Preparation method of corrosion-resistant light piston for fuel cabin

A corrosion-resistant, fuel tank technology is applied in the field of preparation of corrosion-resistant lightweight pistons for fuel tanks, which can solve the problems of strong corrosion, large self-mass, fuel leakage, etc., to improve the interface bonding strength, and the treatment method is simple and easy to implement. , the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

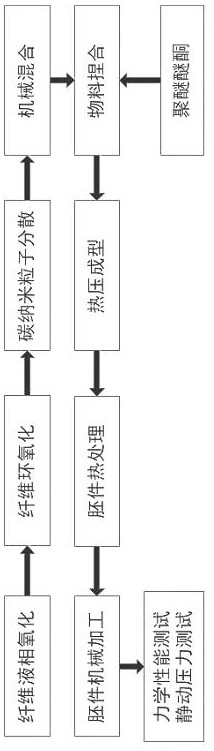

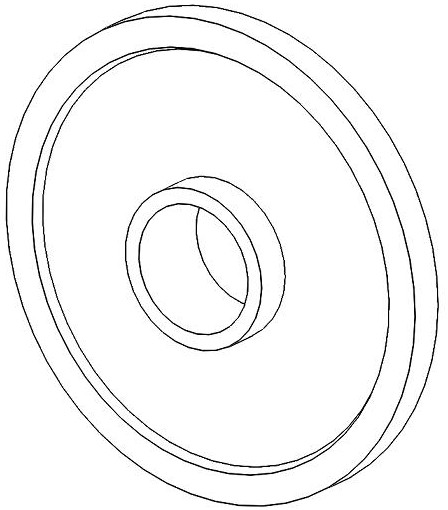

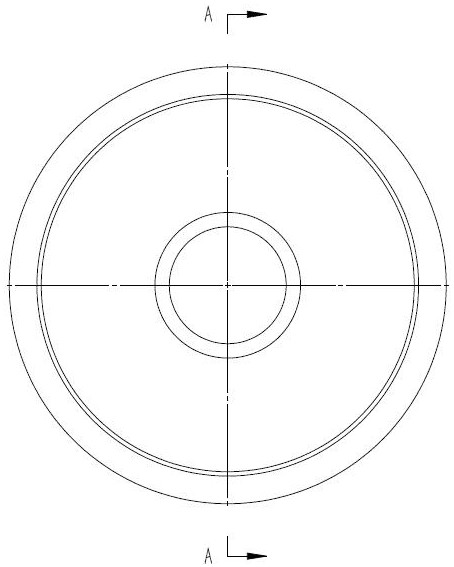

[0053] like figure 1 As shown, a method for preparing a corrosion-resistant lightweight piston for a fuel tank, comprising the following steps:

[0054] ⑴Weigh the following components by weight percentage: 40%~90% of polyetheretherketone (PEEK) powder, 5%~45% of inorganic short fibers and 0.1%~5% of carbon nanoparticles.

[0055] Among them: the weight average molecular weight of the polyetheretherketone (PEEK) powder is 65000~80000g / mol. The molecular weight of the resin matrix will affect the physical and mechanical properties of the piston and the molding process. The lower molecular weight will make the molecular chain entanglement weaker, and the mechanical strength of the piston will be reduced; too high molecular weight will lead to high molding temperature and resin melting. Mobility decreases.

[0056] The inorganic short fibers are glass fibers or carbon fibers. Glass fiber is alkali-free fiber, its length is more than 1mm chopped fiber, the fiber degree is 2000~...

Embodiment 1

[0073] Embodiment 1 A method for preparing a corrosion-resistant lightweight piston for a fuel tank, comprising the following steps:

[0074] (1) Weigh the following components: polyetheretherketone (PEEK) powder 64%, glass fiber 33%, graphene 3%.

[0075] (2) Fiber liquid-phase oxidation: soak the glass fiber to 1000ml of a mixture of nitric acid and sulfuric acid, control the temperature to 60 °C, stir for 60 minutes, cool and stand for centrifugation, wash the precipitate with distilled water, adjust the pH to 7, and then adjust the pH to 7 at 100 °C. Dry at °C.

[0076] (3) Fiber epoxidation: Dissolve 350g m-chloroperoxybenzoic acid (mCPBA) in 2000ml chloroform solvent; then immerse 1320g surface-oxidized glass fiber in chloroform solution for more than 4 hours. Intermittent stirring; after the reaction is completed, it is processed by standing, centrifugal filtration and drying.

[0077] (4) Dispersion of carbon nanoparticles: Add 120 g of graphene to 2400 ml of polyeth...

Embodiment 2

[0088] Embodiment 2 A method for preparing a corrosion-resistant lightweight piston for a fuel tank, comprising the following steps:

[0089] (1) Weigh the following components: 50% polyetheretherketone (PEEK) powder, 45% carbon fiber, and 5% carbon nanotube.

[0090] (2) Fiber liquid-phase oxidation: soak the glass fiber to 1500ml of nitric acid and sulfuric acid mixture, control the temperature to 60℃, stir for 60 minutes, cool and stand for centrifugation, wash the precipitate with distilled water, adjust the pH to 7, and then adjust the pH to 7 at 100 Dry at °C.

[0091] (3) Fiber epoxidation: Dissolve 350g m-chloroperoxybenzoic acid (mCPBA) in 2800ml 2000ml imitation solvent; then soak 1800g surface-oxidized carbon fiber in chloroform solution for more than 4 hours, in this process, the material is subjected to Intermittent stirring; after the reaction is completed, it is processed by standing, centrifugal filtration and drying.

[0092] (4) Carbon nanoparticle dispersi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com