A rotor structure, electromagnetic bearing and electromagnetic loading device

A technology of rotor structure and electromagnetic bearing, which is applied in the direction of electromechanical devices, bearings, shafts and bearings, and can solve the problems of reduced precision of displacement test, unstable size, and decreased electromagnetic force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

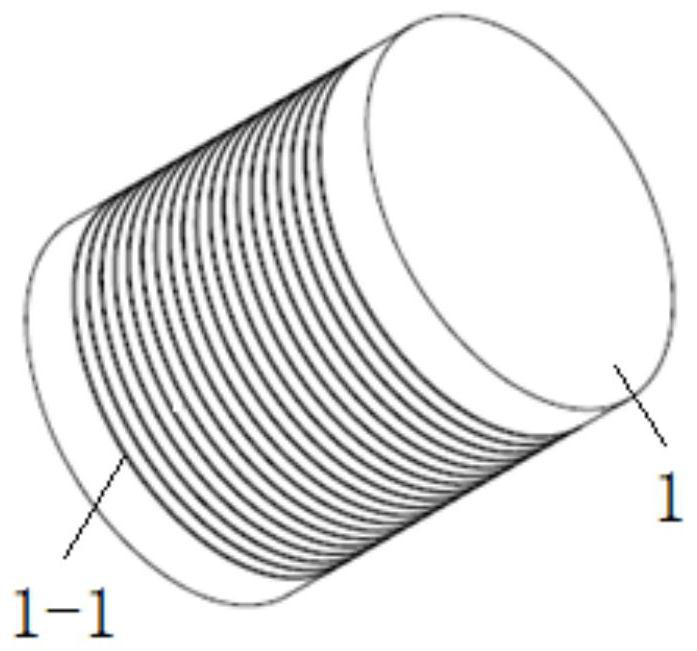

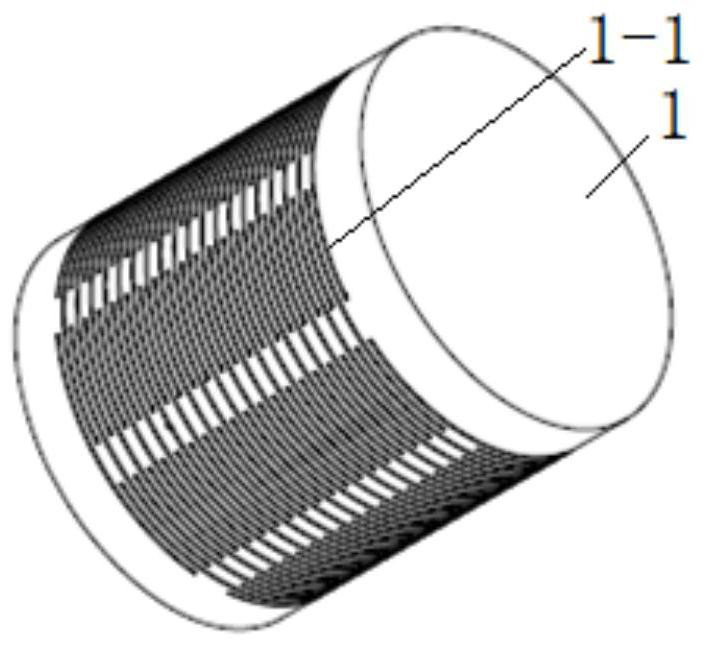

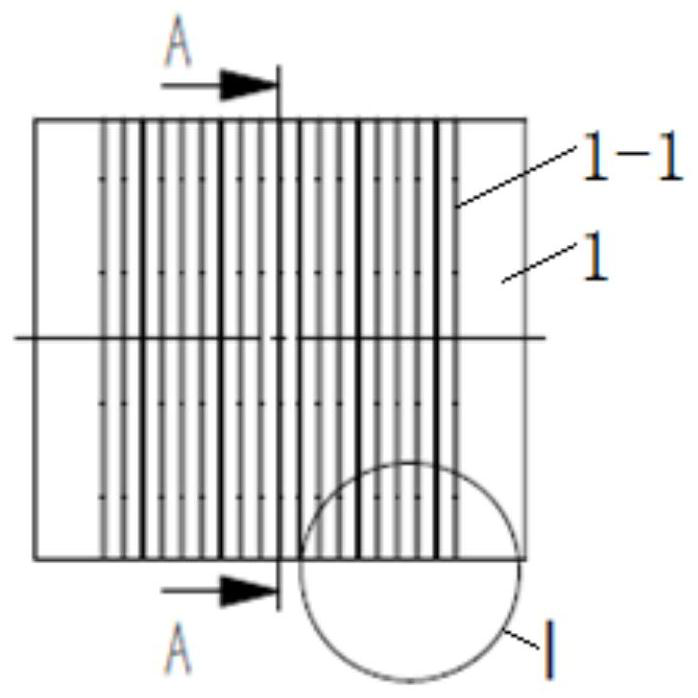

[0034] The technical principle of the rotor structure of the present invention is: when the solid rotor rotates in the magnetic field, the magnetic flux distribution inside the rotor is uneven, so that the magnetic flux is mainly concentrated on the surface of the rotor, and the eddy current is mainly concentrated on the shallow layer of the rotor. The closer to the rotor surface, the current The greater the density, the less current actually flows inside the rotor. The invention evenly cuts grooves on the cylindrical surface of the solid rotor, uses narrow and dense cut grooves to cut off the annular eddy current, limits the eddy current within a limited range, and greatly reduces the eddy current loss due to the high resistance of the circuit and greatly weakens the eddy current.

[0035] refer to figure 1 and figure 2 , the rotor structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com