Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Does not affect heat retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

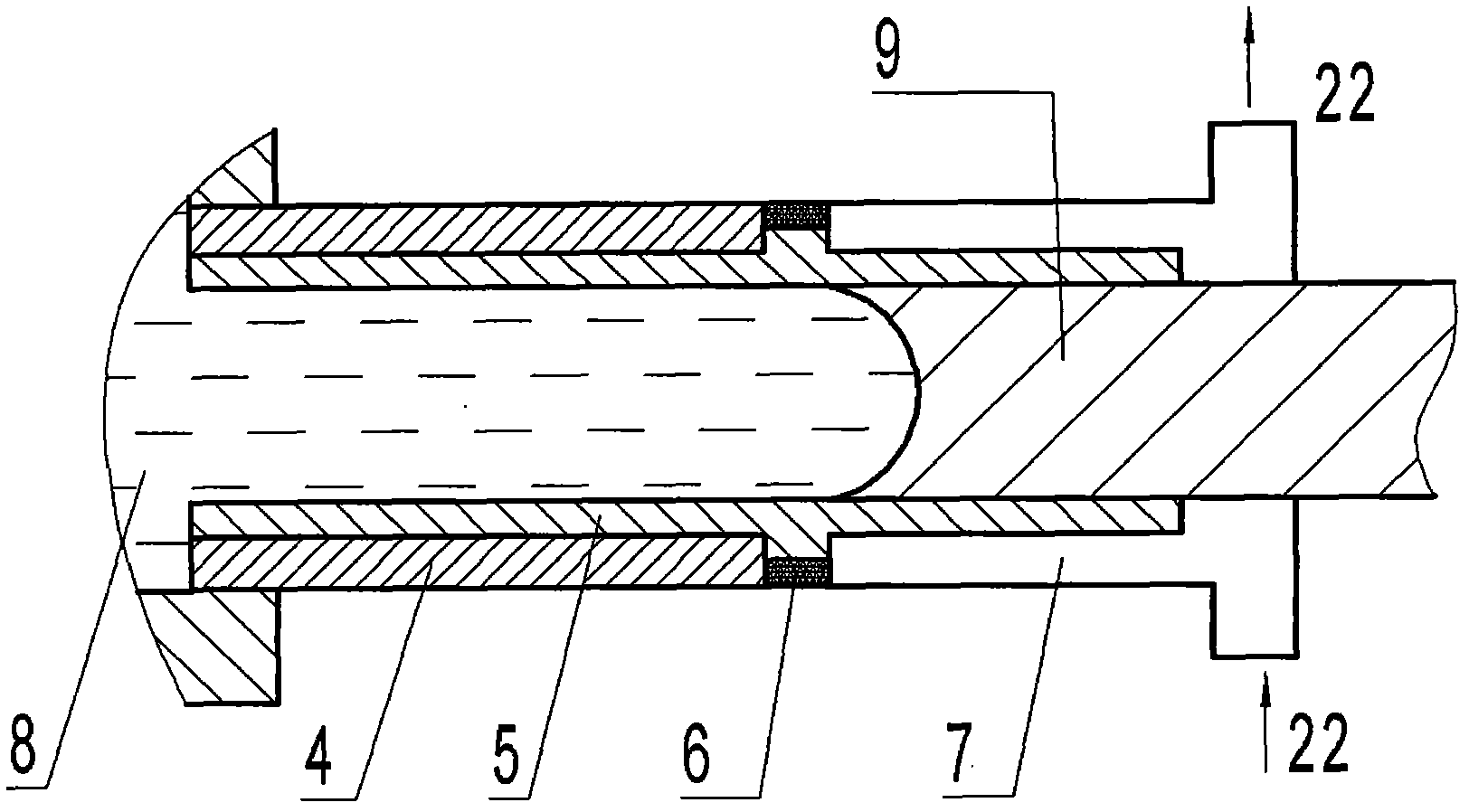

Device and method for continuously preparing bulk amorphous alloy ingots

The invention relates to a device and a method for continuously preparing bulk amorphous alloy ingots, which are characterized in that the preparation device comprises two vacuum chambers which are mutually independent. A main vacuum chamber is used for alloy melting and forming, and an auxiliary chamber is used for balancing pressure to facilitate throwing and secondary cooling. The primary cooling section of the preparation device and the method adopts a graphite pipe to be cast with a water cooling copper model embedding nest and is a main cooling part. The secondary cooling section adopts water cooling or natural cooling modes protected by inert gas and is an auxiliary cooling part. The device and the method have the advantages of having large cooling speed, meeting requirements of the bulk amorphous alloy ingots for formation, being simple in structure and capable of conveniently achieving metal continuous formation control and operation under vacuum inert gas atmosphere, and being strong in adaptability and capable of achieving continuous formation of ingots with various section shapes due to the fact that nesting cast with different inner cavity shapes and sizes, thereby being mainly suitable for continuous manufacture fields of the bulk amorphous alloy ingots.

Owner:王东

Heating covering agent for casting steel piece

The invention discloses heating covering agent for casting a steel piece. The heating covering agent comprises components by weight percent: 5-25% of heating agent, 10-20% of heat preservation agent, 3-8% of triggering agent, 1% of sawdust, and the balance of slag accretion agent, wherein the heating agent is aluminium powder or aluminium ash, the heat preservation agent is a mixture of vermiculite and floating beads, fluorite powder and sodium fluorosilicate are adopted as the triggering agent, and the slag accretion agent is pearlite. By the study on new materials, the heating covering agent is further improved in the heating and heat preservation performance, and simultaneously realizes an effect of cleaning molten steel. By the application of carbon-free slag accretion materials, the heating covering agent obtains good heat preservation performance while solving problems with recarburization and slag accretion. The carbon-free heating heat preservation covering agent with a slag accretion effect is skillfully designed.

Owner:鑫工艺(上海)材料科技有限公司

High-toughness silicon oxide aerogel super-adiabatic thermal-insulation coating and preparation method thereof

The invention relates to a high-toughness silicon oxide aerogel super-adiabatic thermal-insulation coating. The high-toughness silicon oxide aerogel super-adiabatic thermal-insulation coating is prepared from the following raw materials in parts by weight: 36-40 parts of tetraethylortho silicate, an appropriate amount of hydrochloric acid, ammonia water, ethanol and deionized water, 0.01-0.02 part of azobis isobutyronitrile, 0.2-0.3 part of styrene, an appropriate amount of chlorobenzene, 1-1.5 part of vinyltrimethoxysilane, 0.5-0.9 part of diisocyanate, 70-75 parts of E-12 epoxy resin, 9-12 parts of ethylene glycol dimethyl ether and 7-7.5 parts of triethanolamine. Silicon oxide aerogel is modified with styrene and diisocyanate in the production process so that the strength and toughness of the aerogel are increased, the water absorption is decreased, the breaking phenomenon is avoided, the thermal-insulation property is not affected and the coating can be used as indoor and outdoor wall coating and has broad market space.

Owner:WUHU BAOYI AMUSEMENT EQUIP

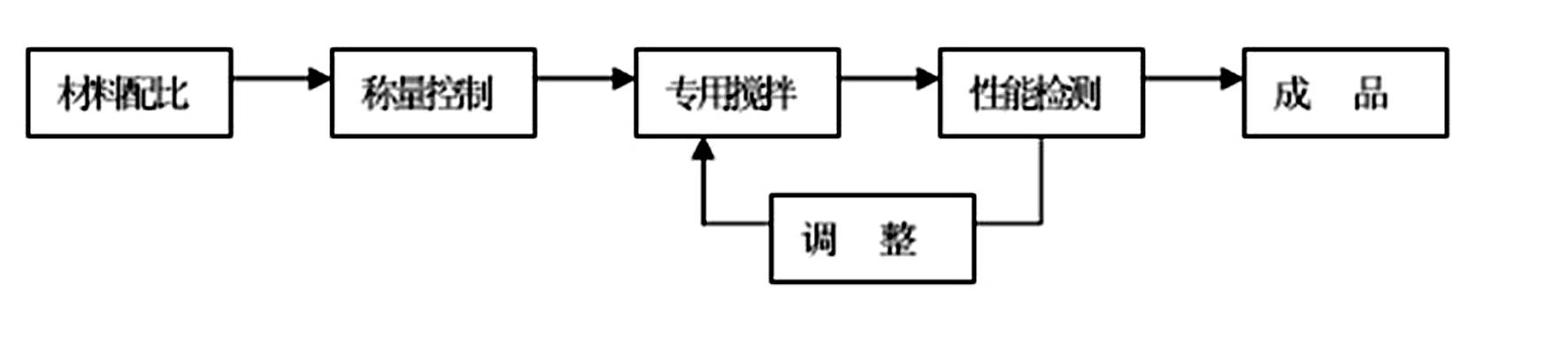

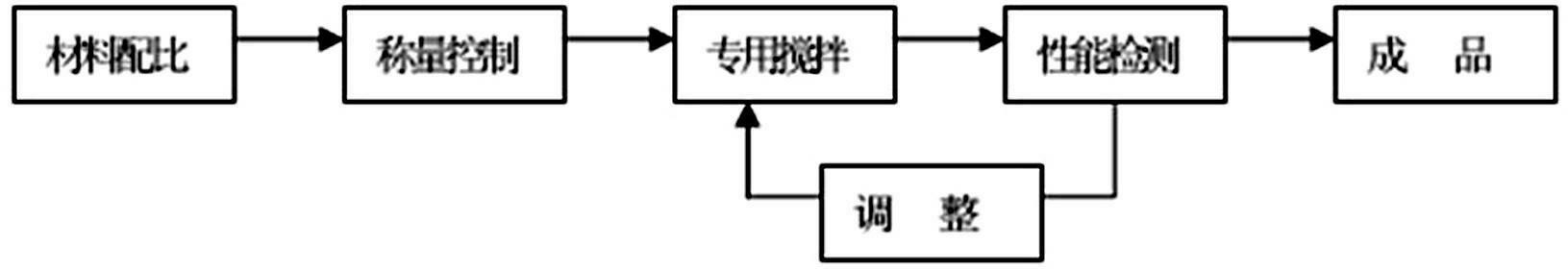

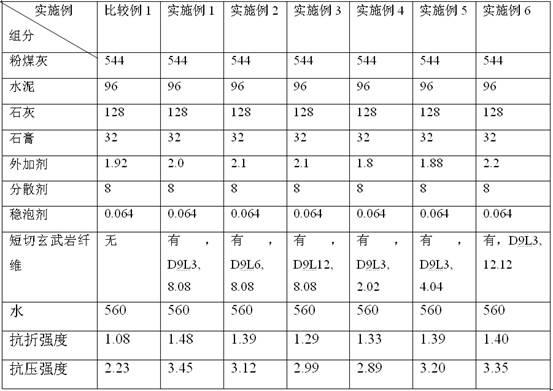

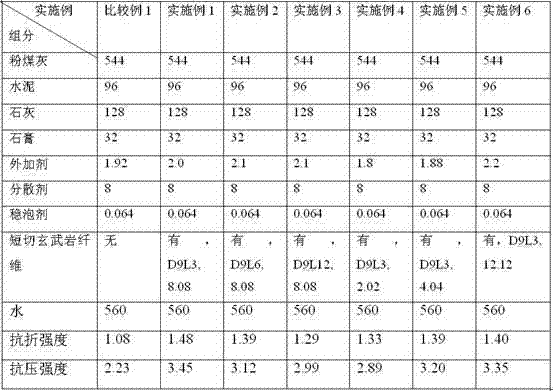

Process method for chopped fiber reinforced aerated concrete

InactiveCN102092999AHigh strengthDoes not affect heat retentionAutoclaved aerated concreteInorganic chemical compound

The invention discloses a process method for chopped fiber reinforced aerated concrete. A process for sequentially coating resin and inorganic compound particles on a fiber surface and adding coated chopped fibers and a dispersing agent into mixed slurry of autoclaved aerated concrete before the resin is cured is adopted, so that heat resistance and alkali resistance are improved, the bonding problem of the chopped fibers and a substrate and the dispersing problem of the chopped fibers are solved, and the reinforcing function of the chopped fibers can be brought into full play during high-temperature and high-pressure curing of the autoclaved aerated concrete. The aerated concrete reinforced by the method can keep the original light and heat preservation properties, and has the advantage of high intensity. By the reinforcing method, the formula of the original aerated concrete is not required to be changed; and the method is simple and practicable.

Owner:SOUTHEAST UNIV

Down feather washing technology

InactiveCN104153006AReduce usageDoes not affect loftSucessive textile treatmentsWool fibre washing/scouringWarm waterDeodorant

The invention discloses a down feather washing technology. The technology includes the following steps that first, down feather is added; second, primary washing is performed through cold water; third, fine washing is performed through warm water; fourth, rinsing is performed through cold water; fifth, drying is performed so that fat-extracted down feather can be obtained. According to the washing technology, industrial sodium carbonate, detergent and deodorant are added in the washing process, the washing effect is good, dust extraction, fat extraction and deodorization are integrated, the technology is convenient and fast to perform, water consumed for washing down feather is reduced by 30% or so under the condition that the whiteness, the fluffy degree, the cleanness and the oxygen consumption amount are not influenced, the washing efficiency is improved, no harm happens to a human body, and the technology is safe and reliable.

Owner:ANHUI XIAZHEN GRP

Environment-friendly building brick and preparation method thereof

InactiveCN107814557AGood physical propertiesHigh strengthCeramic materials productionClaywaresBrickMaterials science

The invention discloses an environment-friendly building brick and a preparation method thereof. The environment-friendly building brick is prepared from the following raw materials in parts by weight: 60 to 80 parts of construction waste, 10 to 18 parts of coal ash, 15 to 30 parts of mineral residue, 3 to 10 parts of marble, 1 to 2 parts of magnet, 1 to 3 parts of medical stone, 3 to 7 parts of fluorite, 1 to 2 parts of alundum powder, 15 to 30 parts of clay, 0.1 to 0.5 part of shell active carbon, 0.1 to 0.3 part of nanoscale aluminum oxide, 0.08 to 0.12 part of sodium rosinate, 0.05 to 0.1part of sodium tripolyphosphate, and 10 to 15 parts of water. The building brick has the advantages of high strength, good wear resistance, acid and alkali corrosion resistance, high compactness and the like, also has insecticidal and healthcare functions, and has a good visual effect.

Owner:QINGYANG DUNBO TECH DEV CO LTD

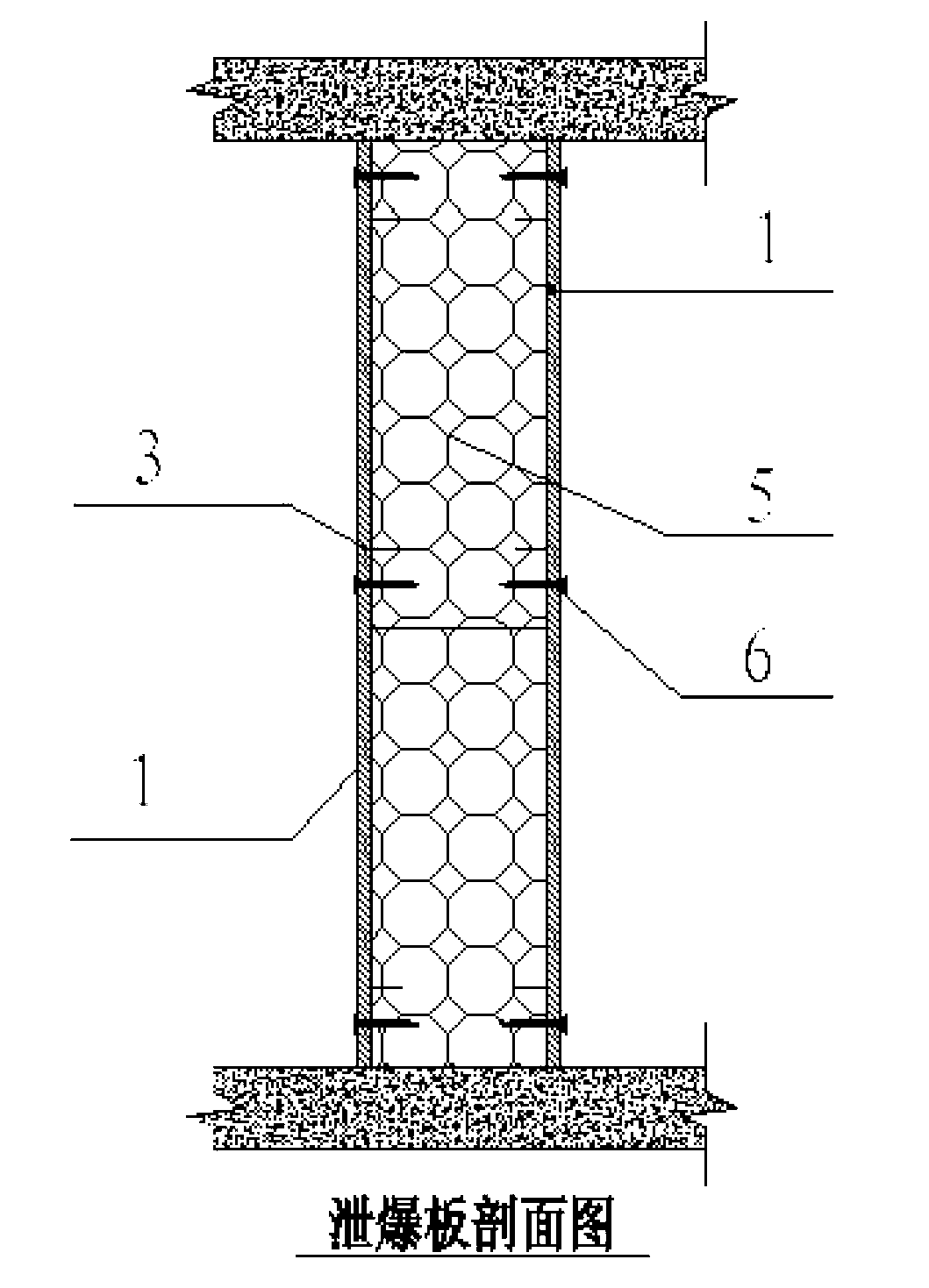

Method for reducing destructive force of explosion and explosion venting device

InactiveCN102839763AStability is not affectedGuaranteed StrengthBuilding constructionsCalcium silicateEngineering

The invention discloses an explosion venting device which is used for wall or ceiling materials of normal buildings; the explosion venting device is characterized in that the explosion venting device is composed of calcium silicate plates which are arranged at two outermost sides and a filling material which is arranged between the calcium silicate plates at the two sides; and the filling material is a mineral wool.

Owner:李宝龄

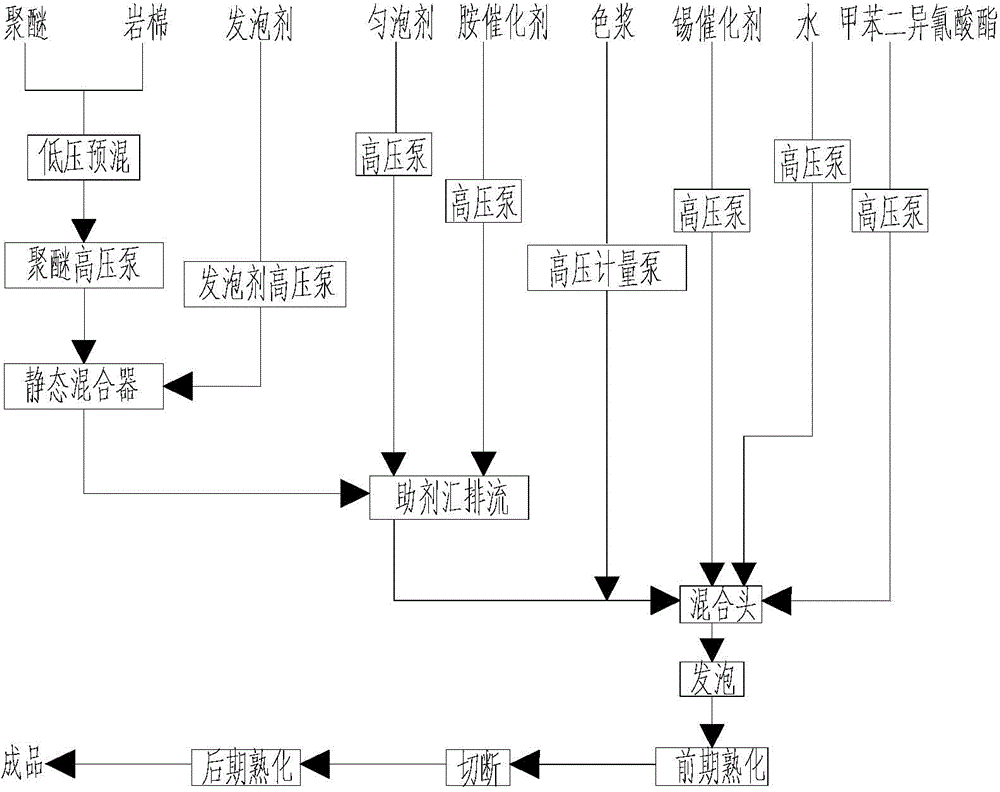

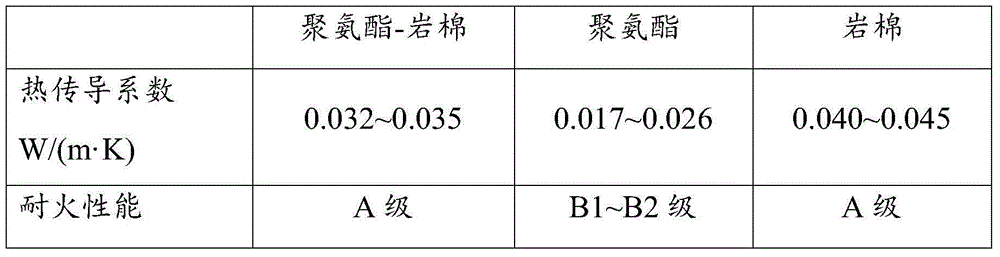

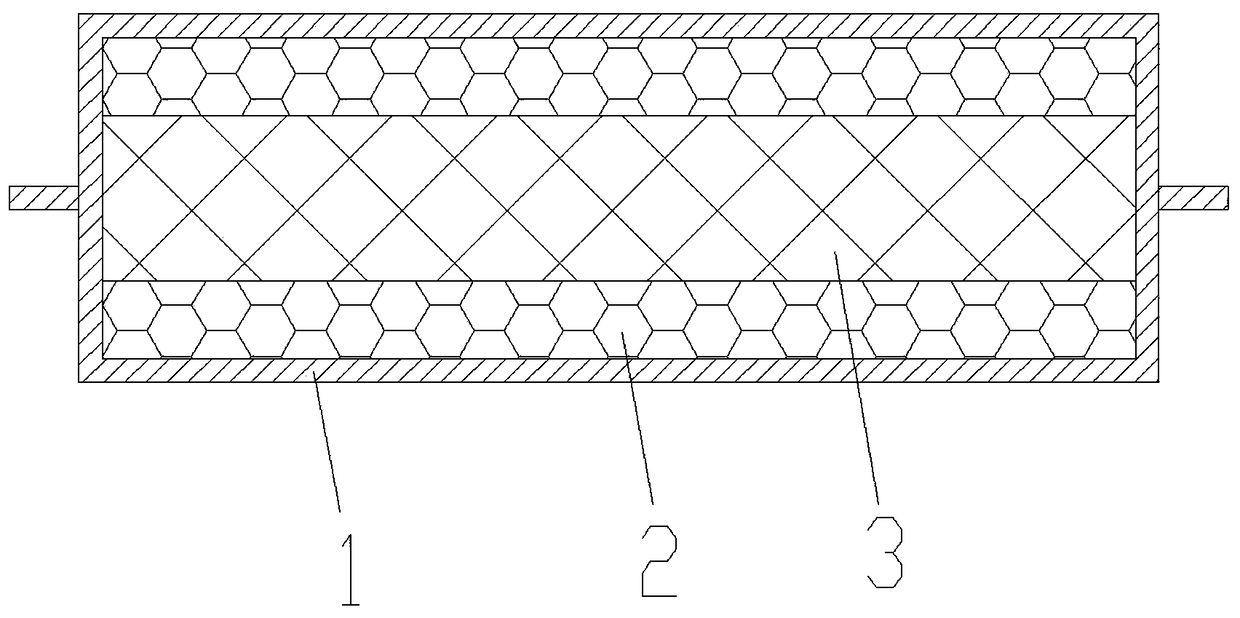

Polyurethane-rock wool insulating and fireproof material and preparation method thereof

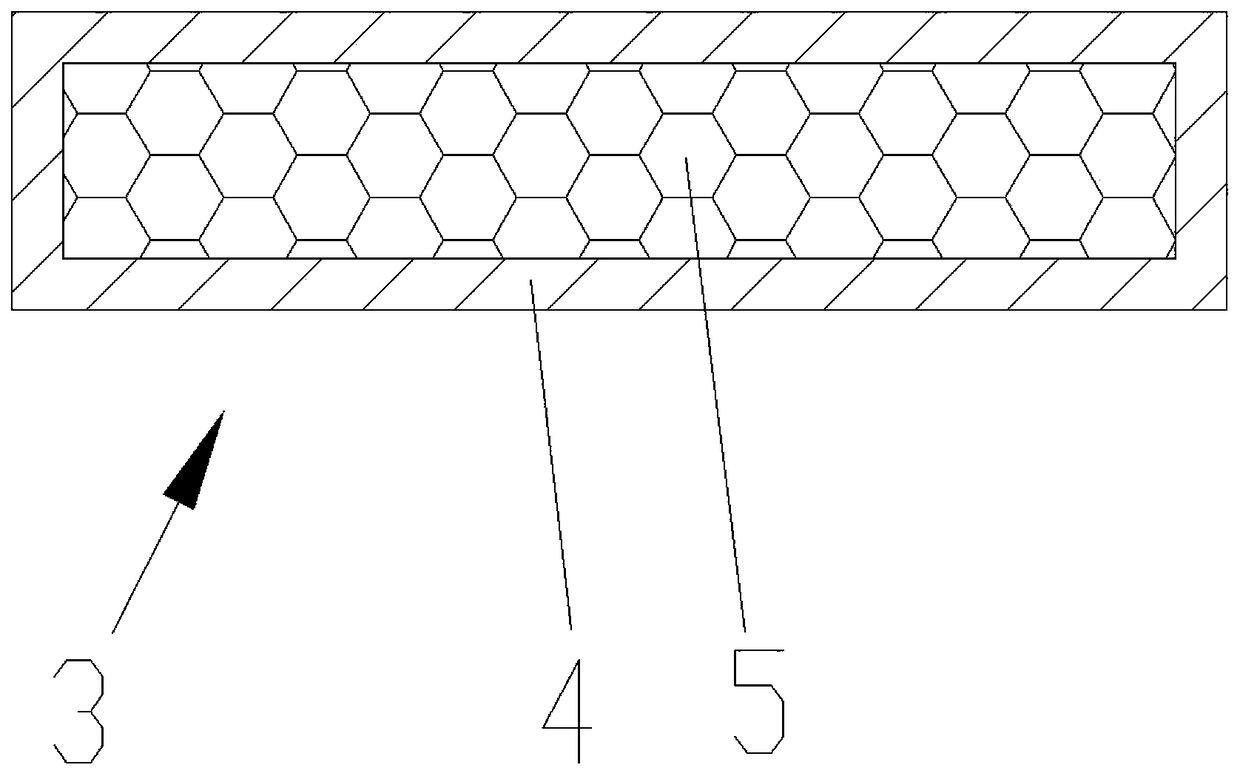

InactiveCN104672415ADoes not affect hole formationDoes not affect heat retentionSandwich boardIndustrial equipment

The invention provides a preparation method (production process) of a polyurethane-rock wool insulating and fireproof material. The preparation method comprises the following steps: (1) firstly grinding rock wool by using a grinder to form powder, wherein the grain size of rock wool particles is less than 0.6mm; (2) carrying out low-pressure premixing on a polyether mixture and the rock wool in the grain size for over 30 minutes, uniformly and fully mixing the materials, and pressurizing to a high pressure state by a pressurizing pump to 3.0-4.0MPa; and further adding a foaming agent, a foam stabilizer and the like. The polyurethane-rock wool insulating and fireproof material prepared by the method provided by the invention satisfies the requirement A of combustion performance of building materials in GB8624-2006 of national standard Building Material and Product Combustion Performance Rating. The material is relatively good in insulating performance, and heat transfer satisfies the requirement of G / T23932-2009 of national standard Metal Surface Insulating Sandwich Board for Building, so that the fire resistance of a single polyurethane material is improved. The material can be widely applied to actual projects of industrial equipment, buildings and pipelines on a large scale.

Owner:查晓雄

Preparation method of high-performance heat-insulating composite plate

The invention discloses a preparation method of a high-performance heat-insulating composite plate. The preparation method of the high-performance heat-insulating composite plate particularly comprises the following steps: firstly, preparing cellulose toughened silicon dioxide aerogel particles from a cotton raw material as a raw material; secondly, mixing and stirring the prepared cellulose toughened silicon dioxide aerogel particles and cement uniformly; thirdly, sequentially adding a polycarboxylic acid water reducer, river sand, nanometer titanium dioxide, a foam stabilizer, a curing agentand deionized water, and mixing and stirring uniformly; fourthly, adding a foaming agent and stirring to prepare slurry; and finally, putting the prepared slurry into a mold to perform compression molding, and maintaining, demolding and cutting to prepare the high-performance heat-insulating composite plate. The prepared composite plate has excellent mechanical property and high heat-insulating property.

Owner:DONGGUAN JIAQIAN NEW MATERIAL TECH CO LTD

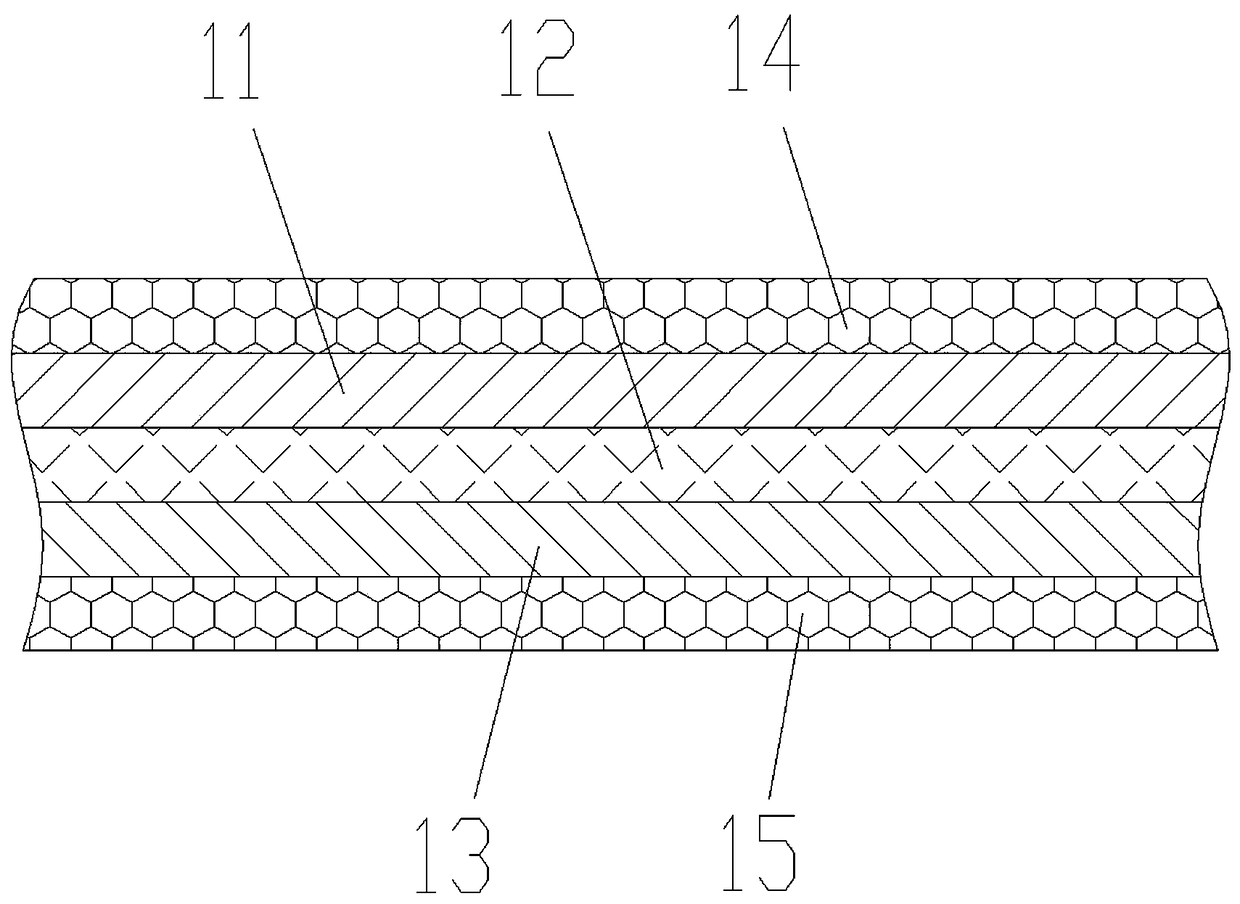

Novel vacuum insulated panel

InactiveCN108086505AHigh strengthImprove puncture resistanceClimate change adaptationInsulation improvementPuncture resistanceHot melt

The invention discloses a novel vacuum insulated panel, which comprises an inner core; the inner core comprises two panel-shaped heat insulation materials in parallel; an inner vacuum insulated panelis arranged between two panel-shaped heat insulation materials, an outer blocking bag is coated at outside of the inner core in a sealing manner. The novel vacuum insulated panel has the advantages that after the novel vacuum insulated panel is vaccumized and sealed, the inner blocking bag is in hot melting connection with the heat insulation core material, the outer blocking bag is also in hot melting connection with the inner core; two insides of the inner core are provided with two panel-shaped heat insulation materials; on the one hand, the intensity of the novel vacuum insulated panel isenhanced; on the other hand, the puncture resistance is enhanced; even though the outer blocking bag is accidentally damaged, the heat insulation performance of the novel vacuum insulated panel cannotbe influenced.

Owner:安徽百特新材料科技有限公司

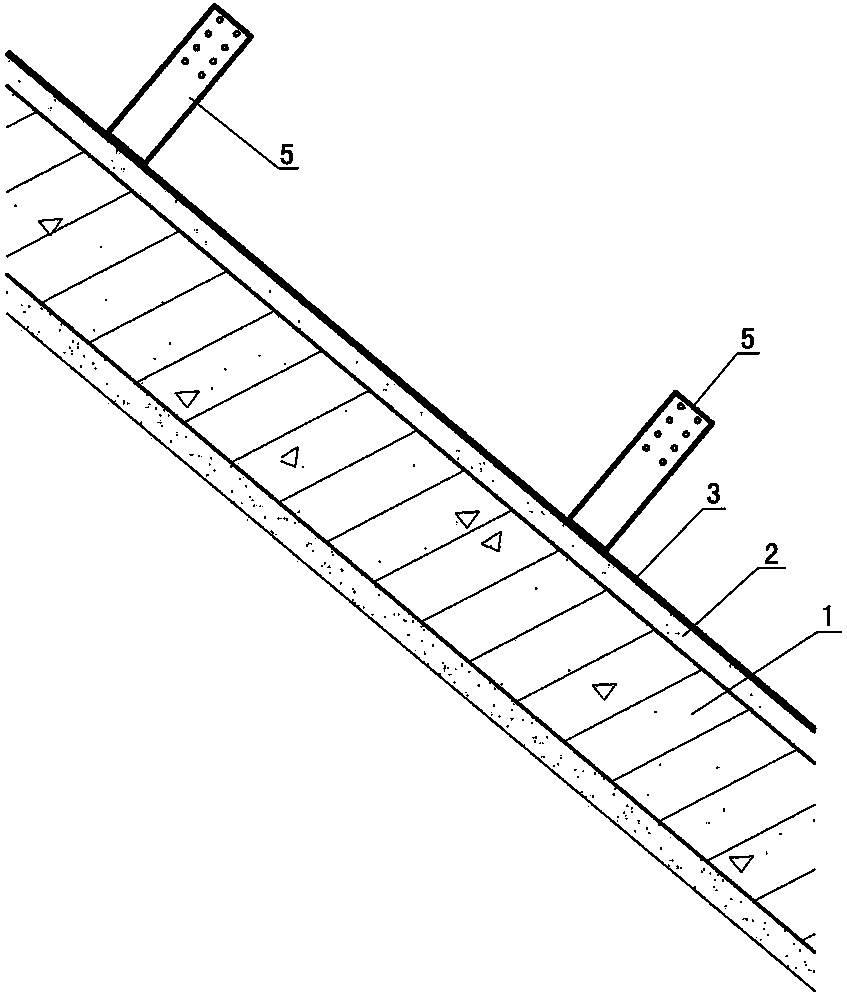

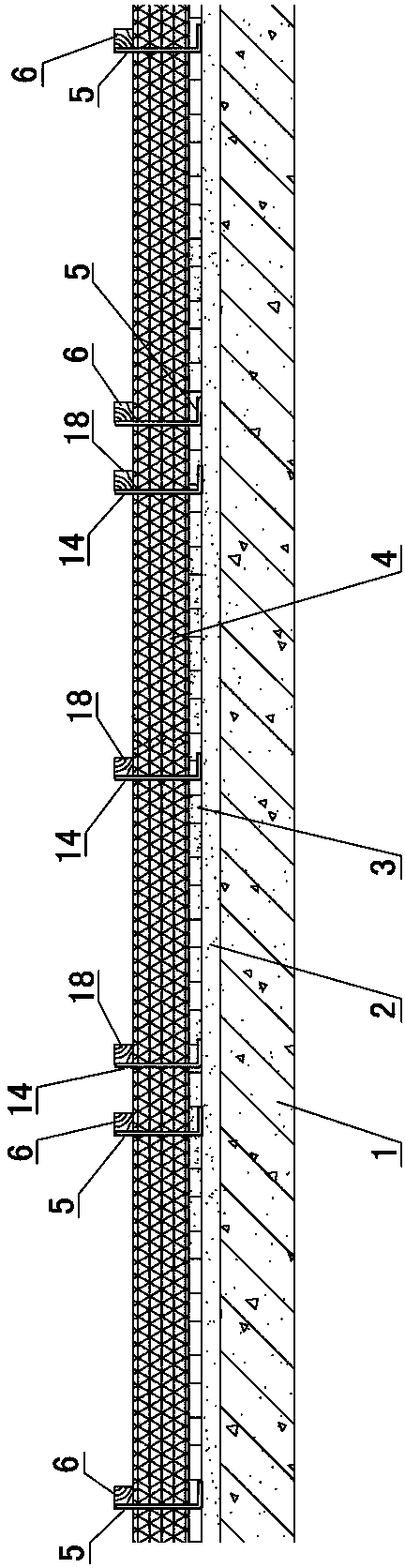

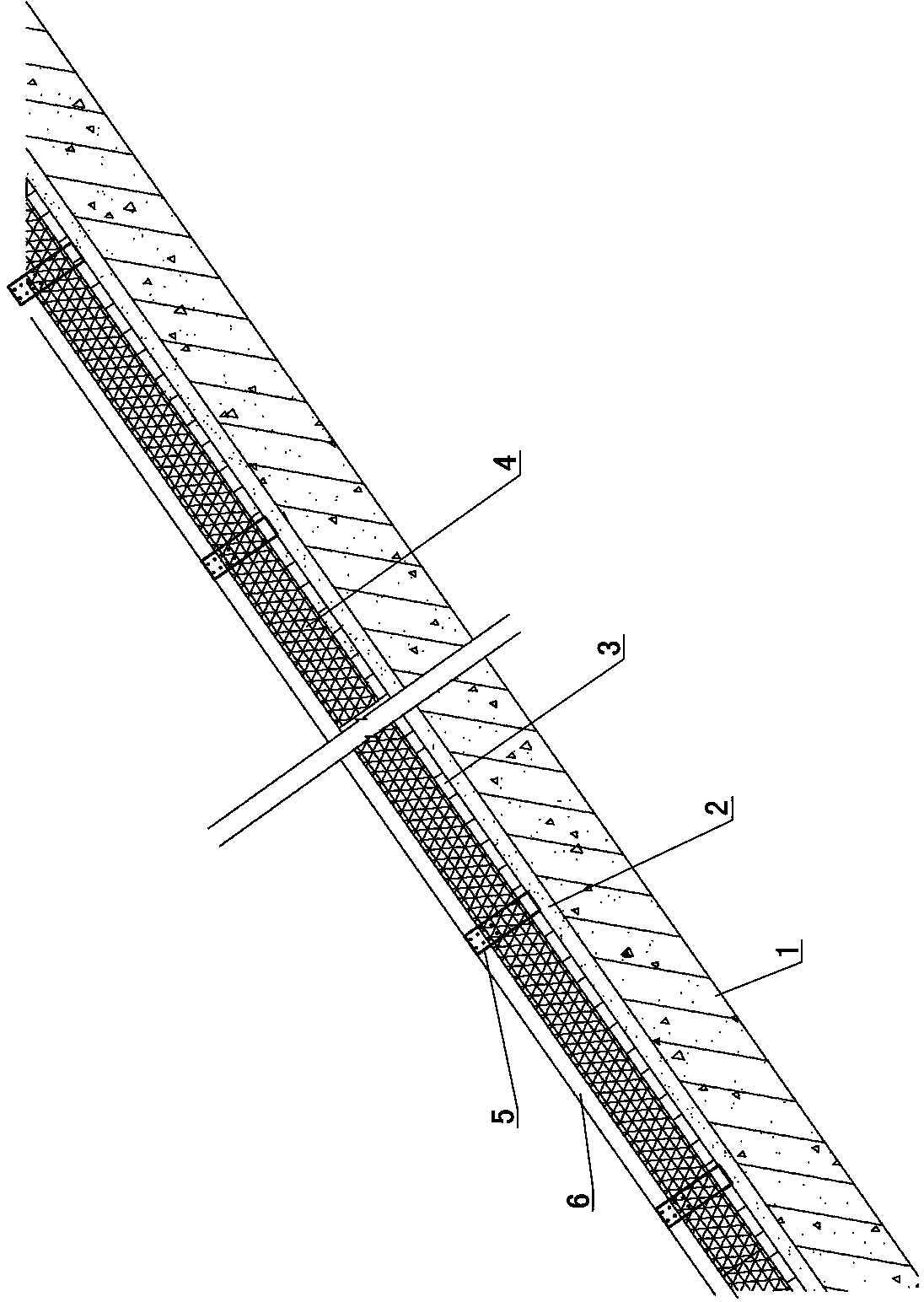

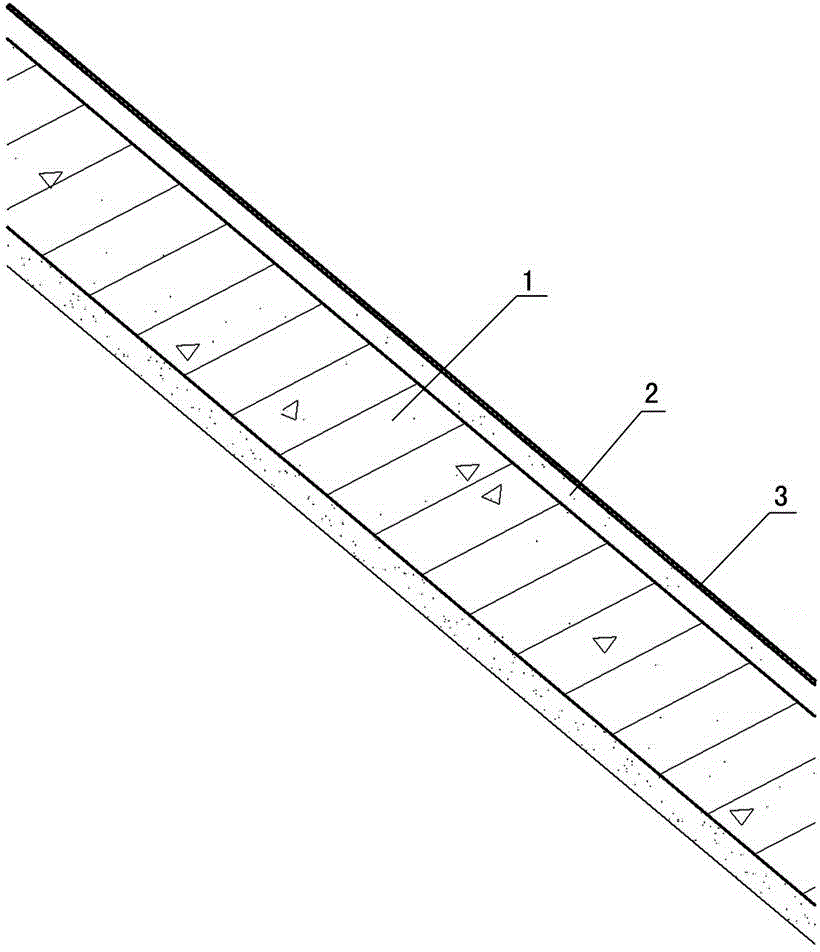

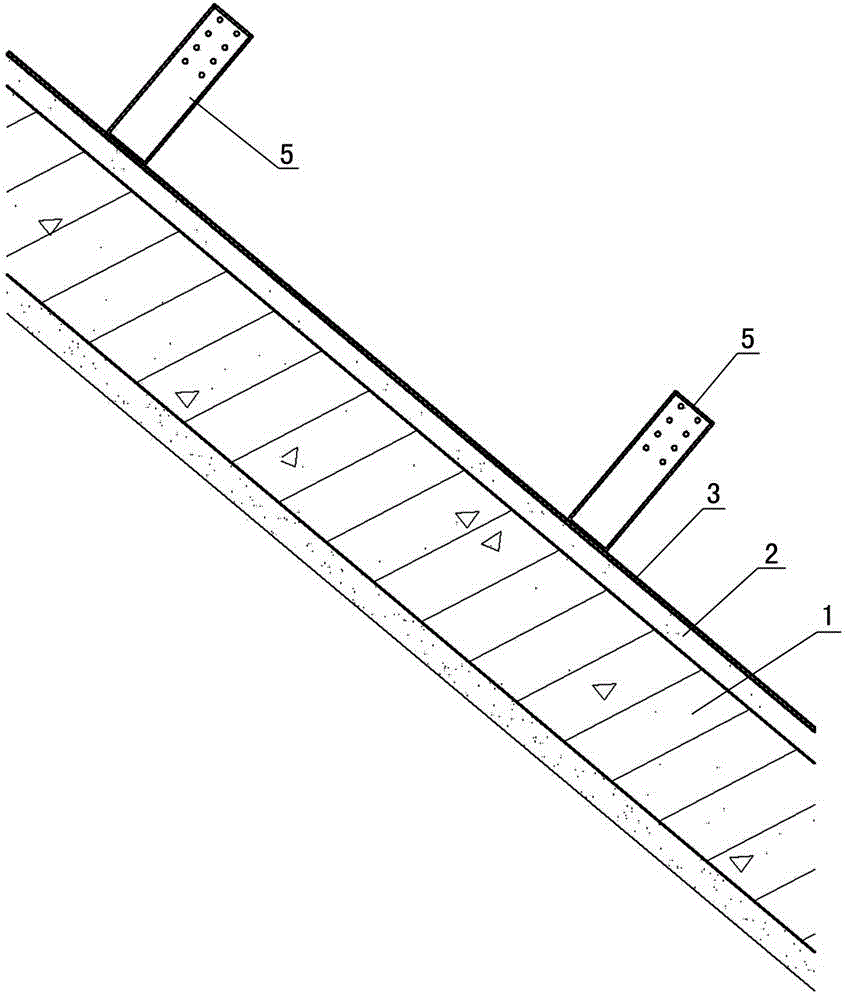

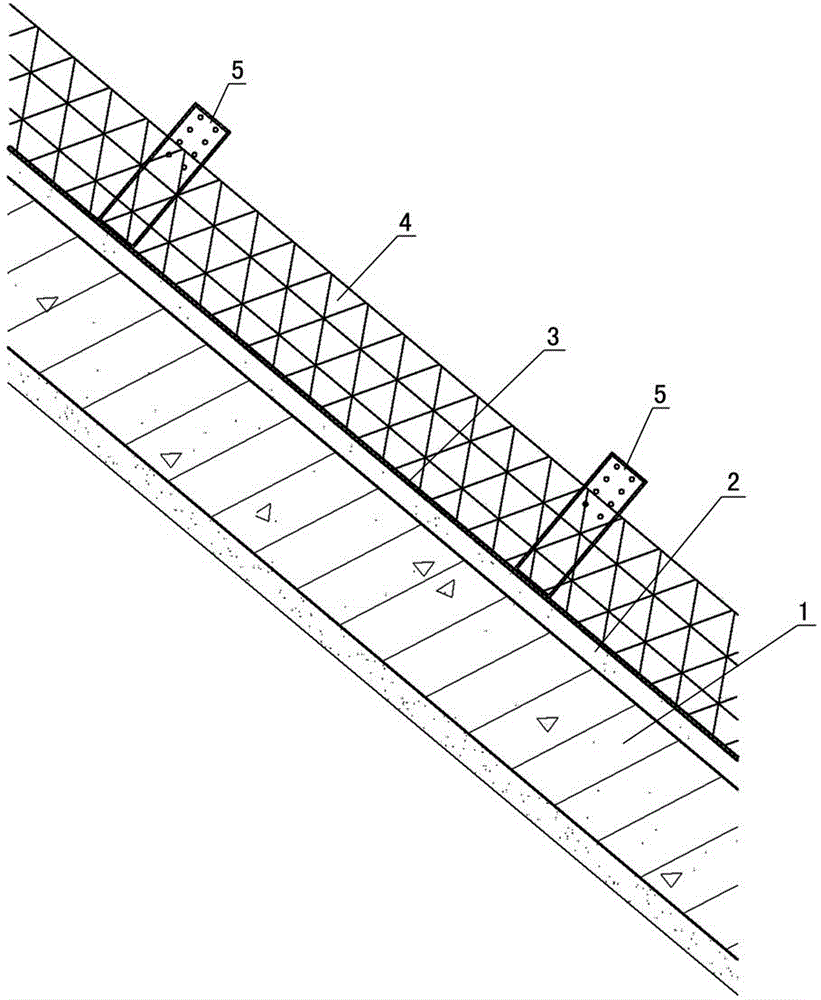

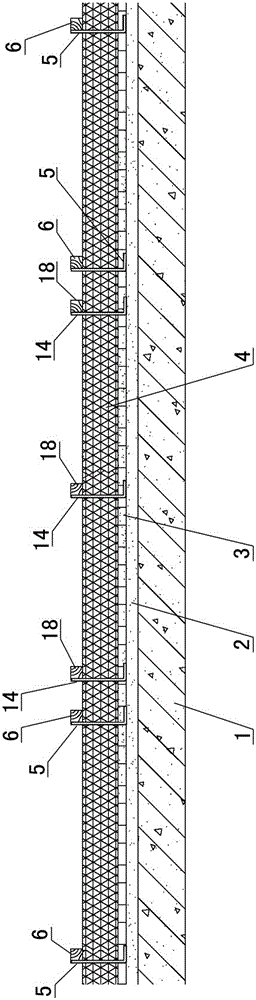

Temperature-keeping, ventilating and energy-saving dry-method structure of slope roof and construction method thereof

ActiveCN103628634ARegulating heat conductionImprove insulation effectBuilding roofsLighting and heating apparatusBattenAluminum foil

The invention discloses a temperature-keeping, ventilating and energy-saving dry-method structure of a slope roof and a construction method thereof. The structure comprises a cement mortar leveling layer, a waterproof cushion layer, a temperature-keeping and draining layer, cross roof wood battens and roof tiles, wherein the temperature-keeping and draining layer consists of temperature-keeping plates, supporting wood brackets, longitudinal downstream wood strips and aluminum foil coil materials; the supporting wood brackets are arranged on the waterproof cushion layer; the temperature-keeping plates are fully paved on the waterproof cushion layer; the temperature-keeping plates are clamped between the supporting wood brackets; the longitudinal downstream wood strips are pressed on the temperature-keeping plates; the aluminum foil coil materials are paved on the longitudinal downstream wood strips and are fixedly connected with the longitudinal downstream wood strips through nails; the aluminum foil coil materials, the longitudinal downstream wood strips and the temperature-keeping plates enclose to form a longitudinal airtight air layer. The structure has the best advantages of very good heat-insulating ability and good temperature-keeping and energy-saving property, the heat conductivity of the roof can be effectively adjusted, and the energy-saving effect of a house can be greatly improved.

Owner:LJLZ BEIJING BUILDING MATERIALS CO LTD

Special detergent for down jacket

InactiveCN104804888ADoes not affect heat retentionEasy to useInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsCelluloseSulfite salt

A special detergent for a down jacket is prepared from the following raw materials in part by weight: 5-10 parts of carboxymethyl cellulose, 6-10 parts of polyethylene glycol distearate, 4-11 parts of fatty alcohol-polyoxyethylene ether, 5-9 parts of sodium dodecyl benzene sulfonate, 3-6 parts of EDTA (Ethylene Diamine Tetraacetic Acid), 3-8 parts of Chinaberry bark , 7-9 parts of sodium citrate, 4-9 parts of sodium carboxymethylcellulose, 3-7 parts of sodium sulfite heptahydrate, 1-5 parts of coconut oil powder, 3-5 parts of sodium polyacrylate, 2-5 parts of sodium carbonate, 1-4 parts of glycerinum, 4-7 parts of propylene glycol. The special detergent has the benefits of capable of cleaning various stains on the surface of the down jacket without influencing the heat preservation property of the down jacket, and convenient to use and easy to clean.

Owner:QINGDAO TOPLINK INFORMATION TECH

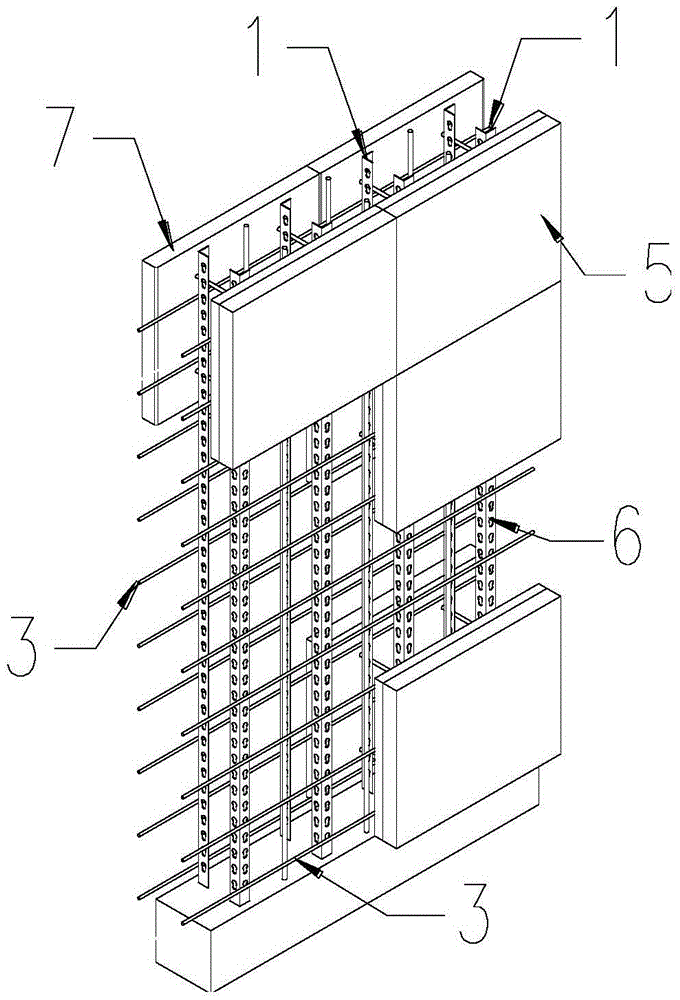

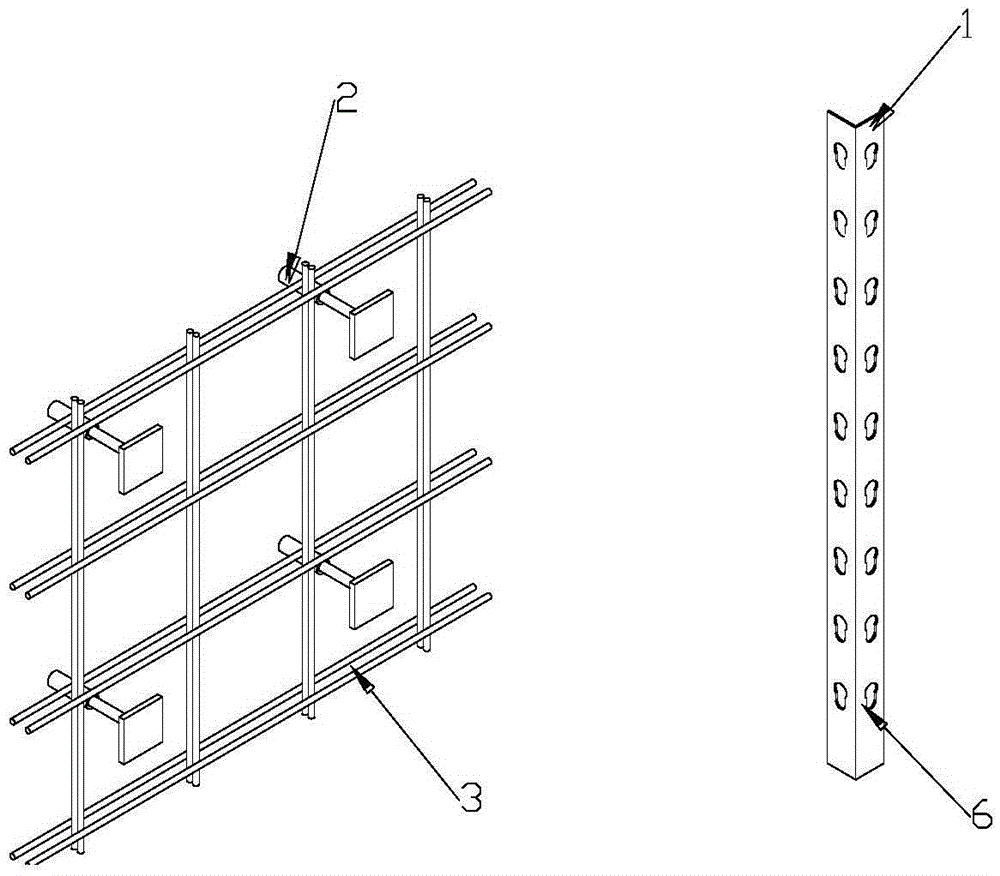

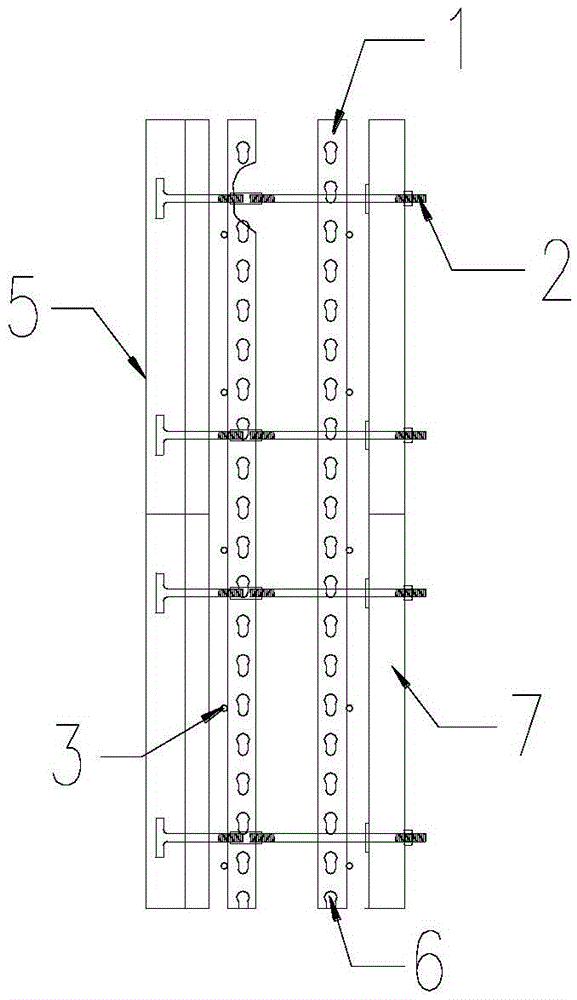

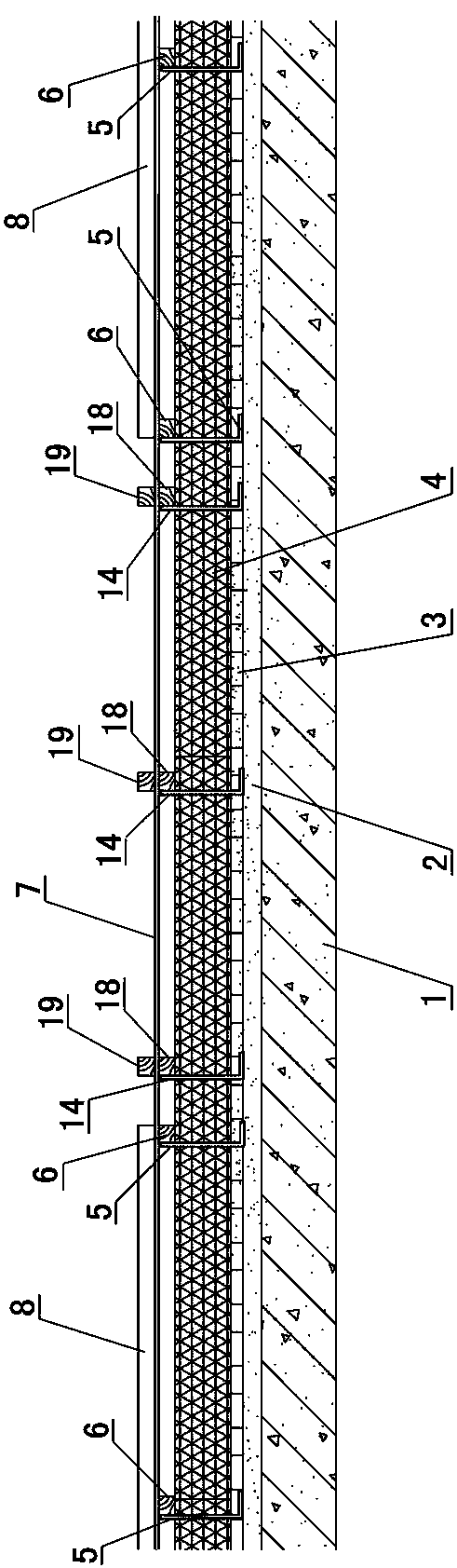

Exterior wall cladding system integrating insulating layer, decorative layer and formwork and construction method thereof

InactiveCN105484392AEliminate scaffolding worksSave manpower and material resourcesWallsFalseworkMaterial resources

The invention discloses an exterior wall cladding system integrating an insulating layer, a decorative layer and a formwork and a construction method thereof. The system comprises multiple cold-bending profiles, multiple pre-punched holes are formed in the side face of each cold-bending profile, and the cold-bending profiles are connected in pairs through multiple tie bars and are placed in a reinforcement cage; the system further comprises multiple external hanging formworks, each external hanging formwork integrates the insulating layer, the decorative layer and the formwork, multiple hanging parts are arranged on each external hanging formwork, and the external hanging formworks are hung on the pre-punched holes through the hanging parts and can be connected again through the tie bars; multiple internal formworks are arranged at the relative positions parallel to the external hanging formworks, and opposite pull is formed between the external hanging formworks and the internal formworks to offset mold expanding force. The cold-bending profiles serve as a part of rebars of a shear wall system, the tie bars are additionally arranged in the reinforcement cage to ensure the accurate size of the reinforcement cage, and the hanging parts can be arranged to be of a clamping groove suspension structure. By means of the specially-made reinforcement cage and the prefabricated external hanging formworks, the system is assembled into a container shape high in integral rigidity, a great number of original scaffold projects for ensuring stability of the system are omitted, manpower and material resources are saved greatly, and the economic effect is remarkable.

Owner:SHANGHAI OPEN STEEL JOIST

Ecological plant outer wall

PendingCN108824677AGood sunshineEffect on physical propertiesWallsSelf-acting watering devicesThermal insulationPlant cultivation

The invention discloses an ecological plant outer wall which comprises a steel framework and a wall board fixed to one side of the steel framework. The wall board is provided with a bearing part whichextends inwards and is provided with a stud or an internal thread connector in an embedded mode. An inserting fixing part is fixed on the bearing part through the stud or the internal thread connector. Inserting grooves are formed in the two ends of the inserting fixing part. A cultivation plate rack and an outer cover are connected into the inserting grooves correspondingly. An overturning coverplate is rotatably connected to the wall board at one side of the bearing plate, and plant through holes are formed. The steel formwork is fixedly connected with cultivation containers. According tothe technical scheme, plants can gain sunlight well, the physical performance of a curtain wall is not influenced, and the wind resistance, thermal insulation, and watertight and airtight performanceof the curtain wall are not influenced. Mounting, maintaining and plant cultivation are more convenient, and popularization is facilitated.

Owner:NANJING AOJIE WALL MATERIAL

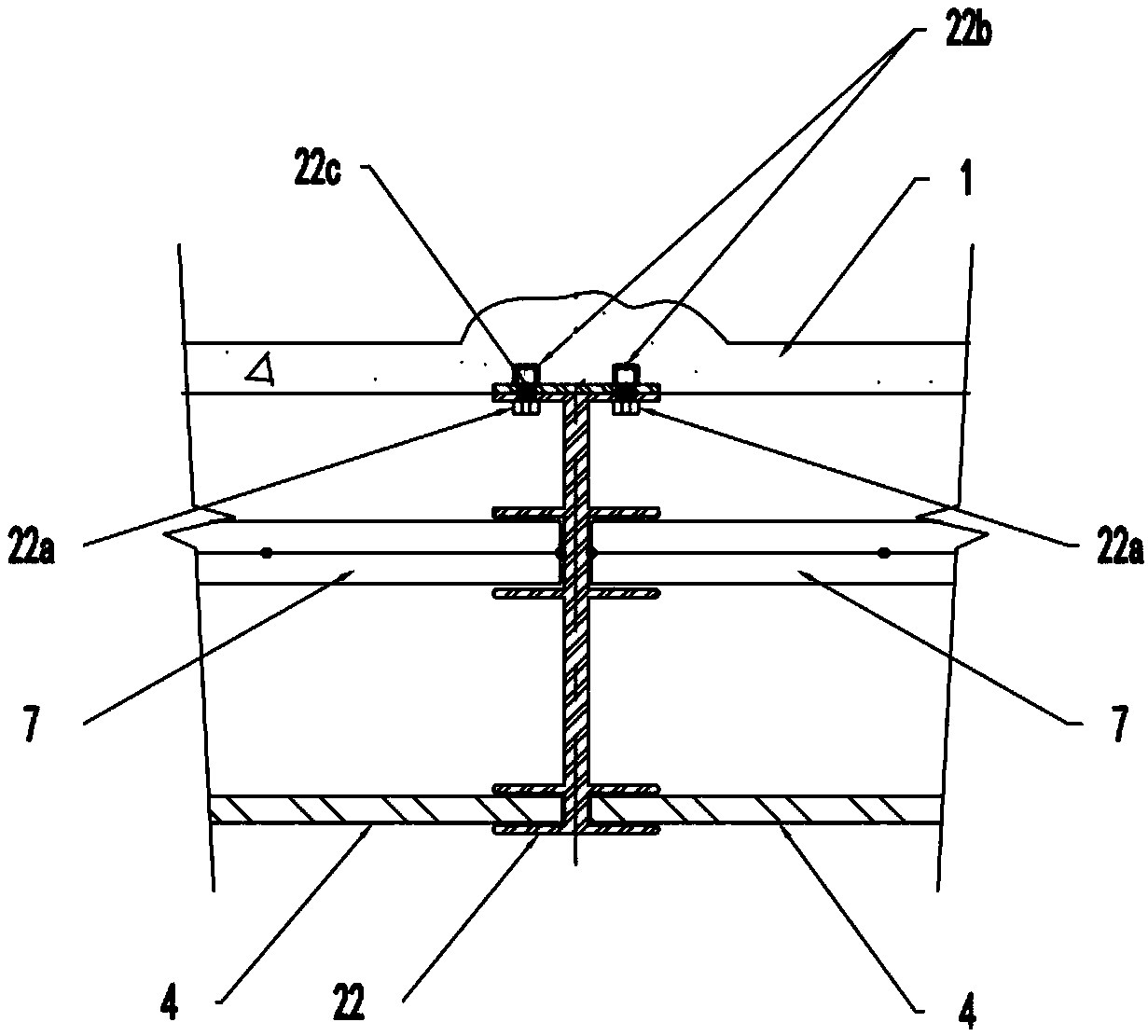

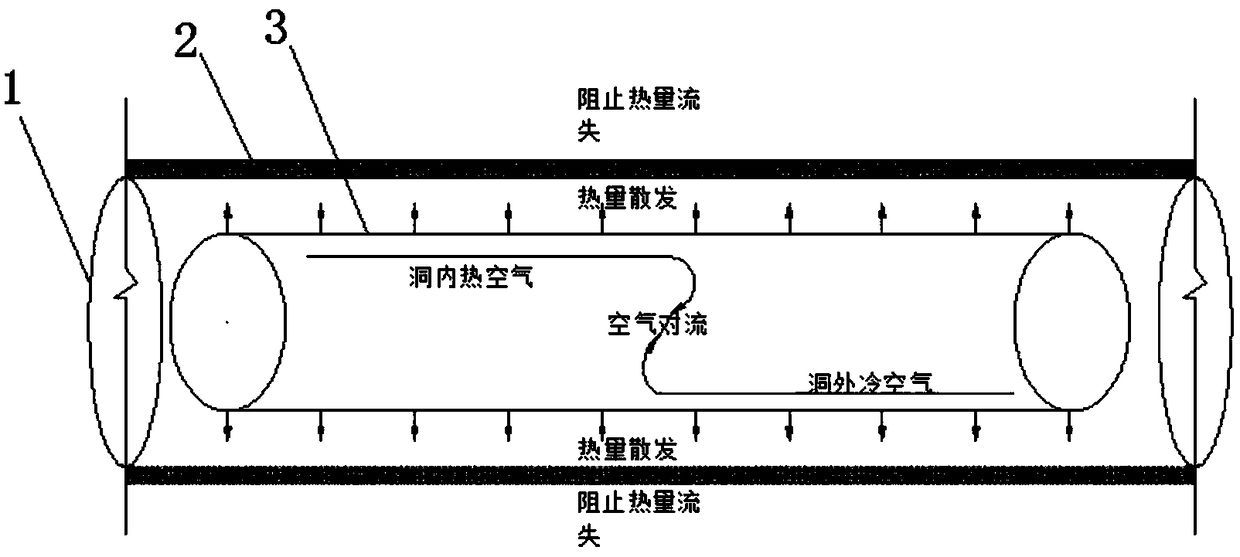

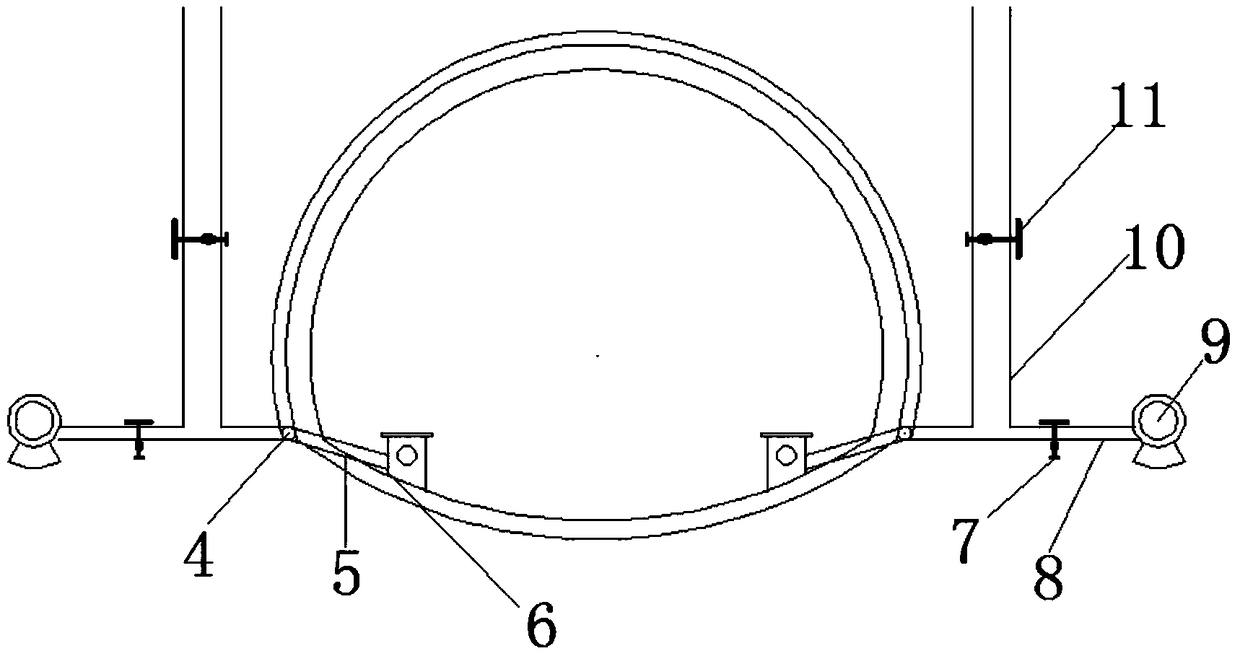

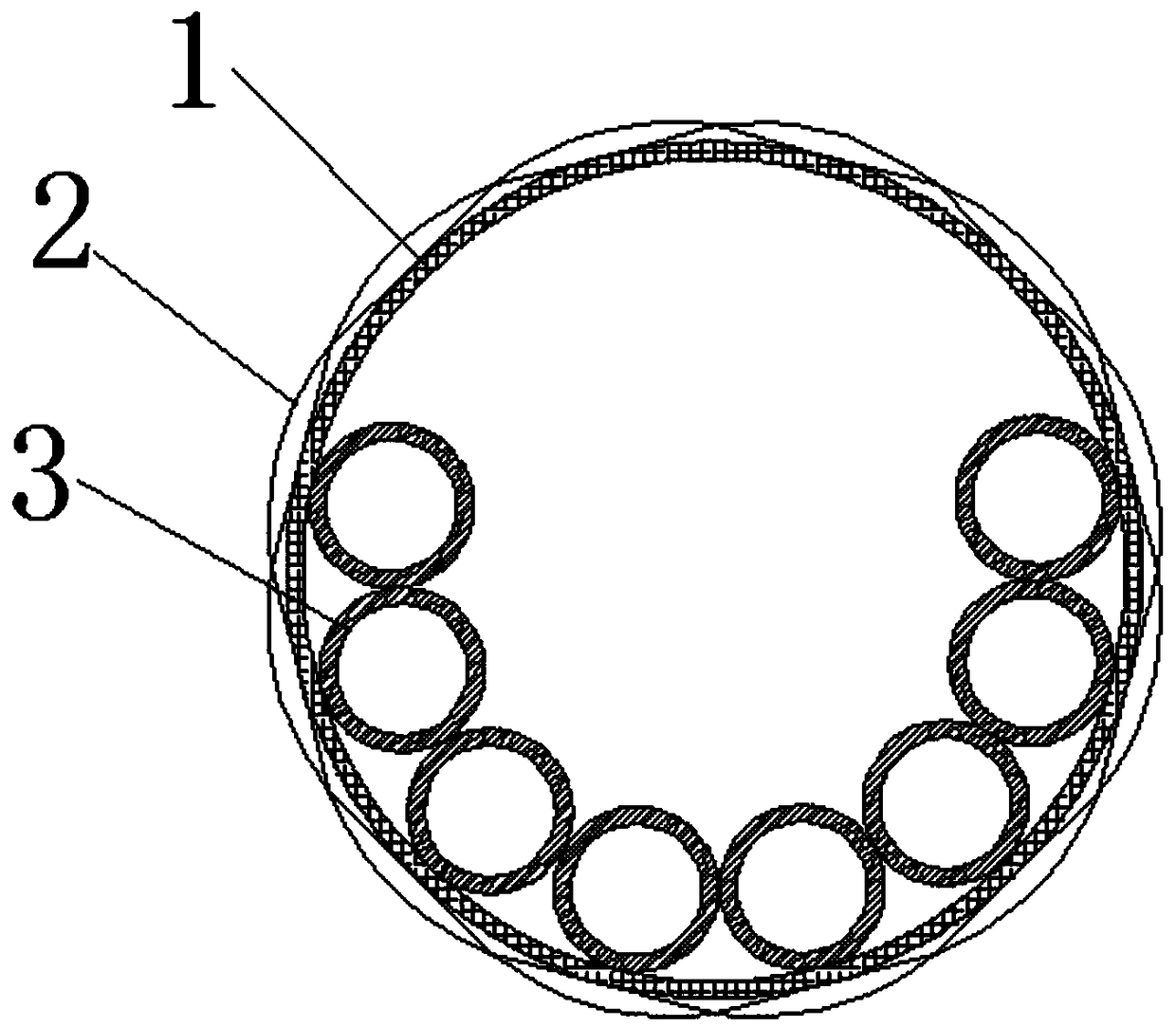

Waterproof and drainage structure for multi-year frozen soil sections of tunnels in cold areas

PendingCN108757029ALow costImprove construction convenienceTunnel/mines ventillationDrainagePipe burstingEngineering

The invention discloses a waterproof and drainage structure for multi-year frozen soil sections of tunnels in cold areas. The waterproof and drainage structure comprises drainage pipes including the longitudinal drainage pipe and the transverse drainage pipe. A plurality of sets of ventilating pipes are laid in the drainage pipes and connected through nylon buckles. The drainage pipes are wrappedwith air films. The ventilating pipes communicate with connecting pipes, one ends of the connecting pipes stretch out of the ground, and heating rods are arranged on the peripheries of the other endsof the connecting pipes. The connecting pipes communicate with a transverse pipe which is connected with a draught fan. A transverse switch is arranged on the transverse pipe which communicates with avertical pipe, and a vertical switch is arranged on the vertical pipe. The waterproof and drainage structure is low in cost and convenient to construct and mount, it can be ensured that when underground water is drained, the phenomenon of pipe bursting or pipe blocking caused by water freeze is avoided, meanwhile the heating rods and the draught fan serve as insurance facilities, and thus it is ensured that a drainage system is not frozen under the condition of the extremely cold weather.

Owner:JILIN UNIV

Halogen-free flame-retardant polystyrene foam composite material and preparation method thereof

The invention discloses a halogen-free flame-retardant polystyrene foam composite material which is prepared through the following steps: evenly mixing 100 parts of foam particles prepared by a conventional technology with a binder which consists of 10-80 parts of an aerogel matrix, 0-10 parts of an aerogel crosslinking agent, 10-50 parts of nano clay and 10-40 parts of a halogen-free flame retardant so as to obtain a mixture, performing compression-molding refrigeration and drying the mixture, wherein the weight ratio of the foam particles to the aerogel matrix binder in the foam composite material is 1:(0.3-1.8), the density is 21-44kg / m<3>, the vertical burning grade is UL-94V-0, the limit oxygen index is 26-45% and the heat conductivity is 0.031-0.035W / mK. Since the aerogel is low in density and heat conductivity, excellent in binding performance, and capable of jointly acting with nano clay and halogen-free flame retardant to provide outstanding flame retarding performance and charring performance, the foam composite material can keep low density and good heat preserving performance and the flame retarding performance of the composite material is greatly enhanced; besides, the technology is mature, simple to operate, easy to control and beneficial to popularization and application.

Owner:SICHUAN UNIV

Process method for chopped fiber reinforced aerated concrete

InactiveCN102092999BHigh strengthDoes not affect heat retentionAutoclaved aerated concreteInorganic chemical compound

The invention discloses a process method for chopped fiber reinforced aerated concrete. A process for sequentially coating resin and inorganic compound particles on a fiber surface and adding coated chopped fibers and a dispersing agent into mixed slurry of autoclaved aerated concrete before the resin is cured is adopted, so that heat resistance and alkali resistance are improved, the bonding problem of the chopped fibers and a substrate and the dispersing problem of the chopped fibers are solved, and the reinforcing function of the chopped fibers can be brought into full play during high-temperature and high-pressure curing of the autoclaved aerated concrete. The aerated concrete reinforced by the method can keep the original light and heat preservation properties, and has the advantage of high intensity. By the reinforcing method, the formula of the original aerated concrete is not required to be changed; and the method is simple and practicable.

Owner:SOUTHEAST UNIV

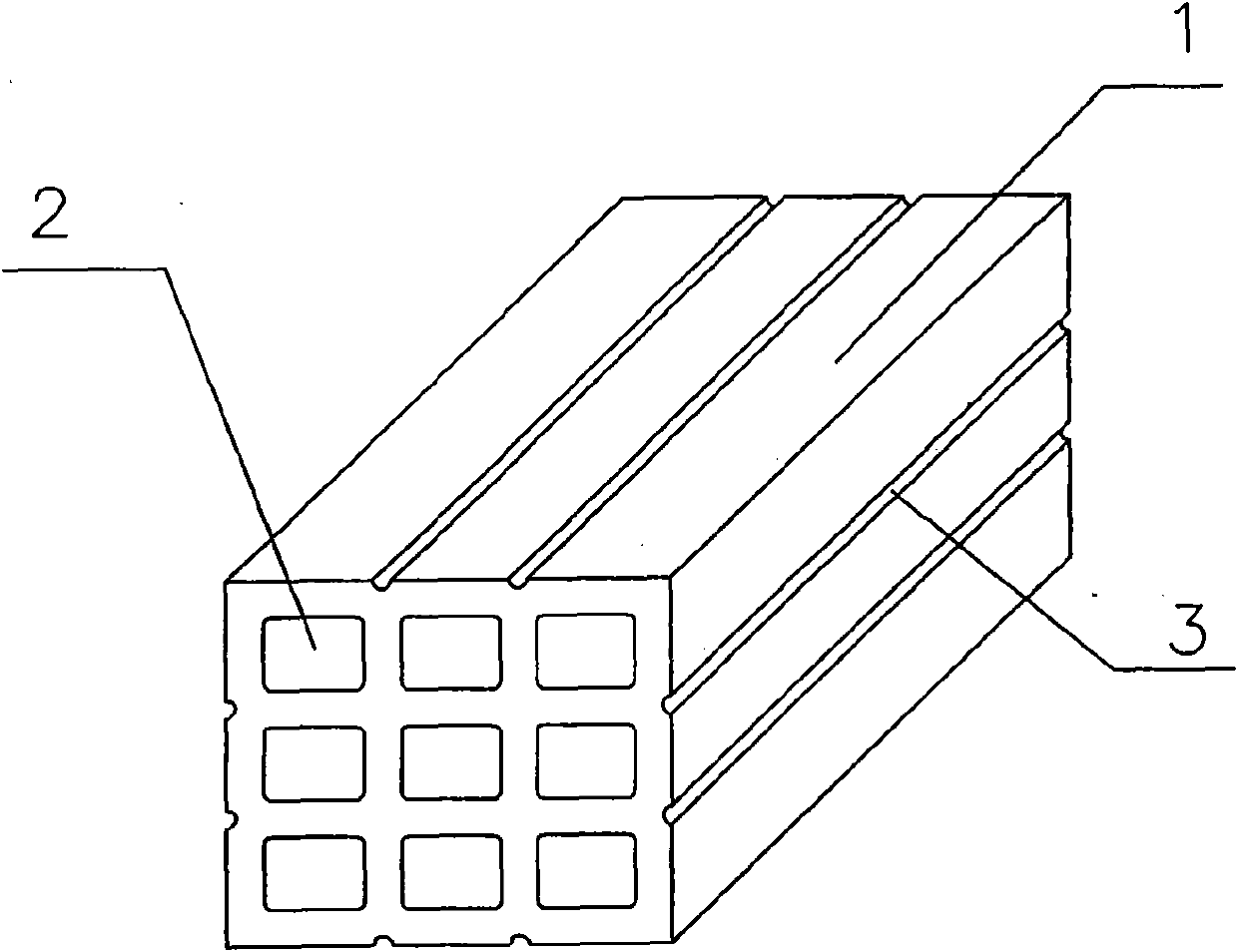

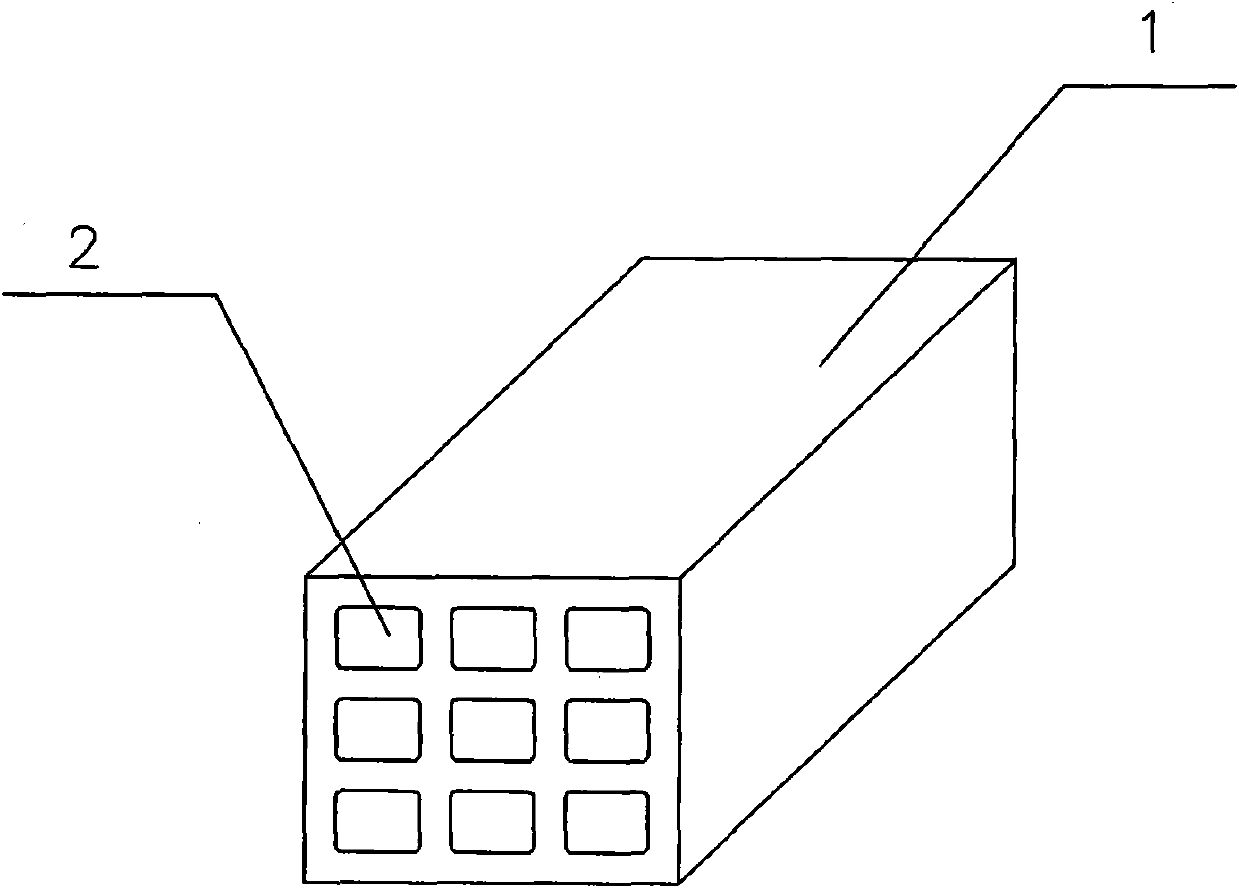

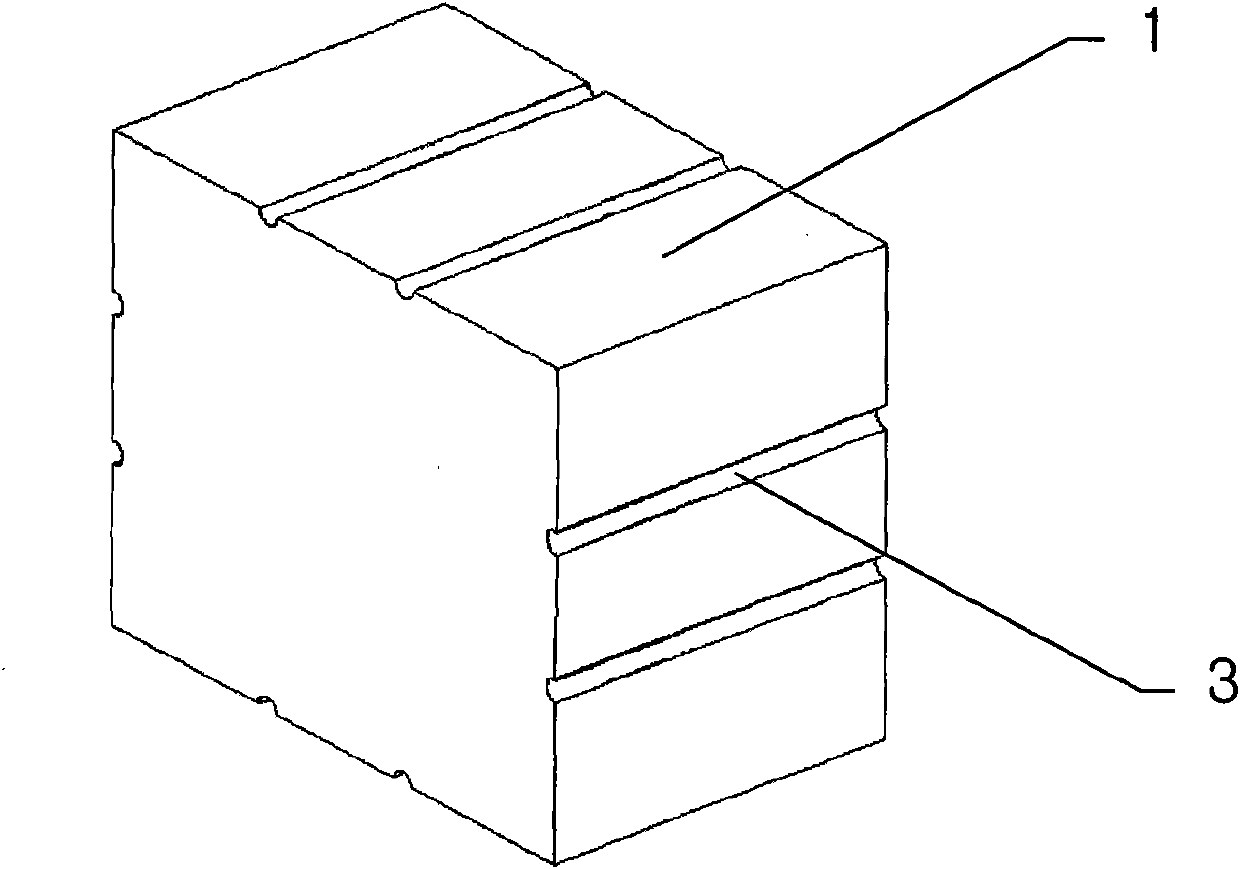

Concrete energy-saving hollow brick

InactiveCN101906842AEnergy savingGood structural performanceBuilding componentsBonding strengthBlind hole

The invention relates to a concrete energy-saving hollow brick. The concrete energy-saving hollow brick comprises building blocks, wherein brick holes are formed on the building blocks; the building blocks comprise a main block and more than two auxiliary blocks; three rows of rectangular holes are formed in the length direction of the building blocks uniformly; the number of the rectangular holes is 9; the rectangular holes are through holes or blind holes; more than one groove is formed on the four sides in the length direction of the building blocks uniformly; and the length of each auxiliary block is 1 / 2 to 3 / 4 of that of the main block. The widths of a bedding face and a top face of the concrete energy-saving hollow brick are the same as the thickness of a wall body, so the compressive resistance and the shear resistance are enhanced, the bonding strength of the wall body is high, and the fundamental problem of generating cracks of the wall body is solved. The cost of the concrete energy-saving hollow bricks per square meter is about 15 percent lower than that of the conventional novel wall body materials; secondary decoration can be directly performed after the wall body is built, without interface treatment and outer wall heat preservation; the construction time is shortened; and compared with the comprehensive cost of the conventional product wall body, the comprehensive cost of the wall body is reduced by over 35 percent.

Owner:安徽皋新建材有限公司

Manufacturing method for novel vacuum thermal insulation plate

InactiveCN108223972AHigh strengthImprove puncture resistanceThermal insulationPipe protection by thermal insulationPuncture resistanceVacuum insulated panel

The invention discloses a manufacturing method for a novel vacuum thermal insulation plate. The manufacturing method comprises the following steps that a heat insulation core material is dried and isarranged in an inner insulation bag; the inner insulation bag is vacuumized and sealed to obtain an inner vacuum thermal insulation plate; the inner vacuum thermal insulation plate is placed between two plate-shaped heat insulation materials to obtain an inner core; the inner core is arranged in an outer insulation bag; and the outer insulation bag is vacuumized and sealed; and the vacuum thermalinsulation plate is obtained after core-and-film-integration treatment. By adopting the manufacturing method for the novel vacuum thermal insulation plate provided by the invention, strength and anti-stabbing performance of the vacuum thermal insulation plate are enhanced; and even if the outer insulation bag is broken accidentally, thermal insulation performance cannot be affected.

Owner:安徽百特新材料科技有限公司

Assembled wall with vacuum box and preparation method of assembled wall

InactiveCN108425443AImprove insulation effectImprove sound insulationWallsClimate change adaptationSurface layerPulp and paper industry

The invention discloses an assembled wall with a vacuum box and a preparation method of the assembled wall. The assembled wall comprises a wall surface layer and a plurality of vacuum box heat insulation modules, a cavity is enclosed by the wall surface layer, the vacuum box heat insulation modules are uniformly arranged in the cavity, a vacuum cavity is formed in each vacuum box heat insulation module, the vacuum box heat insulation modules comprise vacuum films and gas-guide tubes, the gas-guide tubes penetrate the vacuum films, one end of each gas-guide tube exposed outside the corresponding vacuum films is sealed, the gas-guide tubes are communicated with the vacuum cavities, the cavity is filled with foaming fillers, the foaming fillers are distributed in gaps among the vacuum box heat insulation modules and the wall surface layer, and the preparation method is used for preparing the assembled wall with the vacuum box. The assembled wall with the vacuum box can have good heat insulation function and better sound insulation effect. The invention can provide a thin wall, so that indoor use space is furthest increased without affecting the strength of the wall.

Owner:HEBEI ZHUOQIU IND CO LTD

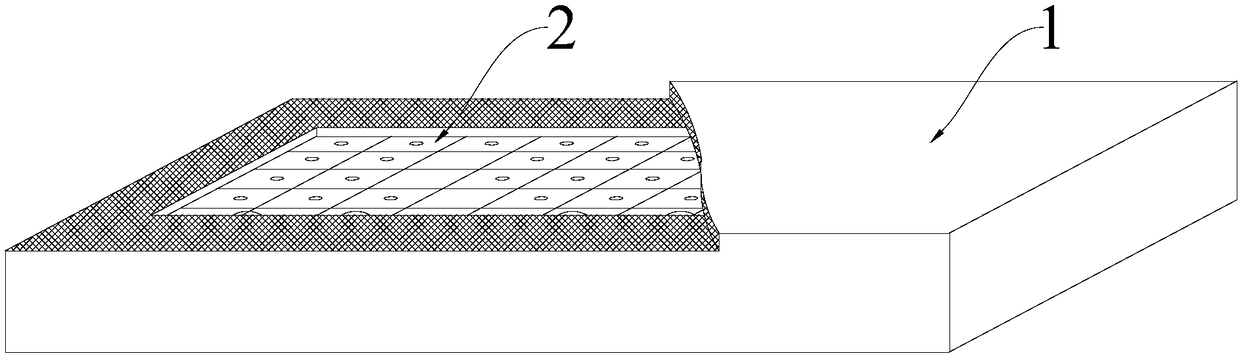

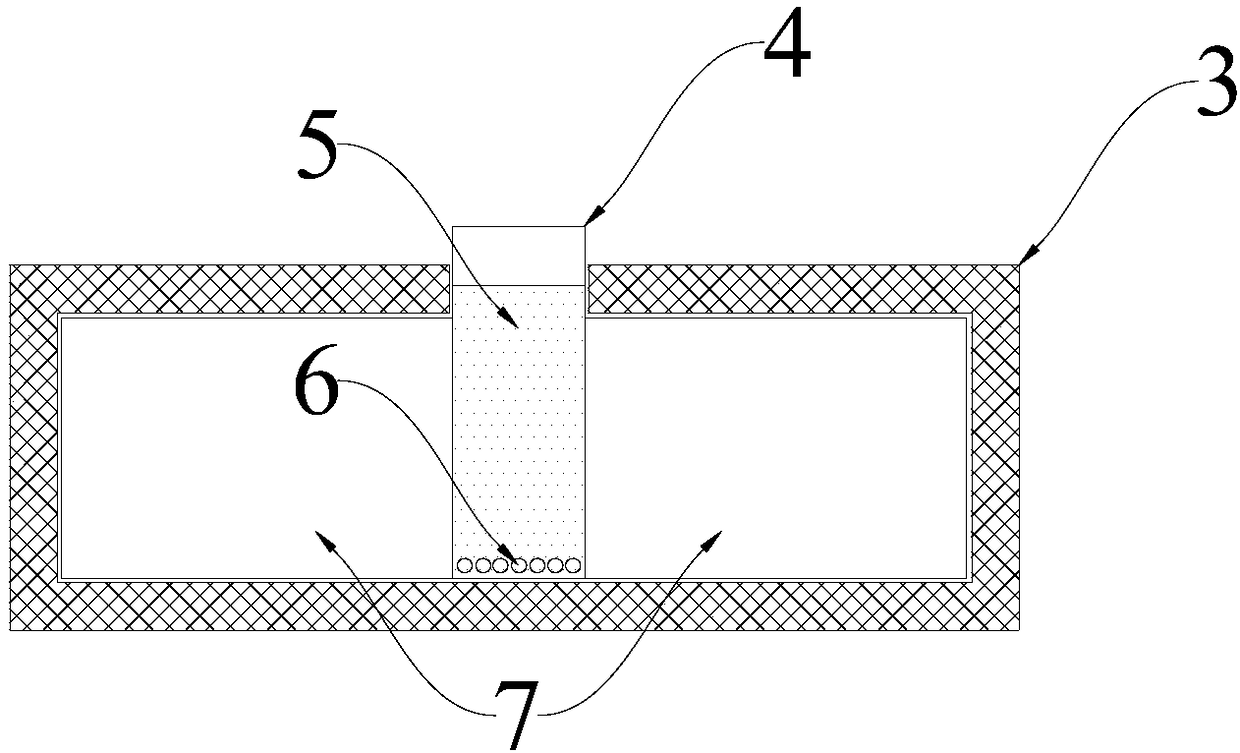

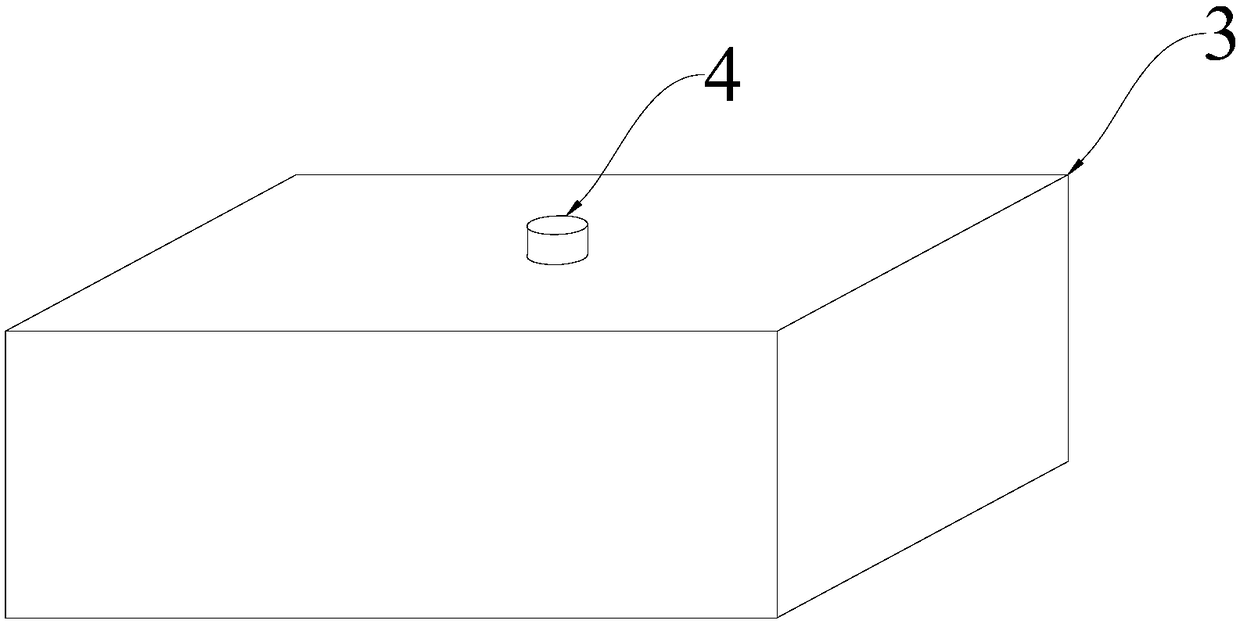

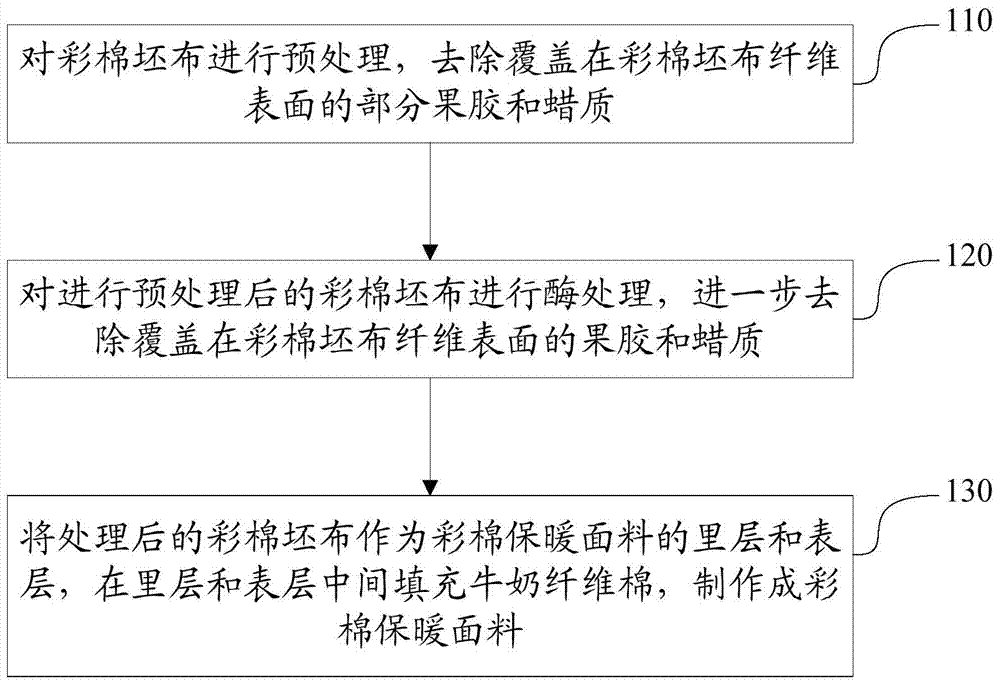

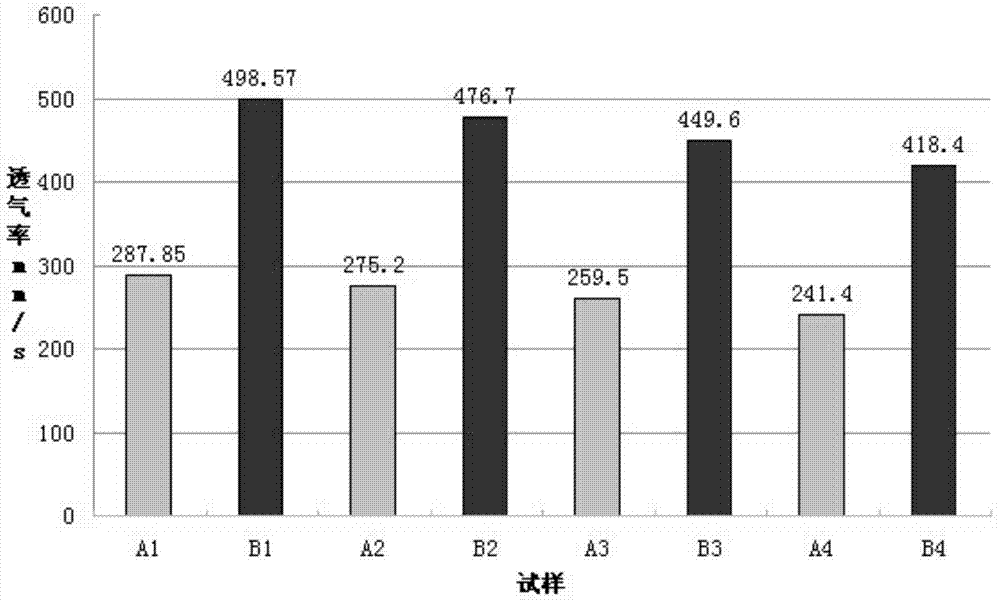

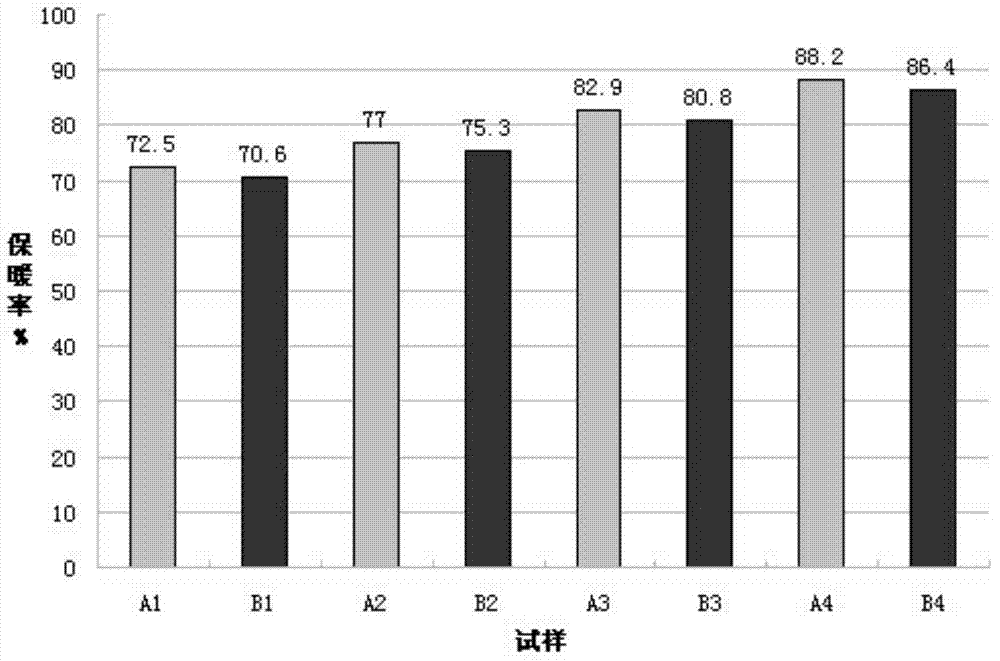

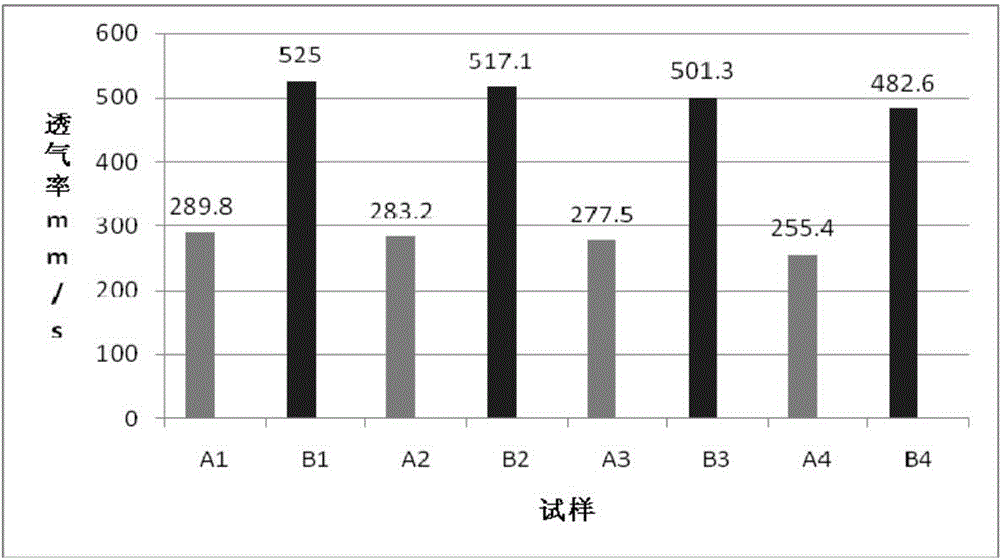

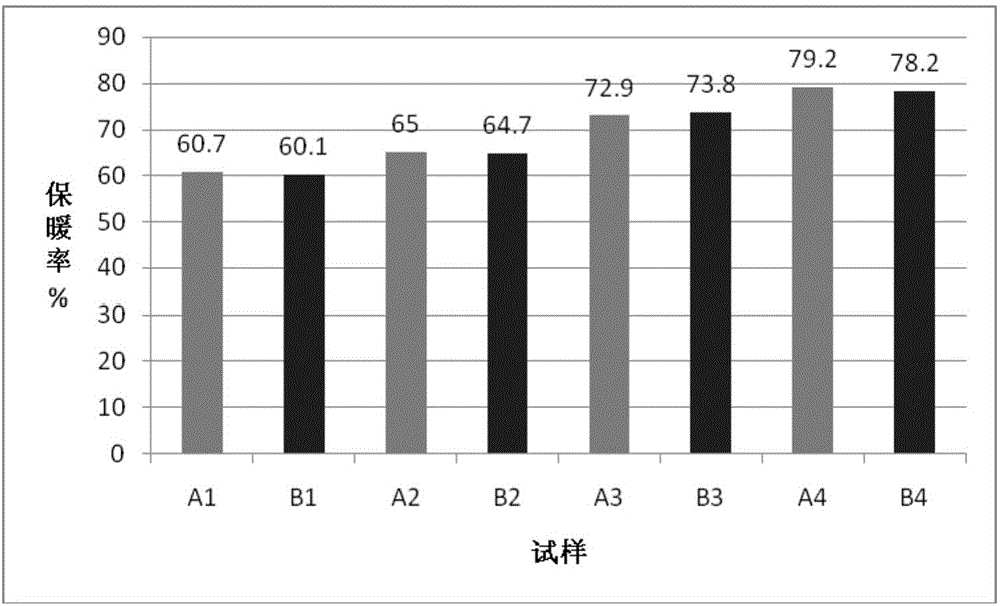

Preparation method for colored cotton thermal fabric

ActiveCN104489941ADoes not affect heat retentionReduce consumptionBiochemical fibre treatmentLayered productsFiberWax

The invention relates to the technical field of textiles, in particular to a preparation method for a colored cotton thermal fabric. The preparation method comprises the following steps: pre-treating colored cotton grey cloth to remove part of pectin and wax which cover the fiber surface of the colored cotton grey cloth; performing enzyme treatment on the pre-treated colored cotton grey cloth to further remove the pectin and the wax which cover the fiber surface of the colored cotton grey cloth; taking the treated colored cotton grey cloth as an inner layer and a surface layer of the colored cotton thermal fabric, and filling the space between the inner layer and the surface layer with milk fiber cotton to obtain the colored cotton thermal fabric. According to the preparation method provided by the invention, the colored cotton is used as the surface layer and inner layer of the thermal fabric, so that compared with used white cotton, the processing steps are reduced, the energy consumption is reduced, and the production cost is reduced; moreover, the colored cotton as the surface layer and the inner layer is treated, so that the ventilation property and the productwearability are improved on the basis of not influencing the warmth retention ratio of the thermal fabric.

Owner:BEIJING GUANGHUA TEXTILE GRP +1

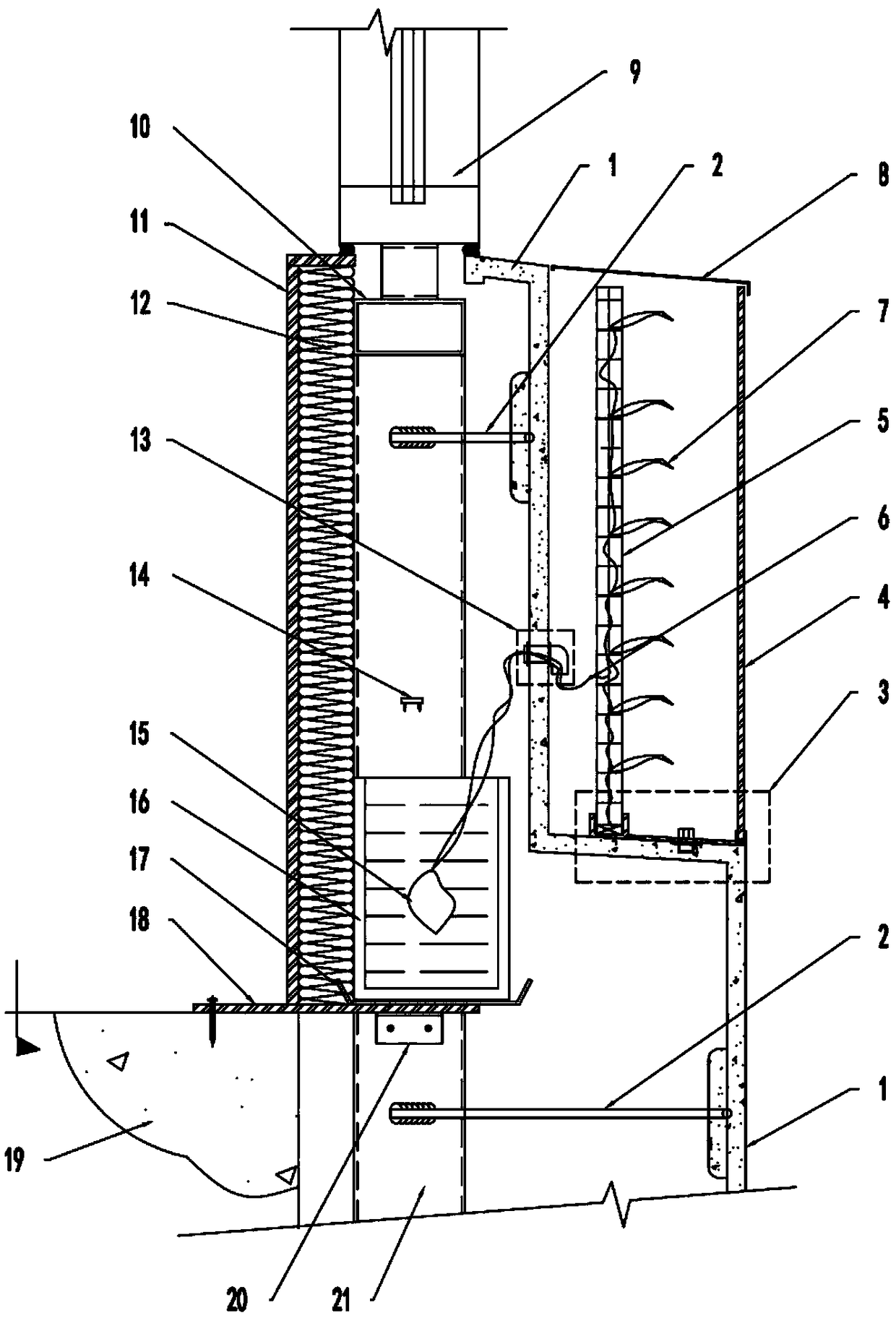

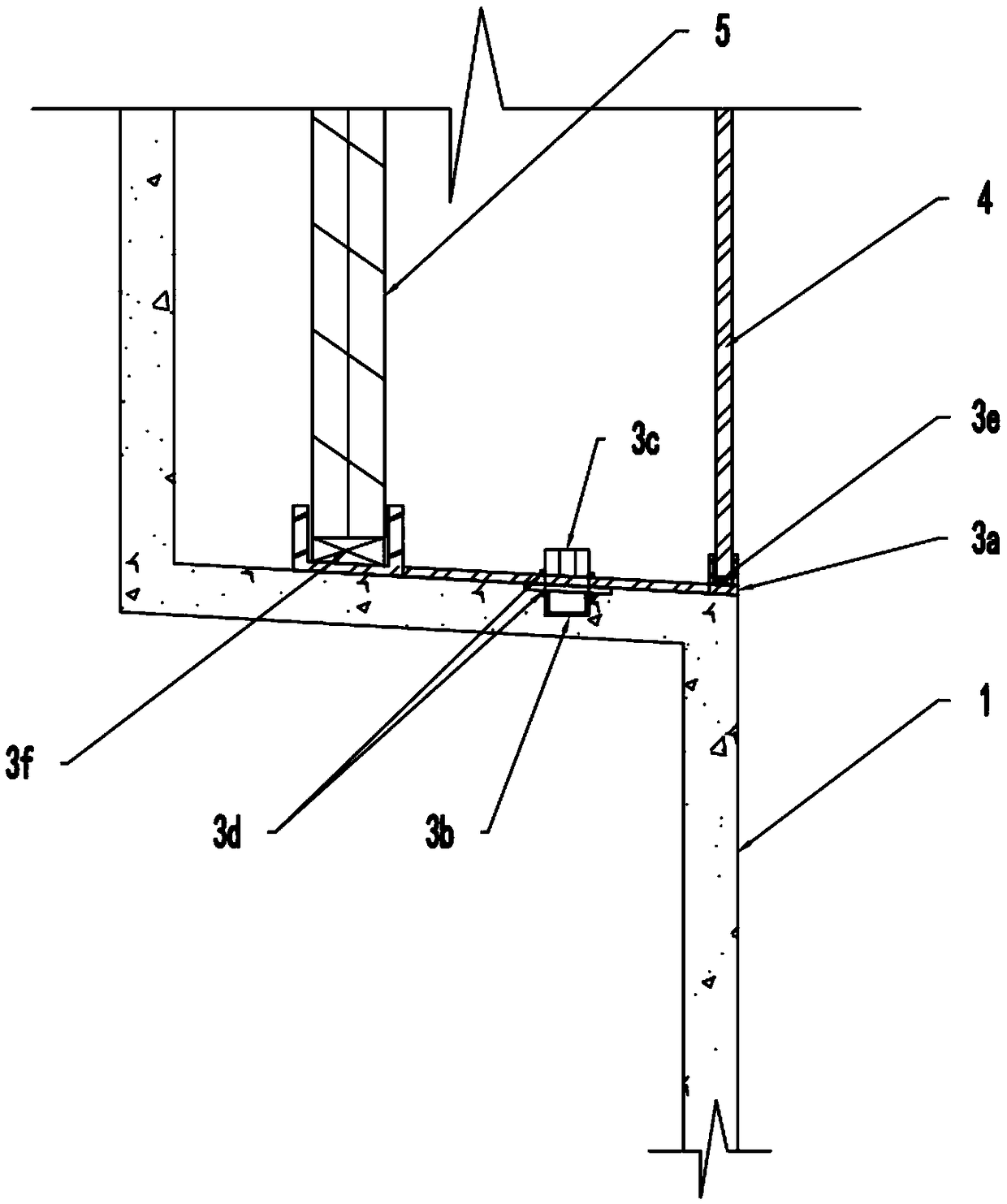

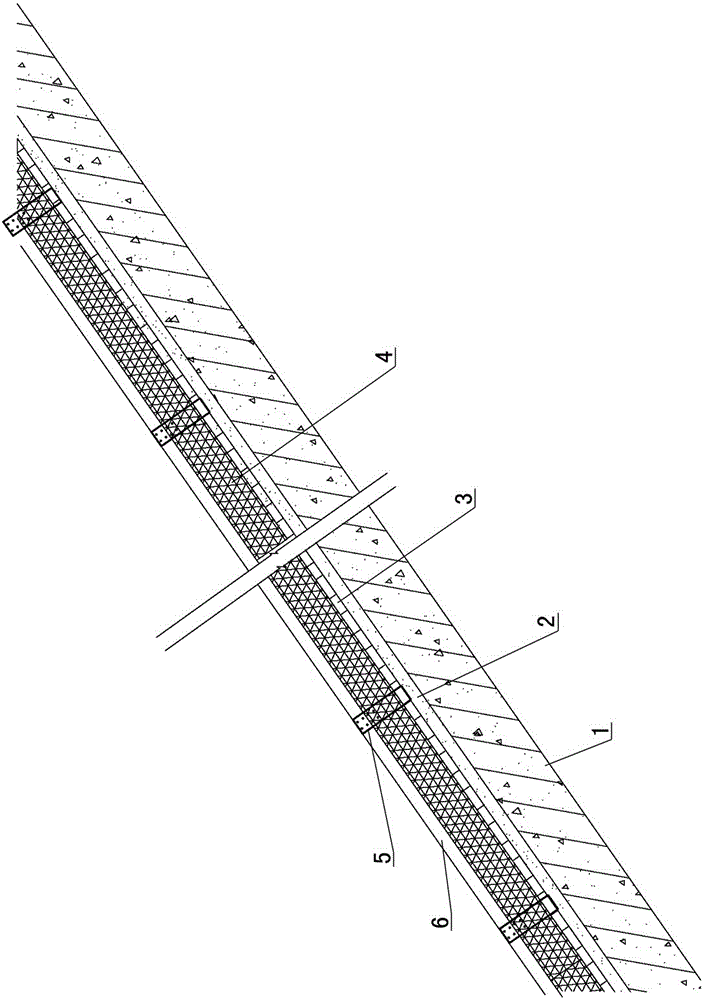

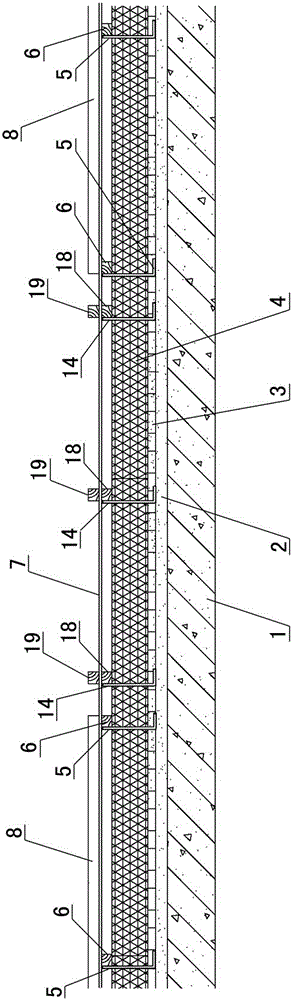

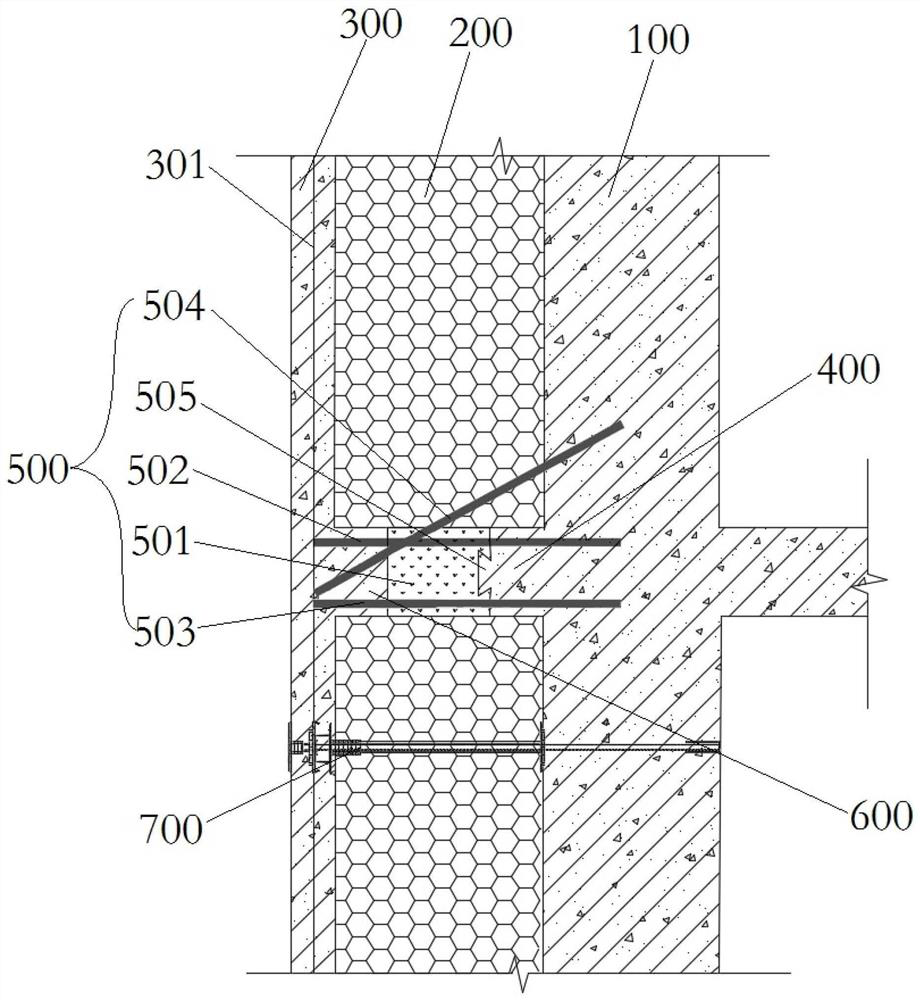

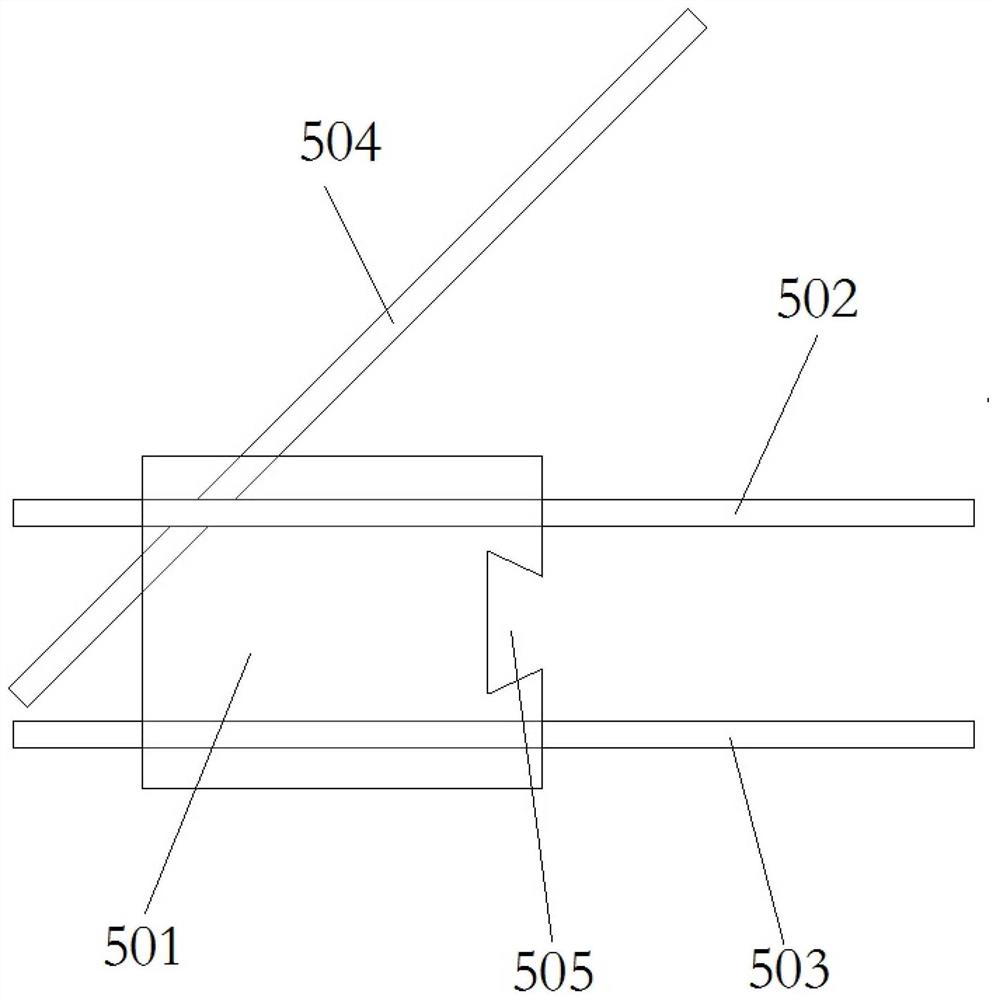

Pitched roof mounting system for solar thermal collector and construction method of pitched roof mounting system

ActiveCN103711263AEasy to installSimplify the construction processSolar heat devicesBuild-up roofsRoof tileEngineering

The invention discloses a pitched roof mounting system for a solar thermal collector and a construction method of the pitched roof mounting system. The system comprises a pitched roof and the solar thermal collector arranged on the pitched roof, wherein the pitched roof consists of a structural layer, a cement mortar leveling layer, a waterproof pad layer, a heat preservation water drainage layer, transverse tile hanging wood bars and roof tiles, wherein the heat preservation water drainage layer consists of a heat preservation plate, wood carrying brackets I, longitudinal downstream wood bars and an aluminum foil coiled material; two-side concave-shaped water drainage ditches are formed between the solar thermal collector and the longitudinal downstream wood bars on the left side and the right side of the solar thermal collector; an upper-side concave-shaped water drainage ditch is formed between the solar thermal collector and transverse lap-joint wood bars; a lower-side concave-shaped water drainage ditch is formed between the solar thermal collector and the roof tiles on the lower side of the solar thermal collector. According to the system and the construction method which are disclosed by the invention, the construction technology is changed; the solar thermal collector can be firmly and stably mounted; the pitched roof has energy-saving and ventilating effects; the heat insulation and preservation efficiency of the pitched roof can be improved, and the surface of a building is attractive.

Owner:LJLZ BEIJING BUILDING MATERIALS CO LTD

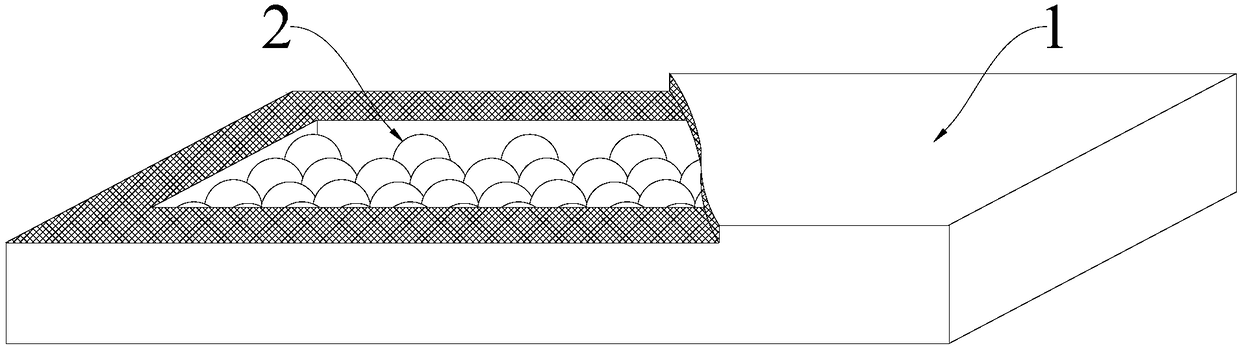

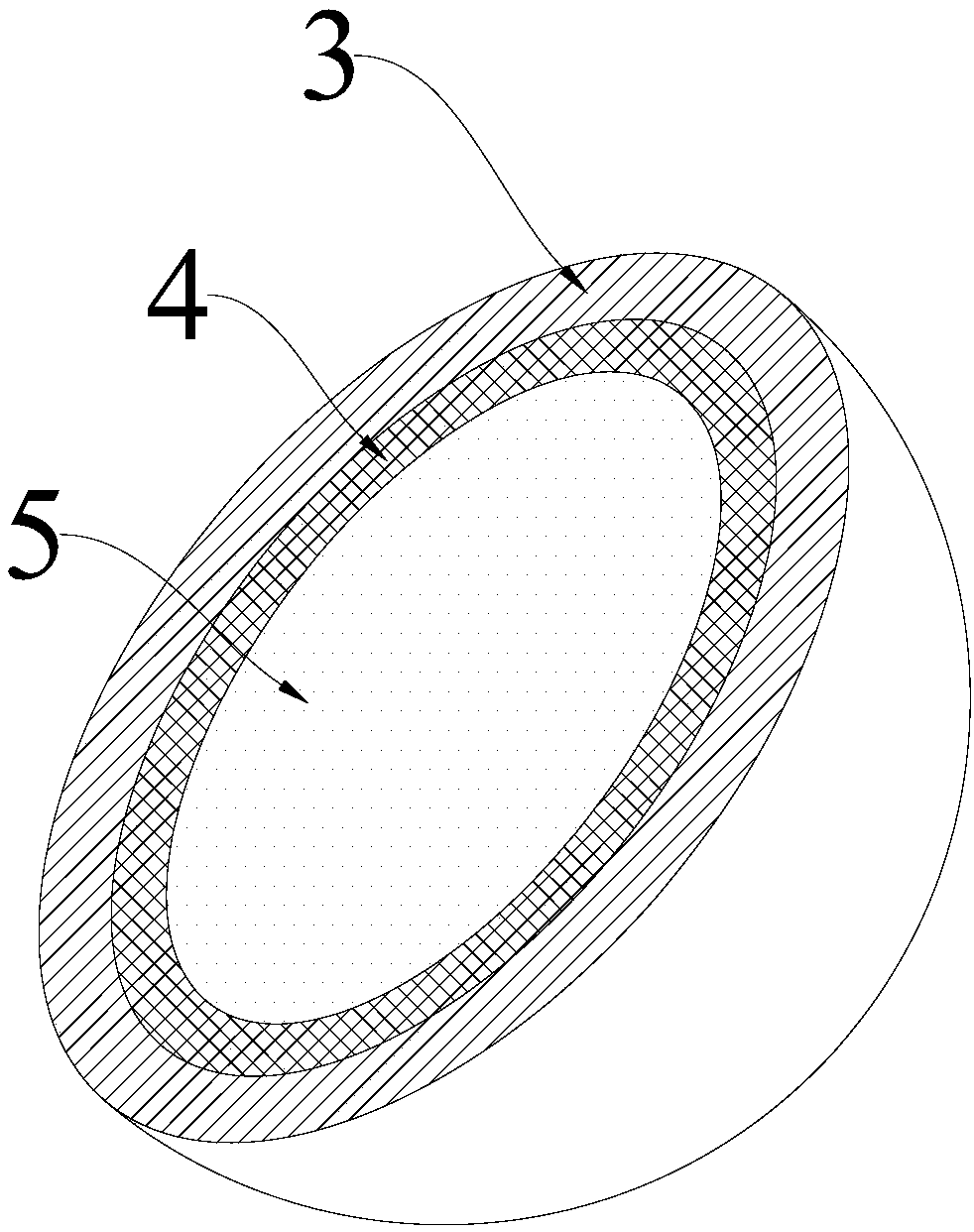

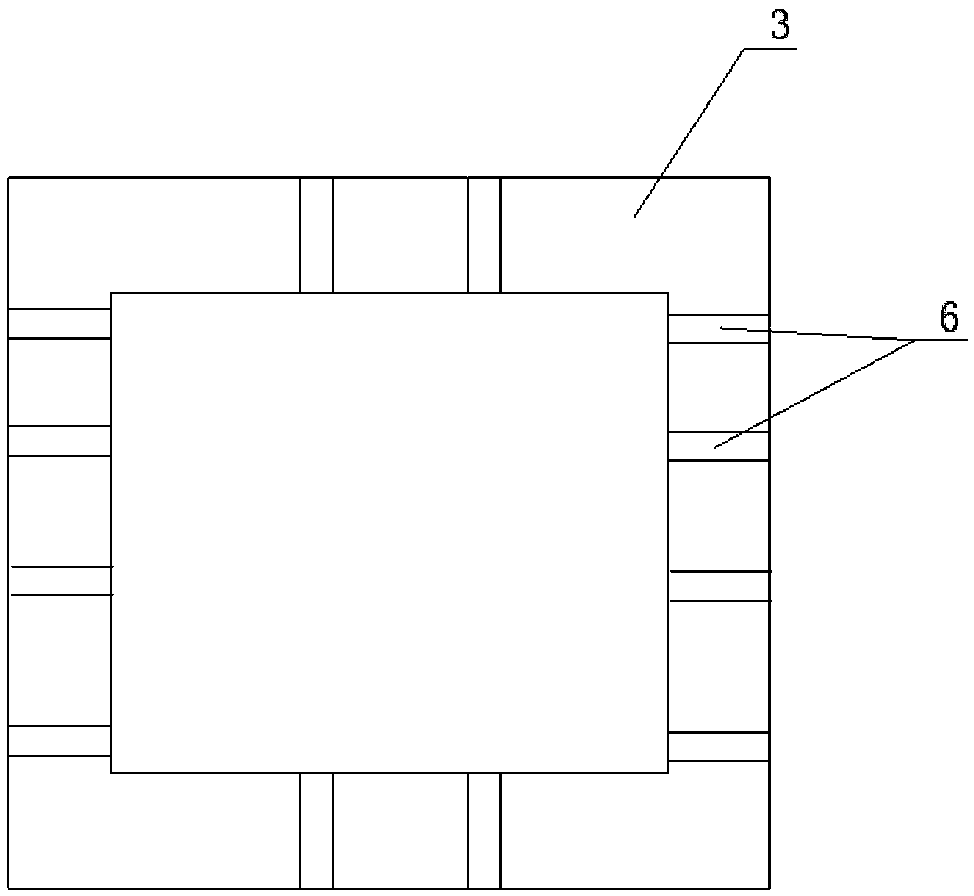

Assembling type vacuum foam wall body and preparation method thereof

InactiveCN108532779AImprove insulation effectImprove sound insulationClimate change adaptationInsulation improvementSurface layerThermal insulation

The invention discloses an assembling type vacuum foam wall body and a preparation method thereof. The wall body comprises a wall surface layer and vacuum balls, wherein a first containing cavity is surrounded by the wall surface layer; the vacuum balls are arranged in a first containing cavity and are in a closest accumulation arrangement way; the first containing cavity is filled with foamed filler which is distributed in a gap between each vacuum ball and the wall surface layer and in a gap between vacuum walls; each vacuum ball comprises an external protection layer, a vacuum diaphragm andfoam, wherein the external protection layer, the vacuum diaphragm and the foam are arranged in sequence from the outside of the ball body to the inner side of the ball body; a second containing cavity is surrounded by the vacuum diaphragm and is filled with foam. The preparation method is used for manufacturing the assembling type vacuum foam wall body. The assembling type vacuum foam wall body provided by the invention not only can perform a relatively good thermal insulation and heat insulation function but also can perform a relatively good sound insulation effect. In addition, the invention can provide a thinner wall body so as to realize a purpose that indoor use space is increased to a maximum degree under a situation that wall body strength is not influenced.

Owner:HEBEI ZHUOQIU IND CO LTD

Manufacturing method for colored cotton thermal insulation fabric

ActiveCN104397886ADoes not affect heat retentionReduce consumptionLayered productsBiochemical treatment with enzymes/microorganismsFiberWax

The invention relates to the technical field of textiles, in particular to a manufacturing method for colored cotton thermal insulation fabric. The method includes the following steps of preprocessing colored cotton gray fabric, removing part of pectin and wax which cover the surface of colored cotton gray fabric fiber, conducting enzyme treatment on the preprocessed colored cotton gray fabric, further removing the pectin and wax which cover the surface of the colored cotton gray fabric fiber, using the processed colored cotton gray fabric as a lining and a surface layer of the colored cotton thermal insulation fabric, filling the space between the lining and the surface layer with 100% antibiosis cotton, and manufacturing the colored cotton thermal insulation fabric. According to the manufacturing method, due to the fact that the colored cotton serves as the lining and the surface layer of the thermal insulation fabric, compared with thermal insulation fabric made of white cotton, the machining procedures are reduced, the energy consumption is lowered, and the production cost is reduced; in addition, the colored cotton serving as the lining and the surface layer is processed, and on the basis of making the thermal insulation fabric not influence the warm keeping rate, breathability and wearability of the product are improved.

Owner:BEIJING GUANGHUA TEXTILE GRP +1

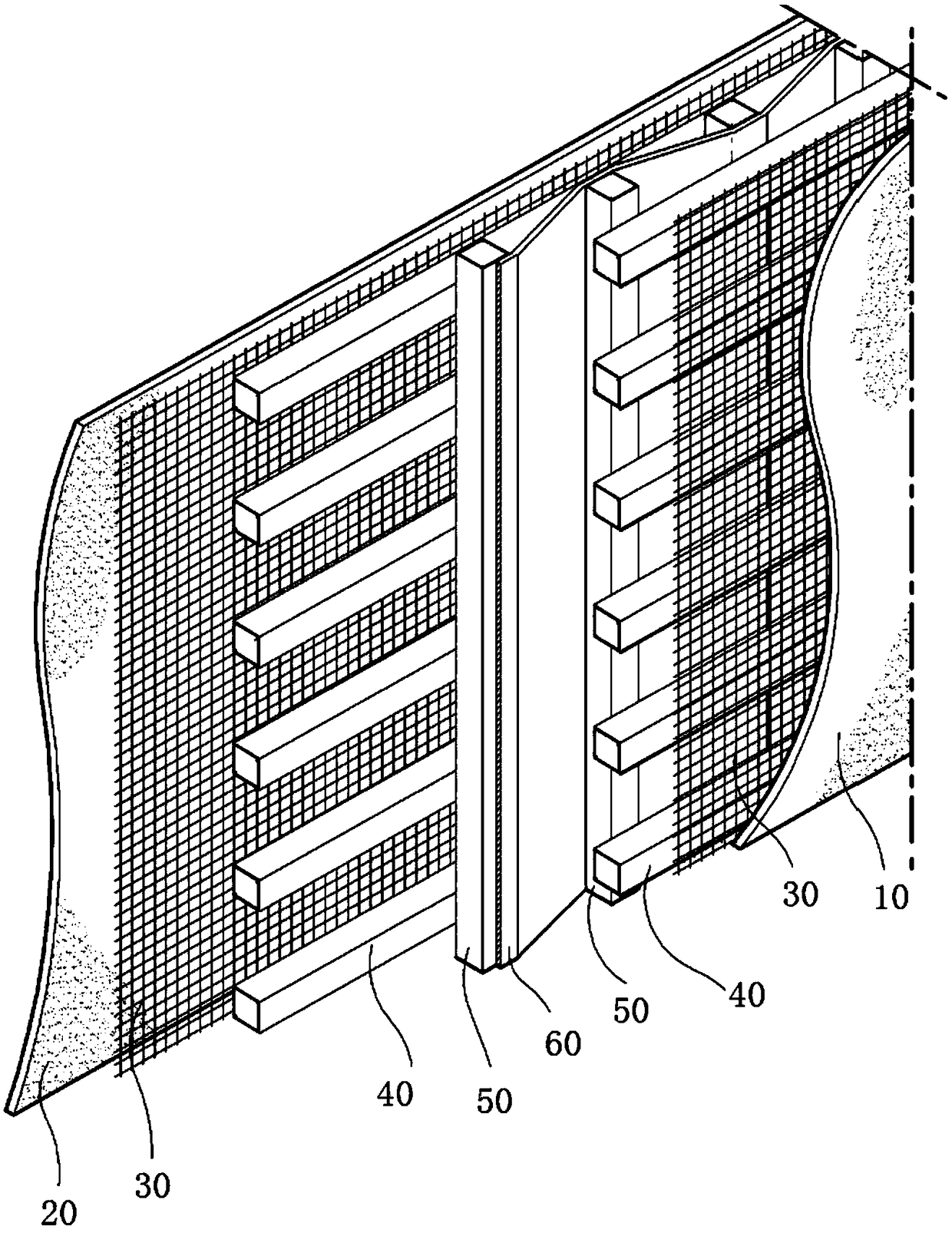

Lightweight external hanging prefabricated wallboard and production method thereof

PendingCN109296125AImprove sound insulationNo damageBuilding componentsThermal insulationEngineering

The invention provides a lightweight external hanging prefabricated wallboard and a production method thereof. The lightweight external hanging prefabricated wallboard includes a core skeleton, an inner wallboard and an outer wallboard, the core skeleton comprises two outer skeleton layers and an inner skeleton layer arranged between the two outer skeleton layers, each outer skeleton layer comprises a plurality of horizontal lightweight skeletons arranged at intervals, and the inner skeleton layer comprises a plurality of vertical lightweight skeleton arranged at intervals; and the inner skeleton layer is internally provided with a sound insulation felt in a zigzag mode, a void inside the core skeleton is filled with polyurethane foam, the outer surfaces of the outer framework layers are fixed with a steel wire mesh, and the outer surface of the steel wire mesh is provided the inner wallboard or the outer wallboard integrally. The lightweight external hanging prefabricated wallboard has the advantages of light weight, excellent thermal insulation performance, good sound insulation effect and so on, and meanwhile rapid production can be carried out.

Owner:SUZHOU CROWNHOMES TIMBER STRUCTURE TECH CO LTD

A kind of insulation structure of isobutane dehydrogenation device

InactiveCN107166138BDoes not affect heat retentionInhibition of agglomerationThermal insulationPipe protection by thermal insulationInsulation layerHydrogen

The invention discloses a heat insulation structure of an isobutane dehydrogenation device. The heat insulation structure comprises pipelines connected through flanges, and heat insulation layers are arranged outside the pipelines. The heat insulation structure is characterized in that heat insulation chambers wrapping the flanges are arranged outside the flanges on the pipelines, each heat insulation chamber comprises a lower heat insulation chamber which can wrapping the corresponding flange and an upper heat insulation cover, the upper portion of each lower heat insulation chamber is provided with an opening, each upper heat insulation cover covers the opening of the corresponding lower heat insulation chamber, an upper port of each lower heat insulation chamber is provided with multiple grooves penetrating through the interior and exterior of the corresponding heat insulation chamber, the outer side of a lower port of each upper heat insulation cover is provided with a shield cover, each shield cover can cover the openings in the outer sides of the grooves in the upper port of the corresponding lower heat insulation chamber after closing of the corresponding upper heat insulation cover, and a gap is reserved between the outer side wall of each shield cover and the outer side wall of the corresponding lower heat insulation chamber. According to the heat insulation structure of the isobutane dehydrogenation device, the heat insulation effect is good, maintenance is convenient, leaked hydrogen can be effectively prevented from being gathered in the heat insulation chambers, and operation safety of the device is ensured.

Owner:山东海丰能源科技有限公司

Slope roof thermal insulation, ventilation and energy-saving dry structure and its construction method

ActiveCN103628634BRegulating heat conductionImprove insulation effectBuilding roofsLighting and heating apparatusRoof tileDry structure

Owner:LJLZ BEIJING BUILDING MATERIALS CO LTD

Slope roof installation system and construction method of solar heat collector

ActiveCN103711263BEasy to installSimplify the construction processSolar heat devicesBuild-up roofsEngineeringCement mortar

Owner:LJLZ BEIJING BUILDING MATERIALS CO LTD

Building external wall heat preservation system

ActiveCN113605561ATo undertakeLower heat transfer coefficientWallsClimate change adaptationFloor slabInsulation layer

The invention provides a building external wall heat preservation system, and belongs to the technical field of wall heat preservation. The building external wall heat preservation system comprises a structural layer, a heat preservation layer and a construction layer; a cornice structure is arranged in the heat preservation system, and the cornice structure is arranged opposite to a reinforced concrete floor in the structural layer; and the cornice structure comprises a first cornice and a second cornice. According to the building external wall heat preservation system, the second cornice is provided with a fixing block, the heat transfer coefficient of the fixing block is smaller than that of concrete, so that the heat transfer coefficient of the overall cornice structure in the scheme is reduced, the heat bridge effect cannot be formed while the heat preservation system can be borne, and the heat preservation performance of a wall cannot be affected.

Owner:HEBEI SANKAISHENFA SCI & TECH CORP LTD +1

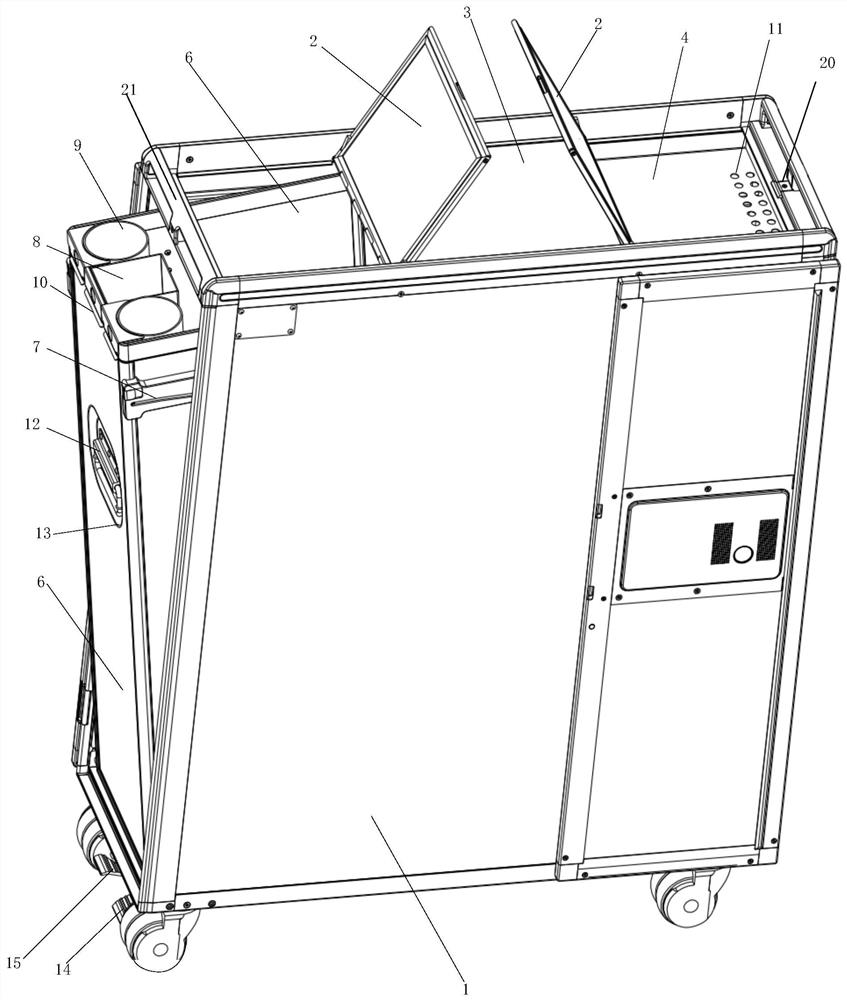

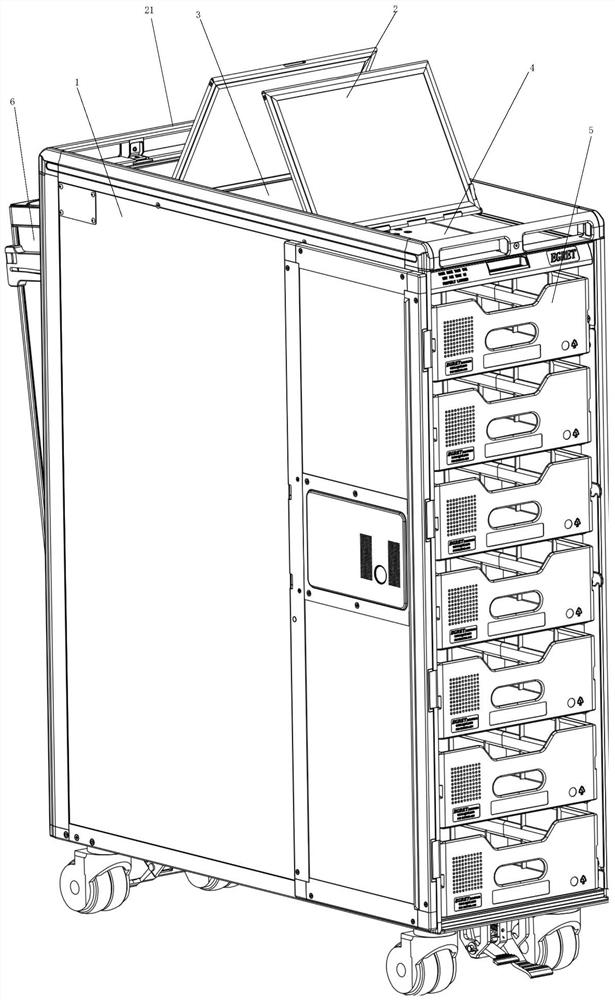

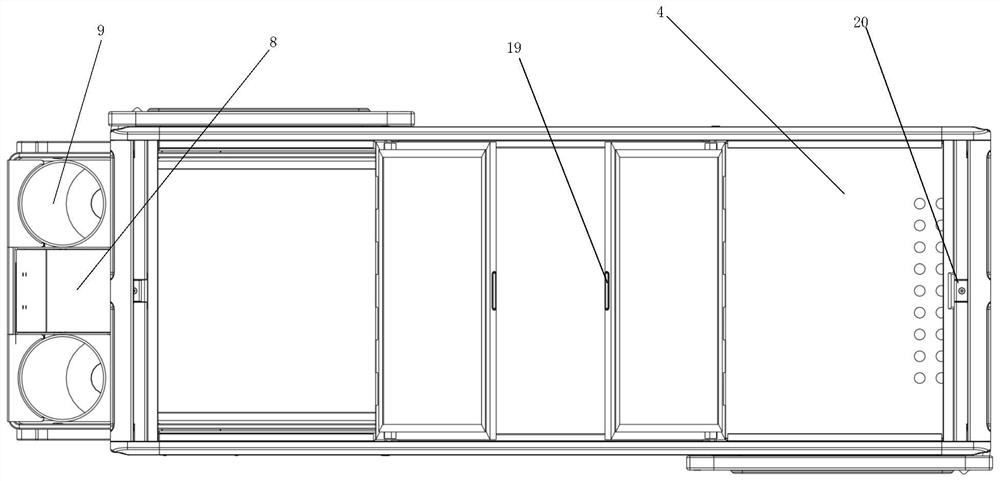

Universal aviation trolley

PendingCN113264190AAvoid damageAvoid lossServing tablesAircraft crew accommodationDry iceEngineering

The invention relates to a universal aviation trolley. The interior of a trolley body is provided with a first storage area and a second storage area, two flip doors located above the first storage area and the second storage area respectively are arranged in a placement area arranged at the top of the trolley body, the two flip doors are hinged to the two sides of a cover plate located in the middle of the top surface of the trolley body respectively, a dry ice box and a plurality of layers of drawers which can be pulled out or pushed back from the back face of the trolley body are arranged in the first storage area, a garbage can which can be obliquely pulled out from the front face of the trolley body is arranged in the second storage area, the side face of the garbage can is hinged into a lower clamping groove formed in the inner side wall of the trolley body, sliding grooves are formed in the two side walls of the garbage can, sliding blocks with one ends capable of sliding in the sliding grooves are arranged in the sliding grooves, the other ends of the sliding blocks are clamped in the upper clamping grooves, a liquid barrel and two paper cup barrels which are hung on the same front wall of the garbage can are arranged in the garbage can, and the liquid barrel and the paper cup barrels are integrally formed with hooks respectively. The universal aviation trolley provided by the invention is convenient to use and high in utilization rate.

Owner:苏州鹭翔航空设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com