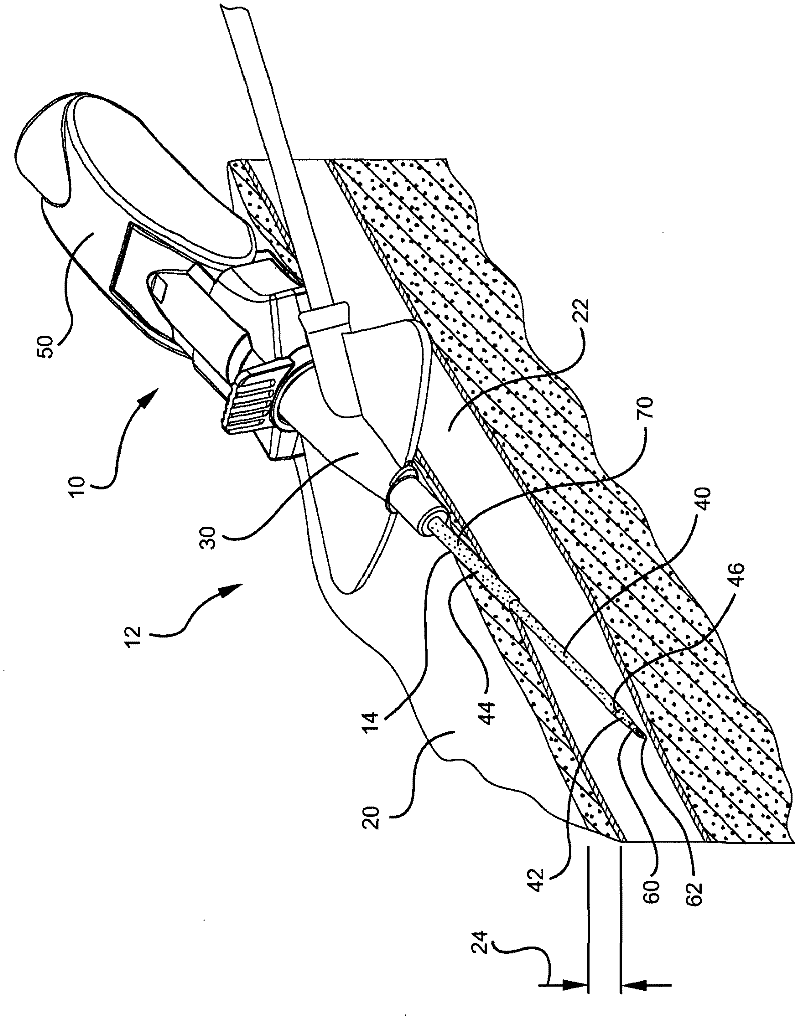

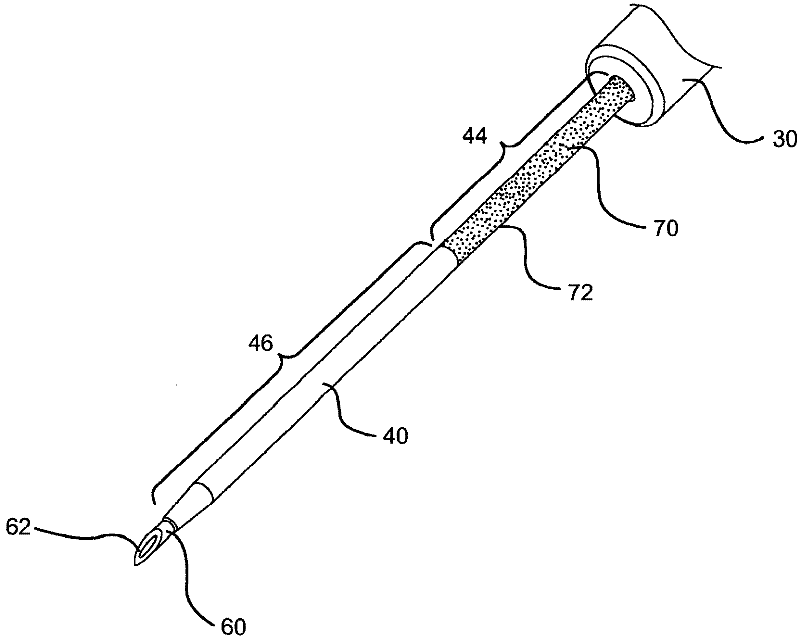

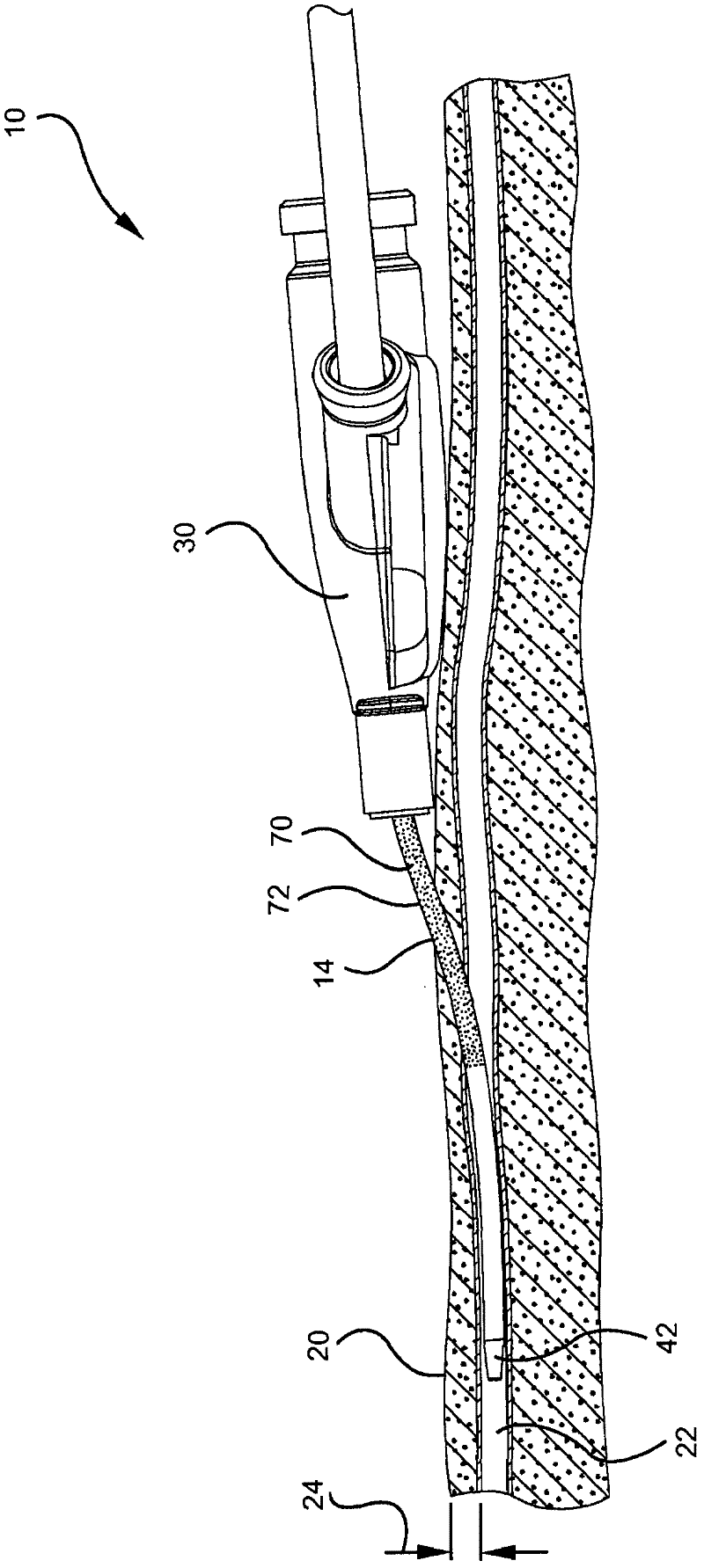

Antimicrobial coating for dermally invasive devices

An antimicrobial coating applied to a transdermal surface of a catheter device. An antimicrobial coating applied to catheter device such that when the catheter device is fully inserted, the antimicrobial coating is interposed between the catheter device and the dermal layers of the patient.

Owner:BECTON DICKINSON & CO

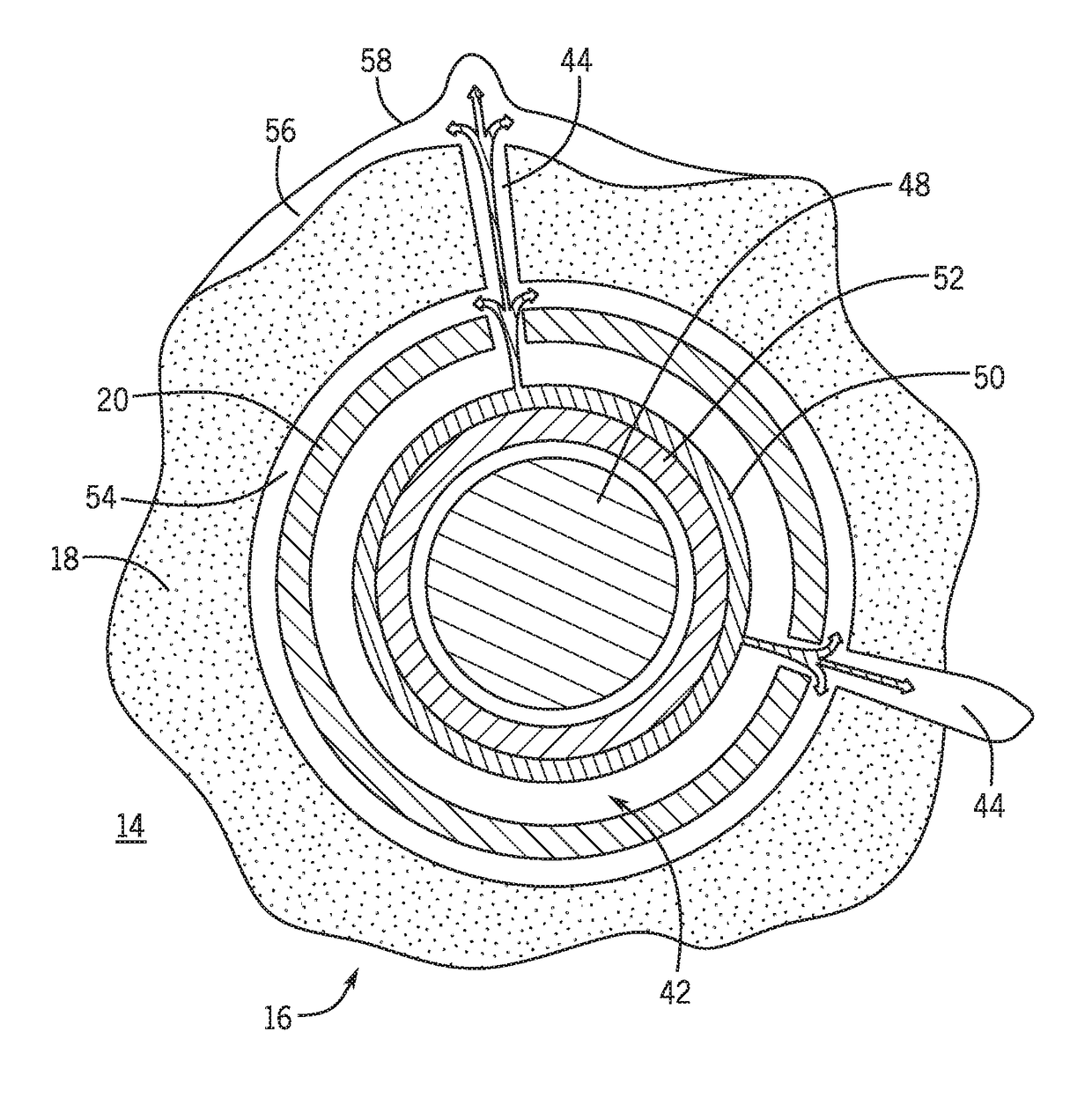

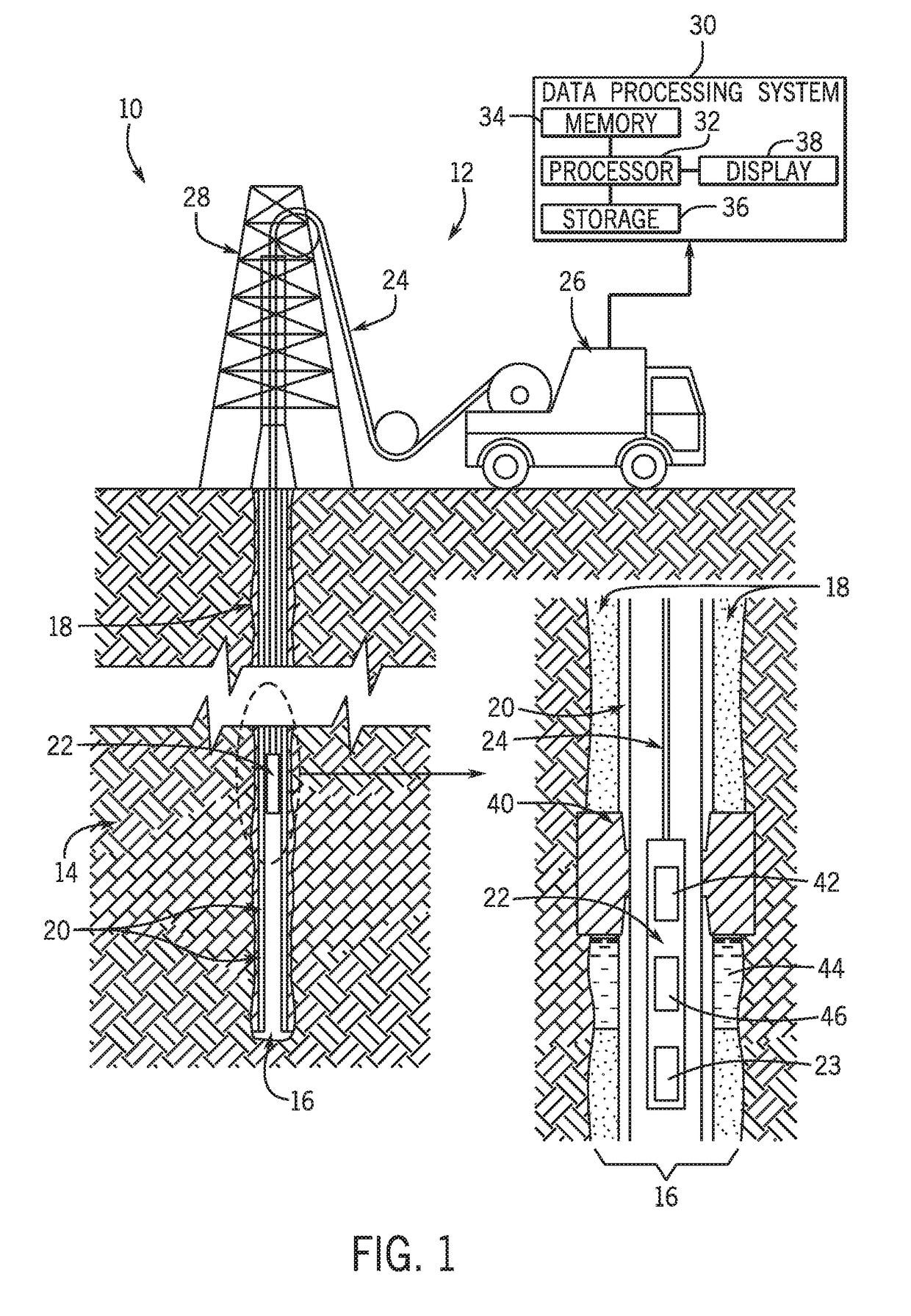

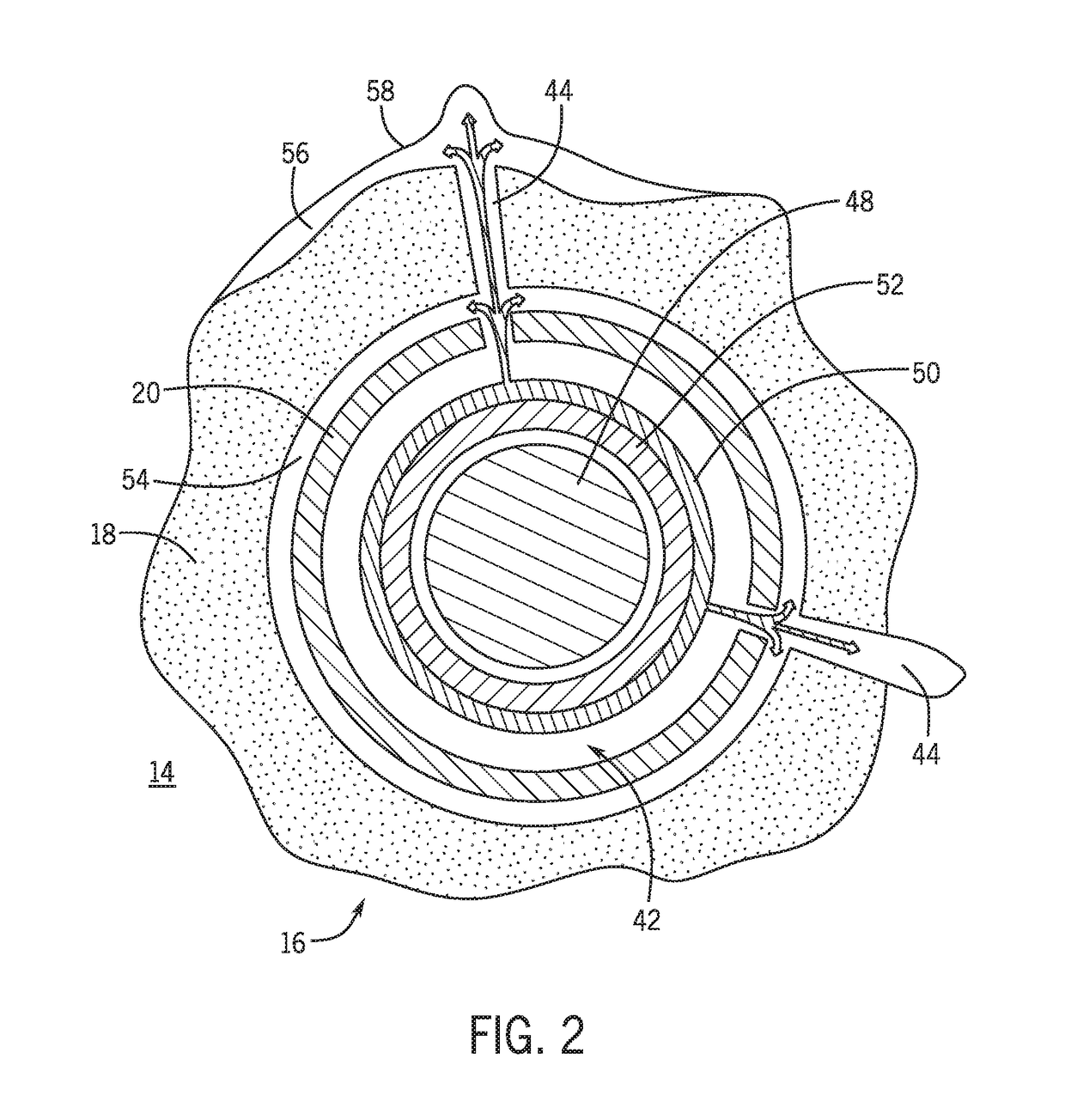

Systems and methods for remediating a microannulus in a wellbore

ActiveUS20180298720A1Easy to solidifyRestoring zonal isolationInsulationFluid removalFilling materialsEngineering

A method for remediating a microannulus in a cased wellbore may include conveying a downhole tool into the cased wellbore to a location of interest. The location of interest may include one or more perforations in a casing and a microannulus. The downhole tool may include a heat generation device. The method may also include activating the heat generation device to melt a fill material at the location of interest such that the fill material flows through the perforations into one or more voids, including the microannulus, in or around cement disposed between the casing and the cased wellbore. Additionally, the method may include deactivating the heat generation device to facilitate solidification of the fill material in the one or more voids and sealing of the microannulus.

Owner:SCHLUMBERGER TECH CORP

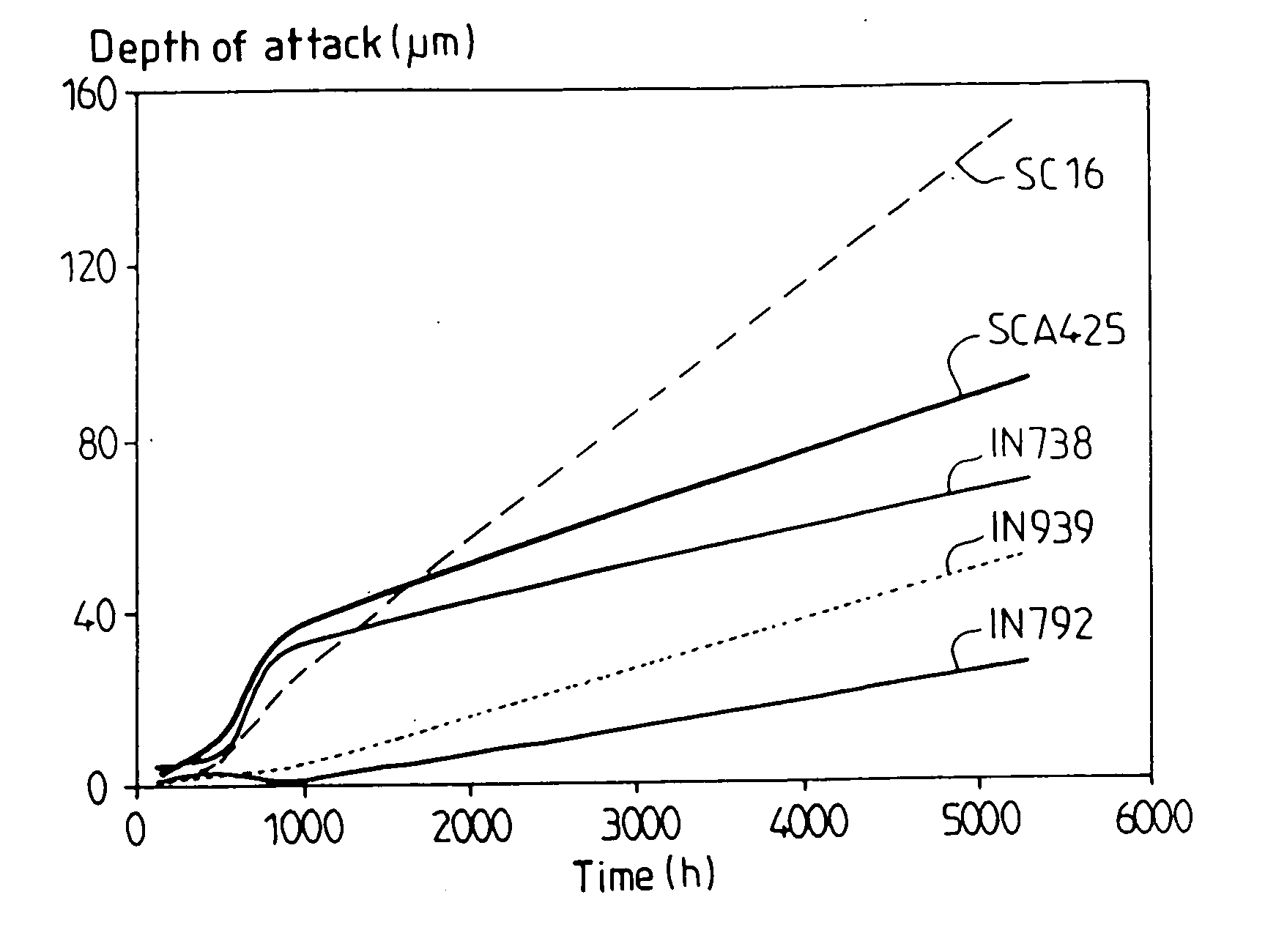

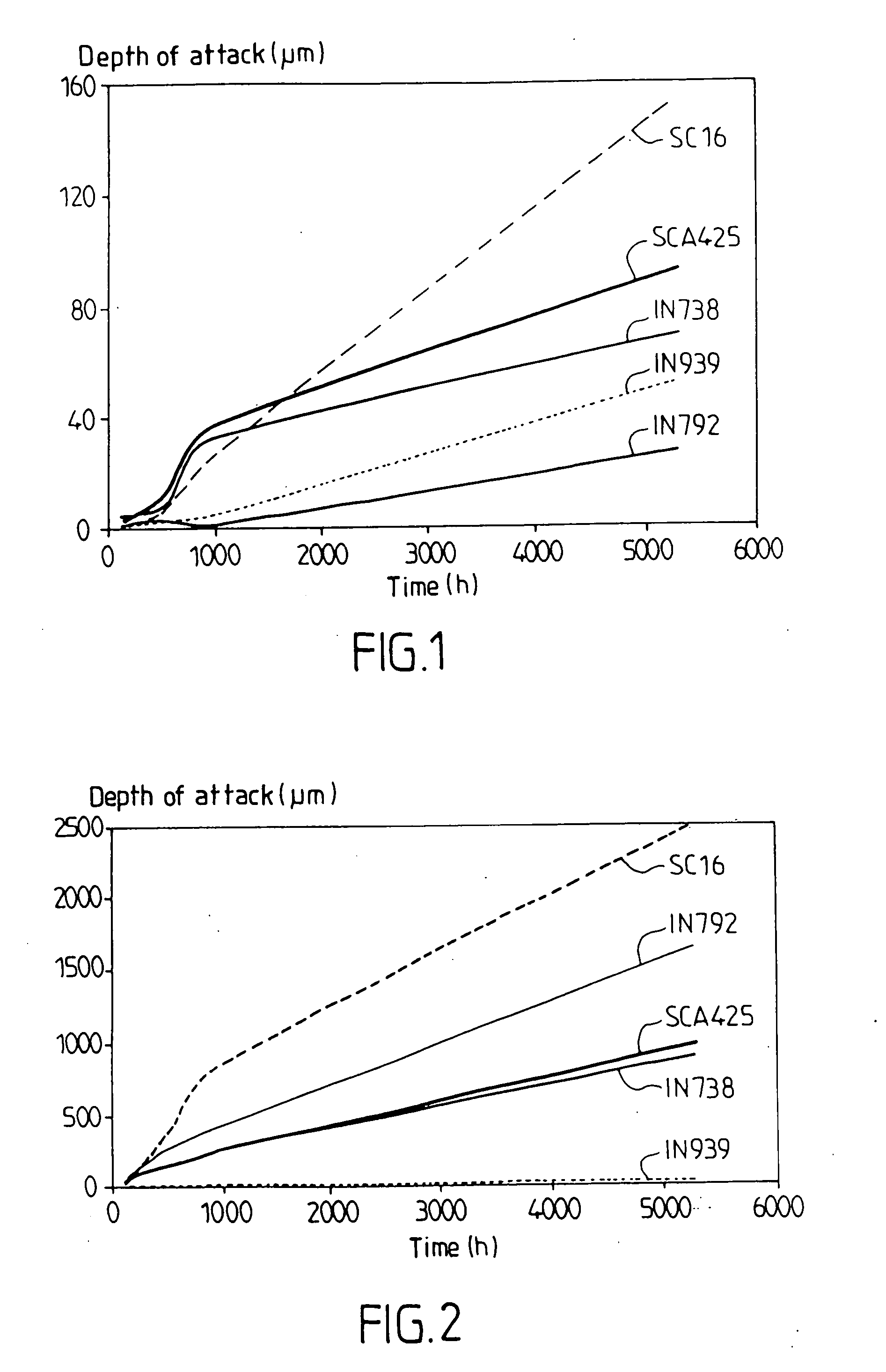

Nickel-based superalloy having very high resistance to hot-corrosion for monocrystalline blades of industrial turbines

InactiveUS20050194068A1Good micro-structural stabilityOverall light weightBlade accessoriesMachines/enginesHigh resistanceNiobium

Nickel-based superalloy, suitable for monocrystalline solidification, having the following composition by weight: Co: 4.75 to 5.25%Cr: 15.5 to 16.5%Mo: 0.8 to 1.2%W: 3.75 to 4.25%Al: 3.75 to 4.25%Ti: 1.75 to 2.25%Ta: 4.75 to 5.25%C:0.006 to 0.04%B:≦0.01%Zr:≦0.01%Hf: ≦1%Nb: ≦1%Ni and any impurities:complement to 100%.

Owner:HOWMET CORPORATION +2

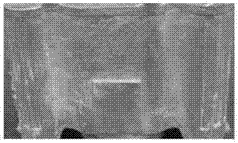

Magnesium alloy casting method and device thereof

The invention discloses a magnesium alloy casting method which comprises the steps of smelting magnesium alloy and deslagging; preheating a gypsum mould; using a gas mixture containing 1-10% of sulfur hexafluoride and 90-99% of argon to pressing a lower tank for 1-2 minutes with the gas pressure of 1-5Kpa; vacuumizing an upper tank to reach a specified negative pressure value k1, injecting a gas mixture containing 1-10% of the sulfur hexafluoride and 90-99% of the argon into the upper tank to rise to a specified negative pressure value k2; pressing the lower tank with the gas pressure of 10-80KPa to realize pressing casting. The invention discloses a magnesium alloy casting device. According to the technical scheme disclosed by the invention, a produced casting has the average wall thickness of 1.0-1.5mm, the tensile strength of 190MPa and the ductility of 2-3%, and is high in surface quality, compact in internals and good in performance, oxidation, cold shut and slag inclusion defects are avoided, and simple process, convenience in operation and low cost are realized.

Owner:HENAN POLYTECHNIC UNIV

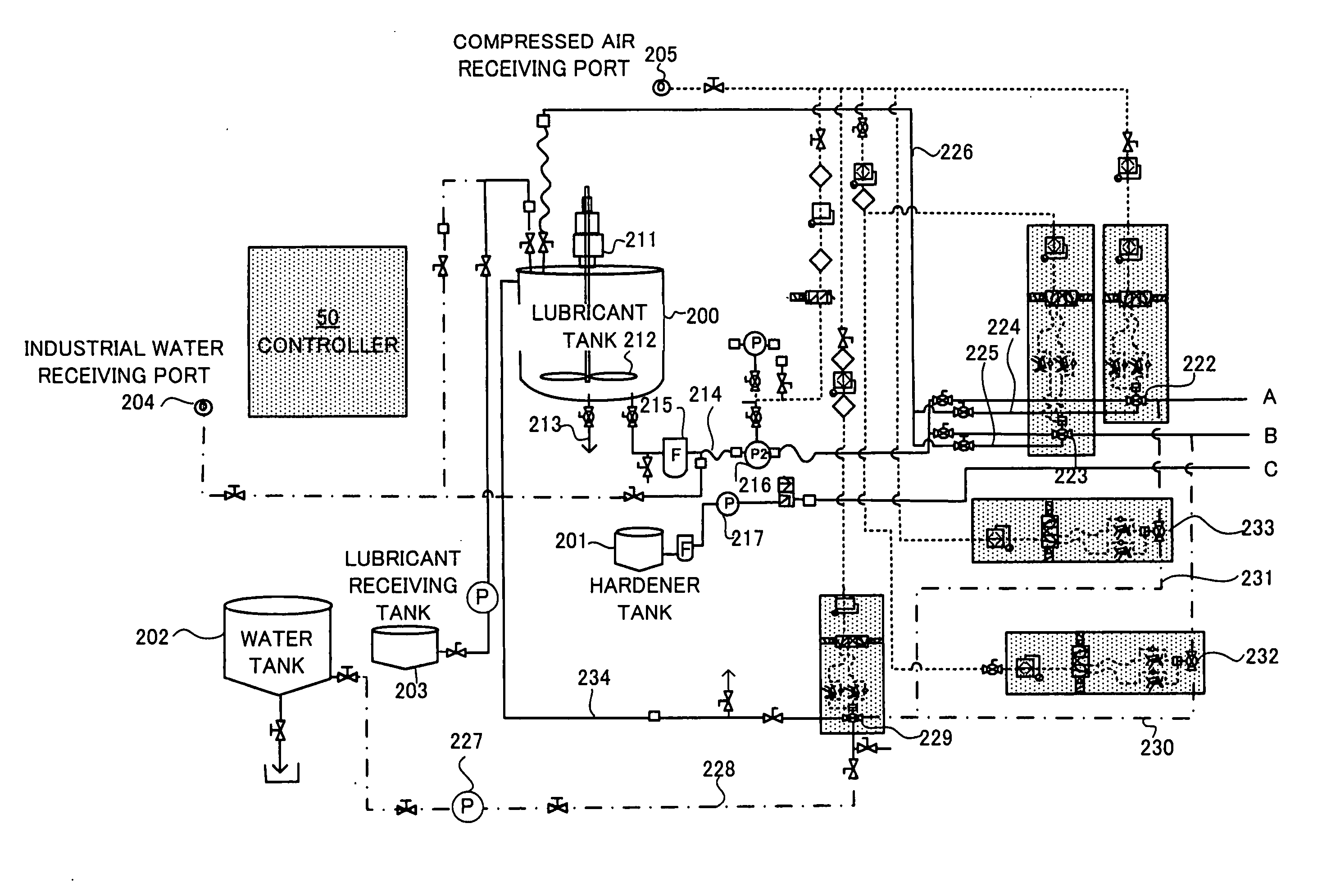

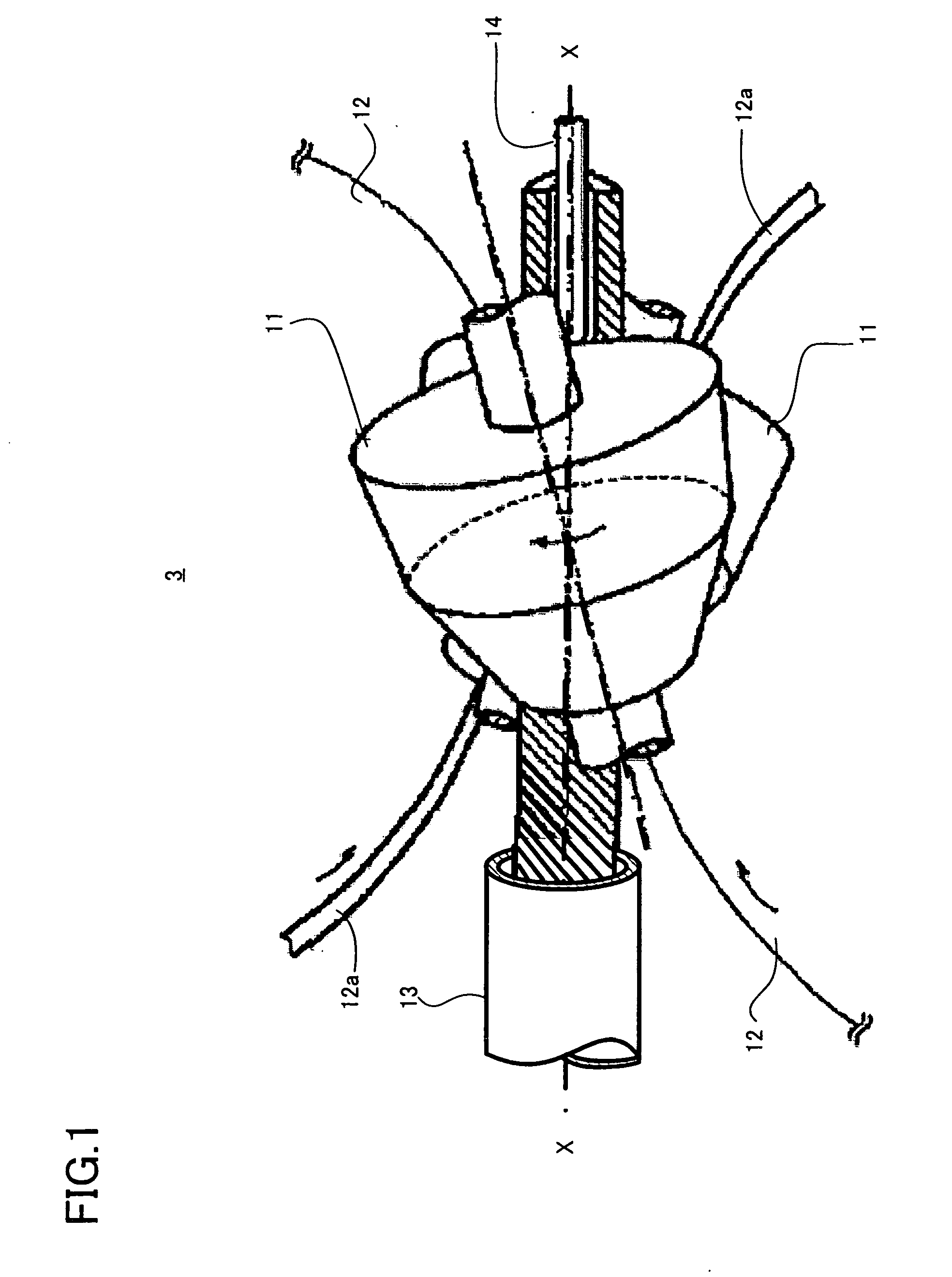

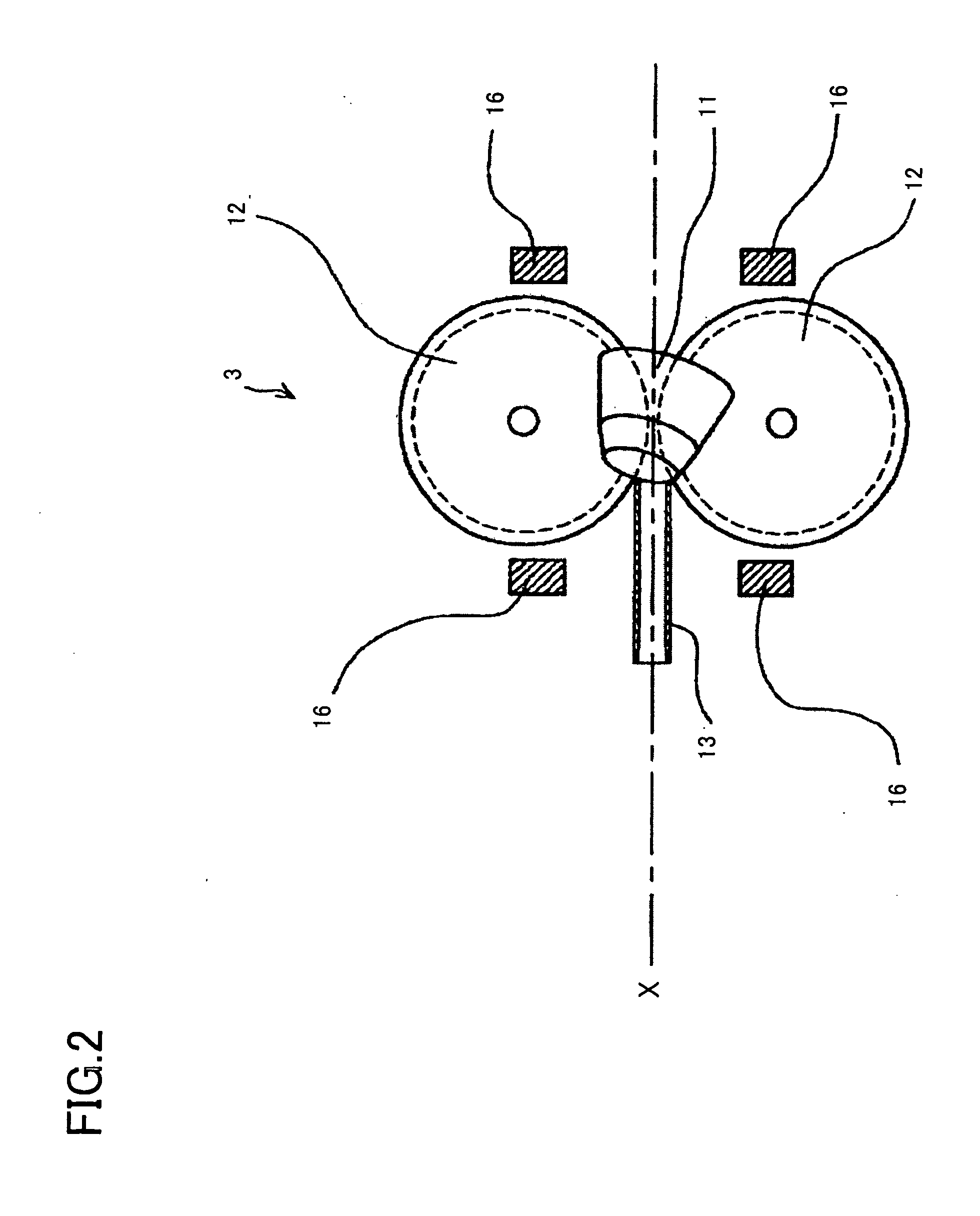

System For Supplying Lubricant, Apparatus For Manufacturing Seamless Pipes Or Tubes, And Method Of Manufacturing Seamless Pipes Or Tubes

The present invention provides a system for supplying a lubricant necessary for efficiently manufacturing high-quality seamless pipes or tubes in a piercing mill, an apparatus for manufacturing seamless pipes or tubes having the supply system, and seamless pipes or tubes manufacturing method. The system for supplying a lubricant has a storage tank of the lubricant, a plumbing extending from the storage tank to a position near disk rolls, a nozzle provided at the tip of the plumbing, a device for switching flow direction provided in some midpoint of the plumbing, a plumbing extending from the device for switching flow direction to the storage tank, and a device for releasing pressure in a plumbing, provided between the switching device and the nozzle.

Owner:NIPPON STEEL CORP

Medical analgesic and hemostatic dressing for anesthesiology department and preparation method of medical analgesic and hemostatic dressing

InactiveCN108187120AEasy to solidifyImprove playbackAbsorbent padsMicrocapsulesBiocompatibility TestingAnalgesics effects

The invention relates to the technical field of medical anesthesia, in particular to a medical analgesic and hemostatic dressing for anesthesiology department and a preparation method of the medical analgesic and hemostatic dressing. The dressing comprises a non-woven fabric surface layer, a water absorbing middle layer and a functional bottom layer from top to bottom, wherein the water absorbingmiddle layer is a compressed modified loofah sponge, and pores of the modified loofah sponge are filled with modified sepiolite and modified chitosan; the functional bottom layer is hydrogel doped with an analgesic. The preparation method of the dressing comprises the following steps: the functional bottom layer and the water absorbing middle layer are expanded and overlapped to be placed into a needling machine for needling, and then the non-woven fabric surface layer is placed on the water absorbing middle layer in an overlapping manner for needling. The medical analgesic and hemostatic dressing can stop bleeding rapidly, can also realize sedative and analgesic effects and has good biocompatibility and biodegradability.

Owner:AFFILIATED YONGCHUAN HOSPITAL OF CHONGQING MEDICAL UNIV

Metal-based powder metallurgy brake lining material and preparation methods thereof

The invention discloses a metal-based powder metallurgy brake lining material and preparation methods thereof. The invention aims to solve the problems that the strength of a material is reduced along with the adding of ceramic particles when the powder metallurgy brake lining material is produced by the prior art and the like. The material comprises the following components in percentage by weight: 10 to 80 percent of Cu-Sn mechanical alloy powder, 1.25 to 15 percent of Ti-C mechanical activated powder, 2 to 65 percent of Fe powder, 0 to 10 percent of Ni powder, 0 to 12 percent of Cr powder,2 to 8 percent of Al2O3 powder, and 7.75 to 23 percent of graphite, wherein the Cu-Sn mechanical alloy powder is prepared from Sn powder and Cu powder which contains 6 to 10 percent of Sn powder by mechanical alloying beforehand; and the Ti-C mechanical activated powder is prepared from Ti powder and C powder according to the ratio of 2:1-8:1 through mechanical activation beforehand, and forms TiC during the sintering. The invention also provides two preparation methods which combine the mechanical activation and the mechanical alloying with the prior powder metallurgy or discharge plasma sintering method.

Owner:JILIN UNIV

Wild chrysanthemum flower jam and preparation method thereof

The invention relates to a preparation method of jam, specifically relates to a wild chrysanthemum jam and a preparation method thereof, and belongs to the technical field of food processing. Compared with a prior art, the invention has the following advantages: the wild chrysanthemum flower jam of the present invention maintains most nutrition components in lemon, wild chrysanthemum flower, rose and honey, and a processing process causes little active ingredient loss; the wild chrysanthemum jam of the present invention contains no food additive and can avoid nutrition loss and denaturation under high temperature, and jelly powder is added in the processing process to better solidify the jam; a production technology of the wild chrysanthemum jamof the present invention is simple, at low cost, with a short period and suitable for large-scale batch production.

Owner:DALIAN ZHAOYANG SOFTWARE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com