Ball roller bearing

A ball roller and bearing technology, applied in the field of single-row ball roller bearings, can solve the problems of aggravated bearing wear, aggravated swing motion and reciprocating motion, aggravated cage ribs, etc., and achieves the improvement of spring action and lubricant distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

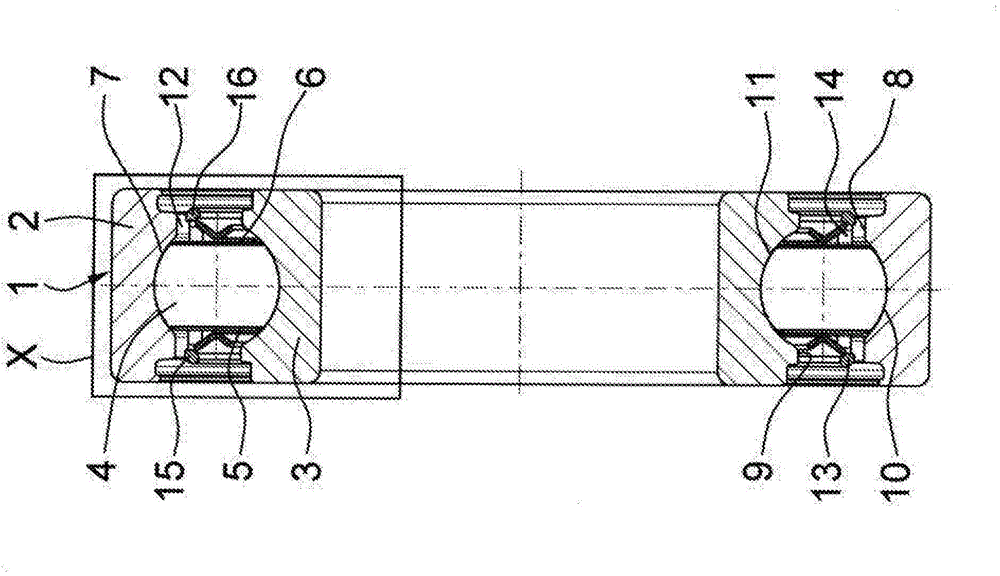

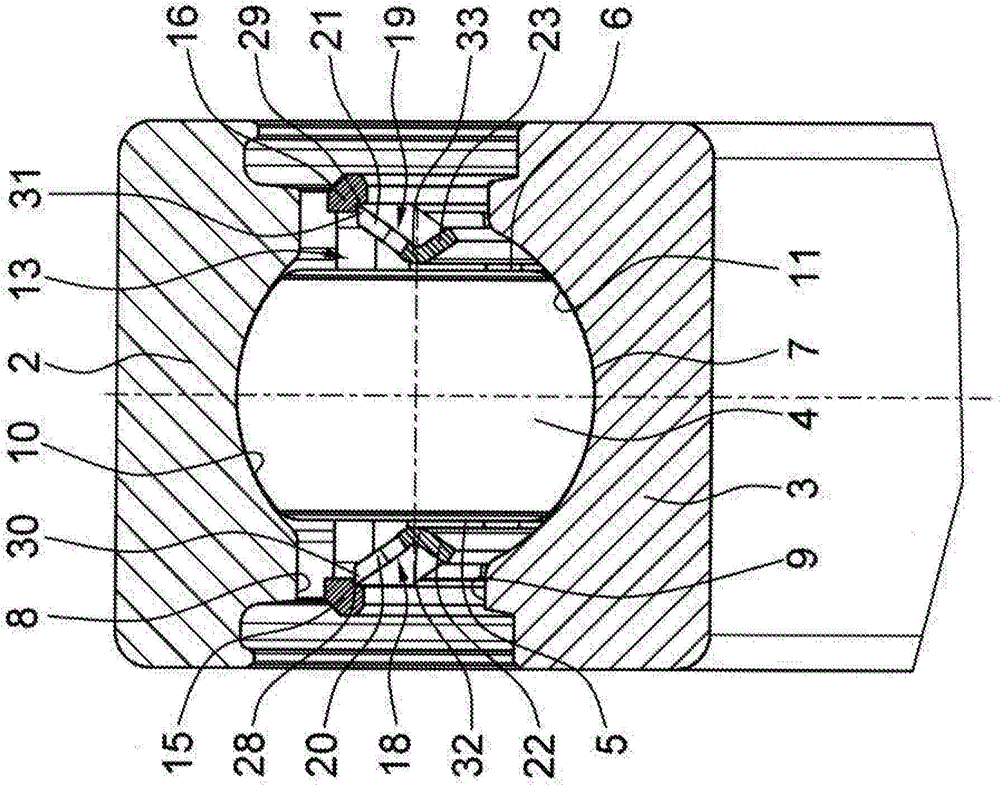

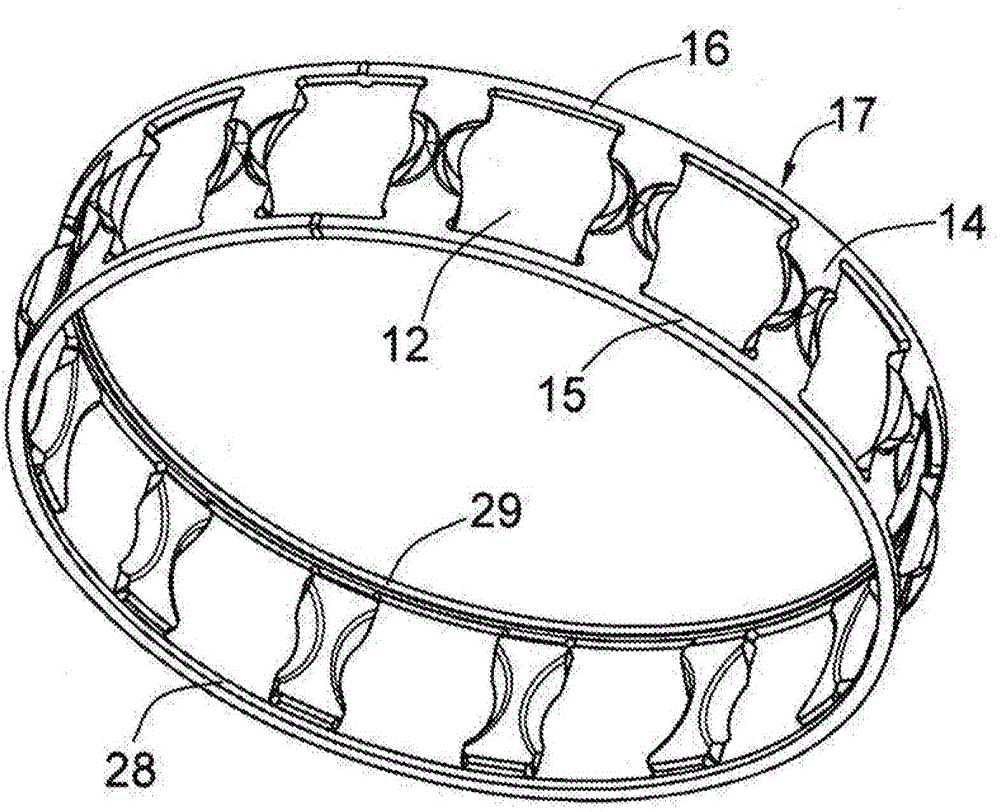

[0020] Depend on figure 1 and 2 A single-row ball roller bearing 1 is clearly shown, which is mainly composed of an outer bearing ring 2 and an inner bearing ring 3 and a plurality of bearing rings 2, 3 arranged between the bearing rings 2, 3 and constructed with two in each case of a spherical base. The ball rollers 4 are formed with flattened, parallel flanks 5 , 6 , which with their running surfaces 7 extending between the flanks 5 , 6 are machined on the inner side 8 of the outer bearing ring 2 and the inner bearing. The groove-shaped raceways 10 , 11 in the outer side 9 of the ring 3 roll and are held in the respective cage pockets 12 of the bearing cage 13 at the same distance from each other in the circumferential direction. The bearing cage 13 here has two side rings 15 , 16 which are connected to one another by a plurality of pocket webs 14 and two cage ribs which are connected to these side rings 15 , 16 and point towards the inner bearing ring 3 . The two cage rib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com