Application of hierarchical pore structure high polymer material as slow-release base material

A polymer material and multi-level pore technology, which is applied to medical preparations containing active ingredients, medical preparations with non-active ingredients, plant raw materials, etc., can solve the problem of short release time of active substances, low utilization rate, and inconvenient operation and other issues to achieve the effect of low volume ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

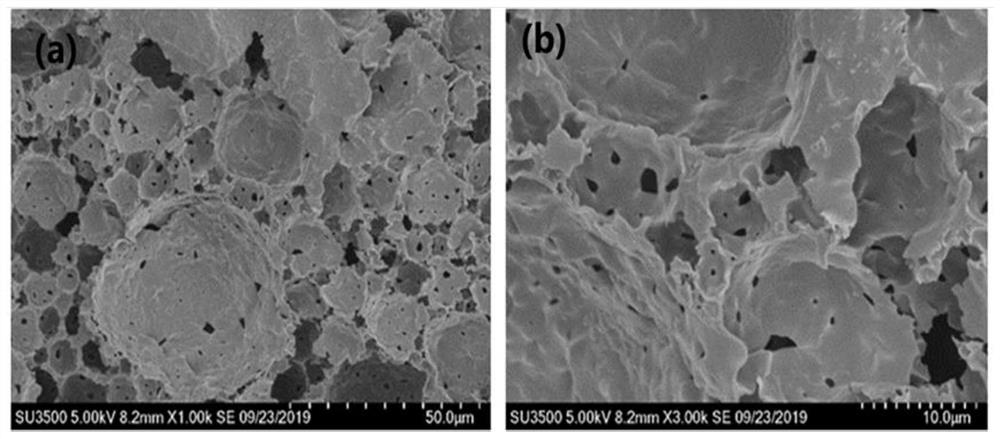

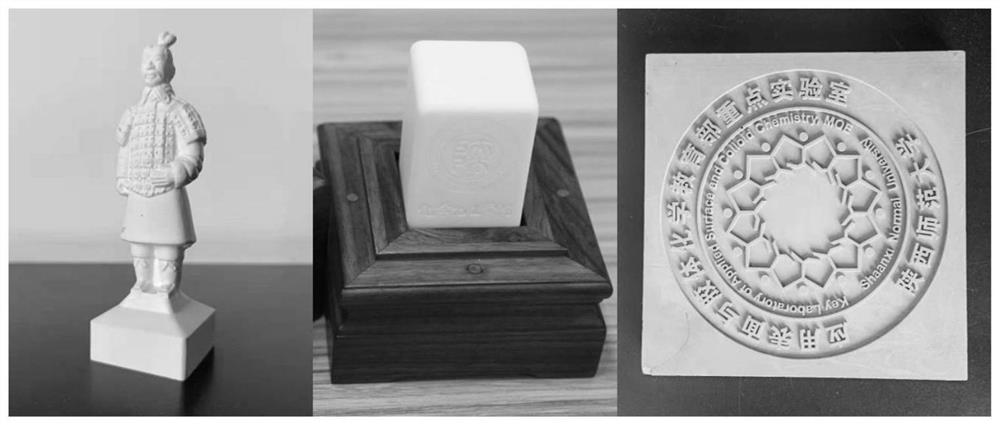

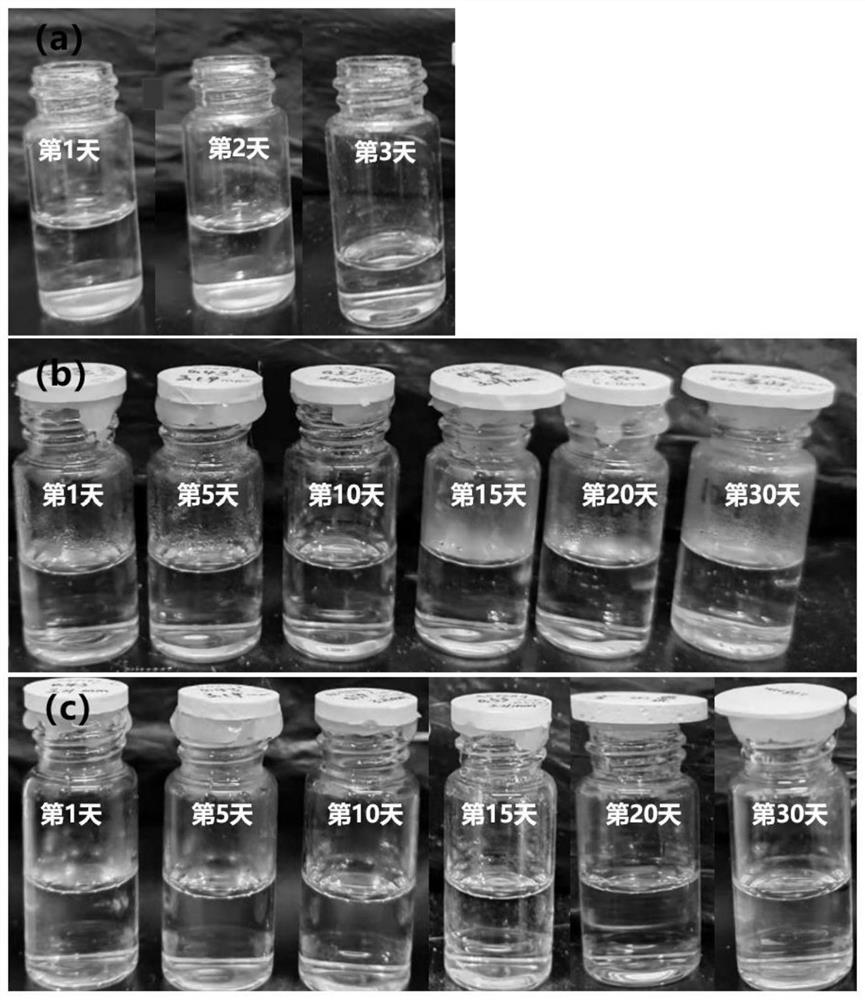

Embodiment 1

[0040] Add 0.40g of hydrophobic silica particles and 0.40g of dibenzoyl peroxide into the beaker, then add 12.86g of p-chlorostyrene, 2.88g of divinylbenzene, 0.58g of trimethylolpropane triacrylate, 2.88 g polylactic acid (molecular weight: 10,000), stir evenly with a PTFE stirrer to form a uniform reaction mixture; add 80 g of deionized water to the mixture, and stir with a dispersion plate for 10 minutes to form a viscous, stable gel emulsion ; Thermally polymerize the gel emulsion in a water bath, react at room temperature for 8 hours, heat up to 70°C for 12 hours; dry at 80°C to obtain a complete appearance, uniform and delicate density of 0.20g / cm 3 Hierarchical porous polymer materials.

Embodiment 2

[0042] Add 0.80g of hydrophobic silica particles and 0.80g of azobisisobutyronitrile into the beaker, then add 25.73g of α-methylstyrene, 5.76g of diallyl phthalate, and 1.16g of trimethylolpropane in sequence Trimethacrylate, 5.76g polyvinyl chloride paste resin (molecular weight is 62,000), and the dispersing plate is stirred evenly to form a uniform reaction mixture; 60g deionized water is added to this mixture, and the emulsifier is stirred for 15 minutes to form Viscous and stable gel emulsion; thermally polymerize the gel emulsion in a water bath, react at room temperature for 8 hours, heat up to 80°C for 12 hours; dry at 80°C to obtain a complete appearance, uniform and delicate density of 0.40g / cm 3 Hierarchical porous polymer materials.

Embodiment 3

[0044] Add 1.20g of hydrophobic silica particles and 1.20g of dicumyl peroxide into the beaker, then add 35.72g of 4-methylstyrene, 8.64g of ethylene glycol dimethacrylate, and 1.73g of cyanuric acid Triallyl ester, 8.84g polyacrylamide (molecular weight is 15,000), the PTFE stirrer stirs evenly, forms the uniform reaction mixture; Adds 40g deionized water to this mixture, emulsifier stirs 20 minutes, forms viscose Thick and stable gel emulsion; thermally polymerize the gel emulsion in a water bath, react at 40°C for 4 hours, heat up to 90°C for 10 hours; dry at 80°C to obtain a complete appearance, uniform and delicate density of 0.60g / cm 3 Hierarchical porous polymer materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com