Device and method for continuously preparing bulk amorphous alloy ingots

A technology for amorphous alloys and preparation equipment, which is applied in the field of continuous preparation at low cost, can solve the problems of reducing the vacuum degree of the vacuum system, high cooling speed, and low cooling speed, so as to prevent the mold from heating up, ensure coaxial alignment, and large The effect of cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

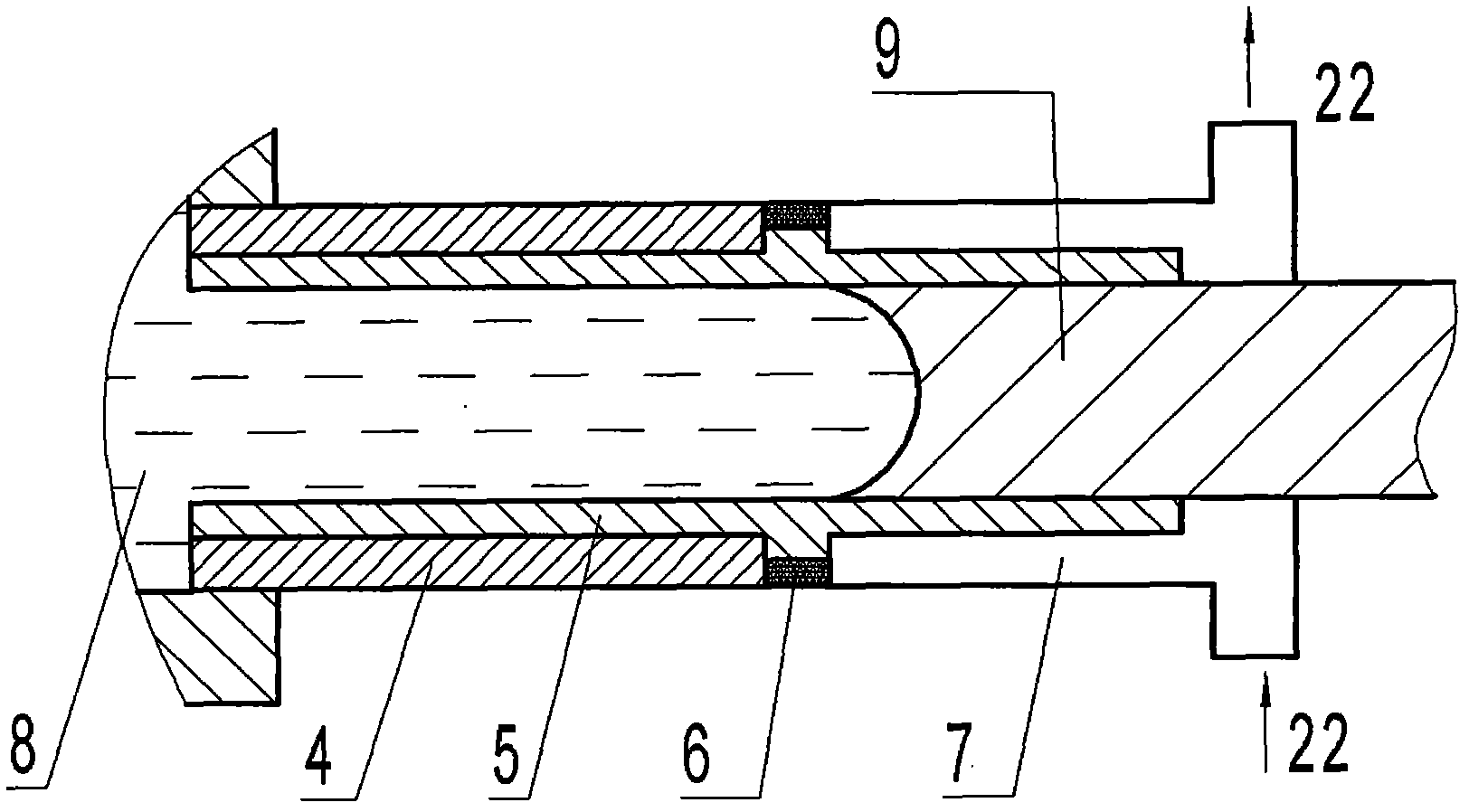

[0033] Example 1: figure 1 It is a horizontal continuous preparation device for large amorphous alloy ingots. It includes a main vacuum chamber 24 and an auxiliary vacuum chamber 25; the boron nitride heat preservation crucible 1 is placed in the main vacuum chamber, the crucible heat preservation device 2 heats the boron nitride heat preservation crucible 1, and the second thermocouple 11 is used to measure the boron nitride heat preservation The temperature of the metal melt 8 in the crucible 1; the sleeve pipe 4 in the nested mold, the thin-walled graphite embedded pipe 5, the heat insulation pad 6 and the front end of the water-cooled copper mold 7 are also located in the main vacuum chamber, and the sleeve pipe 4 and the water-cooled The copper molds 7 are coaxially arranged adjacent to each other, and the casing 4 is connected to the boron nitride heat preservation crucible 1, and is heated by the nested mold heating device 3, and the first thermocouple 10 is used to mea...

Embodiment 2

[0043] Example 2: figure 2 It is a vertical continuous preparation device for large amorphous alloy ingots; Figure 4 is a structural schematic diagram of the nested mold of the vertical continuous preparation device; Image 6 It is a structural schematic diagram of the dummy device of the vertical continuous production device. It can be seen from the drawings that the principle and structure of the vertical continuous preparation device and the horizontal continuous preparation device are the same, the difference is that the direction of ingot lead-out is different, so that the nested mold is located under the vacuum chamber, and its axis direction is vertical direction, one end of the sleeve is connected to the bottom of the heat preservation crucible, the other end is fixed to the wall of the main vacuum chamber, and one end of the water-cooled copper mold is embedded in the sleeve.

[0044] The method for continuous preparation of bulk amorphous alloy ingots using a ver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com